Page 1

AllenBradley

ASCII I/O Module

(Cat.

No. 1771-DA)

User

Manual

Page 2

Table of Contents

To Our Customers 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience 11

Notational Conventions 11

Some Tips on Using This Manual 12

Typical

Applications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started With Y

PLC2 Family Processors 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What You Need to Get Started 22

Reading Data from Your ASCII Device 210

Writing

Data to Y

PLC3 Processors 218

What You Need T

Reading Data from Your ASCII Device 228

Writing

Data to Y

our ASCII Device 214. . . . . . . . . . . . . . . . . . . . . . . .

o Get Started

our ASCII Device 232. . . . . . . . . . . . . . . . . . . . . . . .

our ASCII Module

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . .

218. . . . . . . . . . . . . . . . . . . . . . . . . .

Choosing Module Features 31. . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Choosing

Choosing the Mode of Module Operation, IW1(0204) 313

Using BCD Delimiters (Report Generation Mode, Only), IW4(1016) 314

Justifying Margins, IW3(03) 315. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the EndofString Delimiter, IW3(1016) 317

Setting String Length, IW2(0013) 318

Determining Block Transfer Length 320

Removing the Fill Character (Data Mode, Only), IW4(1016) 321

Removing Header and Trailing Characters, IW4(0003, 0407) 323

Choosing

Choosing Transmission Mode, IW1(0507) 325

Choosing

Selecting Delay for Carriage Return, IW3(0607) 326

Setting Remaining Bits in IW1(1017) 326

Selecting

Recording

Objectives

the Mode of Communication

I/O Buf

fer Size, IW3(0002) 324. . . . . . . . . . . . . . . . . . . . .

Single or Multiple T

the Number of Initialization W

Bit Settings in Initialization W

ransfers, IW2(17) 325. . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

ords, IW1(0001) 329. . . . . . . .

ords 330. . . . . . . . . . . . . . . . .

Page 3

Table of Contentsii

ASCII

I/O Module T

utorial 41. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

PLC2 Family Processors 42

Adding

Setting

Expanding

Changing

Justifying

Demonstrating EndofString Delimiter 49

Removing the Fill Character 414

Removing Header and Trailing Characters 415

Demonstrating Data Conversion 417

Selecting Report Generation Mode, Data Conversion,

Formatting a SingleLine Message 421

Formatting a MultiLine Message 424

PLC3 Processors 427

Adding

Setting

Expanding

Changing

Justifying

Demonstrating EndofString Delimiter 435

Removing the Fill Character 440

Removing Header and Trailing Characters 442

Selecting Report Generation Mode, Data Conversion,

Formatting a SingleLine Message 446

Formatting a MultiLine Message 449

Demonstrating Data Conversion 452

Summary 455

Objectives

Initialization Rungs

Bits in Initialization W

the Number of Initialization W

the Module'

Data

and BCD Delimiter

Initialization Rungs

Bits in Initialization W

the Number of Initialization W

the Module'

Data

and BCD Delimiter

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

s String Length (Read, Only) 45. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

s String Length (Read, Only) 432. . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ords 44. . . . . . . . . . . . . . . . . . . . . . . .

ords 45. . . . . . . . . . . . . . . .

47. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

419. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

427. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ords 430. . . . . . . . . . . . . . . . . . . . . . . .

ords 432. . . . . . . . . . . . . . . .

434. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

443. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Handshaking 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Understanding Handshaking Fundamentals 51

Reading Status and/or Data from the Module 53

Objectives

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

Function of Control and Status Bits 61. . . . . . . . . . . . . . . . . .

Chapter

Command Words 61

Initialization Words 63

Status Words 613

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contents iii

Troubleshooting 71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Recognizing

How You Interpret Status Indicators 72

How You Interpret Codes in Status Word One 74

Testing the ASCII Module and Cables 77

Objectives

Initialization Errors

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

PLC2 Family Processors A1. . . . . . . . . . . . . . . . . . . . . . . . .

Complete Getting Started Program, PLC2 Family A1. . . . . . . . . . . . .

Block Transfer Programming A3

Block Transfer Timing A5

Example Read (Only) Program A15

Example Write (Only) Program A18

Example Read/Write Program A19

Example Application Write Program A22

For PLC-3 Family Processor A26

Complete Getting Started Program, PLC-3 A26

Block Transfer Programming A30

Example Read (Only) Program A41

Example Write (Only) Program A45

Example Read/Write Program A47

Example Application Read/Write Program A50

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

For PLC3 Family Processor B1. . . . . . . . . . . . . . . . . . . . . . .

Complete Getting Started Program, PLC3 B1. . . . . . . . . . . . . . . . . .

Block Transfer Programming B5

Example Read (Only) Program B16

Example Write (Only) Program B20

Example Read/Write Program B22

Example Application Read/Write Program B25

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

ASCII Conversion Tables C1. . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

To Our Customers

Preface

Overview of This Manual

This manual tells you in a tutorial manner how to install and use your

ASCII module.

In

Chapter

1

2

3

4 Handshaking

5

6 T

Appendix

Getting Started with

Y

our ASCII Module

Choosing Module

Features

ASCII Module T

Functions of Control

and Status Bits

roubleshooting Y

Module

Entitled W

Read data from your ASCII module and write data to it

using an industrial terminal

Choose module features so you can match your ASCII

module with your ASCII device

utorial

our ASCII

Select and demonstrate module features, and format

messages

Program the handshaking logic that controls

communication between your ASCII module and your PC

processor

Select desired features and read module status by

describing the function of bits in command and status

words

Interpret status indicators and status codes, and use a

simple program to test your ASCII module.

Program block transfer communication and estimate the

time required for read/write handshaking. W

included numerous example programs

e W

ill Show Y

ou How T

o

e have

Intended Audience

Notational Conventions

Index

Locate concepts and definitions in the text

We assume that you are familiar with operating and programming your

Allen-Bradley controller. Because of the functions that your module

performs, your programming skills should include file manipulation and

message formatting. Refer to the Programming and Operations Manual

for your PLC-2 family controller or to the Programming Manual for your

PLC-3 controller.

Some chapters in this manual contain examples of how you enter data or

commands. When you read these chapters, remember the following

notational conventions:

1

Page 6

Preface

To Our Customers

A symbol or word in brackets represents a single key you would press.

These include keys such as [ENTER], [SHIFT], or [

].

Spaces would be entered as shown, except that the space preceding and

following the brackets is not an entered space. (We put a space before

the left bracket and after the right bracket to make it easier to read).

Numbers and capital letters not in brackets would be entered as shown.

Punctuation such as commas, and symbols such as / would be entered

as shown.

For example, typical data and a typical command that you would enter on

the industrial terminal keyboard are as follows:

Enter: ALLEN 123/AB[ENTER] (data)

Enter: DD,O3:0,[SHIFT]%A[ENTER] (PLC-3 command)

Some Tips on Using This Manual

We have included numerous examples of CRT displays resulting from

data or commands that you enter. All CRT displays are shown with a

shaded background. Enter all commands on the industrial terminal

keyboard. The only exception is for some PLC-3 entries where we tell

you to use the PLC-3 front panel.

Read chapters 1 and 2 before proceeding to other chapters of this manual

that pertain to your needs. For example, you may want to use only

selected module features (chapter 3) and read only selected bit

descriptions (chapter 5).

We have developed forms to assist you in selecting module features and in

troubleshooting. Make a copy of each of the following and refer to them

as needed.

Initialization Words for Data Mode Form 5175, chapter 2

Initialization Words for Report

Generation Mode Form 5176, chapter 2

Command and Status Words Figure 5.2-5.4 chapter 5

Fault Status Table 6.E, chapter 6

2

Page 7

Preface

To Our Customers

You will use several procedures frequently in the tutorial chapters of this

manual. You may want to memorize the steps or have a reference copy of

the following procedures:

Reading Data From Your ASCII Device

Writing Data To Your ASCII Device

Setting Bits in Initialization Words

Typical Applications

You can use an ASCII I/O module to input data to the processor from a

data source such as a bar code reader, output messages from the processor

to a display device, or bidirectionally exchange messages and/or data

between an intelligent data terminal and the processor. Typical examples

are as follows:

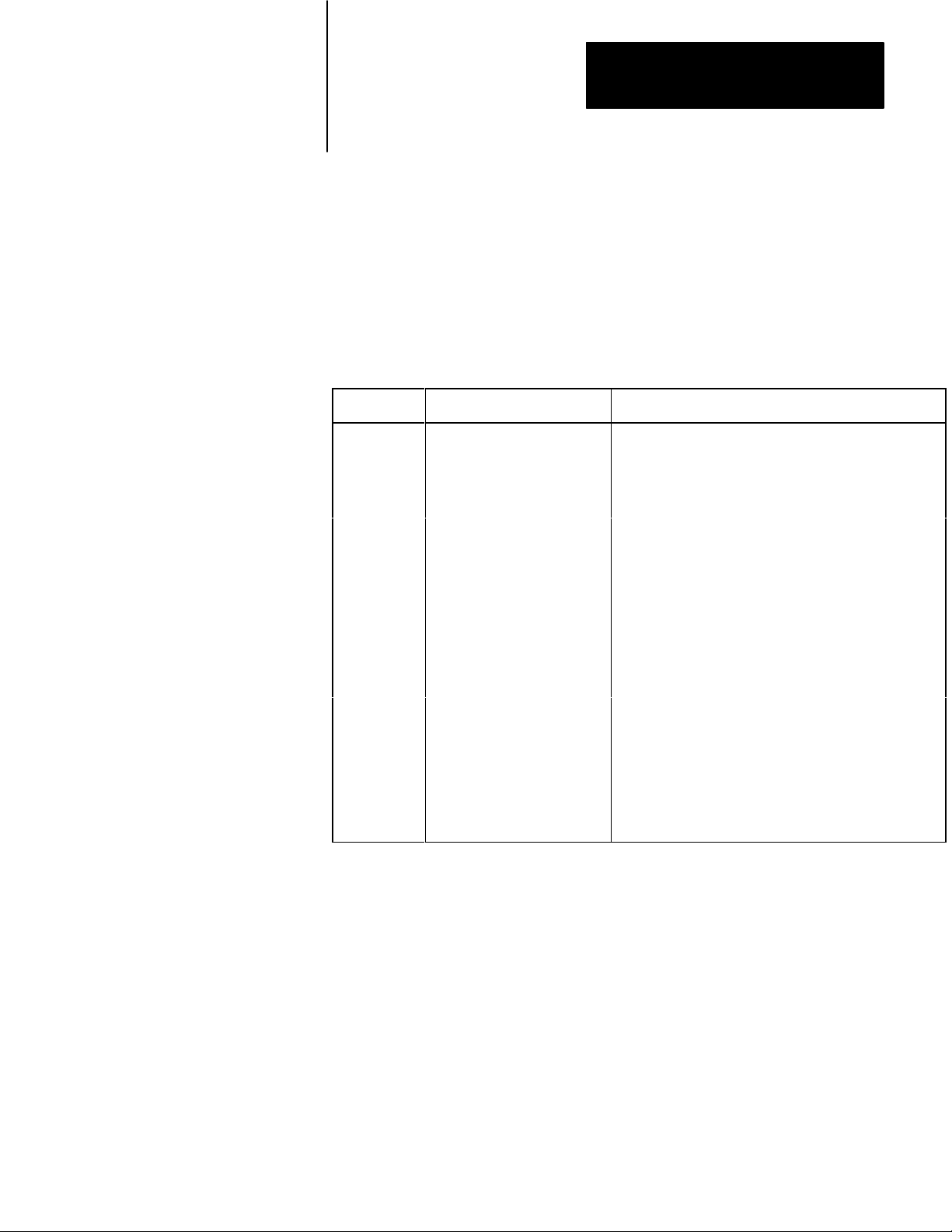

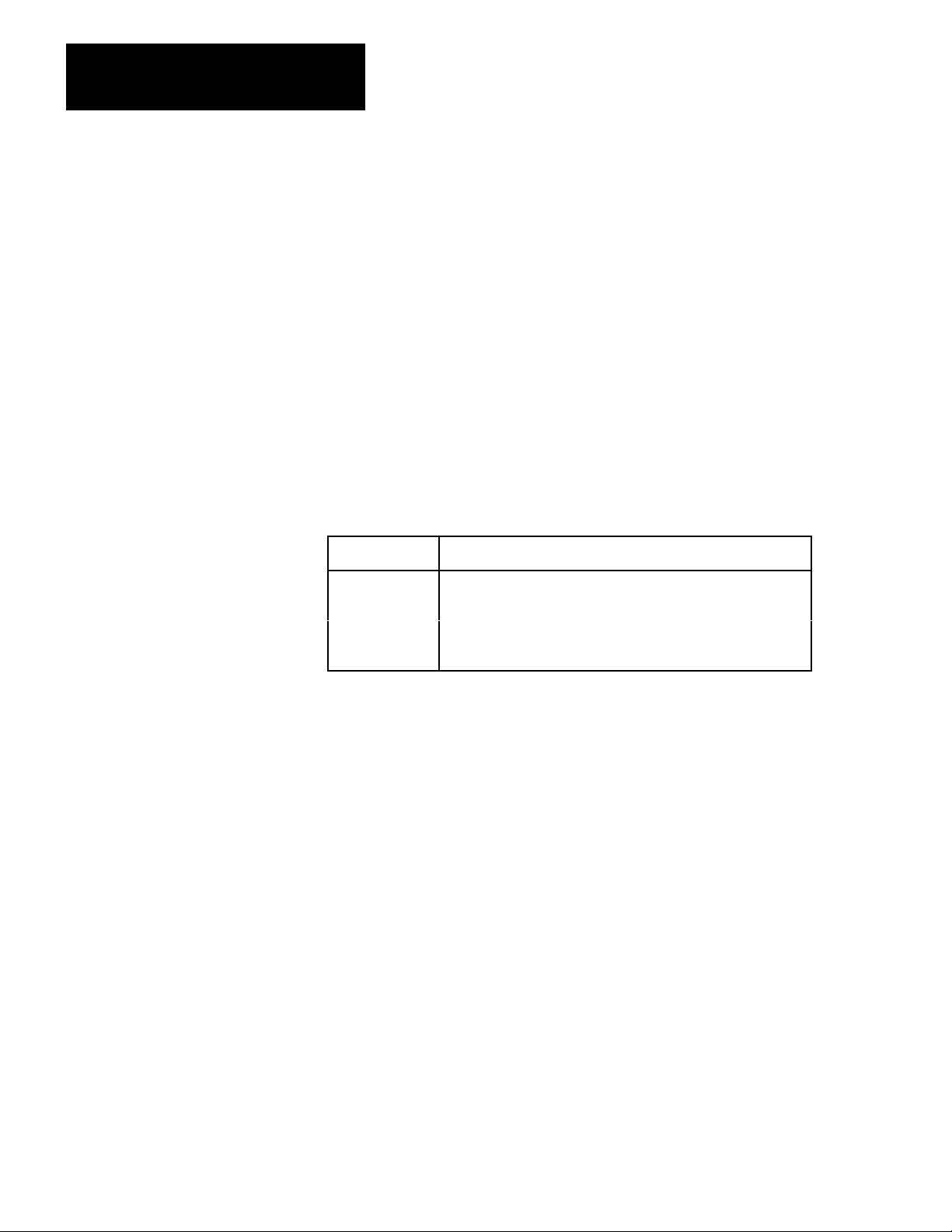

Type

of

Devices

Bar code readers

Keypads Input

Dotmatrix scrolling

displays, terminals, or

printers

Intelligent data

terminals

Computers Input/Output

Device Applications

Input

Output

Input/Output

Part recognition, sorting, inventory control

Enter values, change data

Display warnings or diagnostic messages,

print production reports

Enter values, change data, monitor or

troubleshoot a process

Exchange data files

3

Page 8

Chapter

2

Getting Started With Your ASCII Module

ASCII is the acronym for American Standard Code for Information

Interchange. The standard includes a 7-bit code for 128 data and control

characters.

