Page 1

Trusted

TM

PD-8162

TM

Trusted

CS300 Bridge Module

Introduction

The CS300 Bridge Module presents a new opportunity to combine the CS300 I/O structure with the

latest processing and communications features of Trusted

Combining the two products will enable CS300 users to benefit from features such as 3-3-2-0

Processor fault tolerance, IEC 1131 programming suite, Ethernet networks, OPC, Ethernet peer to

peer and remote diagnostics. The CS300 Bridge Module replaces the CS300 ICCB in the CS300

Primary chassis.

Any system using the CS300 Bridge Module and Trusted

Expanders and I/O modules forming a Hybrid system. To the Trusted

and CS300 chassis appear in the same system map. All systems using Trusted

can be seamlessly integrated together.

TM

.

TM

TMR Processor can also include TrustedTM

TM

TMR Processor, the TrustedTM

TM

TMR Processors

Upgrade Features

• Triple Modular Redundant (TMR), fault tolerant (3-3-2-0) operation

• Dedicated hardware and software test regimes which provide very fast fault

recognition and response times

• Automatic fault handling without nuisance alarming

• Hot replacement, self-configuration.

TM

• Interfaces to Trusted

• Front panel indicators that show module health data transmission status

• TÜV certification and IEC61508 SIL3

TMR Expander Bus

Issue 02 Feb 10 PD-8162 1

Page 2

TrustedTM CS300 Bridge Module

Issue Record

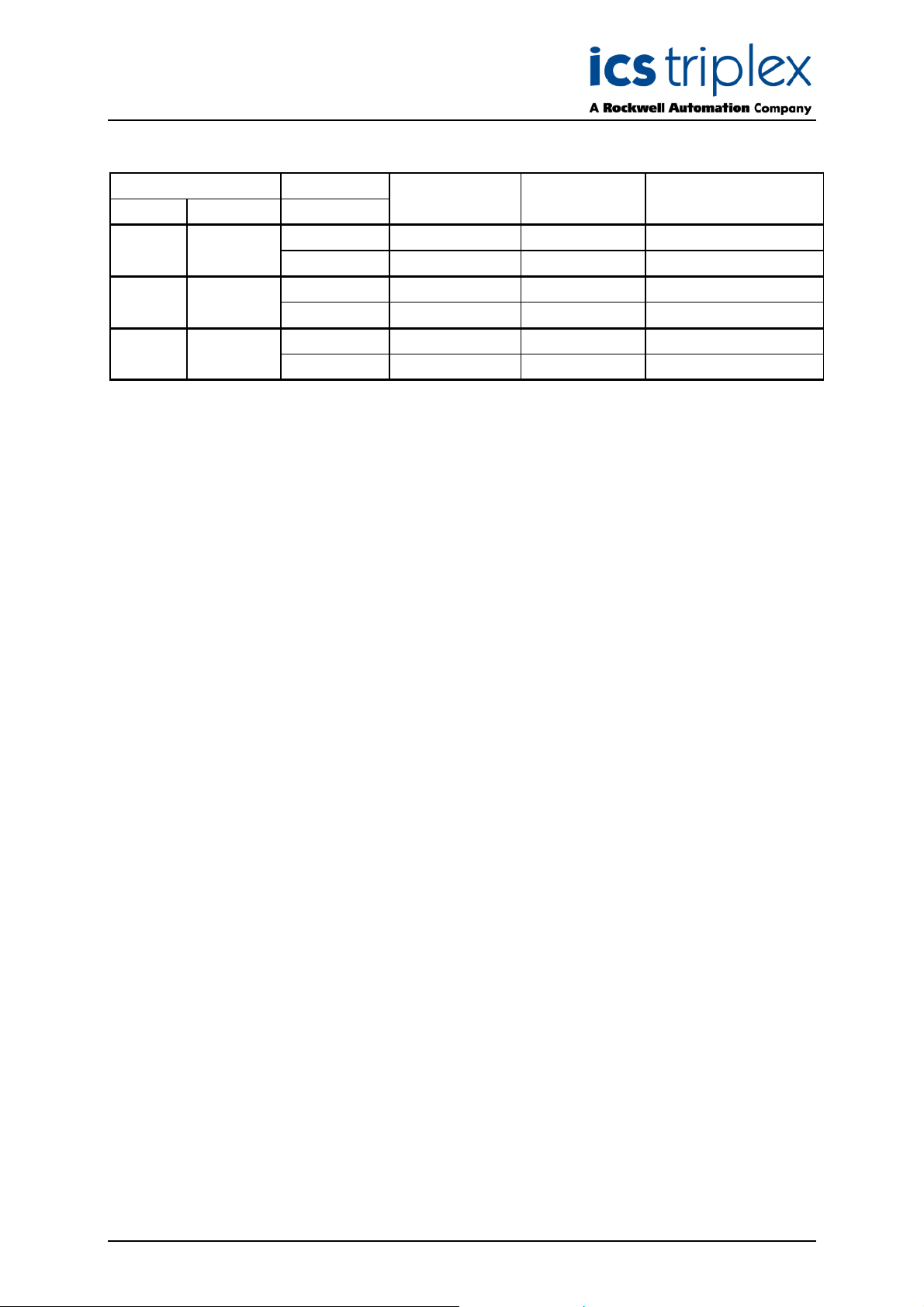

Issue

umber Date Revised by Technical CheckAuthorised by Modification

N

1 Apr 08 A Holgate Nick Owens Pete Stock Initial Issue

2 Feb 10 A Holgate Nick Owens Pete Stock TC-322 details

Issue 02 Feb 10 PD-8162 2

Page 3

TrustedTM CS300 Bridge Module

Table of Contents

1. Description ...................................................................................................................................7

1.1. Overview......................................................................................................................................7

1.2. Power Distribution........................................................................................................................8

1.3. Communication Busses...............................................................................................................8

1.3.1. The TrustedTM to CS300 Primary Chassis...................................................................................8

1.3.2. Inter-Module Link (IML)................................................................................................................8

1.4. Function .......................................................................................................................................8

2. Installation....................................................................................................................................9

2.1. Module .........................................................................................................................................9

2.2. TC-322-02 Interface Cable assembly........................................................................................10

2.3. Module Configuration.................................................................................................................11

3. Application .................................................................................................................................13

3.1. System Configuration.................................................................................................................13

3.2. Board definitions........................................................................................................................17

3.3. Module – 8162 (Bridge Module).................................................................................................18

3.4. Module – bic (bus interface controller).......................................................................................19

3.5. Module – pi632 / pi732 (analogue input module).......................................................................20

3.6. Module – pi641 / pi741 (analogue output module).....................................................................21

3.7. Module – pi616_5 / pi616_9 / pi716 / pi717 (digital input module).............................................23

3.8. Module – pi626 / pi726 (digital output module)..........................................................................24

3.9. Module – pi627 / pi727 / pi627_fs / pi727_fs (digital output module).........................................26

3.10. Module – dmx_m (de-multiplexed display driver) ......................................................................28

3.11. Module – dmx_o (de-multiplexed display driver card) ...............................................................29

4. Operation ...................................................................................................................................30

4.1. Front Panel Indicators and Controls ..........................................................................................31

4.1.1. Tx & Rx Indicators .....................................................................................................................31

