Page 1

ControlLogix 5570/5560 Redundancy

User Manual

Original Instructions

Page 2

ControlLogix 5570/5560 Redundancy User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential

Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory

requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 3

Table of Contents

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Summary of Changes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

About ControlLogix

Redundancy Systems

Design a ControlLogix

Redundancy System

Features of the ControlLogix Redundancy System . . . . . . . . . . . . . . . 12

Redundancy System Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

I/O Modules in Redundancy Systems . . . . . . . . . . . . . . . . . . . . . . . 14

Redundancy System Operations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

System Qualification and Synchronization. . . . . . . . . . . . . . . . . . . 15

Switchovers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Restrictions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Chapter 2

Redundant Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Redundant Chassis Configuration Requirements . . . . . . . . . . . . 22

Controllers in Redundant Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Redundancy Modules in Redundant Chassis. . . . . . . . . . . . . . . . . 24

Communication Modules in Redundant Chassis. . . . . . . . . . . . . 25

Power Supplies and Redundant Power Supplies in

Redundancy Systems. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

EtherNet/IP Networks with Redundant Systems . . . . . . . . . . . . . . . . 28

Unicast Functionality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Possible Communication Delays on EtherNet/IP and

ControlNet Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Bridge from an EtherNet/IP Network to a ControlNet

Network. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

ControlNet Networks with Redundant Systems . . . . . . . . . . . . . . . . . 30

ControlNet Network Requirements . . . . . . . . . . . . . . . . . . . . . . . . 30

Redundant ControlNet Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Other Communication Networks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

I/O Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

1715 Redundant I/O Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using HMI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

HMI Connected Via an EtherNet/IP Network . . . . . . . . . . . . . . 38

HMI Connected Via a ControlNet Network . . . . . . . . . . . . . . . . 39

Optional Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 3

Page 4

Table of Contents

Chapter 3

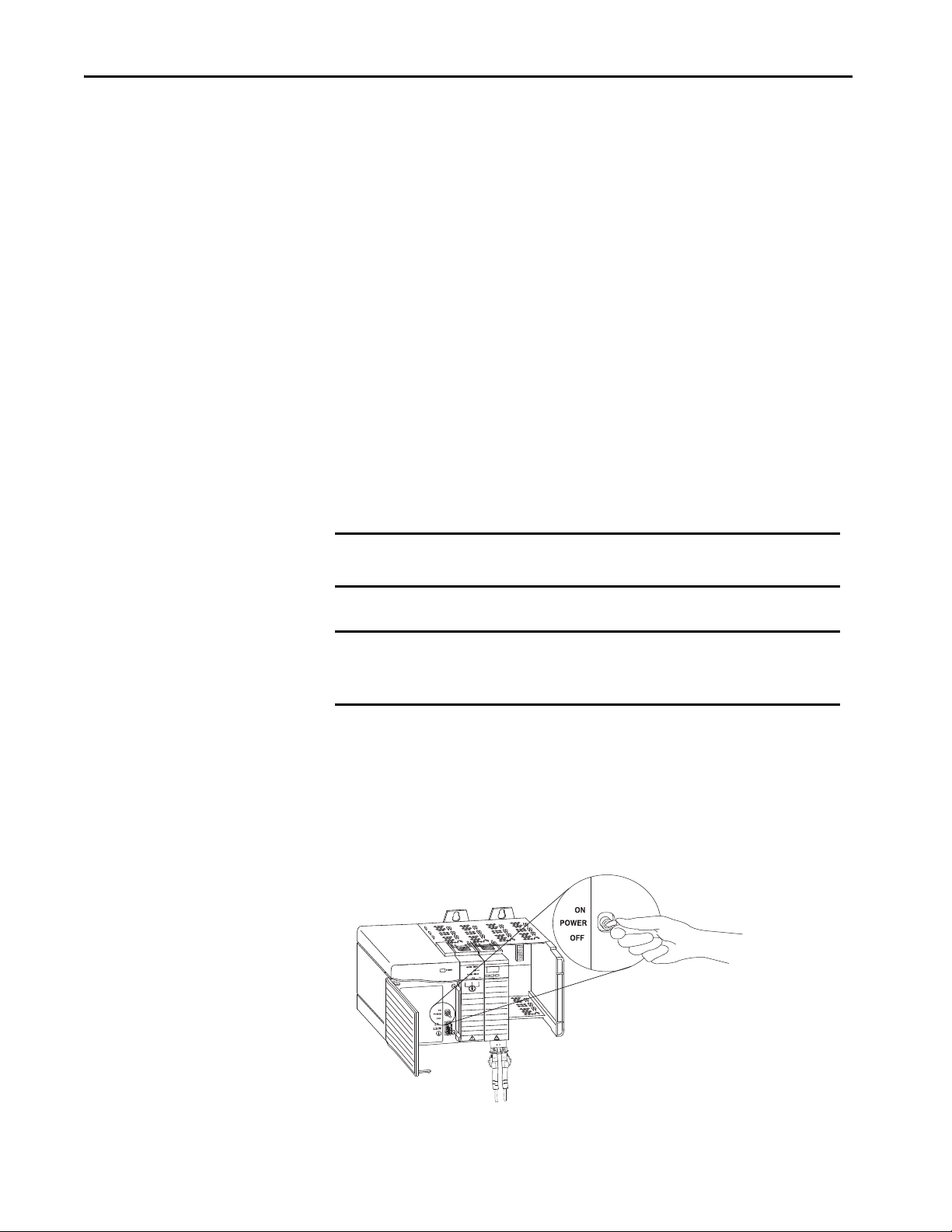

Install the Redundancy System Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Redundancy System Quick Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Install the Hardware. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install the First Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Install the Redundancy Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Environment and Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Removal and Insertion Under Power (RIUP) . . . . . . . . . . . . . . . . 47

European Hazardous Location Approval . . . . . . . . . . . . . . . . . . . . 48

Safety-related Programmable Electronic Systems . . . . . . . . . . . . . 48

Optical Ports. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Small Form-factor Pluggable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

North American Hazardous Location Approval. . . . . . . . . . . . . . 49

Laser Radiation Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Install the Second Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Connect the Redundancy Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Connect the Fiber-optic Communication Cable to

Redundant Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Connect the Fiber-optic Communication Cable to

Single Channels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Fiber-optic Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Use Dual Fiber Ports with the 1756-RM2 Redundancy

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Update Redundant Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Upgrade the Firmware in the First Chassis. . . . . . . . . . . . . . . . . . . 58

Upgrade the Firmware in the Second Chassis . . . . . . . . . . . . . . . . 61

Designate the Primary and Secondary Chassis . . . . . . . . . . . . . . . . . . . 61

After Designation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Conversion from a Non-redundant to a Redundant System . . . 62

Qualification Status Via the RMCT . . . . . . . . . . . . . . . . . . . . . . . . 63

Reset the Redundancy Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Remove or Replace the Redundancy Module. . . . . . . . . . . . . . . . . 64

Chapter 4

Configure the EtherNet/IP

Network

4 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Requested Packet Interval. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

CPU Usage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

IP Address Swapping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Static Versus Dynamic IP Addresses. . . . . . . . . . . . . . . . . . . . . . . . . 68

Reset the IP Address for an EtherNet/IP Communication

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

CIP Sync . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Produce/Consume Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Page 5

Table of Contents

Configure EtherNet/IP Communication Modules in a

Redundant System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Before You Begin. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Options for Setting the IP Addresses of EtherNet/IP

Communication Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Half/Full Duplex Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Use a Redundancy System with Device Level Ring . . . . . . . . . . . . . . . 76

Use a Redundancy System with Parallel Redundancy Protocol . . . . 77

Chapter 5

Configure the ControlNet

Network

Configure the Redundancy

Modules

Produce/Consume Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Network Update Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