With your ASCII I/O module you can transfer data, by means of the I/O

scan, from an ASCII device to the PC processor data table, and vice versa.

The module has two modes of operation, data mode and report generation

mode. In data mode, you can transfer ASCII, BCD, or hex characters.

Generally, use this mode to transfer data to the processor data table. In

report generation mode, you can include BCD values in the string of

ASCII characters. Generally, use this mode when you want to transfer

messages.

You can use your ASCII module with any Allen-Bradley programmable

controller that has an expandable data table, block transfer capability, and

uses the 1771 I/O structure. If you use a PLC-2/20 controller (cat. no.

1772-LP2), your programming will be lengthier because its processor

does not have file move or block transfer instructions.

Getting Started with Your ASCII Module is a hands-on exercise. By

going step by step through two easy examples, you will quickly learn

operation of your module’s basic features.

This chapter is divided into two sections, one for PLC-2 family

processors, the other for PLC-3 processors. Proceed to the section that

pertains to your processor.

21

Page 9

Chapter 2

Getting Started with Your ASCII Module

PLC2 Family Processors

What You Need to Get Started

You will demonstrate the operation of your ASCII module by reading data

from the industrial terminal to the processor data table, and by writing

data from the data table to the industrial terminal. You will use your

industrial terminal as an ASCII device for entering data (read), and for

displaying data (write).

You will need to set up a PC processor with an I/O chassis, power supply,

industrial terminal, cables, and your ASCII module. You will need about

an hour to complete the tutorial exercises in this chapter, and about two

hours to complete those of chapter 3, once you have the equipment

operating properly.

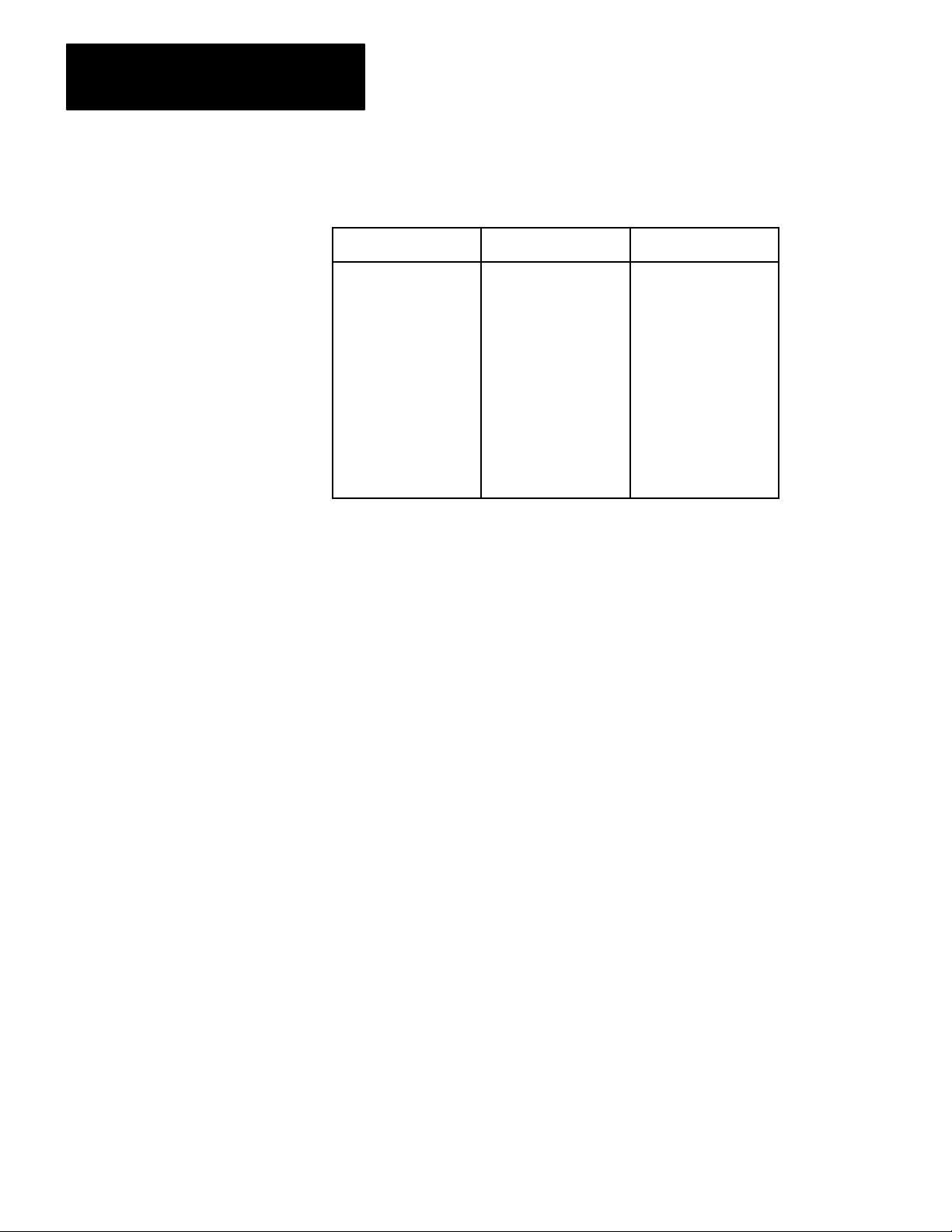

Equipment That You Need

You will need the following equipment (Table 1.A) using your existing

system and/or spare equipment.

Table 1.A

Equipment

(PLC2 Family)

22

Equipment

ASCII I/O module

Industrial T

PLC2 Family Keytop Overlay

Alphanumeric Keytop Overlay

Processor Interface Cable

IT/DH Adapter Cable

Processor PLC2/20, 2/30

I/O Interconnect Cable 1777CB, CA

Local Adapter Module

T

ermination Plug

erminal 1770T3

I/O Chassis

Power Cable

Catalog Number

1771DA

1770KCB

1771KAA optional

1772TC

1770CB (figure 1.4)

1771A1, A2, A4

1771CJ, CK

1771AL

1777CP

Page 10

Chapter 2

Getting Started with Your ASCII Module

or

Processor

MiniPLC2/15

Power Supply

Power Cable

1771P1

1771CL

Note: You must use battery back-up.

The ASCII module draws 1.3A from the backplane. Be sure that the total

current drain of all modules in the chassis does not exceed the maximum

for the backplane and power supply.

If you use an existing system, consider disconnecting all other chassis

except the one containing your ASCII module. Disconnect field wiring

arms from output modules for safety purposes.

How to Connect Your Equipment

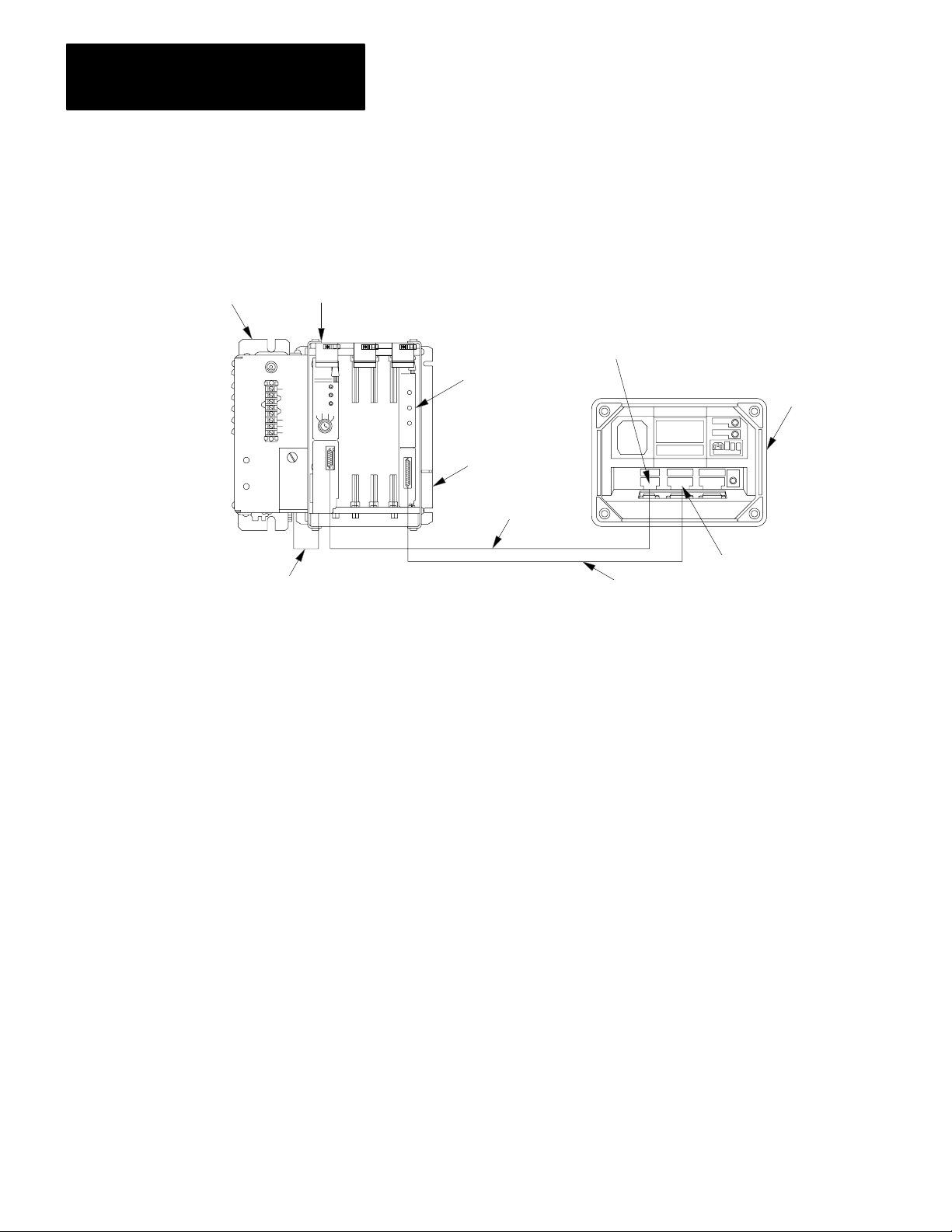

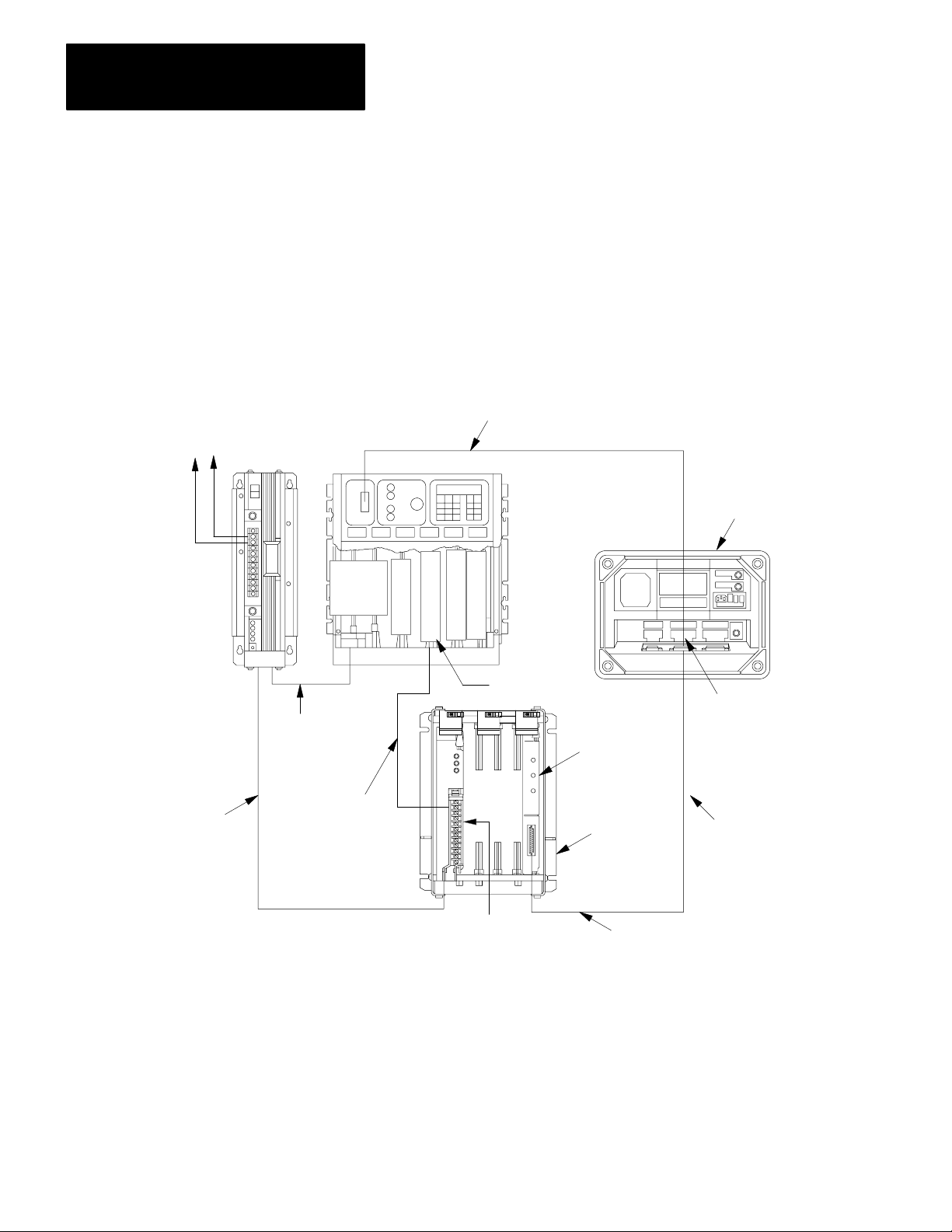

Connect your equipment with the appropriate cables (Figure 1.1 for

Mini-PLC-2/15 controllers, Figure 1.2 for PLC-2/20 or-2/30 controllers).

