Page 1

AllenBradley

Analog Input

Module

User

(Cat.

No. 1771-IE)

Manual

Page 2

Table of Contents

Using This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Purpose of This Manual 11

Audience 11

Warnings and Cautions 11

Related

Quick Locator 11

Objective

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of the Analog Input Module 21. . . . . . . . . . . . . . . .

Chapter

Description 21

Input Channels 22

How Analog Modules Communicate With Programmable Controllers 22

How the Input Module Converts Analog Signals 23. . . . . . . . . . . . . .

Input Data Format 24

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Analog Input Module 31. . . . . . . . . . . . . . . . . . .

Chapter

Before Y

Electrostatic Damage 31

Power Requirements 32

Module Location 33

Keying 33

Wiring 34

Grounding 37

Setting Configuration Switches 38

Installing

Objectives

ou Install the Input Module

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

the Input Module

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . .

38. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming the Analog Input Module 41. . . . . . . . . . . . . . .

Chapter

Block Transfer Programming 41

General Example 41

PLC2

PLC3

PLC5/15 Example 45

Programming Considerations 45

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Family Example

Family Example

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

44. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

Calibrating the Analog Input Module 51. . . . . . . . . . . . . . . . .

Chapter

Service

Calibration

Before You Calibrate 52

Calibrating

Setting

Offset (Part A) 54

Offset (Part B) 56

Objective

Information

Equipment

the Input Module

the Switches

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

52. . . . . . . . . . . . . . . . . . . . . . . . . . . .

53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer (Multiple GET) for PLC2/20 A1. . . . . . . . . . . .

Example Program A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assumptions A1

Description A3

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Single Channel Transfer for PLC Processors B1. . . . . . . . . . .

Example Program B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Logic B6

Assumptions B7

Using Less Than Eight Input Channels B7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Page 4

Using This Manual

Chapter

1

Chapter Objective

Purpose of This Manual

Audience

Warnings and Cautions

This chapter tells you how to use this manual efficiently.

This manual shows you how to use your 8-bit Analog Input Module with

an Allen-Bradley programmable controller. It helps you install, program,

calibrate, and troubleshoot your module.

We assume that you know how to program and operate an Allen-Bradley

programmable controller. In particular, you should know how to program

block transfer. If you do not, refer to the appropriate programming and

operations manual before you use the 8-bit Analog Input Module.

This manual contains warnings and cautions. A warning tells where you

may be injured if you use your equipment improperly. Cautions tell

where equipment may be damaged from misuse.

You should read and understand cautions and warnings before performing

the procedures they precede.

Related Publications

Quick Locator

For a list of publications with information on the Allen-Bradley line of

modules and programmable controllers, consult our publication index

(SD499).

You will find the following terms or concepts described as follows:

Block Transfer Programs Page 4-1

Calibration Page 5-1

Configuration Switches Page 3-9, 5-3

External Power Supply Page 3-2

Input Channel Ranges Page 2-2

Input Data Format Page 2-4

Specifications Page 2-6

Status Bits Page 2-5

Wiring/Grounding Page 3-4, 3-8

11

Page 5

Chapter

2

Overview of the Analog Input Module

Chapter Objectives

Description

This chapter gives you a functional and hardware overview of the analog

input module.

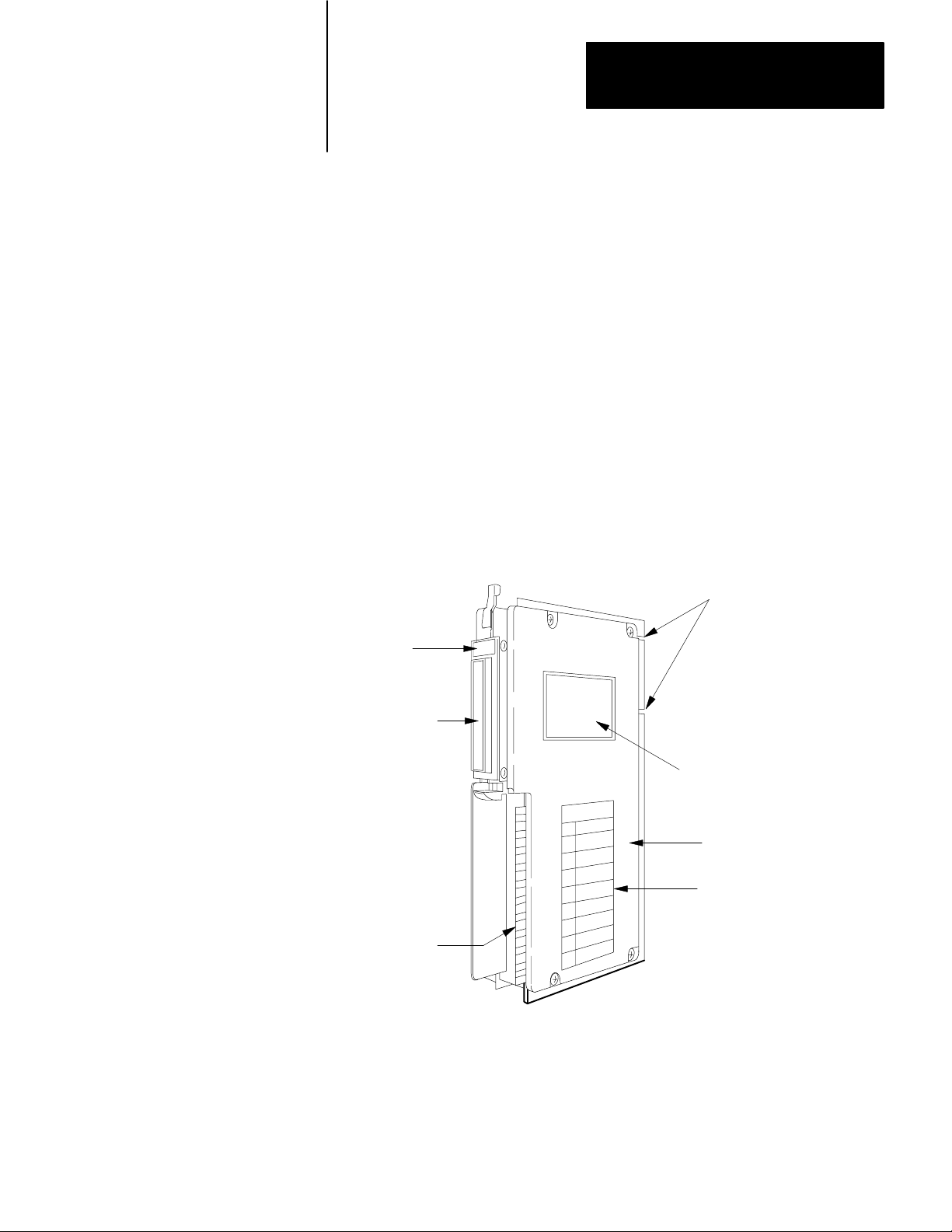

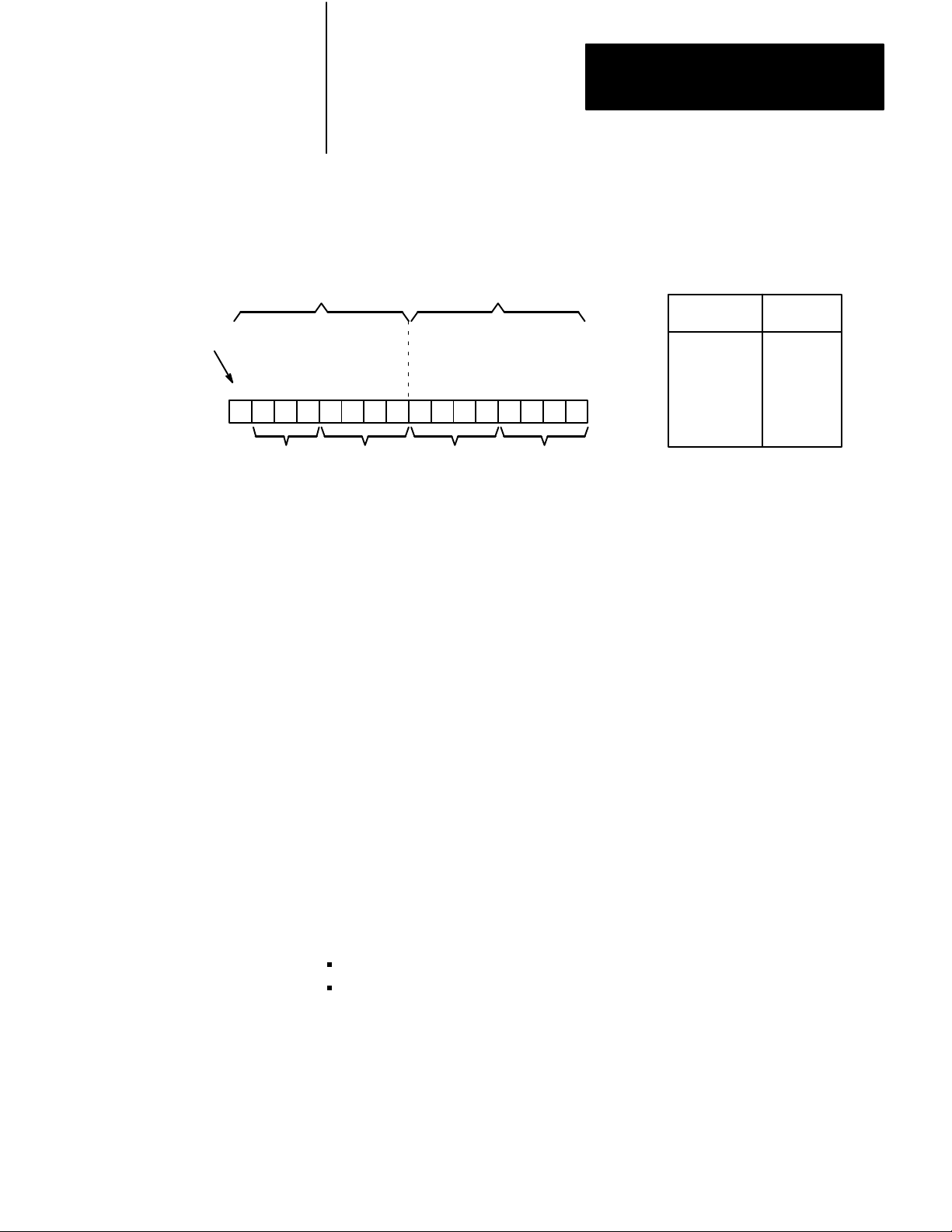

The module (Figure 2.1) senses analog signals at its inputs and converts

these signals to 3-digit Binary Coded Decimal (BCD) values (0 to 255

BCD) for use by your programmable controller.