NUTs with Multiple ControlNet Networks. . . . . . . . . . . . . . . . . 81

Scheduled or Unscheduled Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Use a Scheduled Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Use an Unscheduled Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Add Remote ControlNet Modules While Online . . . . . . . . . . . . 84

Schedule a New Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Update an Existing Scheduled Network . . . . . . . . . . . . . . . . . . . . . . . . . 87

Check the Network Keeper States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Save the Project for Each Primary Controller . . . . . . . . . . . . . . . . 90

Automatic Keeper Crossloads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Chapter 6

About the Redundancy Module Configuration Tool (RMCT). . . . 91

Determine If Further Configuration Is Required. . . . . . . . . . . . . . . . . 92

Use the RMCT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Identify the RMCT Version. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Update the RMCT Version . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Module Info Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Configuration Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Auto-synchronization. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Chassis ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Enable User Program Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

Redundancy Module Date and Time . . . . . . . . . . . . . . . . . . . . . . . 100

Synchronization Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Commands in the Synchronization Tab . . . . . . . . . . . . . . . . . . . . 102

Recent Synchronization Attempts Log . . . . . . . . . . . . . . . . . . . . . 103

Synchronization Status Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

System Update Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105

System Update Commands. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 106

System Update Lock Attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Locked Switchover Attempts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 5

Page 6

Table of Contents

Chapter 7

Program the Redundant

Controller

Configure the Redundant Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 112

Enable Time Synchronization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

Crossloads, Synchronization, and Switchovers . . . . . . . . . . . . . . . . . . 116

Changing Crossload and Synchronization Settings . . . . . . . . . . 116

Default Crossload and Synchronization Settings . . . . . . . . . . . . 117

Recommended Task Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Continuous Task After Switchover . . . . . . . . . . . . . . . . . . . . . . . . 117

Multiple Periodic Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Crossloads and Scan Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Estimate the Crossload Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Redundancy Object Attributes for Crossload Times. . . . . . . . . 121

Equation for Estimating Crossload Times . . . . . . . . . . . . . . . . . . 122

Program to Minimize Scan Times . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Use a ControlLogix 5570 Controller with a 1756-RM2

Redundancy Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Use Multiple Controllers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Minimize the Number of Programs . . . . . . . . . . . . . . . . . . . . . . . . 124

Manage Tags for Efficient Crossloads . . . . . . . . . . . . . . . . . . . . . . 124

Use Concise Programming . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

Program to Maintain Data Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Array (File)/Shift Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Scan-dependent Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Optimize Task Execution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 134

Periodic Task Configuration Optimization . . . . . . . . . . . . . . . . . 135

Continuous Task Configuration Optimization . . . . . . . . . . . . . 137

Change the System Overhead Time Slice . . . . . . . . . . . . . . . . . . . 138

Conduct a Test Switchover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

Synchronization After a Switchover. . . . . . . . . . . . . . . . . . . . . . . . 140

Program Logic to Run After a Switchover . . . . . . . . . . . . . . . . . . . . . . 141

Use Messages for Redundancy Commands . . . . . . . . . . . . . . . . . . . . . 142

Verify User Program Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Use an Unconnected Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Configure the MSG Instruction . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

Set the Task Watchdog . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Minimum Value for the Watchdog Time . . . . . . . . . . . . . . . . . . . 148

Download the Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Store a Redundancy Project to Nonvolatile Memory . . . . . . . . . . . . 149

Store a Project While the Controller is in Program or

Remote Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Store a Project While a System is Running . . . . . . . . . . . . . . . . . . 151

Load a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Online Edits

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Support for Partial Import Online . . . . . . . . . . . . . . . . . . . . . . . . . 152

Plan for Test Edits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Assemble Edits with Caution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Reserve Memory for Tags and Logic. . . . . . . . . . . . . . . . . . . . . . . . 158

6 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 7

Chapter 8

Table of Contents

Monitor and Maintain a

Redundancy System

Troubleshoot a Redundant

System

Controller Logging. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 159

Controller Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Controller Logging in Redundancy Systems . . . . . . . . . . . . . . . . 160

Component Change Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Monitor System Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Verify Date and Time Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Verify System Qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

Check Qualification Status Via Module Status Displays . . . . . 164

Check Qualification Status Via the RMCT. . . . . . . . . . . . . . . . . 166

Check the EtherNet/IP Module Status . . . . . . . . . . . . . . . . . . . . . . . . 166

EtherNet/IP Module CPU Usage. . . . . . . . . . . . . . . . . . . . . . . . . . 167

EtherNet/IP Module Connections Used . . . . . . . . . . . . . . . . . . . 167

Monitor the EtherNet/IP Network . . . . . . . . . . . . . . . . . . . . . . . . 167

Check the ControlNet Module Status . . . . . . . . . . . . . . . . . . . . . . . . . 168

ControlNet Module CPU Usage . . . . . . . . . . . . . . . . . . . . . . . . . . 169

ControlNet Module Connections Used . . . . . . . . . . . . . . . . . . . . 169

Monitor the ControlNet Network. . . . . . . . . . . . . . . . . . . . . . . . . 169

Chapter 9

General Troubleshooting Tasks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Check the Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . 172

Use Programming Software to View Errors . . . . . . . . . . . . . . . . . . . . . 173

Redundant Controller Major Fault Codes . . . . . . . . . . . . . . . . . . 175

Use the RMCT for Synchronization Attempts and Status . . . . . . . 176

Recent Synchronization Attempts . . . . . . . . . . . . . . . . . . . . . . . . . 176

Module-level Synchronization Status. . . . . . . . . . . . . . . . . . . . . . . 177

Use the RMCT Event Log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Interpret Event Log Information . . . . . . . . . . . . . . . . . . . . . . . . . . 178

Export All Event Logs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 182

Export Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 184

Contact Rockwell Automation Technical Support . . . . . . . . . . 186

Controller Events . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 186

Event Log Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 187

Event Classifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 188

Access Extended Information about an Event . . . . . . . . . . . . . . . 190

Interpret Extended Information for an Event . . . . . . . . . . . . . . . 191

Export Event Log Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 191

Clear a Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 196

System Event History. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 197

System Event History Column Descriptions . . . . . . . . . . . . . . . . 197

Edit a User Comment for a System Event. . . . . . . . . . . . . . . . . . . 198

Save System Event History . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 198

Event Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 7

Page 8

Table of Contents

Keeper Status Causing Synchronize Failure. . . . . . . . . . . . . . . . . . . . . 201

Check the Module Status Display. . . . . . . . . . . . . . . . . . . . . . . . . . 201

Check Keeper Status in RSNetWorx for ControlNet

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 201

Valid Keeper Status and Signatures. . . . . . . . . . . . . . . . . . . . . . . . . 202

Partner Network Connection Lost . . . . . . . . . . . . . . . . . . . . . . . . . . . . 204

Redundancy Module Connection Lost. . . . . . . . . . . . . . . . . . . . . . . . . 206

Redundancy Module Missing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 207

Qualification Aborted Due to a Non-redundant Controller . . . . . 208

Redundancy Module Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . 209

1756-RM2 and 1756-RM2XT Status Indicators . . . . . . . . . . . . 209

1756-RM/A and 1756-RM/B Status Indicators. . . . . . . . . . . . . 213

Redundancy Module Fault Codes and Display Messages . . . . . 216

Recovery Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 217

Appendix A

Convert from a Non-redundant

System

Update the Configuration in Programming Software. . . . . . . . . . . . 220

Replace Local I/O Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 222

Replace Aliases to Local I/O Tags . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 223

Remove Other Modules from the Controller Chassis. . . . . . . . . . . . 224

Add an Identical Chassis. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Upgrade to Redundancy Firmware . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225

Update the Controller Revision and Download the Project . . . . . . 225

Appendix B

Redundancy Object Attributes Table of Redundancy Object Attributes. . . . . . . . . . . . . . . . . . . . . . . . 227

Appendix C

Redundancy System Checklists Chassis Configuration Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . 231

Remote I/O Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

Redundancy Module Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . 232

ControlLogix Controller Checklist . . . . . . . . . . . . . . . . . . . . . . . . 233

ControlNet Checklist . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 234

EtherNet/IP Module Checklist. . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Project and Programming Checklist. . . . . . . . . . . . . . . . . . . . . . . . 236

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .237

8 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 9

Preface

Summary of Changes

Overview

This table contains the changes that are made to this revision.