4.1.2. Health Indicator..........................................................................................................................31

4.1.3. On-Line Indicator and Switch.....................................................................................................31

5. Fault Finding and Maintenance..................................................................................................32

6. Specifications.............................................................................................................................33

Figures

Figure 1 Block Diagram showing interface between TrustedTM system and CS300 I/O ..........................7

Figure 2 8162 Bridge Module ...................................................................................................................9

Figure 3 TC-322-02 Interface Cable assembly.......................................................................................10

Figure 4 CS300 main chassis rear view .................................................................................................10

Figure 5 TrustedTM controller chassis rear view .....................................................................................11

Figure 6 CS300 Chassis Backplane.......................................................................................................11

Figure 7 TrustedTM Processor Chassis with Expander Interface ............................................................13

Figure 8 Insert New Chassis...................................................................................................................13

Issue 02 Feb 10 PD-8162 3

Page 4

TrustedTM CS300 Bridge Module

Figure 9 CS300 Main Chassis................................................................................................................14

Figure 10 Chassis Connection................................................................................................................14

Figure 11 Connected Chassis ................................................................................................................14

Figure 12 Jumper Setting .......................................................................................................................15

Figure 13 BIC Chassis Addressing.........................................................................................................15

Figure 14 CS300 Modules......................................................................................................................16

Figure 15 Module Options ......................................................................................................................16

Figure 16 Front Panel Layout .................................................................................................................30

Tab le s

Table 1 Bridge Module Associated Equipment.........................................................................................6

Issue 02 Feb 10 PD-8162 4

Page 5

TrustedTM CS300 Bridge Module

Precautionary Information

WARNING

Warning notices call attention to the use of materials, processes, methods, procedures or limits which

ust be followed precisely to avoid personal injury or death.

m

CAUTION

Caution notices call attention to methods and procedures which must be followed to avoid damage to

the equipment.

Notes:

Notes highlight procedures and contain information to assist the user in the understanding of the

information contained in this document

Warning

RADIO FREQUENCY INTERFERENCE

Most electronic equipment is influenced by Radio Frequency Interference (RFI). Caution should be

exercised with regard to the use of portable communications equipment around such equipment.

Signs should be posted in the vicinity of the equipment cautioning against the use of portable

communications equipment.

MAINTENANCE

Maintenance must be performed only by qualified personnel, otherwise personal injury, death, or

damage to the system may be caused.

Caution

HANDLING

Under no circumstances should the module housing be removed.

Associated Documents

Product Descriptions (PD) provide product specific information.

The Safety Manual contains the recommended safety requirements for the safety system design.

The PD-T8082 – Toolset Suite provides specific guidance on system configuration and application

generation.

The Operator and Maintenance Manual contains general guidelines on maintenance and diagnostic

procedures.