Figure 2.1

Input Module

Analog

Keying Slots

Pink

Identification

Label

Range/Calibration

Date Label

Labels Identify Module

Type/Series

Protective

Covers

Label Specif ies

Terminal Connection

Wiring Arm

Connects Here

17996

The module accepts up to eight analog signals having a single voltage or

current range that you select based on the type of input devices required

by your application. It allows your programmable controller to

21

Page 6

Chapter 2

Overview of the Analog Input Module

manipulate values representing temperature, pressure, rotational speed,

light intensity, and position.

A wiring arm (cat. no. 1771-WB) accompanies the module. It acts as a

terminal strip for input connections. The wiring arm pivots on the I/O

chassis to connect with terminals on the front of the input module. Thus,

the wiring arm lets you quickly connect or disconnect your input wiring

when inserting or removing the input module from the I/O chassis.

The input module meets the requirements of the Instrument Society of

America, Standard S50.1 (1975), “Compatibility of Analog Signals for

Electronic Industrial Process Instruments.”

Input Channels

The input module supports eight single-ended input channels. All eight

channels have the same voltage or current range that you select when

ordering the module. The range is factory set and calibrated.

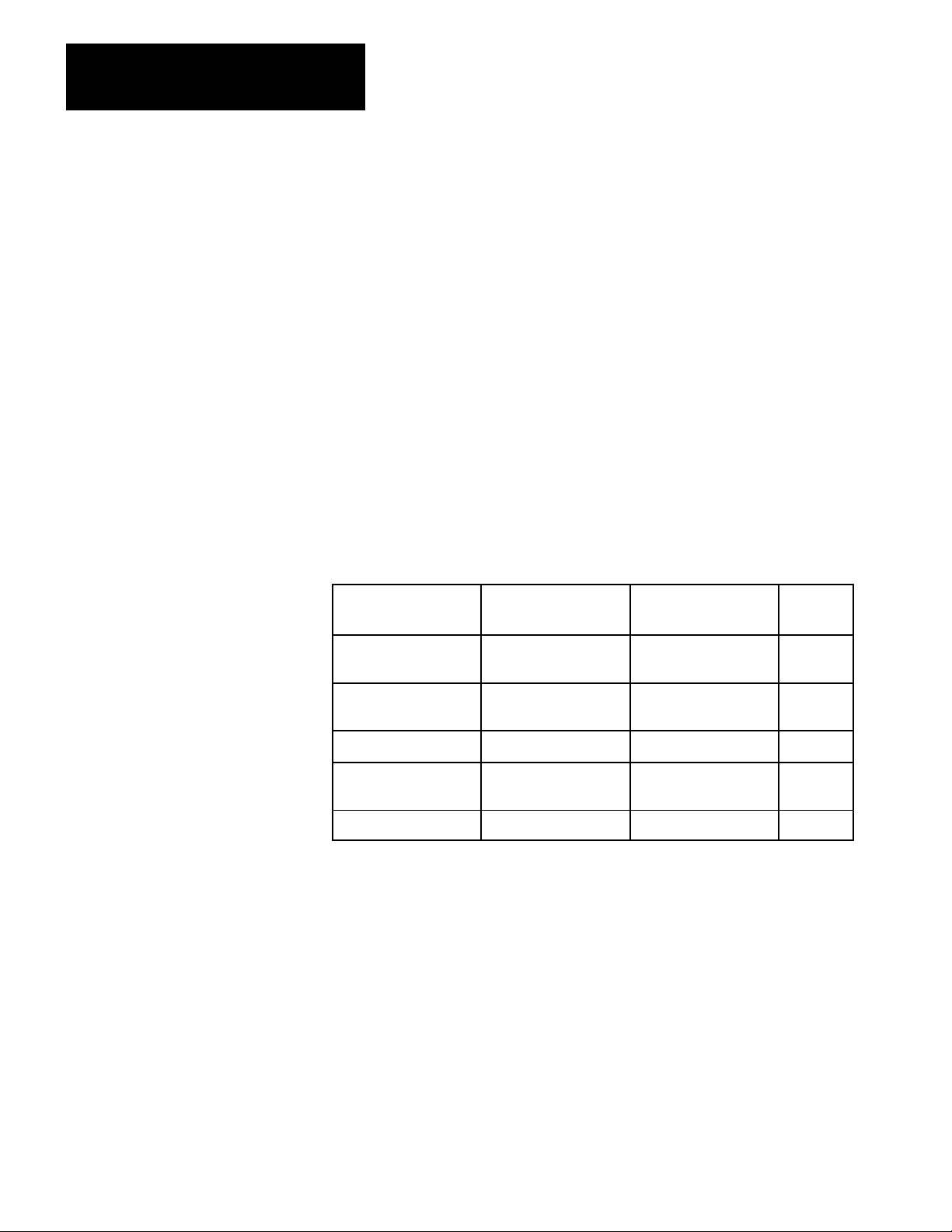

Nominal

Range:

1 to 5 V

4 to 20mA

0 to 5 V

0 to 20 mA

10 to 10V

20 to 20 mA

0 to 10 V

Precise Range:

1 to 4.9844 V

4 to 19.937 mA

0 to 4.980 V

0 to 19.922 mA

10 to 9.922V

20 to 19.844

mA

0 to 9.96 V

Units/Bit: Order

Code

15.60 mV/bit

0.063 mA/bit

19.53 mV/bit

0.078 mA/bit

78.13 mV/bit

0.156 mA/bit

39.06 mV/bit

01

05

02

06

03

07

04

When ordering 1771-IE modules, place the order code as a suffix to the

catalog number. For example, 1771-IE-04.

You can change from a voltage range to the equivalent current range and

vice versa within limited catagories. For example, from the above table

you can switch from a range of (1 to 5 VDC) to (4 to 20 mA) or (0 to 5

VDC) to (0 to 20 mA) without recalibrating.

