Page 1

RTD Input Module

Cat. No. 1771-IR Series B

User Manual

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences

between solid state products and electromechanical products, those responsible

for applying and using this product must satisfy themselves as to the

acceptability of each application and use of this product. For more information,

refer to publication SGI–1.1 (Safety Guidelines For The Application,

Installation and Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended

solely to illustrate the text of this manual. Because of the many variables and

requirements associated with any particular installation, Allen–Bradley

Company cannot assume responsibility or liability for actual use based upon the

illustrative uses and applications.

No patent liability is assumed by Allen–Bradley Company with respect to use of

information, circuits, equipment or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen–Bradley Company is prohibited.

Throughout this manual we make notes to alert you to possible injury to people

or damage to equipment under specific circumstances.

WARNING: Tells readers where people may be hurt if procedures

are not followed properly.

CAUTION: Tells readers where machinery may be damaged or

economic loss can occur if procedures are not followed properly.

Warnings and Cautions:

- Identify a possible trouble spot.

- Tell what causes the trouble.

- Give the result of improper action.

- Tell the reader how to avoid trouble.

Important: We recommend you frequently backup your application programs

on appropriate storage medium to avoid possible data loss.

1991 Allen-Bradley Company

PLC is a registered trademark of Allen-Bradley Company

, Inc.

, Inc.

Page 3

Table of Contents

Important User Information

. . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Purpose

Audience 11

Vocabulary 11

Manual Organization 11

Warnings and Cautions 12

Related Products 12

Product

Related

of Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility

Publications

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of the RTD Input Module 21. . . . . . . . . . . . . . . . . . .

Chapter

Module Description 21

Features

How Analog Modules Communicate with Programmable Controllers 22

Accuracy 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 23

Chapter Summary 23

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

of the Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Installing the RTD Input Module 31. . . . . . . . . . . . . . . . . . . . .

Chapter

Before Y

Electrostatic Damage 31

Power Requirements 32

Module

Module Keying 32

Connecting Wiring 33

Grounding

Installing

Interpreting the Indicator Lights 36

Chapter Summary 36

Module

Chapter

Block Transfer Programming 41

PLC-2 Program Example 42

PLC-3 Program Example 44

PLC-5 Program Example 46

Module Scan Time 47

Objectives

ou Install Y

Location in the I/O Chassis

the Input Module

the Input Module

our Input Module 31. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

32. . . . . . . . . . . . . . . . . . . . . . .

35. . . . . . . . . . . . . . . . . . . . . . . . . . . .

35. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Chapter Summary 47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Configuration 51. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Configuring Your RTD Module 51

Data Format 52

RTD Type 52

Units of Measure 52

Real T

Configuring Block for a Block Transfer Write 54

Bit/Word Descriptions 55

Default Configuration for the R

Chapter Summary 56

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ime Sampling

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TD Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

56. . . . . . . . . . . . . . .

Module Status and Input Data 61. . . . . . . . . . . . . . . . . . . . . .

Chapter

Reading

Chapter Summary 63

Objectives

Data from the R

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TD Module 61. . . . . . . . . . . . . . . . . . . . . . .

Module Calibration 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Tools and Equipment 71

Calibrating your Input Module 71

About Auto-calibration 71

Performing Auto-calibration 72

Performing

Chapter Summary 78

Objective

Manual Calibration

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

75. . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Diagnostics Reported by the Module 81

Chapter Summary 83

Objective

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Examples B1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Sample Programs for the R

PLC-2 Family Processors B1

PLC-3 Family Processors B3

PLC-5 Family Processors B4

TD Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B1. . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

Data Table Formats C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4-Digit Binary Coded Decimal (BCD) C1. . . . . . . . . . . . . . . . . . . . . .

Signed-magnitude Binary C2

Two's Complement Binary C3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer (Mini-PLC-2 and PLC-2/20 Processors) D1. .

Multiple GET Instructions - Mini-PLC-2 and PLC-2/20 Processors D1

Setting the Block Length (Multiple GET Instructions only) D4. . . . . . . .

2 and 4-Wire RTD Sensors E1. . . . . . . . . . . . . . . . . . . . . . . .

About 2 and 4-Wire Sensors E1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting 4-Wire Sensors E2

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differences Between Series A and Series B

RTD Input Modules F1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Major

Dif

ferences between Series F1. . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Using This Manual

Chapter

Purpose of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your RTD input module with an

Allen–Bradley programmable controller. It helps you install, program,

calibrate, and troubleshoot your module.

You must be able to program and operate an Allen–Bradley programmable

controller (PLC) to make efficient use of your input module. In particular, you

must know how to program block transfer instructions.

We assume that you know how to do this in this manual. If you do not, refer to

the appropriate PLC programming and operations manual before you attempt to

program this module.

In this manual, we refer to:

The RTD input module as the “input module”

The Programmable Controller, as the “controller.”

This manual is divided into eight chapters. The following chart shows each

chapter with its corresponding title and a brief overview of the topics covered in

that chapter.

Chapter Title Topics Covered

2 Overview of the Input Module Description of the module, including general and hardware features

3 Installing the Input Module Module power requirements, keying, chassis location

Wiring of field wiring arm

4 Module Programming How to program your programmable controller for these modules

Sample programs

5 Module Configuration Hardware and software configuration

Module write block format

6 Module Status and Input Data Reading data from your module

Module read block format

7 Module Calibration How to calibrate your module

8 Troubleshooting Diagnostics reported by the module

11

Page 7

Chapter 1

Using This Manual

Chapter Topics CoveredTitle

Appendix A Specifications Your module's specifications

Appendix B Programming Examples

Appendix C Data Formats Information on BCD, signed magnitude (12-bit) binary, and 2's

complement binary

Appendix D Block Transfer with Mini-PLC-2

Appendix E 2 and 4-wire RTD Sensors Shows wiring connections for 2 and 4-wire sensors

Appendix F Differences Between Series A

Warnings and Cautions

How to use GET-GET instructions for block transfer with Mini-PLC-2

and Mini-PLC-2/20

and B

and Mini-PLC-2/20 processors

Identifies major differences between the series A version and the

series B version of the RTD module.

This manual contains warnings and cautions.

WARNING: A warning indicates where you may be injured if you

use your equipment improperly.

CAUTION: Cautions indicate where equipment may be damaged

from misuse.

You should read and understand cautions and warnings before performing the

procedures they precede.

Related Products

Product Compatibility

12

You can install your input module in any system that uses Allen–Bradley

programmable controllers with block transfer capability and the 1771 I/O

structure.

Contact your nearest Allen–Bradley office for more information about your

programmable controllers.

This input module can be used with any 1771 I/O chassis. Communication

between the discrete analog module and the processor is bidirectional. The

processor block–transfers output data through the output image table to the

module and block–transfers input data from the module through the input image

table. The module also requires an area in the data table to store the read block

and write block data. I/O image table use is an important factor in module

placement and addressing selection. The module’s data table use is listed in the

following table.

Page 8

Chapter 1

Using This Manual

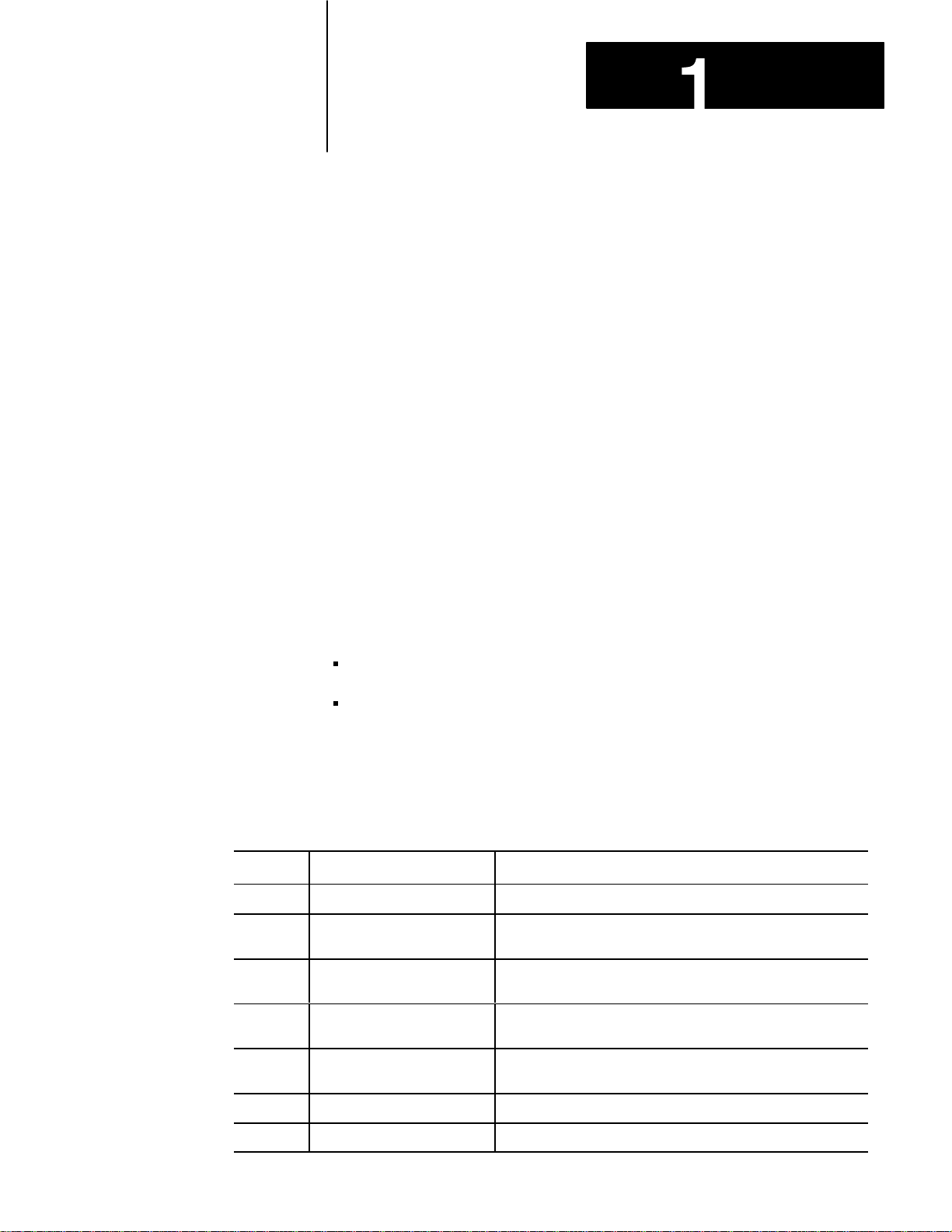

Table 1.A

Compatibility

and Use of Data T

Use of Data Table

Catalog

Number

1771-IR

Series

A

= Compatible with 1771-A1, A2, A4 chassis.

B = Compatible with 1771-A1B, A2B, A3B, A4B chassis.

Y

es = Compatible without restriction

No = Restricted to complementary module placement

Input Output Read Write

Image Image Block Block

Bits Bits Words Words

8 8 8/9 14/15 Ye s Yes Ye s

B

able

Compatibility

Addressing Chassis

1/2 -slot 1-slot 2-slot

Series

A and B

You can place your input module in any I/O module slot of the I/O chassis. You

can put:

two input modules in the same module group

an input and an output module in the same module group.

Do not put the module in the same module group as a discrete high density

module unless you are using 1 or 1/2 slot addressing. Avoid placing this module

close to AC modules or high voltage DC modules.

Related Publications

For a list of publications with information on Allen–Bradley programmable

controller products, consult our publication index SD499.

13

Page 9

Chapter

Overview of the RTD Input Module

Chapter 2

2

Chapter Objectives

Module Description

Features of the Input Module

This chapter gives you information on:

features of the input module

how an input module communicates with programmable controllers

The RTD input module is an intelligent block transfer module that interfaces

analog input signals with any Allen–Bradley programmable controllers that

have block transfer capability. Block transfer programming moves input data

words from the module’s memory to a designated area in the processor data

table in a single scan. It also moves configuration words from the processor data

table to module memory.

