Page 1

ControlLogix 5580 Redundant

Controller

For Use in High Availability Systems

User Manual

Original Instructions

Page 2

ControlLogix 5580 Redundant Controller User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

ControlLogix 5580 High

Availability Systems

Configure the Redundancy

System

Features of the ControlLogix 5580 High Availability System . . . . . . . . . 12

Controller Keyswitch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Redundancy System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

I/O Modules in Redundancy Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Fiber-optic Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Use Dual Fiber Ports with the 1756-RM2 Redundancy Module . . . . 15

Redundancy System Operations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

System Qualification and Synchronization. . . . . . . . . . . . . . . . . . . . . 17

Switchovers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Download the Redundancy Firmware Bundle. . . . . . . . . . . . . . . . . . . . . . 22

Install the Firmware Bundle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Install the Redundancy Module Configuration Tool . . . . . . . . . . . . . . . . 22

Install the Redundancy System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Configure Redundant Firmware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Upgrade the Firmware in the First Chassis . . . . . . . . . . . . . . . . . . . . . 24

Upgrade the Firmware in the Second Chassis . . . . . . . . . . . . . . . . . . 25

Set the initial Primary and Secondary Chassis . . . . . . . . . . . . . . . . . . . . . 25

After Designation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Conversion from a Non-redundant to a Redundant System. . . . . . 26

Qualification Status Via the RMCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Reset the Redundancy Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Remove or Replace the Redundancy Module . . . . . . . . . . . . . . . . . . . 28

Configure the EtherNet/IP

Network

Chapter 3

Requested Packet Interval (RPI) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

IP Address Swapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Static Versus Dynamic IP Addresses. . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Reset the IP Address for an EtherNet/IP Communication Module 32

CIP Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Produce/Consume Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 3

Page 4

Table of Contents

Configure EtherNet/IP Communication Modules in a Redundant

System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Options for Setting the IP Addresses of EtherNet/IP

Communication Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Half/Full Duplex Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Use a Redundancy System with Device Level Ring. . . . . . . . . . . . . . . . . . 38

Use a Redundancy System with Parallel Redundancy Protocol. . . . . . . 38

Chapter 4

Configure the Redundancy

Modules

Configure the Redundant

Controller

Determine If Further Configuration Is Required . . . . . . . . . . . . . . . . . . . 40

Configure the Redundancy Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Identify the RMCT Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Module Info Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Auto-synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chassis ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

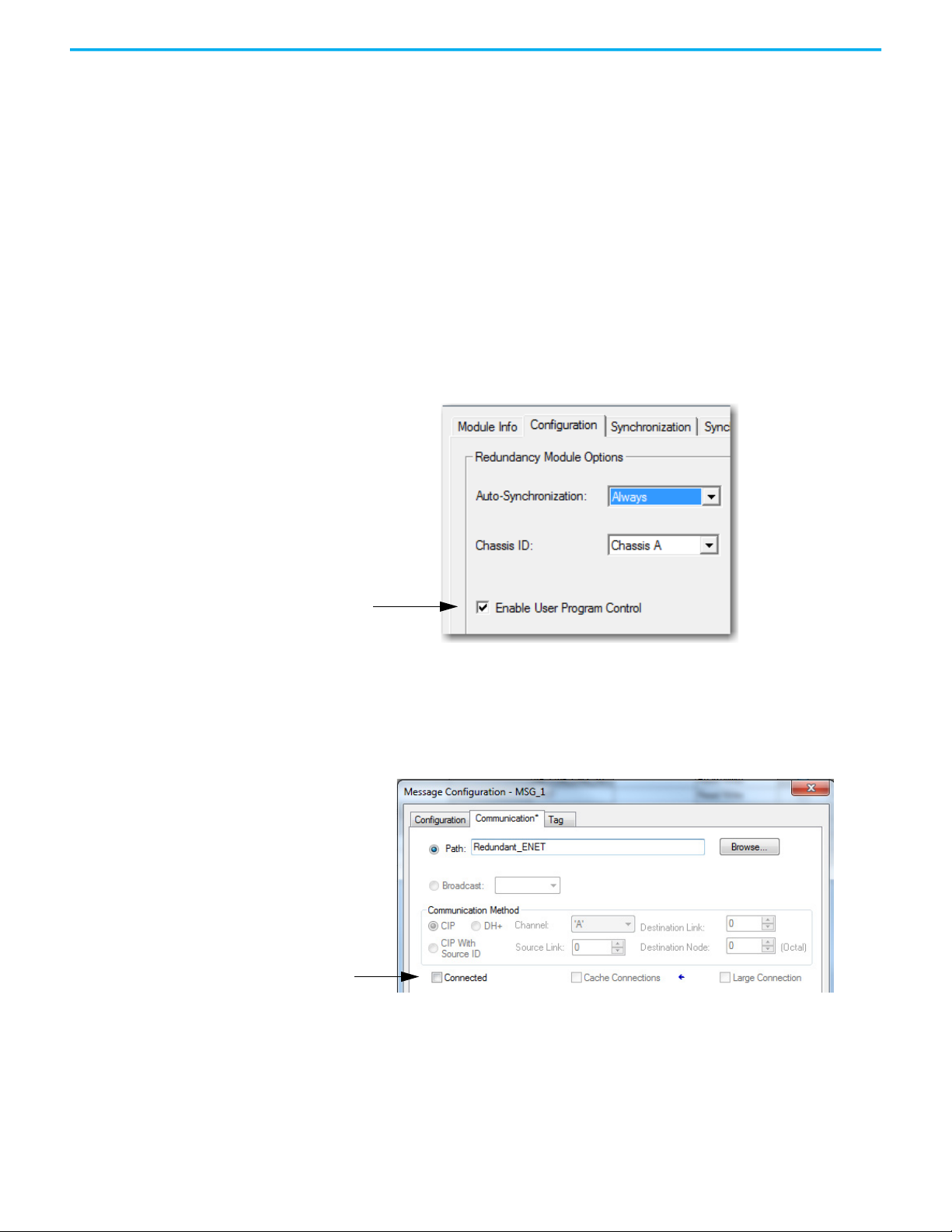

Enable User Program Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Redundancy Module Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

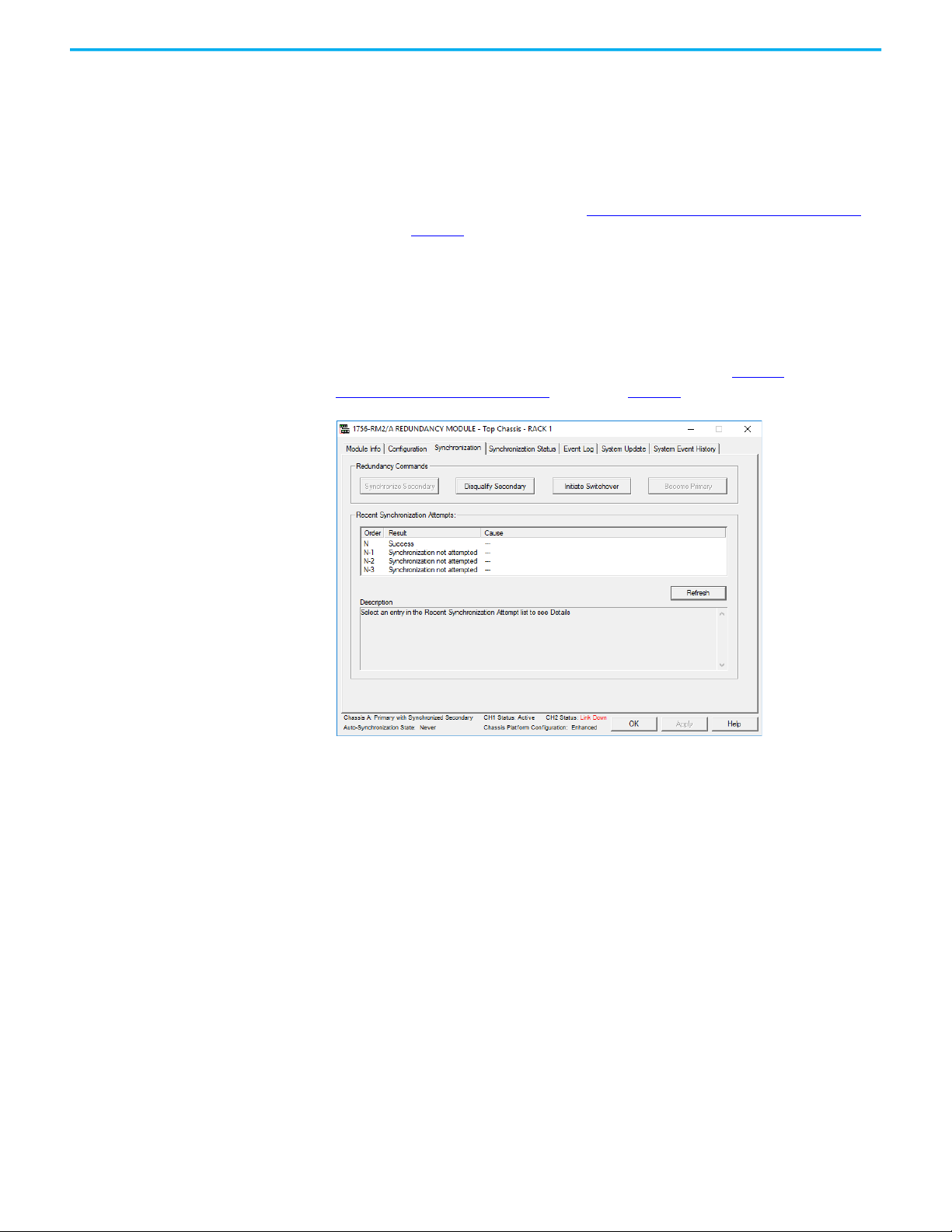

Synchronization Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Commands in the Synchronization Tab. . . . . . . . . . . . . . . . . . . . . . . . 48

Recent Synchronization Attempts Log . . . . . . . . . . . . . . . . . . . . . . . . . 48

Synchronization Status Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

System Update Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

System Update Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

System Update Lock Attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Locked Switchover Attempts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Chapter 5

Configure the Redundant Controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Enable Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

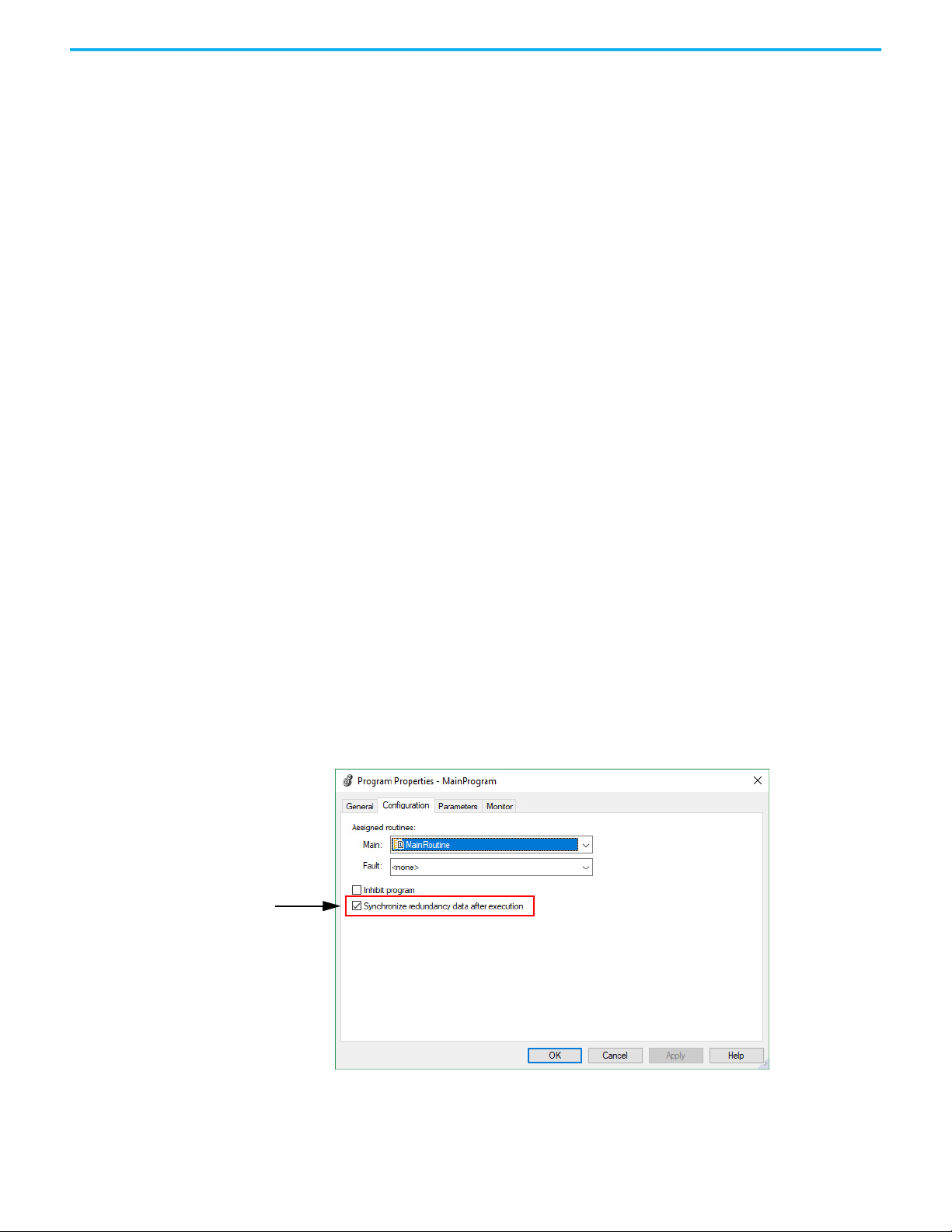

Crossloads, Synchronization, and Switchovers. . . . . . . . . . . . . . . . . . . . . 61

Changing Crossload and Synchronization Settings . . . . . . . . . . . . . 61

Default Crossload and Synchronization Settings . . . . . . . . . . . . . . . 62

Recommended Task Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Continuous Task After Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Multiple Periodic Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Crossloads and Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Estimate the Crossload Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Redundancy Object Attributes for Crossload Times . . . . . . . . . . . . . 66

Equation for Estimating Crossload Times. . . . . . . . . . . . . . . . . . . . . . 67

Set the Task Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Minimum Value for the Watchdog Time . . . . . . . . . . . . . . . . . . . . . . . 69

4 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 5

Table of Contents

Chapter 6

Programming Best Practices Program to Minimize Scan Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Minimize the Number of Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