For technical support email: support@icstriplex.com

Issue 02 Feb 10 PD-8162 5

Page 6

TrustedTM CS300 Bridge Module

Associated Equipment

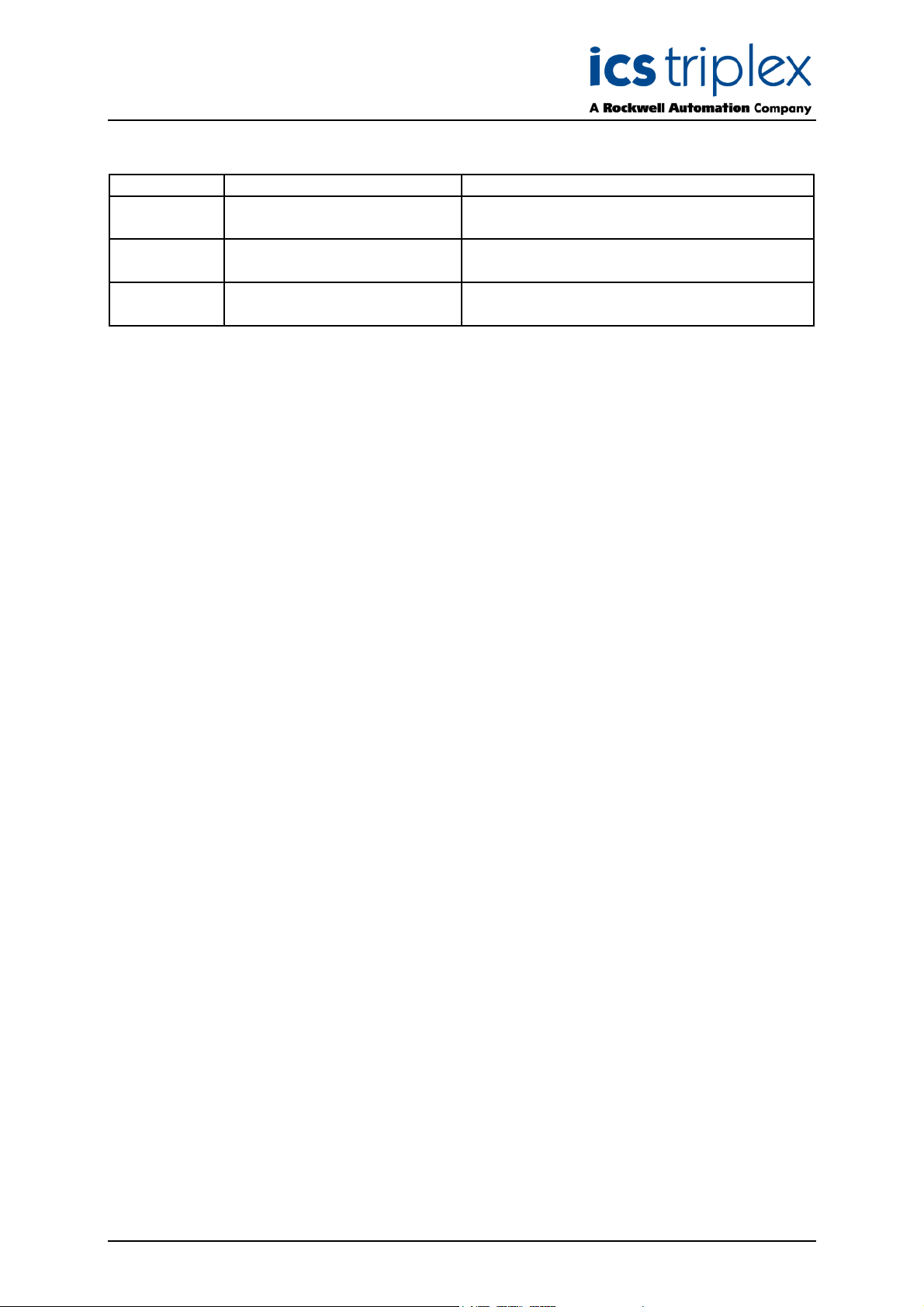

Part Number Product Name Description

Adds equipment definitions for CS300 modules

T8043 CS300 Toolset Library

CS300/SC300E Interface Cable

TC-322-02

TC-324-02

Assembly

CS300 Interface Cable

Connector Card

Table 1 Bridge Module Associated Equipment

to the Trusted

To connect between Trusted

Interface Adaptor and CS300 Controller Chassis

To attach TC-322-02 cable to CS300 Controller

Chassis

TM

Toolset

TM

Expander

Issue 02 Feb 10 PD-8162 6

Page 7

TrustedTM CS300 Bridge Module

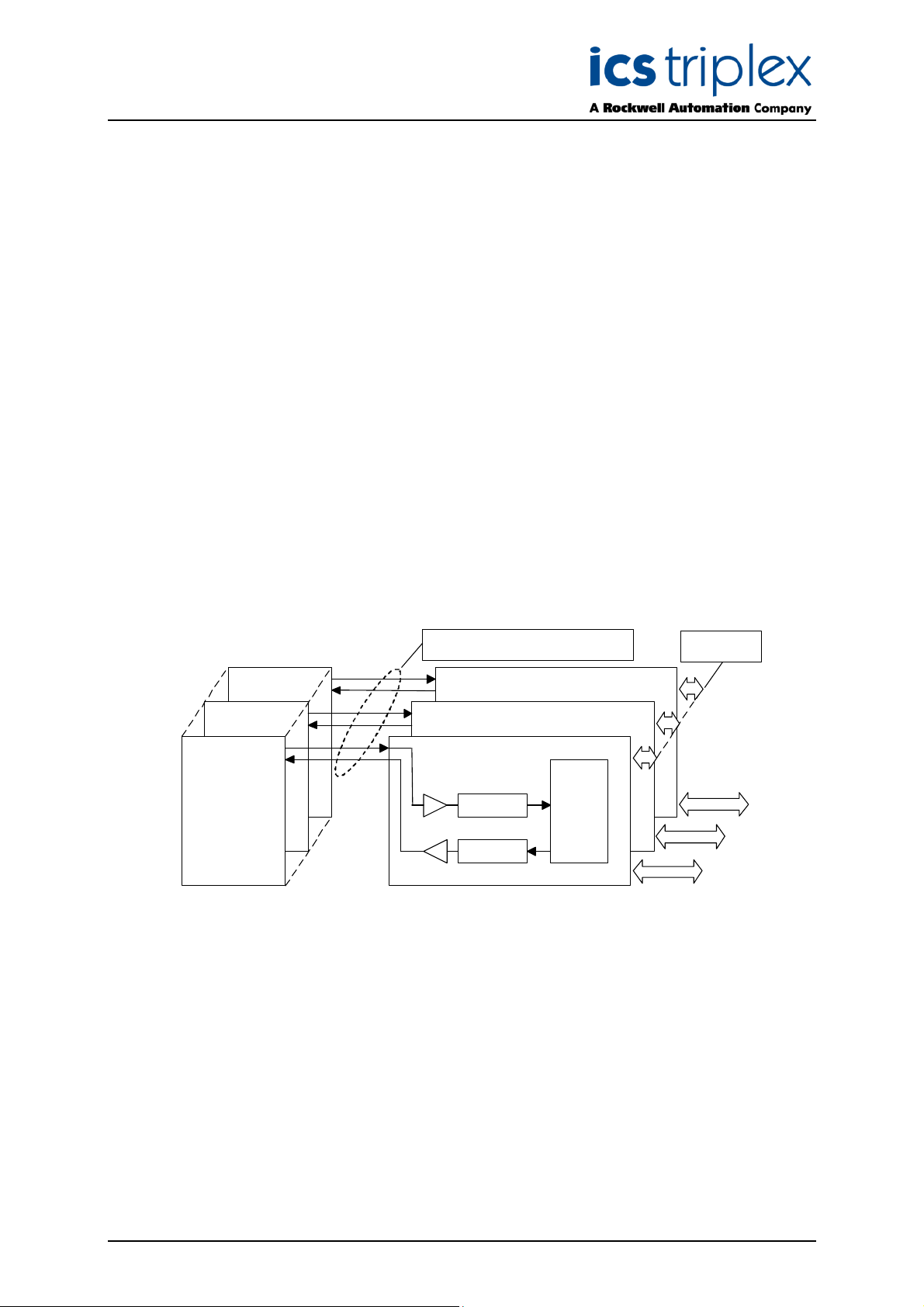

Module

Bridge Module (A)

Backplane

1. Description

1.1. Overview

The CS300 Bridge Module enables connection between a CS300 I/O sub system and the TrustedTM

TMR Processor. Three CS300 Bridge modules replace the three ICCB modules in a CS300 primary

chassis.

The Bridge module has a fast serial ("Hotlink") interface that transfers command and response packets

between the two product families via the Trusted

Programmable Gate Array (FPGA) for decoding instructions from the Trusted

accessing the specified CS300 I/O module and returning any data requested.

Command data received by the three Bridge modules and responses to the Trusted

are synchronised in accordance with the Lock Step operational characteristics of the Trusted

Expander Bus. For this reason, the three bridge modules share their data and arrange their response

packets in the same order for simultaneous transmission. The clock signal received from the Expander

Bus is used to ensure that data from all three Bridge modules is transmitted on the same clock edge.

TM

The Trusted

TMR processor stores and executes the application program, scans and updates the

CS300 I/O modules and detects system faults. Each of the three slices of the TMR Processor

executes the application program independently, but in lock-step synchronisation with the other two.

All CS300 I/O actions are executed by polling only. This means that all CS300 I/O modules are

supported, with the exception of Serial I/O modules (which generate interrupts). All communications to

workstations and DCS systems are enabled through the Trusted

(C)

Expansion Bus (TC-322-02 Cable)

TM

Expander Bus. The module uses a Field

TM

Communications Interfaces.

(TC-324-02 Board)

Bridge Module (C)

TM

TMR processor,

TM

TMR Processor

Inter Module

Link

TM

(B)

(A)

FCR A

Trusted

Expander

Interface

Trusted™

Main Chassis

FCR A

Bridge Module (B)

hotlin k

receiver

hotlin k

transmitter

CS30 0

Main Chassis

FPGA

Figure 1 Block Diagram showing interface between TrustedTM system and CS300 I/O

CS300

to CS300 I/O

Modules

Issue 02 Feb 10 PD-8162 7

Page 8

TrustedTM CS300 Bridge Module

1.2. Power Distribution

Each of the Bridge modules is powered from triple redundant PSUs (situated in a separate chassis)

that support the main I/O chassis with 5V, 12V & +/-20Vdc supplies and up to three CS300 extension

chassis with 12V and +/-20Vdc only.

1.3. Communication Busses

1.3.1. The TrustedTM to CS300 Primary Chassis

Communication between the TrustedTM Expander Interface Module and the CS300 Primary Chassis is

via one of a possible four or seven triplicated two-way interface cables. A single backplane connector

card routes the individual links in the cable to the three Bridge modules. Data voting is provided at the

Expander Module Interface to ensure that cable faults are detected.

The link handles the following triplicated signals:

Data - Serial bi-directional bus.

Control - Bus clocks, module-enables and bus direction control.

Slot - Indicating the CS300 I/O slot position to the Bridge.

M

T

Expander Chassis ID - 4 bit Trusted

chassis address code.

1.3.2. Inter-Module Link (IML)

When returning data for TrustedTM Read requests, I/O Module data received by each Bridge module is

shared with the other two using the serial IML via the backplane. The three sets of data are then

arranged sequentially into the response packet for Trusted

requests.