The input module is a single slot module and requires no external power supply.

After scanning the analog inputs, the input data is converted to a specified data

type in a digital format to be transferred to the processor’s data table on request.

The block transfer mode is disabled until this input scan is complete.

Consequently, the minimum interval between block transfer reads (50ms) is the

same as the total input update time for each analog input module.

The RTD input module senses up to 6 RTD signals at its inputs and converts

them to corresponding temperature or resistance in 4–digit BCD or 16–bit

binary format.

Module features include:

Six resistance temperature detector inputs

Reports oC, oF, or ohms for 100 ohm platinum or 10 ohm copper sensors

Reports ohms for other types of sensors

software configurable

0.1 degree/10 milliohm input resolution

auto–calibration

open wire detection

The module can be configured for 100 ohm platinum or 10 ohm copper RTDs,

or other sensor types such as 120 ohm nickel RTDs. Temperature ranges are

available in degrees C or F. Values can also be measured in ohms.

When using 10 ohm copper RTDs, it is necessary to dedicate your module for

exclusive use with 10 ohm copper RTDs. You can configure the module to

accept signals from any combination of 100 ohm platinum and other types of

non–copper RTDs. Both cases are determined by block transfer write (BTW)

selection.

21

Page 10

Chapter 2

Overview of the RTD Input Module

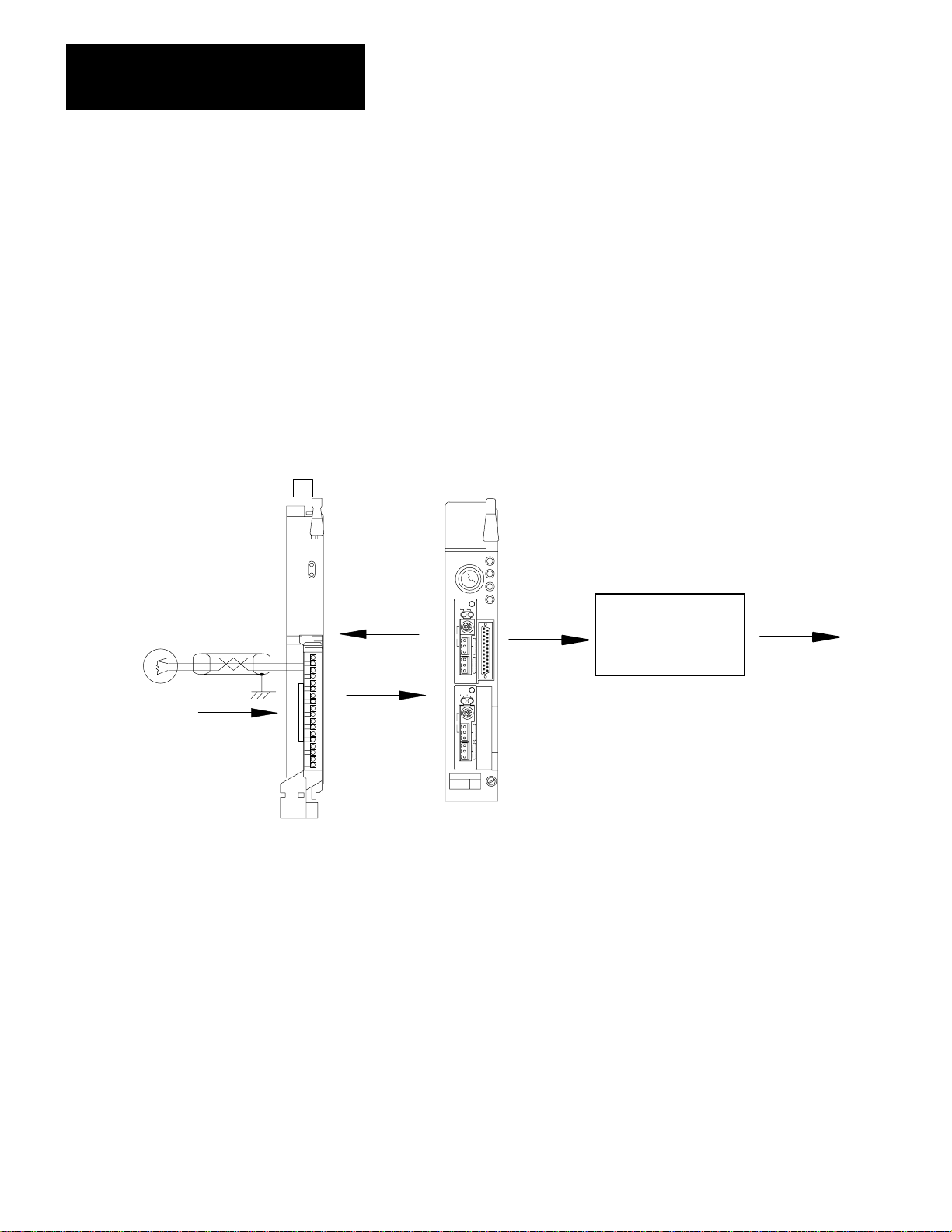

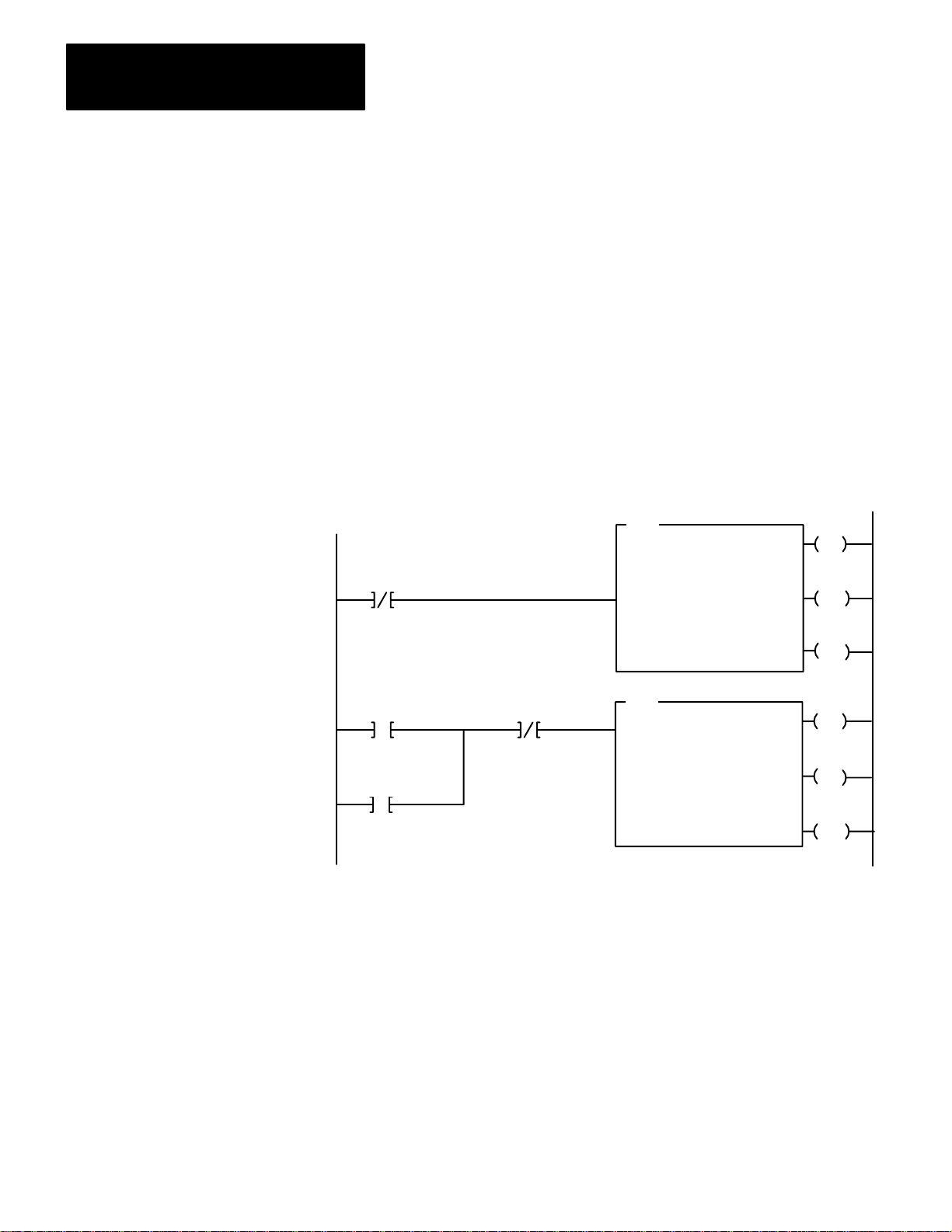

How Analog Modules Communicate with Programmable Controllers

RTD

2

The processor transfers data to and from the module using block transfer write

(BTW) and block transfer read (BTR) instructions in your ladder diagram

program. These instructions let the processor obtain input values and status

from the module, and let you establish the module’s mode of operation (figure

2.1).

1. The processor transfers your configuration data and calibration values to

the module using a block transfer write instruction.

2. External devices generate analog signals that are transmitted to the

module.

Figure 2.1

Communication

3

18

16

1

4

12

10

8

6

4

2

BTW 1

BTR 4

Between Processor and Module

5

Memory

User Program

To

Output Devices

6

22

RTD Input Module

1771-IR Series B

3. The module converts analog signals into binary or BCD format, and

4. When instructed by your ladder program, the processor performs a read

5. The processor and module determine that the transfer was made without

6. Your ladder program can use and/or move the data (if valid) before it is

PC Processor

(PLC-5/40 Shown)

12933-I

stores theses values until the processor requests their transfer.

block transfer of the values and stores them in a data table.

error, and that input values are within specified range.

written over by the transfer of new data in a subsequent transfer.

Page 11

Chapter 2

Overview of the RTD Input Module

7. Your ladder program should allow write block transfers to the module only

when enabled by the operator at power–up.

Accuracy

Getting Started

The accuracy of the input module is described in Appendix A.

Your input module package contains the following items. Please check that each

part is included and correct before proceeding.

RTD Input Module

Cat. No. 1771–IR Series B

User’s Manual

Chapter Summary

Input Module Field Wiring Arm User's Manual

1771-IR

Series B Cat. No. 1771-WF

In this chapter you read about the functional aspects of the input module and

how the module communicates with programmable controllers.