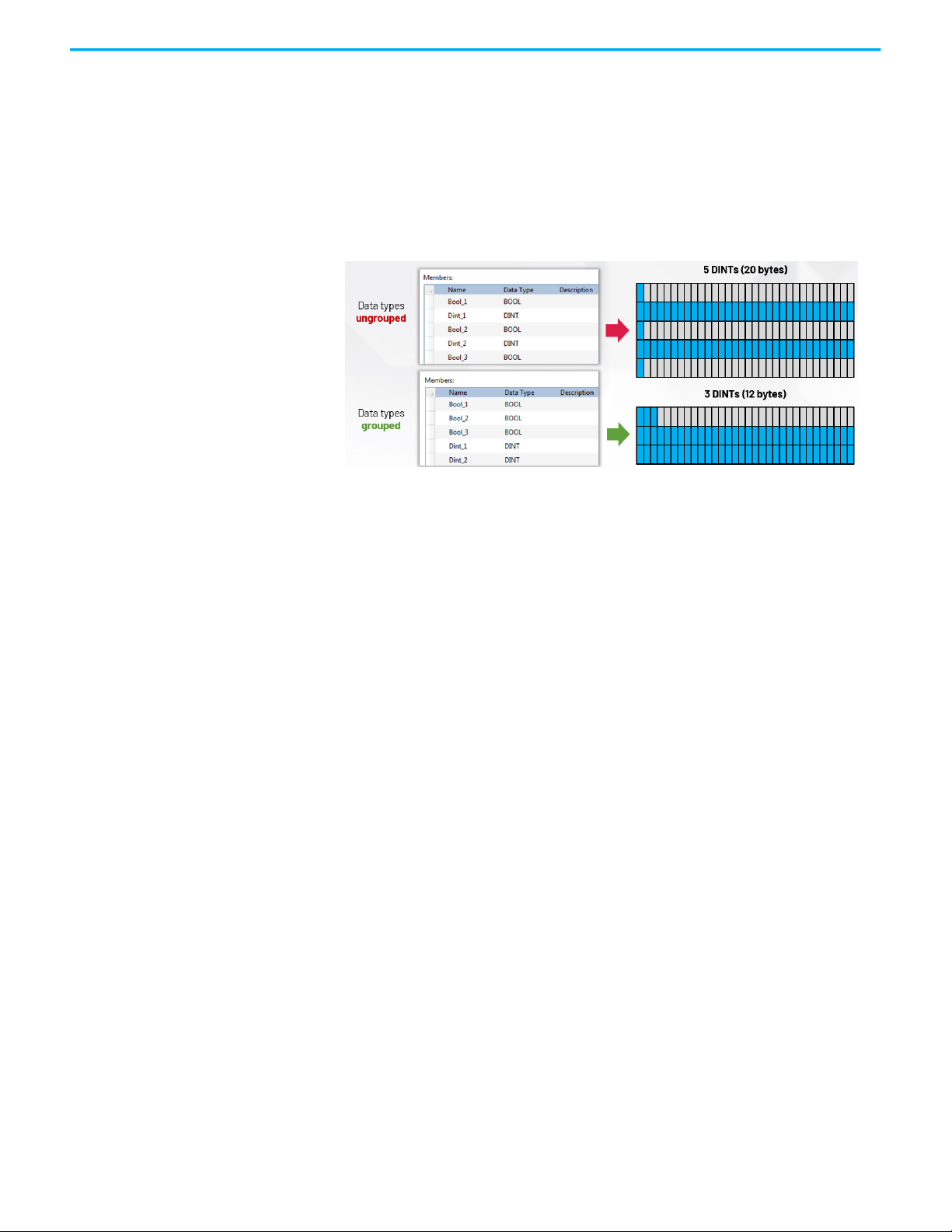

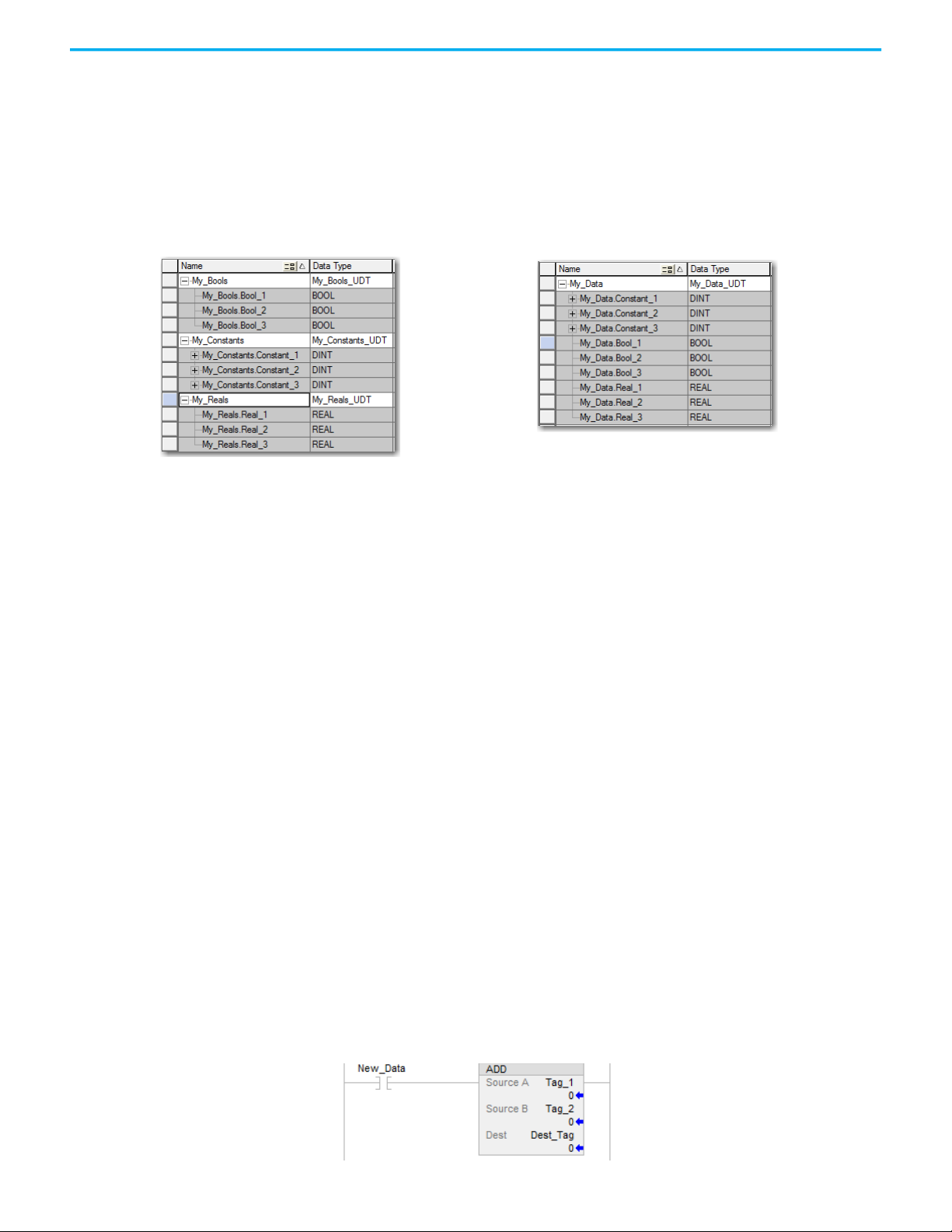

Manage Tags for Efficient Crossloads . . . . . . . . . . . . . . . . . . . . . . . . . 73

Use Concise Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Program to Maintain Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Timer Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

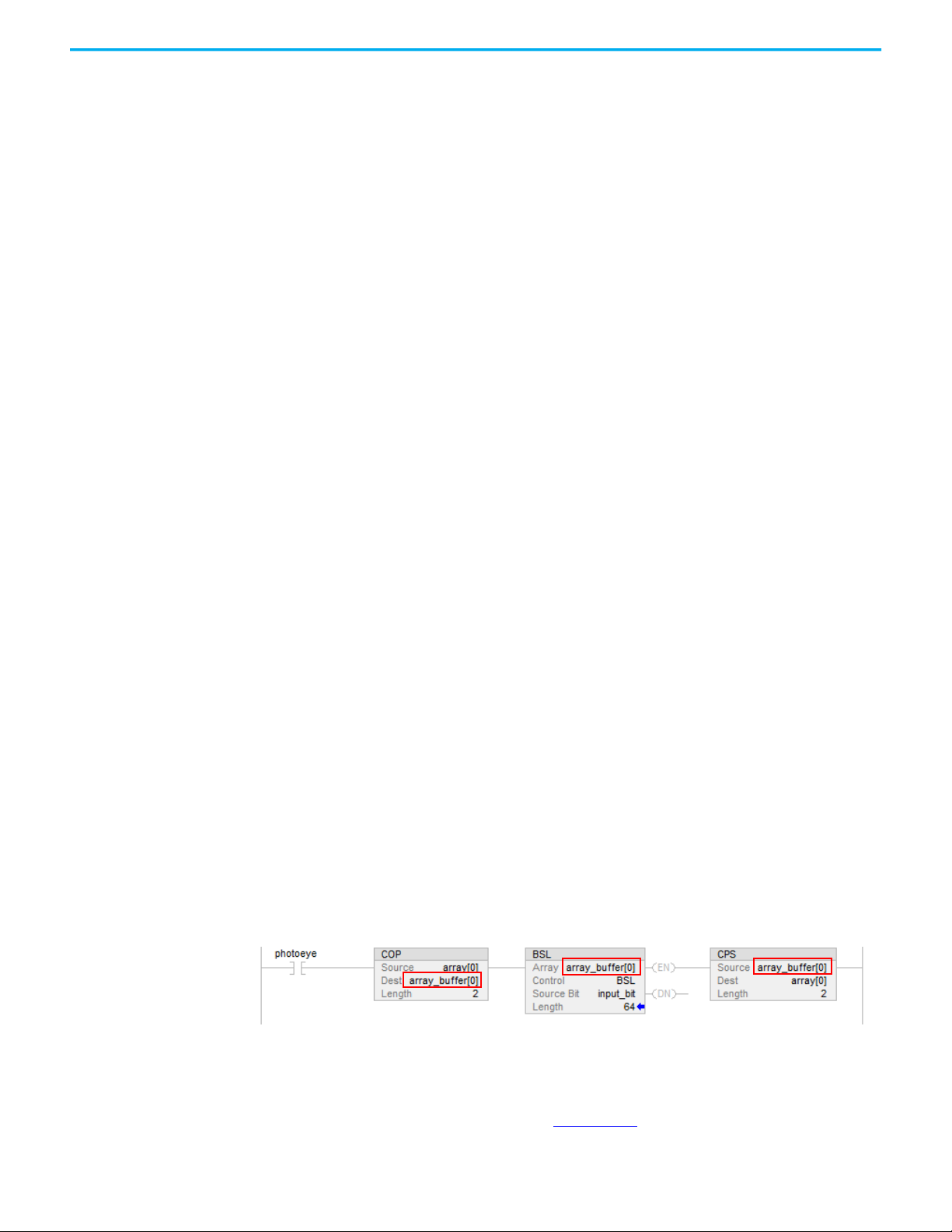

Array (File)/Shift Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

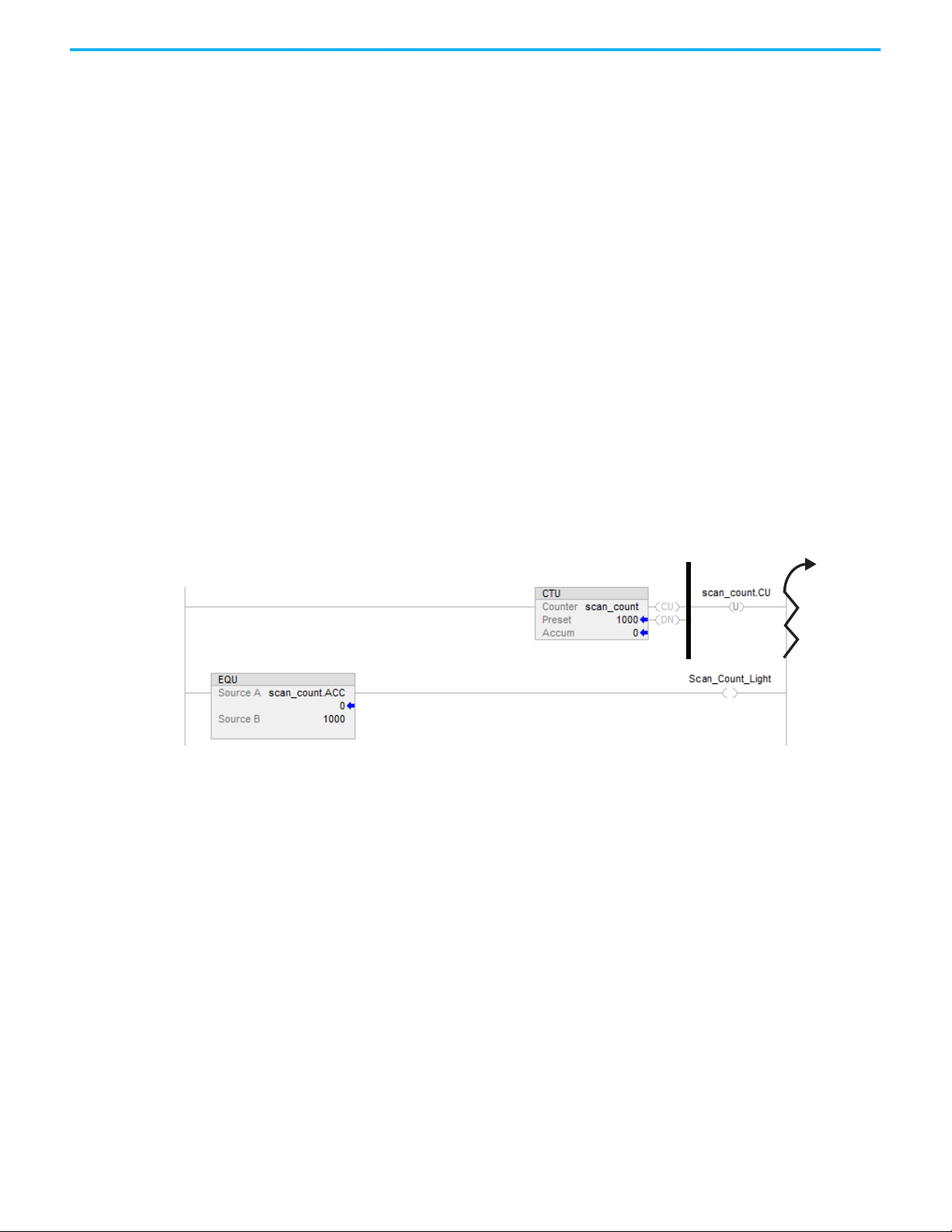

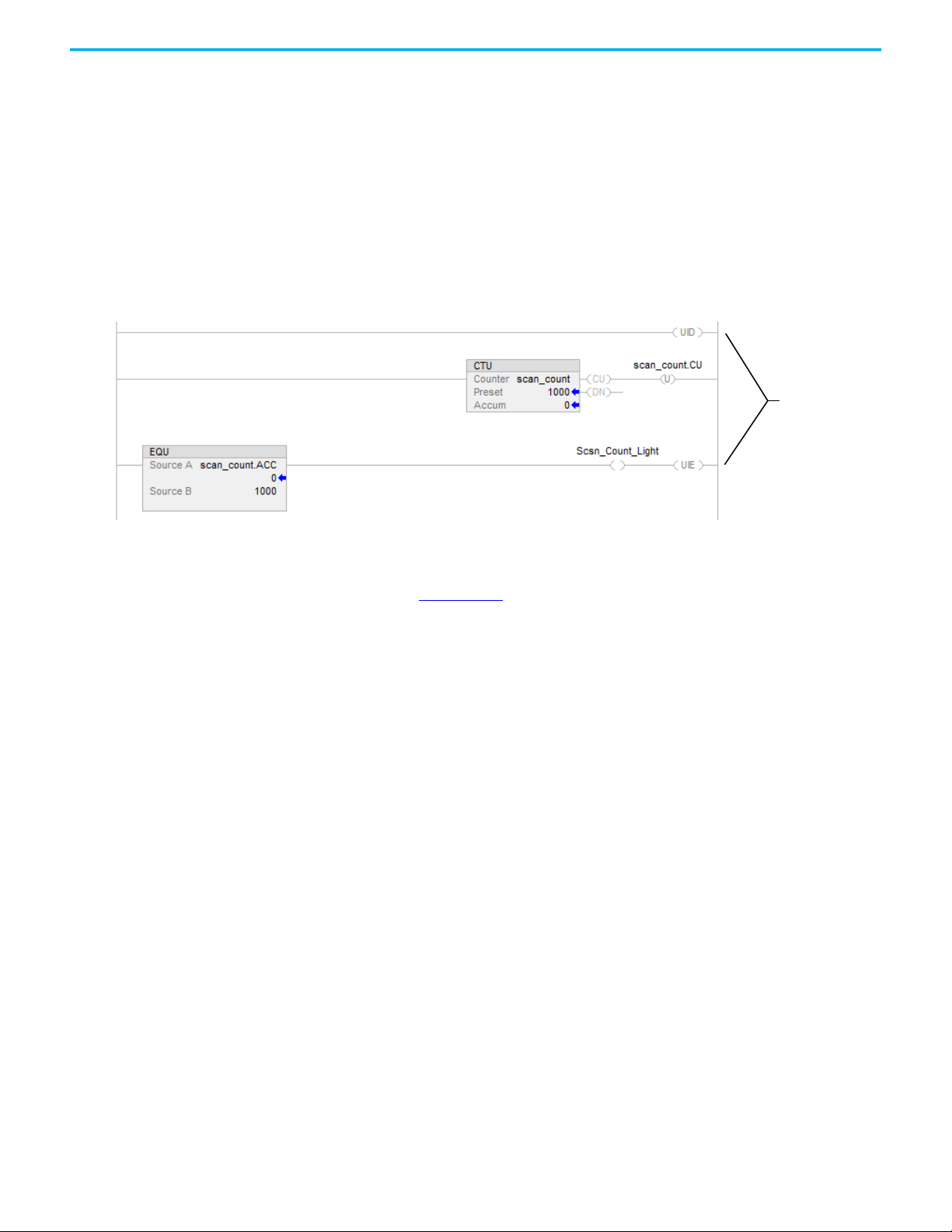

Scan-dependent Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Optimize Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Programming Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Data Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

SSV Instruction Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Communications Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Programed-scoped Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Redundant System Update (RSU) Operation . . . . . . . . . . . . . . . . . . . 82

Instruction Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Alarms. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

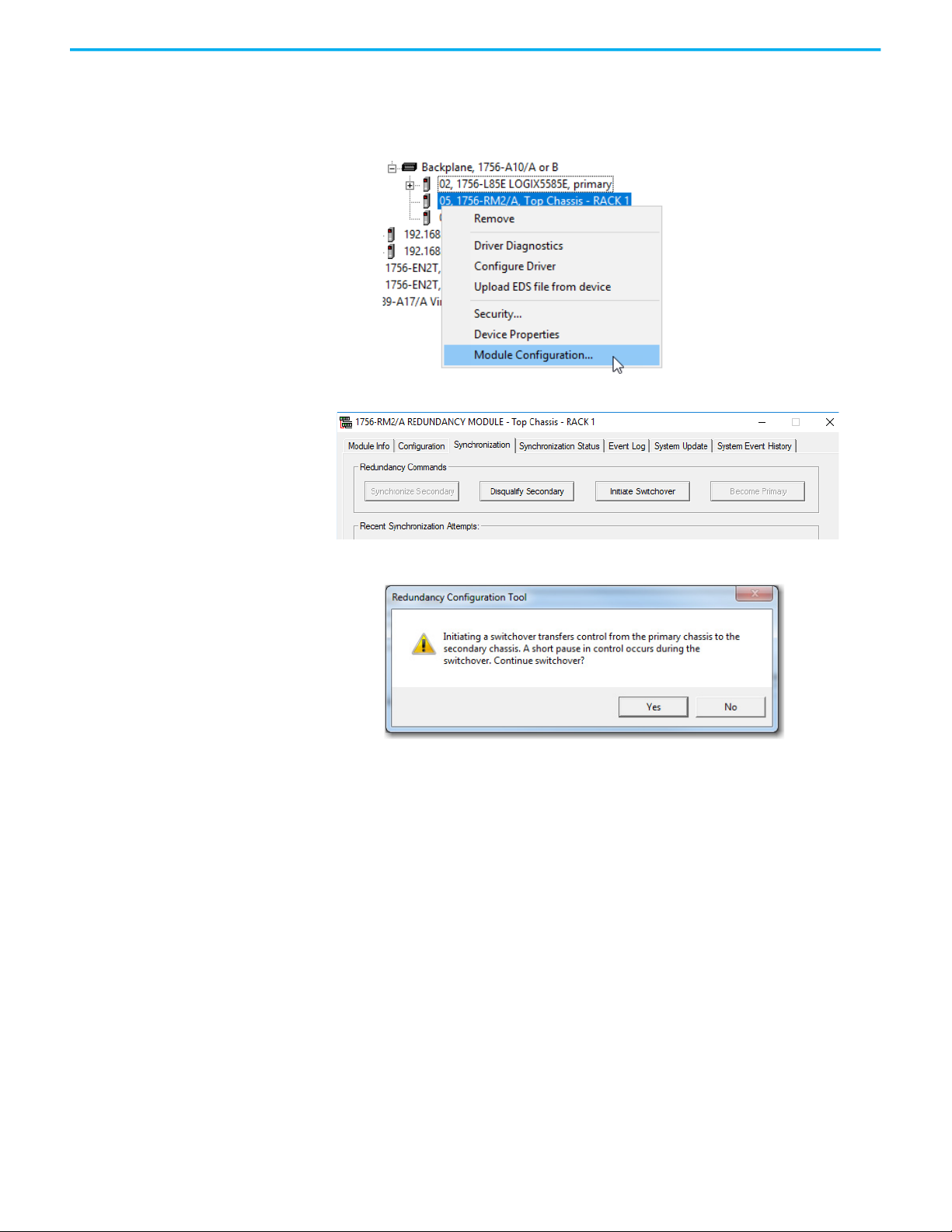

Conduct a Test Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Synchronization After a Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Program Logic to Run After a Switchover. . . . . . . . . . . . . . . . . . . . . . . . . . 86