Be sure that the end of your IT/DH adapter cable labeled CHANNEL B is

connected to channel B on the industrial terminal.

23

Page 11

Chapter 2

Getting Started with Your ASCII Module

1771-P1

Power Supply

1771-CL

Power Cable

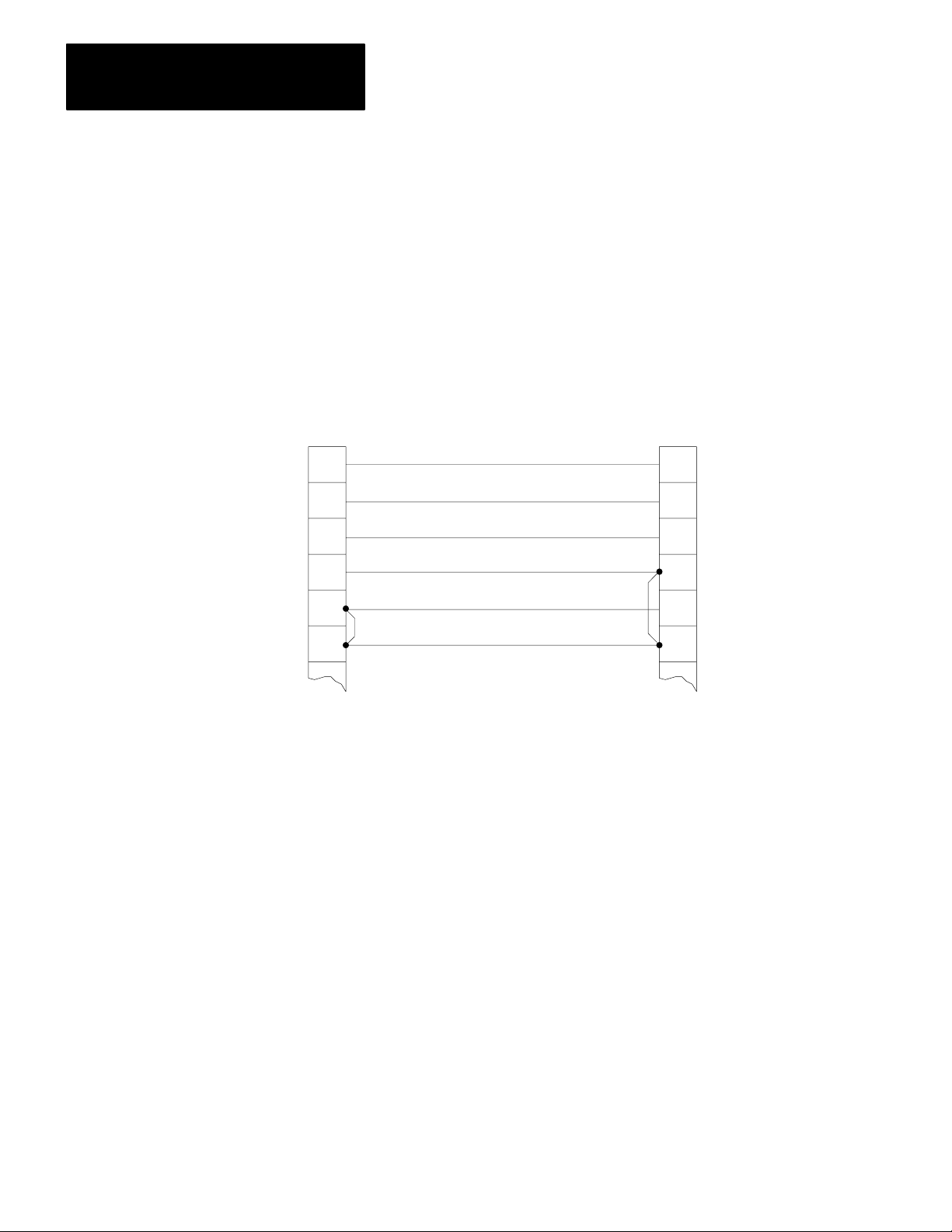

Figure 1.1

Connections

Mini-PLC-2/15

Processor

for MiniPLC2/l5 Controller

Module Group 1,

Slot 1

1771-DA ASCII

I/O Module

1771-A1, -A2, -A4

I/O Chassis

1772-TC

Processor Interface Cable

See WARNING in section titled How

to Connect Your Equipment." Using Channels

A & B

Channel A

1770-T3

Industrial Terminal

(rear view)

Channel B

1770-CB IT/DH

Adapter Cable

11817

1. Connect the power cable between the power supply and the I/O

chassis. The cable connects to the backplane of the I/O chassis

behind the processor/adapter slot.

2. Connect the processor interface cable between the PC processor and

channel A on the industrial terminal.

3. Connect the IT/DH adapter cable between the ASCII module and

channel B on the industrial terminal.

24

Page 12

Chapter 2

Getting Started with Your ASCII Module

1771-CK,-CJ

PowerCable

Figure 1.2

Connections

PLC-2/30

Processor

1771-ALLocal

AdapterModule

for PLC2/20 or PLC2/30 Controller

1772-TCProcessor

InterfaceCable

1771-CA,-CB

I/OInterconnect

Cable

ModuleGroup1,

Slot1

ChannelA

1771-DAASCII

I/OModule

See WARNING in section titled How

to Connect Your Equipment." Using Channels

A & B

1770-T3

IndustrialTerminal

(rearview)

ChannelB

1770-CBIT/DH

AdapterCable

1771-A1,-A2,-A4

I/OChassis

1777-CP

TerminationPlug

11818

4. (PLC-2/20, -2/30, only) Connect the I/O interconnect cable between

the PC processor and the I/O adapter module

If the IT/DH adapter cable is too short or not available, make your own.

It should not exceed 50 feet (Figure 1.4).

Using Channels A and B

You may or may not be able to connect cables to channels A and B at the

same time depending on the revision of your industrial terminal.

25

Page 13

Chapter 2

Getting Started with Your ASCII Module

Industrial terminals manufactured before May 1982 allow cross talk

between channels A and B. As a result, data table values could be altered.

Therefore, you should alternate cables between channels for the tutorials

of this manual when using these terminals. When using a series A

industrial terminal, you must alternate cables.

Your industrial terminal has a date code stamped in white on the upper

right corner of the rear label. If your industrial terminal (cat. no.

1770-T3/TA series B) is date coded T 8218 or earlier, or is not date coded,

alternate cables and observe the following warning:

WARNING: When cables are connect to channels A and B at

the same time, cross talk between these channels could cause

the processor to misread inputs and/or misapply outputs, with

possible damage to equipment and/or injury to personnel. For

this reason, do not remove the slide bar that prevents you from

connecting cables to channels A and B at the same time.

If your industrial terminal (cat. no. 1770-T3/TA series B) is date coded T

8219 or later, you can use channels A and B at the same time.

If alternating between channels A and B, connect the 1770-CB cable to

channel B when using the industrial terminal in alphanumeric mode as a

data terminal. Connect the 1772-TC cable to channel A when using the

industrial terminal in PLC-2 (ladder diagram) mode.

As an alternative, use a second industrial terminal in alphanumeric mode

on channel B, or use a Silent 700 data terminal. Connect either to the

1770-CB cable.

Checking ASCII Module Configuration

Your module is configured for RS-232-C operation when shipped from

the factory. If you suspect that its internal configuration (settings of

internal programing plugs) has been altered, you should check module

configuration (refer to section titled Choosing the Mode of

Communication in chapter 3). Do this as follows:

26

1. Remove covers from the module’s printed circuit board.

Page 14

Chapter 2

Getting Started with Your ASCII Module

2. Locate the programming plugs and set them according to RS-232-C

without control lines (figure 2.8).

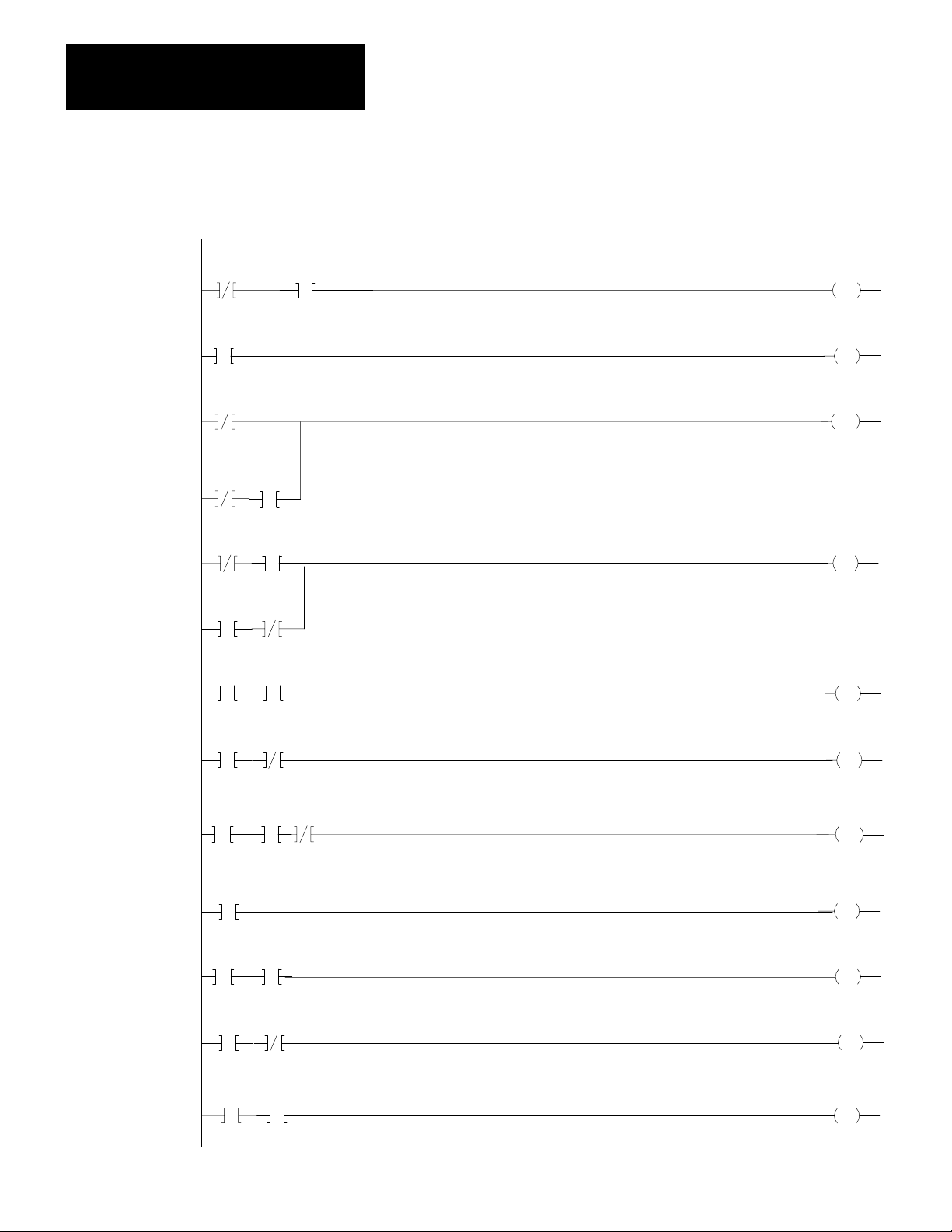

Entering the ““Getting Started Program””

You may want to record on tape the ladder diagram of your application

program before proceeding because you will need to load ASCII logic

into a cleared memory for chapters 1 and 3.

Using your industrial terminal, enter the ““Getting Started Program””

(Figure 1.3) into processor memory. At this point, you do not need to

understand how the program works, but you should enter it exactly as

shown.

27

Page 15

Chapter 2

Getting Started with Your ASCII Module

Figure 1.3

Getting

LADDER DIAGRAM DUMP

020

02

252

07

020

02

063

15

252

15

252

327

G

000

063

17

200

15

200

Started Program" (PLC2 Family)

START

200

PUT

000

200

07

063

TON

.01

PR 300

AC 000

035

00

15

15

03500252

15

03500252

15

251

063

G

000

020

063

G

000

02001252

02001252

=

100

01

247

=

200

16

16

020

00

200

L

OFF 15

200

U

OFF 15

020

01

020

L

OFF 00

020

U

OFF 00

200

L

ON 16

200

U

ON 16

28

Page 16

Chapter 2

Getting Started with Your ASCII Module

011

BLOCK XFER READ

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

BLOCK XFER WRITE

DATA ADDR:

MODULE ADDR:

BLOCK LENGTH:

FILE:

252 - 271

200 - 217

030

111

16

031

111

16

EN

17

111

DN

17

011

EN

16

111

DN

16

020

END 00460

NOTE: Configure the data table for two racks using [SEARCH][5][0]

before entering this program.

Installing Your ASCII Module

Be sure that power to the I/O chassis is turned off when installing (or

removing) your ASCII module as follows:

1. Remove power from the I/O chassis.

2. Insert the ASCII module in rack 1, module group 1, slot 1. The

program makes the processor communicate with the ASCII module

at that specific location. (If you must use another rack location and

are familiar with block transfer operation, change the rack, group,

and slot number of the module address in the block transfer read and

write instructions, accordingly.)

02

3. Turn on power to the I/O chassis. Three LED indicators on the

ASCII module illuminate momentarily. Their functions are:

FAULT: Normally off. This red LED indicator illuminates when the

module detects an internal fault.