How Analog Modules

Communicate With

Programmable Controllers

22

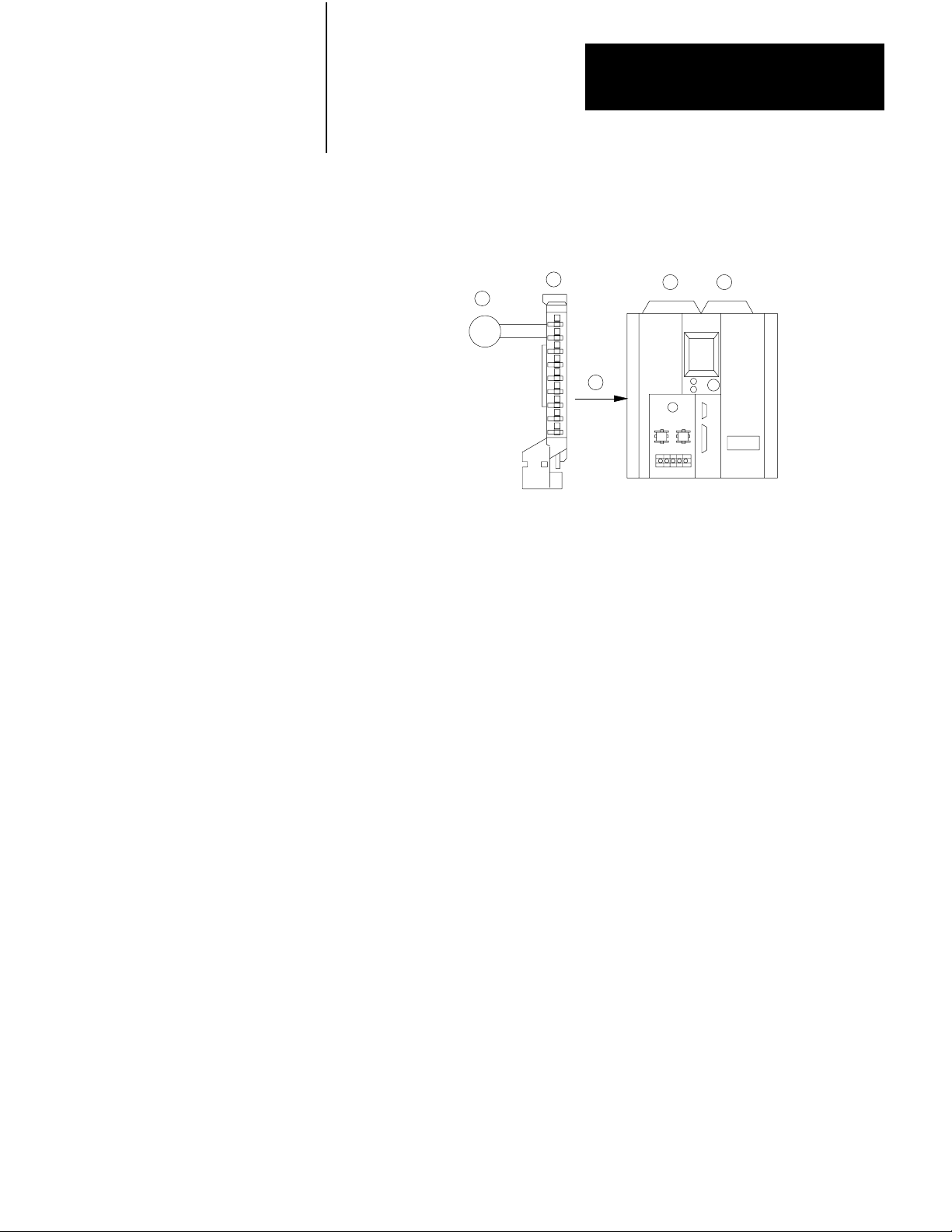

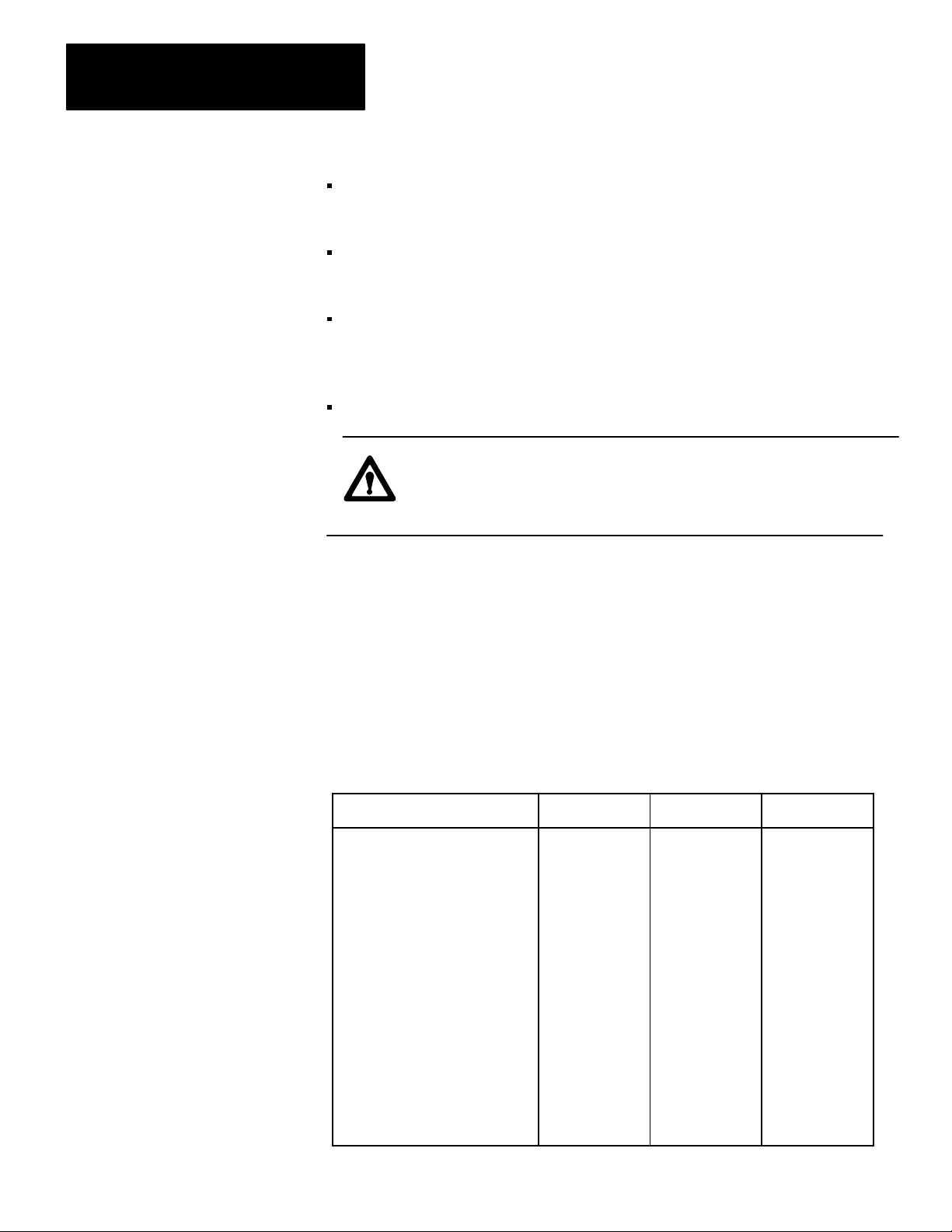

Analog input modules communicate with a programmable controller by

block transfer in the following manner (Figure 2.2).

Page 7

Chapter 2

Overview of the Analog Input Module

Figure 2.2

Communication

Between Input Module and Processor

2

1

Input

Device

8- BIT Input Module

(cat.no.1771-IE)

3

BTR

4 5

PC Processor

(PLC2/30 Processor

Shown)

14164

1. Input devices generate analog signals which are transmitted to the

input module.

How the Input Module Converts

Analog Signals

2. The input module converts analog signals into BCD values and

stores them until the processor requests a transfer of data.

3. When instructed by your ladder diagram program, the processor

performs a read block transfer of the values and stores them in its

data table.

4. Your program can determine that the transfer was made without

error, and that the values are within a specified range.

5. Your program can use and/or move the data before it is written over

by the transfer of new data in a subsequent block transfer.

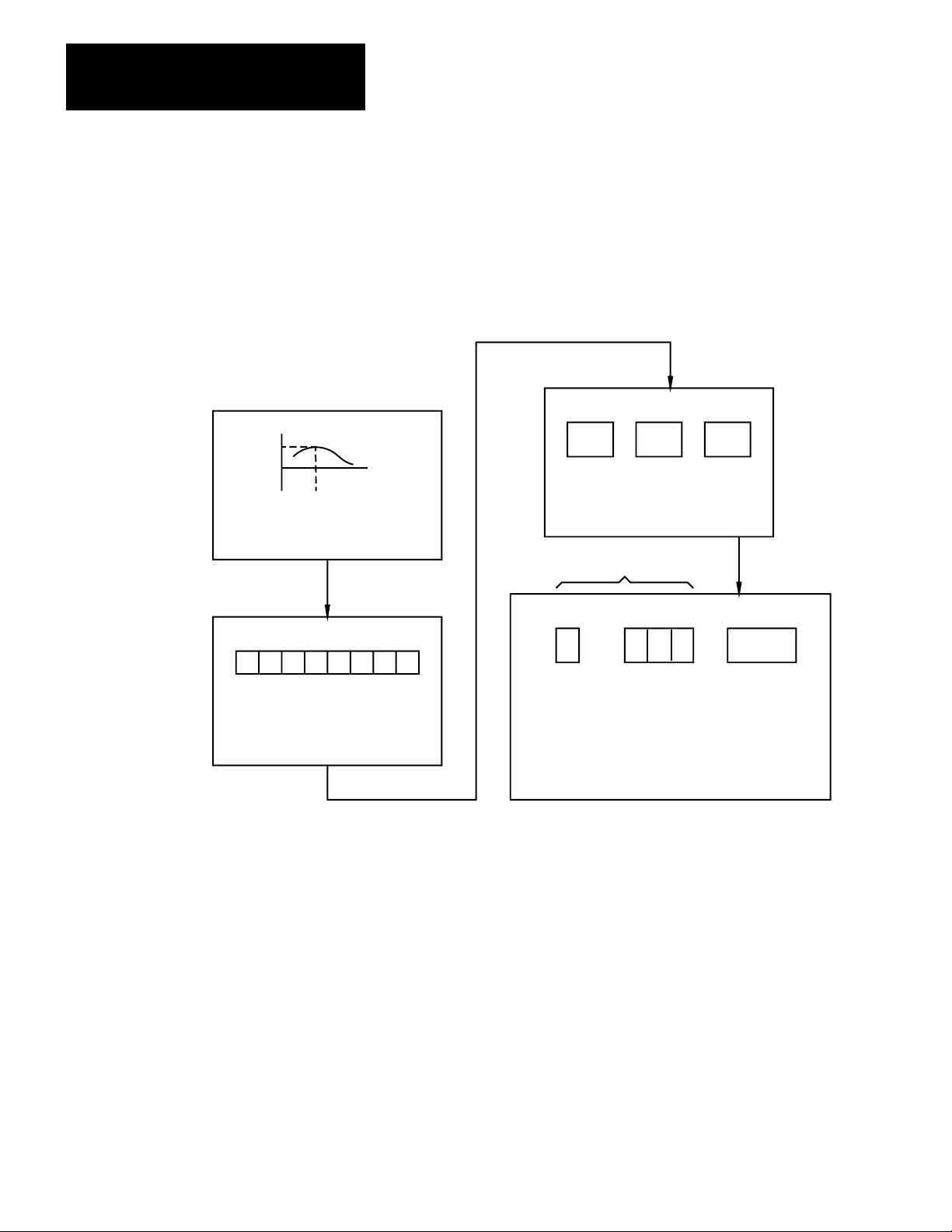

The input module converts analog signals to digital values readable by

your processor (Figure 2.3).