Use Messages for Redundancy Commands . . . . . . . . . . . . . . . . . . . . . . . . 87

Verify User Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Use an Unconnected Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configure the MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

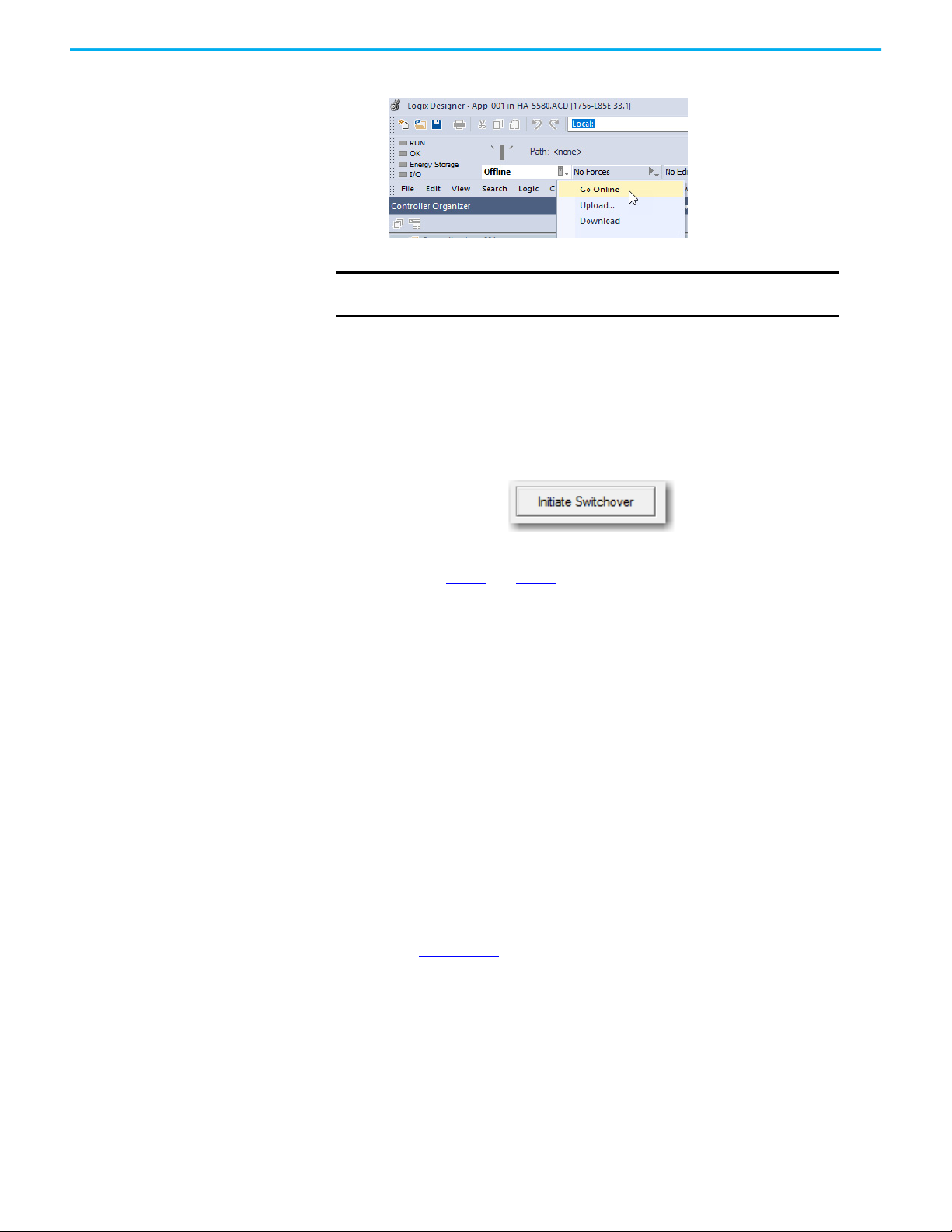

Download the Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Store a Redundancy Project to Nonvolatile Memory . . . . . . . . . . . . . . . . 91

Store a Project While the Controller is in Program or Remote

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Store a Project While a System is Running . . . . . . . . . . . . . . . . . . . . . 92

Load a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Online Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Partial Import Online (PIO). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

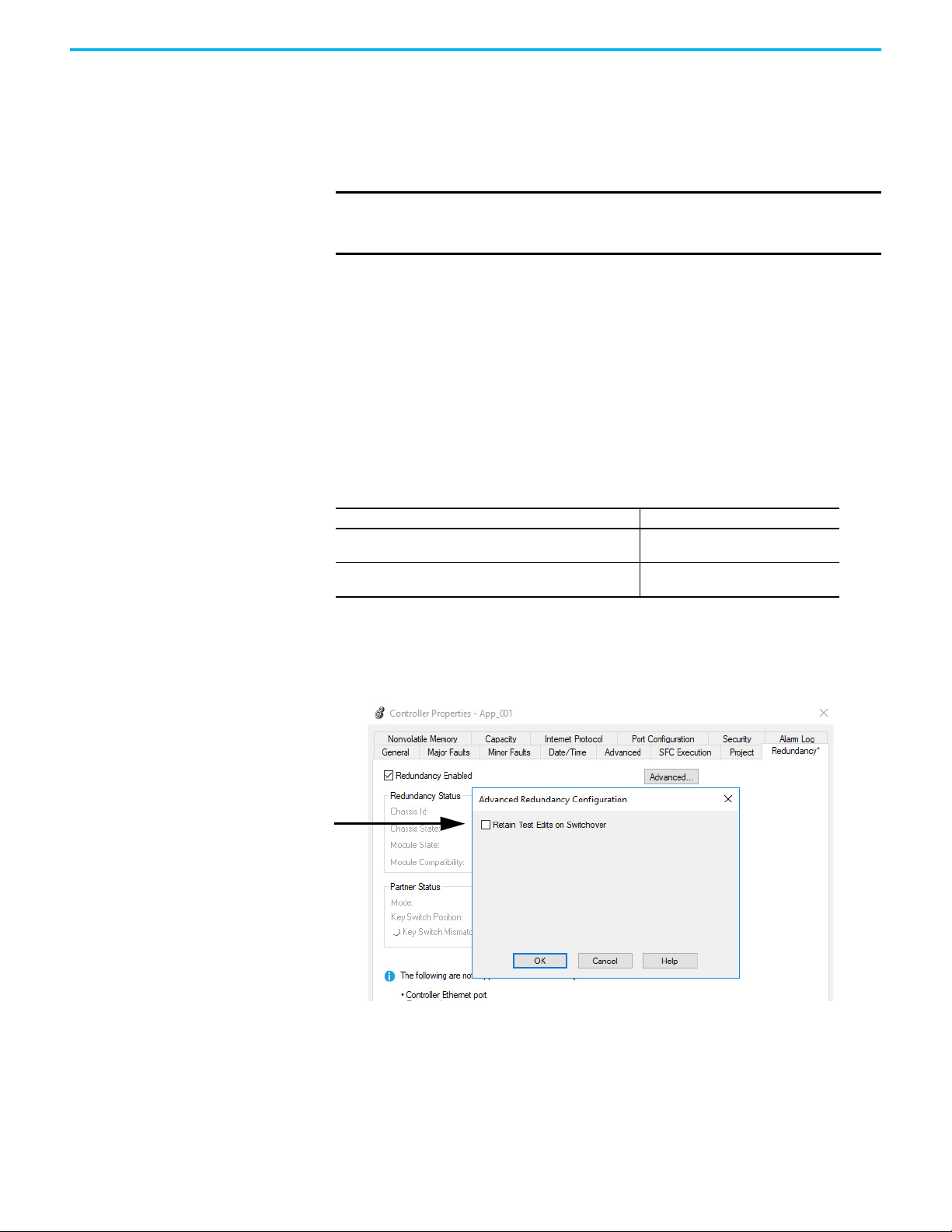

Plan for Test Edits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Assemble Edits with Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Monitor and Maintain a

Redundancy System

Chapter 7

Controller Logging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Controller Log. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Controller Logging in Redundancy Systems . . . . . . . . . . . . . . . . . . . 100

Component Change Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Monitor System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Verify Date and Time Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

Verify System Qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Check Qualification Status Via Module Status Displays . . . . . . . . 103

Check Qualification Status Via the RMCT . . . . . . . . . . . . . . . . . . . . . 105

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 5

Page 6

Table of Contents

Troubleshoot a Redundant

System

Check the EtherNet/IP Module Status. . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

CPU Usage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Connections Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

Chapter 8

General Troubleshooting Steps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Check the Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Use Programming Software to View Errors. . . . . . . . . . . . . . . . . . . . . . . 109

Redundant Controller Major Fault Codes . . . . . . . . . . . . . . . . . . . . . . 111

Use the RMCT for Synchronization Attempts and Status. . . . . . . . . . . . 111

Recent Synchronization Attempts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 111

Module-level Synchronization Status . . . . . . . . . . . . . . . . . . . . . . . . . 112

Use the RMCT Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Controller Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Event Classifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Access Extended Information about an Event . . . . . . . . . . . . . . . . . 116

Interpret Extended Information for an Event . . . . . . . . . . . . . . . . . 117

Interpret Event Log Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Export Event Log Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Export Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Contact Rockwell Automation Technical Support . . . . . . . . . . . . . . 127

Clear a Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

System Event History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

System Event History Column Descriptions. . . . . . . . . . . . . . . . . . . 129

Edit a User Comment for a System Event . . . . . . . . . . . . . . . . . . . . . 130

Save System Event History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Event Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Partner Network Connection Lost . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Redundancy Module Connection Lost. . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Redundancy Module Missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Qualification Aborted Due to a Non-redundant Controller . . . . . . . . . 136

Redundancy Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 138

1756-RM2 and 1756-RM2XT Status Indicators. . . . . . . . . . . . . . . . . . 138

Redundancy Module Fault Codes and Display Messages. . . . . . . . 141

Recovery Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Appendix A

Convert from a Non-redundant

System

Update the Configuration in Programming Software. . . . . . . . . . . . . . 144

Replace Local I/O Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Replace Aliases to Local I/O Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 147

Remove Other Modules from the Controller Chassis. . . . . . . . . . . . . . . 148

Add an Identical Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Upgrade to Redundancy Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Update the Controller Revision and Download the Project . . . . . . . . . 148

Appendix B

Redundancy Object Attributes Table of Redundancy Object Attributes. . . . . . . . . . . . . . . . . . . . . . . . . . . 149

6 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 7

Table of Contents

Appendix C

Redundancy System Checklists Chassis Configuration Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Remote I/O Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Redundancy Module Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

ControlLogix Controller Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

EtherNet/IP Module Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Project and Programming Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Appendix D

Online Firmware Update

Considerations

Module Replacement

Considerations

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

RSU Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Redundancy System Update Migration Paths . . . . . . . . . . . . . . . . . 156

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Verify Your Redundancy Module Configuration Tool (RMCT)

Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Prepare the Controller Project for the Update . . . . . . . . . . . . . . . . . . . . . 158

Update the Redundancy System Firmware . . . . . . . . . . . . . . . . . . . . . . . 159

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Prepare the Redundant Chassis for the Firmware Update. . . . . . . 160

Update the Redundancy Module Firmware in the

Primary Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Update Redundancy Module Firmware and Other

Module Firmware in the Secondary Chassis . . . . . . . . . . . . . . . . . . . 162

Lock the System and Initiate a Switchover to Update. . . . . . . . . . . 163

Update the New Secondary Chassis Firmware . . . . . . . . . . . . . . . . . 165

Synchronize the Redundant Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . 165

EDS Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Appendix E

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 169

Replace a Module in the Secondary Chassis That Has the

Same Catalog Number and Firmware Revision . . . . . . . . . . . . . . . . . . . 170

Replace an EtherNet/IP Module with a New Series . . . . . . . . . . . . . . . . 171

Synchronization and Switchover for EtherNet/IP Modules . . . . . 171

Replace a 1756-RM2 Module with a 1756-RM2 Module . . . . . . . . . . . . . . 174

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 7

Page 8

Table of Contents

Notes:

8 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 9

Preface

Catalog Numbers

This publication applies to these controllers:

• 1756-L81E, 1756-L81EK,1 756-L81E-NSE, 1756-L81EXT, 1756-L81EP

• 1756-L82E, 1756-L82EK, 1756-L82E-NSE, 1756-L82EXT

• 1756-L83E, 1756-L83EK, 1756-L83E-NSE, 1756-L83EXT, 1756-L83EP

• 1756-L84E, 1756-L84EK, 1756-L84E-NSE, 1756-L84EXT

• 1756-L85E, 1756-L85EK, 1756-L85E-NSE, 1756-L85EXT, 1756-L85EP

Summary of Changes This manual contains new and updated information. This list includes

substantive updates only and is not intended to reflect all changes.

Top ic Pa ge

Added Online Firmware Update Considerations. 155

Added Module Replacement Considerations. 169

Overview This publication provides information specific to ControlLogix 5580 high

availability systems:

• Installation procedures

• Configuration procedures

• Maintenance and troubleshooting methods

This publication is designed for use by anyone responsible for planning and

implementing a ControlLogix® redundancy system:

• Application engineers

• Control engineers

• Instrumentation technicians

The contents of this publication are for anyone who already has an

understanding of Logix 5000™ control systems, programming techniques, and

communication networks.

Additional Resources These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

High Availability System Reference Manual, publication HIGHAV-RM002

ControlLogix 5580 and GuardLogix 5580 Controllers User Manual, publication 1756-

UM543

ControlLogix 5580 Controllers Installation Instructions, publication 1756-IN043

ControlLogix Redundancy Modules Installation Instructions, publication 1756-IN087

1756 EtherNet/IP Communication Modules Installation Instructions,

publication 1756-IN050

ControlLogix Power Supply Installation Instructions, publication 1756-IN619

ControlLogix Redundant Power Supply Installation Instructions, publication 1756-IN620

ControlLogix Chassis Installation Instructions, publication 1756-IN621

Provides information to help design and plan high availability systems.

Provides information on how to configure, select I/O modules, manage

communication, develop applications, and troubleshoot the ControlLogix 5580

controllers.

Describes how to install ControlLogix 5580 controllers.

. Describes how to install ControlLogix redundancy modules.

Describes how to install ControlLogix EtherNet/IP communication modules.

Describes how to install standard power supplies.

Describes how to install redundant power supplies.

Describes how to install ControlLogix chassis.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 9

Page 10

Preface

Resource Description

1715 Redundant I/O System Specifications Technical Data, publication 1715-TD001 Contains specifications on a Redundant I/O system.

1756 ControlLogix Controllers Technical Data, publication 1756-TD001

ControlFLASH Plus Quick Start Guide, publication CFP-QS001C-EN-E

ControlLogix System Selection Guide, publication 1756-SG001 Provides information on how to select components for a ControlLogix system.

EtherNet/IP Parallel Redundancy Protocol Application Technique, publication ENET-

AT0 06

EtherNet/IP Device Level Ring Application Technique, publication ENET-AT007

EtherNet/IP Socket Interface Application Technique, publication ENET-AT002

EtherNet/IP Network Configuration User Manual, publication ENET-UM006

Integrated Architecture and CIP Sync Configuration Application Technique,

publication IA-AT003

Logix 5000 Controllers Common Procedures Programming Manual,

publication 1756-PM001

Logix 5000 Controllers General Instructions Reference Manual, publication 1756-RM003

PlantPAx Process Automation System Reference Manual, publication PROCES-UM001

Redundant I/O System User Manual, publication 1715-UM001

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications

. Provides declarations of conformity, certificates, and other certification details.

Contains specifications on ControlLogix controllers and redundancy modules.

Describes how to use the ControlFLASH Plus™ software to upgrade device

firmware.

Describes how to configure a Parallel Redundancy Protocol (PRP) network with the

1756-EN2TP EtherNet/IP™ communication module and a Stratix® 5400 or 5410

switch.

Describes how to install, configure, and maintain linear and Device Level Ring

(DLR) networks that use Rockwell Automation® EtherNet/IP devices with

embedded switch technology.

Logix 5000Describes the socket interface that you can use to program MSG

instructions to communicate between a Logix 5000 controller via an EtherNet/IP

module and Ethernet devices that do not support the EtherNet/IP application

protocol.

Describes how to use EtherNet/IP communication modules with your Logix 5000

controller and communicate with various devices on the Ethernet network.

Provides an explanation of CIP Sync™ technology and how you can synchronize

clocks within the Rockwell Automation Integrated Architecture®.

Provides links to a collection of programming manuals that describe how to use

procedures that are common to all Logix 5000 controllers projects.

This manual provides details about each available instruction for a Logix-based

controller.

Elaborates on the application rules that are required to configure a PlantPAx®

system.

Contains information on how to install, configure, program, operate, and

troubleshoot a Redundant I/O system.

You can view or download publications at rok.auto/literature.