29

Page 17

Chapter 2

Getting Started with Your ASCII Module

BUFFER FULL: Normally off. This yellow LED indicator

illuminates when the input buffer becomes full.

CHANNEL ACTIVE: This green LED indicator illuminates when

the industrial terminal is on, properly connected to the ASCII

module’s interface port, and set for alphanumeric mode.

Reading Data from Your ASCII

Device

In this demonstration, you will enter data and observe how it is stored in

the processor data table. You will use the industrial terminal in

alphanumeric mode as an ASCII data terminal when you enter data. Then

you will change the industrial terminal to PLC-2 mode and observe the

transferred data by displaying the contents of the block transfer read file.

You will use the following procedures:

In

Procedure

P1

P2

P3

P4

Set your industrial terminal to alphanumeric mode

Enter your data

Set your industrial terminal to PLC2 mode

See how data is stored in the data table

Y

ou W

ill

Later in this chapter and in chapter 3 you will combine these procedures

with others. The order in which you will perform them may vary.

Even if you are familiar with these procedures, we suggest that you read

them completely. If you deviate from them, proper operation may not

occur.

210

If you have not already done so, load the “Getting Started Program”

(Figure 1.3) into processor memory.

Procedure P1

Set Your Industrial Terminal to Alphanumeric Mode

1. Turn on the industrial terminal.

2. Insert the Alphanumeric Keytop Overlay (cat. no. 1770-KAA).

Page 18

Chapter 2

Getting Started with Your ASCII Module

To avoid switching keytop overlays every time you change the industrial

terminal operating mode, you can label numbers, letters, and [RETURN]

on the corresponding keytops of the PLC-2 family overlay.

3. Select alphanumeric mode.

Press 12 on the keyboard

The ASCII module’s CHANNEL ACTIVE LED illuminates.

4. Set the communication rate to 300 baud.

Press 13 [RETURN]

The cursor in the upper left corner of a blank screen tells you the terminal

is ready for your input.

5. Change the processor mode select switch to the RUN/PROG

position. (Failure to do this step now will prevent a transfer.)

Procedure P2

Enter Your Data

1. Be sure the processor mode select switch is in the RUN/PROG

position.

2. Enter data such as your first name followed by a couple of numbers.

Enter 11 characters including a space between your name and

numbers (Table 1.B).

211

Page 19

Chapter 2

Getting Started with Your ASCII Module

Table 1.B

Commonly

ASCII Hex ASCII Hex ASCII Hex

space 20

0 30

1 31

2 32

3 33

4 34

5 35

6 36

7 37

8 38

9 39

Used Data Characters

A 41

B 42

C 43

D 44

E 45

F 46

G 47

H 48

I 49

J 4A

K 4B

L 4C

M 4D

N 4E

O 4F

P 50

Q 51

R 52

S 53

T 54

U 55

V 56

W 57

X 58

Y 59

Z 5A

The industrial terminal displays the characters as you enter them. If

characters are not displayed, check the program that you loaded into

memory. If you find no errors, refer to Need Help? below.

3. Change the processor mode select switch to the PROG position.

(Failure to do this step now will prevent correct operation.)

Procedure P3

Set Your Industrial Terminal to PLC-2 Mode

1. Press [MODE SELECT]

2. Change the keytop overlay to PLC-2 family.

3. Select PLC-2 mode.

Press 11 on the keyboard

Procedure P4

See How Data Is Stored in the Data Table

1. Move the cursor to the rung containing the read block transfer

instruction (rung 14). The cursor will illuminate the instruction title

BLOCK XFER READ.

2. Display the contents of the read block transfer file in hex.

212

Page 20

Chapter 2

Getting Started with Your ASCII Module

Press [DISPLAY] 1

Results The industrial terminal displays the name and numbers (first 10

characters) that you entered in step 2. For example,

ALLEN 12345 would be displayed as:

POSITION FILE

001 E010

002 0000

003 414C

004 4C45

005 4E20 N

006 3132 1 2

007 3334 3 4

DA

TA

ASCII Equivalent

status word one

status word two

A L

L E

Entering the eleventh character caused the module to transfer the data.

Note the space entered between ALLEN and 12345.

The display of status word one (E010) and status word two (0000)

indicates normal status of the module.

3. Terminate this display by pressing [CANCEL COMMAND], and

return to ladder diagram.

Need Help?

If your display was all zeros, the data did not transfer. You may have

altered the procedure.

Did you enter your program exactly as shown?

Did the module’s CHANNEL ACTIVE LED go on?

Did you perform Procedure P1 before P2?

Did you perform Step 1 in Procedure P2?

Did you perform Step 3 in Procedure P2?

213

Page 21

Chapter 2

Getting Started with Your ASCII Module

If you are still having trouble, refer to “Testing the ASCII Module and

Cables,” to verify communication between the ASCII module and the

industrial terminal. If you suspect a cable problem, check the 1770-CB

cable (Figure 1.4).

Then try again, starting at Procedure P1.

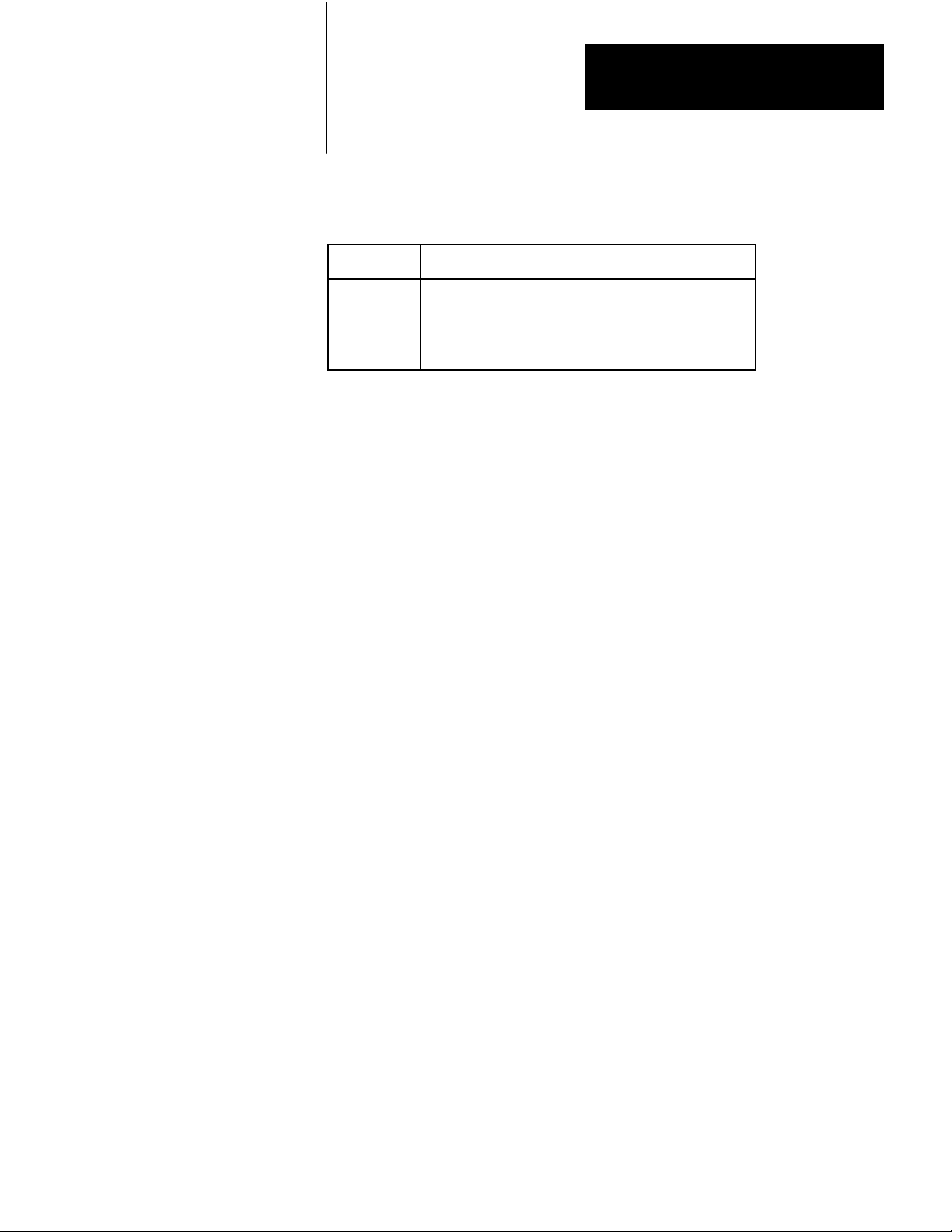

Figure 1.4

Minimum

Connections in the 1770CB Cable

1

2

3

7

18

25

ASCII Module

Interface Port

* Protective Ground

Transmitted Data

Received Data

Ground

1

2

3

7

18

25

Industrial Terminal

Channel B

Connectors:

25pin DShell

Male Connector

Cable Kit

1770XXP (each

end)

Cable:

Belden 8723 or

equivalent

* In cable but not

required for ASCII

module

11819

Writing Data to Your ASCII

Device

214

In this demonstration, you will load data characters into the write block

transfer file and observe how they are displayed. You will use the

industrial terminal in PLC-2 mode to load data. Then you will change the

industrial terminal to alphanumeric mode and observe the transferred data.

Page 22

Chapter 2

Getting Started with Your ASCII Module

You will use the following procedures where Procedures P1 and P3 are

repeated from the section titled Reading Data from Your ASCII Device.

In

Procedure

Y

ou W

ill

P3

P5

P1

Set your industrial terminal to PLC2 mode

Load data into the write block transfer file

Set your industrial terminal to alphanumeric mode (and

observe the transferred data)

Procedure P3

Set Your Industrial Terminal to PLC-2 Mode

NOTE: Skip this procedure if your processor is already in PLC-2 mode.

1. Press [MODE SELECT]

2. Check that the PLC-2 family keytop overlay is in place.

3. Select PLC-2 mode.

Press 11 on the keyboard

The beginning of your ladder diagram program will be displayed.

Procedure P5

Load Data into an Instruction File

1. Check that the processor mode select switch is in the PROG position.

2. Move the cursor to the instruction whose file you want to load

(BLOCK XFER WRITE).

3. Display the file in hex.

Press [DISPLAY] 1

4. Load new data starting in position 003 for a write block transfer

instruction, position 001 for other file instructions. (Positions 001

and 002 are reserved for command words in a write block transfer

instruction.)

215

Page 23

Chapter 2

Getting Started with Your ASCII Module

For example, load the following hex codes that are equivalent to

BRADLEY 12345 as follows: (Note the space between BRADLEY and

12345.)

POSITION FILE

003 4252 B R

004 4144 A D

005 4C45

006 5920 Y

007 3132 1 2

008 3334 3 4

009 3500 5

DA

TA

ASCII Equivalent

L E

Check your display of FILE DATA to be sure that you entered all data

exactly as shown.

Don’t forget to press [INSERT][

] after entering data in each position.

Use the shift key to enter the hex character C.

Procedure P1

Set Your Industrial Terminal to Alphanumeric Mode

216

1. Insert the alphanumeric keytop overlay.

2. Select alphanumeric mode.

Press [MODE SELECT] 12

3. Set the communication rate to 300 baud.

Press 13 [RETURN]

The module’s CHANNEL ACTIVE LED turns on.

4. Change the processor mode select switch to the RUN/PROG

position.

Page 24

Chapter 2

Getting Started with Your ASCII Module

Results The following display appears at the upper left corner of the

industrial terminal:

BRADLEY 12345

5. Terminate the display and return to ladder diagram. Use the PLC-2

family keytop overlay.

Press [MODE SELECT] 11

Summary

Now that you have demonstrated the transfer of data from your ASCII

device to the data table and vice versa, you are ready to use these

procedures further. First, read the next chapter, “Choosing Module

Features.” It defines key words and concepts. Then in chapter 3, “ASCII

Tutorial”, you will use these procedures to demonstrate operating

characteristics of your module.

217

Page 25

Chapter 2

Getting Started with Your ASCII Module

PLC3 Processors

What You Need To Get Started

You will demonstrate the operation of your ASCII module by reading data

from the industrial terminal to the processor data table, and by writing

data from the data table to the industrial terminal. You will use your

industrial terminal as an ASCII device for entering data (read), and for

displaying data (write).

You will set up a test I/O chassis with a PC processor, power supply,

industrial terminal, cables, and your ASCII module. You will need about

an hour to complete the procedures in this chapter and about two hours to

complete the procedures in chapter 3.

You may want to record your application ladder diagram program before

proceeding because you will need to load ASCII logic into a cleared

memory for tutorial chapters 1 and 3 in this manual.