M

T

. The IML is not used during Write

1.4. Function

When an I/O access is to be performed, the TrustedTM TMR Processor issues a command packet to

an Expander Interface Module. The Expander Interface decodes the chassis address and transmits

the packet through an Expander bus to receivers in the 8162 Bridge modules.

For short distances of a few metres, a twisted-pair copper cable is used, whilst on longer runs the

copper cable is connected to three T8312 fibre optic units at each end of three pairs (Tx and Rx) of

fibre optic cable. The Bridge modules, receiving the command signals, decode the packet.

The Bridge modules then implement the read or write access on the CS300 I/O module selected and

return a response packet via the serial expander bus. The packet will contain both data and diagnostic

information.

Issue 02 Feb 10 PD-8162 8

Page 9

TrustedTM CS300 Bridge Module

2. Installation

2.1. Module

Each of the three Bridge modules replaces one of the CS300 ICCB modules. Figure 2 shows the

module. The replacement must be carried out with the system offline.

The modules consist of a single PCB assembly.

Figure 2 8162 Bridge Module

Issue 02 Feb 10 PD-8162 9

Page 10

TrustedTM CS300 Bridge Module

2.2. TC-322-02 Interface Cable assembly

The interface cable connects from the TrustedTM Interface Adaptor T8312 to an identical 12 way socket

on the interface cable connector card.

Figure 3 TC-322-02 Interface Cable assembly

Figure 4 CS300 main chassis rear view

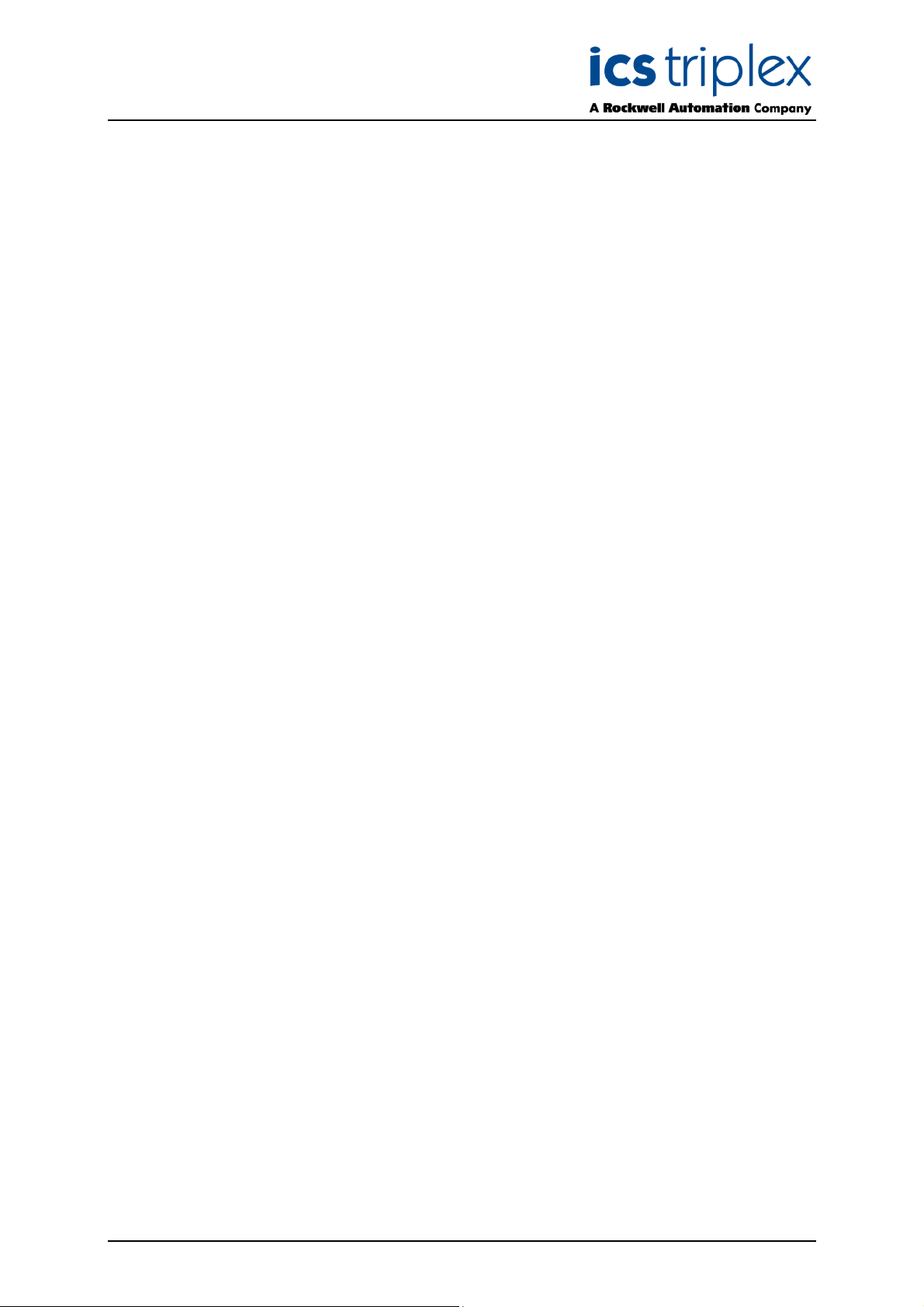

Figure 4 shows the interface cable connector card (top left) fitted to the rear of the CS300 controller

chassis which is connected to the Trusted

TM

Expander Interface adaptor via the TC322-02 interface

cable (braided cable at top left).

Connectors J1-3 on the TC-324-02 card plug into the three 26-way headers on the CS300 backplane.

The expander cable TC-322-02 from the Trusted

TM

Expander Interface plugs into 12-way socket J4.

Issue 02 Feb 10 PD-8162 10

Page 11

TrustedTM CS300 Bridge Module

Figure 5 TrustedTM controller chassis rear view

Figure 5 shows a four socket version of the T8312 Expander Interface Adaptor with a TC-301-01 cable

attached, which connects to a Trusted

or seven connections available to individual Trusted

TM

expander chassis. The Expander Interface Adapter has four

TM

Expander chassis or to the CS300 controller

chassis using the TC-322-02 Interface Cable Assembly.