1771-6.5.76

23

Page 12

Chapter

Installing the RTD Input Module

3

Chapter Objectives

Before You Install Your Input Module

Electrostatic Damage

This chapter gives you information on:

calculating the chassis power requirement

choosing the module’s location in the I/O chassis

keying a chassis slot for your module

wiring the input module’s field wiring arm

installing the input module

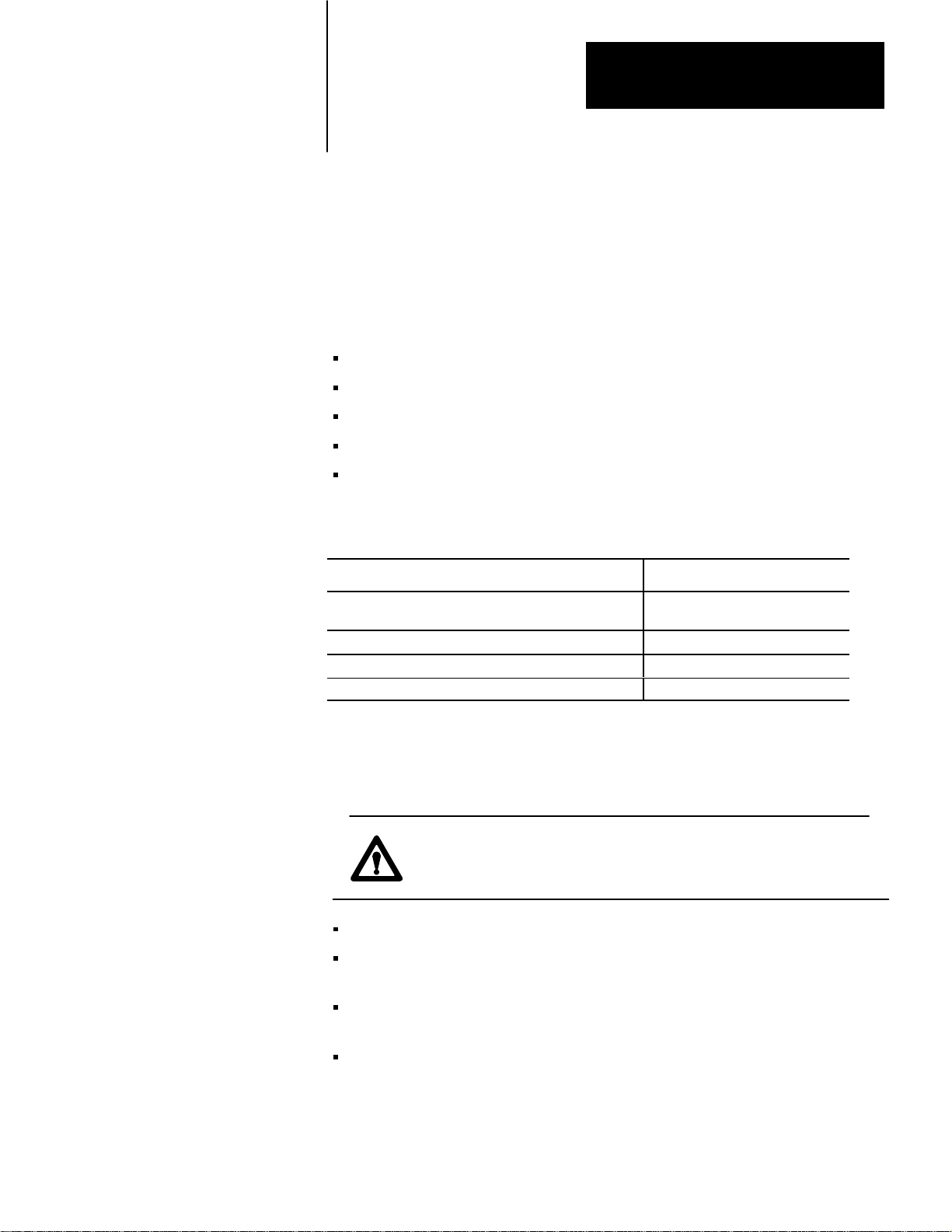

Before installing your input module in the I/O chassis you must:

Action required: Refer to:

Calculate the power requirements of all modules in each

chassis.

Determine where to place the module in the I/O chassis. Module Location in the I/O Chassis

Key the backplane connector in the I/O chassis. Module Keying

Make connections to the wiring arm. Connecting Wiring and Grounding

Electrostatic discharge can damage semiconductor devices inside this module if

you touch backplane connector pins. Guard against electrostatic damage by

observing the following warning:

Power Requirements

CAUTION: Electrostatic discharge can degrade performance or

cause permanent damage. Handle the module as stated below.

Wear an approved wrist strap grounding device when handling the module.

Touch a grounded object to rid yourself of electrostatic charge before

handling the module.

Handle the module from the front, away from the backplane connector. Do

not touch backplane connector pins.

Keep the module in its static–shield bag when not in use, or during shipment.

31

Page 13

Chapter 3

Installing the RTD Input Module

Power Requirements

Module Location in the I/O Chassis

Your module receives its power through the 1771 I/O chassis backplane from

the chassis power supply. The maximum drawn by the RTD module from this

supply is 850mA (4.2 Watts).

Add the listed value to the requirements of all other modules in the I/O chassis

to prevent overloading the chassis backplane and/or backplane power supply.

Place your module in any slot of the I/O chassis except for the extreme left slot.

This slot is reserved for processors or adapter modules.

Group your modules to minimize adverse affects from radiated electrical noise

and heat. We recommend the following.

Group analog input and low voltage DC modules away from AC modules or

high voltage DC modules to minimize electrical noise interference.

Do not place this module in the same I/O group with a discrete high–density

I/O module when using 2–slot addressing. This module uses a byte in both

the input and output image tables for block transfer.

After determining the module’s location in the I/O chassis, connect the wiring

arm to the pivot bar at the module’s location.

Module Keying

Use the plastic keying bands, shipped with each I/O chassis, for keying the I/O

slot to accept only this type of module.

The input module is slotted in two places on the rear edge of the circuit board.

The position of the keying bands on the backplane connector must correspond

to these slots to allow insertion of the module. You can key any connector in an

I/O chassis to receive this module except for the leftmost connector reserved for

adapter or processor modules. Place keying bands between the following

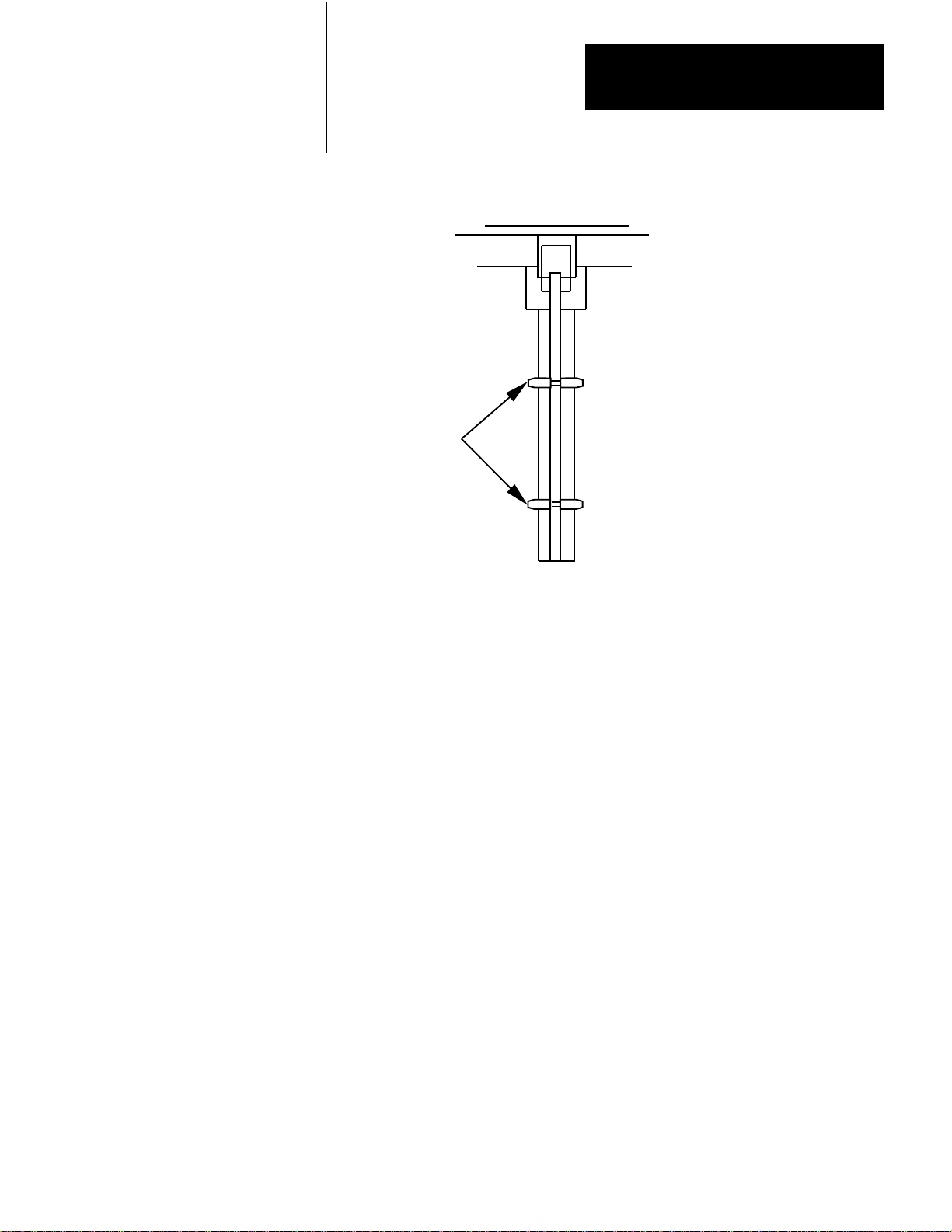

numbers labeled on the backplane connector (Figure 3.1):

Between 10 and 12

Between 28 and 30

You can change the position of these bands if subsequent system design and

rewiring makes insertion of a different type of module necessary. Use

needlenose pliers to insert or remove keying bands.

