Page 1

Smart Transmitter Toolkit

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes and

standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for purposes of example. Since there are

many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellectual property liability) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control (available from your

local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this

publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen-Bradley Company, Inc., is

prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention statements help you to:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is critical for successful application

and understanding of the product.

Page 3

Table of Contents

Using This Manual

What's In This Preface

Purpose of This Manual

Who Should Use This Manual

How To Use This Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terms

Abbreviations

Conventions

Related

STT Software License

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iii

iii

iii

Introducing The Smart Transmitter Toolkit 11. . . . . . . . . . . . .

What's In This Chapter 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What's The Smart Transmitter Toolkit 11

What You Get With The STT Subroutine 12

What You Need to Use The STT Subroutine 13

Why You Should Use The STT Subroutine 13

How a PLC5 Processor Communicates With a HART Field Device 14

How You Use The STT Subroutine 16. . . . . . . . . . . . . . . . . . . . . . .

What

to Do Next

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

i

i

i

ii

ii

ii

Installing The Smart Transmitter Toolkit 21. . . . . . . . . . . . . . .

What's In This Chapter 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin 21

1. Copy STT Subroutine File to the Hard Drive 22

2. Create and Name a New Program File 23

3. Paste The STT Subroutine File 24

4. Save Your Work (optional) 25

5. Change The STT Default Data File (optional) 26

What's

Next

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using The Smart Transmitter Toolkit 31. . . . . . . . . . . . . . . . .

What's In This Chapter 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1. Create Data T

2. Provide The STT Subroutine Inputs 33

3. Use The STT Subroutine Status Word 34

4. Call The STT Subroutine 35

5. Interpret The STT Subroutine Outputs 36

Programming

With Single 1770HT1 37

able Files

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 1: Single HAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

T Device

Page 4

Table of Contentsii

Programming

With Single 1770HT1 39

Programming

With Multiple 1770HT1s 313

Example 2: Multiple HAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Example 3: Multiple HAR

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

T Devices

T Devices

HART Command Data Table Layouts A1. . . . . . . . . . . . . . . . .

What's In This Appendix A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HART Command 0 Read HART Address A2

HART Command 0

Read HART Address A3

HART Command 1

Read Primary Variable A4. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HART Command 3

Read Dynamic Variables & Primary Variable Current A6

HART Command 3

Read Dynamic Variables & Primary Variable Current A7

HART Command 35

Write Primary Variable Range Values A8. . . . . . . . . . . . . . . . . . .

HART Command 35

Write Primary Variable Range Values A9

HART Command 38

Reset Configuration Change Flag A10

HART Command 38

Reset Configuration Change Flag A11

HART Command 43

Set Primary Variable Zero A12

HART Command 43

Set Primary Variable Zero A13

HART Command 44

Write Primary V

HART Command 44

Write Primary V

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

ariable Units

ariable Units

. . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

A14. . . . . . . . . . . . . . . . . . . . . . . . .

A15. . . . . . . . . . . . . . . . . . . . . . . . .

Codes B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What's In This Appendix B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STT Subroutine Error Codes B1

Smart Transmitter Interface Error Codes B2

HART Protocol Communication Error Codes B3

Integer Word 34 B3

HART Command Response Summary Error Codes B3

Integer Word 35 B3

HART Field Device Error Codes B4

Unit Codes B5

Integer Words 10 and 40 B5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Using This Manual

Preface

What's

In This Preface

Purpose of This Manual

This preface describes how to properly and efficiently use this manual.

Smart T

User

ransmitter T

Manual

oolkit

It tells you about:

the purpose of this manual

who should use this manual

how to use this manual

terms

abbreviations

conventions

related publications

publication 17706.5.21

Use this manual to install and use the Smart Transmitter Toolkit.

Throughout this manual we refer to this utility as the STT subroutine.

Who Should Use

This Manual

This manual is intended for use by:

persons who install Smart Transmitter Interface products, in connection

with Allen-Bradley PLC controllers or other intelligent controllers

system integrators who design and establish network systems that

involve plant floor machinery, programmable controllers, HART field

devices, Smart Transmitter Interface products, and host computers

We assume that you have:

a strong working knowledge of your plant’s process and equipment

a familiarity with personal computers, MS-DOS or PC-DOS,

ControlView, and 6200 programming software

i

Page 6

Preface

Using This Manual

How To Use This Manual

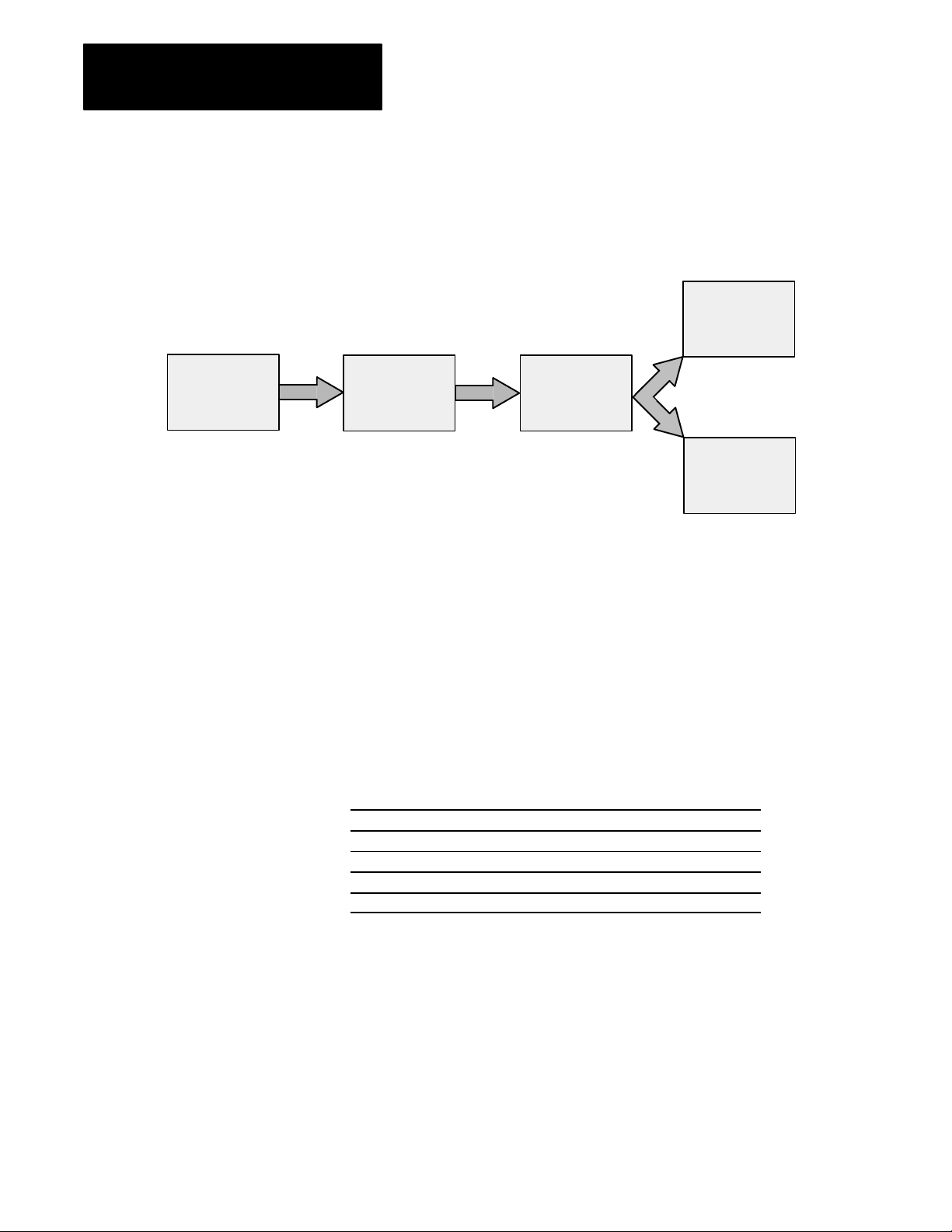

Read about the

STT subroutine

chapter 1

Terms

Start by reading about the STT subroutine. Then, follow the instructions in

chapter 2 to install the STT subroutine. Finally, use chapter 3 and the

appendices to help you incorporate the STT subroutine into your ladder

logic.

See

HART Command

Data Table Layouts

appendix A

Install the STT

subroutine

chapter 2

Use the STT

subroutine

chapter 3

See

Codes

appendix B

Some of the tasks described in this manual assume that you have an

acquaintance with basic computer terminology.

Abbreviations

For a glossary of terms related to Smart Transmitter Interface products, see

the Smart Transmitter Interface Products (HART Protocol) User Manual,

publication 1770-6.5.19.

In this manual, we use these abbreviations.

This abbreviation: is for:

BTR

BTW Blocktransfer Write

HART Highway Addressable Remote Transducer

JSR Jump to Subroutine

STT Smart Transmitter Toolkit

Blocktransfer Read

ii

Page 7

Preface

Using This Manual

Conventions

Related

Publications

We use these conventions in this manual:

In this manual, we show: Like this:

prompts and messages

literal text that you type

variable text that you type

keys that you press

screens that you see

that there is more information about the

topic in another manual

Press a function key

STT_SUB

filename

F1

Program

Directory

AllenBradley Publications

Publication Publication Number

Smart Transmitter Interface Products (HART Protocol) User Manual

PLC5 Programming Software Programming Manual

17706.5.19

62006.4.7

STT Software License

For a list of publications for Allen-Bradley programmable controller

products, see the Automation Group Publication Index, publication SD499.

HART Publications

Publication Reference Number and Date

HART - Smart Communications

Protocol Specification

STT is not a licensed software product. It is provided to help you quickly

communicate with HART field devices. Please feel free to use this

software on any and all machines that you have.

Revision 5.1, January 4, 1991

Rosemount, Inc. Document No. D9000047, Revision A

iii

Page 8

Chapter

1

Introducing The Smart Transmitter Toolkit

What's

What'

In This Chapter

s The Smart

Transmitter Toolkit

HART Universal Commands

The functions performed by these commands

are performed by all HART devices.

HART Commonpractice Commands

The functions performed by these commands

may not be possible for all HART devices.

HART Transmitterspecific Commands

Only one or at most a few HART devices

implement these functions. The functions

performed by these commands allow each

device type to implement their own

commands for special functions, calibration,

and special data handling.

Refer to the product manual for your HART

field device for a list of supported commands.

This chapter gives you an overview of the Smart Transmitter Toolkit

that you received with your Smart Transmitter Interface (cat. no. 1770-HT1).

The Smart Transmitter Toolkit (STT) is a PLC-5 ladder logic subroutine

utility that saves development time by simplifying the communication

among Allen-Bradley PLC-5 processors, Allen-Bradley Smart Transmitter

Interfaces, and HART-compliant field devices, such as a smart transmitter

or actuator.

✔ The STT subroutine provides a shell that lets you use a PLC processor

to communicate with a HART field device, without having detailed

knowledge of the HART protocol.

✔ The STT subroutine supports the HART commands that are most

commonly used with PLC processors. The STT subroutine does not

support vendor-specific HART commands, such as totalization.

✔ STT focuses on digital data that is associated with the HART protocol.

Use Allen-Bradley Analog I/O modules to acquire 4-20mA analog data.

✔ STT does not include faceplates or operator interface screens. However,

you can configure operator interface software, such as ControlView

software, to display/modify data that is received/sent to the STT

subroutine.

✔ STT supports:

HART Universal Commands 0, 1, and 3

HART Common Practice Commands 35, 38, 43, and 44

Both long- and short-frame addressing

Both point-to-point and multi-drop configurations

Allen-Bradley PLC-5 processors

Important: Do not view STT as a configuration tool. We assume you take

the appropriate steps to configure and calibrate the HART field device

using either Cornerstone software or a hand-held terminal.