10 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 11

Chapter 1

Catalyst 9300 24S

Catalyst 9300 24S

NE

-NM-2Q

Catalyst 9300 24S

ControlLogix 5580 High Availability Systems

Top ic Pa ge

Features of the ControlLogix 5580 High Availability System 12

Controller Keyswitch 13

Redundancy System Components 14

Fiber-optic Cable 15

Redundancy System Operations 17

Restrictions 19

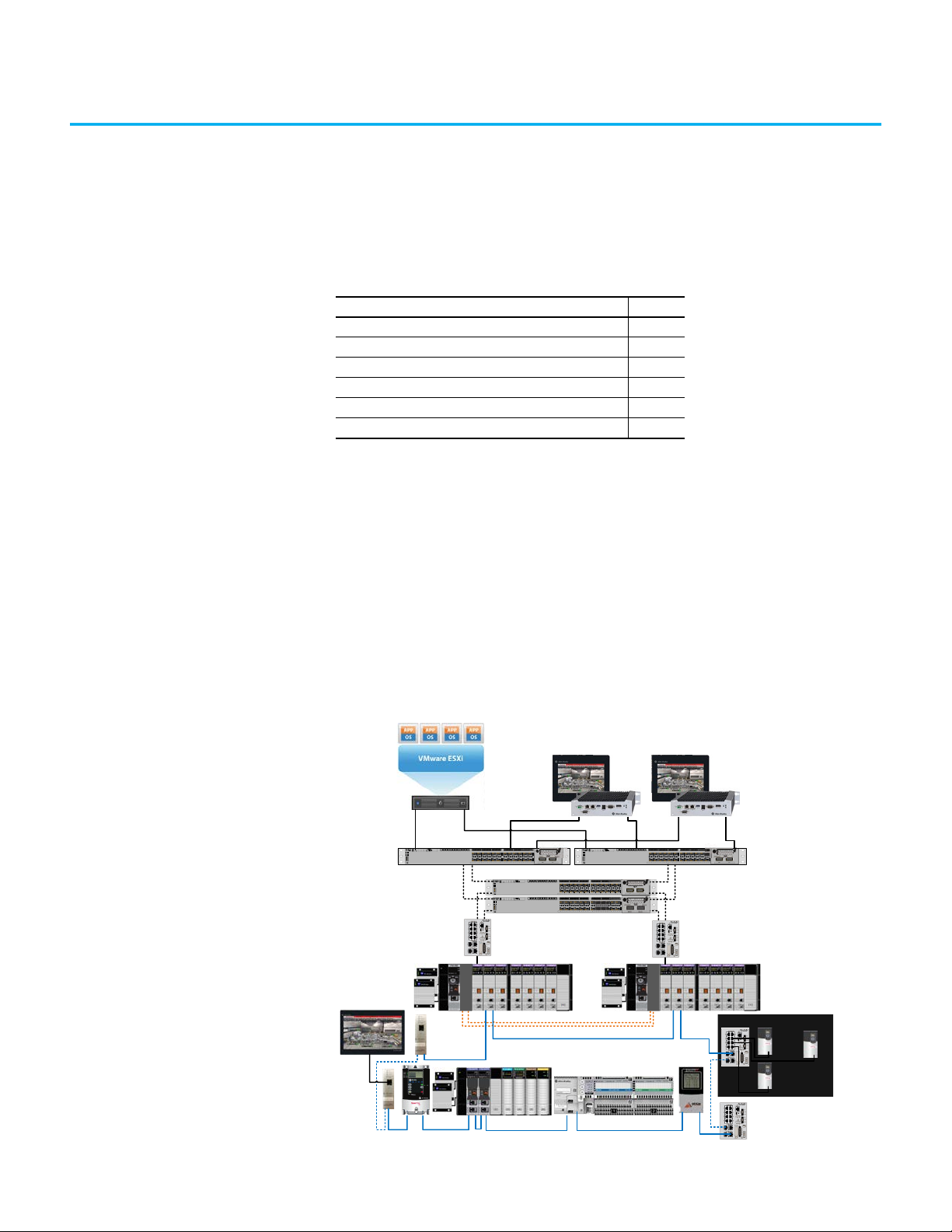

The ControlLogix® 5580 high availability system uses a redundant chassis pair

to maintain process operation when events occur that stop process operation

on non-redundant systems, such as a fault on a controller.

The redundant chassis pair includes two synchronized ControlLogix chassis

with specific, identical components in each. For example, one redundancy

module and at least one EtherNet/IP™ communication module are required.

Controllers are typically used in redundancy systems, but are not required if

your application only requires communication redundancy. Your application

operates from a primary chassis, but can switch over to the secondary chassis

and components if necessary.

NETWOR

2Q

40G 1

01 12 13 24

40G 2

01 12 13 24

01 12 13 24

NETWORK MODULE

Catalyst 9300 24S

NET

01 12 13 24

C9300-NM-2Q

40G 1

40G 2

2Q

40G 1

40G 2

40G 1

40G 2

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 11

Page 12

Chapter 1 ControlLogix 5580 High Availability Systems

Features of the ControlLogix 5580 High Availability System

The software and hardware components that are required to configure and use

a ControlLogix 5580 high availability system provide these features:

• All non-safety ControlLogix 5580 controller catalog numbers are

supported.

• ControlLogix 5580 redundant controllers use the same controller

firmware revision as standard controllers.

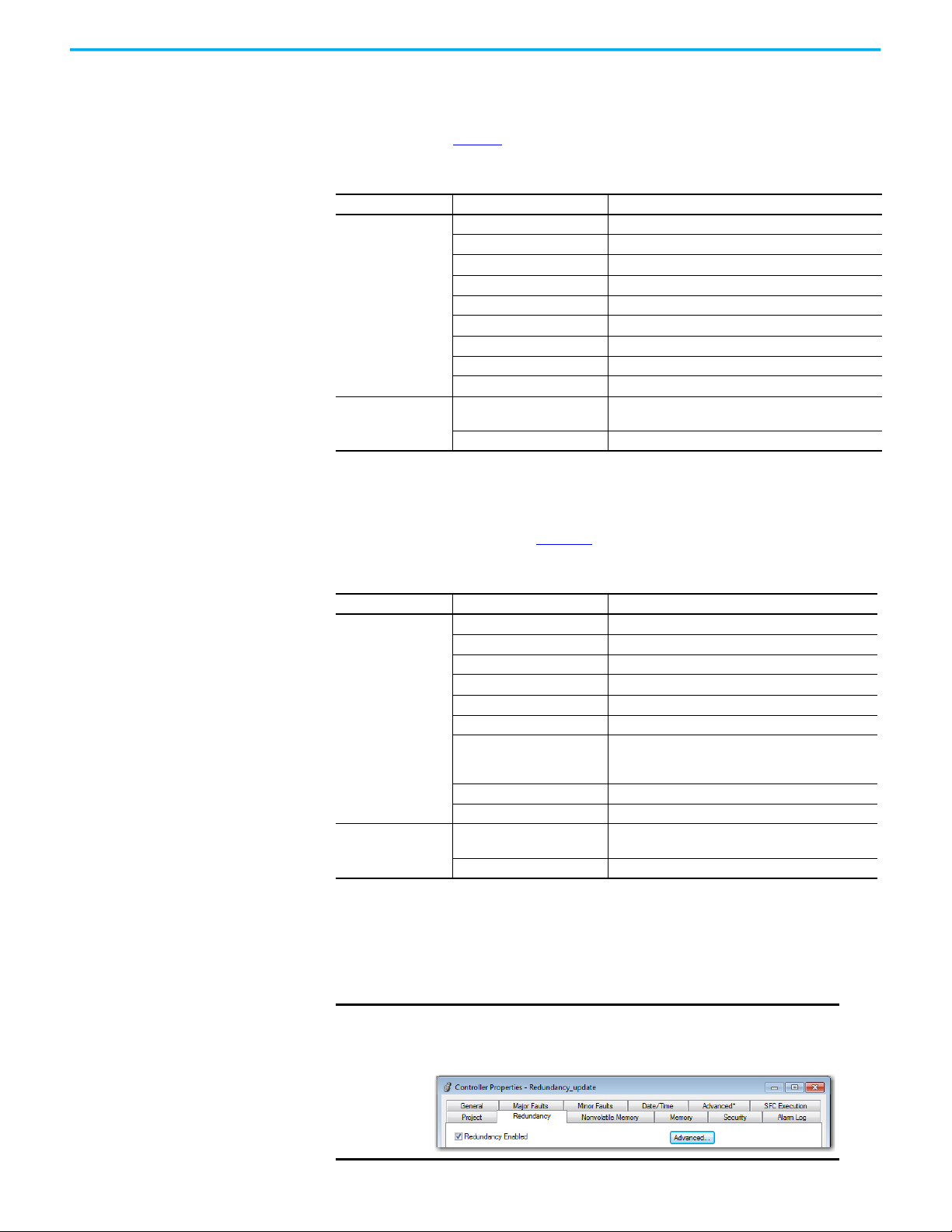

• Configure a redundant controller with a checkbox on the Controller

Properties dialog box in Studio 5000 Logix Designer application

software.

• Partnered sets of 1756-RM2 modules can reach speeds as fast as

1000 Mbps.

• Redundant fiber ports for crossloading; no single point of failure of a

fiber cable.

• Plug-and-play-style commissioning and configuration that does not

require extensive programming.

• Support for produced unicast connections.

• EtherNet/IP network for the redundant chassis pair.

• Support for Device-level Ring (DLR) and Parallel Redundancy Protocol

(PRP) networks.

• Easy-to-use, fiber-optic communication cable that connects redundant

chassis pairs.

• A redundancy system ready to command and monitor the redundant

system states after basic installation, connection, and powerup.

• Switchovers occur as fast as 20 ms.

• Support for FactoryTalk® applications for Ethernet communication

modules including, but not limited to:

- FactoryTalk Alarms and Events

- FactoryTalk Batch

- FactoryTalk PhaseManager™

• Logix tag-based alarms considerations:

- ControlLogix 5580 controllers support up to 7500 Logix tag-based

alarms per software guidelines.

• Logix instruction-based alarms considerations:

- ControlLogix 5580 controllers support up to 3000 Logix instruction-

based alarms with 3000 burst.

• Support for CIP Sync™ technology over an EtherNet/IP network to

establish time coordination across the redundant system.

• Access to remote I/O modules over an EtherNet/IP network.

• Access to 1715 Redundant I/O systems over an EtherNet/IP network.

• Supports FLEX 5000 I/O.

• Supports PhaseManager.

• Supports DLR topologies with the use of an EtherNet/IP communication

module. For more information about DLR, see the EtherNet/IP Device

Level Ring Application Technique, publication ENET-AT007

• Sockets are supported in the 1756-EN2T, 1756-EN2TP, 1756-EN2TR and

1756-EN2F modules, firmware revision 5.008 or later. For additional

information, see the EtherNet/IP Socket Interface Application

Technique, publication ENET-AT002

• For information on how to best organize a process application, see the

PlantPAx DCS Configuration and Implementation User Manual

publication PROCES-UM100

12 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

.

.

.

Page 13

Chapter 1 ControlLogix 5580 High Availability Systems

Features Not Supported

• Compact 5000 I/O

• The embedded Gigabit Ethernet port of the controller.

• DeviceNet

• Messaging to PLC2, PLC3, PLC5, SLC, and other legacy controllers.

• IEC62443-4-2 secure communications

• License-based Source and Execution Protection

• Any motion feature

• Firmware Supervisor

•Event Tasks

• Input or consumed unicast connections

• SequenceManager

(1)

, ControlNet, RIO, DH+ networks

IMPORTANT

For Ethernet modules, signed and unsigned firmware are available.

Signed modules provide the assurance that only validated firmware can

be upgraded into a module.

Signed and unsigned firmware:

• Both signed and unsigned firmware are available.

• Product is shipped with unsigned firmware. To obtain signed firmware,

you must upgrade the firmware for your product.

• To obtain signed and unsigned firmware, go to

http://www.rockwellautomation.com/global/support/firmware/

overview.page.

• Once signed firmware is installed, subsequent firmware updates must be

signed also.

There are no functional/feature differences between signed and

unsigned communication modules.

Controller Keyswitch The position of the keyswitch on the controllers in both chassis must match

(both in REM or both in RUN). There should NOT be a mismatch. See

Knowledgebase Technote Processor Key Switches in ControlLogix Redundancy

System.

For more information on operation modes of the controller see Choose the

Controller Operation Mode in the ControlLogix 5580 and GuardLogix 5580

Controllers User Manual, publication 1756-UM543

.

(1) DeviceNet modules are supported if accessed across an Ethernet bridge but may experience

a bump during a ControlLogix Redundancy switchover.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 13

Page 14

Chapter 1 ControlLogix 5580 High Availability Systems

Redundancy System Components

Communication between a redundant chassis pair that includes matching

components makes redundancy possible.

Each chassis in the redundant chassis pair contains these ControlLogix

components:

• One ControlLogix power supply - Required

• One ControlLogix 1756-RM2 redundancy module - Required

Redundancy modules link the redundant chassis pair to monitor events

in each chassis and initiate system responses as required.

• At least one ControlLogix EtherNet/IP communication module - up to

seven, optional (any combination)

• One ControlLogix 5580 controller.

If the chassis is used as a redundant gateway, then a controller is not

required.

In addition, redundant chassis are connected to other components outside the

redundant chassis pair, for example, remote I/O chassis or human machine

interfaces (HMIs).

For more information about components you can use in a redundancy system,

see the High Availability System Reference Manual, publication

HIGHAV-RM002

.

I/O Modules in Redundancy Systems

A ControlLogix 5580 redundancy system supports I/O modules in a remote

chassis connected via EtherNet/IP. You cannot use I/O modules in the

redundant chassis pair.

You can put DeviceNet modules in a remote rack but DeviceNet devices will

not be bumpless during a switchover event.

14 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 15

Chapter 1 ControlLogix 5580 High Availability Systems

Fiber-optic Cable If you choose to make your own fiber-optic cables, consider the following:

• Fiber-optic Communication Cable Specifications:

Attribute 1756-RM2 1756-RM2XT

Temperature, operating 0…60 °C (32…140 °F) -25…70 °C (-13…158 °F)

Connector type LC-type (fiber-optic)

Cable type 8.5/125 micron single-mode fiber-optic cable

Channels 1 (transmit and receive fiber)

Length, max 10 km (10,000 m, 10936.13 yd

Transmission 1000 Mbps

Wavelength 1310 nm

SFP transceiver

• Determine Optical Power Budget

You can determine the maximum optical-power budget in decibels (dB)

for a fiber-optic link by computing the difference between the minimum

transmitter-output optical power (dBm avg) and the lowest receiver

sensitivity (dBm avg). As shown in Table 1

budget for the 1756-RM2 module is -9.5 - (-19) or 9.5 dB.

Transceiver Rockwell Automation PN-91972

Connector/cable: LC duplex connector, 1000BASE-LX-compliant

, the maximum optical power

The optical-power budget provides the necessary optical-signal range to

establish a working fiber-optic link. You must account for the cable

lengths and the corresponding link penalties. All penalties that affect the

link performance must be accounted for within the link optical power

budget.

Table 1 - Optical Power Budget Ranges for 1756-RM2 and 1756-RM2XT Modules

Transmitter Min Typical Max Unit

Output optical power -9.5 — -3 dBm

Wavelength 1270 — 1355 nm

Receiver Min Typical Max Unit

Receiver sensitivity — — -19 dBm

Receiver overload — — -3 dbm

Input operating wavelength 1270 — 1355 nm

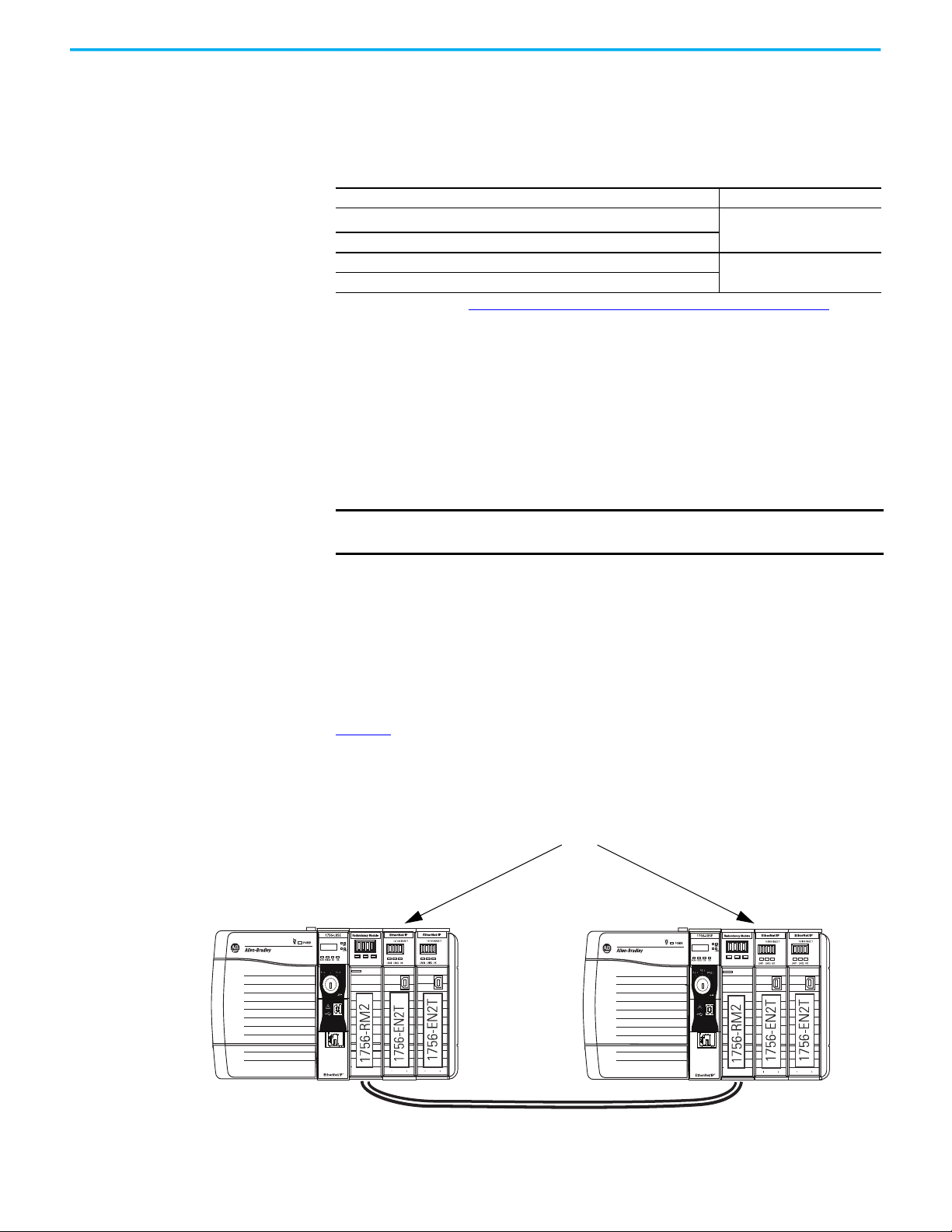

Use Dual Fiber Ports with the 1756-RM2 Redundancy Module

The dual fiber ports of the 1756-RM2 module constitute a redundant pair of

communication channels between the partner 1756-RM2 modules in a

redundant chassis pair. One of the channels is termed as 'ACTIVE', while the

other channel is termed as 'REDUNDANT'. All data communication between

the partner redundancy modules is conducted exclusively over the ACTIVE

channel. If or when the ACTIVE channel fails, a 'Fiber Channel Switchover' is

initiated automatically and all data communication shifts to the REDUNDANT

channel, which then becomes the new ACTIVE channel.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 15

Page 16

Chapter 1 ControlLogix 5580 High Availability Systems

Fiber Channel Switchover

Due to the fiber channel switchover, the redundant chassis pair remains

synchronized even after a failure of the ACTIVE channel. Any of the following

failures of the ACTIVE channel trigger an automatic fiber channel switchover

to the REDUNDANT channel, provided the REDUNDANT channel is still

operating in a normal condition:

• Signal attenuation along the fiber cable path that is routed between the

• A broken or damaged fiber cable that is routed between the partner

• Improper or loosely fit cable connector

• SFP transceiver fault

• Removal or loose connection of the SFP transceiver

• Data communication error (signaled by a failed CRC check)

Chassis synchronization is lost only when both of the channels have failed or

are disconnected.