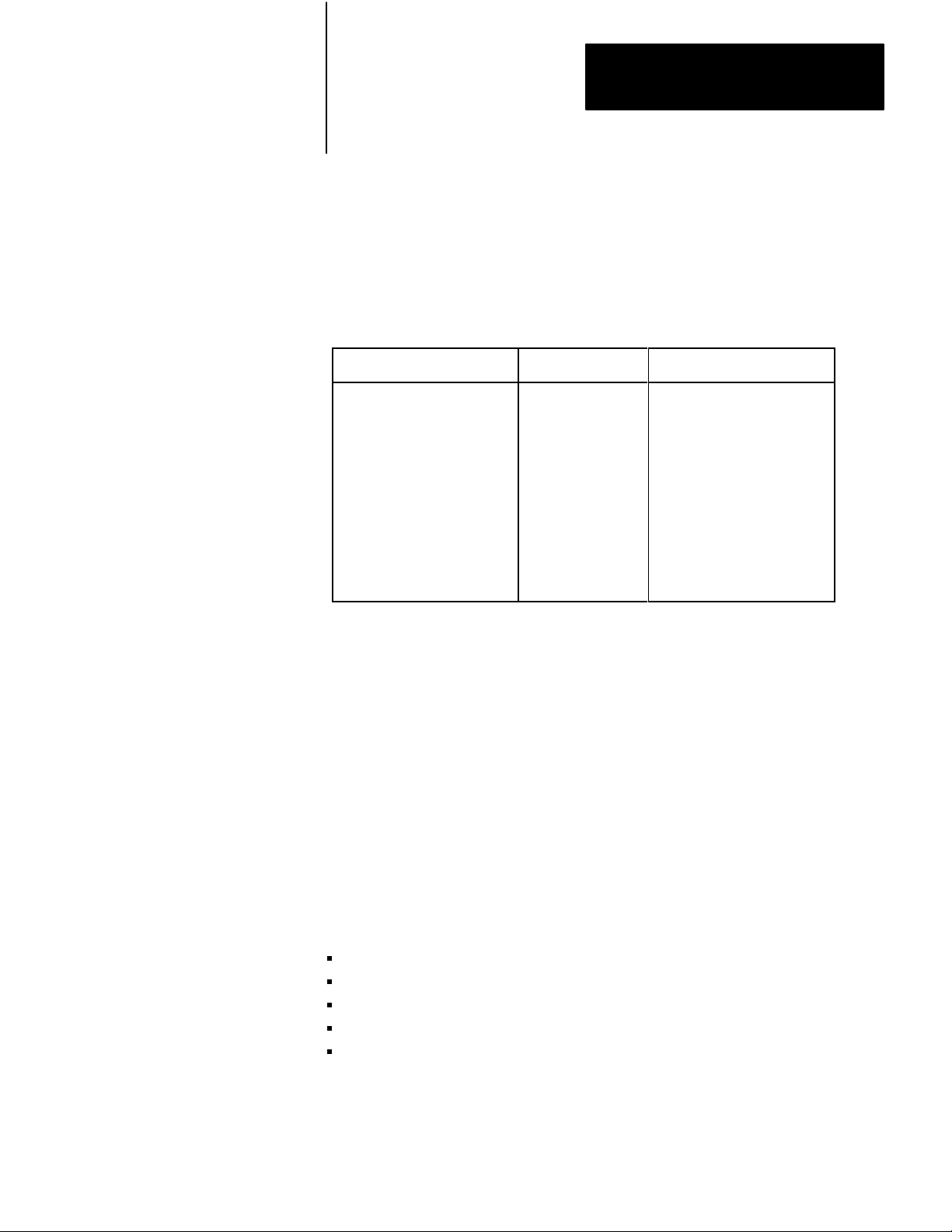

Equipment That You Need

You will need the following equipment (Table 1.C) using your existing

system and/or spare equipment.

218

Page 26

Chapter 2

Getting Started with Your ASCII Module

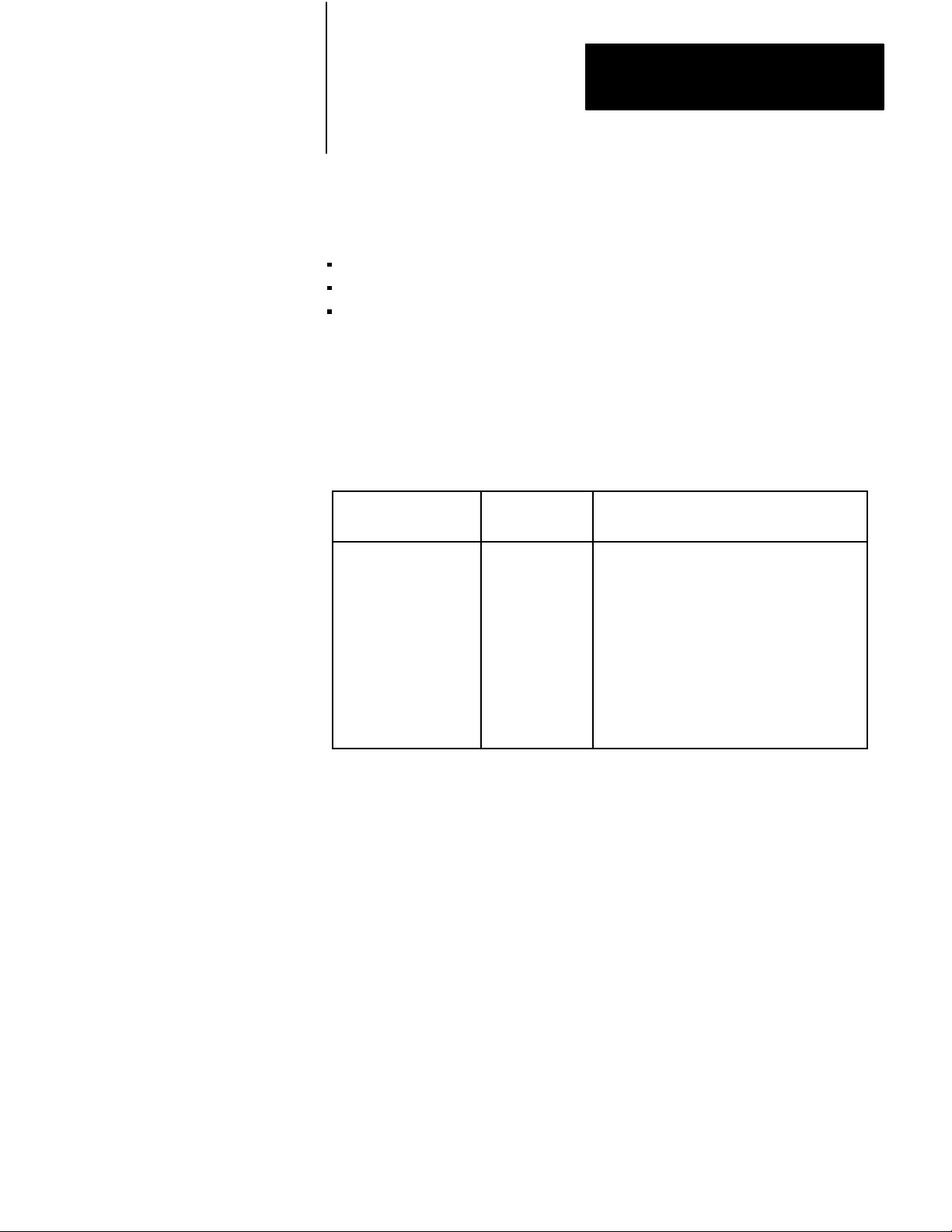

Table 1.C

Equipment

PLC3 Main Chassis

Main Processor Module

I/O ScannerProgrammer Interface Module

Memory Module

Power Supply

Industrial T

PLC3 Keytop Overlay

I/O Chassis

Remote I/O Adapter Module

ASCII i/O Module

T

winaxial I/O Interface Cable

IT/DH Adapter Cable

PLC3 Industrial T

Chassis Power Cable

I/O Power Cable

Terminators

[1]

[2]

(PLC3)

Equipment

erminal

erminal Cable

Supplied with the Industrial T

Supplied with the PLC3 Main Chassis

erminal

Catalog Number

1775A1

1775L1,L2

1775S4A

1775MR

1775P1

1770T4

1770KDA

1771Al,A2,A4

1771AS

1771DA

1770CD

1770CB

1775CAT

1775CAP

1775CH

1775XT

[1]

[2]

If you use an existing system, place the ASCII module in a chassis on a

separate channel. Use a spare scanner module (cat. no. 1775-S4A,-S4B)

if necessary.

The ASCII module draws 1.3A from the backplane. If you place the

module in a chassis containing other modules, be sure that the total

current drain of all modules in the chassis does not exceed the maximum

for the backplane and power supply.

219

Page 27

Chapter 2

Getting Started with Your ASCII Module

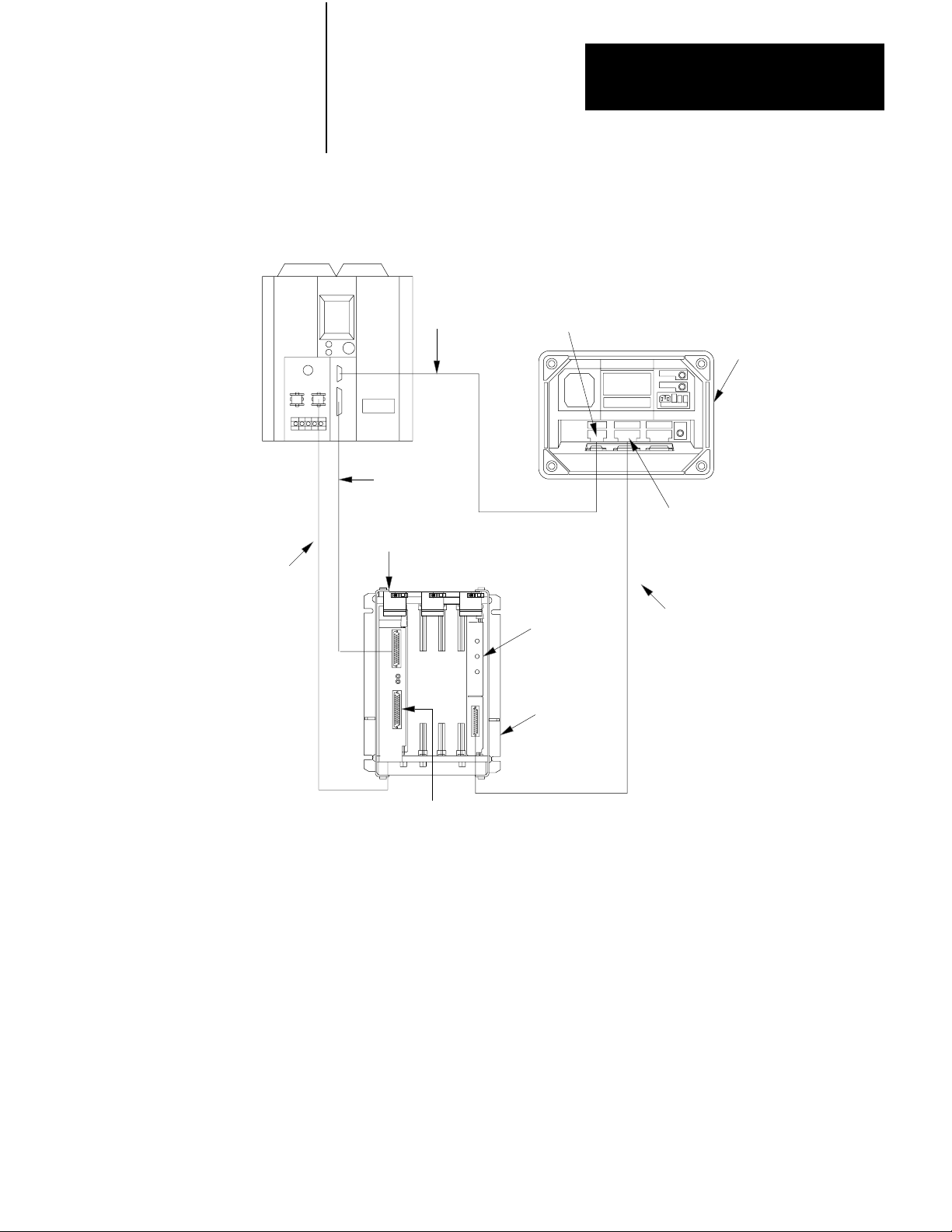

How to Connect Your Equipment

Connect your equipment using the appropriate cables (Figure 1.5).

120V AC

L2

L1

1775-P1

Power Supply

1775-CAP

Chassis

Power Cable

Figure 1.5

Connections

UNIT

(CPU)

RAM

G

CENTRAL

PROCESSIN

for PLC3 Controller

1775-CAT

Industrial Terminal Cable

O

I/O

S

M

C

E

A

M

N

O

N

R

E

Y

R

O

P

P

T

T

I

I

O

O

N

N

A

A

L

L

1775-S4A

Scanner

PLC-3

Processor Chassis

1771-DA ASCII

I/O Module

1771-T4

Industrial Terminal

(rear view)

Channel B

Change Cables

as required

220

1771-CH

I/O Power

Cable

1770-CD

Twinaxial Cable,

10,000 ft. Max.

total each

I/O Channel

1771-AS Romote

I/O Adapter Module

1771-A1, -A2, -A4

I/O Chassis

1772-TC

Processor Interface Cable

1770-CB IT/DH

Adapter Cable

1. Connect the chassis power cable between the power supply and the

processor chassis.

11820

Page 28

Chapter 2

Getting Started with Your ASCII Module

2. Connect the I/O power cable between the power supply and the I/O

chassis.

3. Connect the twin axial cable between the I/O scanner in the

processor chassis and the remote I/O adapter module in the I/O

chassis (Figure 1.6).