2.3. Module Configuration

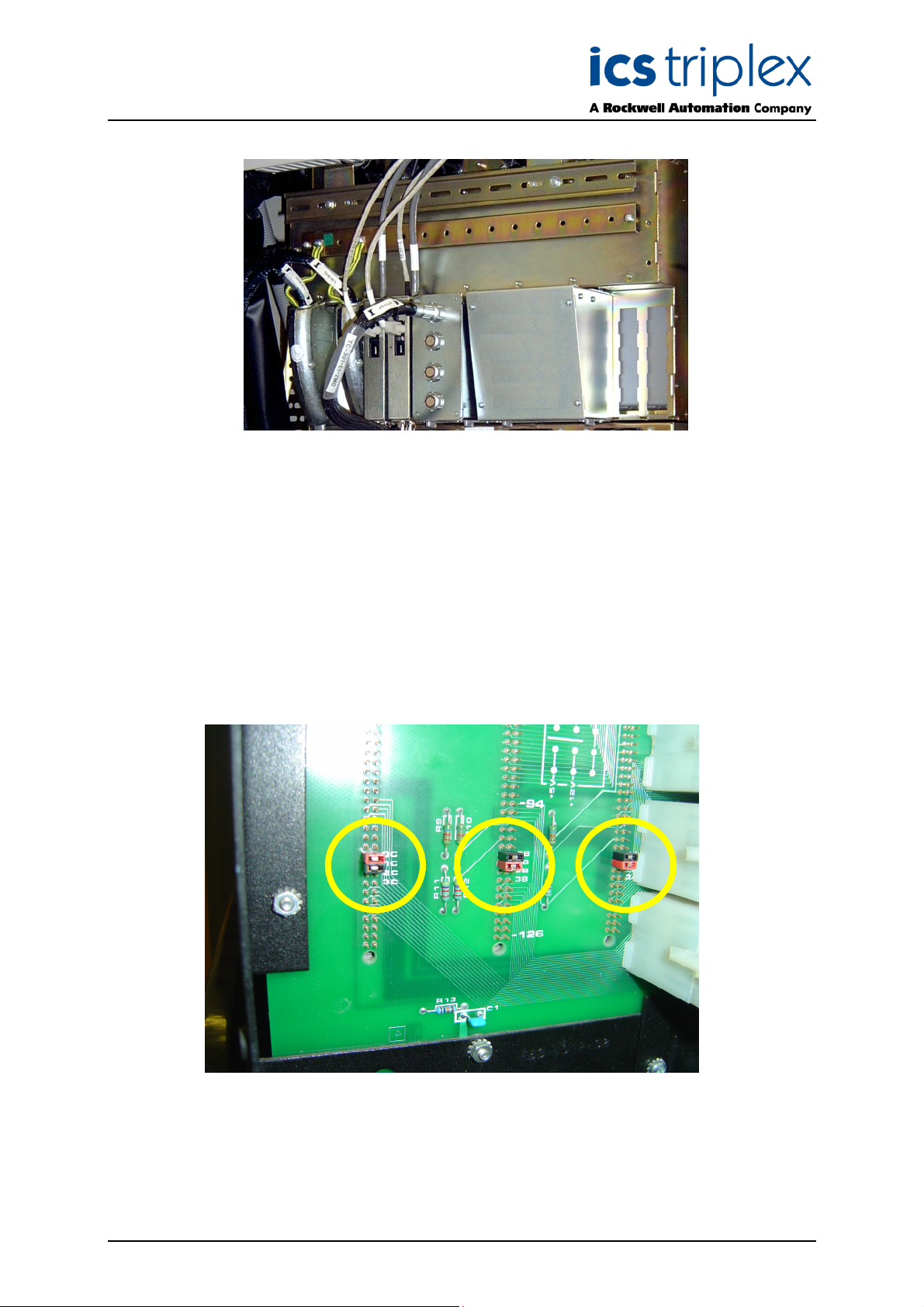

The Bridge module requires minimum configuration, namely the setting of three sets of jumpers 0 to 3

to define the chassis address to Trusted

shown here.

TM

. These are situated on the CS300 chassis backplane as

Figure 6 CS300 Chassis Backplane

Issue 02 Feb 10 PD-8162 11

Page 12

TrustedTM CS300 Bridge Module

The four backplane jumpers 0,1,2,3 (A,B,C) represent the binary address bits 1,2,4 & 8 respectively. A

itted jumper signals a binary digit ‘1’. The address is set to between 2 and 8. On the first CS300

f

chassis (containing the CS300 Bridge Modules), fit jumper 1 (A,B,C) to represent Trusted

'2'. The jumpers on all three sets must be set to the same address. Leave the jumpers as they were on

the other CS300 chassis. It is usual to attach the chassis with address 2 to the first Expander Interface

Adapter socket, for both Trusted

TM

chassis and CS300 chassis. This makes the software configuration

easier.

TM

address

Issue 02 Feb 10 PD-8162 12

Page 13

TrustedTM CS300 Bridge Module

3. Application

M

All CS300 I/O modules are configured using the IEC1131 application Toolset provided with Trusted

his configuration requires entries in the System Configuration (System.INI) for the chassis and

T

modules and their hardware operational parameters, and also in the workbench I/O connection table,

for software settings and data connection.

3.1. System Configuration

T

.

All TrustedTM systems need a system configuration file, specifying the chassis and modules in the

system. For Trusted

Trusted

TM

controller chassis, as for TrustedTM -only systems. An example with Expander Interfaces in

M

T

/CS300 hybrid systems, a T8311 Expander Interface is required in the

slots 1 and 2 (companion slots) and communications interfaces in slots 7 and 8 is shown below. For

details of the System Configuration Tool please refer to product description PD-T8082.

TM

Figure 7 Trusted

The CS300 chassis are attached to the Expander Interface as if they were Trusted

Processor Chassis with Expander Interface

TM

expander

chassis, but the various chassis options for Triguard and CS300 are provided on the ‘Insert New

Chassis’ dialog. Right-click on the background of the configurator window to insert a new chassis.