Top ic Pag e

Added firmware revision 33.051 219, 224

In this publication, ‘ControlLogix Redundancy’ refers to

ControlLogix 5570/5560 Redundancy.

This publication provides this information specific to redundancy systems:

• Design and planning considerations

•Installation procedures

• Configuration procedures

• Maintenance and troubleshooting methods

This publication is designed for use by anyone responsible for planning and

implementing a ControlLogix® redundancy system:

• Application engineers

• Control engineers

• Instrumentation technicians

The contents of this publication are for anyone who already has an understanding

of Logix 5000™ control systems, programming techniques, and communication

networks.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Table 1 - Additional Documentation

Resource Description

1715 Redundant I/O System Specifications Technical Data, publication 1715-TD001 Contains specifications on a Redundant I/O system.

1756 ControlLogix Controllers Technical Data, publication 1756-TD001 Contains specifications on ControlLogix controllers and redundancy modules.

ControlLogix 5580 Redundant Controller User Manual, publication 1756-UM015

High Availability Systems Reference Manual, publication HIGHAV-RM002

ControlFL ASH Firmware Upgrade Software User Manual, publication 1756-UM105

ControlFLASH Plus Quick Start Guide, publication CFP-QS001C-EN-E

ControlLogix Redundancy Update and Module Replacement Guidelines Reference Manual,

publication 1756-RM010

ControlLogix System Selection Guide, publication 1756-SG001

ControlLogix System User Manual, publication 1756-UM001

Describes how to install, configure, program, operate, and troubleshoot

a ControlLogix® 5580 redundancy system..

Provides information to help design and plan high availability systems.

Describes how to use the ControlFLASH™ software to upgrade device firmware.

Describes how to use the ControlFLASH Plus™ software to upgrade device firmware.

Provides instructions for replacing modules or updating firmware in a powered-up

redundancy system.

Provides information on how to select components for a ControlLogix system.

Contains information on how to install, configure, program, and operate a

ControlLogix system.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 9

Page 10

Preface

Table 1 - Additional Documentation

Resource Description

ControlNet Network Configuration User Manual, publication CNET-UM001 Describes ControlNet® modules and how to use ControlNet modules with a Logix

EtherNet/IP Parallel Redundancy Protocol Application Technique, publication ENET-AT006 Describes how to configure a Parallel Redundancy Protocol (PRP) network with the

EtherNet/IP Device Level Ring Application Technique, publication ENET-AT007 Describes how to install, configure, and maintain linear and Device Level Ring (DLR)

EtherNet/IP Socket Interface Application Technique, publication ENET-AT002 Logix 5000Describes the socket interface that you can use to program MSG

EtherNet/IP Network Devices User Manual, publication ENET-UM006

Integrated Architecture and CIP Sync Configuration Application Technique,

publication IA-AT003

Logix 5000 Controllers Common Procedures Programming Manual,

publication 1756-PM001

Logix 5000 Controllers General Instructions Reference Manual, publication 1756-RM003

Logix 5000 Controllers Information and Status Programming Manual,

publication 1756-PM015

Logix 5000 Controllers I/O and Tag Data Programming Manual, publication 1756-PM004 Provides information on how to access I/O and tag data in Logix 5000 controllers.

Logix 5000 Controllers Major, Minor, and I/O Faults Programming Manual,

publication 1756-PM014

Logix 5000 Controllers Nonvolatile Memory Card Programming Manual,

publication 1756-PM017

Logix 5000 Produced and Consumed Tags Programming Manual,

publication 1756-PM011

Logix 5000 Controllers Quick Start, publication 1756-QS001

Logix 5000 Controllers Tasks, Programs, and Routines Programming Manual,

publication 1756-PM005

PlantPAx DCS Configuration and Implementation User Manual, publication

PROCES-UM100

Using ControlLogix in SIL 2 Applications Safety Reference Manual,

publication 1756-RM001

Redundant I/O System User Manual, publication 1715-UM001

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1

Product Certifications website, rok.auto/certifications

5000 controller.

1756-EN2TP EtherNet/IP™ communication module and a Stratix® 5400 or 5410

switch.

networks that use Rockwell Automation® EtherNet/IP devices with embedded switch

technology.

instructions to communicate bet ween a Logix 5000 controller via an EtherNet/IP

module and Ethernet devices that do not support the EtherNet/IP application

protocol.

Describes how to use EtherNet/IP communication modules with your Logix 5000

controller and communicate with various devices on the Ethernet network.

Provides an explanation of CIP Sync™ technology and how you can synchronize clocks

within the Rockwell Automation Integrated Architecture®.

Provides links to a collection of programming manuals that describe how to use

procedures that are common to all Logix 5000 controllers projects.

This manual provides details about each available instruction for a Logix-based

controller.

Describes how Logix 5000 controllers use connections with other devices.

Describes how to monitor and handle major and minor controller faults.

Provides information on how to access and use a memory card in Logix 5000

controllers.

Provides information to produce and consume system-shared tags and produce a

large array with a Logix 5000 controller.

Provides information to program and maintain Logix 5000 controllers.

Provides information to configure controller tasks and the programs and routines for

the proper execution of these tasks.

Elaborates on the application rules that are required to configure a PlantPAx® system.

Provides safety-related information specific to the use of ControlLogix modules in SIL

2 systems.

Contains information on how to install, configure, program, operate, and

troubleshoot a Redundant I/O system.

Provides general guidelines for installing a Rockwell Automation industrial system.

Provides declarations of conformity, certificates, and other certification details.

You can view or download publications at

http://www.rockwellautomation.com/global/literature-library/overview.page

To order paper copies of technical documentation, contact your local

Allen-Bradley distributor or Rockwell Automation sales representative.

10 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

.

Page 11

Chapter 1

About ControlLogix Redundancy Systems

Top ic Pa ge

Features of the ControlLogix Redundancy System 12

Redundancy System Components 13

Redundancy System Operations 15

Restrictions 19

IMPORTANT In this publication, ‘ControlLogix Redundancy’ refers to

ControlLogix 5570/5560 Redundancy.

The ControlLogix® Redundancy System is a system that provides greater

availability. The system has greater availability because it uses a redundant chassis

pair. The redundant chassis pair maintains process operation when events, such as

a fault on a controller, occur that stop process operation on

non-redundant systems.

The redundant chassis pair includes two synchronized ControlLogix chassis with

identically specific components in each. For example, one redundancy module

and at least one ControlNet® or EtherNet/IP™ communication module are

required.

Controllers are typically used in redundancy systems, but are not required if your

application only requires communication redundancy. Your application operates

from a primary chassis, but can switch over to the secondary chassis and

components if necessary.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 11

Page 12

Chapter 1 About ControlLogix Redundancy Systems

Features of the ControlLogix Redundancy System

The software and hardware components that are required to configure and use a

ControlLogix redundancy system provide these features:

• Redundancy module speeds of up to 1000 Mbps when using a 1756-RM2

module with another 1756-RM2 module. Redundancy module speeds up

to 100 Mbps when using a 1756-RM/A with another 1756-RM/A

module, and a 1756-RM/B module with another 1756-RM/B module.