32

Page 14

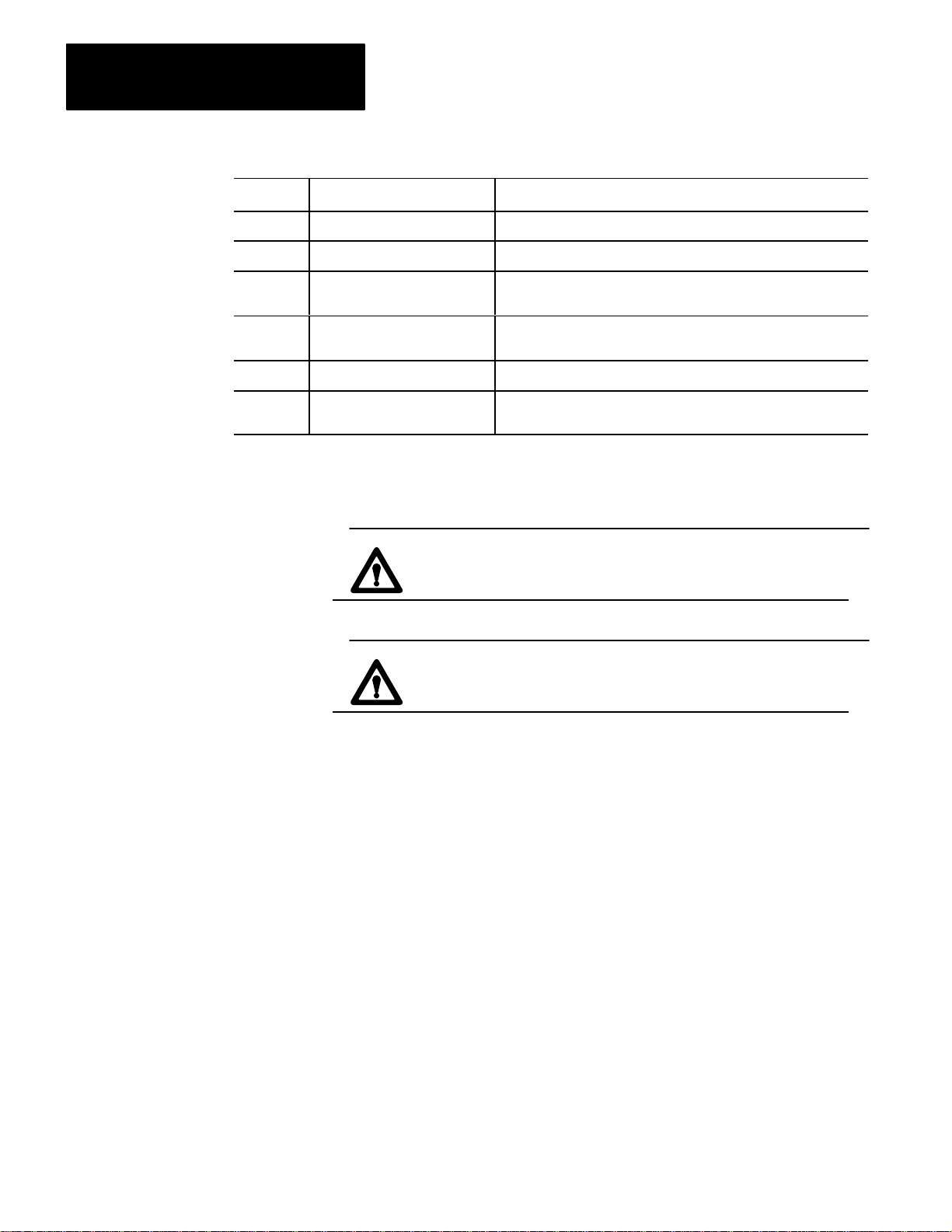

Figure 3.1

Positions for the RTD Input Module

Keying

Keying Bands

Chapter 3

Installing the RTD Input Module

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Between 10 and 12

Between 28 and 30

Connecting Wiring

Upper Connector

12934

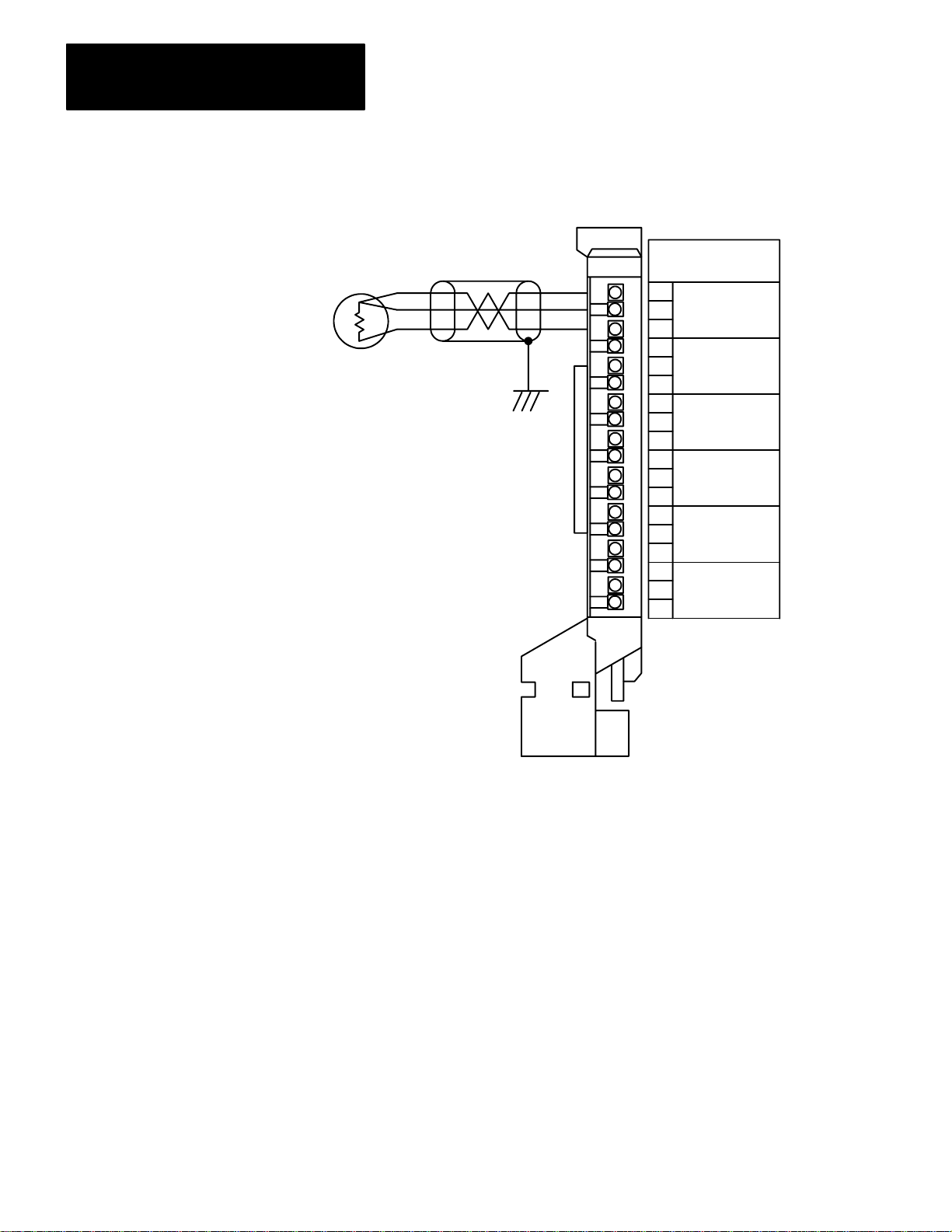

Connect your I/O devices to the field wiring arm shipped with the module (see

Figure 3.2). Attach the field wiring arm to the pivot bar at the bottom of the I/O

chassis. The field wiring arm pivots upward and connects with the module so

you can install or remove the module without disconnecting the wires.

The wiring arms are specific to the input module. The RTD input module uses

field wiring arm cat. no. 1771–WF.

Use the inputs in numerical sequence from 1 to 6. Unused inputs that are left

open cause the module to report an open input condition. To avoid this, tie all

three terminals of the open channel together. Wiring connections are shown in

Figure 3.2.

The module requires three–conductor shielded cable for signal transmission

from RTD devices. This cable consists of three insulated conductors, covered

along their entire length by a foil shield and encased in plastic. The shield

reduces the effect of induced noise at any point along the cable. In order to do

this, the shield must cover the enclosed wires as completely as possible.

33

Page 15

Chapter 3

Installing the RTD Input Module

Figure 3.2

Connection

RTD

Diagram for RTDs

Chassis

Ground

18

16

14

12

10

Terminal

Identification

C

Channel 1

B

A

C

Channel 2

B

A

C

Channel 3

B

A

8

6

4

2

C

B

A

C

B

A

C

B

A

Channel 4

Channel 5

Channel 6

34

12935

Most importantly, you must ground the shield at the chassis end only. We

recommend connecting each input cable’s shield to a properly grounded

common bus.

Refer to Appendix E for 2–wire and 4–wire RTD connections.

Cable impedance –– Since the operating principle of the RTD module is based

on the measurement of resistance, you must take special care in selecting your

input cables. Select a cable that has a consistent impedance throughout its entire

length. We recommend Belden 9533 or equivalent. As cable length is directly

related to overall cable impedance, keep input cables as short as possible by

locating your I/O chassis as near the RTD sensors as I/O module considerations

permit. Keep the cable free of kinks and nicks to the shielding material.

Maximum cable length is limited by an overall cable impedance of 10 ohms on

a single wire. This recommendation is based on considerations of signal

degradation due to resistance mismatch between the three conductors within the

cable.

Page 16

Chapter 3

Installing the RTD Input Module

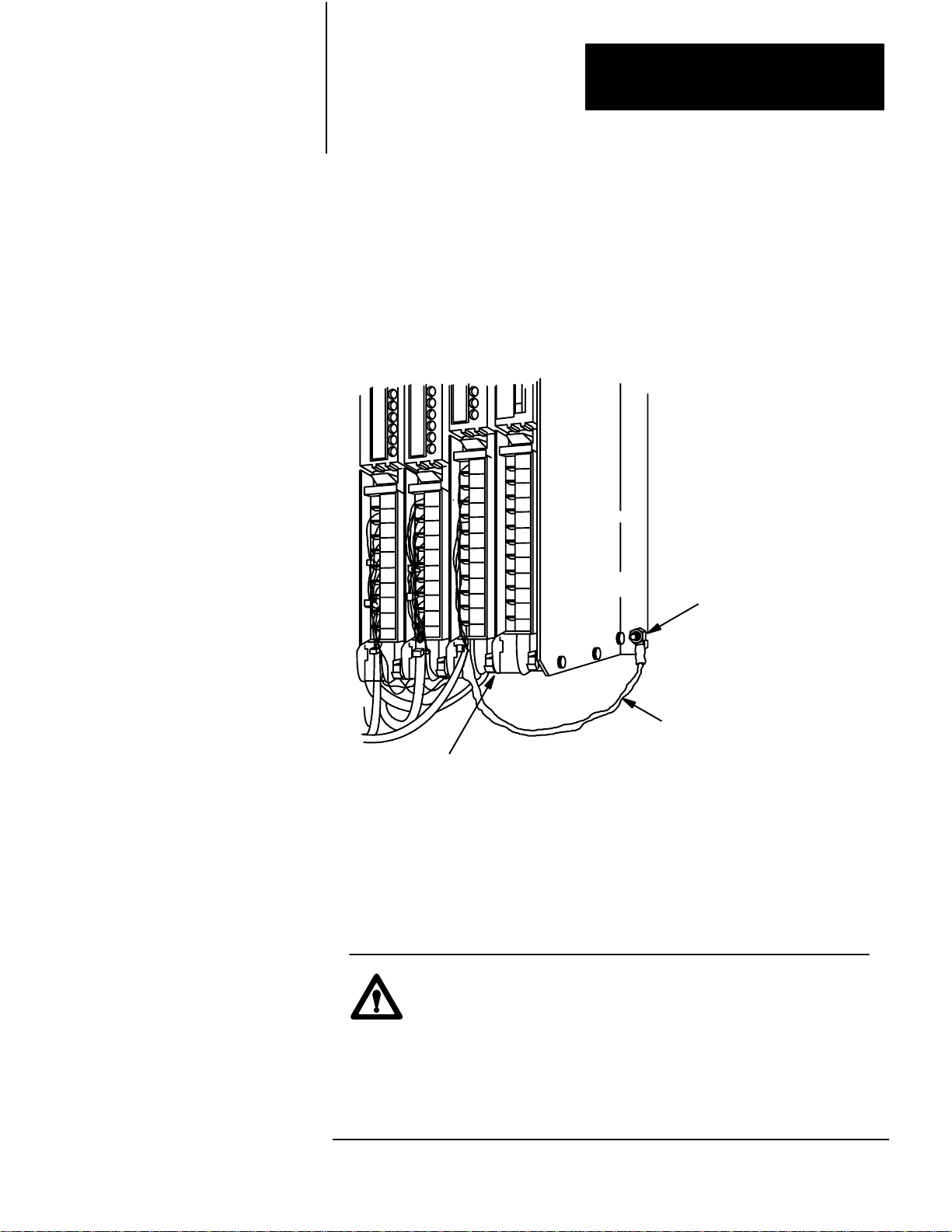

Grounding the Input Module

When using shielded cable, ground the foil shield and drain wire only at one

end of the cable. We recommend that you wrap the foil shield and drain wire

together and connect them to a chassis mounting bolt (Figure 3.3). At the

opposite end of the cable, tape exposed shield and drain wire with electrical tape

to insulate it from electrical contact.

Figure 3.3

Grounding

Cable

Ground Shield at

I/O chassis

mounting bolt

Installing the Input Module

Shield and drain

twisted into

single strand

Field Wiring Arm

Refer to Wiring and Grounding Guidelines, publication 1770-4.1 for additional information.

17798

When installing your module in an I/O chassis:

1. First, turn off power to the I/O chassis:

WARNING: Remove power from the 1771 I/O chassis backplane

and wiring arm before removing or installing an I/O module.

Failure to remove power from the backplane could cause injury or

equipment damage due to possible unexpected operation.

Failure to remove power from the backplane or wiring arm could

cause module damage, degradation of performance, or injury.

35

Page 17

Chapter 3

Installing the RTD Input Module

2. Place the module in the plastic tracks on the top and bottom of the slot that

guides the module into position.

3. Do not force the module into its backplane connector. Apply firm even

pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure it.

5. Connect the wiring arm to the module.

Interpreting the Indicator Lights

The front panel of the input module contains a green RUN and a red FLT (fault)

indicator (Figure 3.4). At power–up, the green and red indicators are on. An

initial module self–check occurs. If there is no fault, the red indicator turns off.