The input module scans its inputs every 2.5ms and converts analog data to

a digital format. It stores this data momentarily until transferred to the

processor’s data table. The module reserves the last 200 microseconds of

23

Page 8

Chapter 2

Overview of the Analog Input Module

each input scan for formatting data, and cannot accept block transfers

during this time.

Figure 2.3

Conversion and Formatting

Input

129

Measurement of analog

voltage or current value

10000001

(129)

Converted to a

binary value

0001 0010

(1) (2) (9)

Converted to

a BCD value

Status added by the module

17 16 - 14 13 - 0

Over/

Under

flow

Channel

number

Stored in memory

1001

(129)

Analog

value

(BCD)

14159

Input Data Format

24

Input data is transferred to the processor in 12-bit 3-digit BCD format

with a range of 0-255.

The processor stores the data in 16-bit input words (Figure 2.4). The 16

bits are used as follows:

Page 9

Figure 2.4

Input W

Analog

Chapter 2

Overview of the Analog Input Module

ord

Overflow/

Underflow Bit

High Byte Low Byte

0 = within range

1 = out of range

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

00

Channel

Address

(see table)

Most

Significant

Digit

(0-2)

Middle

Digit

(0-9)

Least

Significant

Digit

(0-9)

Bits 00-11 These bits contain input values which range from 0 to 255

BCD (8 bit resolution).

Channel Address Codes

Bits

16 15 14

0 0 0

0 0 1

0 1 0

0 1 1

1 0 0

1 0 1

1 1 0

1 1 1

Channel

Number

1

2

3

4

5

6

7

8

14165

Bits 12-13 These bits must remain reset (to 0) for proper operation.

Bits 14-16 These bits indicate by binary code which channel is being

read.

Bit 17 This bit indicates an overflow/underflow condition, and is set (to 1)

under the following conditions:

input value is zero or negative

input value is greater than or equal to 255

25

Page 10

Chapter 2

Overview of the Analog Input Module

Specifications

Inputs

Per Module

8 singleended

Humidity Rating

5 to 95% (noncondensing)

Input Voltage Ranges (nominal)

1 to 5 V

0 to 5 V

0 to 10 V

10 to 10 V

Input Current Ranges (nominal)

0 to 20 mA

4 to 20 mA

20 to 20 mA

Input Overvoltage Protection

+

35 VDC

25 VRMS (sinusoidal)

Input Overcurrent Protection

+

30 mA

Input Impedance

10

10

Ohms

for voltage ranges

250 Ohms (+

0.1%) for current ranges

ElectricalOptical Isolation

between input circuit and control

logic: 1500 V

Backplane Current Requirement

400 mA at 5 VDC

Keying (between)

4 and 6

26 and 28

A/D Converter T

ype

successive approximation, monotonic

Resolution

1 part in 256 (28)

Linearity

+

0.1% of full scale at 25o C

Offset

0.15% of full scale at 25o C

+

Gain

0.15% of full scale at 25o C

+

Quantizing Error

+

1/2 LSB (0.19% of full scale)

Absolute Accuracy (including linearity

and gain at 25

o

C)

of full scale +

0.3%

1/2 LSB

Stability (drift over the full temperature

range)

temperature coef

ficient = +

85 ppm/oC

of full scale

, offset,

26

Ambient T

emperature Rating

operating: 0 to 60

(32 to 140oF)

storage 40 to 85oC

(40 to 185oF)

o

C

Inaccuracy (due to internal electrical noise)

3 sigma noise 0.2% RMS of full scale

Page 11

Chapter

3

Installing the Analog Input Module

Chapter Objectives

Before You Install the Input Module

This chapter gives you information on:

choosing an external power supply

wiring the input module’s field wiring arm

keying a chassis slot for your module

setting internal configuration switches

installing the input module

The input module is shipped to you configured for block transfer

operation. If you want to use single transfer, see Appendix C for proper

switch settings.

Before installing your input module in the I/O chassis you should:

1. Calculate the power requirements of all modules in each chassis. See

“Power Requirements.”

2. Determine where to place the module in the I/O chassis. See

“Module Location in the I/O Chassis.”

Electrostatic Damage

3. Key the backplane connector in the I/O chassis. See “Keying.”

4. Make connections to the wiring arm. See “Wiring” and

“Grounding.”

5. Set configuration switches (only if you want single transfer, or to

change to the alternate input range).

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins, or when you set

configuration plugs or switches inside the module. Guard against

electrostatic damage by observing the following precautions:

31

Page 12

Chapter 3

Installing the Analog Input Module

Touch a grounded object to rid yourself of elctrostatic charge before

handling the module.

Handle the module from the front, away from the backplane connector.

Do not touch backplane connector pins.

When setting internal switches or configuration plugs, do not touch

semiconductor devices inside the module. Use a static-safe work

station if available.

Keep the module in its static-shield bag when not in use.

CAUTION: Electrostatic discharge can degrade performance

or cause permanent damage. Handle this module as stated

above.

Power Requirements

Your module requires 400 mA from the I/O chassis backplane. Calculate

the power usage of all modules in the I/O chassis so you do not exceed the

power rating of the chassis backplane or the backplane power supply.

The input module also requires an external power supply exclusively for

analog modules. Using a separate supply protects the analog signal from

transients caused by the switching of digital circuits. The specifications

for the external DC power supply are:

Specifications 5V 15V 15V

current

per input module

voltage tolerance

regulation (type)

line regulation

(for 10 VAC RMS input change)

load regulation

150mA 70mA 70mA

1% 1% 1%

linear

(series or

shunt)

.02% .02% .02%

.04% .02% .02%

linear

(series or

shunt)

linear

(series or

shunt)

32

ripple

overvoltage protection

current limit

(% of full load)

1 mV 1 mV 1 mV

7 V

125% 125% 125%

18 V

18 V

Page 13

Chapter 3

Installing the Analog Input Module

We recommend either of two Allen-Bradley power supplies:

Power Supply (cat. no. 1770-P1) provides sufficient current for two

1771-IE input modules. This supply operates on either 120 or 220/240

VAC.

The Remote Power Supply (cat. no. 1778-P2) provides external power

for up to ten 1771-IE input modules. Do not use this supply for I/O

chassis power when powering analog modules. We recommend that you

order one or two power cables (cat. no. 1771-CF), and connect no more

than five 1771-IE input modules with a single power cable.

Power and common connections can be jumpered from one 1771-IE input

module to the next. Be careful to minimize the voltage drop in your

power connections.

Module Location

Keying

WARNING: Maintain at least 5.0 VDC between the 5 VDC

terminal and common terminal measured at the wiring arm. A

lower voltage could cause intermittent operation resulting in

possible damage to equipment and personal injury.

Place your module in any I/O module slot except for the extreme left slot

of the I/O chassis. This slot is reserved for PC processors or adapter

modules. We recommend the following:

Do not put this input module in the same module group with a discrete

high density I/O module when using 2-slot addressing because this

input module uses both the input and output image tables for block

transfer. Two analog input modules, however, may be put in the

same module group.

Group analog input modules away from AC or high voltage DC I/O

modules to minimize electrical noise interference.

Once you designate a slot for your input module, you should not place

other types of modules in this slot. We recommend that you use the

keying bands, shipped with your I/O chassis, to accept only one type of

module in a designated I/O slot.