• The 1756-RM2 and 1756-RM2XT modules are interference-free

regarding safety functions and can be used in ControlLogix SIL 2

applications. See the Using ControlLogix in SIL 2 Applications Safety

Reference Manual, publication 1756-RM001

• Redundant fiber ports for crossloading; no single point of failure of a fiber

cable.

• Plug-and-play-style commissioning and configuration that does not

require extensive programming.

• ControlNet and EtherNet/IP network options for the redundant

chassis pair.

• Easy-to-use, fiber-optic communication cable that connects redundant

chassis pairs. Use the same cable for the 1756-RM2 or 1756-RM/B

modules.

• Simple redundant controller configuration by using a checkbox in the

Controller Properties dialog box in the Studio 5000 Automation &

Engineering Design Environment® programming software.

• A redundancy system ready to accept commands and monitor the

redundant system states after basic installation, connection, and powerup.

• Switchovers occur as fast as 20 ms.

• Support for FactoryTalk® applications for Ethernet communication

modules including, but not limited to:

– FactoryTalk Alarms and Events

– FactoryTalk Batch

– FactoryTalk PhaseManager™

• Instruction Based Alarms (IBA) considerations:

– 5560 supports up to 250 IBA's with 250 burst

– 5570 supports up to 500 IBA's with 250 burst

– For more information see the Knowledgebase Article, ALMA/ALMD

instructions limits

• Support for CIP Sync™ technology over an EtherNet/IP network to

establish time coordination across the redundant system.

• Access to remote I/O modules over an EtherNet/IP network.

• Access to 1715 Redundant I/O systems over an EtherNet/IP network.

• Ethernet socket support.

• Support for PhaseManager.

• Supports PRP topologies. See the EtherNet/IP Parallel Redundancy

Protocol Application Technique, publication ENET-AT006

• Supports DLR and topologies. See the EtherNet/IP Device Level Ring

Application Technique, publication ENET-AT007

.

.

.

12 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 13

About ControlLogix Redundancy Systems Chapter 1

Features Not Supported

•Any motion feature

• Any SIL 3 functional safety feature within the redundancy controllers

•Firmware Supervisor

• SequenceManager™

•Event Tasks

IMPORTANT For Ethernet modules, signed and unsigned firmware are available. Signed

modules provide the assurance that only validated firmware can be upgraded

into a module.

Signed and unsigned firmware:

• Both signed and unsigned firmware are available.

• Product is shipped with unsigned firmware. To obtain signed firmware,

you must upgrade the firmware for your product.

• To obtain signed and unsigned firmware, go to

http://www.rockwellautomation.com/global/support/firmware/

overview.page.

• Once signed firmware is installed, subsequent firmware updates must be

signed also.

There are no functional/feature differences between signed and unsigned

communication modules.

Redundancy System Components

Communication between a redundant chassis pair that includes matching

components makes redundancy possible.

Each chassis in the redundant chassis pair contains these ControlLogix

components:

• One ControlLogix power supply - Required

• One ControlLogix redundancy module - Required

• Redundancy modules link the redundant chassis pair to monitor events in

each of chassis and initiate system responses as required.

• At least one ControlLogix ControlNet or EtherNet/IP communication

module - up to seven, optional (any combination)

• At least one controller - up to two controllers in the same family, optional

If the chassis is used as a redundant gateway, then a controller is not

required.

In addition, redundant chassis are connected to other components outside the

redundant chassis pair, for example, remote I/O chassis or human machine

interfaces (HMIs).

For more information about components you can use in a redundancy system, see

Chapter 2

, Design a ControlLogix Redundancy System on page 21.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 13

Page 14

Chapter 1 About ControlLogix Redundancy Systems

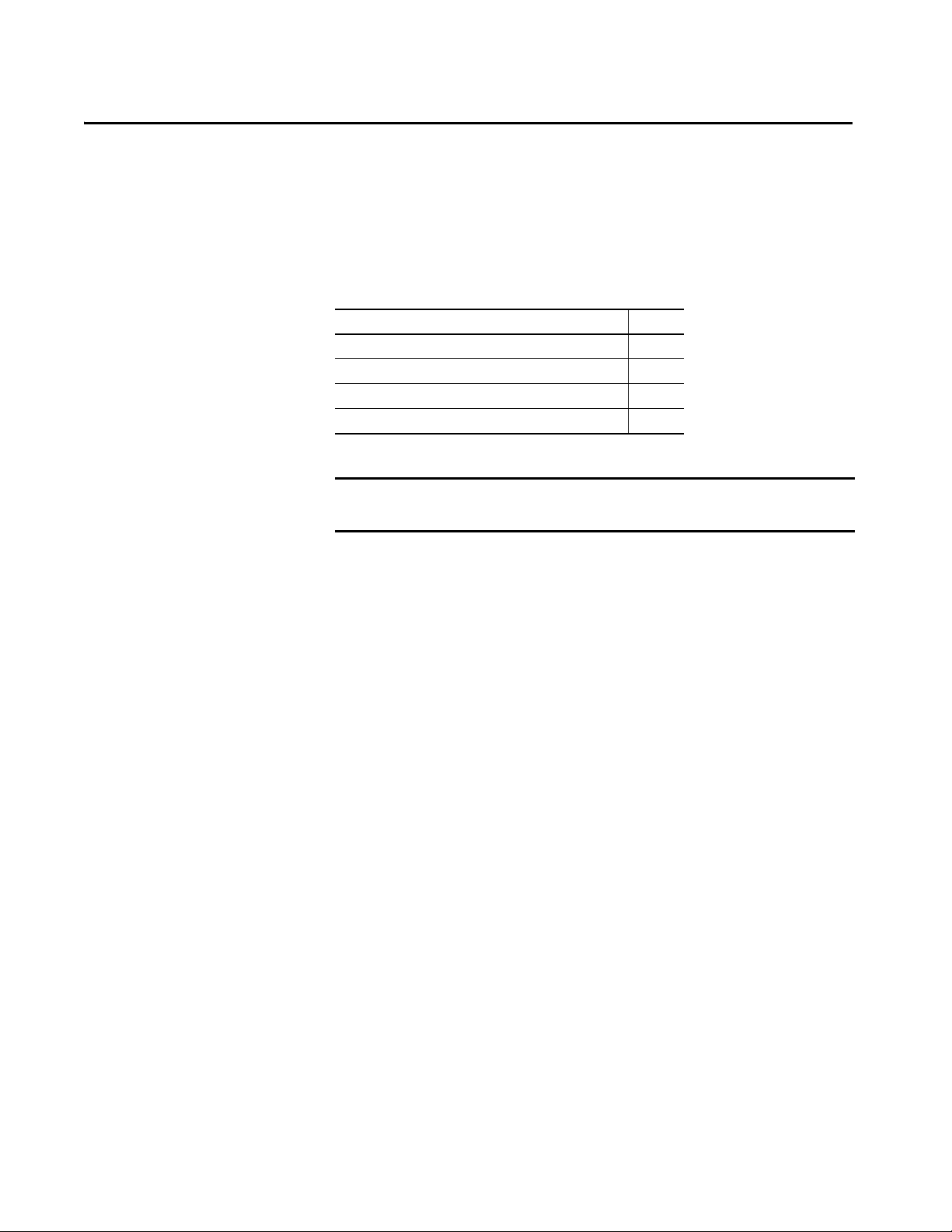

I/O Modules in Redundancy Systems

In a redundancy system, you can only use I/O modules in a remote chassis. You

cannot use I/O modules in the redundant chassis pair.

This table describes differences in network use for I/O in redundancy systems.

Remote I/O Module Placement Available with Redundancy System, Revision 19 and Later Available with Redundancy System, Revision 16 or Earlier

EtherNet/IP I/O network x -

ControlNet network x x

DeviceNet® network

Data Highway Plus™

Universal remote I/O

(1) In a redundancy system, you can access remote I/O modules on this network only via a ControlNet or EtherNet/IP network bridge.