The green indicator will blink until the processor completes a successful write

block transfer to the module. If a fault is found initially or occurs later, the red

FLT indicator lights. Possible module fault causes and corrective action are

discussed in Chapter 8, Troubleshooting.

Figure 3.4

Diagnostic

Indicators

RTD

INPUT

RUN

FLT

Chapter Summary

36

In this chapter you learned how to install your input module in an existing

programmable controller system and how to wire to the field wiring arm.

Page 18

Module Programming

Chapter

Chapter Objectives

Block Transfer Programming

In this chapter, we describe

Block Transfer programming

Sample programs in the PLC–2, PLC–3 and PLC–5 processors

Module scan time issues

Your module communicates with the processor through bidirectional block

transfers. This is the sequential operation of both read and write block transfer

instructions.

The block transfer write (BTW) instruction is initiated when the analog module

is first powered up, and subsequently only when the programmer wants to write

a new configuration to the module. At all other times the module is basically in

a repetitive block transfer read (BTR) mode.

The following example programs accomplish this handshaking routine. These

are minimum programs; all rungs and conditioning must be included in your

application program. You can disable BTRs, or add interlocks to prevent writes

if desired. Do not eliminate any storage bits or interlocks included in the sample

programs. If interlocks are removed, the program may not work properly.

Your analog input module will work with a default configuration of all zeroes

entered in the configuration block. See the configuration default section to

understand what this configuration looks like. Also, refer to Appendix B for

example configuration blocks and instruction addresses to get started.

Your program should monitor status bits (such as overrange, underrange) and

block transfer read (BTR) activity.

The following example programs illustrate the minimum programming required

for communication to take place.

41

Page 19

Chapter 4

e

e

Module Programming

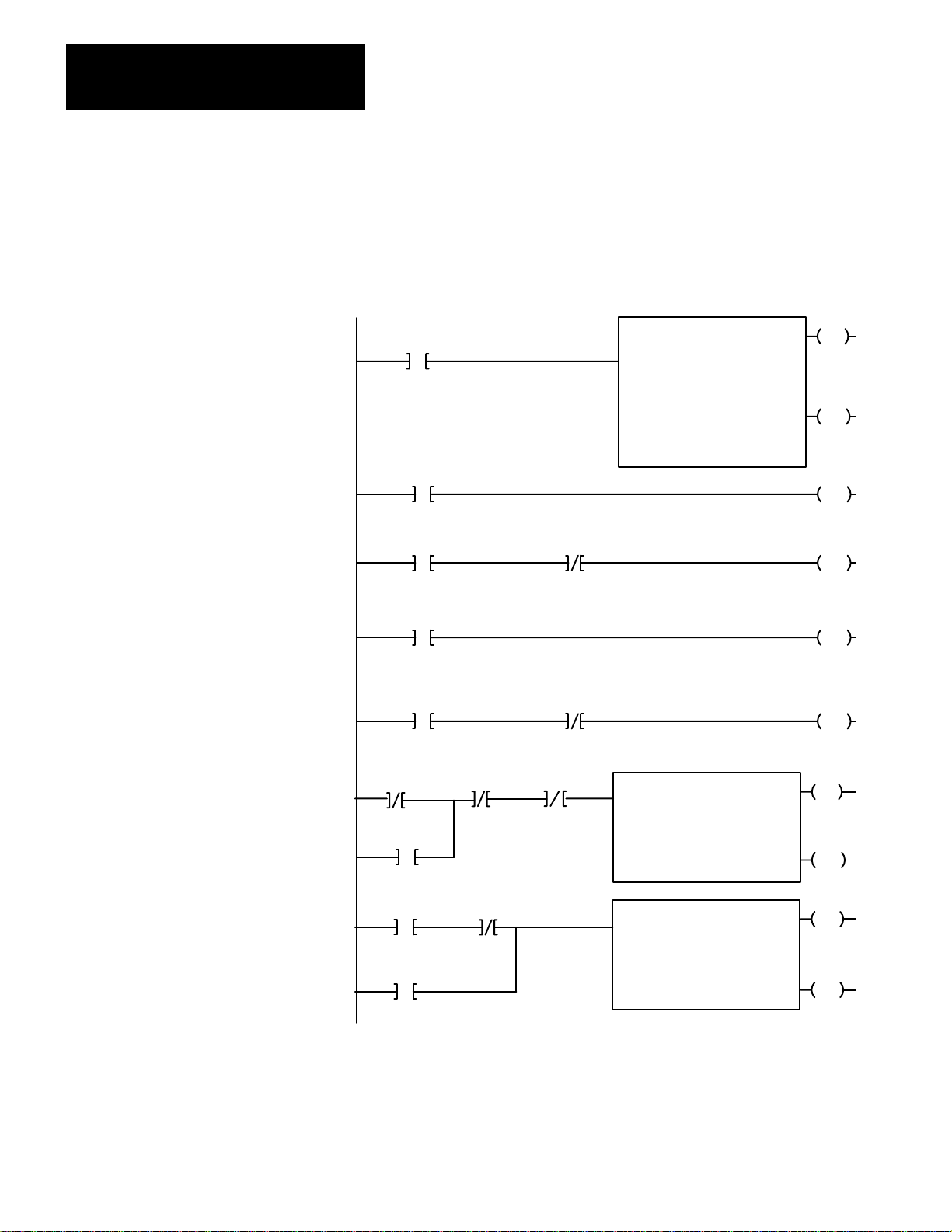

PLC-2 Program Example

Note that PLC–2 processors that do not have the block transfer instruction must

use the GET–GET block transfer format which is outlined in Appendix D.

Figure 4.1

Family Sample Program Structure

PLC-2

XXX

XXX

XXX

XXX

Enable

EN

17

Done

DN

15

Storag

Bit A

L

Storag

Bit A

U

Storage

Bit B

L

Block Transfer

Read Done Bit

1

Pushbutton

2

Block Transfer Write

Done Bit

3

Block Transfer Write

Done Bit

4

FILE TO FILE MOVE

COUNTER ADDR:

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RATE PER SCAN:

1

Pushbutton

YYYY-XXXX

XXX-XXX

Block Transfer Read

Done Bit

5

Storage

Power-up Bit

6

Storage

Bit B

Power-up

Bit

7

Storage

Bit A

1

Y

ou can replace the pushbutton with a timer "done" bit to initiate the block transfer

write on a timed basis. You can also use any storage bit in memory

Bit A

Storage

Bit B

Power-up Bit

BTR Done Bit

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

BLOCK XFER WRITE

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

XXX

RGS

XX

XXXX:XXXX

XXX

RGS

XX

XXXX:XXXX

.

Storage

Bit B

U

Enable

EN

Done

DN

Enable

EN

Done

DN

X7

X7

X6

X6

42

Page 20

Chapter 4

Module Programming

Program Action

Rung 1 - Block transfer read buffer: the file–to–file move instruction

holds the block transfer read (BTR) data (file A) until the processor

checks the data integrity.

1. If the data was successfully transferred, the processor energizes the BTR

done bit, initiating a data transfer to the buffer (file R) for use in the

program.

2. If the data is corrupted during the BTR operation, the BTR done bit is not

energized and data is not transferred to the buffer file. In this case, the data

in the BTR file will be overwritten by data from the next BTR.

Rungs 2 and 3 - These rungs provide for a user–initiated block transfer

write (BTW) after the module is initialized at power–up. Pressing the

pushbutton locks out BTR operation and initiates a BTW that configures

the module. Block transfer writes will continue for as long as the

pushbutton remains closed.

Rungs 4 and 5 - These rungs provide a ”read–write–read” sequence to the

module at power–up. They also insure that only one block transfer (read

or write) is enabled during a particular program scan.

Rungs 6 and 7 - These rungs are the conditioning block transfer rungs.

Include all the input conditioning shown in the example program.

43

Page 21

Chapter 4

Module Programming

PLC-3 Program Example

Block transfer instructions with the PLC–3 processor use one binary file in a

data table section for module location and other related data. This is the block

transfer control file. The block transfer data file stores data that you want

transferred to the module (when programming a block transfer write) or from

the module (when programming a block transfer read). The address of the block

transfer data files are stored in the block transfer control file.

The industrial terminal prompts you to create a control file when a block

transfer instruction is being programmed. The same block transfer control file

is used for both the read and write instructions for your module. A different

block transfer control file is required for every module.

A sample program segment with block transfer instructions is shown in

Figure 4.2, and described below.

Figure 4.2

Family Sample Program Structure

PLC-3

1

Pushbutton

2

Block T

ransfer

Read Done Bit

Power-up

Bit

Block T

ransfer

rite Done Bit

W

BTR

BLOCK XFER READ

RACK:

GROUP:

MODULE:

DATA:

LENGTH:

CNTL:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

,MODULE:

DATA:

LENGTH:

CNTL:

X = XXXX

XXXX:XXXX

XXXX:XXXX

X = XXXX

XXXX:XXXX

XXXX:XXXX

XXX

XXX

X

X

X

X

ENABLE

EN

12

DONE

DN

15

ERROR

ER

13

ENABLE

EN

02

DONE

DN

05

ERROR

ER

03

44

Program Action

At power–up, the user program examines the BTR done bit in the block transfer

read file, initiates a write block transfer to configure the module, and then does

consecutive read block transfers continuously. The power–up bit can be

examined and used anywhere in the program.

Rungs 1 and 2 - Rungs 1 and 2 are the block transfer read and write

instructions. The BTR enable bit in rung 1, being false, initiates the first

read block transfer. After the first read block transfer, the module

performs a block transfer write and then does continuous block transfer

reads until the pushbutton is used to request another block transfer write.

Page 22

Chapter 4

Module Programming

After this single block transfer write is performed, the module returns to

continuous block transfer reads automatically.

45

Page 23

Chapter 4

Module Programming

PLC-5 Program Example

The PLC–5 program is very similar to the PLC–3 program with the following

exceptions:

You must use enable bits instead of done bits as the conditions on each rung.

A separate control file must be selected for each of the BT instructions. Refer

to Appendix B.

Figure 4.3

PLC-5

Family Sample Program Structure

BTR

1

2

BTR Enable

Pushbutton BTW Enable

Power-up Bit

BLOCK XFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS:

XXX:XX

XXX:XX

XXX:XX

XXX:XX

XX

XX

EN

X

X

DN

X

ER

N

EN

X

X

DN

X

ER

N

46

Program Action

Rungs 1 and 2 - At power–up, the program enables a block transfer read

and examines the power–up bit in the BTR file (rung 1). Then, it initiates

one block transfer write to configure the module (rung 2). Thereafter, the

program continuously reads data from the module (rung 1).

A subsequent BTW operation is enabled by a pushbutton switch (rung 2).

Changing processor mode will not initiate a block transfer write unless the first

pass bit is added to the BTW input conditions.

Page 24

Chapter 4

Module Programming

Module Scan Time

Scan time is defined as the amount of time it takes for the input module to read

the input channels and place new data into the data buffer. Scan time for your

module is shown in Figure 4.4.

The following description references the sequence numbers in Figure 4.4.

Following a block transfer write “1” the module inhibits communication until

after it has configured the data and loaded calibration constants “2”, scanned the

inputs “3”, and filled the data buffer “4”. Write block transfers, therefore,

should only be performed when the module is being configured or calibrated.

Any time after the second scan begins “5”, a BTR request “6” can be

acknowledged.

When operated in real time sample mode (RTS) = 00, a BTR may occur at any

time after “4.” When operated in RTS = T, a BTR will be waived until ”T”

milliseconds, at which time 1 BTR will be released.