Figure 8 Insert New Chassis

Issue 02 Feb 10 PD-8162 13

Page 14

TrustedTM CS300 Bridge Module

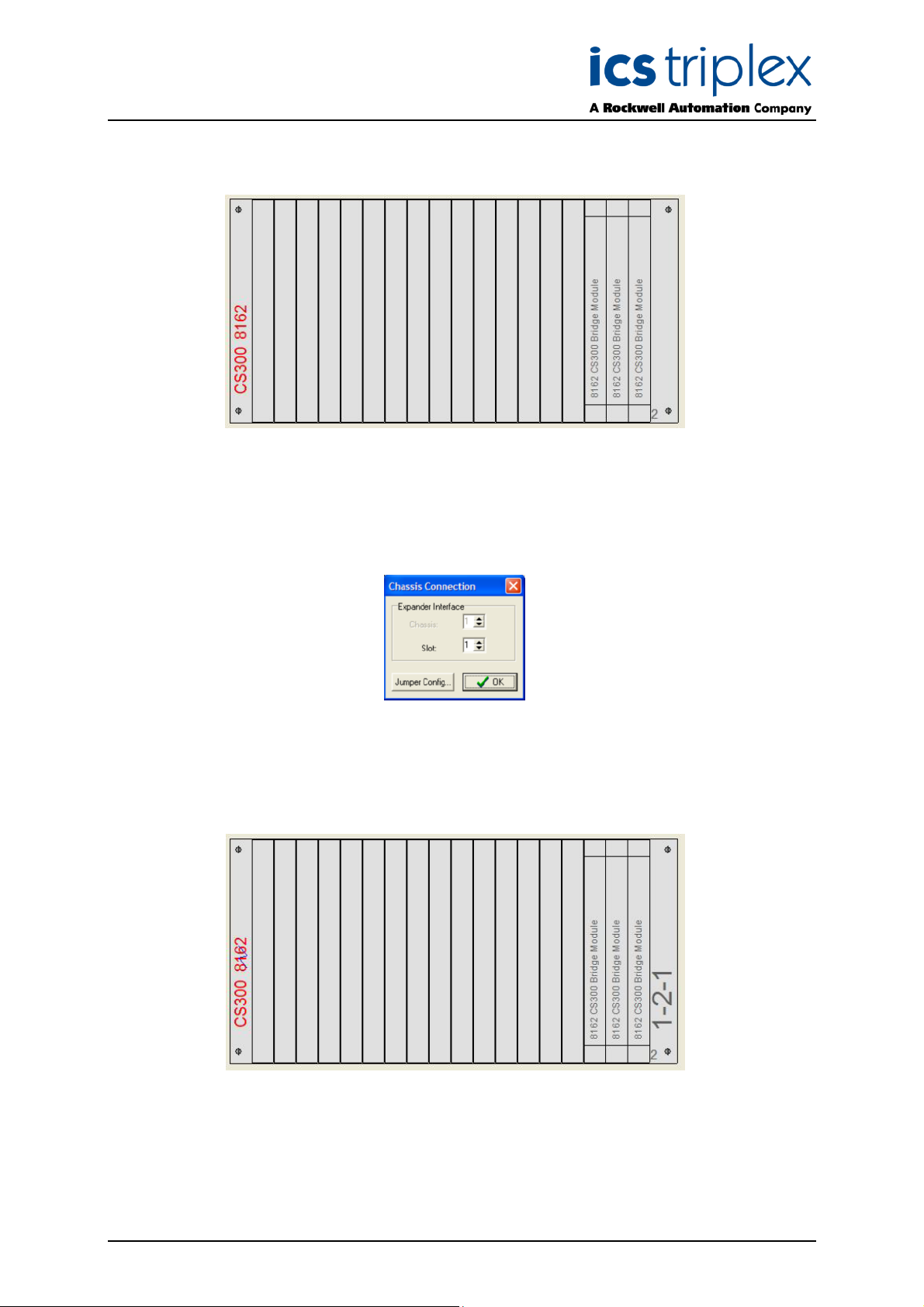

The first chassis to be created is a CS300 8162. This includes the bridge modules in place of the

CS300 processors. Choose typeCS300 8162 and select a logical chassis number. This chassis

number will define the switch configuration described in section 2.3.

Figure 9 CS300 Main Chassis

TM

The chassis should then be allocated to the Trusted

or right end of the CS300 8162 chassis to open the Chassis Connection dialog. Select the slot number

of the left-hand Expander Interface module.

Expander Interface module. Left-click on the left

Figure 10 Chassis Connection

On closing this dialog, the CS300 8162 chassis should have a blue flash symbol on the left. The right

hand side shows the chassis address as:

TM

< Trusted

expander Interface slot> - <Expander socket number> - <CS300 chassis number>

Figure 11 Connected Chassis

Left-click on the left or right end of the CS300 8162 chassis to open the Chassis Connection dialog

again. The ‘Jumper Config’ button now demonstrates how to set the backplane jumpers.

Issue 02 Feb 10 PD-8162 14

Page 15

TrustedTM CS300 Bridge Module

Figure 12 Jumper Setting

This chassis then links into the extension chassis BIC, which is linked to the main CS300 8162 chassis

by ribbon cables.

To add a BIC chassis, right click again on the background and select CS300 BIC. The switch settings

on these chassis should not be changed from their old configuration in the CS300 system. Select the

8162 chassis to connect the new chassis to (Parent 8162 Chassis Number), and enter the chassis

number as configured on the chassis address switches on the BIC chassis (Triguard Chassis

Number). Closing this window and left-clicking on the chassis ends will show the Jumper Config button,

which will confirm the switch settings that have been selected.

Figure 13 BIC Chassis Addressing

The chassis will now show its address on the right end as:

TM

< Trusted

expander Interface slot> - <Expander socket number> - <CS300 chassis number>

e.g. 1-2-2 in the above example.

Issue 02 Feb 10 PD-8162 15

Page 16

TrustedTM CS300 Bridge Module

Having added all the chassis in the system, the next step is to insert modules. For each module, rightclick on the appropriate chassis slot. Select the module from the list.

Figure 14 CS300 Modules

On left-clicking the module, the module options are displayed.

Figure 15 Module Options

If the module has been allocated a Hot Repair partner slot, so that the partner module can take over on

failure, then check the Hot Repair Module option. The configurator will automatically allocate the next

appropriate slot, but this may be edited. There is no need to insert a module for the hot repair slot; the

configurator will add this automatically There is also no need to edit the options for the hot repair

module. The hot repair partnership is set up using the interlinking ribbon cable between the modules.

The ‘Mode’ is included for PI727 modules which can be set to 3-2-1 or 3-2-0 operation..

For output modules, an input module may be configured to monitor the outputs as a diagnostic

feedback. Where this is required, check the Enable Monitor option and select the chassis and slot of

the input module. For analogue output modules, also select the monitor channel.

With monitoring enabled, it is possible to add LFD testing. Complete testing is only possible with two

online output cards (in a hot repair configuration).

To allow the system to run with a module absent, check ‘Simulate’.

Ensure that the options selected are as configured in the original application.

Issue 02 Feb 10 PD-8162 16

Page 17

TrustedTM CS300 Bridge Module

3.2. Board definitions

There are no restrictions in the order of the boards set out in the connection table except in cases

where TM117-DMX (64-Channel De-Multiplexed Driver) termination cards are configured in the

system. These have to be defined before any CS300I/O modules are specified. The DMX cards are

driven from the Trusted

It is also general convention to specify the Trusted

table.

In a true hybrid system including Trusted

definitions have to be referred to in the associated Product Description.

TM

processor module’s serial ports.

TM

TM

I/O modules, conventions for entering the various board

main processor at the head of the connection

Issue 02 Feb 10 PD-8162 17

Page 18

TrustedTM CS300 Bridge Module

3.3. Module – 8162 (Bridge Module)

DESCRIPTION

This definition provides module status for a 8162 primary chassis expansion interface module that

provides an expansion bridge from Trusted

The logical module accounts for the 3 physical modules FCR-A, FCR-B and FCR-C.

OEM PARAMETERS:

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis number allocated to the primary CS300 chassis in

which the 8162 modules are placed.

SLOT 16 Logical slot within the Primary CS300 chassis by which the Trusted

system identifies the 8162 module. This cannot be configured.

PHYSICAL MODULE:

RACK 1: [STATUS] - 6 BOOL Inputs

Variable 1: TRUE = Logical module responding

Variable 2: TRUE = FCR-A faulted or not responding

Variable 3: TRUE = FCR-B faulted or not responding

Variable 4: TRUE = FCR-C faulted or not responding

RACK 2: [INFO] - 12 ANALOGUE Inputs

Word 1: FCR-A fault code (see note 1)

Word 2: FCR-B fault code (see note 1)

Word 3: FCR-C fault code (see note 1)

Word 4: FCR-A hot-link error count

Word 5: FCR-B hot-link error count

Word 6: FCR-C hot-link error count

Word 7: FCR-A IML own-link error count

Word 8: FCR-A IML down-link error count

Word 9: FCR-A IML up-link error count

Word 10: FCR-B IML own-link error count

Word 11: FCR-B IML down-link error count

Word 12: FCR-B IML up-link error count

Word 13: FCR-C IML own-link error count

Word 14: FCR-C IML down-link error count

Word 15: FCR-C IML up-link error count

[Note 1 - Fault Codes]

0 : No fault

1 : Local backplane fault

2 : Local expansion bus fault

3 : Common fault (applies to both local backplane and expansion busses)

TM

to CS300 systems.