1-1

Page 9

Chapter 1

Introducing The Smart Transmitter Toolkit

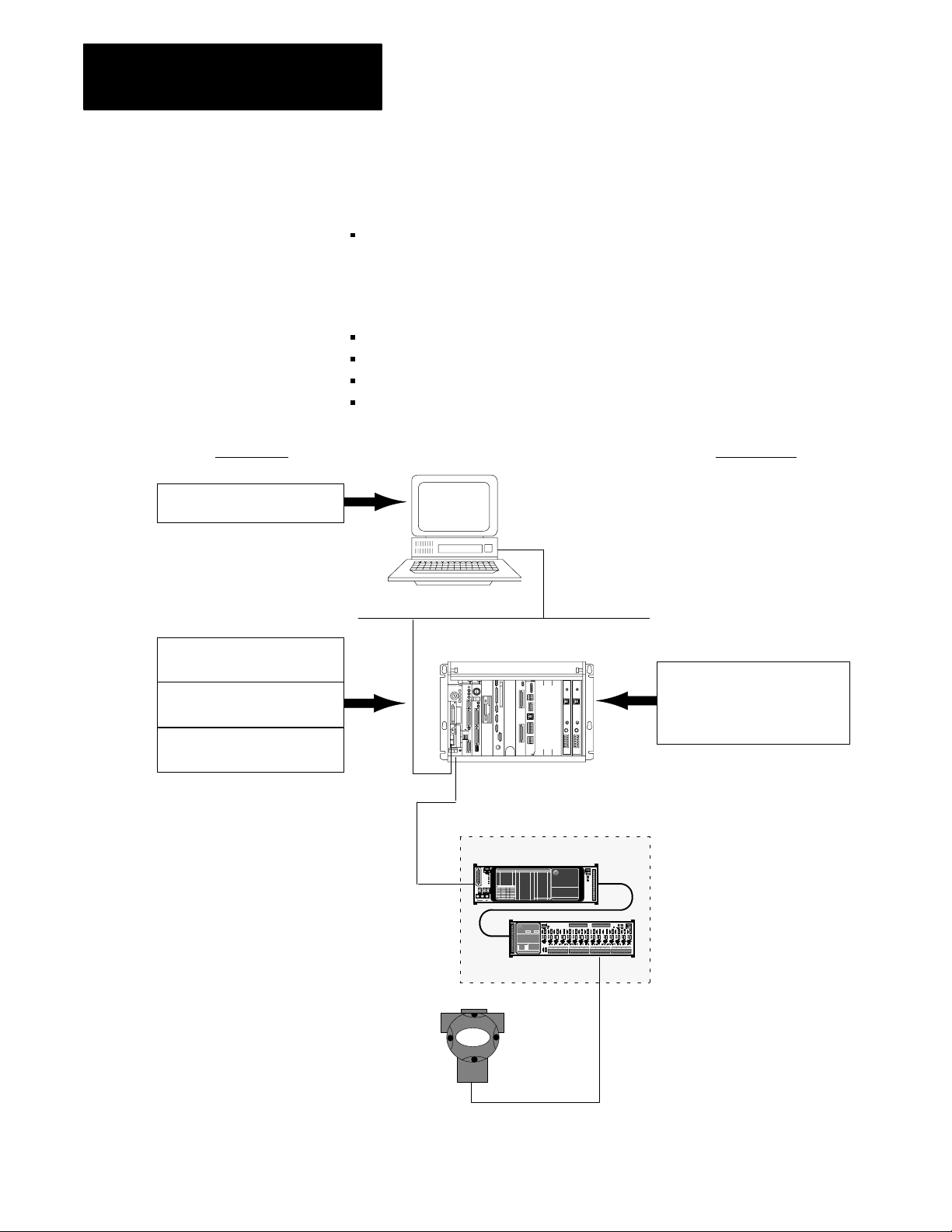

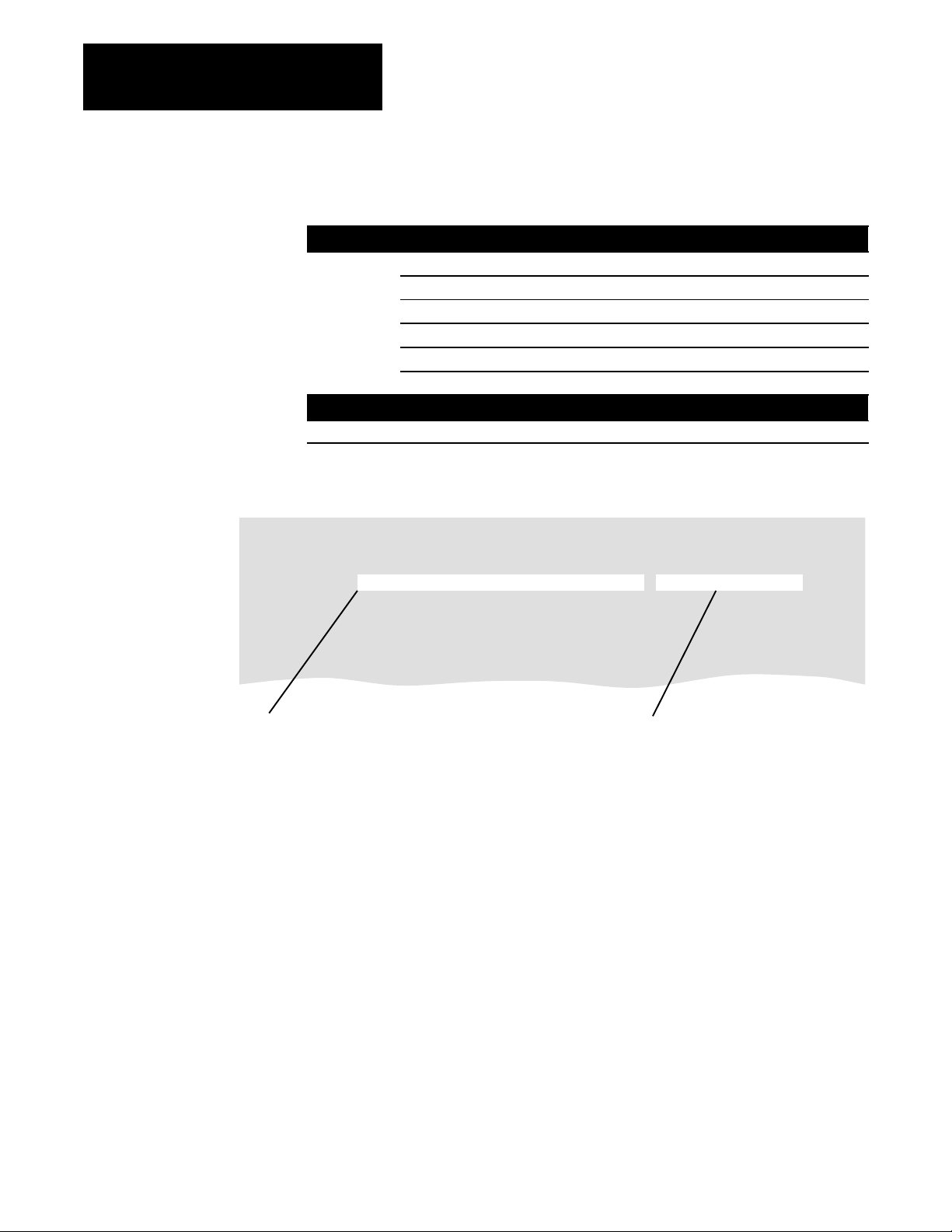

What You Get W

Subroutine

6200 Programming Software

ith The STT

You

Provide

The STT subroutine transfers this digital data between the PLC-5

processor and HART field devices:

Read

- primary variable and unit

- primary variable current

- dynamic variables and unit

- status information

Write/modify primary variable range values

Write primary variable unit

Reset configuration change flag

Set primary variable to zero

STT Provides

Workstation

Data Highway Plus

PLCresident Control Functions

Your Application Program

STT Data Tables and

Subroutine Call

PLC5 ladder logic subroutine

that simplifies the communication

between a PLC5 processor and

a HART field device.

PLC5 Processor

Smart Transmitter Interface

1770HT1

RIO

1770HT16

HART

Field

Devices

4-20 mA Loop

1-2

Page 10

Chapter 1

Introducing The Smart Transmitter Toolkit

What You Need to Use The

STT Subroutine

Why Y

ou Should Use The

STT Subroutine

You need these hardware and software components to integrate STT with

your new or existing PLC-5 processor:

Hardware

(1 or more) 1770-HT1 Smart Communications Controller(s)

(1 or more) 1770-HT8 or 177-HT16 Terminal Block(s)

(1 or more) HART-compliant field device(s)

Software

PLC-5 6200 Programming Software

(2 or more) PLC-5 data table files

(1 or more ) PLC-5 programming file(s)

PLC-5 integer data table file locations N90:0, N90:1, and N90:2

The STT subroutine greatly simplifies sending and receiving data to and

from HART field devices.

Without STT, the ladder developer must:

✔ Format each command from the HART specification using the Smart

Transmitter Interface protocol.

✔ Understand HART protocol internals, such as long frame addressing vs.

short frame addressing, and byte swapping for word alignment.

✔ Parse HART command responses for data.

✔ Convert IEEE-754 data to floating-point data.

✔ Synchronize BTWs with BTRs.

With STT, the ladder developer must only:

✔ Configure a data block.

✔ Make the appropriate call to the STT subroutine.

1-3

Page 11

Chapter 1

Introducing The Smart Transmitter Toolkit

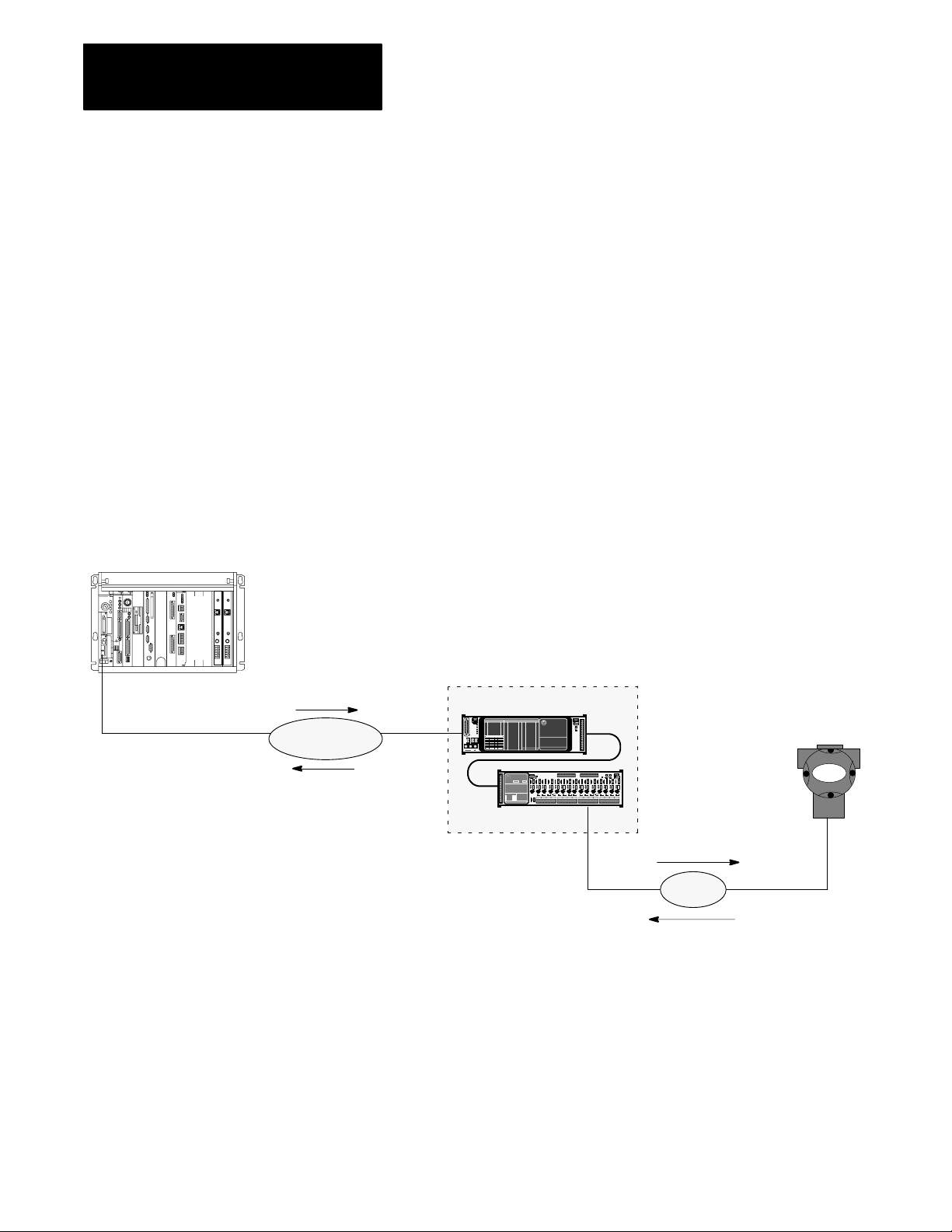

How

a PLC5 Processor

Communicates With a HART

Field Device

To help explain what the STT subroutine can do for you, let’s examine how

communication occurs between a PLC processor and a HART field device.

➊ The PLC-5 processor sends a Smart Transmitter Interface packet to

the 1770-HT1 as block-transfer write (BTW) data.

➋ The 1770-HT1 forwards the Smart Transmitter Interface packet as a

HART packet to the HART field device.

❸ The HART field device receives the HART packet and then responds

back to the 1770-HT1 with a HART packet that contains the

appropriate HART digital data.

➍ The 1770-HT1 routes the response back to the PLC-5 processor in a

Smart Transmitter Interface packet as block-transfer read (BTR) data.

PLC5

Processor

BTW Data

➊

Smart T

ransmitter

Interface packet

BTR Data

➍

RIO

Smart Transmitter Interface

1770HT1

1770HT16

HART Poll

➋

HART

packet

HART Response

❸

420

HART

Field

Device

mA Loop

90065

1-4

Page 12

The PLC-5 processor sends and receives data from the 1770-HT1 as Smart

Transmitter Interface Packets. The HART field device sends and receives

data from the 1770-HT1 as HART packets. The 1770-HT1 converts the

packets that it receives to the required format before transmitting the

packets to their destination.

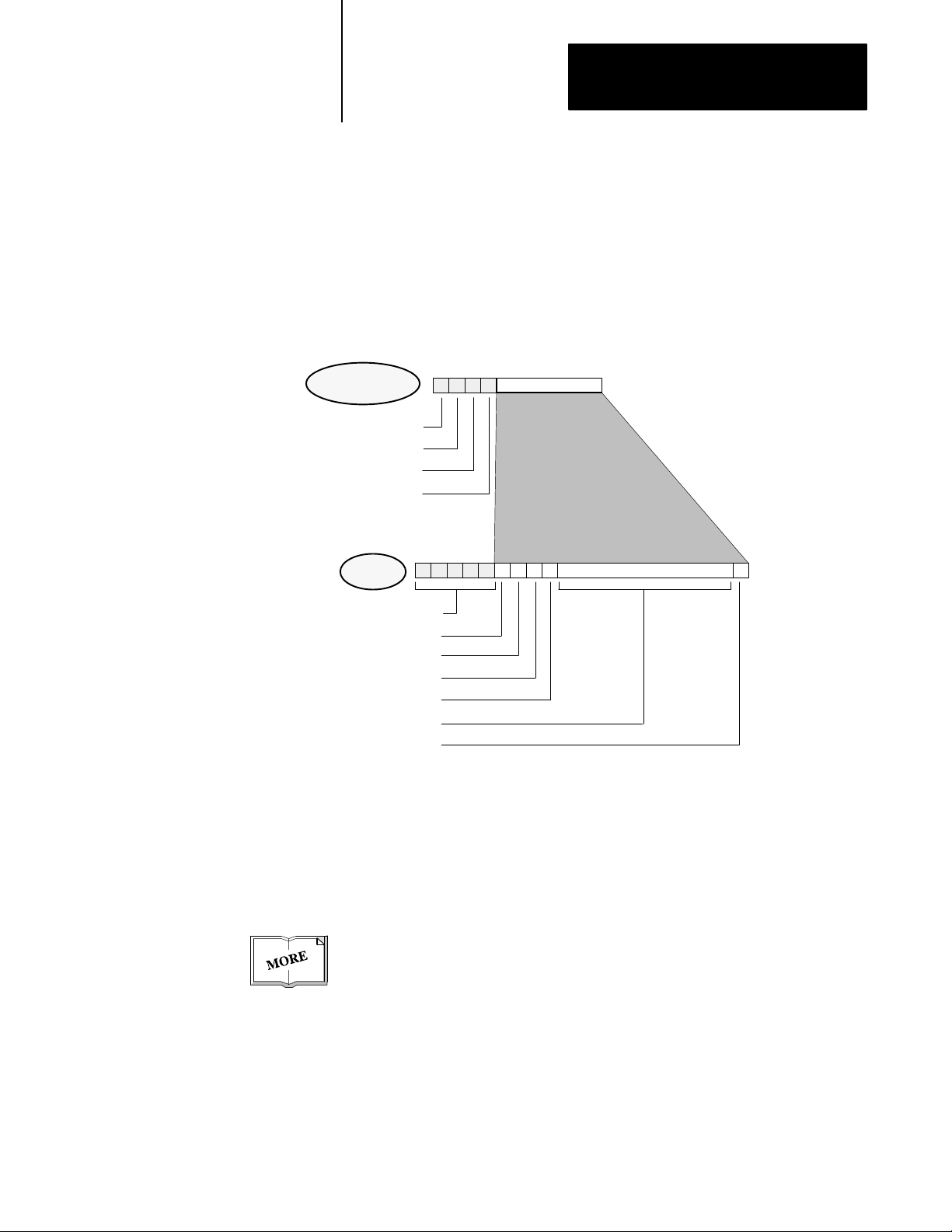

This diagram illustrates the relationship between the two packets.