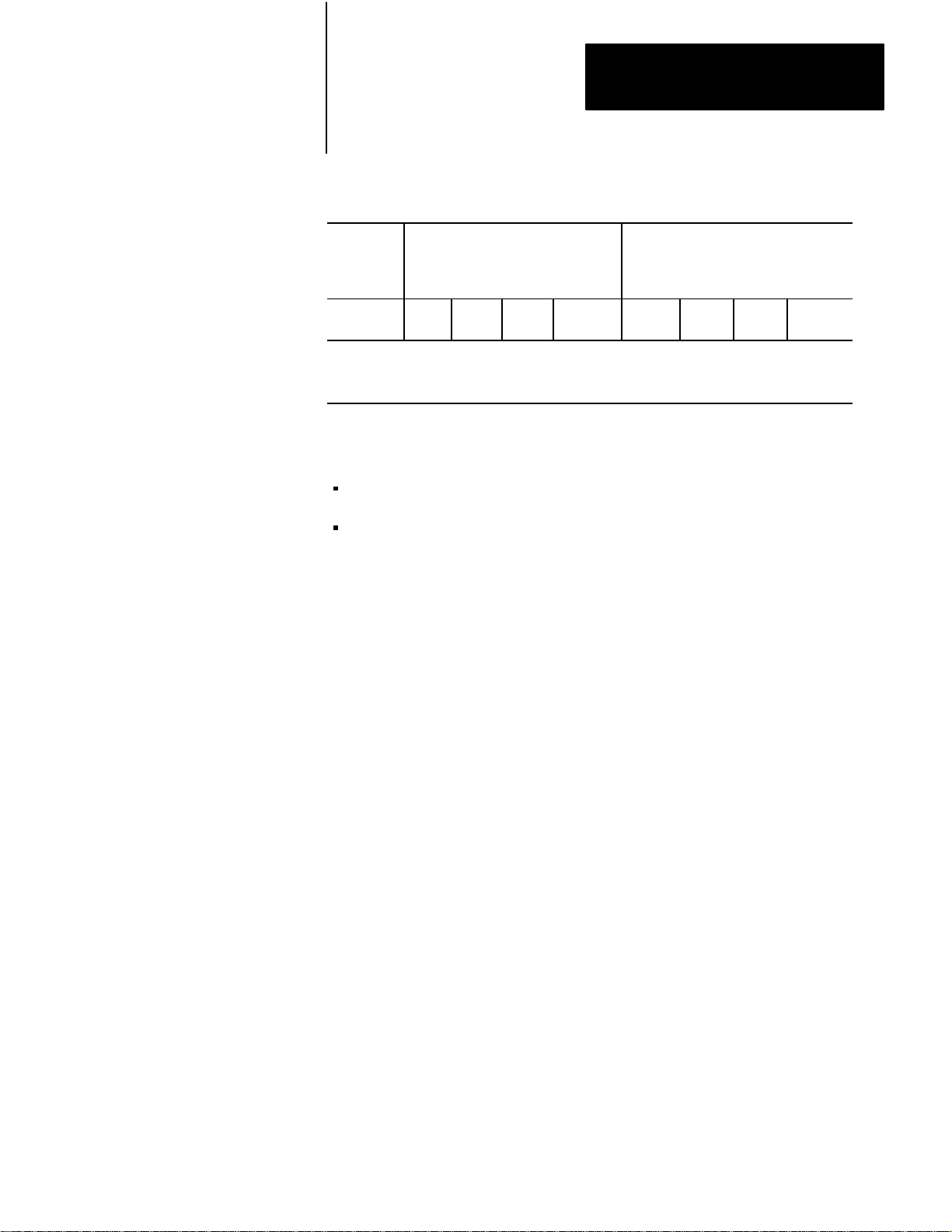

Figure 4.4

T

Block

End of

Block

Transfer

Write

ransfer T

ime

Module available

to perform block

transfer

Chapter Summary

Block

Transfer

Write

Time

1 2 3 456789

Configure

Time

1st Scan 2nd Scan

3rd Scan

Internal Scan time = 50msec

T = 100ms, 200ms, 300ms ... 3.1sec.

In this chapter, you learned how to program your programmable controller. You

were given sample programs for your PLC–2, PLC–3 and PLC–5 family

processors.

You also read about module scan time.

47

Page 25

Module Configuration

Chapter

Chapter Objectives

Configuring Your RTD Module

In this chapter you will read how to configure your module’s hardware,

condition your inputs and enter your data.

Because of the many analog devices available and the wide variety of possible

configurations, you must configure your module to conform to the analog

device and specific application that you have chosen. Data is conditioned

through a group of data table words that are transferred to the module using a

block transfer write instruction.

You can configure the following features for the 1771–IR series B module:

data format

RTD type

units of measure (oC,

real time sampling

calibration

bias

Configure your module for its intended operation by means of your

programming terminal and write block transfers (BTW).

Note: Programmable controllers that use 6200 software programming tools can

take advantage of the IOCONFIG utility to configure this module. IOCONFIG

uses menu–based screens for configuration without having to set individual bits

in particular locations. Refer to your 6200 software literature for details.

o

F or ohms)

During normal operation, the processor transfers from 1 to 14 words to the

module when you program a BTW instruction to the module’s address. The

BTW file contains configuration words, bias values, and calibration values that

you enter for each channel. When a block transfer length of 0 is

programmed, the 1771–IR/B will respond with the Series A default of 14.

51

Page 26

Chapter 5

Module Configuration

Data Format

RTD Type

You must indicate what format will be used to read data from your module.

Typically, BCD is selected with PLC–2 processors, and binary (also referred to

as integer or decimal) is selected with PLC–3 and PLC–5 processors. See

Table 5.A and Appendix C for details on Data Format.

Table 5.A

Selecting

Decimal Bit 10

Octal Bit 12

Format for Reading Data

Decimal Bit 9

Octal Bit 11

0 0 BCD

0 1 2's complement binary

1 0 Signed magnitude binary

1 1 Same as signed magnitude binary

Data Format

The RTD input module accepts the following types of RTD inputs:

RTD Temperature Range Indication

Word 1,

Bit 10

Ohms oC oF

Units of Measure

Platinum -200 to +870oC (-328 to 1598oF) Underrange 0 1.00 -200 -328

Overange 600.00 870 1598

Copper -200 to +260oC (-328 to 500oF) Underrange 1 1.00 -200 -328

Overrange 327.67 260 500

The units of measure reported by the RTD module are selected by setting bits

06–07 in BTW word 1.

Units of Measure

Degrees C 0 0

Degrees F 0 1

Ohms 1 0

Not used 1 1

Bit

07 06

If any of bits 0–5 are set (1), the corresponding input channel will be reported in

ohms.

52

Page 27

Chapter 5

Module Configuration

Real Time Sampling

The real time sampling (RTS) mode of operation provides data from a fixed

time period for use by the processor. RTS is invaluable for time based functions

(such as PID and totalization) in the PLC. It allows accurate time based

calculations in local or remote I/O racks.

In the RTS mode the module scans and updates its inputs at a user defined time

interval (

∆T) instead of the default interval. The module ignores block transfer

read (BTR) requests for data until the sample time period elapses. The BTR of a

particular data set occurs only once at the end of the sample period and

subsequent requests for transferred data are ignored by the module until a new

data set is available. If a BTR does not occur before the end of the next RTS

period, a time–out bit is set in the BTR status area. When set, this bit indicates

that at least one data set was not transferred to the processor. (The actual

number of data sets missed is unknown.) The time–out bit is reset at the

completion of the BTR.

Set appropriate bits in the BTW data file to enable the RTS mode. You can

select RTS periods ranging from 100 milliseconds (msec) to 3.1 seconds in

increments of 100msec. Refer to Table 5.B below for actual bit settings. Note

that the default mode of operation is implemented by placing all zeroes in bits

13 through 17. In default mode, the sample time period is 50msec, and the RTS

time–out is inhibited. Note that binary representation of the RTS bit string is the

RTS period X 100msec. For example, 900msec = 01001 = (9 X 100msec).

Table 5.B

Settings for the Real T

Bit

Decimal Bits

Octal Bits

Important:

Use decimally addressed bit locations for PLC-5 processors.

ime Sample Mode

151714161315121411

13

0 0 0 0 0 R

0 0 0 0 1

0 0 0 1 0

0 0 0 1 1

0 0 1 0 0

0 0 1 0 1

0 0 1 1 0

0 0 1 1 1

0 1 0 0 0

0 1 0 0 1

0 1 0 1 0

0 1 1 1 1

1 0 1 0 0

1 1 0 0 1

1 1 1 1 0

1 1 1 1 1

Sample T

TS inhibited (50msec)

ime Period

100 ms

200 ms

300 ms

400 ms

500 ms

600 ms

700 ms

800 ms

900 ms

1.0 sec

1.5 sec

2.0 sec

2.5 sec

3.0 sec

3.1 sec

53

Page 28

Chapter 5

Module Configuration

Configuring

Block T

ransfer W

Block for a

rite

The complete configuration block for the block transfer write to the module is

defined in Table 5.C below.

Table 5.C

Configuration

Word 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

1 Sample Time

(for RTS)

2 10 ohm resistance @ 25oC

3 Channel 1 Bias

4 Channel 2 Bias

5 Channel 3 Bias

6 Channel 4 Bias

7 Channel 5 Bias

8 Channel 6 Bias

9 Channel 1 calibration

10 Channel 2 calibration

11 Channel 3 calibration

12 Channel 4 calibration

13 Channel 5 calibration

14 Channel 6 calibration

15 Auto-calibration request word

Block for RTD Input Module Block Transfer W

Data

Format

RTD

Type

Units of

Measure

rite

Single channel in ohms

54

Page 29

Chapter 5

Module Configuration

Bit/Word Descriptions

Bit/word descriptions of BTW file words 1 (configuration), 2 (resistance value

of 10 ohm copper RTDs), 3 through 8 (individual channel bias values) and 9

through 14 (individual channel calibration words) are presented below. Enter

data into the BTW instruction after entering the instruction into your ladder

diagram.

Table 5.D

Bit/Word

Word Bits Description

Word 1 bits 00-05 If any of these bits are set, the corresponding input channel will be

Definitions for RTD Input Module

reported in ohms. If RTDs other than 10 ohm copper or 100 ohm

platinum are used you must report those channels in ohms, not

degrees. Data format on a channel displayed in ohms will default to

binary.

bits 06-07 Determines what units of measure the module reports.

Units of measure Bits 07 06

Degrees C 0 0

Degrees F 0 1

Ohms 1 0

Not used 1 1

bit 10 In temperature mode:

0 = Entire module is platinum

1 = Entire module is 10 ohm copper. Enter exact value in word 2.

In ohms mode:

0 = 30mohm/count resolution

1 = 10mohm/count resolution

bits 11-12 Data format bits tell module which format to use for reporting input

values to processsor

Format Bits 12 11

4-digit BCD 0 0

2's complement binary 0 1

Signed magnitude (binary) 1 0

Not used 1 1

bits 13-17 Real time sample bits. See Table 5.B.

Sample Time 17 16 15 14 13

0.1 0 0 0 0 1

0.5 0 0 1 0 1

0.6 0 0 1 1 0

0.7 0 0 1 1 1

0.8 0 1 0 0 0

0.9 0 1 0 0 1

1.0 0 1 0 1 0

55

Page 30

Chapter 5

Module Configuration

Word DescriptionBits

1.5 0 1 1 1 1

Word 1 (cont.) 2.0 1 0 1 0 0

2.5 1 1 0 0 1

3.0 1 1 1 1 0

Word 2 If bit 10 is set in word 1, and temperature readings are desired, word

2 must also be used. Enter the exact resistance of 10 ohm RTD at

25oC in BCD. Range is 9.00 to 11.00 ohms. Values less than 9.00

ohms or greater than 11.00 ohms will default to 10.00 ohms.

Non-BCD values will also default to 10.00 ohms.

Words 3-8 Individual channel bias words entered in BCD. This value is

subtracted from the channel data in the BTR. The bias value is

always a positive number. Bias value range is 0<

Words 9-14 Individual channel calibration words.

Word 15 Auto-calibration request word - used to automatically calibrate

selected channels and save the calibration constants in EEPROM.