The fiber channel switchover can occasionally extend the completion of data

communication packets between the partner redundancy modules. Therefore,

the scan time of the controller can occasionally experience a delay of 10 ms or

less.

partner redundancy modules

redundancy modules

Configuration

The use of dual fiber ports is entirely ‘plug and play’. There is no user

configuration that is needed for any of the operations of the active and

redundant channels. The firmware automatically manages the selection of

active and redundant channels. The dual fiber cables between the partner

redundancy modules can be crossed over between CH1 and CH2 without any

restriction, however, this is not recommended as it can complicate

troubleshooting.

Monitoring and Repair

Synchronization is preserved if the REDUNDANT channel has failed or is

being repaired. The repair of the REDUNDANT channel can be performed

online while the redundant chassis pair is running synchronized. To aid online

repairs, the fiber cable connections and SFP transceiver can be removed and

inserted under power.

It is not mandatory to use the REDUNDANT channel that is connected

between the two redundancy modules. The redundant chassis pair can be

synchronized with just one of the channels connected. The REDUNDANT

channel can be installed later while the chassis is running synchronized.

The status indicators on the front panel and the indicators and counters that

are displayed in the RMCT provide monitoring of the channel status.

16 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 17

Chapter 1 ControlLogix 5580 High Availability Systems

Redundancy System Operations

Once the redundancy modules in the redundant chassis pair are connected

and powered, they determine which chassis is the primary chassis and which is

the secondary chassis.

The redundancy modules in both the primary and secondary chassis monitor

events that occur in each of the redundant chassis. If certain faults occur in the

primary chassis, the redundancy modules execute a switchover to the

unfaulted, secondary chassis.

System Qualification and Synchronization

When the redundant system is first started, the redundancy modules run

checks on the redundant chassis. These checks determine if the chassis

contain the appropriate modules and firmware to establish a redundant

system. This stage of checks is referred to as qualification.

After the redundancy modules complete qualification, synchronization can

take place. Synchronization is a state in which the redundancy modules

execute these tasks:

• Verify that the connection between redundancy modules is ready to

facilitate a switchover

• Verify that the redundant chassis continue to meet qualification

requirements

• Synchronize the data between the redundant controllers, also called

crossloading

This data is crossloaded:

- Updated tag values

-Forced values

- Online edits

- Other project information

Synchronization always takes place immediately following qualification. Also,

depending on your system configuration, synchronization takes place at the

end of each program that is run within the controller project, or at other

intervals that you specify.

Some communication delays can occur during qualification. The existence and

duration of these delays depend on:

• Quantity and types of tags on scan in FactoryTalk Linx software

• Client screen and tag update rates (for example, FactoryTalk Live Data/

FactoryTalk Historian)

• Number of data subscribers (for example, FactoryTalk Alarms and

Events, FactoryTalk Batch, and so on)

• Size of the redundant controller application

•Network traffic

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 17

Page 18

Chapter 1 ControlLogix 5580 High Availability Systems

Switchovers

During redundant system operation, if certain conditions occur on the

primary chassis, primary control is switched to the secondary chassis. These

conditions cause a switchover:

• Loss of power

• Major fault on the controller

• Removal or insertion of any module

• Failure of any module

• Loss of an EtherNet/IP connection - This event only causes a switchover

• A program-prompted command to switchover

• A command that is issued via the Redundancy Module Configuration

After a switchover occurs, the new primary controller continues to execute

programs. For more information about how tasks execute after a switchover,

see Crossloads, Synchronization, and Switchovers

if it results in the EtherNet/IP communication module transition to a

lonely state, that is, the module does not see any devices on the network.

Tool (RMCT)

on page 61.

IMPORTANT

It is required that all messaging communications point to the primary

controller when reading/writing to a ControlLogix Redundancy system.

Do not target message instructions to modules in the secondary

chassis.

Your application can require some programming considerations and potential

changes to accommodate a switchover. For more information on these

considerations, see Chapter 6

IMPORTANT

During a switchover of the fiber channels of the 1756-RM2 module, scan

, Programming Best Practices on page 71.

time encounters a delay of ~10 ms; however, the chassis always remains

synched.

Data Server Communication Recovery Time Reduction During a Switchover

Brief communication interruption occurs between FactoryTalk Linx software

and the redundant chassis pair when a switchover occurs. After the switchover

is complete, communication resumes automatically.

Data server communication recovery time is the time during a switchover

from primary to secondary, when tag data from the controller is unavailable

for reading or writing. Data server communication recovery time applies to

any software that uses tag data, such as HMI displays, data loggers, alarms

systems, or historians. Data server communication recovery time reduction is

important to increase the availability of the system.

When you configure the connection between a FactoryTalk Linx data server,

and a redundant ControlLogix controller, you can configure redundant

shortcut paths to the primary and secondary controllers. These shortcut paths

help reduce data server communication recovery time that occurs during a

redundancy switchover.

18 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 19

Chapter 1 ControlLogix 5580 High Availability Systems

The following are required to take advantage of this:

• A dedicated pair of ControlLogix communication modules with firmware

revision 11.002 or later (1756-EN2TP, 1756-EN2TR, 1756-EN2T), that do

not swap IP addresses. See Do Not Use IP Address Swapping

• ControlLogix 5580 redundancy controllers with redundancy firmware

revision 33.011 or later

• FactoryTalk Linx 6.00 with the FactoryTalk Linx patch available from

Knowledgebase Technote Patch: FactoryTalk Linx 6.00 patch required to

support ControlLogix V31.05 Redundancy, or later versions of FactoryTalk

Linx.

• Redundant ControlLogix Controller shortcut type in FactoryTalk Linx

that points to the Primary and Secondary controllers through the

communication modules, without swapping IP addresses. For

information on shortcuts in FactoryTalk Linx, see the FactoryTalk Linx

Getting Results Guide, publication LNXENT-GR001

.

on page 30.

Restrictions There are restrictions that you must consider when using a redundancy

system. Most of these restrictions apply to all redundancy system revisions.

Exceptions are noted:

• See the release notes of the redundancy bundles for compatible products,

versions, and revisions

• The redundant controller program cannot contain these tasks:

-Event tasks

-Inhibited tasks

For recommendations and requirements that are related to

programming the redundant controller, see Programming Best

Practices on page 71.

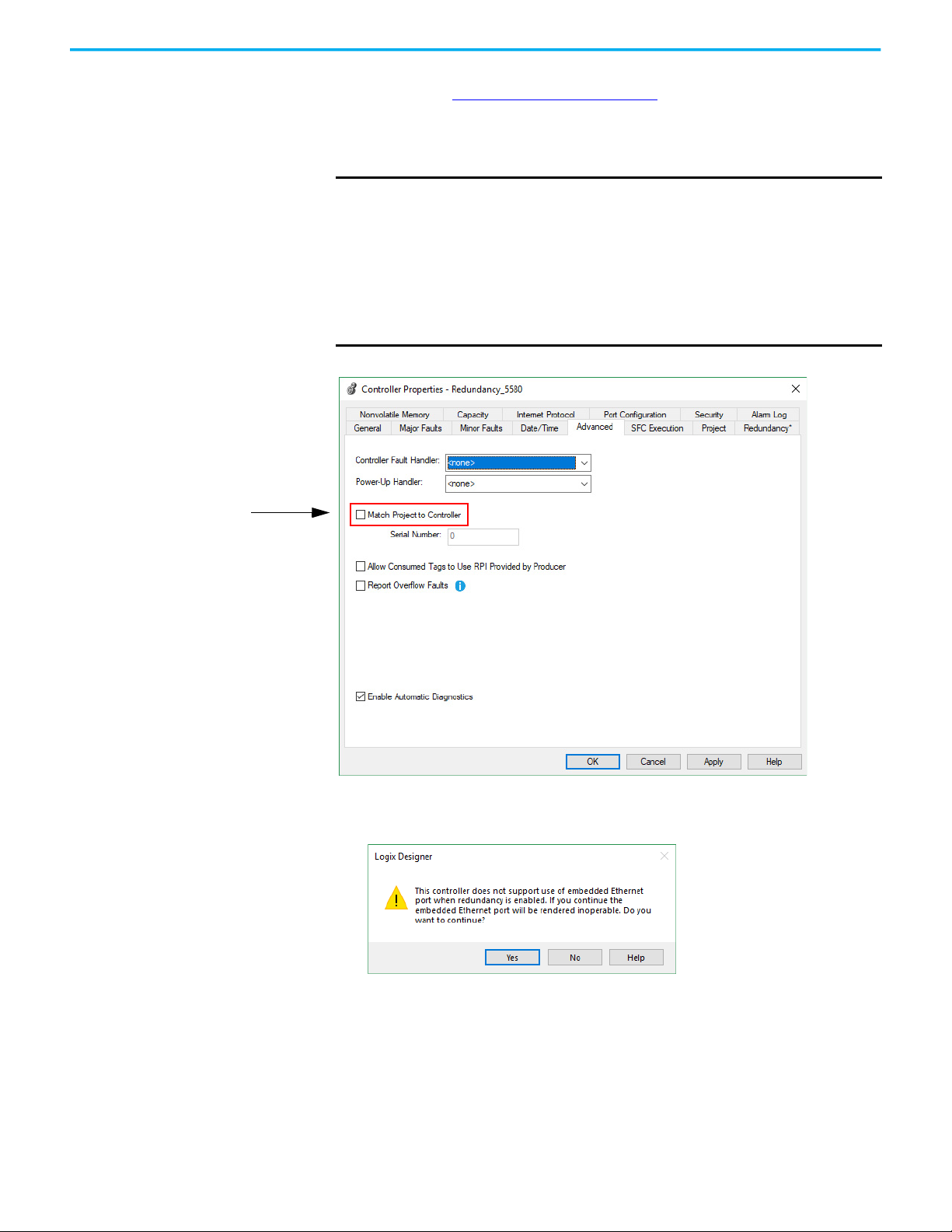

• You cannot use the Match Project to Controller feature available in

Studio 5000 Logix Designer® in a redundancy system.

• You cannot use motion in a redundant controller program.

• You cannot use SequenceManager.

• You cannot use consumed unicast connections in a redundancy system.

You can use produced unicast connections that remote consumers

consume.

• Outputs controlled by IOT instructions are not guaranteed to maintain a

bumpless transition during a switchover. Due to this, it is recommended

to avoid using IOT instructions within a redundancy system.

• The HMIBC instruction is not supported in a redundancy system.

• You can use one controller of the same family, and seven EtherNet/IP

communication modules in each chassis of a redundant chassis pair.

• Cannot use Listen Only or Input Only connections for FLEX 5000 I/O

and ControlLogix 1756 HART I/O from a redundant controller.

- There is no ability for another controller to listen or dual-own

connections to FLEX 5000 I/O.

- This means no sharing of FLEX 5000 I/O or Highly Integrated HART

between a the redundant controller pair and other controllers.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 19

Page 20

Chapter 1 ControlLogix 5580 High Availability Systems

Notes:

20 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 21

Chapter 2

Configure the Redundancy System

Top ic Pa ge

Before You Begin 21

Download the Redundancy Firmware Bundle 22

Install the Firmware Bundle 22

Install the Redundancy Module Configuration Tool 22

Install the Redundancy System 23

Configure Redundant Firmware 24

Set the initial Primary and Secondary Chassis 25

Before You Begin Complete these tasks before you configure the redundancy system:

IMPORTANT

For best performance, place the redundancy module in the

chassis as close as possible to the controller.

• Read and understand the safety and environmental considerations

explained in the installation instructions publication for each

component.

• Order a 1756-RMCx fiber-optic communication cable if you do not have

one.

• If you choose to make your own fiber-optic cable for lengths that the

1756-RMCx catalog numbers do not support, refer to Fiber-optic Cable

on

page 15.

• Download and install the compatible versions of the Studio 5000 Logix

Designer® application, RSLinx® Classic or FactoryTalk® Linx

communication software, and ControlFLASH Plus™ software.

For information on how to download and install ControlFLASH Plus

software, see the ControlFLASH Plus Quick Start Guide, publication

CFP-QS001

IMPORTANT

If RSLinx Classic software or FactoryTalk Linx is already on your system,

make sure to shut it down before installing/upgrading software.

• Review the release notes for the firmware bundle that you are installing.

Make sure that you have compatible hardware and the correct firmware

revisions.

• Determine the IP address for each of your Ethernet/IP™ communication

modules. Both Ethernet/IP communication modules of the redundant

chassis pair will usually have the same IP address. See IP Address

Swapping on page 29.

• System scan time will likely be different between a synchronized and

unsynchronized system. See Crossloads, Synchronization, and

Switchovers on page 61

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 21

Page 22

Chapter 2 Configure the Redundancy System

Download the Redundancy Firmware Bundle

You can download the appropriate redundancy firmware bundle from the

Rockwell Automation Product Compatibility and Download Center (PCDC).

1. Go to https://compatibility.rockwellautomation.com/Pages/home.aspx

2. Search for ‘1756-L8x Redundancy Bundle’.

3. Select and download the appropriate bundle revision.

The Redundancy Module Configuration Tool (RMCT) is included in the

redundancy bundle download, and is not available for separate download.

Install the Firmware Bundle Follow the steps in this section.

Create a firmware directory on your computer first, so you can unzip the files to

this directory.

1. You must first shut down RSLinx Classic software.

2. Browse to the location of the redundancy firmware revision bundle.

3. Unzip the redundancy firmware bundle on your computer. After you

unzip, you will have these files:

•Firmware: Vxx.0xx_kitx_5580CLXRED Bundle.dmk (where x is the

firmware revision and kit number)

• Redundancy Module Configuration Tool

4. Unzip the Redundancy Module Configuration Tool on your computer.

.

Install the Redundancy Module Configuration Tool

The RMCT version that is compatible with your redundancy module firmware

is included in the downloads for the redundancy bundle, and is not available as

a separate download.

IMPORTANT

To install the RMCT:

1. Browse to the RMCT directory on your computer.

2. Double-click setup.exe.

3. On the RMCT Setup dialog, click Next.

4. When the installation is complete, click Finish.

You must uninstall any existing version of the Redundancy Module

Configuration Tool (RMCT) before you install the RMCT, version 8.06.03 or

later. If you do not uninstall the previous version, you can have difficulty

if you try to uninstall version 8.06.03 or later at another time.

22 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 23

Chapter 2 Configure the Redundancy System

Install the Redundancy System

If you need to install the redundancy system, determine the location of your

controller, Ethernet/IP communication modules, and redundancy modules in

both chassis of the system, matching partners slot for slot.

IMPORTANT

1. Install the first chassis and power supply (or redundant power supplies):

• ControlLogix® Chassis Installation Instructions, publication

1756-IN621

• ControlLogix Power Supply Installation Instructions, publication

1756-IN619

• ControlLogix Redundant Power Supply Installation Instructions,

publication 1756-IN620

2. Install and connect the 1756-RM2 redundancy modules in both chassis:

• ControlLogix Redundancy Modules Installation Instructions,

publication 1756-IN087

3. Install the first chassis Ethernet/IP communication modules:

• 1756 EtherNet/IP Communication Modules Installation Instructions,

publication 1756-IN050

4. Install one controller in the first chassis of the redundant pair:

• ControlLogix 5580 Controllers Installation Instructions, publication

1756-IN043

5. Install the second chassis and power supply (or redundant power

supplies).

6. Install the second chassis Ethernet/IP communication modules.

7. Install one controller in the second chassis of the redundant pair.

Do not power on either chassis until you have installed all modules in

both chassis.

.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 23

Page 24

Chapter 2 Configure the Redundancy System

Configure Redundant Firmware

Use ControlFLASH Plus software to upgrade the firmware of each module in

each chassis. For information on how to download, install, and use

ControlFLASH Plus software, see the ControlFLASH Plus Quick Start Guide,

publication CFP-QS001

IMPORTANT

• Apply power ONLY to the chassis that contains modules on which you are

• Redundancy module firmware that is contained in the redundancy

• All modules in both chassis must use firmware as defined in the 1756-L8x

.

upgrading firmware.

system firmware bundle is designed for use with the 1756-RM2 and 1756RM2XT redundancy modules.

Redundancy Bundle.

Upgrade the Firmware in the First Chassis

IMPORTANT

Complete these steps to upgrade the firmware in the first chassis.

1. Apply power to the chassis.

2. Set the keyswitch on the controller to PROG.

Redundancy module firmware that is contained in the redundancy

system firmware bundle is designed for use with the 1756-RM2 and

1756-RM2XT redundancy modules.

3. Wait for the modules to complete their start-up scroll messages. Check

Module and status indicators. During this time, the redundancy module

conducts internal operations to prepare for an update.

Create a firmware directory on your computer first, so you can unzip the files to

this directory.

4. Launch ControlFLASH Plus software, and upgrade the Ethernet

communication module that you going to use as the gateway to the other

modules.

5. Upgrade the 1756-RM2 redundancy module.

6. Once the firmware upgrade is complete, verify that the redundancy

module status displays PRIM, which indicates a successful upgrade.

7. Use ControlFLASH Plus software to upgrade the rest of the modules in

the chassis.

IMPORTANT

• Verify the firmware revision of each module to make sure it matches the

revision in the 1756-L8x Redundancy Bundle.

• Power off the first chassis after you have verified a successful update of

each module.