(2) 1756-DHRIO module must be used with a channel configured for RIO.

(1)

(1)

(1)(2)

xx

xx

xx

For more information on how to use remote and 1715 redundant I/O over an

Ethernet network, see I/O Placement on page 36

User Manual, publication 1715-UM001

.

and the Redundant I/O System

14 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 15

About ControlLogix Redundancy Systems Chapter 1

Redundancy System Operations

Once the redundancy modules in the redundant chassis pair are connected and

powered, they determine which chassis is the primary chassis and which is the

secondary chassis.

The redundancy modules in both the primary and secondary chassis monitor

events that occur in each of the redundant chassis. If certain faults occur in the

primary chassis, the redundancy modules execute a switchover to the unfaulted,

secondary chassis.

System Qualification and Synchronization

When the redundant system is first started, the redundancy modules run checks

on the redundant chassis. These checks determine if the chassis contain the

appropriate modules and firmware to establish a redundant system. This stage of

checks is referred to as qualification.

After the redundancy modules complete qualification, synchronization can take

place. Synchronization is a state in which the redundancy modules execute these

tasks:

• Verify that the connection between redundancy modules is ready to

facilitate a switchover

• Verify that the redundant chassis continue to meet qualification

requirements

• Synchronize the data between the redundant controllers, also called

crossloading

This data is crossloaded:

–Updated tag values

–Forced values

–Online edits

–Other project information

Synchronization always takes place immediately following qualification. Also,

depending on your system configuration, synchronization takes place at the end

of each program that is run within the controller project, or at other intervals that

you specify.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 15

Page 16

Chapter 1 About ControlLogix Redundancy Systems

Switchovers

During redundant system operation, if certain conditions occur on the primary

chassis, primary control is switched to the secondary chassis. These conditions

cause a switchover:

•Loss of power

• Major fault on the controller

• Removal or insertion of any module

• Failure of any module

• Damage to a ControlNet cable or tap - This event only causes a switchover

if it results in the ControlNet communication module transition to a

lonely state, that is, the module does not see any devices on the network.

• Loss of an EtherNet/IP connection - This event only causes a switchover if

it results in the EtherNet/IP communication module transition to a lonely

state, that is, the module does not see any devices on the network.

• A program-prompted command to switchover

• A command that is issued via the Redundancy Module Configuration

To ol (R M CT )

After a switchover occurs, the new primary controller continues to execute

programs, which begin with the highest-priority task that had been executing on

the previous primary controller.

For more information about how tasks execute after a switchover, see Crossloads,

Synchronization, and Switchovers on page 116.

Your application can require some programming considerations and potential

changes to accommodate a switchover. For more information on these

considerations, see Chapter 7

, Program the Redundant Controller on page 111.

IMPORTANT During a switchover of the fiber channels of the 1756-RM2 module, scan

time encounters a delay of ~10 ms; however, the chassis always remains

synched.

16 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 17

About ControlLogix Redundancy Systems Chapter 1

Data Server Communication Recovery Time Reduction During a Switchover

Brief communication interruption occurs between FactoryTalk Linx software

and the redundant chassis pair when a switchover occurs. After the switchover is

complete, communication resumes automatically.

Data server communication recovery time is the time during a switchover from

primary to secondary, when tag data from the controller is unavailable for reading

or writing. Data server communication recovery time applies to any software that

uses tag data, such as HMI displays, data loggers, alarms systems, or historians.

Data server communication recovery time reduction is important to increase the

availability of the system.

IMPORTANT • Prior to firmware revision 30.051, the communication delays apply only

when communication is exclusively over EtherNet/IP networks.

• With fir mware revision 30.051 or later, the communication delays apply to

both EtherNet/IP and ControlNet networks.

IMPORTANT FactoryTalk Linx software is part of FactoryTalk Services, which has been

releasing a series of Service Releases (SRs) that are backward compatible

with any CPR 9 products. Existing and new users who are using FactoryTalk

View version 5.0 (CPR9) or later can use the data server communication

recovery time feature.

As of revision 31.052, the communication delays over Ethernet during a

switchover event have been reduced significantly. When you configure the

connection between a FactoryTalk Linx data server, and a redundant

ControlLogix controller, you can configure redundant shortcut paths to the

primary and secondary controllers. These shortcut paths help reduce data server

communication recovery time that occurs during a redundancy switchover.

The following are required to take advantage of this:

• A dedicated pair of ControlLogix Communication Modules with

firmware revision 11.001 or later (1756-EN2TP, 1756-EN2TR,

1756-EN2T), that do not swap IP addresses. See Do Not Use IP Address

Swapping on page 66.

• ControlLogix 5570 redundancy controllers with redundancy firmware

revision 31.052 or later

• FactoryTalk Linx 6.00 with the FactoryTalk Linx patch available from

Rockwell Automation Knowledgebase Article Patch: FactoryTalk Linx

6.00 patch required to support ControlLogix V31.05 Redundancy, or later

versions of FactoryTalk Linx.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 17

Page 18

Chapter 1 About ControlLogix Redundancy Systems

• Redundant ControlLogix Controller shortcut type in FactoryTalk Linx

that points to the Primary and Secondary controllers through the

communication modules, without swapping IP addresses. For information

on shortcuts in FactoryTalk Linx, see the FactoryTalk Linx Getting Results

Guide, publication LNXENT-GR001

.

18 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 19

About ControlLogix Redundancy Systems Chapter 1

Some communication delays can occur during qualification. The existence and

duration of these delays depend on:

• Quantity and types of tags on scan in FactoryTalk Linx software

• Client screen and tag update rates (e.g. FactoryTalk Live Data/FactoryTalk

Historian)

• Number of data subscribers (i.e. FactoryTalk Alarms and Events,

FactoryTalk Batch)

• Size of the application in the redundant controller

• Controller loading, which includes the following:

• Number of tasks and scan rates (assumes no continuous task)

• Number of programs

•Memory usage

• Null task percentage available

•Network traffic

Restrictions

There are restrictions that you must consider when using a redundancy system.

Most of these restrictions apply to all redundancy system revisions. Exceptions

are noted:

• See the release notes of the redundancy bundles for compatible products,

versions, and revisions

• The redundant controller program cannot contain these tasks:

–Event tasks

– Inhibited tasks

For recommendations and requirements that are related to programming

the redundant controller, see Program the Redundant Controller on

page 111.

• You cannot use the Match Project to Controller feature available in Studio

5000 Logix Designer® in a redundancy system.

• You cannot use motion in a redundant controller program.

• You cannot use SequenceManager.

• You cannot use consumed unicast connections in a redundancy system. If

you attempt to use consumed unicast connections, disqualification occurs

and qualification of an unsynchronized redundant chassis pair is not

allowed. You can use produced unicast connections that remote consumers

consume.

• Outputs controlled by specific instructions are not guaranteed to maintain

a bumpless transition during a switchover. Due to this, it is recommended

to avoid using the following instructions within a redundancy system:

–IOT

–HMIBC

• You can use a maximum of two controllers of the same family, and seven

ControlNet or EtherNet/IP communication modules in each chassis of a

redundant chassis pair.