33

Page 14

Chapter 3

Installing the Analog Input Module

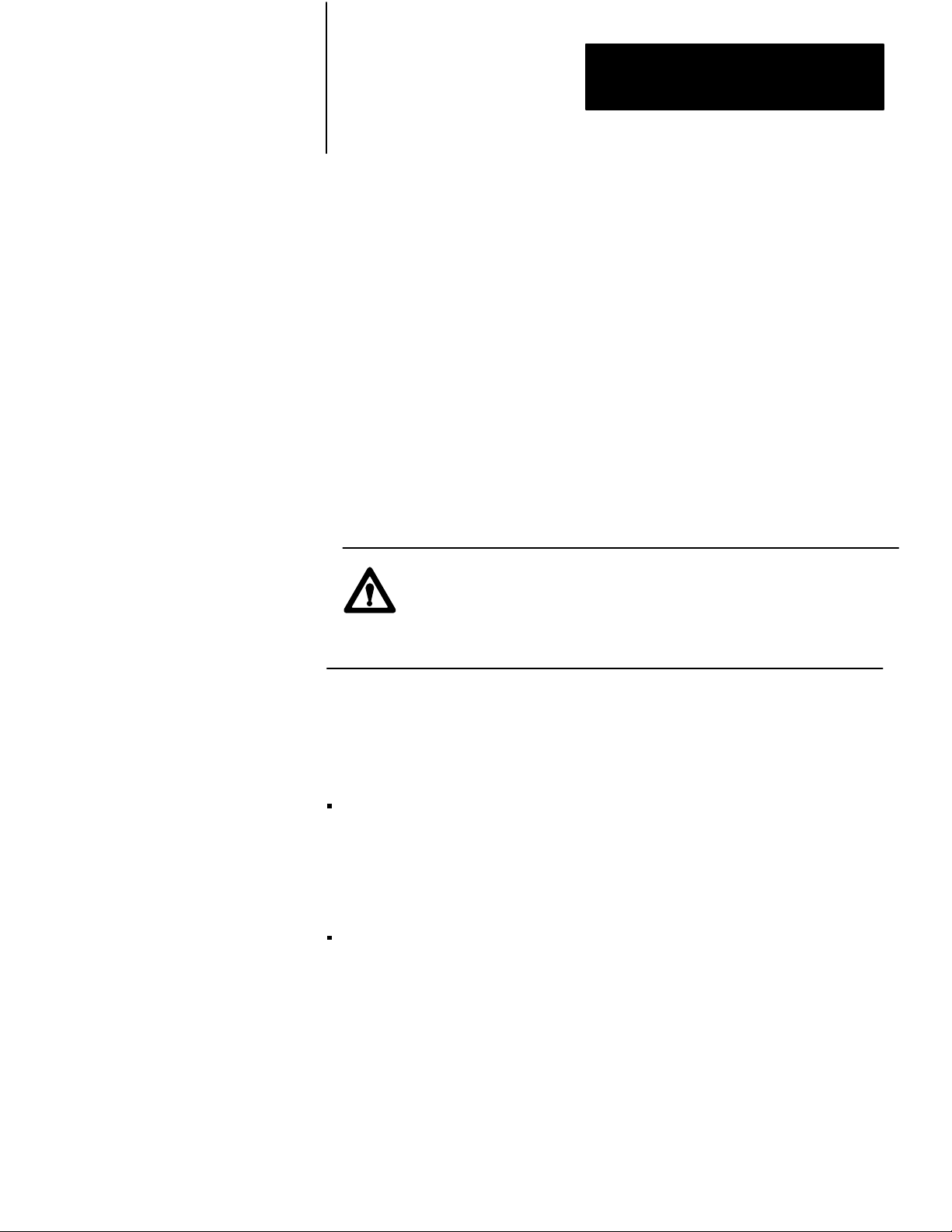

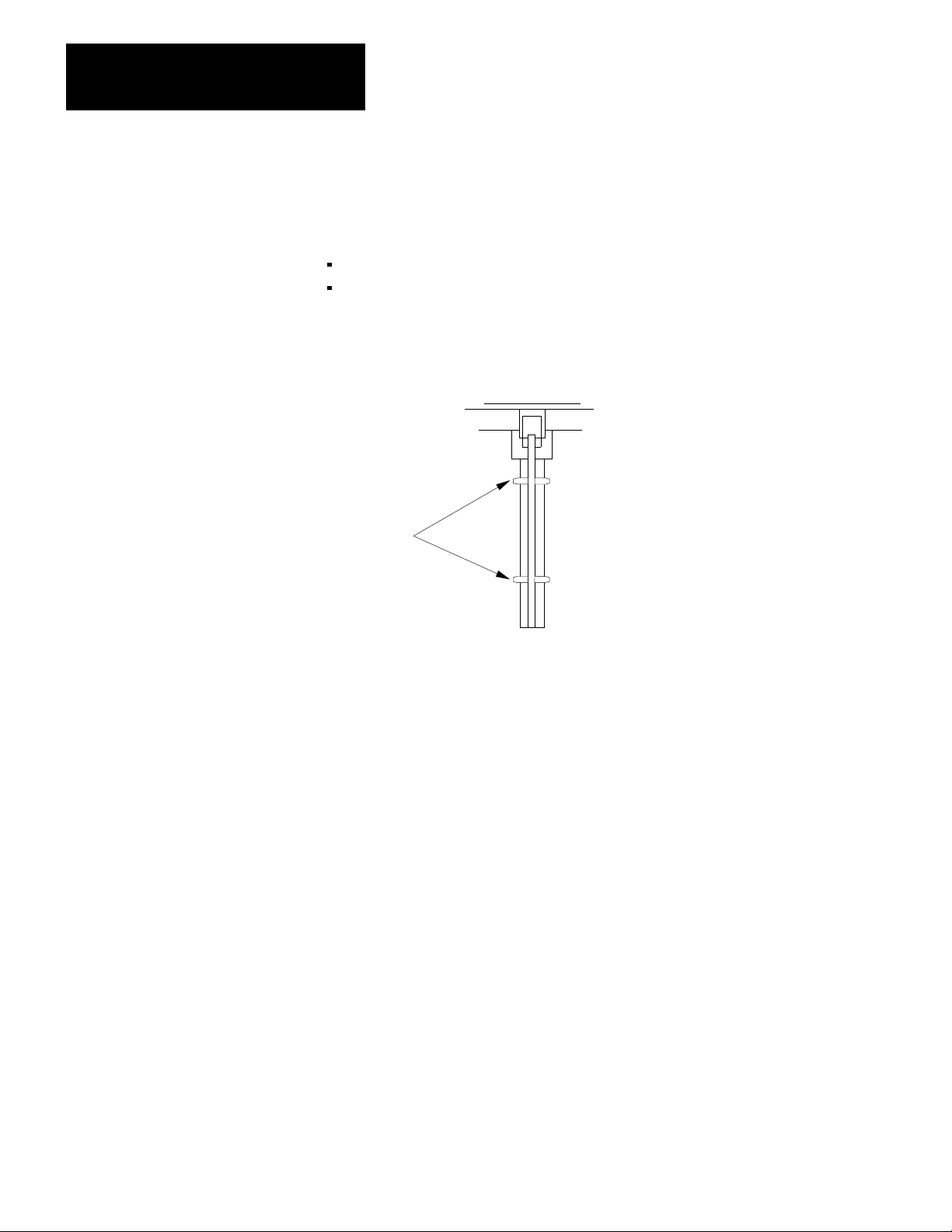

To key a module slot to accept only the 1771-IE module, position the

keying bands on the upper backplane connector at the following positions

(Figure 3.1):

between 4 and 6

between 26 and 28

Figure 3.1

Positions

Keying

2

4

6

8

10

12

Keying

Bands

14

16

18

20

22

24

26

28

30

32

34

36

14169

Wiring

34

Connect analog devices and external power to your input module through

the Field Wiring Arm (cat. no. 1771-WB). The wiring arm pivots on the

front of the I/O chassis to connect with the module. Wiring connections

are made at the wiring arm, so you can remove the module from the

chassis without disconnecting the wiring.

Connection diagram (Figure 3.2) shows connections of analog devices

and power supply to the wiring arm of the input module.

The COMMON terminal on the wiring arm connects to the power supply

COMMON and SIGNAL RETURN wires from each of your input

devices (Figure 3.2). Do not confuse the SIGNAL RETURN wire with

the cable shield. The SIGNAL RETURN is one of the insulated wires of

the cable-twisted pair. The cable shield is discussed in the next section.

When wiring analog devices to the wiring arm, use Belden No. 8761 or an

equivalent cable. We recommend that the cable from voltage mode input

devices does not exceed 50 feet in length. We base this recommendation

on considerations of noise immunity in typical industrial environments.

Page 15

Chapter 3

Installing the Analog Input Module

There is no restriction on cable length for current mode input devices.

Cable length resistance, however, when added to module input resistance,

must not be enough to cause an overload on the analog driving device.

Figure 3.2

Connection

Diagram

(See application codes and laws.)

+5V

1

2

3

4

5

6

7

8

9

10

11

12

+5-15+15DC

Use

power

supply

Ground cable shield at one end only,

preferably at chassis mounting bolt.

COMM

Analog

signal

source

Chassis

ground mounting

bolt

14168

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

Channel 8

Supply Comm/

Sig. Rtn.

+15V

-15V

Field Wiring Arm

(Cat. No. 1771-WB)

If you use a 1770-P1 power supply for your external power source, you

must jumper the 5 VDC COMMON and the 15 VDC COMMON

terminals together either at the power supply or at the module. Figure 3.3

shows the wiring connections for the Power Supply (1770-P1).

35

Page 16

Chapter 3

Installing the Analog Input Module

Figure 3.3

Supply Connections (cat. no. 1770P1)

Power

Jumper Positions

For 120V AC

- 15V DC

+ 15V DC

L1

+

15V DC Common

-

L2

+ 5V DC

+ 5V DC Common

Jumper Both Commons

14167

If you use the 1778-P2 remote power supply, connect it to the wiring arm

using one or two power cables (Figure 3.4).

36

Figure 3.4

Supply Connections (cat. no. 1778P2)

Power

7

DC Common

+ 15V

- 15V

+ 5V

Field Wiring Arm for

Analog Input Module

8

9

10

11

12

Red or Blue

Violet

Yellow

Black or Orange

Analog Power able

(Cat. No. 1770CF)

Remote Power Supply

(Cat. No. 1778P2)

Interlock

I/O

I/O

Wiring for power cable (cat. no. 1770CF

is described in publication 17702.25)

14166

Page 17

Chapter 3

Installing the Analog Input Module

Grounding

Ground the drain wire and shield of the Belden No. 8761 or equivalent

cable (Figure 3.5) at one end of the cable only. Twist the drain wire and

shield into a single strand. The best ground for this connection is an I/O

chassis mounting bolt or stud.

Insulate the shield and drain wire at the other end of the cable using

electrical tape.

You may mount a separate terminal near the input module for DC

COMMON and SIGNAL RETURN wires. This terminal should be

mounted as close to the module as possible to minimize the length of

unshielded wire.

Refer to Wiring and Grounding Guidelines, publication 1770-4.1 for

additional information.

Figure 3.5

Grounding

the Cable Shield

Ground Shield at

I/O Chassis

Mounting Bolt

Shield and Drain

Twisted into

Single Strnd

Field Wiring Arm

Belden No. 8761

or Equivalent Wire Cable

Refer to the connection diagram for eact twistedpair terminal connections.

17798

37

Page 18

Chapter 3

Installing the Analog Input Module

Setting Configuration Switches

The module is set for block transfer operation andcalibrated at the factory

for the voltage or current range that you ordered.