24 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 25

Chapter 2 Configure the Redundancy System

Upgrade the Firmware in the Second Chassis

Complete these steps to update the firmware for the modules in the second

chassis.

1. Apply power to the second chassis.

2. Set the keyswitch on the controller to PROG.

3. Complete steps 3

beginning on page 24

…7 in section Upgrade the Firmware in the First Chassis

for the modules in the second chassis.

Set the initial Primary and Secondary Chassis

IMPORTANT

Power on the chassis you want to set as the initial primary chassis first. After

you have applied power, verify all module pairs are at compatible firmware

revision levels.

IMPORTANT

Complete these steps to designate the primary and secondary chassis of a

redundant pair.

• verify the firmware revision of each module to make sure it matches the

revision in the 1756-L8x Redundancy Bundle.

• Power off the second chassis after you have verified a successful update

of each module.

• Do not apply power to the chassis until you have read the instructions

for designating the primary chassis. Applying power to the chassis in

the correct order is crucial to designating the primary and secondary

chassis.

• Make sure both Ethernet/IP communication modules are set

appropriately. See Data Server Communication Recovery Time

Reduction During a Switchover on page 18.

• It is not recommended to load an application image until the primary

and secondary racks are synchronized.

• Before you set the initial primary chassis and qualify the system, it is

recommended to have the latest firmware installed. See Configure

Redundant Firmware on page 24.

1. Verify that power is removed from both chassis.

2. Apply power to the chassis you want to designate as the primary chassis

and wait for the status indicators of the module to display PRIM.

3. Apply power to the chassis you want to designate as the secondary

chassis.

4. Verify primary and secondary chassis designations by viewing the

redundancy module status displays.

See Redundancy Module Status Indicators

redundancy module display information.

IMPORTANT

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 25

If both modules have power applied to them simultaneously, the module

with the lowest IP address is designated as the primary chassis and

displays PRIM on the four-character display of the module. In addition,

the PRI status indicator on the primary redundancy module is green. The

secondary chassis displays either DISQ or SYNC, depending on the state

of the secondary chassis. In addition, the PRI status light on the

secondary redundancy module is not illuminated.

on page 138 for specific

Page 26

Chapter 2 Configure the Redundancy System

After Designation

When you first apply power to the primary and secondary chassis,

compatibility checks are carried out between the redundant chassis. Then,

because the default Auto-Synchronization parameter is set to Always,

qualification begins.

While the qualification occurs, the module status display transitions from DISQ

(disqualified) to QFNG (qualifying) to SYNC (synchronized). The qualification

completes in 1…3 minutes and the module status display indicates the

qualification status.

After you verify the system is synchronized, you can download the user

application to the primary controller. It automatically crossloads to the

secondary controller.

Use this table as a reference when interpreting the qualification status of the

modules that are displayed on the module status display.

Module Status Display Interpretation

QFNG Qualification processes are in progress.

SYNC displays after qualification processes are complete.

SYNC

DISQ…QFNG…DISQ

This indicates that chassis configuration and the firmware revision levels are

compatible and that the secondary chassis is ready to assume control if there is a

major fault in the primary chassis.

If DISQ continues to display after about 3 minutes, check the following:

• Incorrect chassis configuration. That is, incompatible hardware is used.

• Incompatible firmware revisions are used between the primary and secondary

modules.

• The partnered EtherNet/IP modules are not set to the same IP Configuration.

• The Auto-Synchronization parameter within the Redundancy Module Configuration

Tool is set to Never or Conditional (default setting).

Conversion from a Non-redundant to a Redundant System

To upgrade a standalone chassis to a redundant chassis pair:

1. Insert a redundancy module in a spare slot in the standalone chassis, and

2. Configure an identical chassis with compatible modules in the same slot

as the standalone chassis (including the redundancy module).

A partnered chassis that is set as the secondary chassis stops functioning if it

contains:

• non-redundancy-compliant modules

• modules not compatible with redundancy

• non-redundancy-compliant firmware

For more information, see Convert from a Non-redundant System

on page 143.

26 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 27

Chapter 2 Configure the Redundancy System

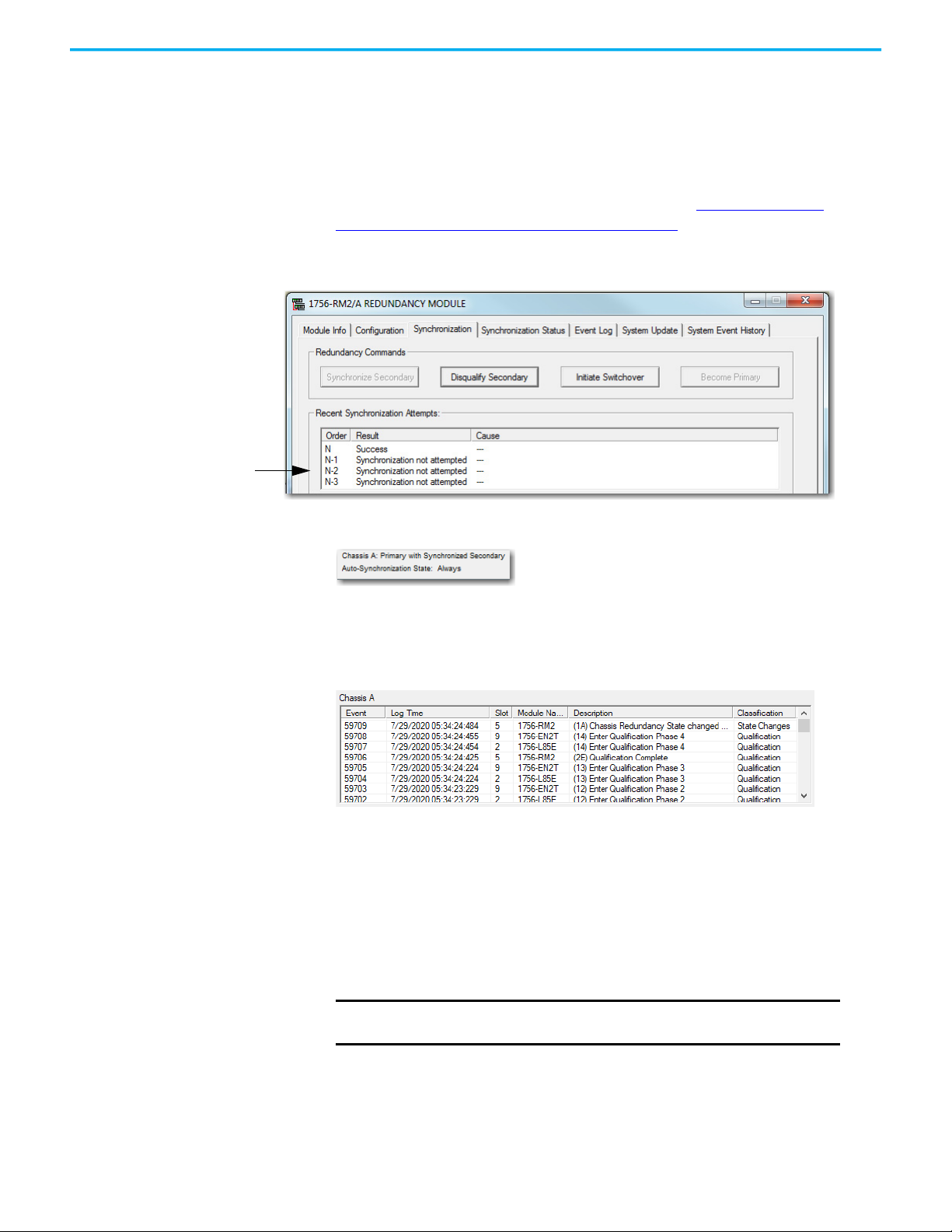

Qualification Status Via the RMCT

To view the details for a qualification attempt, access the Synchronization or

Synchronization Status tabs of the RMCT. These tabs provide information

about qualification attempts and redundant chassis compatibility.

For more information on how to use the RMCT, see Use the RMCT for

Synchronization Attempts and Status on page 111.

RMCT Synchronization Status Tab

Synchronization Status Tab for Chassis Compatibility

You can also view events specific to qualification in the Event Log of the RMCT.

Event Log with Qualification Events

Reset the Redundancy Module

There are two ways to reset the module.

• Cycle power to the chassis.

• Remove the module from the chassis and reinsert the module.

IMPORTANT

Do not choose to cycle power to the chassis if it causes you to

lose control of your process.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 27

Page 28

Chapter 2 Configure the Redundancy System

Remove or Replace the Redundancy Module

IMPORTANT

If you remove the redundancy module, you will lose

redundancy functionality.

To remove or replace the redundancy module, follow these steps.

1. To disengage the upper and lower module tabs, push them.

2. Slide the module out of the chassis.

3. Insert the replacement in the same slot and move the fiber cable(s) to the

new module.

IMPORTANT

If you want to resume system operation with an identical

module, you must install the new module in the same slot.

28 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 29

Configure the EtherNet/IP Network

Top ic Pa ge

Requested Packet Interval (RPI) 29

IP Address Swapping 29

CIP Sync 33

Produce/Consume Connections 35

Configure EtherNet/IP Communication Modules in a Redundant System 37

Use a Redundancy System with Device Level Ring 38

Use a Redundancy System with Parallel Redundancy Protocol 38

Chapter 3

Requested Packet Interval (RPI)

The RPI for I/O connections in a redundant-enabled controller tree are

configured the same way as a with a simplex controller. Adjusting the RPI rates

of I/O connections impact the loading of the associated EtherNet/IP

communications modules.

The RPI for I/O connections in a redundant-enabled controller tree are

configured the same way as a with a simplex controller. Adjusting the RPI rates

of I/O connections impact the loading of the associated EtherNet/IP

communications modules.

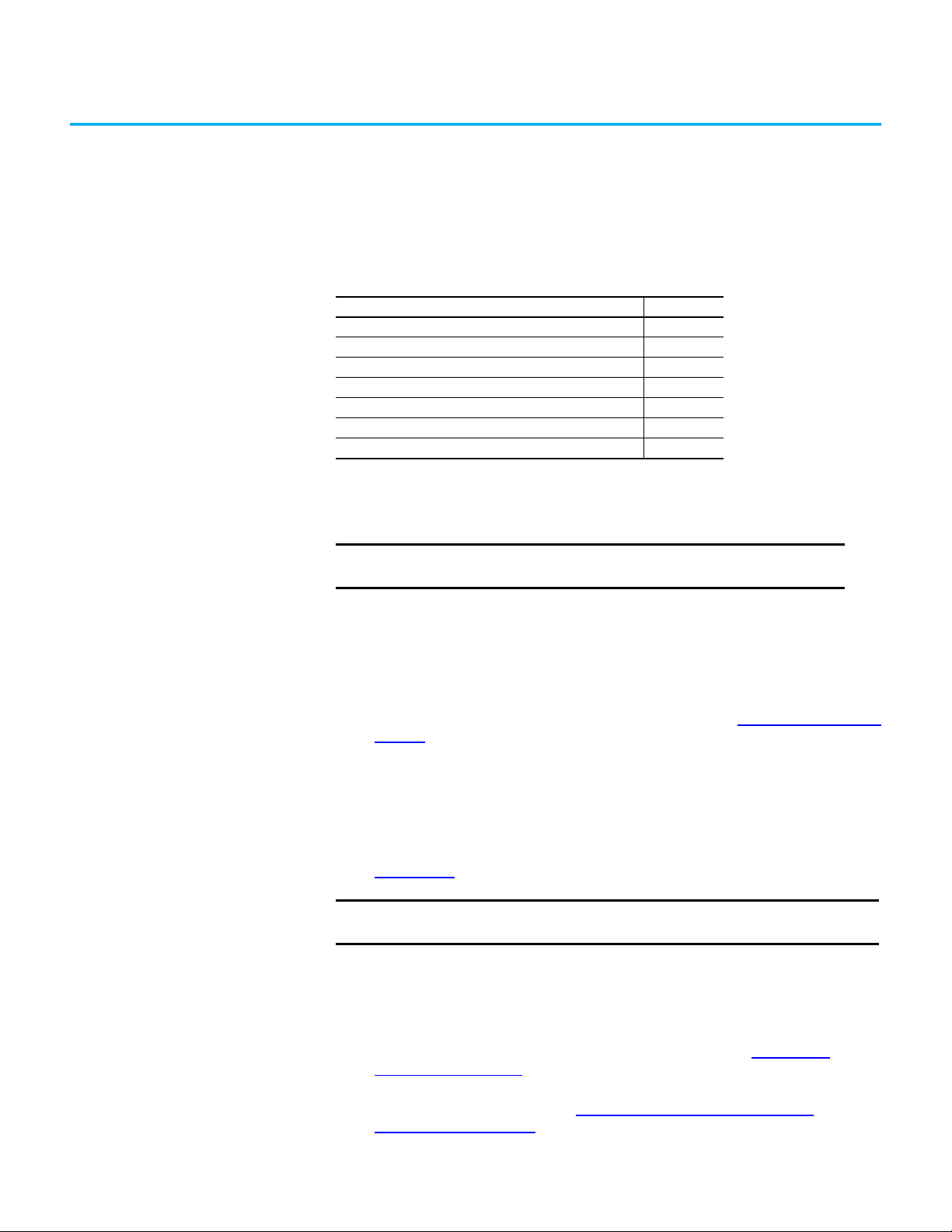

This table describes CPU usage for EtherNet/IP™ communication modules.

If the CPU utilization

percent is

0…80%

Greater than 80%

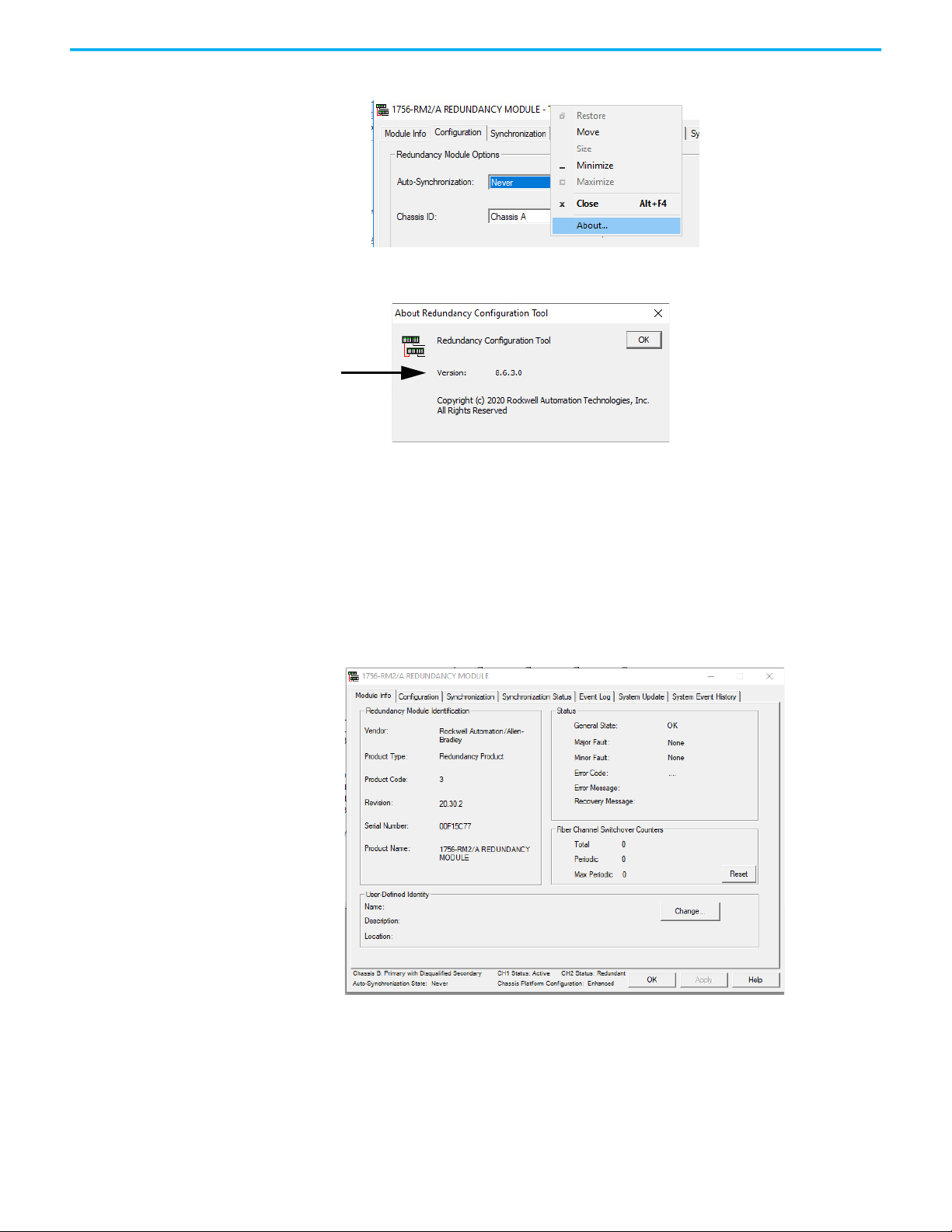

Then

No action is required.

Important: This range is the optimal rate.

• Take steps to reduce your CPU utilization. See the EtherNet/IP Network Configuration User

Manual, publication ENET-UM001

• Adjust the requested packet interval (RPI) of your connection.

• Reduce the number of devices that are connected to your module.

• Add another Ethernet module to the redundant chassis pair (maximum of 7)

Important: Your EtherNet/IP communication module can function at 100% CPU

capacity, but at or near this rate, you run the risk of CPU saturation and

performance degredation.

.

IP Address Swapping IP address swapping is a feature available to EtherNet/IP communication

modules in a redundancy system where a partnered set of EtherNet/IP

communication modules swap IP addresses during a switchover.

IMPORTANT

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 29

You must use IP address swapping to use remote I/O and

produce/consume connections of an EtherNet/IP network.