TM

Issue 02 Feb 10 PD-8162 18

Page 19

TrustedTM CS300 Bridge Module

3.4. Module – bic (bus interface controller)

DESCRIPTION

This definition provides module status for a PI 651/751 Bus Interface Controller that provides

expansion interface for secondary chassis in the CS300 system.

The logical module accounts for the 3 physical modules FCR-A, FCR-B and FCR-C.

OEM PARAMETERS:

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis number allocated to the local secondary CS300

chassis in which the BIC modules are placed.

SLOT 16 Logical slot within the local secondary CS300 chassis by which the

Trusted

configured.

PHYSICAL MODULE:

RACK 1: [STATUS] - 10 BOOL Inputs

Variable 1: FALSE (Not used)

Variable 2: TRUE = FCR-A faulted

Variable 3: TRUE = FCR-B faulted

Variable 4: TRUE = FCR-C faulted

Note: The status of BIC FCR's can only be determined by the discrepancy status of accesses

performed to I/O modules within the chassis of the BIC. If no such modules exist or if no BIC FCR's

are fitted then no faults can be reported.

TM

system identifies the BIC module. This cannot be

Issue 02 Feb 10 PD-8162 19

Page 20

TrustedTM CS300 Bridge Module

3.5. Module – pi632 / pi732 (analogue input module)

DESCRIPTION

This definition will open a single PI632 or PI732.

OEM PARAMETERS

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis and slot number where the CIO_AI is located.

SLOT 1-15

PHYSICAL MODULE:

RACK 1: (AI)

16 INTEGER inputs

RACK 2: (DIAG)

2 INTEGER inputs

Word 1 Diagnostic bits

bit 0 Slice A

=1 slice is not responding or there is an error

=0 slice is responding

bit 1 Slice B

=1 slice is not responding or there is an error

=0 slice is responding

bit 2 Slice C

=1 slice is not responding or there is an error

=0 slice is responding

bit 3 Module offline or missing

=1 offline or missing

=0 online

bit 4 Single slot hot repair

=1 in progress

=0 not in progress

bit 5 Discrepancy errors

=1 faults detected

=0 no faults detected

Word 2 Slot number of active module

RACK 3: (FAULTS)

1 INTEGER inputs

Word 1 Discrepancy errors, channels 1-16 (bit 0 = channel 1)

Issue 02 Feb 10 PD-8162 20

Page 21

TrustedTM CS300 Bridge Module

3.6. Module – pi641 / pi741 (analogue output module)

DESCRIPTION

This definition will open a single PI641 or PI741.

OEM PARAMETERS

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis and slot number where the CIO_AO is located.

SLOT 1-15

PHYSICAL MODULE:

RACK 1: (AO)

4 INTEGER outputs

RACK 2: (DIAG)

2 INTEGER inputs

Word 1 Diagnostic bits

bit 0 Slice A

=1 slice is not responding or there is an error

=0 slice is responding

bit 1 Slice B

=1 slice is not responding or there is an error

=0 slice is responding

bit 2 Slice C

=1 slice is not responding or there is an error

=0 slice is responding

bit 3 Module offline or missing

=1 offline or missing

=0 online

bit 4 Single slot hot repair

=1 in progress

=0 not in progress

bit 5 Discrepancy errors

=1 faults detected

=0 no faults detected

Word 2 Slot number of active module

RACK 3: (FAULTS)

2 INTEGER inputs

Word 1 Discrepancy errors, channels 1-4 (bit 0 = channel 1)

Word 2 LFD errors, channels 1-4 (bit 0 = channel 1)

Issue 02 Feb 10 PD-8162 21

Page 22

TrustedTM CS300 Bridge Module

RACK 4: (CALIB)

4 BOOLEAN outputs (one per channel) which determine if the AO output data is taken from

RACK 1 (AO) or from RACKs 5-7 (CALIB_x).

=0, output data taken from RACK 1 (AO)

=1, output data taken from RACKs 5-7 (CALIB_x)

RACK 5: (CALIB_A)

4 INTEGER outputs

Output data used for Slice A on the AO module. Only used if the corresponding Boolean output

in RACK 4 (CALIB) is TRUE.

RACK 6: (CALIB_B)

4 INTEGER outputs

Output data used for Slice B on the AO module. Only used if the corresponding boolean output

in RACK 4 (CALIB) is TRUE.

RACK 7: (CALIB_C)

4 INTEGER outputs

Output data used for Slice C on the AO module. Only used if the corresponding boolean output

in RACK 4 (CALIB) is TRUE.

NOTES:

Discrepancy errors will only be checked if the AO module has a configured AI monitor module.

Discrepancy errors indicate a difference between the output value on an AO and the voted input value

on the AI monitor.

LFD errors will only be checked if the AO module has a configured AI monitor module and LFD testing

is enabled on that AO module.

The calibration racks (4-7) can be used to aid calibration of the D/A converters on the AO modules.

They allow different values to be sent to each slice's D/A converter, allowing each to be calibrated

individually.

Issue 02 Feb 10 PD-8162 22

Page 23

TrustedTM CS300 Bridge Module

3.7. Module – pi616_5 / pi616_9 / pi716 / pi717 (digital input module)

DESCRIPTION

This definition will open a single PI616 type 5 or PI616 type 9 or PI716 or PI717.

OEM PARAMETERS

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis and slot number where the module is located.

SLOT 1-15

PHYSICAL MODULE:

RACK 1: (DI)

32 BOOLEAN inputs

RACK 2: (DIAG)

2 INTEGER inputs

Word 1 Diagnostic bits

bit 0 Slice A

=1 slice is not responding or there is an error

=0 slice is responding

bit 1 Slice B

=1 slice is not responding or there is an error

=0 slice is responding

bit 2 Slice C

=1 slice is not responding or there is an error

=0 slice is responding

bit 3 Module offline or missing

=1 offline or missing

=0 online

bit 4 Single slot hot repair

=1 in progress

=0 not in progress

bit 5 Discrepancy errors

=1 faults detected

=0 no faults detected

Word 2 Slot number of active module

RACK 3: (FAULTS)

2 INTEGER inputs

Word 1 Discrepancy errors, channels 1-16 (bit 0 = channel 1)

Word 2 Discrepancy errors, channels 17-32 (bit 0 = channel 17)

Issue 02 Feb 10 PD-8162 23

Page 24

TrustedTM CS300 Bridge Module

3.8. Module – pi626 / pi726 (digital output module)

DESCRIPTION

This definition will open a single PI626 or PI726.

OEM PARAMETERS

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis and slot number where the CIO_DO is located.