• You can execute the tasks that were supported previously in a redundancy

system, revision 19.052 or greater.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 19

Page 20

Chapter 1 About ControlLogix Redundancy Systems

01 12 13 24

Catalyst 9300 24S

NETWORK MODULE

C9300-NM-2Q

40G 1

40G 2

01 12 13 24

Catalyst 9300 24S

NETWORK MODULE

C9300-NM-2Q

40G 1

40G 2

01 12 13 24

Catalyst 9300 24S

NETWORK MODULE

C9300-NM-2Q

40G 1

40G 2

01 12 13 24

Catalyst 9300 24S

NETWORK MODULE

C9300-NM-2Q

40G 1

40G 2

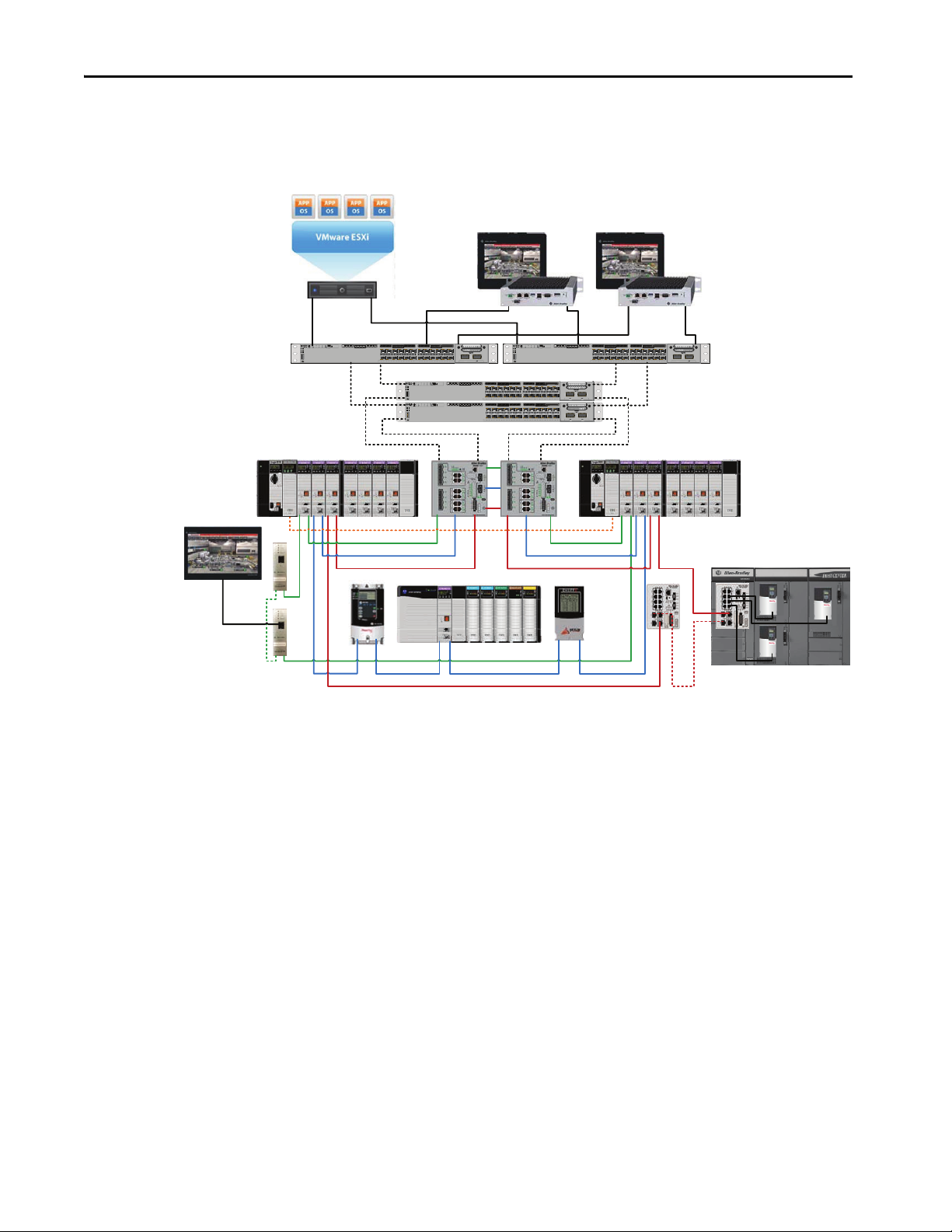

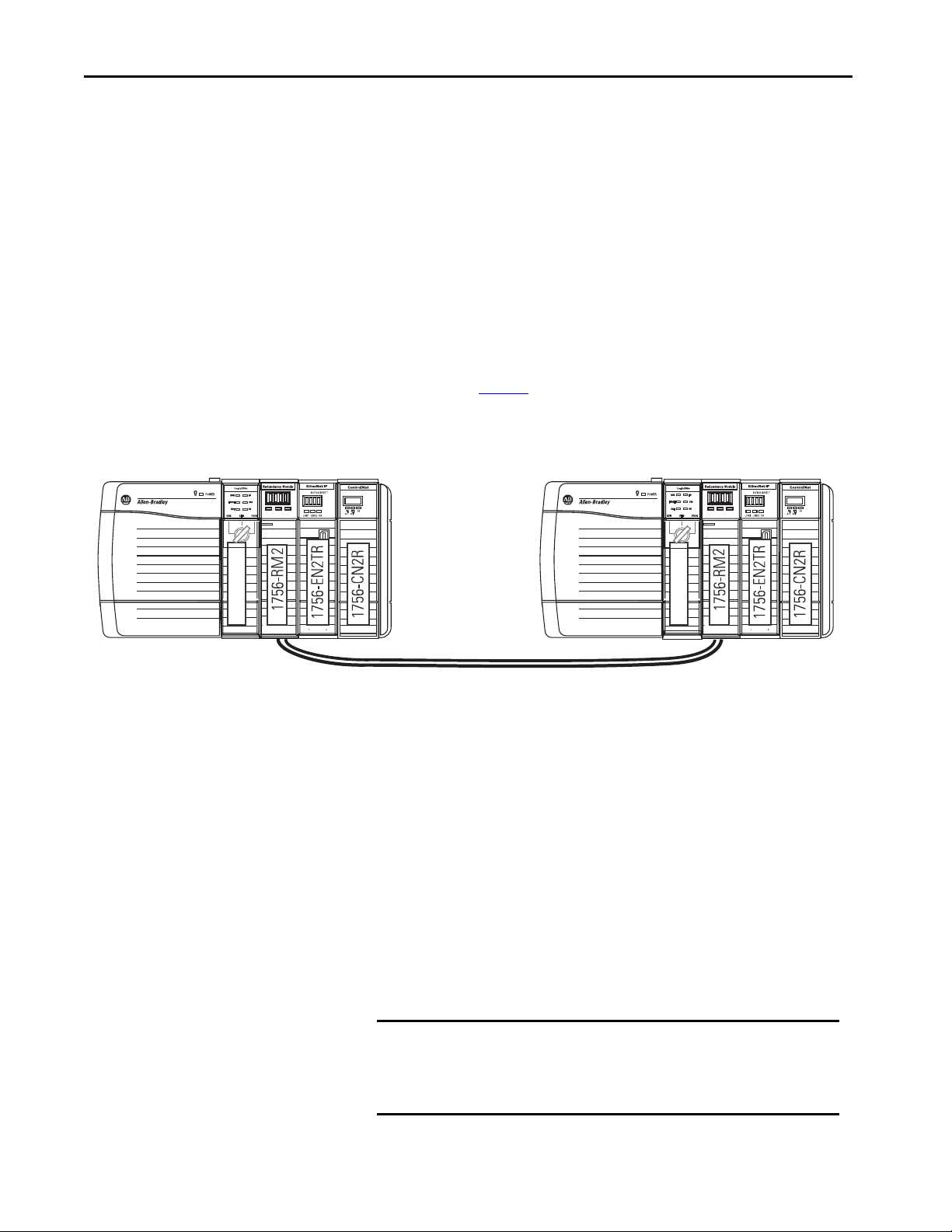

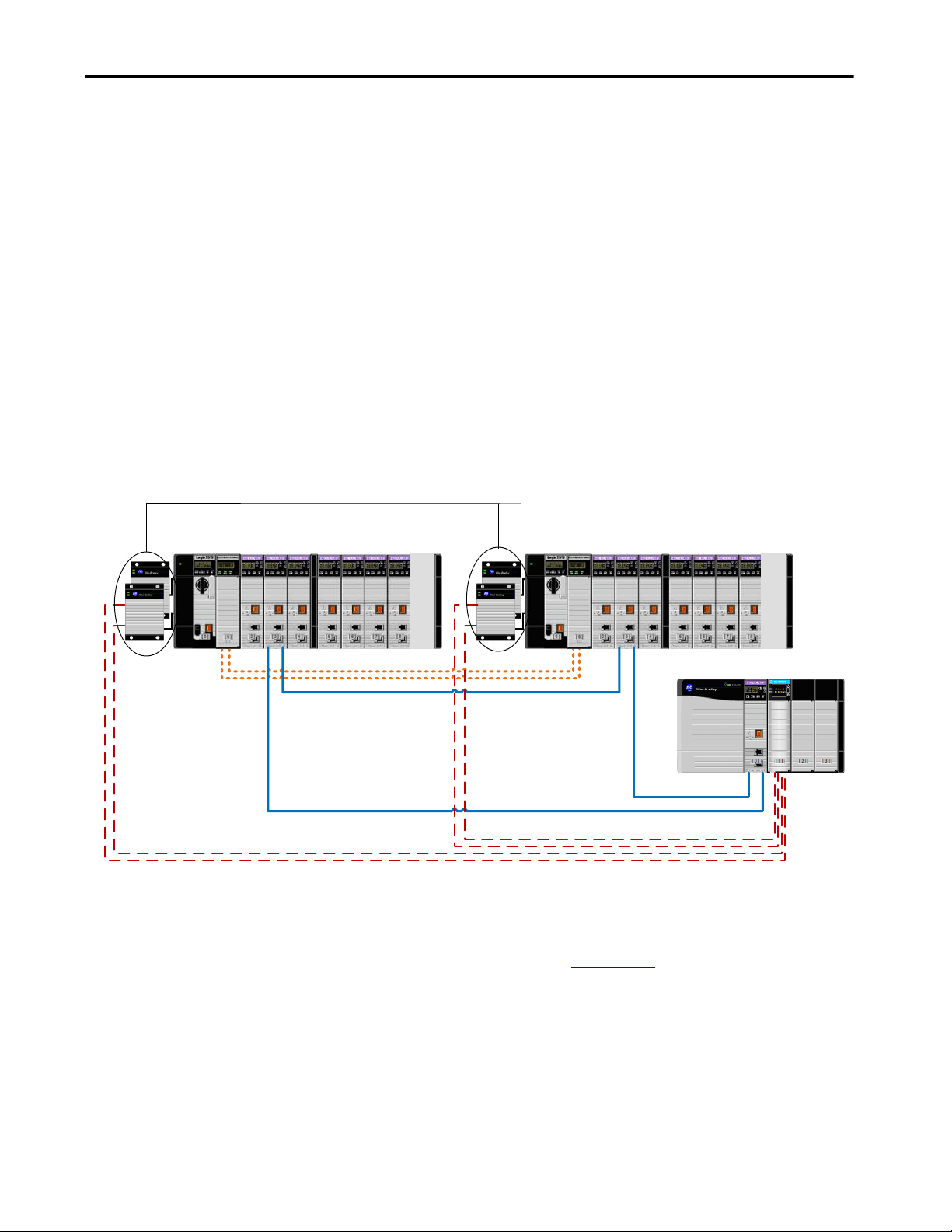

This graphic shows an example ControlLogix redundancy system,

revision 19.053 or greater, which uses EtherNet/IP networks.

Figure 1 - Example ControlLogix Redundancy System using an EtherNet/IP Network

20 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 21

Chapter 2

Design a ControlLogix Redundancy System

Top ic Pa ge

Redundant Chassis 21

Controllers in Redundant Chassis 22

EtherNet/IP Networks with Redundant Systems 28

ControlNet Networks with Redundant Systems 30

Other Communication Networks 34

I/O Placement 36

Using HMI 38

Optional Software 41

This chapter explains how to use the required and optional components to design

a redundancy system.

Redundant Chassis

IMPORTANT There are module series level, firmware revision, and software version

requirements for redundancy systems.

For more information on these module series level, firmware revision, and

version requirements, see the current release notes at:

http://www.rockwellautomation.com/global/literature-library/

overview.page

You can use any ControlLogix® or ControlLogix-XT™ chassis in a redundant

chassis pair as long as the two chassis that are used are the same size. For example,

if the primary chassis in your redundant chassis pair uses a 1756-A4 chassis, the

secondary chassis must use a 1756-A4 chassis.

TIP When using 1756-L72, 1756-L73, 1756-L74, or 1756-L75 Redundant

controllers in your system, you must use firmware revision 19.053 or greater.

When using a 1756-L71 Redundant controller, you must use firmware

20.054 or greater.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 21

Page 22

Chapter 2 Design a ControlLogix Redundancy System

CH2 CH1 OK

CH2 CH1 OK

1756-L64

1756-L64

01 2 3 0 1 23

Redundant Chassis Configuration Requirements