Page 30

Chapter 3 Configure the EtherNet/IP Network

Primary chassis Secondary Chassis

Assigned IP Address: 192.168.1.3

Determine Use of IP Address Swapping

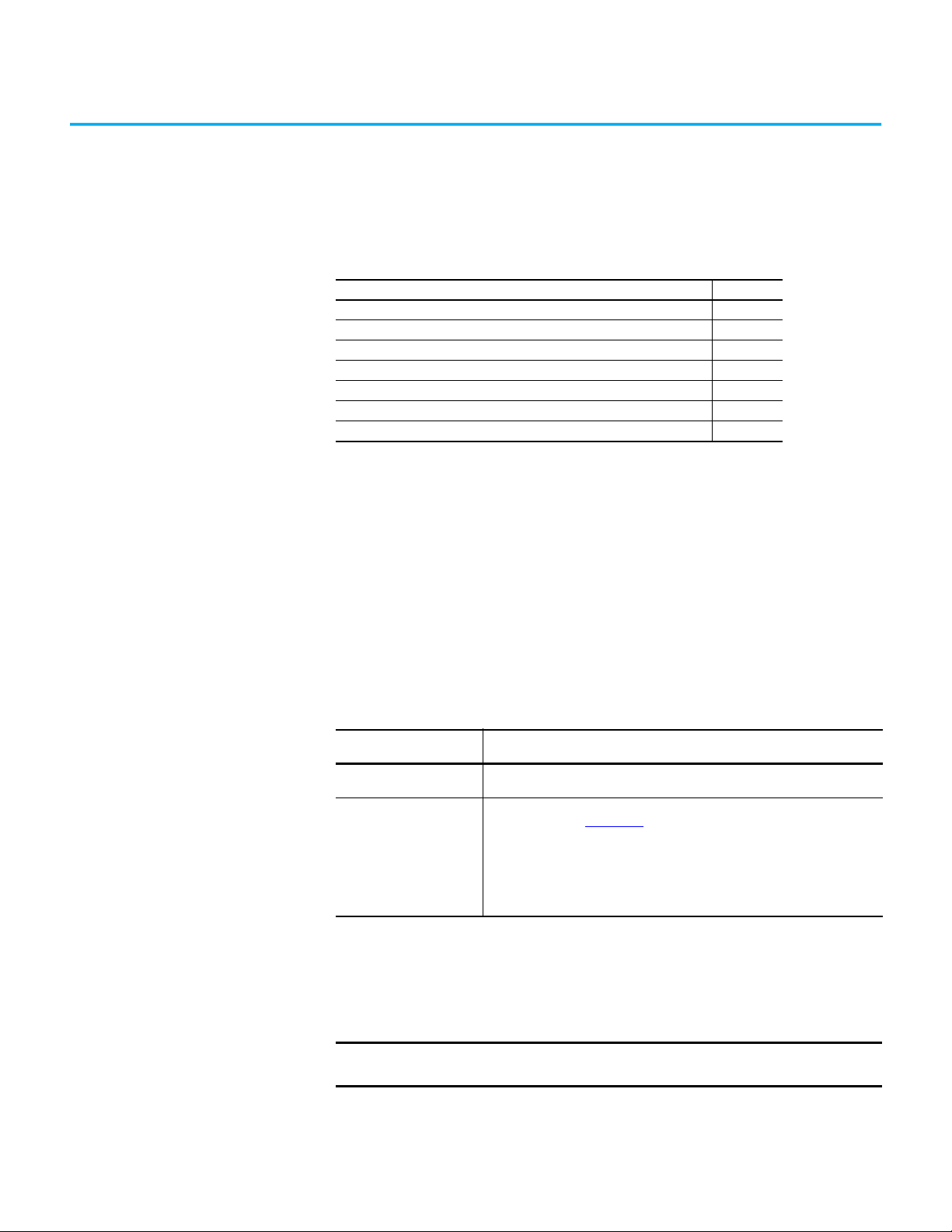

Depending on your EtherNet/IP network configuration, you can choose to use

IP address swapping between your partnered EtherNet/IP communication

modules in the event of a switchover.

If you want to Then

Minimize data server communication recovery time during switchover

Have your partnered EtherNet/IP communication modules on different subnets

Use Remote I/O or produce/consume

Have your partnered EtherNet/IP communication modules on the same subnet.

(1) For more information, see Data Server Communication Recovery Time Reduction During a Switchover on page 18

(1)

Do not use IP address swapping

Use IP address swapping

If you are using different subnets, you are responsible for programming your

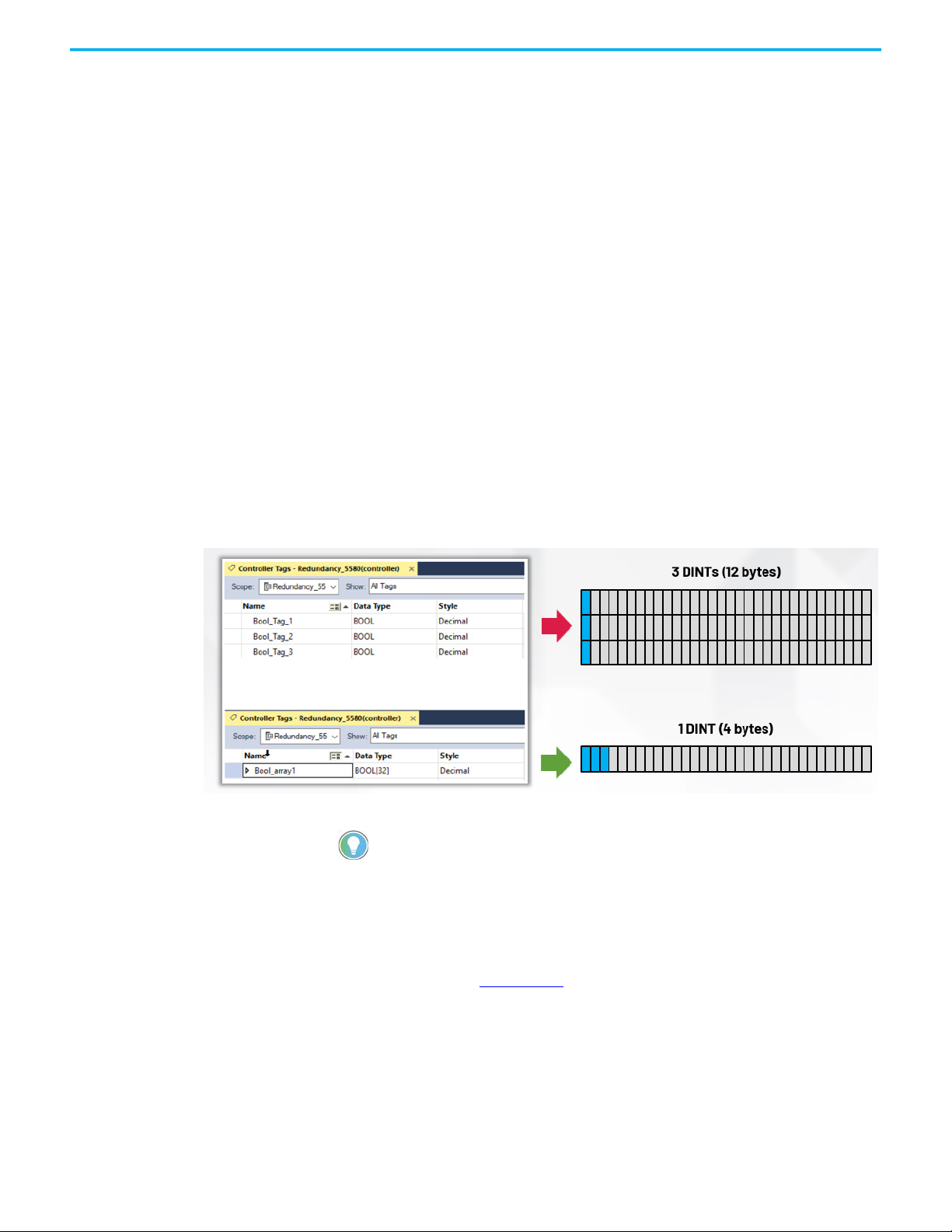

system to use the address and subnet of the new primary chassis in the event

of a switchover.

Do Not Use IP Address Swapping

If you do not use IP address swapping, assign unique values for the IP address

on both EtherNet/IP communication modules in the partnered set:

IMPORTANT

The IP address cannot be of the following format between the partner

EtherNet modules: aaa.bbb.ccc.ddd & aaa.bbb.ccc.(ddd+1)

Use IP Address Swapping

If you use IP address swapping, at minimum, the below parameters must be

configured on both EtherNet/IP communication modules in the partnered set:

• IP address

•Subnet mask

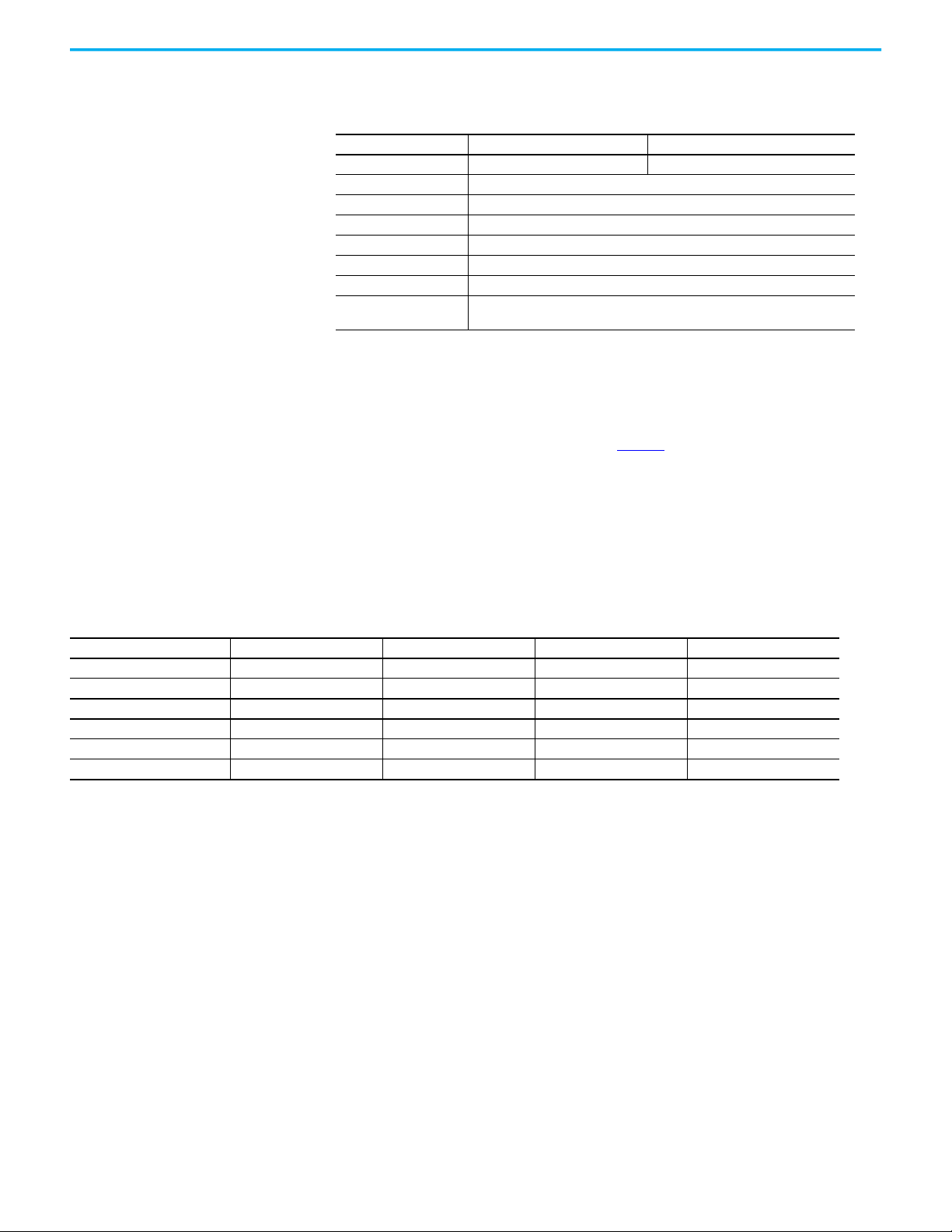

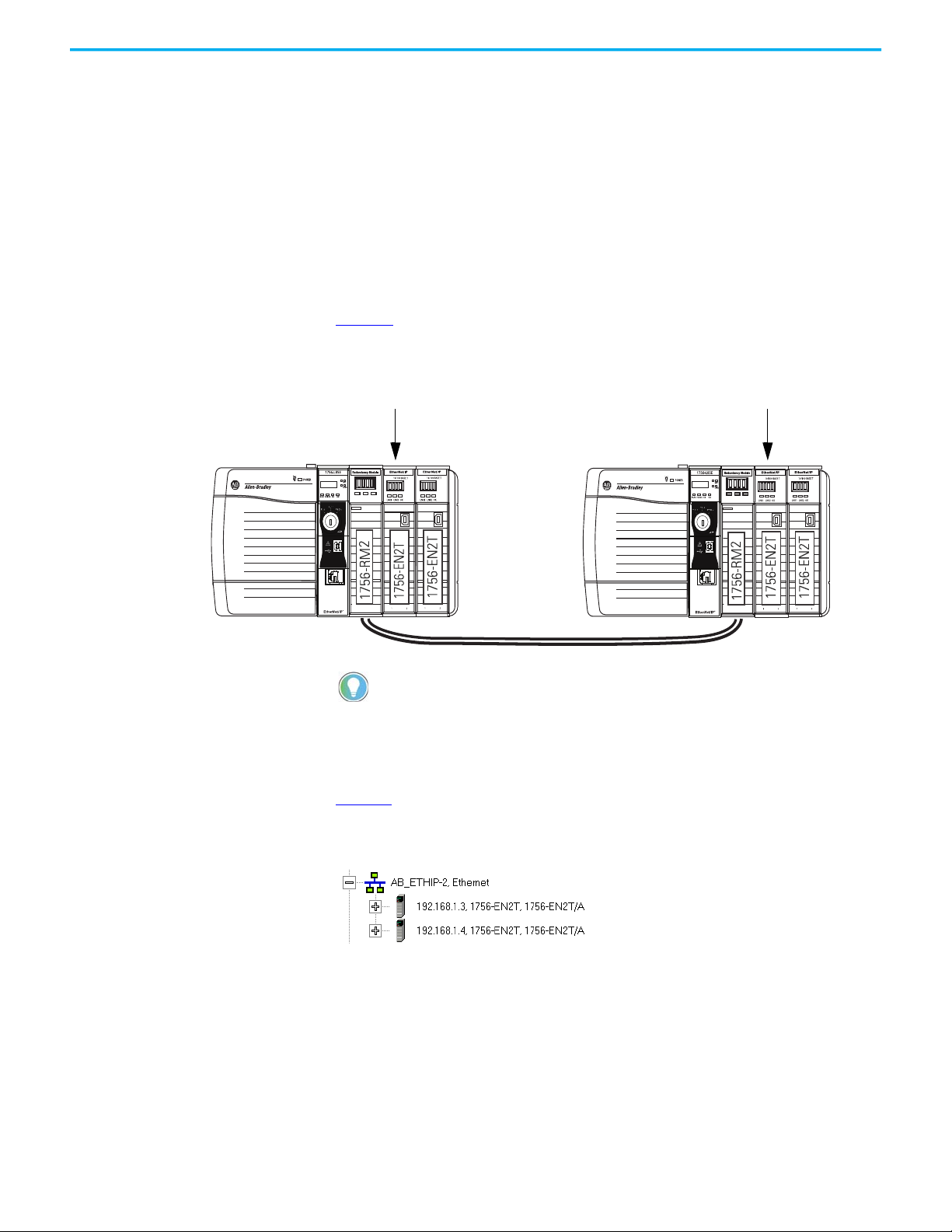

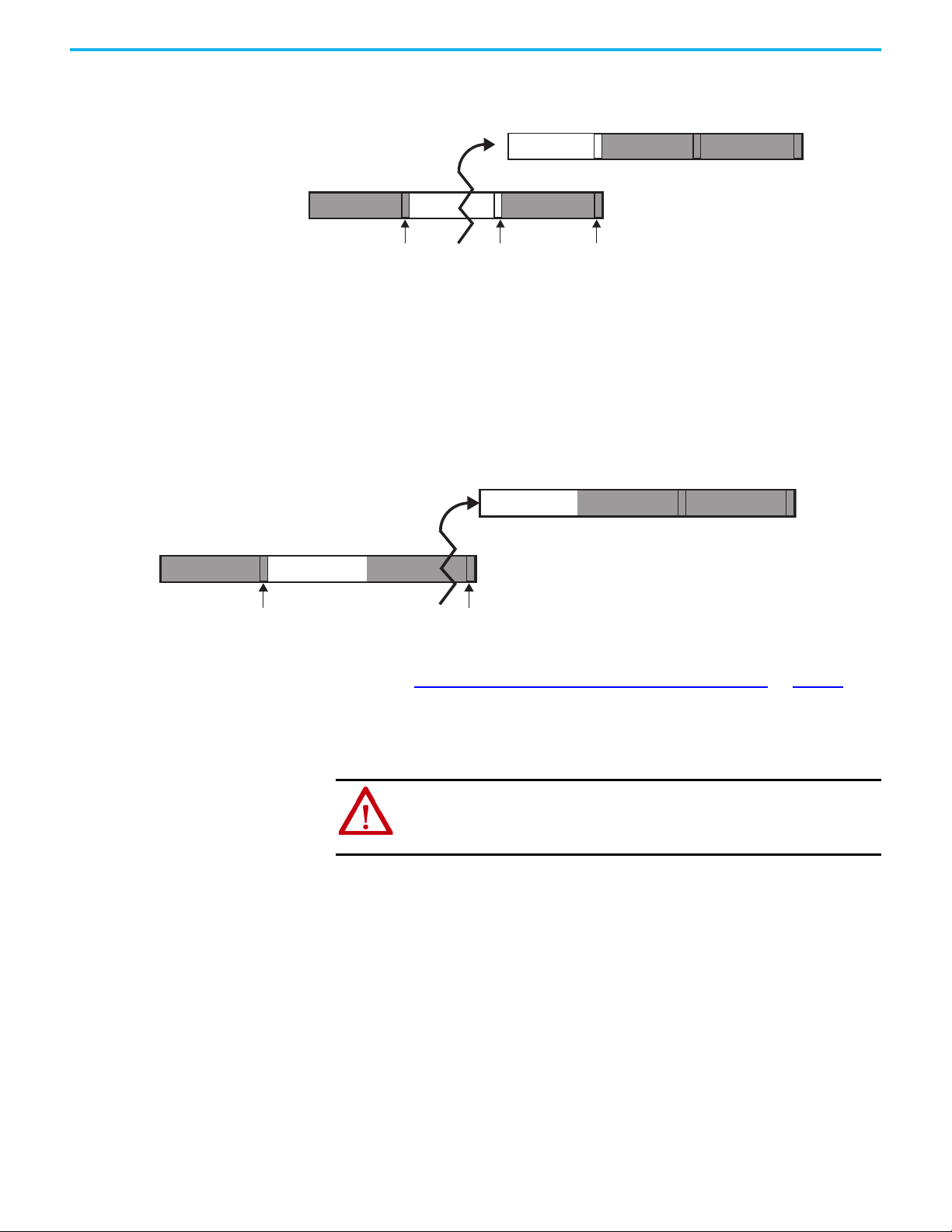

Figure 1

initial configuration.