CAUTION: Electrostatic discharge can degrade performance

or cause permanent damage to the module. Follow the

guidelines on electrostatic discharge located at the beginning of

this chapter before handling the module.

Transfer Mode

You should change the mode of operation to single transfer if your

processor is one of the following:

PLC (now obsolete)

Mini-PLC-2 (cat. no. 1772-LN1, -LN2)

Refer to Chapter 5, “Setting These Switches,” for setting the Transfer

Mode switch to single transfer.

Installing the Input Module

Signal Mode

Without recalibrating, you can change the 1 to 5 VDC or the 0 to 5 VDC

input voltage range to its corresponding 4 to 20 mA or 0 to 20 mA current

range. Refer to Calibration, chapter 5, for the location of the signal mode

switch assembly (Figure 5.1). Set all switches to the same setting as

follows:

If your module is calibrated for one of these two voltage ranges and you

want to change to the corresponding current range: set all switches ON.

If your module is calibrated for one of these two current ranges and you

want to change to the corresponding voltage range: set all switches OFF.

Changing to any other input range requires that you recalibrate your

module to obtain accurate operation.

Now that you have determined the power requirements, location, keying,

wiring, and grounding for the input module, you are ready to install it in

the chassis. Use the following procedure:

38

Page 19

Chapter 3

Installing the Analog Input Module

1. Turn off power to the I/O chassis.

WARNING: Remove power from the 1771 I/O chassis

backplane and wiring arm before removing or installing an I/O

module.

Failure to remove power from the backplane could cause

injury or equipment damage due to possible unexpected

operation.

Failure to remove power from the backplane or wiring arm

could cause module damage, degradation or performance, or

injury.

2. Insert your module into the chassis. Plastic tracks on the top and

bottom of the slots guide the module into position. Do not force the

module into the backplane connector, but apply firm even pressure.

3. Snap the I/O chassis latch over the module. This secures the module

in place.

4. Connect the wiring arm to the module.

5. Turn on power to the I/O chassis.

39

Page 20

Chapter

4

Programming the Analog Input Module

Chapter Objectives

Block Transfer Programming

In this chapter we describe a general block transfer program, and present a

programming example for each family of programmable controllers.

Program your processor to transfer data from the module to the

processor’s data table using a block transfer read (BTR) instruction. We

give you programming examples. Because every application is different,

we urge you not to copy examples but to use the appropriate example as a

guide.

Block transfer programming using the BTR instruction is covered in this

chapter for most PLC-2 family processors, all PLC-3 family processors,

and the PLC-5/15 processor. Other programs for transferring data are

found as follows:

Processor Method Appendix

MiniPLC2

no. 1772LN3)

(cat.

PLC2/20

(cat. no. 1772LP1, LP2)

Block T

ransfer,

Multiple GET

A

General Example

PLC

(cat. no. 1774LB2, LC2)

We assume that you know how to enter ladder diagram programming via

your programming terminal, how to enter instruction parameters, and how

to map your data table or data files for proper data storage. If not, refer to

the manuals that came with your processor. If necessary, refer to

Publications Index, SD499, which lists all publications of the Industrial

Computer Group.

We describe programming rungs in one general example applicable to

most PLC-2 family processors (Figure 4.1). Although instruction formats

are different, the program is also applicable to all PLC-3 family

processors, and the PLC-5/15 processor. We also present an example for

each processor family with specific addresses to show relationships

Single T

ransfer B

41

Page 21

Chapter 4

Programming the Analog Input Module

between instructions. Do not copy these examples. They are for

instructional purposes only.

Figure 4.1

Example

Rung 1

Rung 2

ReadOnly Block T

BTR

DN

ransfer Program

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

FILE TO FILE MOVE

COUNTER ADDR:

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RATE PER SCAN:

EN

DN

EN

DN

PLC2 Family Example

42

Rung 1 This rung uses the BTR instruction to transfer data to the

processor. It transfers data on alternate scans unless you condition it with

instructions that enable it less often.

Rung 2 This rung moves transferred data to a storage location unless old

data was not updated by a new transfer (BTR done bit not set).

Important: Each input word contains an overflow- underflow bit (bit 17)

that your program should monitor to be sure the value is within range.

The module sets this bit when it detects data at or beyond the limits of 0

and 255. We leave this programming logic to you because it is

application dependent.

This example is written for the following conditions (Figure 4.2).

The module resides in rack 1, module group 2, slot 0 8-word block

transfer

Page 22

BTR data (control) address is 030

BTR file address is 050

FFM counter address is 043

FFM number of words moved

is 8

FFM source file A is 050

FFM destination file R is 150

FFM rate per scan is 8

Chapter 4

Programming the Analog Input Module

Figure 4.2

Example

Rung 1

Rung 2

Rung 3

Program for PLC2 Family Processors (Local Chassis)

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

BTR

DN

112

07

Use only when 1771-IE is in a local chassis and block transfers to this

module are inhibited.

FILE TO FILE MOVE

COUNTER ADDR:

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RATE PER SCAN:

030

120

050 - 057

043

050 - 057

150 - 157

08

000

08

08

012

EN

07

112

DN

07

043

EN

17

043

DN

15

012

IOT

Important: When your input module is in a local I/O chassis, random

chance could allow block transfer requests to occur during module

housekeeping and prevent block transfers. This condition is apparent

when the done bit remains reset and no new data is transferred. If this

condition should occur, we recommend that you add rung 3 to your

program. It guards against the possibility of the processor repeatedly

asking for a block transfer each time the module inhibits block transfers

while updating its inputs.

43

Page 23

Chapter 4

Programming the Analog Input Module

This rung adds up to 0.13ms to the processor scan time so use it sparingly.

Locate it at the beginning of your ladder program. This logic is not

required for PLC-2 family remote systems or for any other processor

family.

PLC3 Family Example

This example is written for the following conditions (Figure 4.3).

The module resides in rack 1, module group 2, slot 0

8-word block transfer

BTR control address is FB001:0000

BTR file address is FB002:0001

MVF source file A is FB002:0001

MVF destination file R is FB003:001

MVF counter address is C000l

MVF number of words moved is 8

MVF rate per scan is all/scan

Figure 4.3

Example

Program for PLC3 Family Processors

WB001:0000

(DN)

15

BTR

BLOCK TRANSFER READ

RACK :

GROUP :

MODULE :

DATA :

LENGTH =

CNTL :

FB002:0001

FB001:0000

001

0=LOW

CNTL

LE

12

2

CNTL

DN

15

8

CNTL

ER

13

44

WB001:0000

(DN)

15

MVF

FILES FROM A TO R

A :

R :

COUNTER :

POS/LEN =

MODE=

FB002:0001

FB003:0001

ALL/SCAN

C0001

C0001

EN

12

C0001

DN

8

15

C0001

ER

13

Page 24

Chapter 4

Programming the Analog Input Module

PLC5/15 Example

This example is written for the following conditions (Figure 4.4).

The module resides in rack 1, module group 2, slot 0 8-word block

transfer

BT Array (integer control address) is $N7:51

Data file (integer file address) is $N7:56

Figure 4.4

Example

Program for the PLC5/15 Processor

$N7:51

EN

BTR

BLOCK TRANSFER READ

RACK :

GROUP :

MODULE :

BT ARRAY

DATA FILE:

LENGTH:

CONTINUOUS

1

2

0

$N7:51

$N7:56

8

N

EN

15

DN

13

ER

12

Programming Considerations

Important: The PLC-5/15 processor buffers read block transfer data

automatically, so program buffering is not required.

We suggest that you follow programming considerations applicable to

your programmable controller. They are listed below and described in the

manual that accompanied your controller.

PLC2 Family

Determine the first available block transfer address in the timer and

counter area of the data table. For PLC-2/20 and PLC-2/30 processors,

it depends on the number of assigned remote I/O rack numbers.

Leave unused addresses following your last block transfer address for

future block transfer instructions.

Load zeros into the address following the last (reserved) block transfer

address to establish a boundary that prevents the processor from

looking further for additional block transfer addresses.

Buffer incoming (BTR) data. Be sure it is valid before using it.

Examine the BTR done bit and any other status bit that monitors its

validity.

45

Page 25

Chapter 4

Programming the Analog Input Module

PLC3 Family

If your application requires many block transfer modules, distribute the

modules over as many I/O chassis as possible to optimize transfer time

for the system as a whole.

Where allowed by your application, program block transfers to occur

less often than once per program scan.

Buffer incoming (BTR) data. Be sure it is valid before using it.

Examine the BTR done bit and any other status bit that monitors its

validity.

PLC5/15

Incoming (BTR) data is buffered automatically by the processor.

46

Page 26

Chapter

5

Calibrating the Analog Input Module

Chapter Objective

Service Information

Calibration Equipment

This chapter describes how you calibrate the module.

Your input module is calibrated at the factory. We recommend that you

recalibrate it every year to maintain accuracy. If for some reason you can

not calibrate the module, return it to Allen-Bradley Company for

recalibration. The mailing address is:

Allen-Bradley Company

Industrial Computer Group

747 Alpha Drive

Highland Heights, Ohio 44143

We recommend the following equipment for calibrating the module:

Equipment: Description/Source:

precision

source

digital voltmeter

sealant T

alignment tool

industrial terminal

voltage

+10V

, 0.1mV resolution minimum

Analog 3100, Data Precision 8200, or equivalent

5 1/2 digit, 0.01% accuracy minimum

Keithley 191, Fluke 8300A, or equivalent

orque Seal" by Organic Products or equivalent

P/N 35F616, for potentiometer adjustment,

Newark Electronics or equivalent

cat. no. 1770T3 with cable (cat. no. 1772TC) for

PLC2 family processors

cat. no. 1770T4 with cable (cat. no. 1775CAT) for

PLC3 family processors

cat. no. 1784T50 for PLC5/15 processors

51

Page 27

Chapter 5

Calibrating the Analog Input Module

Before You Calibrate

Before you calibrate, follow these steps:

1. Turn OFF power to the I/O chassis backplane and to your wiring

arm.