Smart Transmitter

Interface packet

Smart Transmitter Interface Command

Channel Number

Control

Parameter

Chapter 1

Introducing The Smart Transmitter Toolkit

HART

packet

Preamble

Delimiter

Address

HART Command

Byte Count

Data

Check Byte

90066

Using a few pieces of data, the STT subroutine creates a Smart Transmitter

Interface packet and sends it to the 1770-HT1. The STT subroutine then

takes the response from the 1770-HT1 and decodes the Smart Transmitter

Interface packet to provide you with useful data.

For more information about communications with Smart Transmitter

Interface products, see the Smart Transmitter Interface Products (HART

Protocol) User Manual, publication 1770-6.5.19.

1-5

Page 13

Chapter 1

Introducing The Smart Transmitter Toolkit

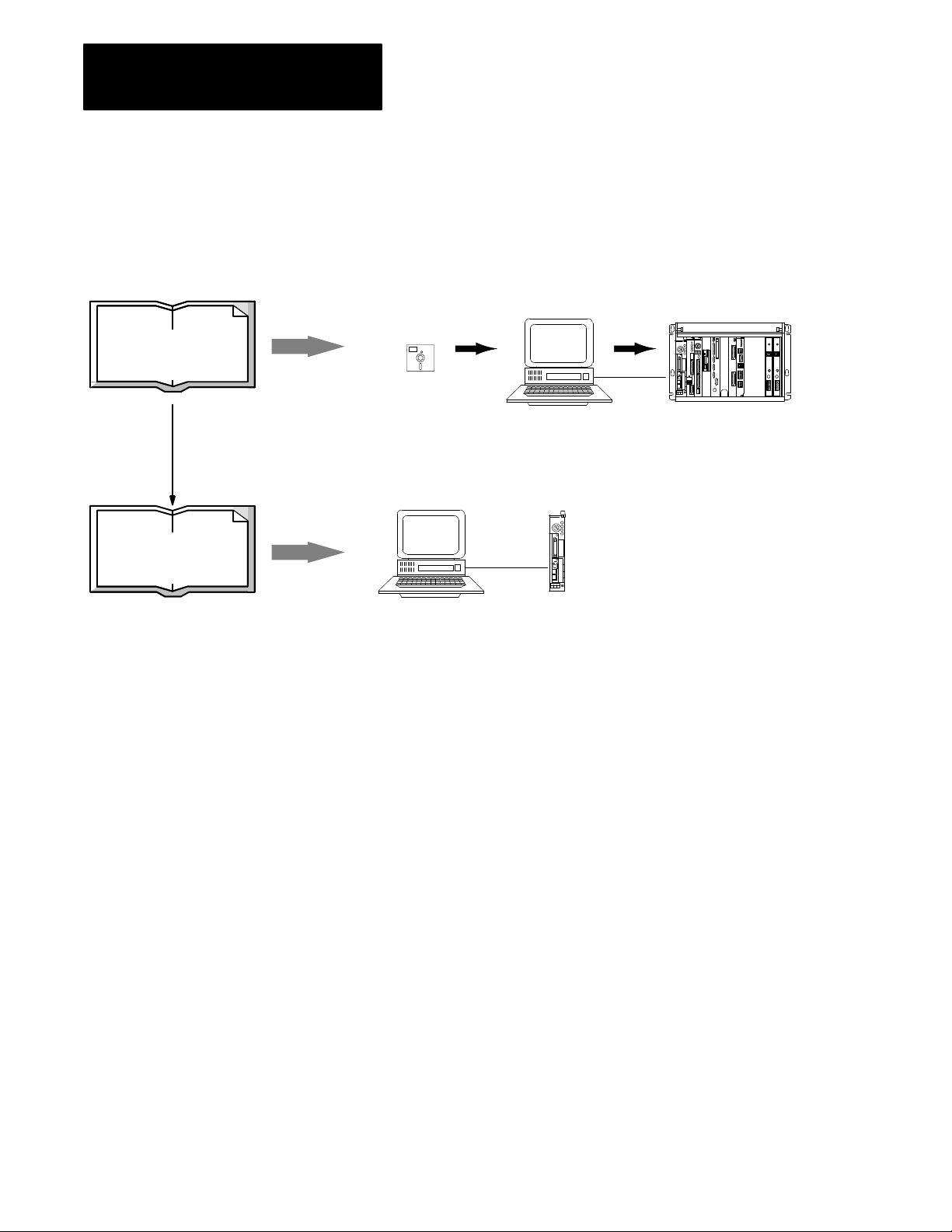

How You Use The STT

Subroutine

Read chapter 2, then

Chapter 2

install the software.

Installing The Smart

Transmitter Toolkit

Chapter 3

Using The Smart

Transmitter Toolkit

We developed the STT Subroutine so that you can easily use a PLC-5

processor to communicate with a HART field device. Here’s how easy it is

to use STT:

1. Install the STT subroutine into your workstation and PLC-5

processor.

STT

Subroutine

2. Customize your PLC-5 ladder logic to use the STT subroutine.

a. Allocate data blocks in your PLC5 processor

for each HART field device in your system.

b. Enter a JSR instruction in your ladder logic

program for each 1770HT1 in your system.

What to Do Next

When you’ve completed these steps, you’re ready to use the STT

subroutine.

Go to chapter 2 to begin installing the Smart Transmitter Toolkit.

1-6

Page 14

Chapter

2

Installing The Smart Transmitter Toolkit

What's

In This Chapter

This chapter provides instructions for installing the Smart Transmitter

Toolkit (STT).

Important: Use 6200 programming software to install the STT subroutine

into your PLC-5 processor. Before you begin, make sure your current

program is loaded.

To install the STT subroutine, you will:

1. Copy the STT subroutine file to the hard drive.

2. Create and name a new program file in your PLC-5 processor.

3. Paste the STT subroutine file into the new program file.

4. Save your work (optional).

5. Change the data table defaults (optional)

Important: The STT subroutine uses three fixed word addresses:

N90:0 through N90:2. When you paste the STT subroutine, these

three addresses are created. If these addresses are already in use and

cannot be freed up for the STT Subroutine, you need to change the

data table defaults. If you need to make these changes, do step 5.

The rest of this chapter contains the instructions for completing these steps.

Before You Begin

You need this diskette to install the STT subroutine:

Allen-Bradley

Software

Smart T

ransmitter T

Disk 1 of 1

Since you install the STT subroutine using 6200 programming software,

you may want to obtain a copy of the PLC-5 Programming Software

Programming Manual, publication 6200-6.4.7.

oolkit

This diskette contains these paste files:

• STT100.CR5 - the STT subroutine

• STT100E1.CR5 - programming example 1

• STT100E2.CR5 - programming example 2

• STT100E3.CR5 - programming example 3

See chapter 3 for an explanation of the programming

examples.

2-1

Page 15

Chapter 2

Installing The Smart Transmitter Toolkit

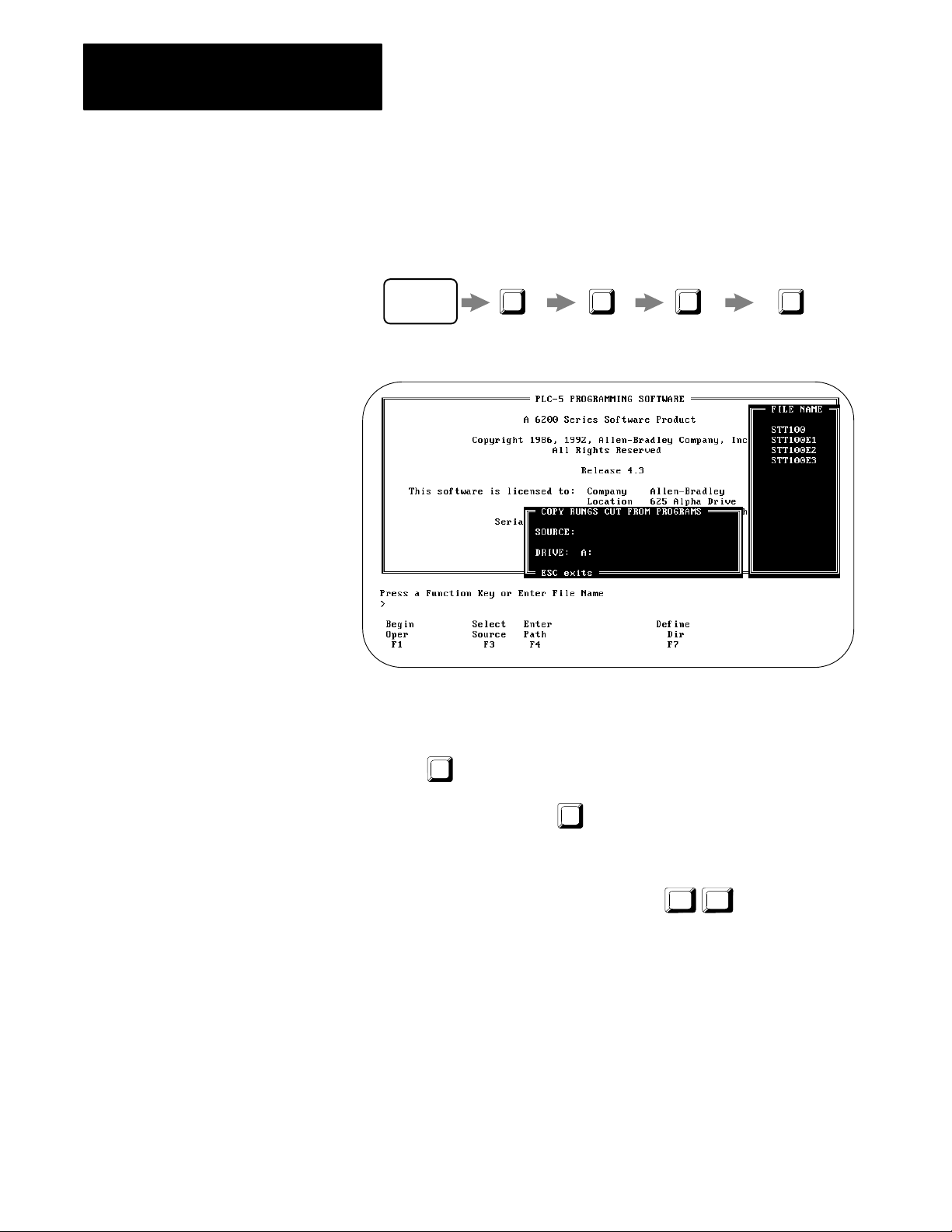

1. Copy STT Subroutine

File to the Hard Drive

A. Insert the STT disk into a floppy drive.

B. Start at the 6200 Main Menu and press these keys:

To/From

Floppy

F9 F2 F7

From Floppy

6200

Main Menu

File

Utils

F7

You see:

Processor

Memory: Cut Rungs

C. Use the cursor keys to highlight the STT100 file.

D. To select the STT100 file as the source of the copy,

press

F3 Select

E. To begin the copy, press

Source

.

F1 Begin

Oper

.

The operation is completed.

F. To return to the 6200 Main Menu, press

Esc Esc .

2-2

Page 16

Chapter 2

Installing The Smart Transmitter Toolkit

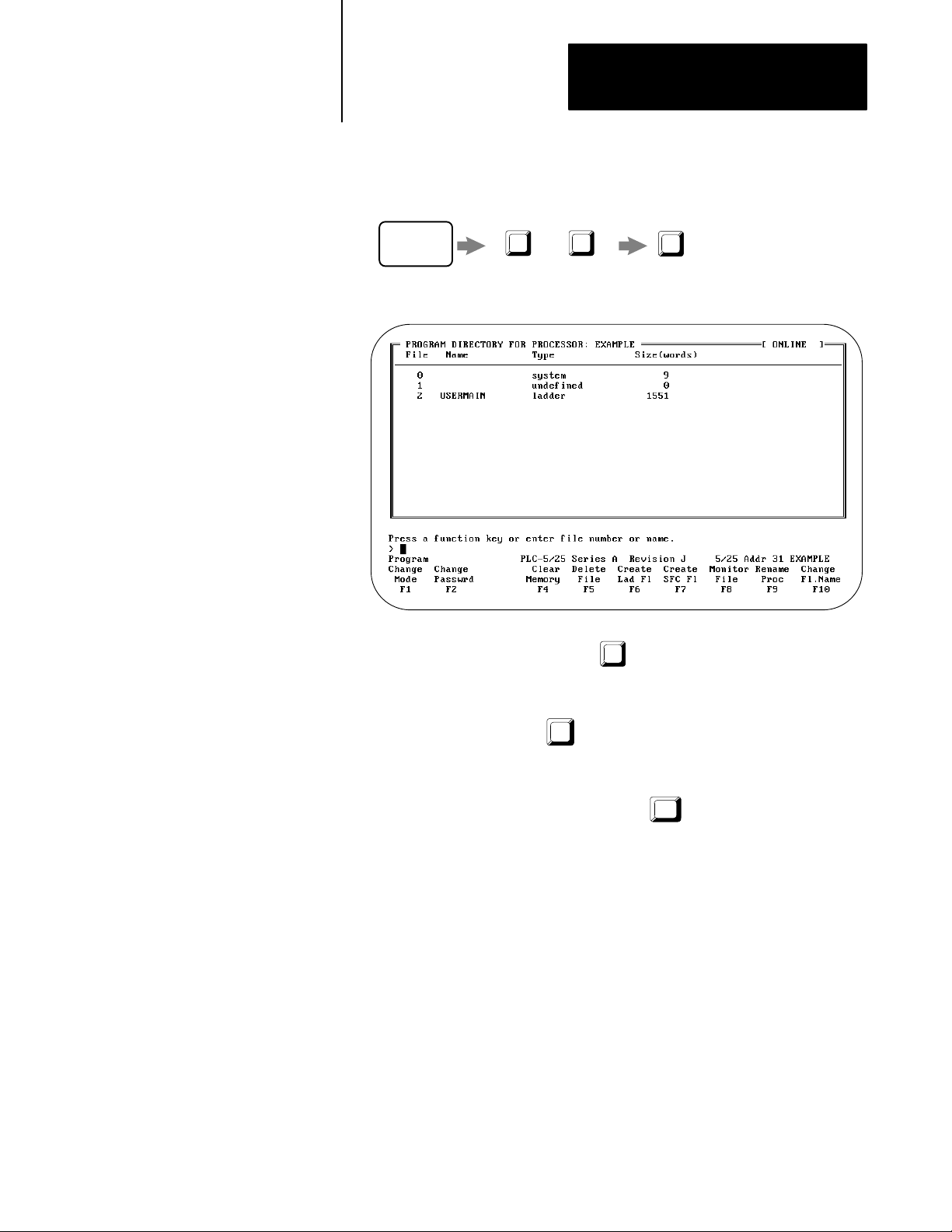

2. Create

Program File

and Name a New

A. Start at the 6200 Main Menu and press these keys:

6200

Main Menu

Online ProgF3Offline Prog

F1

or

Proc Func

F1

You see:

B. To create a program file, press F6 Create

file number.