Figure 1 - IP Addresses of EtherNet/IP Communication Modules During System Configuration

shows a partnered set of EtherNet/IP communication modules during

CH2 CH1 OK

CH2 CH1 OK

30 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 31

Chapter 3 Configure the EtherNet/IP Network

Primary Chassis Secondary Chassis

IP Address: 192.168.1.3

IP Address: 192.168.1.4

When a redundancy system begins operating, the primary EtherNet/IP

communication module uses the IP address that is assigned during initial

configuration. The secondary EtherNet/IP communication module

automatically changes its IP address to the next highest value. When a

switchover occurs, the EtherNet/IP communication modules swap IP

addresses.

For example, if you assign IP address 192.168.1.3 to both EtherNet/IP

communication modules in a partnered set, on initial system operation, the

secondary EtherNet/IP communication module automatically changes its IP

address to 192.168.1.4.

Figure 2

shows a partnered set of EtherNet/IP communication modules after

system operation begins.

Figure 2 - IP Addresses of EtherNet/IP Communication Modules After System Operation Begins

CH2 CH1 OK

CH2 CH1 OK

Do not assign IP addresses to EtherNet/IP communication modules outside the

partnered set to values that conflict with those values that are used in the

partnered set.

In the previous example, the partnered set uses 192.168.1.3 and 192.168.1.4. Use

192.168.1.5 or higher for all EtherNet/IP communication modules outside the

partnered set.

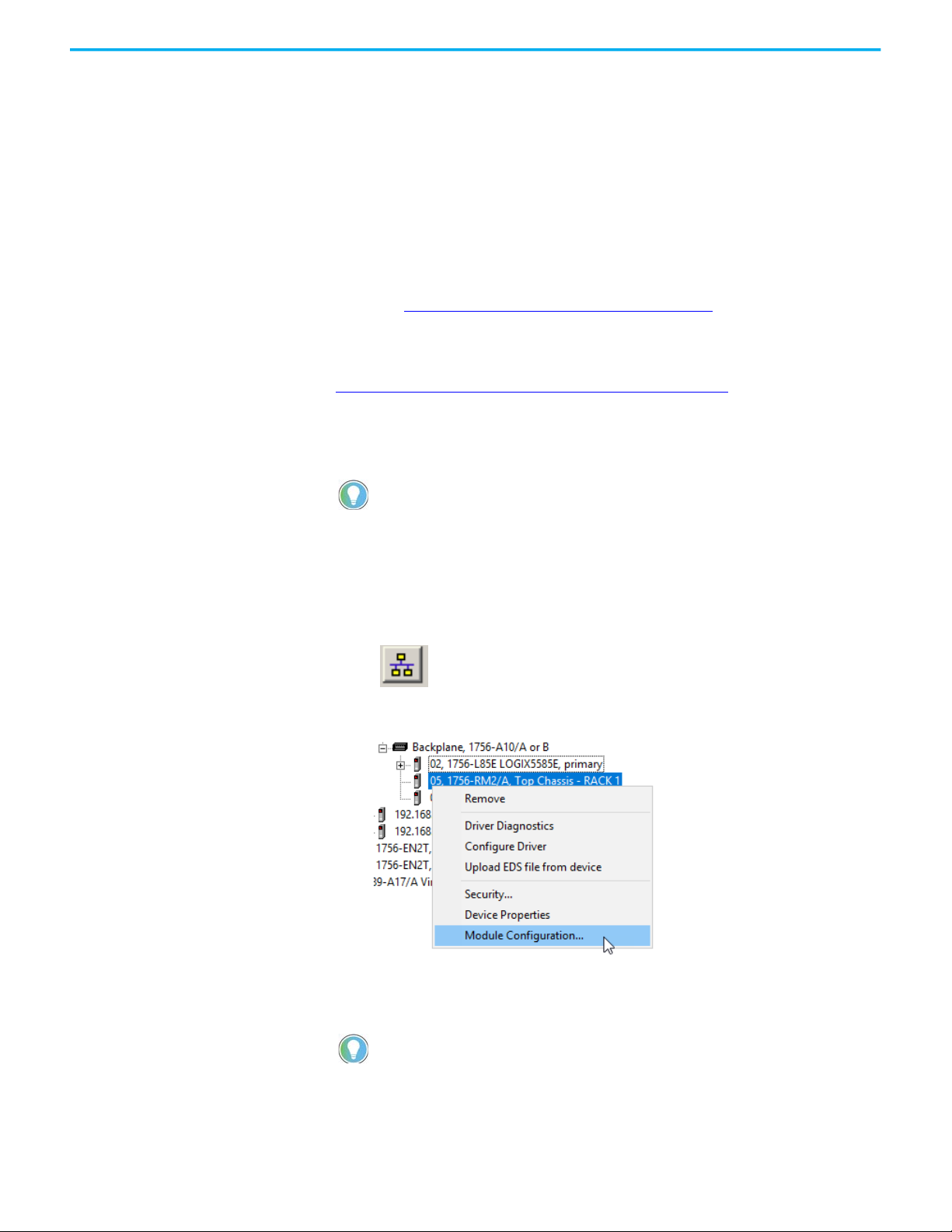

Figure 3 shows the partnered set of EtherNet/IP communication modules in

RSLinx® Classic software after system operation begins.

Figure 3 - IP Addresses in RSLinx Classic Software

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 31

Page 32

Chapter 3 Configure the EtherNet/IP Network

Static Versus Dynamic IP Addresses

A static IP address is manually assigned, and does not change. A dynamic IP

address is automatically assigned by a Dynamic Host Configuration Protocol

(DHCP) server, and can change over time.

We recommend that you use static IP addresses on EtherNet/IP

communication modules in redundancy systems. You cannot use dynamic IP

addresses with IP address swapping.

ATTENTION: If you use dynamic IP addresses and a power outage, or other

network failure occurs, modules that use dynamic IP addresses can be

assigned new addresses when the failure is resolved. If the IP addresses

change, your application could experience a loss of control or other serious

complications with your system.

Reset the IP Address for an EtherNet/IP Communication Module

If necessary, you can reset the IP address of a 1756-EN2x communication

module to the factory default value. To return to the factory default, set the

rotary switches on the module to 888 and cycle power.

After you cycle power to the EtherNet/IP communication module, you can

either set the switches on the module to the desired address, or set the

switches to 999 and use one of these methods to set the IP address:

• BOOTP-DHCP server

• RSLinx Classic communication software

• Studio 5000 Logix Designer® application

32 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 33

Chapter 3 Configure the EtherNet/IP Network

CIP Sync CIP Sync™ provides a mechanism to synchronize clocks between controllers,

I/O devices, and other automation products in your architecture with minimal

user intervention.

CIP Sync uses Precision Time Protocol (PTP) to establish a

Master/Slave relationship among the clocks for each CIP Sync-enabled

component in the system. One master clock, which is known as the

Grandmaster, sets the clock to which all other devices on the network

synchronize their clocks.

IMPORTANT

Before you use this enhancement in a redundancy system, see these

publications for a full understanding of CIP Sync in any system:

• Integrated Architecture™ and CIP Sync Configuration Application

Technique, publication IA-AT003

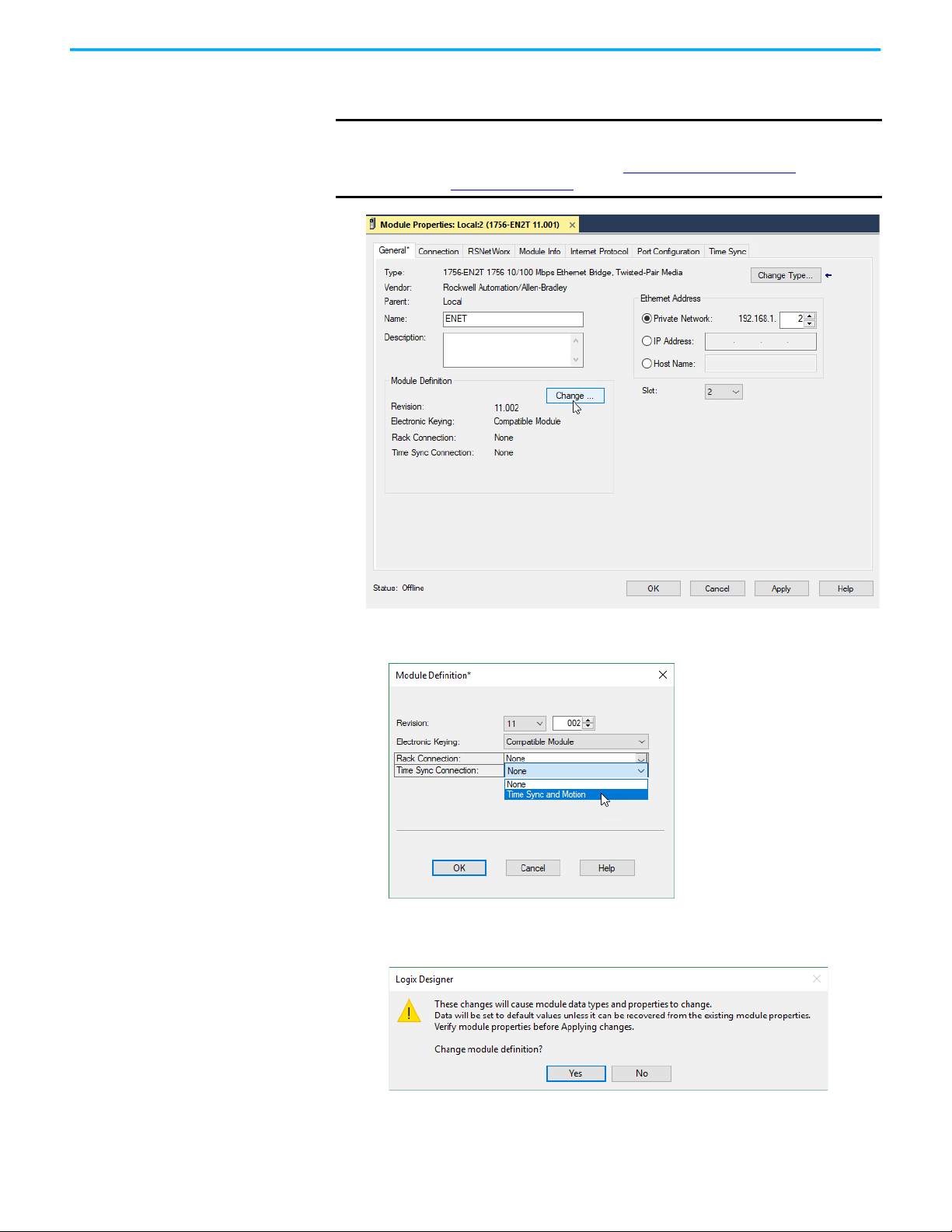

Consider these points when you use CIP Sync in a redundancy system:

• If you enable CIP Sync Time Synchronization in the controllers in a

redundant chassis pair, you must also enable Time Synchronization in

one of the EtherNet/IP communication modules in the redundant

chassis pair so all devices have one path to the Grandmaster. To enable

Time Synchronization in the EtherNet/IP communication modules,

change the Time Sync Connection from None (default) to Time Sync and

Motion.

If time synchronization is enabled in any controller in the primary

chassis of a disqualified redundant chassis pair, and no other device in

the primary chassis has time synchronization enabled, the redundant

chassis pair attempts to qualify. However, in these application

conditions, the attempt to synchronize fails and the application will

remain in the qualifying state for up to 10 minutes before failing

qualification. If viewed in the RMCT, the system will remain at 85%

complete.

• While CIP Sync can handle multiple paths between master and slave

clocks, it resolves mastership most effectively if you configure the

redundant paths so that Time Synchronization is enabled in only the

minimum required number of EtherNet/IP communication modules.

We recommend that PTP should have exactly one path through the

system with no loops.

• If the primary controller is the Grandmaster, the redundancy system

automatically manages the CIP Sync clock attributes so that the

controller in the primary chassis is always set to be the Grandmaster

instead of the secondary controller.

IMPORTANT

We recommend to have the Grandmaster outside the RCP if possible. If

there are time sensitive devices that depend on the clock, there can be

a step in the PTP time during switchover.

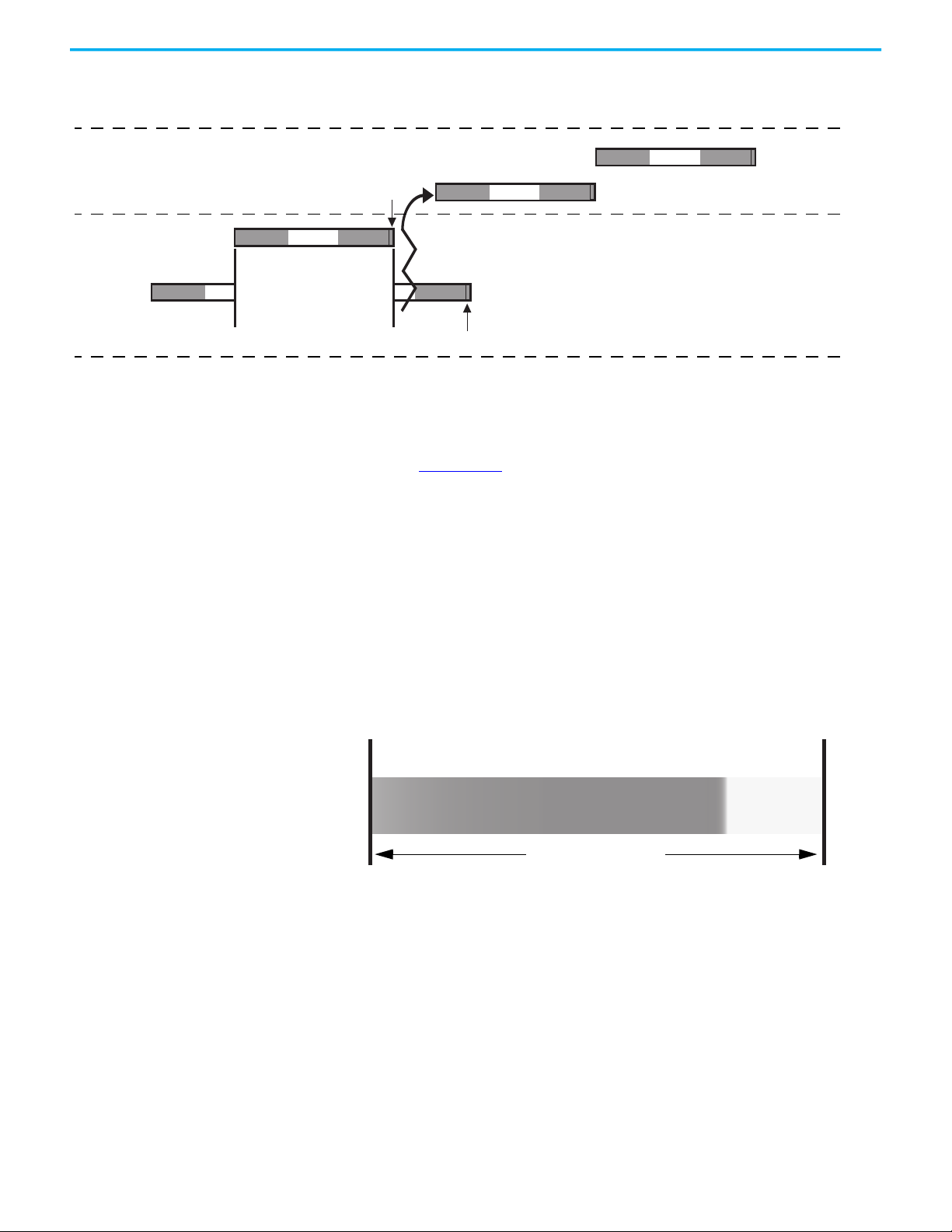

• When a switchover occurs, these events take place:

- The Grandmaster status transfers from the original primary controller

to the new primary controller. This transfer can take longer to

complete than if Grandmaster status was transferred between devices

in a non-redundant system.

Rockwell Automation Publication 1756-UM015B-EN-P - February 2021 33

Page 34

Chapter 3 Configure the EtherNet/IP Network

G

M

S

S

S

S

S

M

P1

P1

S

S

S

S

S

M

S

M

S SS

M

S SS

P2

S

SS

M

Primary Chassis

CIP Sync

Stratix® 5700

Supervisory

CIP Sync

Secondary Chassis

Ethernet

CIP Sync

CIP Sync

CIP Sync

CIP Sync

CIP Sync

CIP Sync

CIP Sync

Ethernet

Fiber Optic Cable

G = Grandmaster (time source)

M = Master

S = Slave

P1 and P2 = Priorities

Stratix® 5700

CIP Sync

CIP Sync

CIP Sync

CIP Sync

CIP Sync

CIP Sync

Figure 4 - Redundancy System, using CIP Sync Technology

34 Rockwell Automation Publication 1756-UM015B-EN-P - February 2021

Page 35

Chapter 3 Configure the EtherNet/IP Network

CH2 CH1 OK

CH2 CH1 OK

Primary Chassis Secondary Chassis

Controller 1

Produced Tag

Controller 2

Consumed Tag

Produce/Consume Connections

Controllers let you produce (send) and consume (receive) system-shared tags

over an EtherNet/IP network.

IMPORTANT

A redundant controller can produce tags to a standard controller using

unicast or multicast. Redundant controllers must always consume tags

using multicast.