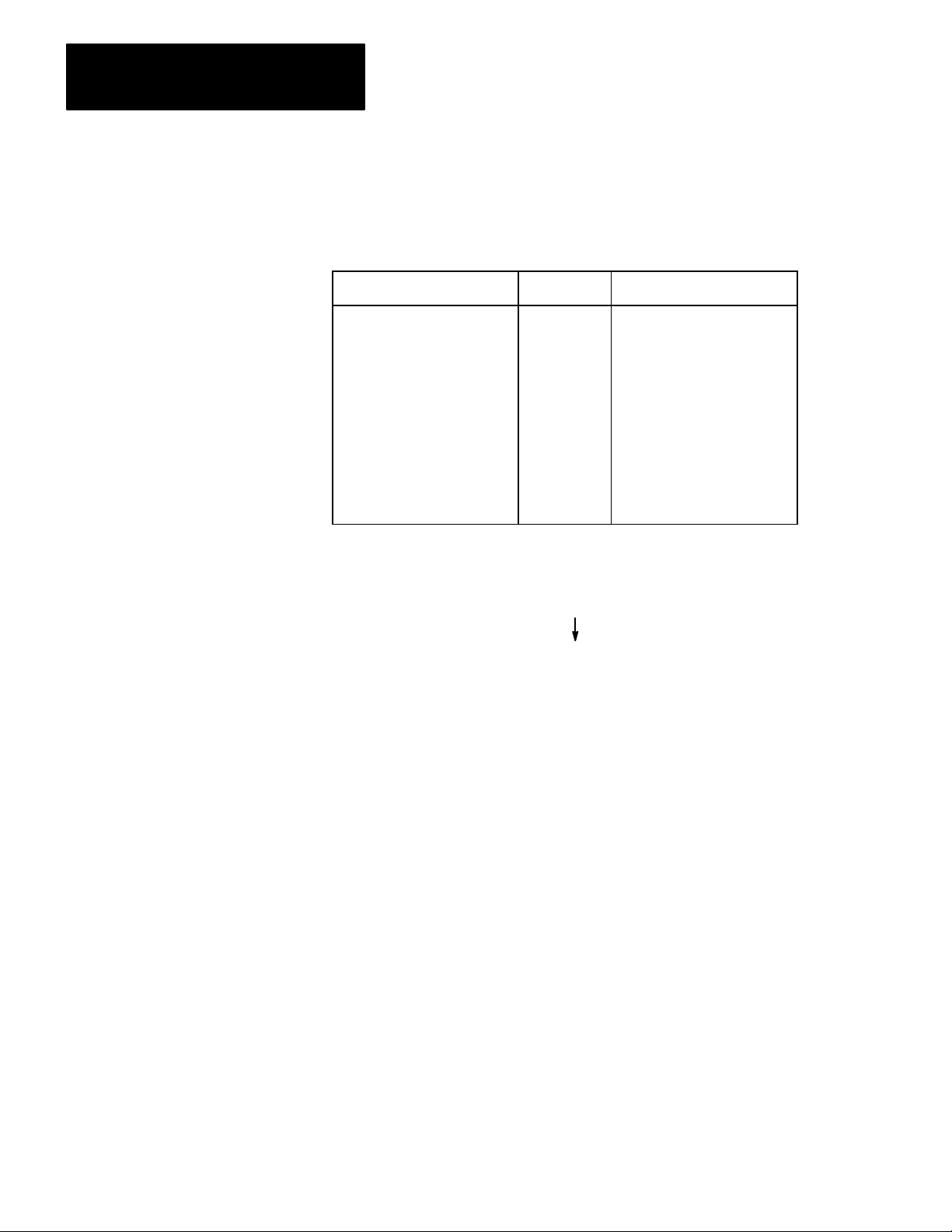

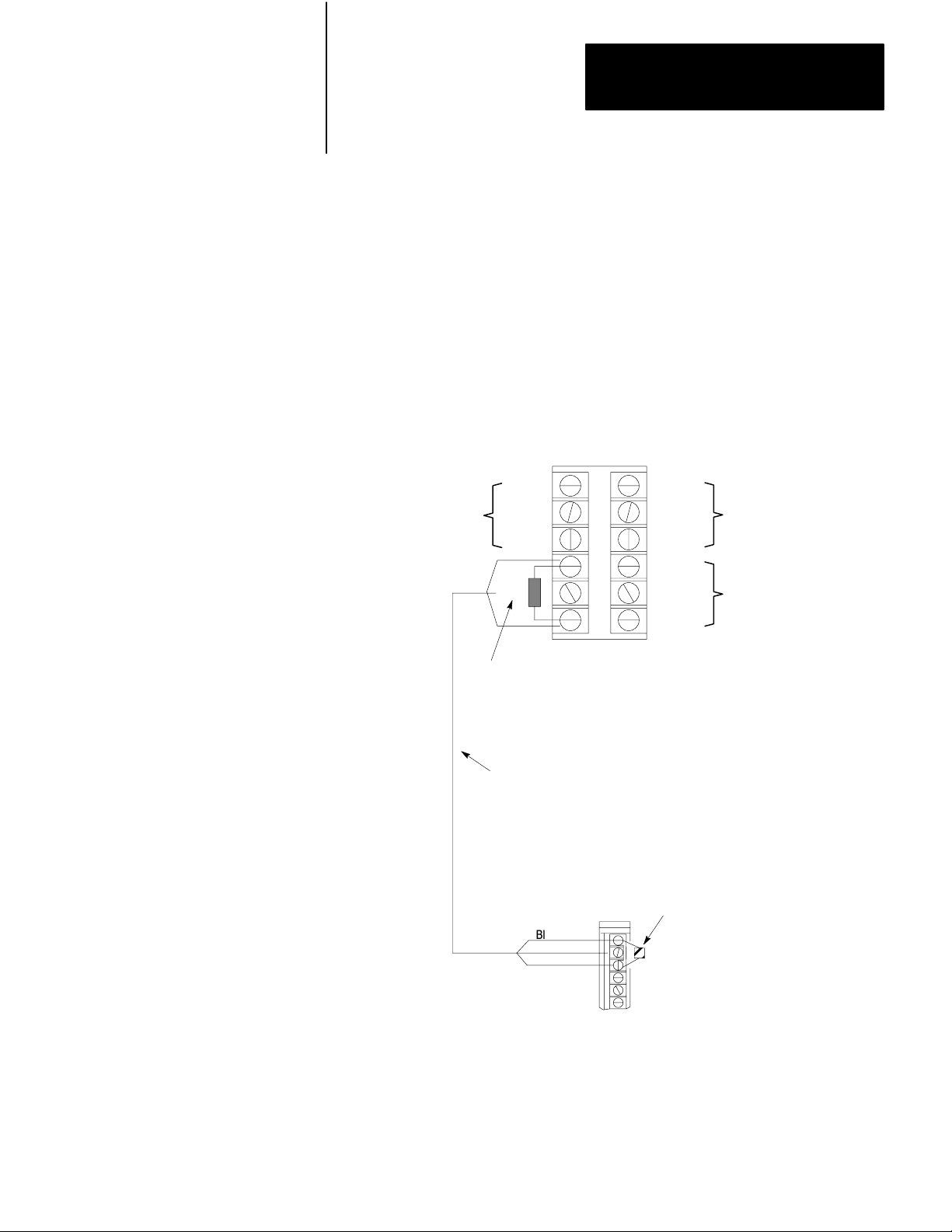

Figure 1.6

Twinaxial

Cable T

erminations

Terminals on I/O Scanner Module

Channel

No. 3

Channel

No. 1

Line 1

Shield

Line 2

Blue

Shield

Clear

Line 2

Terminator Resistor

(Cat. No. 1770-XS or 1770-XT)

150 ohm 0.5 W

1770CD Twinaxial Cable

Terminals on field Wiring Arm

of 1770-AS Adapter Module

Blue

Shield

Clear

Line 1

Shield

Line 2

Line 1

Shield

Line 2

Terminator Resistor

(Cat. No. 1770-XT)

150 ohm 0.5 W

Channel

No. 4

Channel

No. 2

Absence of a terminator resistor can cause block

NOTE:

transfer errors

4. Connect the industrial terminal cable between channel B of the

industrial terminal and the processor chassis.

11821

221

Page 29

Chapter 2

Getting Started with Your ASCII Module

5. Connect the IT/DH adapter cable between the ASCII module and

Channel B

Periodically you will have to switch the cables that connect to channel B

of the industrial terminal.

channel B of the industrial terminal.

You will use the industrial terminal cable (cat. no. 1775-CAT) when

using the industrial terminal in PLC-3 mode and entering or displaying

data in the PLC-3 data table.

You will use the IT/DH adapter cable (cat. no. 1770-CB) when using

the industrial terminal in alphanumeric mode as an ASCII device

connected to your ASCII module.

Be sure to observe the labels on the cable connectors and connect each

to its designated port.

Also, if the IT/DH adapter cable is too short or not available, make your

own. It should not exceed 50 feet (Figure 1.7).

Figure 1.7

Minimum

18

25

ASCII Module

Interface Port

Connections in the 1770CB Cable

1

2

3

7

* Protective Ground

Transmitted Data

Received Data

Ground

1

2

3

7

18

25

Industrial Terminal

Channel B

Connectors:

25pin DShell

Male Connector

Cable Kit

1770XXP (each

end)

Cable:

Belden 8723 or

equivalent

* In cable but not

required for ASCII

module

222

11819

Page 30

Chapter 2

Getting Started with Your ASCII Module

Refer to your PLC-3 Programmable Controller Installation and Operation

Manual (publication 1775-800) for additional installation information

such as switch settings for the adapter module and I/O chassis, and for

grounding information.

Checking ASCII Module Configuration

Your module is configured for RS-232-C operation when shipped from

the factory. If you suspect that its internal configuration (settings of

internal programming plugs) has been altered, you should check module

configuration (refer to section titled ”Choosing the Mode of

Communication,” in chapter 2). Do this as follows:

1. Remove the covers from the module’s printed circuit board.

2. Locate the programming plugs, and set them according to RS-232-C

without control lines (Figure 2.8).

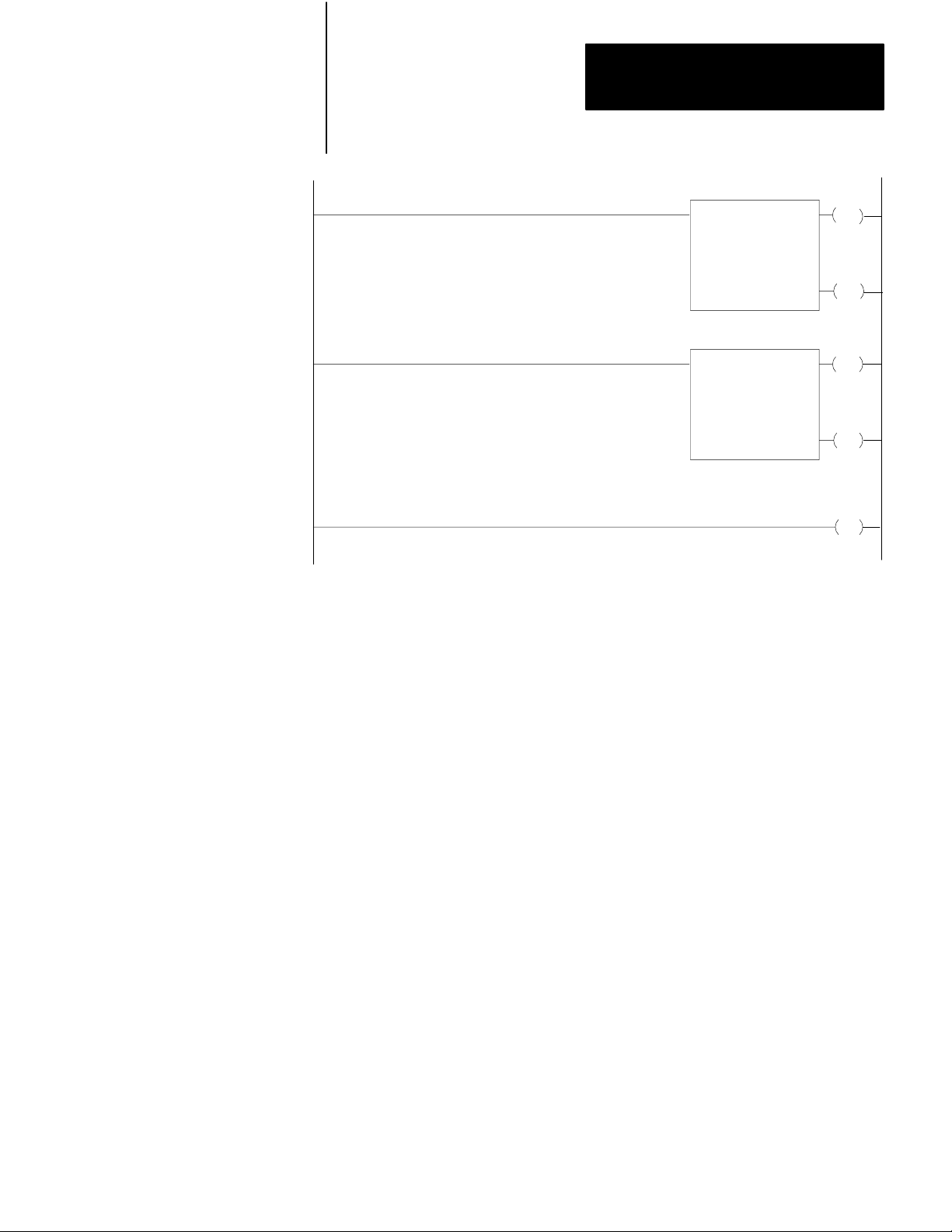

Entering the Getting Started Program"

Using your industrial terminal, enter the “Getting Started Program”

(Figure 1.8) into processor memory. At this point, you do not need to

understand how the program works, but you should enter it exactly as

shown.

223

Page 31

Chapter 2

Getting Started with Your ASCII Module

Figure 1.8

Getting

I0001

00

WO005:0000

00

WO003:0000

07

WO003:000015WO002:0000

WO003:000015WO002:0000

WO005:000002WO003:0000

WO005:000002WO003:0000

Started Program" (PLC3)

15

15

15

15

RUNG NUMBER RM0

RUNG NUMBER RM1

RUNG NUMBER RM2

RUNG NUMBER RM3

RUNG NUMBER RM4

MOV

MOVE FROM A TO R

A : WO001:0000

0000000000000000

R : WO002:0000

0000000000000000

WO002:0000

07

WO005:0000

02

WO002:0000

L

15

WO002:0000

U

15

224

I0001

02

I000102WO005:0000

03

WO005:0000

04

WO005:000004WO003:0000

16

WO005:000004WO003:0000

16

RUNG NUMBER RM5

RUNG NUMBER RM6

RUNG NUMBER RM7

RUNG NUMBER RM8

RUNG NUMBER RM9

WO005:0000

U

03

WO005:0000

04

WO005:0000

L

03

WO002:0000

L

16

WO002:0000

U

16

Page 32

Chapter 2

Getting Started with Your ASCII Module

RUNG NUMBER RM10

001

1

0

001

1

0

CNTL

EN

12

CNTL

DN

15

CNTL

EN

13

CNTL

EN

02

CNTL

DN

05

CNTL

ER

03

WO005:0000

00

WB004:0000

15

WB004:0000

05

WB004:0000

17

RUNG NUMBER RM11

BTR

BLOCK XFER READ

RACK :

GROUP :

MODULE :

DATA :

LENGTH =

CNTL :

BTW

BLOCK XFER WRITE

RACK :

GROUP :

MODULE :

DATA :

LENGTH =

CNTL :

1=HIGH

FO003:0000

FB004:0000

1=HIGH

FO002:0000

FB004:0000

1. Connect the 1775-CAT cable to channel B of the industrial terminal.

2. Turn on power to the I/O chassis and PLC-3 controller.

3. Turn off the memory protect switch on the front panel of the PLC-3

controller.

4. Select program load mode on the PLC-3 front panel.

Press [SHIFT][LIST] 3 [ENTER]

5. Turn on the industrial terminal. It should automatically display

ladder diagram mode. If not,

Press [SHIFT][MODE]1

6. Enter the following key sequence on the industrial terminal keyboard

before entering your program.

Press[INSERT][SHIFT][RUNG][ENTER]

225

Page 33

Chapter 2

Getting Started with Your ASCII Module

The displayed power bars will be replaced by I’s at the left and right

margins of the screen. The prompt EDITING will blink.

7. Enter your instructions and addresses. Refer to the PLC-3

NOTE: Be sure that you have entered the prefix F (file) in the addresses

of your block transfer read (BTR) and block transfer write (BTW)

instructions. Create a (nominal) 64 word file for your BTR and BTW data

files as follows:

where the <> symbols are not entered but designate data that you enter.