C. To name the file, press

F10

Change Fl Name

name. We recommend that you use the filename

D. To go to the Program Directory, press

Esc .

Lad Fl

and then enter a

and then enter a file

STT_SUB.

2-3

Page 17

Chapter 2

Installing The Smart Transmitter Toolkit

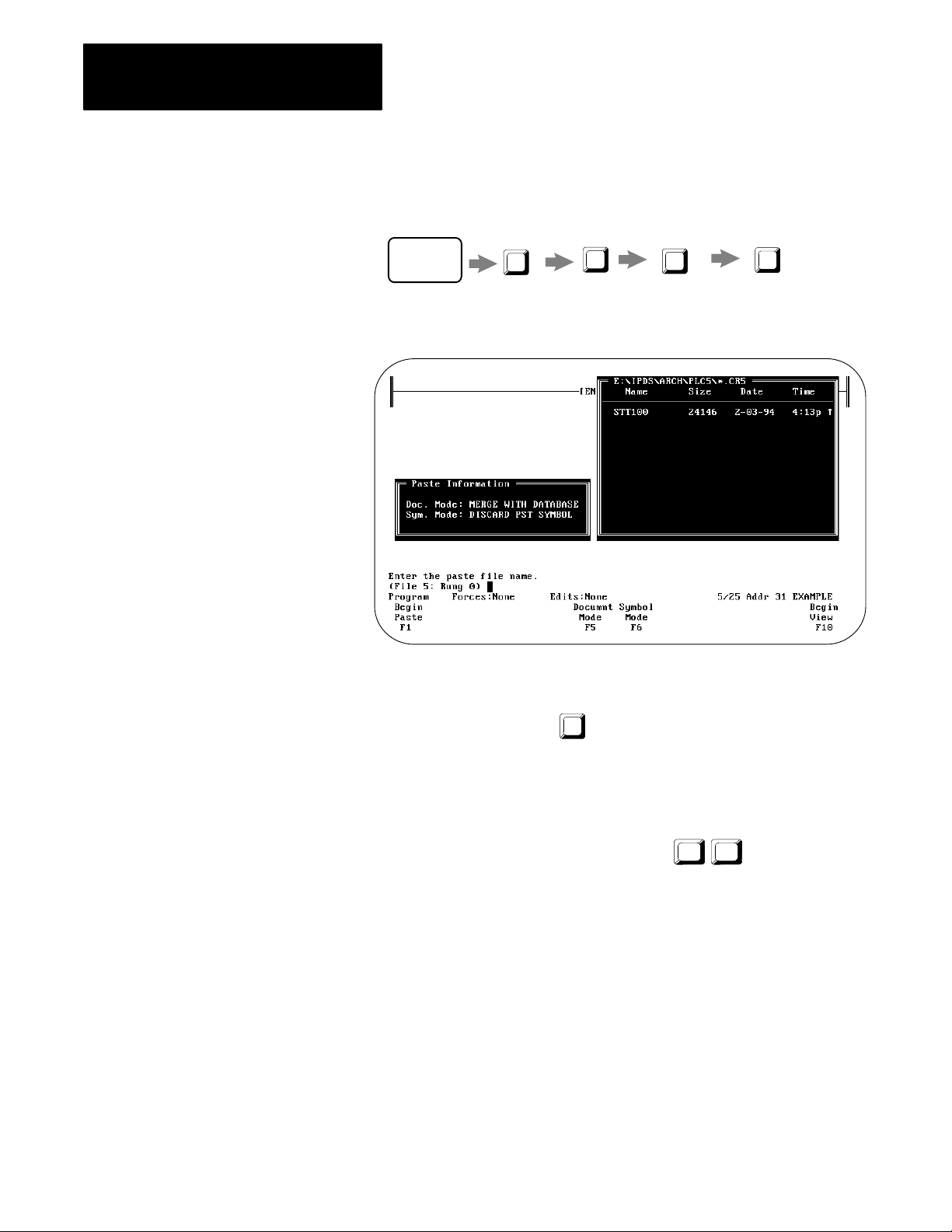

3. Paste

The STT

Subroutine File

A. Start at the Program Directory and press these keys:

Monitor

Program

Directory

File

F8

Edit

F10

Advanced

F8

Edit

You see:

Paste From Disk

F8

B. Use the cursor keys to highlight the STT100 file.

C. To begin the paste, press

F1 Begin

Paste

.

The paste operation takes about 3 minutes. Since the STT subroutine

uses indirect addressing, you may hear beeps during the paste

operation. This is normal.

D. To return to the Program Directory, press Esc Esc .

2-4

Page 18

Chapter 2

Installing The Smart Transmitter Toolkit

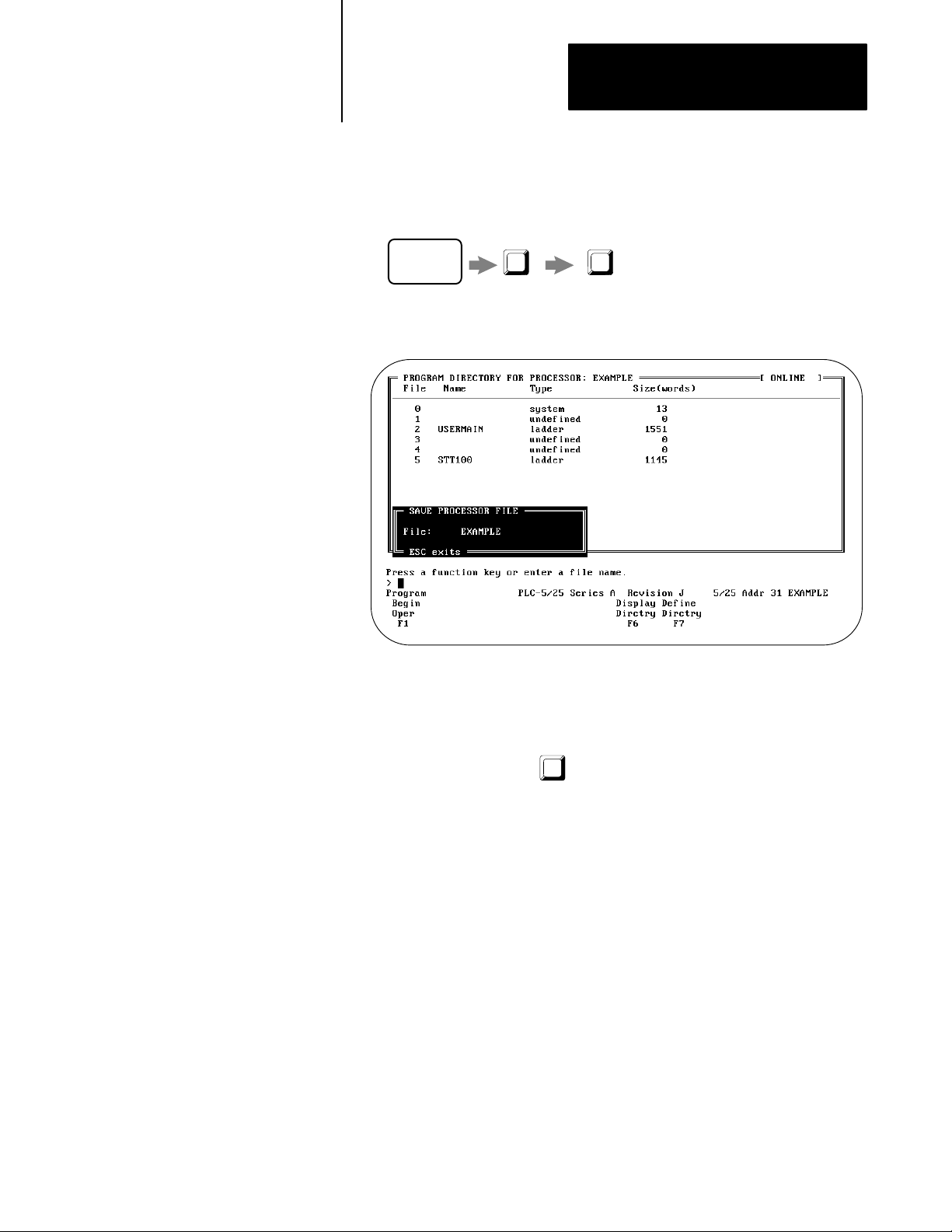

4. Save Your W

ork

(optional)

A. Start at the Program Directory and press these keys:

Save

Program

F2

Program

Directory

Save

Restore

F2

You see:

B. If you want to change the name of the file, enter a new name. If you

don’t enter a new name, the file is saved using the name that you see

on the screen.

C. To save the file, press

F1 Begin

Oper

.

2-5

Page 19

Chapter 2

Installing The Smart Transmitter Toolkit

5. Change The STT Default

Data File

(optional)

You can move the STT subroutine data table file from its default location

of N90.

Important: Moving this file increases the chance of making errors while

setting up your system and complicates the technical support of the STT

subroutine because the file is not in its default location. We recommend

that you only attempt this procedure if you are experienced in ladder-logic

programming and using 6200 programming software.

The STT subroutine uses indirect addresses in block-transfer instructions.

You cannot use 6200 programming software to edit/cut/copy/paste

block-transfer instructions that use indirect addressing or to search for file

references that use indirect addressing. To move the file, follow these

steps:

A. Use the 6200 file utilities to export the processor memory file and

comments/symbols. Make sure that you export all the different types

of comments (address, rung, instruction, etc.).

The exported program file has a .PC5 extension.

The exported comments/symbols file has a .TXT extension.

For more information about using 6200 file utilities, see PLC-5

Programming Software Programming Manual, publication 6200-6.4.7.

What'

s Next

B. Use an ASCII text editor to make the changes as described below.

Moving

a. Edit the .PC5 file

b. Search for all occurrences of integer file number N90 and change

c. Save the changes and close the file.

d. Edit the .TXT file.

e. Search for all occurrences of integer file number N90 and change

f. Save the changes and close the file.

C. Import the modified processor memory file and comments/symbols

file. Use a different name for the imported files to distinguish them

from the original files.

You are finished installing the STT subroutine. Proceed to the next chapter

for instructions on using the STT subroutine in your ladder logic.

the STT Data Table File From N90

to the new integer file number.

to the new integer file number.

2-6

Page 20

Chapter

3

Using The Smart Transmitter Toolkit

What's

1.

In This Chapter

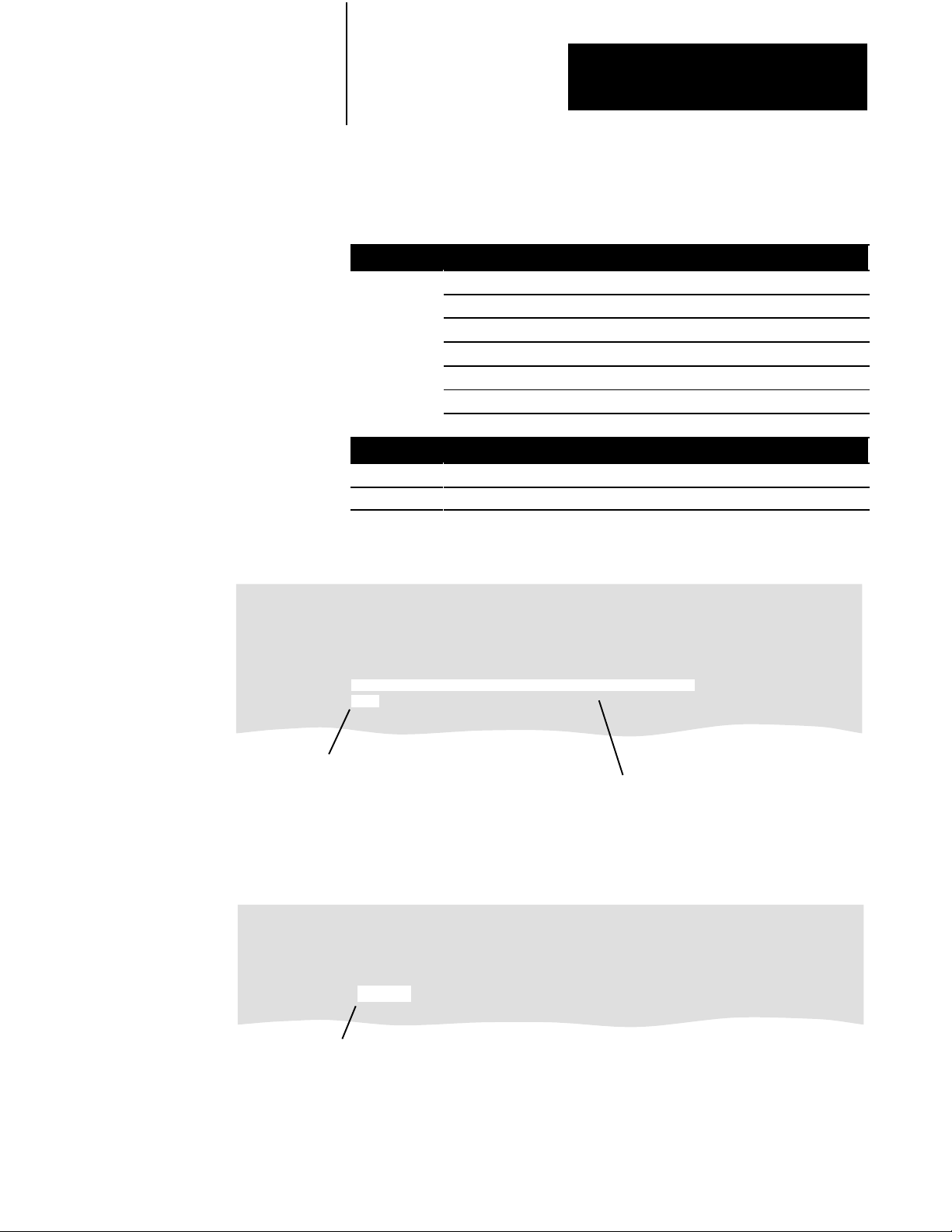

Create Data T

Integer word = 16 bits

Floatingpoint word = 32bits

able Files

Follow the instructions in this chapter to incorporate the STT subroutine

into your ladder code and use the HART commands.