SLOT 1-15

PHYSICAL MODULE:

RACK 1: (DO)

32 BOOLEAN outputs

RACK 2: (DIAG)

2 INTEGER inputs

Word 1 Diagnostic bits

bit 0 Slice A

=1 slice is not responding or there is an error

=0 slice is responding

bit 1 Slice B

=1 slice is not responding or there is an error

=0 slice is responding

bit 2 Slice C

=1 slice is not responding or there is an error

=0 slice is responding

bit 3 Module offline or missing

=1 offline or missing

=0 online

bit 4 Single slot hot repair

=1 in progress

=0 not in progress

bit 5 Discrepancy errors

=1 faults detected

=0 no faults detected

bit 6 LFD faults

=1 faults detected

=0 no faults detected

Word 2 Slot number of active module

Issue 02 Feb 10 PD-8162 24

Page 25

TrustedTM CS300 Bridge Module

RACK 3: (FAULTS)

4 INTEGER inputs

Word 1 Discrepancy errors, channels 1-16 (bit 0 = channel 1)

Word 2 Discrepancy errors, channels 17-32 (bit 0 = channel 17)

Word 3 LFD errors, channels 1-16 (bit 0 = channel 1)

Word 4 LFD errors, channels 17-32 (bit 0 = channel 17)

NOTES:

Discrepancy errors will only be checked if the DO module has a configured DI monitor module.

Discrepancy errors indicate a difference between the output value on a DO and the voted input value

on the DI monitor.

Issue 02 Feb 10 PD-8162 25

Page 26

TrustedTM CS300 Bridge Module

3.9. Module – pi627 / pi727 / pi627_fs / pi727_fs (digital output module)

DESCRIPTION

This definition will open a single PI627 or PI727. If the module is configured as 3-2-1 then the ‘_fs’

version is required and the option must also be marked in the system configuration for this module.

OEM PARAMETERS

OEM parameter Valid numbers Description

CHASSIS 2-29 Logical chassis and slot number where the CIO_DO is located.

SLOT 1-15

PHYSICAL MODULE:

RACK 1: (DO)

32 BOOLEAN outputs

RACK 2: (DIAG)

2 INTEGER inputs

Word 1 Diagnostic bits

bit 0 Slice A

=1 slice is not responding or there is an error

=0 slice is responding

bit 1 Slice B

=1 slice is not responding or there is an error

=0 slice is responding

bit 2 Slice C

=1 slice is not responding or there is an error

=0 slice is responding

bit 3 Module offline or missing

=1 offline or missing

=0 online

bit 4 Single slot hot repair

=1 in progress

=0 not in progress

bit 5 Discrepancy errors

=1 faults detected

=0 no faults detected

bit 6 LFD faults

=1 faults detected

=0 no faults detected

Word 2 Slot number of active module

Issue 02 Feb 10 PD-8162 26

Page 27

TrustedTM CS300 Bridge Module

RACK 3: (FAULTS)

4 INTEGER inputs

Word 1 Discrepancy errors, channels 1-16 (bit 0 = channel 1)

Word 2 Discrepancy errors, channels 17-32 (bit 0 = channel 17)

Word 3 LFD errors, channels 1-16 (bit 0 = channel 1)

Word 4 LFD errors, channels 17-32 (bit 0 = channel 17)

NOTES:

Discrepancy errors will only be checked if the DO module has a configured DI monitor module.

Discrepancy errors indicate a difference between the output value on a DO and the voted input value

on the DI monitor.

Issue 02 Feb 10 PD-8162 27

Page 28

TrustedTM CS300 Bridge Module

3.10. Module – dmx_m (de-multiplexed display driver)

DESCRIPTION

This definition will open a single TM117-DMX Master.

OEM PARAMETERS

OEM parameter Valid numbers Description

PORT_A 1-3 MP serial port number for the DMX chain primary link

PORT_B 0 or 2/3 MP serial port number for the DMX chain secondary link (=0 disables

the secondary link)

PHYSICAL MODULE:

RACK 1: (DMX)

1 BOOLEAN output

not used

NOTES:

The dmx_m module must be defined before the dmx_o modules.

Issue 02 Feb 10 PD-8162 28

Page 29

TrustedTM CS300 Bridge Module

3.11. Module – dmx_o (de-multiplexed display driver card)

DESCRIPTION

This definition will open a single TM117-DMX output card.

OEM PARAMETERS

OEM parameter Valid numbers Description

DMX_BOARD_ID 1-64 DMX board ID

PHYSICAL MODULE:

RACK 1: (DMX)

64 INTEGER outputs

Valid values:

0 = Off

1 = Slow flash on/off

2 = Fast flash on/off

3 = On (steady)

4+ = Invalid (will result in output being off)

NOTES:

The dmx_m module must be defined before the dmx_o modules.

Issue 02 Feb 10 PD-8162 29

Page 30

TrustedTM CS300 Bridge Module

4. Operation

Figure 16 Front Panel Layout

Issue 02 Feb 10 PD-8162 30

Page 31

TrustedTM CS300 Bridge Module

4.1. Front Panel Indicators and Controls

4.1.1. Tx & Rx Indicators

Flashing amber LEDs indicate active transmit and receive communications on the Expander Bus.

4.1.2. Health Indicator

A steady green LED indicates a fault-free Bridge module; an extinguished LED indicates a fault.

4.1.3. On-Line Indicator and Switch

Raising and releasing the on/off-line switch momentarily takes the module off-line, which is mirrored by

the steady On/Off state of the amber On-Line LED. Repeating the action brings the module back online.

Prior to hot-swapping the module for repair, it should be taken off-line using this feature to ensure a

clean exit from the system. The replacement module is then placed on-line using the switch.

Issue 02 Feb 10 PD-8162 31

Page 32

TrustedTM CS300 Bridge Module

5. Fault Finding and Maintenance

The TrustedTM TMR Processor provides fault monitoring, self test and diagnostics functions.

M

T

Fault Detection within a Trusted

M

Trusted

T

TMR Processor and Expander Hardware

CS300 Bridge Hardware

CS300 I/O Hardware

User Application

TM

Using current Trusted

methods for detection of faults, the TMR Processor can monitor for failures up

to the Expander section. The MP is also able to separate Bridge hardware faults from CS300 I/O

module faults. The CS300 I/O modules carry out on-board diagnostic tests which are relayed back to

the TMR Processor via the Bridge module.

The user application can also be programmed to read error flags in the I/O module fault registers to

annunciate the detection of module faults. Second faults that leave the system unable to confirm

healthy operation will result in the TMR Processor stopping all communication with the 8162 bridge

modules, ensuring that critical outputs go to a safe state when the internal watchdogs time out.

/ CS300 system can be categorised into four regions –

Issue 02 Feb 10 PD-8162 32

Page 33

TrustedTM CS300 Bridge Module

6. Specifications

Supply Voltage 5.4Vdc ± 5%

Heat Dissipation 3W max

Operating Temperature (convection cooling) 0°C to 60ºC (32°F to 140°F)

Storage Temperature -40°C to 100ºC (-40°F to 212°F)

Operating Humidity 5 to 95% RH, non-condensing

Vibration 10 to 500 Hz peak to peak 1g

Shock Operating:11ms, ½ sine wave 15g

Electromagnetic Interference:

IEC 801 Part 2 Electrostatic Discharges Contact discharge to 6kV

IEC 801 Part 3 – Radiated Electromagnetic Fields 10V/m, 27MHz to 500Mh

IEC 801 Part 4 - Transients and Bursts 2kV, 2.5kHz for t=60 seconds

Height: 290 mm (11.4 ins)

Width: 37 mm (1.5 ins)

Depth: 370 mm (14.6 in)

Weight (approx) 760g (1.7 lbs.)

Issue 02 Feb 10 PD-8162 33

Page 34

Trusted

TM

PD-8162

Issue 02 Feb 10 PD-8162 34

Loading...

Loading...