Bit 00 Offset calibration complete

Bit 01 Gain calibration complete

Bit 02 Save complete

Bit 06 EEPROM fault

Bit 07 Faulty calibration (no save)

Bits 10-15 Channel failed calibration

bias<9999.

Default Configuration for the RTD Input Module

Chapter Summary

56

If zeroes are written to the module in all configuration positions, the module

will default to:

BCD format

100 ohm platinum RTD

temperature in degrees C

real time sampling = inhibited (sample time = 50msec)

In this chapter you learned how to configure your module’s hardware, condition

your inputs and enter your data.

Page 31

Chapter

Module Status and Input Data

6

Chapter Objectives

Reading Data from the RTD Module

In this chapter you will read about:

reading data from your module

input module read block format

Block transfer read programming moves status and data from the input module

to the processor’s data table in one I/O scan (Table 6.A). The processor user

program initiates the request to transfer data from the input module to the

processor.

During normal operation, the read block transfer for this module moves up to 8

words from the RTD module in one program scan. The words contain module

status and input data from each channel. When a block transfer length of 0 is

programmed, the 1771–IR/B will respond with the Series A default of 8

words.

The user program initiates the request to transfer data from the RTD module to

the processor.

Table 6.A

W

ord Assignments for RTD Input Module (1771-IR/B)

BTR

Decimal Bit 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

Octal Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

1 0 RTS

Timeout

2 Not used Channel Polarity Not used Channel Overflow

3 Channel 1 Data

4 Channel 2 Data

5 Channel 3 Data

6 Channel 4 Data

7 Channel 5 Data

8 Channel 6 Data

9 Auto-calibration Status Word

Channel Overrange

EEPROM

calibration

values not

readable

Power-

up

Channel Underrange

61

Page 32

Chapter 6

Module Status and Input Data

Table 6.B

Bit/Word

Word Bit Definition

Word 1 Bits 00-05 Underrange indication for each channel; set when input is below the

Word 2 Bit 00-05 When set, indicates that default bias has been subtracted from the

Description for RTD Input Module (1771-IR Series B)

normal operating range for copper or platinum RTD. Bit 00 for input 1,

bit 01 for input 2, etc. See Table 6.C.

Bit 06 Power-up bit is set when the module is alive but not yet configured.

Bit 07 EEPROM calibration values could not be read.

Bits 10-15 Overrange bits are set when the input is above the normal operating

range. Bit 10 for input 1, bit 11 for input 2, etc. See Table 6.C.

Bit 16 Real time sample time-out bit. See page 5-2.

Bit 17 Not used

input value. Only the remainder is shown in the data word. Each bit

relates to a single channel; bit 00 for input 1, etc. Default bias is

automatically applied when BCD formatted data cannot be displayed.

This will occur when measuring temperatures in Fahrenheit larger

than 999.9 degrees. The default bias value which is subtracted is

1000.0.

Bits 06-07 Not used

Bits 10-15 Sign bits for each channel. When set indicate that a certain input is

negative. Bit 10 corresponds to input 1, bit 11 to input 2, etc. These

bits are used for BCD and signed magnitude data formats.

Bits 16-17 Not used

Words 3-8 Input data words. The data words must be multiplied or divided by a

factor if whole numbers need to be displayed.

If you are reading temperature in oF or oC:

Then there is an implied decimal point (XXX.X) after the least

significant digit. Resolution is 0.1o.

If you are reading resistance in milliohms (copper RTDs) (BTW word 1, bit 10 = 1):

Then there is an implied decimal point (XXX.XX).

If you are reading resistance in milliohms (all other RTDs) (BTW word 1, bit 10 = 0):

Multiply the data word by 30 to get the actual value in milliohms.

Resolution is 30 milliohms.

Word 9 Auto-calibration word.

Bit 00 Offset calibration complete

Bit 01 Gain calibration complete

Bit 02 Save complete

62

Bit 06 EEPROM fault

Page 33

Word DefinitionBit

Chapter 6

Module Status and Input Data

Chapter Summary

Word 9

(cont.)

Bit 07 Faulty calibration (no save)

Bits 10-15 Channel failed calibration. Bit 10 for input 1, bit 11 for input 2, etc.

Table 6.C

Overrange

Underrange 0 Platinum < 1.00 < -200 < -328

Underrange 1 Copper < 1.00 < -200 < -328

and Underrange V

Indication

Overange > 600.00 > 870 > 1598

Overrange > 327.67 > 260 > 500

BTW

Word 1, Bit 10

alues

RTD

Ohms oC oF

In this chapter you learned the meaning of the status information that the RTD

input module sends to the processor.

63

Page 34

Module Calibration

Chapter

Chapter Objective

Tools and Equipment

Tool or Equipment Description Model/Type Available from:

Industrial Terminal and

Interconnect Cable

Precision Resistors 1.00 ohm, 1% (quantity of 6) CMF-65-0010-F-T-0 Dale

Calibrating your Input Module

In this chapter we tell you how to calibrate your modules.

In order to calibrate your input module you will need the following tools and

equipment:

Programming terminal for A-B

family processors

402.0 ohm, 0.01% (quantity of 6) MAR6-T16-402-.01% TRW

Cat. No. 1770-T3 or Cat. No.

1784-T45, -T50, etc.

Allen-Bradley Company

Highland Heights, OH

You must calibrate the module in an I/O chassis. The module must

communicate with the processor and industrial terminal.

Before calibrating your module, you must enter ladder logic into the processor

memory, so that you can initiate BTWs to the module, and the processor can

read inputs from the module.

Calibration can be accomplished using either of two methods:

About Auto-calibration

auto–calibration

manual calibration

Auto–calibration calibrates the input by generating offset and gain correction

values and storing them in EEPROM. These values are read out of EEPROM

and placed in RAM memory at initialization of the module.

The auto–calibration routine operates as follows:

- Whenever a block transfer write (BTW) is performed to the module (any

time after the module has been powered up), it interrogates word 15 for a

request for auto–calibration.

- The request can be for the following: offset calibration, gain calibration,

save operation (save to EEPROM).

When using auto–calibration, write transfer calibration words 9 through

14 must contain zeroes.

71

Page 35

Chapter 7

Module Calibration

Performing Auto-calibration

Calibration of the module consists of applying 1.00 ohm resistance across each

input channel for offset calibration, and 402.00 ohm across each input channel

for gain correction.

Offset Calibration

Normally all inputs are calibrated together. To calibrate the offset of an input,

proceed as follows:

1. Connect 1.00 ohm resistors across each input channel as shown in

Figure 7.1.

Figure 7.1

Resistor

Location for Offset Calibration

Repeat for

each

channel

1.00 ohm Resistor

Terminal

Identification

18

16

14

12

10

8

6

4

2

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

C

B

A

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

72

12935

2. Apply power to the module.

3. After the connections stabilize, request the offset calibration by setting bit

00 in block transfer write word 15 and sending a block transfer write to the

module. Refer to Table 7.A.

Page 36

W

ord Bit

Chapter 7

Module Calibration

Table 7.A

Block T

Write

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

ransfer W

ord 15

W

Word

ord 9

Bit

W

ord 15

Inhibit Calibration on Channel

Set

these

bits to 0

6 5 4 3 2 1

Set these bits to 0

Requested Auto-Calibration

Requested

Save

Values

Requested

Gain Cal.

NOTE: Normally, all channels are calibrated simultaneously (bits 10–15 of

word 15 are octal 0). To disable calibration on any channel, set (1) the

corresponding bit 10 through 15 of word 15.

4. Queue block transfer reads (BTRs) to monitor for offset calibration

complete and any channels which may have not calibrated successfully.

Refer to Table 7.B.

Table 7.B

Block T

Read

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Uncalibrated Channels

Not

used

6 5 4 3 2 1

ransfer Word 9

Cal.

Fault

EEPROM

Fault

Auto-Calibration Status

Save to

Not used

EEPROM

Complete

Gain Cal.

Complete

Requested

fset Cal.

Of

Of

fset Cal.

Complete

5. Proceed to gain calibration below.

Gain Calibration

Calibrating gain requires that you apply 402.00 ohms across each input channel.

Normally all inputs are calibrated together. To calibrate the gain of an input,

proceed as follows:

1. Connect 402.00 ohm resistors across each input channel as shown in

Figure 7.2.

73

Page 37

Chapter 7

Module Calibration

Figure 7.2

Resistor

Location for Gain Calibration

Repeat for

each channel

402.0 ohm Resistor

18

16

14

12

10

Terminal

Identification

C

Channel 1

B

A

C

Channel 2

B

A

C

Channel 3

B

A

8

6

4

2

C

B

A

C

B

A

C

B

A

Channel 4

Channel 5

Channel 6

74

12935

2. Apply power to the module.

3. After the connections stabilize, request the gain calibration by setting bit

01 in BTW word 15 and sending a block transfer write (BTW) to the

module. Refer to Table 7.A.

NOTE: Normally, all channels are calibrated simultaneously (bits 10–15 of

word 15 are octal 0). To disable calibration on any channel, set (1) the

corresponding bit 10 through 15 of word 15.

4. Queue BTRs to monitor for gain calibration complete and channels which

may not have calibrated successfully.

Page 38

Chapter 7

Module Calibration

Save Calibration Values

If any ”uncalibrated channel” bits (bits 10–15 of BTR word 9) are set, a save

cannot occur. Auto–calibration should be performed again, starting with offset

calibration. If the module has a faulty channel, the remaining functioning

channels can be calibrated by inhibiting calibration on the faulty channel.

The module can be run with the new calibration values, but will lose them on

power down. To save these values, proceed as follows:

1. Request a ”save to EEPROM” by setting bit 02 in BTW word 15 and

sending the BTW to the module. Refer to Table 7.A.

2. Queue BTRs to monitor for ”save complete”, ”EEPROM fault” and

”calibration fault.” An EEPROM fault indicates a nonoperative EEPROM;

a calibration fault indicates at least one channel was not properly offset or

gain calibrated and a save did not occur.

Performing Manual Calibration

Note: During normal operation, make sure bits 00, 01 and 02 of BTW

word 15 are zero (0).

You calibrate each channel by applying a precision resistance across each

channel, comparing correct with actual results, and entering correction into the

corresponding calibration word for that channel. The correction takes affect

after it is transferred to the module by the corresponding BTW instruction in

your ladder diagram program. Always start with offset adjustment followed by

gain adjustment.

Before calibrating the module, you must enter ladder logic into processor

memory, so that you can initiate write block transfers to the module, and the

processor can read inputs from the module.

Words 9 through 14 in the write block transfer file are the module calibration

words. Word 9 corresponds to channel 1, word 10 to channel 2, and so on. Each

word is composed of two bytes: the upper byte is for offset correction and the

lower byte is for gain correction. Refer to Table 7.C.

75

Page 39

Chapter 7

Module Calibration

Table 7.C

Calibration W

Module

Word/Bit 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

9 S Channel 1 Offset S Channel 1 Gain

10 S Channel 2 Offset S Channel 2 Gain

11 S Channel 3 Offset S Channel 3 Gain

12 S Channel 4 Offset S Channel 4 Gain

13 S Channel 5 Offset S Channel 5 Gain

14 S Channel 6 Offset S Channel 6 Gain

ords

Enter the information for each byte in signed magnitude binary format. In each

byte, the most significant bit (bits 17, 7) is a polarity bit. When the polarity bit

is set (1), the module anticipates a negative calibration value.

A negative calibration value means that your readings are too high and you

want to subtract a corrective amount from that reading.

A positive calibration value means that your readings are too low and you want

to add a corrective amount to that reading.

Important: If you have a spare field wiring arm. you may want to temporarily

switch it with the module’s present wiring arm. You can use this spare arm for

test purposes in order to avoid disconnecting your RTD wiring.

Offset Calibration

1. Attach the 1.00 ohm, 1% resistors as shown in Figure 7.1.

2. Examine word 3 (channel 1 data) in the read block transfer file. Note the

value. It should be around 1.00 (100 for 10 mohm resolution; 33 for 30

mohm resolution).