1. Create data table files.

2. Provide the STT subroutine inputs

3. Use the STT subroutine status word.

4. Call the STT subroutine.

5. Interpret the STT subroutine outputs.

At the end of this chapter, you’ll find some programming examples.

In your PLC-5 processor, create one integer and one floating-point file for

each HART field device.

Each integer file must be 150 integer words minimum (0 through 149)

Each floating-point file must be 20 floating-point words minimum

(0 through 19)

In addition, the floating point file must be the data file that immediately

follows the integer data file. For example, if the integer file is N10, the

floating point file must be F11.

Important: The STT utility uses integer data file N90 for indirect

addressing. Do not use this data file for a HART field device data

table file.

Since the STT subroutine uses N90:0 and N90:1 for indirect addressing,

you must place valid file numbers in N90:0 and N90:1. For example, if

you created N10 and F11, you need to place a 10 in data table location

N90:0 and an 11 in data table location N90:1.

Following is an explanation of how the data tables are used by the STT

subroutine.

3-1

Page 21

Chapter 3

Using The Smart Tranmsitter Toolkit

Data Table Report PLC–5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 0 0 0 0 0 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

N10:60 0 0 0 0 0 0 0 0 0 0

N10:70 0 0 0 0 0 0 0 0 0 0

N10:80 0 0 0 0 0 0 0 0 0 0

N10:90 0 0 0 0 0 0 0 0 0 0

N10:100 0 0 0 0 0 0 0 0 0 0

N10:110 0 0 0 0 0 0 0 0 0 0

N10:120 0 0 0 0 0 0 0 0 0 0

N10:130 0 0 0 0 0 0 0 0 0 0

N10:140 0 0 0 0 0 0 0 0 0 0

Example of Newly Created Integer Data File

Integer words 60 through 149 = STT Subroutine Work Area

Integer words 30 through 59 = STT Subroutine Status and Output Area

Integer words 0 through 29 = User Input Area

Example of Newly Created Floatingpoint Data File

Data Table Report PLC–5/25 Addr 31 Data Table File F11:0

Address 0 1 2 3 4

F11:0 0 0 0 0 0

F11:5 0 0 0 0 0

F11:10 0 0 0 0 0

F11:15 0 0 0 0 0

Floatingpoint words 10 through 19 = STT Subroutine Output Area

3-2

Floatingpoint words 0 through 9 = User Input Area

Page 22

Chapter 3

Using The Smart Transmitter Toolkit

2. Provide

The STT

Subroutine Inputs

Standard

Integer Word 0 I/O Rack Number of

Inputs

1770HT1

Word 1 I/O Group Number of

1770HT1

Word 2 Channel Number of HART

field device

Word 3 Polling Address of HART

field device

Word 4 Smart Transmitter Interface

Command Number 16

decimal (10 Hex)

Word 5 HART Command This integer word contains the number of the HART command that the STT subroutine

All data that is used by the STT subroutine is obtained from the integer and

floating point data files that you create for each HART field device.

Before you make a call in your ladder logic to the STT, you must put the

required data into these data files.

There are two types of input data:

Command-specific inputs are specific for each HART command.

See appendix A.

Standard inputs are required for every HART command. This table

explains each of the six standard inputs.

This integer word contains the I/O rack number of the 1770-HT1 that is connected to the HART

field device. Valid values are 1 through 7.

This integer word contains the I/O group number of the 1770-HT1 that is connected to the

HART field device. Valid values are 0, 2, 4, and 6.

This integer word contains the channel on the 1770-HT8 or the 1770-HT16 that is wired to the

HART field device. Valid values are 1 through 32.

This integer word contains the polling address of the HART field device. Use a Rosemount 268

Handheld terminal or Cornerstone software to configure this address.

If you are wired:

• pointtopoint, the polling address is 0 (zero).

• multidrop, the polling address is 1 through 15.

Note: Most HART field devices come from the factory with a default polling address of zero.

This integer word contains the number of the Smart Transmitter Interface command. Currently,

the only supported command is 16. This command indicates that you want to send a HART

command to a HART field device. Always place a 16 in word 4 of the integer data file.

generates and processes. Valid values are 0, 1, 3, 35, 38, 43, and 44.

Every HART command, except 0, requires the HART address returned by HART command 0.

Example: Inputs for HART Command 0

Data Table Report PLC–5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

• N10:0 indicates that the 1770-HT1 is located at I/O rack 4.

• N10:1 indicates that the 1770-HT1 is located at I/O group 6.

• N10:2 indicates that the HART field device is wired to channel 3.

• N10:3 indicates that the HART field device has a polling address of 0.

• N10:4 indicates that the Smart Transmitter Interface command is 16 (for STT release 1.00, it is always 16).

• N10:5 indicates that this example is using HART command 0.

3-3

Page 23

Chapter 3

Using The Smart Tranmsitter Toolkit

3. Use The STT Subroutine

Status W

ord

STT

Subroutine Status W

Bit 0 STT Enter/Exit Bit Use bit 0 to debug your program. When called, the STT subroutine sets bit 0 to 1. When

Bit 1

Bit 2

Bit 3 STT Trigger Bit Bit 3 is the STT subroutine trigger bit. Use bit 3 to tell the STT subroutine to process the

Bit 4 STT Error Bit Bit 4 is the STT subroutine error bit. This bit is set if either the BTW or the BTR has

Bits 57 Reserved Reserved for future use.

Bit 8 STT BTW Retry Bit Bit 8 indicates that the BTW has returned an error and is being retried by the STT

Bit 9 STT BTR Retry Bit Bit 9 indicates that the BTR has returned an error and is being retried by the STT

Bits 1015 Reserved Reserved for future use.

STT Enable Bit

STT Done Bit

The STT subroutine status word handshakes with your PLC ladder logic.

The STT subroutine status word:

tells you when the STT subroutine is entered and exited

tells you when the STT subroutine is enabled and done

lets you trigger the STT subroutine

tells you when the STT subroutine errors

The STT status word is integer word 30 of the integer file that is passed in

with your JSR instruction. This table shows the bits that are used in the

STT subroutine status word.

ord 30

the STT subroutine exits, the subroutine sets bit 0 to 0. This lets you know when the STT

subroutine is entered and exited.

Bit 1 indicates that the STT subroutine is in the middle of processing a HART command.

Bit 2 indicates that the STT subroutine is done processing a command.

When you make an unconditional call to the STT subroutine, if the subroutine is not

already enabled, it sets bit 1 to 1 and bit 2 to 0. When the STT subroutine is done

processing a Hart command (successful or not), it sets bit 2 to 1 and bit 1 to 0. When bit

2 is set to 1, you can process the output data that is returned by the STT subroutine.

requested command. Even though you call the STT subroutine with an unconditional

JSR, it does not process the HART command unless bit 3 is set to 1. When the STT

subroutine sees bit 3 set to 1, it processes the request. When the request is first

detected, the STT subroutine is enabled and it sets bit 3 to 0.

failed. Any data, except words 30 and 31, in the output area is invalid if this bit is set.

subroutine.

subroutine.

3-4

Example

In this example, the STT trigger bit is set to 1 if the STT enable bit is set to 0.

N10:60

01

N10:60

L

03

Page 24

Chapter 3

Using The Smart Transmitter Toolkit

4. Call The STT Subroutine

Insert a JSR on an unconditional rung to call the STT subroutine.

The JSR instruction includes one program file number and one input

parameter. There are no return parameters.

The program file number is the program file number where you installed

the STT subroutine. For example, if you installed the STT subroutine

into program file number 5, the JSR must call program file number 5.

The input parameter is the integer file number for the current HART

field device. For example, if you created N10 and F11 for your HART

field device, the input parameter would be 10.

When the STT routine is called by your ladder logic, it generates the

specified HART command from the data that you provided in the integer

and floating-point data files.

After generating a properly formatted HART command, the STT

subroutine executes a BTW followed by a BTR to execute the command

just generated. It then reformats the returned data and places the outputs in

the locations specific to that HART command. See appendix A for more

detail on the command-specific outputs.

Because of the nature of enabling and finishing BTWs and BTRs, it takes

three calls minimum to the STT subroutine to obtain the outputs from the

HART command. This is a description of the steps that occur in each of

the three passes through the STT subroutine.

1st Pass

• sets the enter/exit bit to 1

• sets the trigger bit to 0

• sets the enable bit to 1

• generates the HART command

specified in integer word 5

• initiates a BTW

• sets the enter/exit bit to 0 and returns

Example

In this example, the JSR calls the STT subroutine unconditionally. The

STT subroutine looks for input data in files N10 and F11. However, since

this example is using HART command 0, there is no input data in the

floating-point file.

2nd Pass

• sets the enter/exit bit to 1

• finishes the BTW

• initiates a BTR

• sets the enter/exit bit to 0 and returns

JSR

JUMP TO SUBROUTINE

Prog file number 5

Input par 10

Return par

3rd Pass

• sets the enter/exit bit to 1

• finishes the BTR

• produces outputs

• sets the done or error bit to 1

• sets the enable bit to 0

• sets the enter/exit bit to 0 and returns

3-5

Page 25

Chapter 3

Using The Smart Tranmsitter Toolkit

5.Interpret

The STT

Subroutine Outputs

Each HART command returns these outputs:

Command-specific outputs returned for a specific HART command.

See appendix A for more detail on the command specific outputs.

Standard Outputs that are returned for every HART command.

This table explains each of the seven standard outputs.

Standard

Integer Word 30 STT Subroutine Status Word

➀

Outputs

(see page 34)

Word 31 STT Subroutine Error Code➀This word contains any error code returned by the STT subroutine.

Word 32 Smart Transmitter Interface

Status Word

Word 33 Smart Transmitter Interface

Error Code

Word 34 HART

ProtocolCommunication Error

Code

Word 35 HART Command Response

Summary Error Code

Word 36 HART Field Device Error

Code

See appendix B for a list of error codes.

➀

➀

➀

➀

All handshaking with the STT subroutine is done with the STT status word.

On powerup, the Smart Transmitter Interface sets bit 7 to a 1. All other bits are set to 0.

Therefore, the value for word 32 is 128 decimal.

The STT utility does not provide any way to reset bit 7 to a zero. Therefore, bit 7 is

always set to 1 in word 32.

This word contains any error code returned by the 1770HT1.

This word contains information that pertains to the reception of a message by a device.

An error in this word indicates that the HART transmitter detected a communications

error and the message was not accepted.

The response data is not returned when errors are reported.

This word contains information relative to the execution of a HART command. This error

code is command dependent.

This word contains information that pertains to the operating status of the HART device

as a whole and is not associated with the completion of any HART command.

3-6

Example: Outputs for HART Command 0

Data Table Report PLC–5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 9858 269 12807 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

These three integer words

are the HART address.

Important: We used this example because every ladder program must

have a JSR instruction and all HART communications must start with

HART command 0. Every HART command (except HART command 0)

requires the HART address.

These seven integer words contain the status of

the STT subroutine and the communications

with the HART field device.