WARNING: Remove power from the 1771 I/O backplane and

wiring arm before removing or installing an I/O module.

Failure to remove power from the backplane could cause

injury or equipment damage due to unexpected operation.

Failure to remove power from the backplane or wiring arm

could cause module damage, degradation of performance, or

injury.

2. Disconnect all analog signal inputs from the module’s wiring arm

(leave 5V, +

15V DC, and COMMON connections attached). Label

the inputs to aid you in reconnection.

Calibrating the Input Module

3. Remove the module from the chassis by pivoting the wiring arm

down and releasing the plastic lever at the top of the module. Pull

the module straight out from the slot.

CAUTION: Electrostatic discharge can degrade performance or

cause permanent damage. Refer to the guidelines at the

beginning of chapter 3.

4. Remove screws from the four corners of each cover plate and

remove the covers. This gives you access to internal switch

assemblies.

Connect your industrial terminal to your processor so you can display

channel input values in BCD during calibration. Be sure your processor is

programmed to block transfer data from the module. For safety purposes,

disable all outputs or disable your ladder program except for transferring

data from the module you are calibrating.

52

To calibrate the module, you

Page 28

set internal switches

adjust the offset (Part A)

adjust the offset (Part B)

calibrate the gain

Chapter 5

Calibrating the Analog Input Module

Setting the Switches

There are three sets of switch assemblies (Figure 5.1) in the module:

Range Select

Signal Mode

Transfer Mode

Figure 5.1

Location

of Switch Assemblies

Transfer

Mode

Range

Select

Signal

Mode

14162

53

Page 29

Chapter 5

Calibrating the Analog Input Module

Set these switches as follows:

1. Range Select switch assembly lets you select a current or voltage

input range by setting switches 1-10. These switch settings remain

the same during and after calibration.

Change these switch settings only if you want to change to another

voltage or current input range group.

Range: Switch

1 2 3 4 5 6 7 8 9 10

1 to 5V

4 to 20 mA

0 to 5V

0 to 20 mA

0 to 10V

+10V ON ON OFF OFF ON OFF ON OFF ON OFF

+20mA ON ON OFF OFF ON OFF ON ON OFF OFF

OFF

OFF

ON

ON

ON ON OFF OFF ON ON OFF ON OFF OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

ON

ON

OFF

OFF

OFF

OFF

ON

ON

Number

ON

ON

ON

ON

OFF

OFF

OFF

OFF

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

OFF

ON

ON

2. Signal Mode switch assembly lets you select current mode (all

switches are ON) or voltage mode (all switches are OFF).

CAUTION: Be sure external power (15, 5 VDC) is OFF before

changing the signal mode switch.

Set all eight switches to OFF (voltage mode) during calibration.

Offset (Part A)

54

3. Transfer Mode switch assembly lets you select single transfer (switch

1 ON) or block transfer (switch 1 OFF).

Change the setting of switch 2 to ON only for the Offset (Part A)

procedure.

This procedure applies only if your input range is (1 to 5 VDC) or (4 to 20

mA).

Important: If the input range of your module is other than a range of (1

to 5 VDC) or (4 to 20 mA), skip this procedure and go directly to Offset

(Part B).

Page 30

Chapter 5

Calibrating the Analog Input Module

Make this adjustment for channel 1, only.

1. Set switch number 2 ON of the transfer mode switch assembly.

2. Place the module back in its I/O slot, and connect the wiring arm.

3. Change the processor mode select switch to test or program mode.

Turn on power to the processor, I/O chassis, and external power

supply to the module.

4. Connect the precision voltage source:

positive lead to input channel 1

negative lead to DC COMMON of the wiring arm

5. Turn on the precision voltage source and set it to 1.0000 Vdc.

6. Connect the DVM leads to the test points on the front of the module,

positive lead to the red test point, negative lead to the black test

point.

7. Read the voltage at the test points. It must be 0.0000 0.2 mV. If not,

adjust potentiometer #1 on the front of the module (Figure 5.2).

55

Page 31

Chapter 5

Calibrating the Analog Input Module

Figure 5.2

Location

of Potentiometers and T

est Points

Potentiometer #1

Potentiometer #2

Potentiometer #3

Red Test Point

Black Test Point

14163

Offset (Part B)

8. Seal the setting with a drop of sealant.

9. Turn off power to the external power supply, I/O chassis, and

processor.

10. Remove the module from the I/O chassis.

11. Reset switch number 2 OFF of the transfer mode switch assembly.

12. After replacing the covers, place the module back in its slot in the

I/O chassis.

Start your calibration procedure here if your input range is NOT (1 to 5

VDC) or (4 to 20 mA).

You make one adjustment for all channels at the same time for offset, then

one adjustment for gain calibration.

56

Page 32

Chapter 5

Calibrating the Analog Input Module

1. Jumper all 8 input terminals together at the wiring arm.

2. Connect the precision voltage source to the jumpered input terminals

and to ground.

3. Set the precision voltage source to the input value required for

minimum output for your particular input range. Remember that you

set the module to operate in voltage mode for calibration.

Range Input

1 to 5 V

0 to 5 V

10 to 10 V

0 to 10 V

for Minimum Output

1.0078 V

0.0098 V

9.9609 V

0.0195 V

4. Observe the BCD value. It should toggle between 000 and 001 for

equal lengths of time. If not, adjust potentiometer #2.

Do not seal the potentiometer until you have finished adjusting the gain.

Gain

5. Set the precision voltage source to the input value required for

maximum output for your particular input range. Remember that

you set the module to

Range Input

1 to 5 V

0 to 5 V

10 to 10 V

0 to 10 V

for Maximum Output

4.9766 V

4.9707 V

9.8828 V

9.9414 V

6. Observe the BCD value. It should toggle between 254 and 255 for

equal lengths of time. If not, adjust potentiometer #3.

7. Recheck offset and gain to be sure that they are properly set. Adjust

if necessary.

8. Seal the potentiometers.

57

Page 33

Chapter 5

Calibrating the Analog Input Module

9. If your input range was a current range, reset the signal mode switch

assembly to current mode (all switches on).

10. Re-install and test the module with known values before operating

with I/O devices.

58

Page 34

Appendix

A

Block Transfer (Multiple GET) for PLC2/20

Example Program

Assumptions

This read-only program (Figure A.1) transfers a block of input data from

the analog input module to a momentary storage (buffer) in the

processor’s data table. If valid, input data is moved elsewhere in the data

table for use by your ladder program. If invalid, it is written over by the

next block transfer. This program performs the same function as the

2-rung program described in chapter 4.

Important: If you place your input module in a local chassis, we

recommend that you add the same rung as described in the PLC-2 family

example (Figure 4.2, Rung 3). This rung guards against the possibility of

the processor repeatedly asking for a block transfer when the module

momentarily inhibits block transfers while updating its inputs.

The example program is based on the following assumptions:

module in rack 1, module group 2, slot 0

8-word block transfer

block transfer (control) address 030

read block transfer (buffer) file 050-057

storage file 150-157

A1

Page 35

Appendix A

Block Transfer (Multiple GET) for PLC-2/20

Figure A.1

Example

Rung 1

Rung 2

Rung 3

Rung 4

Rung 5

Rung 6

Rung 7

Rung 8

Rung 9

Rung 10

Rung 11

Rung 12

Rung 13

Rung 14

Rung 15

Rung 16

Rung 17

Rung 18

Program for PLC2/20

Ladder Diagram Dump

02000 11207

Block Length

030 130

GG

120

050

01207

02002

02002

02002

02002

02002

02002

02002

02002

050

G

000

1

050

G PUT

000

051

G PUT

000

052

G PUT

000

053

G PUT

000

054

G PUT

000

055

G PUT

000

056

G PUT

000

057

G PUT

000

052

051

G

G

000

000

2345

Start

Clears Block Transfer Flag

Block Transfer

Block Transfer Flag

Moves Data

053

054

055

G

G

G

000

000

000

678

056

G

000

057

G

000

02002

02000

U

01200

U

01201

U

01202

U

01203

L

01204

U

01205

U

01207

02000

L

ON

150

1

000

151

2

000

152

3

000

153

4

000

154

5

000

155

6

000

156

7

000

157

8

000

Display

Only

A2

Page 36

Appendix A

Block Transfer (Multiple GET) for PLC-2/20

Description

Scan 1

Rung 9

This rung controls block transfer. Preconditions are optional. The first

available word 030 in the timer/counter accumulated area stores module

location 120. Word 130 in the timer/counter preset area stores the address

of the first word in the BTR (buffer) file.

Output bit 01207 initiates block transfer. The first digit of this output

address is zero, because it is in the output image table. The next three

digits are the module’s location: rack, module group, and slot numbers.

The last digit, 7, is the BTR enable bit (bit 17 if the module was in slot 1).

Rung 10

Bit 01207 is examined to determine if a block transfer was initiated. If

initiated, Bit 02000 is latched until the next program scan.

Scan 2

Rung 1

This rung detects the request (02000) and completion (11207) of a block

transfer to this module. Upon completion, it lets transferred data move to

storage location words 150-157 in rungs 11-17.