These configuration parameters must match for the components in a redundant

chassis pair during normal system operation:

•Module type

• Chassis size

• Slot placement

•Firmware revision

•Series level. See page 25

Figure 2 - Example of Redundant Chassis Pair

Controllers in Redundant Chassis

Remember these points when you place controllers in the redundant chassis pair:

• Controllers are typically included, but not required, in redundancy

systems. If you have a redundancy system without controllers, you have

only a redundant gateway rack.

• You can place up to two controllers in the same chassis. When you use two

controllers in the same chassis, they must be of the same product family.

The series of the controller in the primary and secondary chassis do not

need to match.

For example, you cannot place a ControlLogix 5560 controller and a

ControlLogix 5570 controller in the same chassis.

IMPORTANT When using a ControlLogix redundancy system, revision 16.081 or

earlier, you cannot use two 1756-L64 controllers in the same

chassis. You can, however, use a 1756-L64 controller in the same

chassis as a 1756-L61, 1756-L62, or 1756-L63 controller.

22 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 23

Design a ControlLogix Redundancy System Chapter 2

• You can use different catalog numbers from the same product family in the

same chassis. For example, you can use two ControlLogix 5560 controllers

in a chassis.

• Each ControlLogix 5560/5570 controller must have enough data memory

to store twice the amount of tag data that is associated with a redundant

controller project.

TIP ControlLogix 5580 controllers that are enabled for redundancy do not have

memory constraints.ControlLogix 5580 controllers that are enabled for

redundancy experience no reduction in memory from a standard use

ControlLogix 5580 controller.

• Each controller must have enough I/O memory to store twice the amount

of I/O memory used. To check the I/O memory that is used and available,

access the Memory tab of the Controller Properties dialog box in the

programming software.

For more information about data and I/O memory, see the

Knowledgebase Article Understanding ControlLogix Redundancy Memory

Usage.

• When you use the redundancy system update (RSU) feature to update a

redundancy system while the system continues operation, the updated

controllers must provide the same or greater memory than the existing

controllers.