Page 26

Chapter 3

Using The Smart Transmitter Toolkit

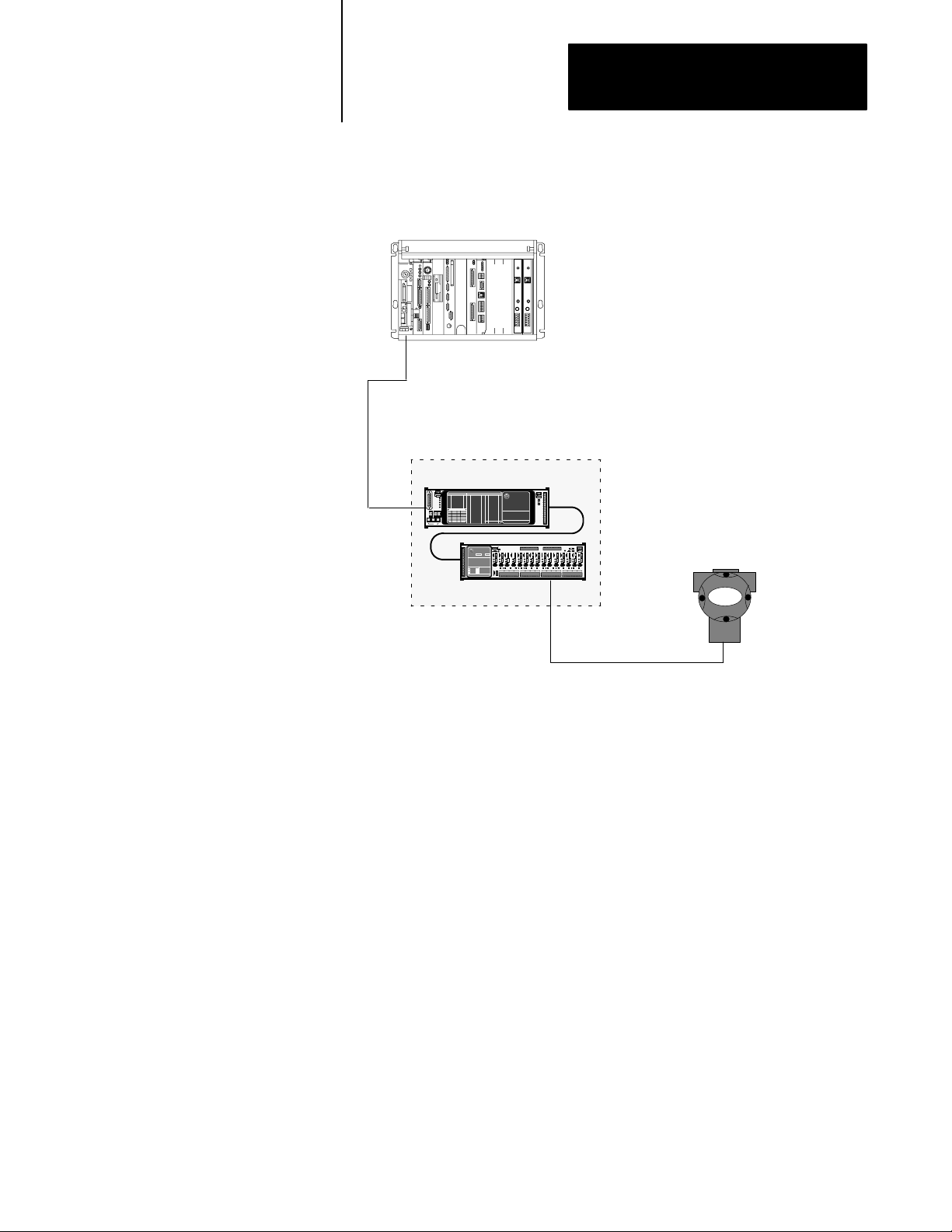

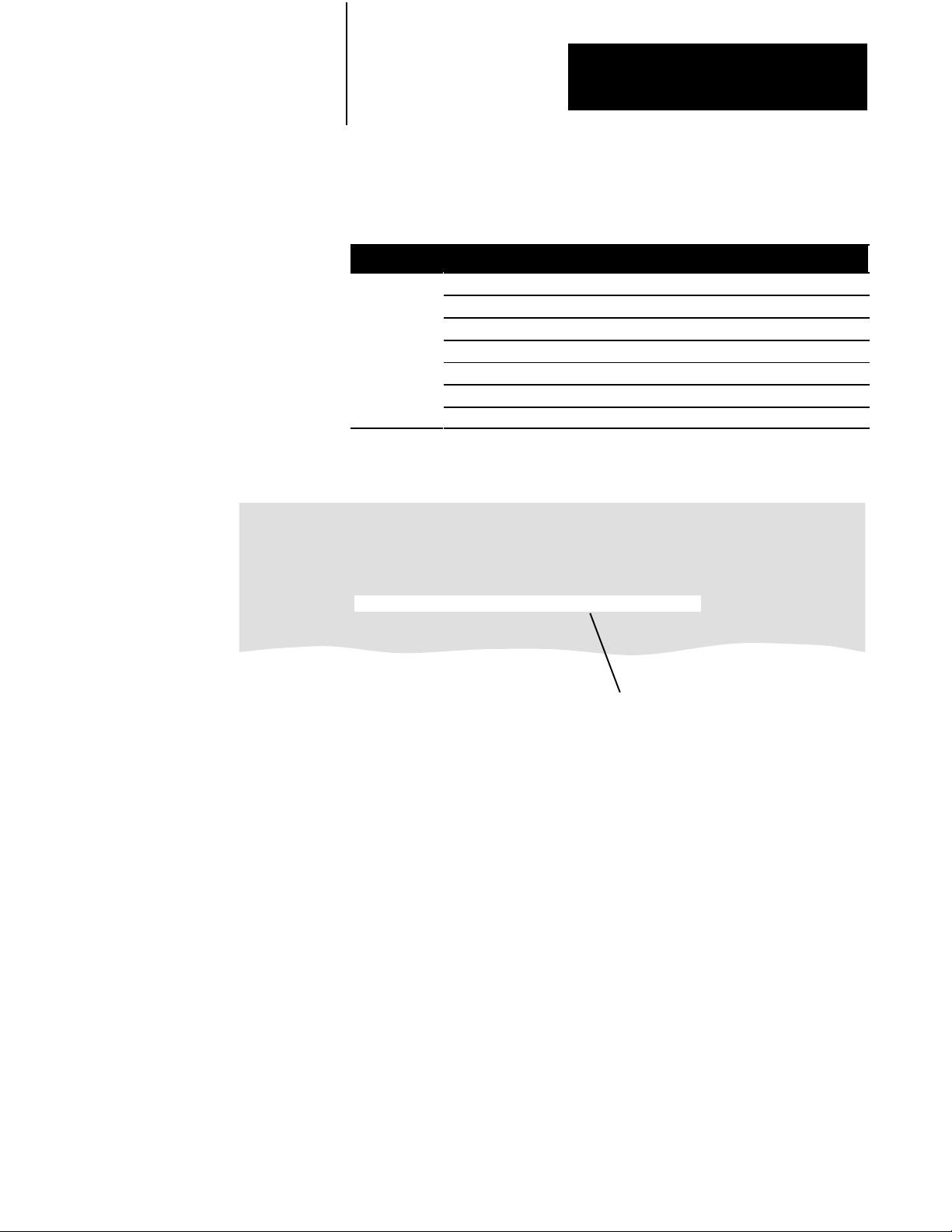

Programming

Example 1:

Single HART Device W

Single 1770HT1

ith

In this example, the primary variable is being read continuously from a

single HART field device.

PLC5

Processor

Smart Transmitter Interface

1770HT1

RIO

HART

Field

Device

1770HT16

4-20 mA Loop

Because we’re dealing with one device we can execute the JSR with a

fixed device data file number. In the course of operation if the device does

not respond, we reissue HART command 0 to try and get a new HART

address for the device.

Important: This example assumes that data table files N10 and F11 exist,

and N10 is populated with the standard inputs for HART command 0 prior

to the execution of this logic. The primary variable value is placed in

F11:10 and the primary variable unit code is placed in N10:40.

3-7

Page 27

Chapter 3

Using The Smart Tranmsitter Toolkit

Rung 2:0

STT 1.00 Programming Example 1.

This example reads the primary variable from 1 HART field device wired to 1

1770-HT1.

When the STT subroutine is not enabled, set the STT subroutine trigger bit.

| STT enable STT trigger |

| N10:30 N10:30 |

+––––]/[–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––(L)–––––+

| 1 3 |

Rung 2:1

Call the STT subroutine unconditionally.

| STT |

| Subroutine |

| +JSR–––––––––––––––+ |

+–––––––––––––––––––––––––––––––––––––––––––––––––––––––––+JUMP TO SUBROUTINE+–+

| |Prog file number 5| |

| |Input par 10| |

| |Return par | |

| +––––––––––––––––––+ |

Example 1 (continued)

Rung 2:2

Only process when the STT subroutine is done. If the Hart command is 0, copy

the Hart address to the input area and request Hart command 1. If the device

does not respond (error 33), try getting a new Hart address for the device by

requesting Hart command 0.

| Hart Hart |

| STT Done Command # Address |

| N10:30 +EQU–––––––––––––––+ +COP–––––––––––––––+ |

+––––] [––––––––––––––––––––––––––++EQUAL +++COPY FILE +++–+

| 2 ||Source A N10:5|||Source #N10:40||| |

| || 1|||Dest #N10:6||| |

| ||Source B 0|||Length 3||| |

| || ||+––––––––––––––––––+|| |

| |+––––––––––––––––––+| Hart || |

| | | Command # || |

| | |+MOV–––––––––––––––+|| |

| | ++MOVE ++| |

| | |Source 1| | |

| | | | | |

| | |Dest N10:5| | |

| | | 1| | |

| | +––––––––––––––––––+ | |

| | Device Not Hart | |

| | Responding Command # | |

| |+EQU–––––––––––––––+ +MOV–––––––––––––––+| |

| ++EQUAL +––+MOVE ++ |

| |Source A N10:33| |Source 0| |

| | 0| | | |

| |Source B 33| |Dest N10:5| |

| | | | 1| |

| +––––––––––––––––––+ +––––––––––––––––––+ |

3-8

Rung 2:3

| |

+––––––––––––––––––––––––––––––––[END OF FILE]–––––––––––––––––––––––––––––––––+

| |

Page 28

Chapter 3

Using The Smart Transmitter Toolkit

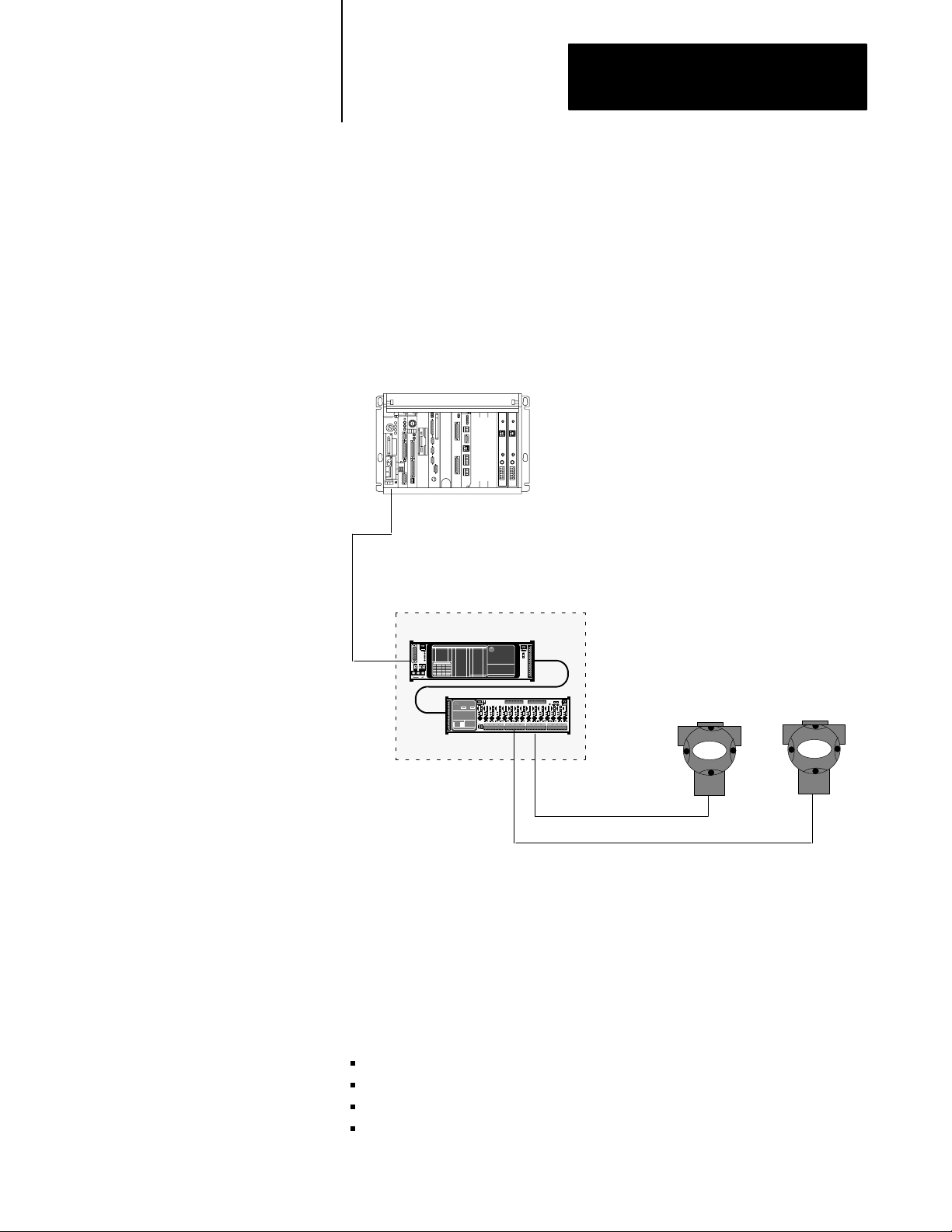

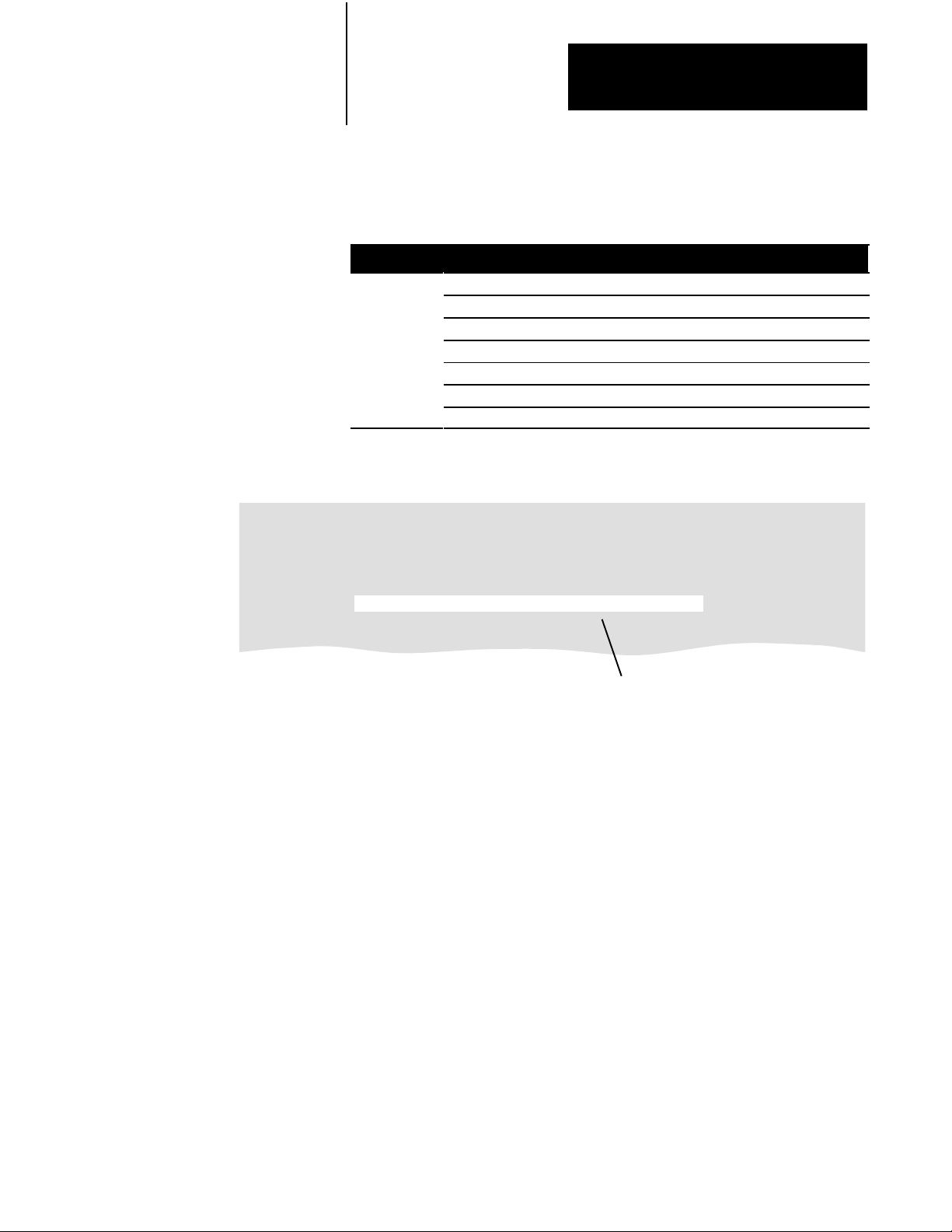

Programming

Example 2:

Multiple HART Devices W

Single 1770HT1

ith

In this example, the primary variable is read continuously from two HART

field devices that are associated with one 1770–HT1 Communications

Controller. You will notice that the example reads the primary variable

from device 1 and then from device 2. If you want to talk to two HART

field devices at the same time, you must use two 1770-HT1s. Example 3

demonstrates reading the primary variable from two HART field devices

using two 1770-HT1s.