Example file addresses are O3:0 and O2:0.

Programming Manual (publication 1775-801) as needed.

Press CR,<file address>100,Y [ENTER]

8. Assemble your program.

Press ASM,Y[ENTER]

The power bars now become solid lines.

9. Check your program using the consecutive display mode starting

with the first rung.

Press [SHIFT][DISPLAY][ENTER]SR[ENTER]

Use [RUNG

↓] and [RUNG ↑] as needed to move from rung to rung.

Installing Your ASCII Module

Be sure that power to the I/O chassis is turned off when installing (or

removing) your ASCII module as follows:

1. Turn off power to the I/O chassis.

226

2. Insert the ASCII module in rack 1, module group 1, slot 1. The

program makes the processor communicate with the ASCII module

at that specific location. (If you must use another rack location and

are familiar with programming block transfer instructions, change

Page 34

Chapter 2

Getting Started with Your ASCII Module

the rack, group, and slot number of the module address in the block

transfer read and write instructions, accordingly.)

3. Turn on power to the I/O chassis. Three LED indicators on the

ASCII module illuminate momentarily. Their functions are:

FAULT: Normally off. This red LED indicator illuminates when the

module detects an internal fault.

BUFFER FULL: Normally off. This yellow LED indicator illuminates

when the input buffer becomes full.

CHANNEL ACTIVE: This green LED indicator illuminates when the

industrial terminal is on, properly connected to the ASCII module’s

interface port, and set for alphanumeric mode.

227

Page 35

Chapter 2

Getting Started with Your ASCII Module

Reading Data from Your ASCII

Device

In this demonstration you will enter data and observe how it is stored in

the processor data table. You will use the industrial terminal in

alphanumeric mode as an ASCII data terminal when you enter data. Then

you will change the industrial terminal to PLC-3 mode and observe the

transferred data by displaying the contents of the block transfer read file.

You must alternate cables that connect to channel B of the industrial

terminal, one cable for alphanumeric mode, the other for PLC-3 mode.

You will simulate the action of an input bit through the PLC-3 front panel

to enable a write block transfer.

You will use the following procedures.

In

Procedure

P1

P2

P3

P4

Connect the 1770CB cable, and set your industrial

terminal to alphanumeric mode

Enter your data

Connect the 1775CA

terminal to PLC3 mode

See how data is stored in the data table

Y

ou W

ill

T cable, and set your industrial

Even if you are familiar with these procedures, read them completely. If

you deviate from these procedures, proper operation may not occur.

If you have not already done so, load the “Getting Started Program”

(Figure 2.8) into processor memory.

Procedure 1

Set Your Industrial Terminal to Alphanumeric Mode

1. Turn on the industrial terminal.

2. Connect the 1770-CB cable to channel B of the industrial terminal.

3. Select alphanumeric mode.

Press [SHIFT][MODE] 2

The CHANNEL ACTIVE LED on the module illuminates.

228

Page 36

Chapter 2

Getting Started with Your ASCII Module

4. Set operating parameters:

Communication rate to 300 baud. Press A (as needed) until the

communication rate, as displayed on the screen, reaches 300 baud.

Hardware handshaking to ON. Press D

DUPLEX to FULL. Press F

B and C to any setting.

E, and G thru M to OFF.

Press [ENTER] to load parameters.

The prompt, ENTERING ALPHANUMERIC TERMINAL MODE, tells

you the terminal is ready for your input.

Procedure P2

Enter Your Data

1. Check that the PLC-3 controller is operating in run monitor. Use the

PLC-3 front panel.

Press [SHIFT][LIST] 2 [ENTER]

2. Enter data, such as your first name, followed by a couple of numbers.

Enter 11 characters counting the space between your name and

numbers. Select the characters from commonly used data characters

(Table 1.D).

Table 1.D

Commonly

Used Data Characters

ASCII Hex ASCII Hex ASCII Hex

space 20 A 41 N 4E

0 30 B 42 O 4F

1 31 C 43 P 50

2 32 D 44 Q 51

3 33 E 45 R 52

4 34 F 46 S 53

5 35 G 47 T 54

6 36 H 48 U 55

7 37 I 49 V 56

229

Page 37

Chapter 2

Getting Started with Your ASCII Module

The industrial terminal displays the characters as you enter them. If

characters are not displayed, check the program that you loaded into

memory. Check step 3, operating parameters, for errors. If you find no

errors, refer to Need Help? below.

Procedure P3

Set Your Industrial Terminal to PLC-3 Mode

ASCII HexASCIIHexASCIIHex

8 38 J 4A W 57

9 39 K 4B X 58

L 4C Y 59

M 4D Z 5A

1. Connect the 1775-CAT cable to channel B.

2. Display your ladder diagram.

Press [SHIFT][MODE]1

Procedure P4

See How Data Is Stored in the Data Table

1. Display the block transfer read file. Enter the address of that file

(O3:0) with the following key sequence.

Press DD,O3:0, [SHIFT]%A [ENTER]

Results The name and numbers (11 characters or more) that you entered

are displayed. For example, if you had entered

ASCII 7890123

230

the space between ASCII and 78790123 would count as an entered

character, and your display would show 10 characters as follows:

RADIX

= %A START = W

WORD #

00000 E0H11H 00H00H ASCII 789000H00H

0 1 2 3 4 5 6 7

A011:0248

Page 38

Chapter 2

Getting Started with Your ASCII Module

2. Display the same file in hex.

Press,%H [ENTER]

The following display appears:

RADIX

= %A START = W

WORD #

00000 E011 0000 4153 4349 4920 3738 3930 0000

0 1 2 3 4 5 6 7

A011:0248

3. You can display the file in other number bases by replacing the H in

step 2 with D for decimal, B for binary, or A for ASCII.

Compare the following displays.

Number

Base

ASCII (A)

Hex (H)

Decimal (D)

Display

A S C I I 7 8 9 0 00H00H

41 53 43 49 49 20 37 38 39 30 0000

41 53 43 49 49 20 37 38 39 30 000

Zero V

alue

Results Entering the eleventh character caused the module to transfer the

data.

Status word one (E011) and status word two (0000) indicate normal

operation of the module. These are shown in display words 0 and 1,

respectively.

4. Terminate this display and return to ladder diagram.

Press [SHIFT][MODE]1

Need Help?

If your display was all zeros (00H00H), ASCII display), the data did not

transfer. You may have altered the procedure.

Did you enter your program exactly as shown?

Did the module’s CHANNEL ACTIVE LED go on?

Did the CHANNEL 1 LED on your scanner go on?

Did the ACTIVE LED on your adapter go on?

Have you configured your PLC-3 controller (LIST function)?

231

Page 39

Chapter 2

Getting Started with Your ASCII Module

If you are still having trouble, refer to “Testing the ASCII Module and

Cables,” to verify communication between the ASCII module and the

industrial terminal. If you suspect a cable problem, check the 1770-CB

cable (Figure 1.7).

Then try again starting with Procedure P1.

Writing Data to Your ASCII

Device

In this demonstration you will load data characters into the write block

transfer file and observe how they are displayed by the industrial terminal.

You will use the industrial terminal in PLC-3 mode to load data. Then

you will change the industrial terminal to alphanumeric mode and observe

the transferred data.

The procedures that you will follow are described below.

In

Procedure

P3 Connect

P5 Load

P1 Connect

P6

the 1775CA

mode

data into the file

the 1770CB cable, and set your industrial terminal to alphanu

mode

meric

Enable the transfer of new data

T cable, and set your industrial terminal to PLC3

Y

ou W

ill

Procedure P3

Set Your Industrial Terminal to PLC-3 Mode

232

NOTE: Skip this procedure if the industrial terminal is already in PLC-3

mode.

1. Connect the 1770-CAT cable to channel B.

2. Set your industrial terminal to PLC-3 mode, and display the

beginning of your ladder diagram program.

Press [SHIFT][MODE]1

Procedure P5

Load Data into a File

1. Place the processor in program load mode using the PLC-3 front

panel.

Page 40

Chapter 2

Getting Started with Your ASCII Module

Press [SHIFT][LIST]3[ENTER]

2. Display the file that you want to load by entering the address of that

file (O2:0) with the following key sequence.

Press DD,O2:0,[SHIFT]%A[ENTER]

3. Load ASCII data into the file starting with the third word (display

word 2) for block transfer instructions (the first word for file move

instructions). The first and second words of a write block transfer

instruction are reserved for command words (handshaking). Press

[ENTER] and [ ] after loading each word.

For example, if you load the following:

BRADLEY 1234

Your file will appear as

RADIX

= %A START = W

WORD #

00000 60H00H 00H00H BRADLE Y 123 4

0 1 2 3 4 5 6 7

A011:0248

4. Change the display to hex and observe how the equivalent data is

displayed.

Press,[SHIFT]%H[ENTER]

Your file display will change to the following:

RADIX

= %A START = W

WORD #

00000 E011 0000 4252 4144 4C45 5920 3132 3334

0 1 2 3 4 5 6 7

A011:0248

Check the display of data to be sure that you entered all data exactly as

shown.

Procedure P1

Set Your Industrial Terminal to Alphanumeric Mode

233

Page 41

Chapter 2

Getting Started with Your ASCII Module

1. Connect the 1770-CB cable to channel B.

2. Select alphanumeric mode.

3. Check operating parameters:

Press [SHIFT][MODE]2

Communication rate is 300 baud.

Hardware handshaking is ON.

DUPLEX is FULL.

B and C are any setting.

E, and G thru M are OFF.

Press [ENTER] to load parameters.

The module’s CHANNEL ACTIVE LED turns on.

4. Change the operation of your PC-3 controller to run monitor from

the PLC-3 front panel.

Press [SHIFT][LIST]2[ENTER]

Procedures P6

Enable the Transfer of New Data

1. Set bit I001/02 to enable program logic (the write block transfer

handshaking) using the PLC-3 front panel.

Press [CLEAR][SHIFT]I0[SHIFT][BIT]1[BIT]2

[DISPLAY]

The front panel displays the bit address with an asterisk showing its

status, 1 or 0.

234

I000:0001/02*0

2. Set the bit using the PLC-3 front panel.

Press 1 [ENTER]

Results The industrial terminal displays

Page 42

Chapter 2

Getting Started with Your ASCII Module

BRADLEY 12345

at the upper left corner of the screen.

3. Reset the bit using the PLC-3 front panel.

Press 0 [ENTER]

4. Terminate the display and return to ladder diagram by connecting the

1770-CB cable to channel B, and entering the following keystrokes

on the industrial terminal keyboard.

Press [SHIFT][MODE]1

Summary

Now that you have demonstrated how data is transferred from your ASCII

device to the data table and vice versa, you are ready to use these

procedures further. Next, read “Choosing Module Features,” Chapter 2.

It will define key words and concepts. Then, in Chapter 3, “ASCII

Tutorial,” you will use these procedures to demonstrate operating

characteristics of your module.

235

Page 43

Chapter

Choosing Module Features

3

Chapter Objectives

Choosing the Mode of

Communication

Because of the many types of ASCII devices available and the variety of

possible applications, you must configure your module according to the

ASCII device and specific application that you have chosen. To do this,

you must make some decisions. We will show you how to configure your

module using programming plugs and by setting bits in initialization

words.

Following the description of each module feature, we will show you how

to record your decision whether to use the feature, and when appropriate,

the quantity pertaining to the feature. At the end of this chapter, you will

consolidate your decisions on a worksheet. You can use the worksheet to

configure your module for your specific ASCII device and application.

This manual uses the following notation when referring to initialization

words and bits. There are four initialization words to configure your

module: IW1, IW2, IW3, and IW4. Bits within an initialization word are

shown in parentheses after the word. For example, bits 10 thru 17 in

initialization word three would appear as IW3(10-17).

The ASCII module responds to three modes of communication.

RS-232-C

Current Loop, 20mA

A-B Long Line

RS232C

Use this mode for communicating up to approximately 50 cable feet

between a printer or CRT and the ASCII module. The Electronics

Industry Association (EIA) standard RS-232-C sets data and control line

voltage levels for serial data communication. Data transmission is

negative true logic: -5 to -15Vdc for a logic 1, +5 to +15Vdc for a logic 0.

Control line commands are positive true logic: +5 to +15Vdc for enable,

-5 to -15Vdc for inhibit. The standard also specifies a 25-pin connector

and defines pin functions. Most systems use only the following pins:

31

Page 44

Chapter 3

Choosing Module Features

Pin Signal

2

transmit

data

receive data

3

request to send

4

clear to send

5

ground

7

Refer to Table 2.A for a detailed listing of RS-232-C pin functions.

Table 2.A

RS232C

Pin

No

2 T

3

4

5

6

7

8

Connector Pin Functions

Signal Name

ransmitted Data

Received Data

Request to Send

Clear to Send

Data Set Ready

Signal Ground

Receive Line Signal

Detector

EIA

Circuit

BA DTE

BB 1771DA

CA DTE T

CB 1771DA

CC 1771DA

AB

CF 1771DA

Source Functions

(DCE)

(DCE)

(DCE)

(DCE)

Data T

ransfer to

1771DA (DCE)

Data T

ransfer to DTE

ells the 1771DA data is

transmitted.

T

ells DTE that data is

transmitted. Enabled only

if pin 4 is Vdc (of

T

ells DTE that 1771DA

(DCE) is ready

Common ground for all

signals thru interface port

on 1771DA.

T

ied to +12V dc

f).

.

32

20

Data T

erminal Ready

CD DTE T

ells 1771DA (DCE) that

DTE is ready

+V dc to send or receive.

. Must be

Current Loop

Use the current loop for communicating up to approximately 500 cable

feet between your ASCII device and ASCII module. A current loop has

high immunity to errors caused by electrical noise, has no signal

attenuation, eliminates ground loops, and is low cost.

A current loop is a loop that carries current (generally 20mA) between

electronic equipment by means of a twisted pair of wires. A transmitting

device in the loop transmits digital signals by interrupting the current

Page 45

Chapter 3

Choosing Module Features

flow. A receiving device in the loop senses the interruptions. By

convention, a logic 1 corresponds to the presence of loop current; a logic

0 corresponds to the absence of loop current.

A current loop transmitter or receiver can be either of two types: active

(source) or passive (sink). An active transmitter supplies current to the

loop. Any receivers or other transmitters within that loop must be passive

units that accept the supplied loop current. Alternately, an active receiver

supplies current to passive transmitters or other passive receivers in the

loop.