3. Examine word 9 of the write block transfer data file. Bits 16–10 make up

the offset correction byte. Bit 17 is the sign bit.

4. Subtract the data value that you noted in step 2 from 100. The difference

should be within +127 to –127. If it is not, the required correction is

beyond the range of software calibration. If the difference is within range,

input the difference (positive or negative), in binary form, in bits 17–10 of

word 9 in the write block transfer file.

76

For example, if, at 1.00 ohm, word 3 of the read block transfer data file

shows 147, you would subtract 147 from 100, which equals –47. You

would then enter 10101111 (–47) in the upper byte of word 9. The leading

1 (bit 17) is the polarity bit. It indicates a negative correction factor. That

Page 40

Chapter 7

Module Calibration

is, you want to subtract 47 counts from your input data. The lower byte

remains 00 during offset calibration.

5. Repeat above steps for channels 2 through 6 respectively.

6. Apply the values by sending a BTW to the module.

Gain Calibration

1. Connect the 402.00, .01% resistors to the swing arm as shown in

Figure 7.2.

2. Place the module in platinum ohm mode. This provides 30 mohm

resolution display.

3. Examine word 3 of the read block transfer data file. It should be around

13400 decimal. Your actual value will be a percentage of 13400.

For example, if the data in word 3 is 13408, then:

(13400–13408)/134000 = –0.000597.

Your actual data value differs from the theoretical value (at 402.0 ohms

input resistance) by –0.000597, or –0.0597%.

You can compensate for this error by entering the percentage difference in

binary coded fraction form. Table 7.D lists the value for bits 7–0.

Table 7.D

for Bits 7 through 0

Value

Bit Value

Bit 07 Sign bit

Bit 06 = 0.0976562%

Bit 05 = 0.0488281%

Bit 04 = 0.024414%

Bit 03 = 0.012207%

Bit 02 = 0.00610351%

Bit 01 = 0.00305175%

Bit 00 = 0.00152587%

77

Page 41

Chapter 7

Module Calibration

You use the values that most nearly add up to the percentage that you

determined in step 8. For example, to attain the value of 0.0597%, you need to

add:

Percentage Bit Number

0.0488281 Bit 05

0.00610351 Bit 02

0.00305175 Bit 01

0.00152587 Bit 00

Total = 0.0595%

As you can see, 0.0595 is smaller than 0.0597, but this value is as close as you

can come using the 7 possible values listed in Table 7.D.

You would enter 10100111 in the lower byte of word 9. This sets bits 05, 02, 01

and 00, which subtracts a gain correction of 0.0595% from the actual input data

value.

Chapter Summary

Important: When you enter data in the least significant byte, remember to

reenter the data in the most significant byte in the word. If you don’t, the data in

the MSB is lost.

4. Repeat above steps for channels 2 through 6.

5. Apply the values by sending a BTW to the module.

In this chapter, you learned how to calibrate your input module.

78

Page 42

Troubleshooting

Chapter

8

Chapter Objective

Diagnostics Reported by the Module

We describe how to troubleshoot your module by observing LED indicators and

by monitoring status bits reported to the processor.

At power–up, the module momentarily turns on both indicators as a lamp test,

then checks for

correct RAM operation

EPROM operation

EEPROM operation

a valid write block transfer with configuration data

Thereafter, the module lights the green RUN indicator when operating without

fault, or lights the red fault (FLT) indicator when it detects fault conditions. If

the red FLT indicator is on, block transfer will be inhibited.

The module also reports status and specific faults (if they occur) in every

transfer of data to the PC processor. Monitor the green and red LED indicators

and status bits in word 1 of the BTR file when troubleshooting your module.

Figure 8.1

Indicators

LED

RTD

INPUT

RUN

FLT

This module uses a read block transfer to transmit data and to monitor module

and data status. Word 1 of the read block transfer data file contains module

status, power–up, and data out–of–range information. Word 2 contains data

polarity and overflow information. Words 3 through 8 are data words.

Green RUN LED

Red Fault (FLT) LED

81

Page 43

Chapter 8

Troubleshooting

Table 8.A shows LED indications and probable causes and recommended

actions to correct common faults.

Table 8.A

Troubleshooting

Indication Probable Cause Recommended Action

Both LEDs are OFF No power to module

Possible short on the module

LED driver failure

Red FLT LED ON and

Green RUN LED is ON

Red FLT LED ON If immediately after power-up, indicates RAM or

Green RUN LED is flashing Power-up diagnostics successfully completed. Normal operation.

1

When red LED is on, the watchdog timer has timed out and backplane communications are terminated. Your user program should monitor

communication.

Microprocessor, oscillator or EPROM failure Replace module.

EPROM failure.

If during operation, indicates possible

microprocessor or backplane interface failure.

If LED continues to flash, and write block transfers

(BTW) cannot be accomplished, you have a

possible interface failure.

Chart for the RTD Input Module (1771-IR/B)

Check power to I/O chassis. Recycle as necessary.

Replace module.

1

Replace module.

Replace module.

1

Check ladder logic program. If correct, replace module.

Status Reported in Words 1 and 2

Design your program to monitor status bits in words 1 and 2, and to take

appropriate action depending on your application requirements. You may also

want to monitor these bits while troubleshooting with your industrial terminal.

The module sets a bit (1) to indicate it has detected one or more of the following

conditions.

Table 8.B

Status

Reported in W

Word Bit Indication

1 00-05 Data underrange. Bit 05 corresponds to channel 6, bit 04 corresponds

ords 1 and 2

to channel 5, and so on. If input connections and resistances are

correct, this status may indicate failed communications between the

channel and microprocessor. If all channels are underrange, a blown

fuse or failed dc-dc converter may be the cause.

06 Successful power-up and module is waiting for configuration data. Bit

06 is reset after the first successful block transfer write.

07 EEPROM calibration constants could not be read. The module will

continue to operate but readings may be inaccurate.

82

Page 44

Chapter 8

Troubleshooting

Word IndicationBit

Word 1 (cont.) 10-15 Data overrange. Bit 15 corresponds to channel 6, bit 14 corresponds

to channel 5, and so on. If input connections and resistances are

correct, this status may indicate a failed RTD functional analog block

(RTD FAB).

16 RTS timed out. The module updated its inputs before the processor

read them.

17 Not used.

2 00-05 Indicates that the default bias of 1000.0 has been subtracted from the

measured value. If sending binary data, no overflow occurs unless

there is a hardware malfunction.

06-07 Not used

10-15 Data sign bits formatted for BCD or signed magnitude. Bit 10

corresponds to channel 1, bit 11 to channel 2, and so on.

16-17 Not used

Chapter Summary

Status Reported in Word 9

Design your program to monitor status bits in word 9 during calibration, and to

take appropriate action depending on your requirements. You may also want to

monitor these bits while troubleshooting with your industrial terminal. The

module sets a bit (1) to indicate it has detected one or more of the following

conditions.

Table 8.C

Reported in W

Status

Word Bit Condition

9 6 The EEPROM could not be written.

7 Channel(s) could not be calibrated as indicated by bits 10 through 15 respectively.

10-15 Bit 10 (channel 1) through bit 16 (channel 6) could not be calibrated. Check field

In this chapter, you learned how to interpret the LED status indicators and

troubleshoot your input module.

ord 13

wiring arm connections and source for proper resistance.

83

Page 45

Appendix

A

Specifications

Module Capacity Six RTD input channels

Module Location 1771 I/O Chassis

Sensor Type 100 ohm platinum (alpha = 0.00385) or 10 ohm copper (alpha =

0.00386)

Other types may be used with report in ohms only

Units of measure Temperature in oC

Temperature in

RTD resistance in ohms (10milliohms or 30milliohms resolution)

Temperature Range Platinum: -200 to +870oC (-328 to 1598oF)

Copper: -200 to +260oC (-328 to +500oF)

Resistance Range 1.00 to 600.00 ohms

Resolution Platinum: 0.1oC (0.1oF)

Copper: 0.3

Sensor Excitation 1mA constant current source supplied by module

Input Isolation Dielectric Test 1000V peak channel to channel, channel to backplane, for 1 second

Common Mode Rejection 120db @ 60Hz up to 1000V peak

Common Mode Impedance Greater than 10 megohms

Normal Mode Rejection 60db @ 60Hz

Input Overvoltage Protection 120V rms continuous

Open RTD Response Time Open excitation (terminal A) to overrange: <0.5sec

Open common (terminal C) to underrange: <0.5sec

Open sense (terminal B): drift high

Scan Time (all 6 channels) 50ms

o

F

o

C (0.5oF)

Environmental Conditions

Operating Temperature

Rate of Change

Storage Temperature

Relative Humidity

Backplane Power Consumption 4.25W maximum, 0.85A at 5V

Keying Between 10 and 12

Field Wiring Arm Cat. No. 1771-WF

0 to 60oC (32 to 140oF)

Ambient changes greater than 1.0

degrade performance during periods of change.

-40 to 85

5 to 95% noncondensing

Between 28 and 30

o

C (-40 to 185oF)

o

C/minute may temporarily

A-1

Page 46

Appendix A

Specifications

Table A.A

1771-IR

RTD Type Range

Copper -200 to +260oC (-328 to +500oF) +0.344oC/+0.564oF +0.1306

Platinum -200 to +870oC (-328 to 1598oF) +0.100oC/+0.152oF +0.0717

Series B Error Summary Based on Temperatures above -200oC

Error @ Calibration

Temperature (25

(over range)

o

C)

oC/o

Drift

C or oF/oF

Table A.B

1771-IR

Series B Resistance Error Summary

RTD Type Resistance Error @ 25oC

(over range)

Copper +0.074 ohm +0.0213

Platinum +0.075 ohm +0.0213

Resistance Drift

Ohm/

o

C

A-2

Page 47

Programming Examples

Appendix

Sample Programs for the RTD Input Module

PLC-2 Family Processors

The following are sample programs for entering data in the configuration words

of the write block transfer instruction when using the PLC–2, PLC–3 or PLC–5

family processors.

To enter data in the configuration words, follow these steps. NOTE: For

complete programming sample, refer to Figure 4.1.

Example:

Enter the following rung for a write block transfer:

Power Up Bit

BTW

BLOCK XFER WRITE

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

100-115

030

110

14

010

EN

06

110

DN

06

100 is the address of the write block transfer data file. You want to examine

configuration word 1.

In RUN/PROG Mode

Action Result

1. Press [SEARCH]8<data address> Finds the block address transfer

instruction

2. Press CANCEL COMMAND Removes preceeding command

3. Press [DISPLAY]0 or 1 Displays the file in binary or BCD

4. Press [SEARCH]51 On line data change

Cursor defaults to first entry in file when

SEARCH 51 is pressed.

5. Press [INSERT] Writes data to file element

B1

Page 48

Appendix B

Programming Examples

In PROG Mode

Action Result

1. Press [SEARCH]8<data address> Finds the block transfer instruction

2. Press CANCEL COMMAND Removes preceeding command

3. Press [DISPLAY]0 or 1 Displays the file in binary or BCD

4. Press [DISPLAY]001 and enter data Puts cursor on word 1

5. Press [INSERT]

Use the above procedure to enter the required words of the write block transfer

instruction. Be aware that the block length will depend on the number of

channels selected and whether biasing and/or calibration is or is not performed;

for example, the block may contain only 1 word if no bias or calibration is

performed but may contain 14 words if using 6 inputs with bias and calibration.

The PLC–2 family write block transfer data file should look like Figure B.1.

Figure B.1

Block T

Write

DAT

A ADDR: 030

POSITION FILE DATA

ransfer Data Transfer for a PLC-2 Family Processor

BINAR

Y DA

001

002

003

004

005

006

007

008

TA MONITOR

BLOCK XFER WRITE

MODULE ADDR: 1

FILE: 100-1

00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000