PLC5

Processor

Smart Transmitter Interface

1770HT1

RIO

HART

Field

Device

HART

Field

Device

1770HT16

4-20 mA Loop

4-20 mA Loop

In this example, we used separate data areas for each device. This forced

us to load the device data file number into the JSR input variable prior to

making the call to the STT subroutine.

In the course of operation, if either HART field device does not respond,

we reissue command 0 to try and get a new HART address for the field

device. This example assumes that each device data area is setup with the

standard inputs for command 0, prior to the execution of this logic.

Device 1 uses N10 and F11

Device 2 uses N12 and F13

N14 is the JSR variable

F15 contains both primary variable values

3-9

Page 29

Chapter 3

Using The Smart Tranmsitter Toolkit

Rung 2:0

STT 1.00 Programming Example 2

This example reads the primary variable from 2 HART field devices wired to 1

1770-HT1.

If neither device is current, make device 1 the current device.

| Doing |Doing Doing |

| Device 1 |Device 2 Device 1 |

| B3 B3 B3 |

+––––]/[––––––––]/[––––––––––––––––––––––––––––––––––––––––––––––––––––(L)–––––+

| 1 2 1 |

Rung 2:1

Set the device 1 STT subroutine trigger bit and load the JSR input variable for

device 1 processing.

| Device 1 |

| Doing |Device 1 STT |

| Device 1 |STT enable trigger |

| B3 N10:30 N10:30 |

+––––] [––––––––]/[–––––––––––––––––––––––––––––––––––––+–––––––––––––(L)––––+–+

| 1 1 | 3 | |

| | JSR Input | |

| | Variable | |

| |+MOV–––––––––––––––+| |

| ++MOVE ++ |

| |Source 10| |

| | | |

| |Dest N14:0| |

| | 12| |

| +––––––––––––––––––+ |

Rung 2:2

This rung is identical to 2:1, except it uses device 2.

| Device 2 |

| |Doing |Device 2 STT |

| Device 2 |Device 2 |STT enable trigger |

| 2 B3 N12:30 N12:30 |

+–––[LBL]–––––––] [––––––––]/[––––––––––––––––––––––––––+–––––––––––––(L)––––+–+

| 2 1 | 3 | |

| | JSR Input | |

| | Variable | |

| |+MOV–––––––––––––––+| |

| ++MOVE ++ |

| |Source 12| |

| | | |

| |Dest N14:0| |

| | 12| |

| +––––––––––––––––––+ |

Rung 2:3

Call the STT subroutine unconditionally.

| STT |

| Subroutine |

| +JSR–––––––––––––––+ |

+–––––––––––––––––––––––––––––––––––––––––––––––––––––––––+JUMP TO SUBROUTINE+–+

| |Prog file number 5| |

| |Input par N14:0| |

| |Return par | |

| +––––––––––––––––––+ |

Example 2 (continued)

3-10

Page 30

Chapter 3

Using The Smart Transmitter Toolkit

Example 2 (continued)

Rung 2:4

Only process when the STT subroutine is done. If the Hart command is 1, copy

the primary variable to file F15. If the Hart command is 0, copy the Hart

address to the input area and request Hart command 1. If device 1 does not

respond (error 33), try getting a new Hart address for device 1 by requesting

Hart command 0. Make device 2 the current device.

| Device 1 Device 1 |

| Doing |Device 1 Hart Process |

| Device 1 |STT Done Command # Variable |

| B3 N10:30 +EQU–––––––––––––––+ +MOV–––––––––––––––+ |

+––––] [––––––––] [–––––––––––––––++EQUAL +––+MOVE ++–+

| 1 2 ||Source A N10:5| |Source F11:10|| |

| || 1| | 0.5372856|| |

| ||Source B 1| |Dest F15:1|| |

| || | | 0.5372856|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Device 1 Device 1 | |

| | Hart Hart | |

| | Command # Address | |

| |+EQU–––––––––––––––+ +COP–––––––––––––––+ | |

| ++EQUAL +++COPY FILE +++ |

| ||Source A N10:5|||Source #N10:40||| |

| || 1|||Dest #N10:6||| |

| ||Source B 0|||Length 3||| |

| || ||+––––––––––––––––––+|| |

| |+––––––––––––––––––+| Device 1 || |

| | | Hart || |

| | | Command # || |

| | |+MOV–––––––––––––––+|| |

| | ++MOVE ++| |

| | |Source 1| | |

| | | | | |

| | |Dest N10:5| | |

| | | 1| | |

| | +––––––––––––––––––+ | |

| | Device 1 Device 1 | |

| | Not Hart | |

| | Responding Command # | |

| |+EQU–––––––––––––––+ +MOV–––––––––––––––+| |

| ++EQUAL +––+MOVE ++ |

| ||Source A N10:33| |Source 0|| |

| || 0| | || |

| ||Source B 33| |Dest N10:5|| |

| || | | 1|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Doing | |

| | Device 1 | |

| | B3 | |

| +–––––––––––––––––––––––––––––––––––(U)––––+ |

| | 1 | |

| | Doing | |

| | Device 2 | |

| | B3 | |

| +–––––––––––––––––––––––––––––––––––(L)––––+ |

| | 2 | |

| | Device 2 | |

| | 2 | |

| +––––––––––––––––––––––––––––––––––(JMP)–––+ |

3-11

Page 31

Chapter 3

Using The Smart Tranmsitter Toolkit

Rung 2:5

This rung is identical to 2:4 except it uses device 2.

| Device 2 Device 2 |

| Doing |Device 2 Hart Process |

| Device 2 |STT Done Command # Variable |

| B3 N12:30 +EQU–––––––––––––––+ +MOV–––––––––––––––+ |

+––––] [––––––––] [–––––––––––––––++EQUAL +––+MOVE ++–+

| 2 2 ||Source A N12:5| |Source F13:10|| |

| || 1| | –0.0260029|| |

| ||Source B 1| |Dest F15:2|| |

| || | | –0.0260029|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Device 2 Device 2 | |

| | Hart Hart | |

| | Command # Address | |

| |+EQU–––––––––––––––+ +COP–––––––––––––––+ | |

| ++EQUAL +++COPY FILE +++ |

| ||Source A N12:5|||Source #N12:40||| |

| || 1|||Dest #N12:6||| |

| ||Source B 0|||Length 3||| |

| || ||+––––––––––––––––––+|| |

| |+––––––––––––––––––+| Device 2 || |

| | | Hart || |

| | | Command # || |

| | |+MOV–––––––––––––––+|| |

| | ++MOVE ++| |

| | |Source 1| | |

| | | | | |

| | |Dest N12:5| | |

| | | 1| | |

| | +––––––––––––––––––+ | |

| | Device 2 Device 2 | |

| | Not Hart | |

| | Responding Command # | |

| |+EQU–––––––––––––––+ +MOV–––––––––––––––+| |

| ++EQUAL +––+MOVE ++ |

| ||Source A N12:33| |Source 0|| |

| || 0| | || |

| ||Source B 33| |Dest N12:5|| |

| || | | 1|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Doing | |

| | Device 2 | |

| | B3 | |

| +–––––––––––––––––––––––––––––––––––(U)––––+ |

| | 2 | |

| | Doing | |

| | Device 1 | |

| | B3 | |

| +–––––––––––––––––––––––––––––––––––(L)––––+ |

| 1 |

Example 2 (continued)

3-12

Rung 2:6

| |

+––––––––––––––––––––––––––––––––[END OF FILE]–––––––––––––––––––––––––––––––––+

| |

Page 32

Chapter 3

Using The Smart Transmitter Toolkit

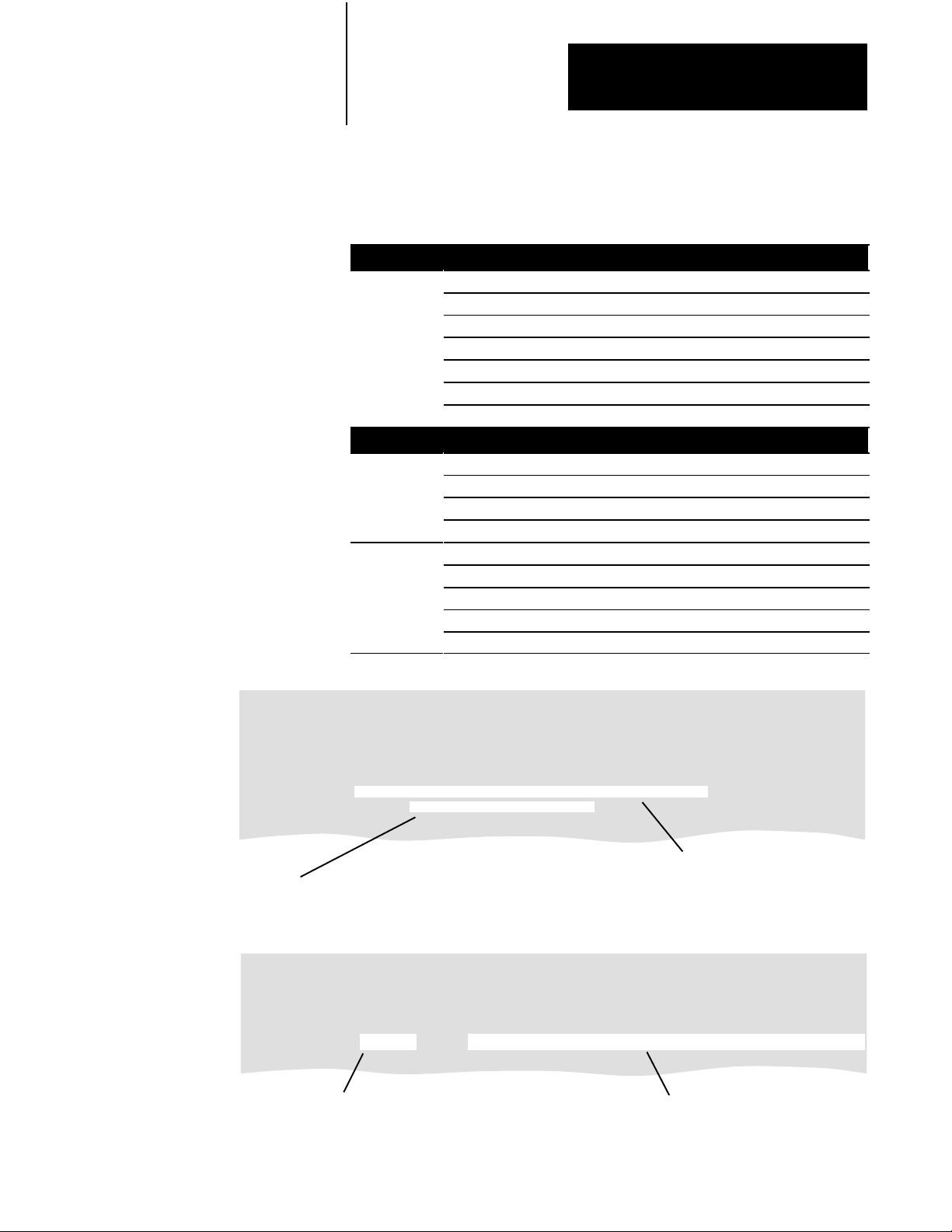

Programming

Example 3:

Multiple HART Devices W

Multiple 1770HT1s

ith

In this example, the primary variable is read continuously from two HART

field devices that are wired to separate 1770-HT1s. Communication with

multiple 1770-HT1s can occur asynchronously when calling the STT

subroutine.

PLC5

Processor

Smart Transmitter Interface

1770HT1

RIO

HART

Field

Device

1770HT16

4-20 mA Loop

Smart Transmitter Interface

1770HT1

RIO

HART

Field

Device

1770HT16

4-20 mA Loop

In the course of operation, if the field device does not respond, we reissue

HART command 0 to get the HART address. This example assumes that

each device data area is setup with the standard inputs for HART command

0 prior to the execution of this logic.

Device 1 uses N10 and F11

Device 2 uses N12 and F13

F15 contains both primary variable values

3-13

Page 33

Chapter 3

Using The Smart Tranmsitter Toolkit

Rung 2:0

STT 1.00 Programming Example 3.

This example reads the primary variable from 2 HART field devices wired to 2

1770-HT1s.