Current sources that power a current loop vary in complexity. The

simplest is a resistor and voltage source. More complex current sources

contain active elements or integrated circuits to provide constant current

under various power supply and load conditions.

Refer to Table 2.B and Table 2.C for a detailed listing of current loop pin

functions.

Pin No.

11

12

18

24

Pin No.

11

Table 2.B

Current

Passive Receive/Passive T

Signal Name

Module T

Module Receiver Circuit

Module T

Module Receiver Circuit Return

Module T

Control and Return

ransmitter Circuit

ransmitter Circuit Return

Table 2.C

Current Loop Connector Pin Functions

Passive Receive/Active T

Signal Name

ransmitter

, Circuit

Loop Connector Pin Functions

ransmit

Source Function

Peripheral or Power Supply Controls current loop, allowing

Peripheral Device

ransmit

Source Function

peripheral device to read data

Completes current loop, allowing

transfer of data to 1771DA

Return for module transmitter circuit

Return for module receiver circuit

Controls current loop, allowing

peripheral device to read data. Serves

as return for transmitter circuit.

12

13

24

Module Receiver Circuit

Module T

Module Receiver Circuit Return

ransmitter Circuit Source

Peripheral Device

1771DA

Completes current loop, allowing

transfer of data to 1771DA

Supplies current for current loop

interface

Return for module receiver circuit

33

Page 46

Chapter 3

Choosing Module Features

AB Long Line

Use A-B Long Line for communicating up to 5000 cable feet between an

industrial terminal, serving as an ASCII device, and the ASCII module.

Refer to Table 2.D for a detailed listing of A-B Long Line pin functions.

Table 2.D

AB

Long Line Connector Pin Functions

Pin No.

2 T

7 T

11

25

Signal Name

ransmitted Data

ransmitted Data Return Return for transmitted data

Received Data

Received Data Return

AB Long Line Device

1771DA

Source Function

Data T

ransfer to 1771DA

Data transfer to AB Long Line Device

Return for received data

Selecting the Communication Mode

The communication mode that you choose depends on the cable distance

from your ASCII device to your ASCII module, and on characteristics of

your ASCII device (Table 2.E).

Table 2.E

of Communication

Mode

If Distance is

Less Than

50 feet

And Y

our ASCII Device is a

Data T

erminal Equipment (DTE) and conforms

to RS232C

without control lines

with control lines

Then Choose this

T

ransmission Mode

RS232C (Figure 2.1)

4wire cable

8wire cable

34

Data Set (modem) and conforms to RS232C

without control lines

with control lines

500 feet

5000 feet AB industrial terminal or contains a line driver

DTE and provides a 20mA current source for

the transmit line, only

DTE and requires a 20mA external current

source for its transmit line

DTE and provides 20mA current sources for

transmit and receive lines

receiver for AB long line operation.

RS232C (Figure 2.2)

4wire cable

8wire cable

Current Loop (Figure 2.3)

The module powers its own transmit line.

Current Loop (Figure 2.4)

Y

ou add the power supply for the DTE.

Current Loop (Figure 2.5)

The module operates in passive transmit.

AB Long Line (Figure 2.6)

Page 47

Chapter 3

Choosing Module Features

The functions of the cable conductors (Figure 2.1 thru Figure 2.7) are

referenced to your ASCII device, not to your ASCII module.

Figure 2.1

RS232C

Connections (50 ft. max): Data T

erminal to Data Set

(Refer to specifications in Appendix D)

Device

Data Terminal

Equipment (DTE)

Drain Wire (Shield)

2

Transmit

7

Receive

3

4

Transmitted Data (BA)

Signal Ground (AB)

Received Data (BB)

Request to Send (CA)

ASCII Module

Data Set (DCE)

2

7

3

4

To I/O

Chassis

Ground

Receive

Transmit

2

Belden

8723

or

Equiv.

Belden

8778

or

Equiv.

Control

Lines

20

5

6

8

NOTE: (AB) thru (CD) refer to RS232C circuit labels.

Clear to Send (CB)

Data Set Ready (CC)

Received Line Signal Detector

Data Terminal Ready

1 Tied to +12Vdc

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

2

Connect it to the I/O chassis ground lug. Ground the shield at this end only

1

5

6

8

20

.

.

11822

35

Page 48

Chapter 3

Choosing Module Features

Receive

Transmit

Device

Data Set (DCE)

2

7

3

4

Figure 2.2

RS232C

Connections (50 ft. max): Data Set to Data Set

(Refer to specifications in Appendix D)

Drain Wire (Shield)

Received Data (BB)

Signal Ground (AB)

Transmitted Data (BA)

Request to Send (CA)

ASCII Module

(DCE)

2

7

3

4

To I/O

Chassis

Ground

Receive

Transmit

2

Belden

8723

or

Equiv.

Belden

8778

or

Equiv.

Control

Lines

20

5

6

8

Clear to Send (CB)

Data Set Ready (CC)

Received Line Signal Detector

1

Data Terminal Ready

1 Tied to +12Vdc

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

2

Connect it to the I/O chassis ground lug. Ground the shield at this end only

NOTE: (AB) thru (CD) refer to RS232C circuit labels.

5

6

8

20

.

.

11822

36

Page 49

Chapter 3

Choosing Module Features

When configured for current loop and you use terminals 13 and 11 for

transmit, your ASCII module powers its own transmit loop (Figure 2.3

and Figure 2.4). Your module can accept an active receive current loop

powered by the ASCII device. In this case, module operation is passive

transmit and you use module terminals 11 and 18 (Figure 2.5).

Figure 2.3

Loop Connections (500 ft. Max): Device is Active T

Current

(Refer to specifications in Appendix D)

ransmit, Passive Receive

ASCII ModuleDevice

Transmit with

Current Source

Passive Receive

Drain Wire (Shield)

Transmitted Data

Return

Received Data

Return

1

an external ground wire (14 ga.) to the drain wire at the cable connector

Solder

Connect it to the I/O chassis ground lug. Ground the shield at this end only

To I/O

Chassis

Ground

12

24

13

11

.

.

1

(+)

Passive

Receive

(-)

(+)

Transmit with

Current Source

(-)

11823

Belden

8723

or

Equiv.

37

Page 50

Chapter 3

Choosing Module Features

Figure 2.4

Loop Connections (500 ft. max): Device is Passive T

Current

(Refer to specifications in Appendix D)

ransmit, Passive Receive

ASCII ModuleDevice

Passive Transmit

Passive Receive

Drain Wire (Shield)

Transmitted Data

4-20mA mark state

Power

+-

Supply

Received Data

Return

1

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

Connect it to the I/O chassis ground lug. Ground the shield at this end only

Figure 2.5

Loop Connections (500 ft max.): Device is Active T

Current

(Refer to specifications in Appendix D)

Drain Wire (Shield)

Return

ASCII ModuleDevice

To I/O

Chassis

Ground

(+)

12

Passive

Receive

(-)

24

(+)

13

Transmit with

Current Source

(-)

11

.

.

ransmit, Active Receive

.

To I/O

Chassis

Ground

1

Belden

8723

or

Equiv.

11824

1

38

Transmitted Data

Transmit with

Current Source

Return

Received Data

Receive with

Current Source

1

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

Connect it to the I/O chassis ground lug. Ground the shield at this end only

Return

NOTE: Device and its power supply must float in respect to the module for passive transmit.

(+)

12

24

11

Passive

Receive

(-)

(+)

Belden

8723

or

Equiv.

Passive

Transmit

(-)

18

.

.

11825

Page 51

Chapter 3

Choosing Module Features

Use a 25-pin male D-shell connector such as Amp DB-25P for your cable

connections to the ASCII module. Terminate the shield to pin 1 at the

module end only.

Figure 2.6

AB

Long Line Connections (5000 ft max)

Receive

Channel B

Drain Wire (Shield)

2

25

3

18 25

1

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

Connect it to the I/O chassis ground lug. Ground the shield at this end only

Transmitted Data

Return

Received Data

Return

.

.

ASCII ModuleIndustrial Terminal

Figure 2.7

RS232C

Simplex W

rite Connections

(Refer to Specifications in Appendix D)

2

7

11

11826

To I/O

Chassis

Ground

Receive

Transmit

1

Belden

8723 or

Equiv.

ASCII ModuleDevice

(DTE)

Drain Wire (Shield)

7 7

Receive Transmit

3 3

Belden

8723

or

Equiv.

[1]

Solder

an external ground wire (14 ga.) to the drain wire at the cable connector

Connect it to the I/O chassis ground lug. Ground the shield at this end only

NOTE: Jumper pin 2 to pin 18 at the module end of the cable (special case).

Signal Ground (AB)

Received Data (BB)

.

.

(DCE)

To I/O

Chassis

Ground

2

18

11827

[1]

39

Page 52

Chapter 3

Choosing Module Features

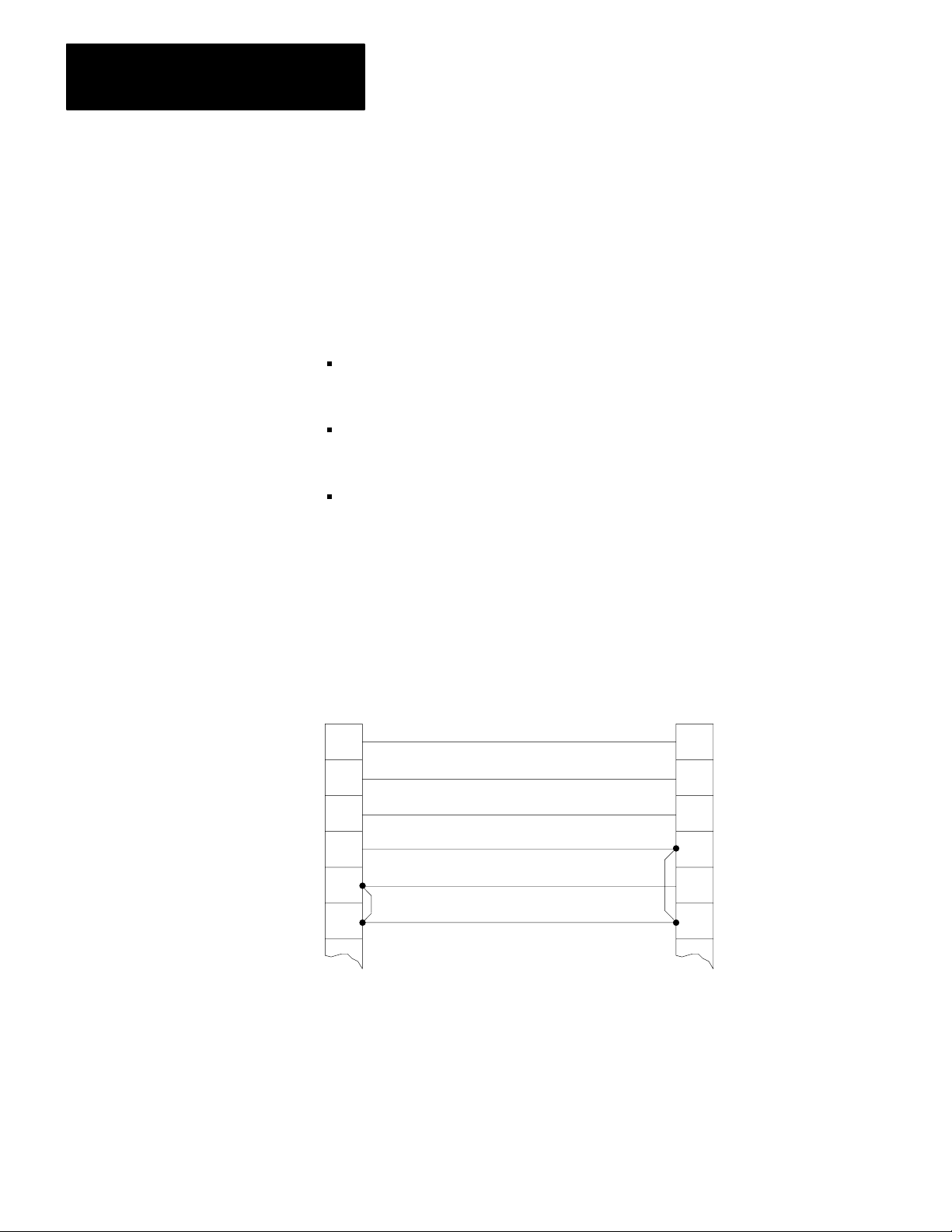

Setting the Module's Programming Plugs

Implement your choice of cable configuration by setting programming

plugs inside the module. Remove the module’s left-hand cover plate (the

one without the labels). Locate and adjust the programming plugs

according to Figure 2.8.

NOTE: The locations of programming plug sockets (Figure 2.8) are

labeled El thru E16 on the printed circuit board. The settings of

programming plugs are defined as follows:

IN refers to the plug jumpering the pair of pins at the designated

location.

1-2 or 2-3 refers to the pins on which you insert the plug. Pins 1 and

3 are labeled on the circuit board next to the pins.

OUT refers to removing the plug or inserting it on only one pin

(electrically floating). You can store up to four plugs in the area

labeled JUMPER STORAGE at the right-hand side of the board.

SPECIAL CASE When operating an ASCII device in RS-232-C simplex

write mode without a transmit line from the ASCII device (Figure 2.7),

jumper pin 2 to pin 18 at the cable connector (module end of cable) and

insert a programming plug in location E16 on the ASCII module.

Re-assemble the module after you have finished setting and/or checking

the programming plugs.

310

Page 53

Chapter 3

Choosing Module Features

Figure 2.8

Programming

Plug Locations and Settings

Jumper

Storage

E2

E4

E3

E5

E6

E8

E7

E9

E12

E16

E15

E14

E11

E10

E13

Bottom

of

Module

RS-232-C

Programming

Plug

Location

E-1

E-2

E-3

E-4

E-5

E-6

E-7

E-8

E-9

E-10

E-11

E-12

E-13

E-14

E-15

[2]

E-16

[1]

3-prong connector:

[2]

See Special Case, Choosing the Mode of Communication"

[3]

Remove E4 when initializing the module (IW 1 B05, B06, B07) in half-duplex mode

Without

Control

Lines

[1]

1-2

Out

[3]

In

In

In

Out

Out

Out

1-2

Out

In

In

In

In

Out

12 place programming plug toward pin 1 as labeled

on the circuit board

23 place programming plug toward pin 3 as labeled