Rung 2

This rung resets the block transfer operation. Bit 02000 is unlatched. It

will be latched again if a block transfer request is made this program scan.

Rungs 3 7

These rungs determine the block length by setting a binary code equal to

the number of words transferred.

A3

Page 37

Appendix A

Block Transfer (Multiple GET) for PLC-2/20

Rungs 11 18

These rungs move data from the BTR read file to storage. When the

block transfer one-shot (02002) is set, data in each (buffer) word address

050-057 is moved to storage location 150-157 where it can be used by

your ladder program. If data is not moved, it is written over by the next

block transfer.

Important: Each input word contains an overflow- underflow bit (bit 17)

that your program should monitor to be sure the value stored in that word

is within range. The module sets this bit when it detects data at or beyond

the limits of 0 and 255. We leave this programming logic to you because

it is application dependent.

Last Rung

These GET instructions display the BCD value of each transferred word,

and are for display only.

A4

Page 38

Appendix

B

Single Channel Transfer for PLC Processors

Example Program

Programming techniques used in this example program (Figure B.1) for

the PLC processor include:

I/O scan counter

conditional ignore zone

I/O Scan Counter

The I/O scan counter (rungs 1-3) controls the transfer sequence and gives

the module sufficient time to respond to channel byte and update select

commands.

The scan counter increments only when a program scan and I/O scan have

occurred. It does this by manipulating a specially chosen bit. The bit

must be in the input image table, and must have an input module

associated with it. The terminal corresponding to this bit must NOT have

an input device wired to it so it can be turned OFF each I/O scan. Choose

a bit which satisfies these conditions:

It has an input address with the same assigned rack number as the input

module.

The input terminal associated with that bit address should be in a

module group with a higher module group number than the one the

input module is in.

The input terminal associated with that bit address must be unused.

Wire it to DC COMMON or L2 (AC Low) to guard against wiring it to

an input device.

Conditional Ignore Zone

The conditional ignore zone controls multiple output instructions based on

a set of overriding conditions. When these conditions are true, the outputs

within the zone are controlled by the conditions in their individual rungs.

When false, the zone outputs are held in their last state, whether ON or

OFF.

B1

Page 39

Appendix B

Single Channel Transfer for PLC Processor

The rungs within the conditional ignore zone (rungs 6-25) reconstruct and

store the 16-bit input word from each channel. The override condition of

the zone must be true (I/O scan counter accumulated value = 007) for the

state of any output within the zone to be changed.

B2

Page 40

Appendix B

Single Channel Transfer for PLC Processor

Figure B.1

Example

Rung

No.

Program for the PLC Processor

02200 11111

1

20017

2

3

200

365

005

365

005

367

007

110

=

G

000

=

=

4

G

000

200

5

G

000

200

6

G

000

200

7

G

000

25100 25010

8

200

CTU

PR 007

AC 000

11111

20017

250

PUT

000

01007

L

37710

251

PUT

000

L

/

L

Scan counter

Store low byte

Latch high byte

select

Begin

condiional

ignore zone

Store high byte

25101 25011

9

25102 25012

10

25103 25013

11

25104 25014

12

25105 25015

13

25106 25016

14

25107 25017

15

25017 25016 25015 25014

16

250

G

000

360

=

000

02002

Reconstruct

channel

upper byte

bit-by-bit

Fault

diagnostic rung

B3

Page 41

Appendix B

Single Channel Transfer for PLC Processor

22

23

24

25

26

27

28

29

30

31

B4

02002 250

17

18

19

20

21

01000 01001 01002 01003 01004 01005 01006

02002 01000

02002 01001

02002 01002

02002 01003

02002 01004

02002 01005

02002 01006

200

G

000

200

G

000

200

G

000

203

G

000

200

G

000

203

G

000

200

G

000

203

G

000

367

007

367

007

367

007

361

001

363

003

362

002

363

003

363

003

250

G

000

250

G

000

250

G

000

250

G

000

250

G

000

250

G

000

250

G

000

=

=

363

=

G

002

=

<

=

<

=

G

000

260

PUT

000

261

PUT

000

262

PUT

000

263

PUT

000

264

PUT

000

265

PUT

000

266

PUT

000

267

PUT

000

37710

U

01007

U

203

CTU

PR =008

AC = 000

200

PUT

000

01000

01001

01002

Channel No.

1

2

3

4

Store

channel

values

5

6

7

8

End

conditional

ignore zone

Unlatch byte

select

Increment

reference

counter

Load Scan

Counter with

002

Update

SELECT

Bits

Channel

SELECT

Bits

Page 42

32

33

34

35

36

203

G

000

203

G

000

203

G

000

203

G

000

203

G

000

02200

364

=

004

365

005

366

006

367

007

370

008

Appendix B

Single Channel Transfer for PLC Processor

Channel

SELECT

01003

=

=

=

=

01004

01005

01006

200

CTR

Bits

Reset

Counters

37

38

203

G

000

260

G

000

370

008

261

G

000

=

262

263

264

265

266

267

G

G

G

G

G

G

END 0400

000

000

000

000

000

000

203

CTR

Display

Rung

B5

Page 43

Appendix B

Single Channel Transfer for PLC Processor

Program Logic

Rung

No.

1-3

29 30

Start

Increment I/O

scan counter

(200)

Is

Scan count

<3?

No

Is Yes

Scan count

= 3?

No

In single channel transfer, the processor transfers data one byte at a time.

Your program must reconstruct the data into 16-bit words in the correct

sequence. We developed a flow chart (Figure B.2) that describes single

transfer programming to help you understand the logic.

Figure B.2

Chart for PLC Example Program

Flow

Yes

1. Store input word (110) containing

high byte.

2. Reconstruct channel word.

3. Check Module fault diagnostics.

4. Store channel word.

5. Reset Byte SELECT bit.

6. Increment Reference Counter (203).

7. Load Scan Counter (200) with 002.

Yes Set Update

SELECT bits

Reset Update

SELECT bits. Set

Channel No. 1

SELECT

command.

(Bits 0-6 of output

byte OFF.)

Is

Scan count

= 7?

No

Set Channel

SELECT bits

Rung

No.

6

7

8-15

16

17-24

26

27

28

29-35

B6

Is No

Scan count

= 5?

4

5

Yes

Store input word

(110) containing

low byte

Set Byte SELECT

bit to 1. (Selects

High Byte.)

Have

all Module

Channels been

Read?

(Does CTU 203

= 8?)

No

To balance of program

Yes

Reset both scan

and reference

counters (200

and 203)

36, 37

14161

Page 44

Appendix B

Single Channel Transfer for PLC Processor

Assumptions

Using Less Than Eight Input Channels

The example program is based on the following assumptions:

The input module is in slot 0 of module group 0 in rack 1.

All eight channels are used. If fewer channels are used, rungs may be

eliminated.

The following data table addresses are used to store values:

- words 250-251 serve as momentary storage

- words 260-267 store input channel values

- words 360-370 store constants 000-008

Often fewer than eight input channels are connected to the module. If

using fewer than eight inputs, omit channels in reverse order. Omit

channel 8 first, channel 7 second, etc, when connecting analog devices

and when programming.

You can shorten the program to conserve memory and decrease program

scan time. To reduce program size, study the sequence of events used to

update module data and to read the data from each channel. Reduce the

program as follows:

Omit channel select bit instructions starting with 10116, 01005, etc.

(rung 17).

Omit rungs that store channel values starting with rung 24, rung 23, etc.

Reduce the byte select comparison value in word 367 (rung 26).

Reduce the preset of the increment reference counter (rung 27).

Program channel select bits only for those channels you are using.

Omit rung 35 for channel 8, rung 34 for channel 7, etc.

Reset counters to the number of channels used by reducing the

comparison value stored in word 370 (rungs 36 and 37) accordingly.

Reduce the number of GET instructions in the display rung (rung 38).

B7

Page 45

Index

A

audience, 11

C

Calibration equipment, 51

Calibration procedure, 52

gain, 57

offset (part A), 54

offset (part B), 56

Communication, module to processor, 23

configuraion switches, 38

Connection Diagram, 35

E

Electrostatic Damage, 31

G

Grounding, 37

L

Location of module, 33

Location of potentiometers, 56

Location of switch assemblies, 53

P

Power requirements, 32

Power supply connections, 36

Programming block transfer, 41

general example, 41

PLC-2 family example, 42

PLC-2/20 (using multiple GET), A1

PLC-3 family example, 44

PLC-5/15 example, 45

Programming considerations, 45

S

Service information, 51

Specifications, 26

Switch assemblies, 53

I

Input channels, 22

Input Data Format, 24

K

Keying, 33

W

Wiring, 34

Page 46

AllenBradley

ductivity and quality for more than 90 years. W

, a Rockwell Automation Business, has been helping its customers improve pro

e design, manufacture and support a broad range

of automation products worldwide. They include logic processors, power and motion control

devices, operator interfaces, sensors and a variety of software. Rockwell is one of the worlds

leading technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic •

Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland

•

Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands •New Zealand • Norway • Pakistan • Peru •

Philippines

Sweden

AllenBradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, T

• Poland • Portugal • Puerto Rico • Qatar • Romania • RussiaCIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain •

•

Switzerland • Taiwan • Thailand • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • V

enezuela

• Yugoslavia

el: (1) 414 3822000 Fax: (1) 414 3824444

Publication 1771-6.5.7 - December, 1986

Supersedes 1771-810 - February

Publication 1771-6.5.7 - December, 1986

, 1981

Copyright

1986 AllenBradley Company

PN 955100-45

, Inc. Printed in USA

Loading...

Loading...