When the STT subroutine is not enabled, set the STT subroutine trigger bit.

| Device 1 |

| Device 1 STT |

| STT enable trigger |

| N10:30 N10:30 |

+––––]/[–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––(L)–––––+

| 1 3 |

Rung 2:1

Call the STT subroutine unconditionally.

| STT |

| Subroutine |

| +JSR–––––––––––––––+ |

+–––––––––––––––––––––––––––––––––––––––––––––––––––––––––+JUMP TO SUBROUTINE+–+

| |Prog file number 5| |

| |Input par 10| |

| |Return par | |

| +––––––––––––––––––+ |

Example 3 (continued)

3-14

Page 34

Chapter 3

Using The Smart Transmitter Toolkit

Example 3 (continued)

Rung 2:2

Only process when the STT subroutine is done. If the Hart command is 1, copy

the primary variable to file F15. If the Hart command is 0, copy the Hart

address to the input area and request Hart command 1. If device 1 does not

respond (error 33), try getting a new Hart address for device 1 by requesting

Hart command 0.

| Device 1 Device 1 |

| Device 1 Hart Process |

| STT Done Command # Variable |

| N10:30 +EQU–––––––––––––––+ +MOV–––––––––––––––+ |

+––––] [––––––––––––––––––––––––––++EQUAL +––+MOVE ++–+

| 2 ||Source A N10:5| |Source F11:10|| |

| || 0| | 0.000000|| |

| ||Source B 1| |Dest F15:1|| |

| || | | 0.000000|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Device 1 Device 1 | |

| | Hart Hart | |

| | Command # Address | |

| |+EQU–––––––––––––––+ +COP–––––––––––––––+ | |

| ++EQUAL +++COPY FILE +++ |

| ||Source A N10:5|||Source #N10:40||| |

| || 0|||Dest #N10:6||| |

| ||Source B 0|||Length 3||| |

| || ||+––––––––––––––––––+|| |

| |+––––––––––––––––––+| Device 1 || |

| | | Hart || |

| | | Command # || |

| | |+MOV–––––––––––––––+|| |

| | ++MOVE ++| |

| | |Source 1| | |

| | | | | |

| | |Dest N10:5| | |

| | | 0| | |

| | +––––––––––––––––––+ | |

| | Device 1 Device 1 | |

| | Not Hart | |

| | Responding Command # | |

| |+EQU–––––––––––––––+ +MOV–––––––––––––––+| |

| ++EQUAL +––+MOVE ++ |

| |Source A N10:33| |Source 0| |

| | 33| | | |

| |Source B 33| |Dest N10:5| |

| | | | 0| |

| +––––––––––––––––––+ +––––––––––––––––––+ |

Rung 2:3

This rung is identical to 2:0, except it uses device 2.

| Device 2 |

| Device 2 STT |

| STT enable trigger |

| N12:30 N12:30 |

+––––]/[–––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––––(L)–––––+

| 1 3 |

3-15

Page 35

Chapter 3

Using The Smart Tranmsitter Toolkit

Rung 2:4

Call the STT subroutine unconditionally.

| STT |

| Subroutine |

| +JSR–––––––––––––––+ |

+–––––––––––––––––––––––––––––––––––––––––––––––––––––––––+JUMP TO SUBROUTINE+–+

| |Prog file number 5| |

| |Input par 12| |

| |Return par | |

| +––––––––––––––––––+ |

Rung 2:5

This rung is identical to 2:2 except it uses device 2.

| Device 2 Device 2 |

| Device 2 Hart Process |

| STT Done Command # Variable |

| N12:30 +EQU–––––––––––––––+ +MOV–––––––––––––––+ |

+––––] [––––––––––––––––––––––––––++EQUAL +––+MOVE ++–+

| 2 ||Source A N12:5| |Source F13:10|| |

| || 1| | 0.000000|| |

| ||Source B 1| |Dest F15:2|| |

| || | | 0.000000|| |

| |+––––––––––––––––––+ +––––––––––––––––––+| |

| | Device 2 Device 2 | |

| | Hart Hart | |

| | Command # Address | |

| |+EQU–––––––––––––––+ +COP–––––––––––––––+ | |

| ++EQUAL +++COPY FILE +++ |

| ||Source A N12:5|||Source #N12:40||| |

| || 1|||Dest #N12:6||| |

| ||Source B 0|||Length 3||| |

| || ||+––––––––––––––––––+|| |

| |+––––––––––––––––––+| Device 2 || |

| | | Hart || |

| | | Command # || |

| | |+MOV–––––––––––––––+|| |

| | ++MOVE ++| |

| | |Source 1| | |

| | | | | |

| | |Dest N12:5| | |

| | | 1| | |

| | +––––––––––––––––––+ | |

| | Device 2 Device 2 | |

| | Not Hart | |

| | Responding Command # | |

| |+EQU–––––––––––––––+ +MOV–––––––––––––––+| |

| ++EQUAL +––+MOVE ++ |

| |Source A N12:33| |Source 0| |

| | 2| | | |

| |Source B 33| |Dest N12:5| |

| | | | 1| |

| +––––––––––––––––––+ +––––––––––––––––––+ |

Example 3 (continued)

3-16

Rung 2:6

| |

+––––––––––––––––––––––––––––––––[END OF FILE]–––––––––––––––––––––––––––––––––+

| |

Page 36

Appendix

A

HART Command Data Table Layouts

What's In This Appendix

This appendix contains the data table layouts for the HART commands that

are supported in the Smart Transmitter Toolkit (STT).

If you want to: Use Hart Command: See page:

Read HART Address

Read Primary Variable 1 A4

Read Dynamic Variables & Primary Variable Current 3 A6

Write Primary Variable Range Values 35 A8

Reset Configuration Change Flag 38 A10

Set Primary Variable Zero 43 A12

Write Primary Variable Units 44 A14

Important: All data table layout examples in this appendix are shown

assuming that these conditions exist:

The 1770-HT1 is located at I/O rack 4 and I/O group 6.

The HART field device is wired:

-to channel 3 of a 1770-HT8 or 1770-HT16

-point-to-point (polling address is 0)

0 A2

The HART field device uses a long-frame address.

A-1

Page 37

Appendix A

HART Command Data Table Layouts

HART Command 0

Read HART Address

Use this command to read the HART address from a HART field device.

Important: To use STT, you must include this command at least once in

your program prior to any calls with other HART commands. This

command returns the HART address of the HART field device. The

HART address is used in all other HART commands.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 0

A-2

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

Page 38

Appendix A

HART Command Data Table Layouts

Standard Outputs

Integer Word 30 STT Subroutine Status Word

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Error Code

Word 36 HART Field Device Error Code

Commandspecific Outputs

Integer Words 40 42 HART Address of HART field device

HART Command 0

Read HART Address

Long Frame HART Address

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 9858 269 12807 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

This is the HART address that is needed

as an input to the other HART commands.

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device (see page 36).

Short Frame HART Address

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 0 0 0 0 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 1538 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

This is the HART address that is needed

as an input to the other HART commands.

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device (see page 36).

A-3

Page 39

Appendix A

HART Command Data Table Layouts

HART Command 1

Read Primary Variable

Use this command to read the primary variable and unit code from a

HART field device. The primary variable is returned in floating-point

format and the unit code is returned as an integer.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Commandspecific

Integer Words 6 8 HART Address of HART field device

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 1 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 1

Inputs

A-4

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

This is the HART address that is returned

from HART Command 0 (see page A3).

Page 40

Appendix A

HART Command Data Table Layouts

Standard Outputs

Integer Word 30 STT Subroutine Status Word

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Error Code

Word 36 HART Field Device Error Code

Commandspecific Outputs

Integer Word 40 Primary Variable Unit Code

Floatingpoint Word 10 Primary Variable

HART Command 1

Read Primary Variable

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 1 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 32 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

This integer word is a commandspecific

output that contains the unit code for the

primary variable (see page B5).

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device (see page 36).

Data Table Report PLC-5/25 Addr 31 Data Table File F11:0

Address 0 1 2 3 4

F11:0 0 0 0 0 0

F11:5 0 0 0 0 0

F11:10 20.58 0 0 0 0

F11:15 0 0 0 0 0

This floatingpoint word is a commandspecific

output that contains the primary variable.

A-5

Page 41

Appendix A

HART Command Data Table Layouts

HART Command 3

Read

Dynamic V

V

ariable Current

ariables & Primary

Use this command to read the primary variable current and up to four

predefined dynamic variables from the HART field device.

The primary variable current always matches the analog output current

of the device including alarm conditions and set values.

The secondary, tertiary, and 4th variables are defined by each device

type. For example, the secondary variable is the sensor temperature for

the 3051 pressure transmitter.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Commandspecific

Integer Words 6 8 HART Address of HART field device

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 3

Inputs

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 3 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

This is the HART address that is returned

from HART Command 0 (see page A3).

A-6

Page 42

Standard Outputs

Integer Word 30 STT Subroutine Status Wordg

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Code

Word 36 HART Field Device Error Code

Commandspecific Outputs

Integer Word 41 Primary Variable Unit Codeg

Word 42 Secondary Variable Unit Code

Word 43 Tertiary Variable Unit Code

Word 44 4th Variable Unit Code

Floatingpoint Word 10 Primary Variable Currentgp

Word 11 Primary Variable

Word 12 Secondary Variable

Word 13 Tertiary Variable

Word 14 4th Variable

Appendix A

HART Command Data Table Layouts

HART Command 3

Read

Dynamic V

ariables & Primary

V

ariable Current

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 3 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 0 32 250 250 250 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

These four integer words are the commandspecific outputs

that contain the unit codes for the variables (see page B5).

Data Table Report PLC-5/25 Addr 31 Data Table File F11:0

Address 0 1 2 3 4

F11:0 0 0 0 0 0

F11:5 0 0 0 0 0

F11:10 7.29 20.58 0 0 0

F11:15 0 0 0 0 0

This floatingpoint word is a commandspecific

output that contains the primary variable current.

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device. (see page 36).

These four floatingpoint words are commandspecific outputs

that contain the variables from the HART field device.

A-7

Page 43

Appendix A

HART Command Data Table Layouts

HART Command 35

Write Primary V

Values

ariable Range

Use this command to write new upper and lower primary variable range

values to the data memory of the HART field device. This command then

outputs the actual upper and lower primary range values from the data

memory of the HART field device.

If the write operation was successful, you should see the same values

that you entered.

If the write operation was unsuccessful, you will see the original values

from the data memory of the field device. These values may or may not

be the same as the values that you entered. Check the status and error

codes.

Standard

Integer Word 0 I/O Rack Number of 1770HT1g

Commandspecific

Integer Words 6 8 HART Address from HART Command 0g

Floatingpoint Word 0 Primary Variable Upper Range Valuegp

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 35

Inputs

Word 10 Primary Variable Range Values Unit Code

Word 1 Primary Variable Lower Range Value

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 35 9858 269 12807 0

N10:10 32 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

This integer word is a commandspecific

input and contains the (new) unit code for

the primary variable (see page B5).

Data Table Report PLC-5/25 Addr 31 Data Table File F11:0

Address 0 1 2 3 4

F11:0 100.0 0.0 0 0 0

F11:5 0 0 0 0 0

F11:10 0 0 0 0 0

F11:15 0 0 0 0 0

These two floatingpoint words are commandspecific inputs that

contain the new upper and lower range values for the primary variable.

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

This is the HART address that is returned

from HART Command 0 (see page A3).

A-8

Page 44

Appendix A

HART Command Data Table Layouts

HART Command 35

Write Primary V

Standard Outputs

Integer Word 30 STT Subroutine Status Wordg

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Code

Word 36 HART Field Device Error Code

Commandspecific Outputs

Integer Word 40 Primary Variable Range Values Unit Code

Floatingpoint Word 10 Primary Variable Upper Range Valuegp

Word 11 Primary Variable Lower Range Value

ariable Range

Values

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 35 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 32 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

This integer word is a commandspecific output

that should contain the unit code that you

entered for the primary variable (see page B5).

Data Table Report PLC-5/25 Addr 31 Data Table File F11:0

Address 0 1 2 3 4

F11:0 100.0 0.0 0 0 0

F11:5 0 0 0 0 0

F11:10 100.0 0.0 0 0 0

F11:15 0 0 0 0 0

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device. (see page 36).

These two floatingpoint words are commandspecific

outputs that should contain the new upper and lower

range values that you entered for the primary variable.

A-9

Page 45

Appendix A

HART Command Data Table Layouts

HART Command 38

Reset Configuration Change Flag

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 38 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

Use this command to reset the configuration change flag.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Commandspecific

Integer Words 6 8 HART address from HART Command 0

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 38

Inputs

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

This is the HART address that is returned

from HART Command 0 (see page A3).

A-10

Page 46

Appendix A

HART Command Data Table Layouts

Reset Configuration Change Flag

Standard Outputs

Integer Word 30 STT Subroutine Status Word

g

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Code

Word 36 HART Field Device Error Code

HART Command 38

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 38 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device (see page 36).

A-11

Page 47

Appendix A

HART Command Data Table Layouts

HART Command 43

Set Primary V

ariable Zero

Use this command to trim the primary variable so that it reads zero with

the existing process applied to the HART field device. The resulting offset

must be within the limits defined by each device.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Commandspecific

Integer Words 6 8 HART Address from HART Command 0

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 43 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 43

Inputs

A-12

These six integer words are the

standard inputs that are required for

each HART command (see page 33).

This is the HART address that is returned

from HART Command 0 (see page A3).

Page 48

Appendix A

HART Command Data Table Layouts

Standard Outputs

Integer Word 30 STT Subroutine Status Word

g

Word 31 STT Subroutine Error Code

Word 32 Smart Transmitter Interface Status Word

Word 33 Smart Transmitter Interface Error Code

Word 34 HART ProtocolCommunication Error Code

Word 35 HART Command Response Summary Code

Word 36 HART Field Device Error Code

HART Command 43

Set Primary V

ariable Zero

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 43 9858 269 12807 0

N10:10 0 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 4 0 128 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

These seven integer words are the standard outputs

that contain the status of the communications with

the HART field device (see page 36).

A-13

Page 49

Appendix A

HART Command Data Table Layouts

HART Command 44

Write Primary V

ariable Units

Use this command to select the units in which the primary variable and the

primary variable range will be returned by the HART field device. This

command also selects the units for sensor limits and minimum span.

Standard

Integer Word 0 I/O Rack Number of 1770HT1

Commandspecific

Integer Words 6 8 HART Address from HART Command 0

Data Table Report PLC-5/25 Addr 31 Data Table File N10:0

Address 0 1 2 3 4 5 6 7 8 9

N10:0 4 6 3 0 16 44 9858 269 12807 0

N10:10 32 0 0 0 0 0 0 0 0 0

N10:20 0 0 0 0 0 0 0 0 0 0

N10:30 0 0 0 0 0 0 0 0 0 0

N10:40 0 0 0 0 0 0 0 0 0 0

N10:50 0 0 0 0 0 0 0 0 0 0

Inputs

Word 1 I/O Group Number of 1770HT1

Word 2 Channel Number of HART field device

Word 3 Polling Address of HART field device

Word 4 Smart Transmitter Interface Command Number 16 (decimal)

Word 5 HART Command Number 44

Inputs

Word 10 Primary Variable Unit Code

A-14

This integer word is a commandspecific

input that contains the (new) unit code for