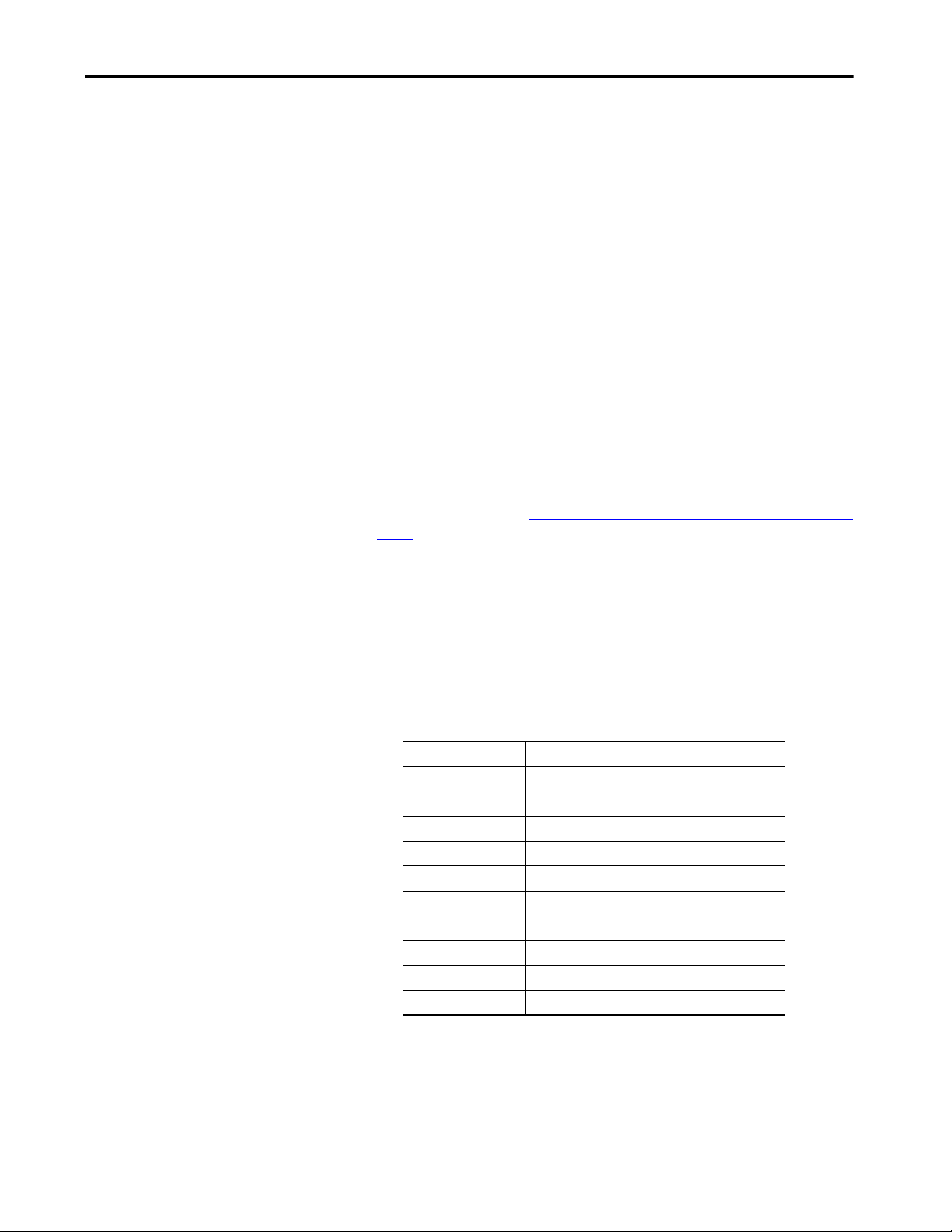

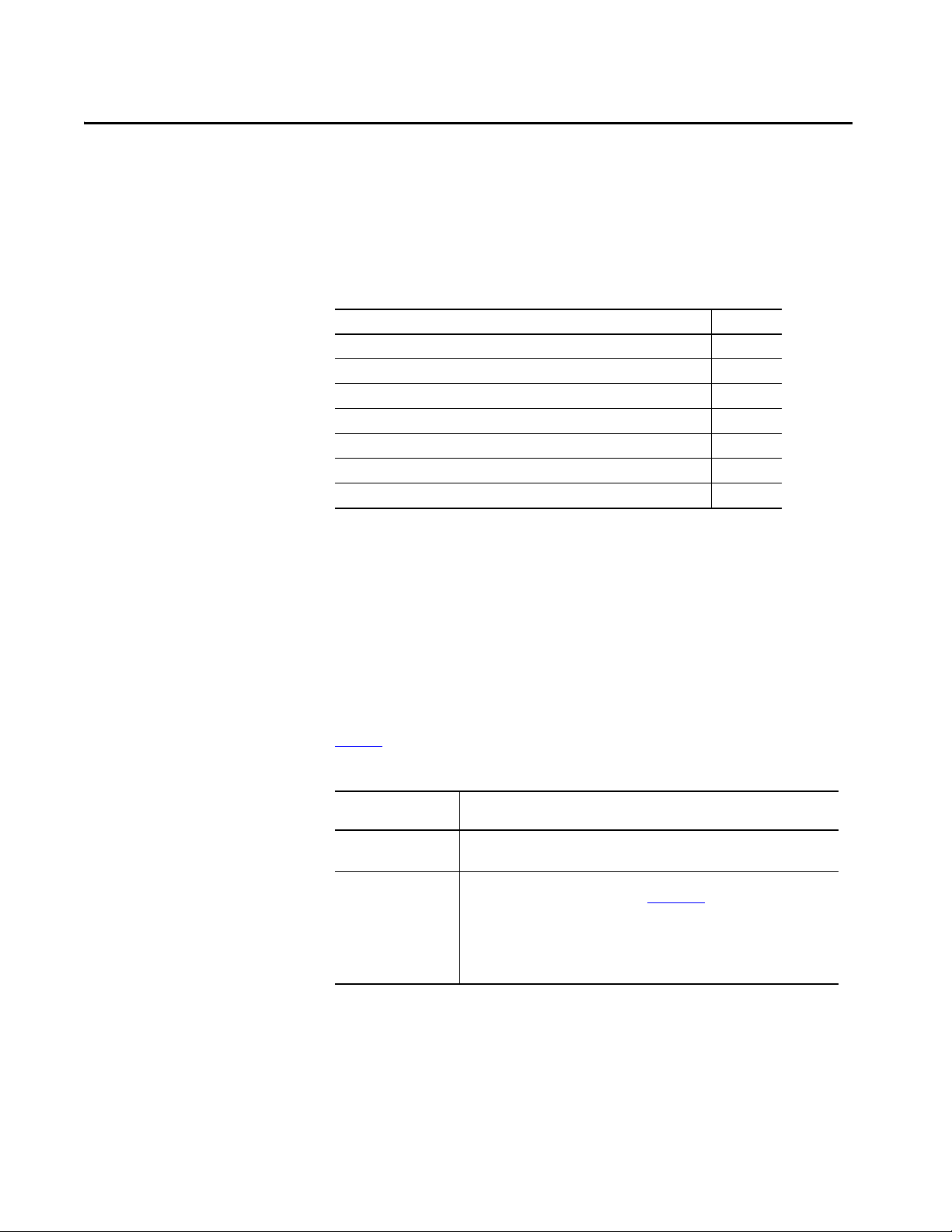

This table describes the controllers to which you can upgrade, based on the

existing controller that is used, when using RSU.

Existing New Controller

1756-L61 1756-L61, 1756-L62, 1756-L63, 1756-L64, 1756-L65

1756-L62 1756-L62, 1756-L63, 1756-L64, 1756-L65

1756-L63 1756-L63, 1756-L64, 1756-L65

1756-L64 1756-L64, 1756-L65

1756-L65 1756-L65

1756-L71 1756-L71, 1756-L72, 1756-L73, 1756-L74, 1756-L75

1756-L72 1756-L72, 1756-L73, 1756-L74, 1756-L75

1756-L73 1756-L73, 1756-L74, 1756-L75

1756-L74 1756-L74, 1756-L75

1756-L75 1756-L75

Differences in controller types between chassis can exist only during the

system upgrade process. When you complete the system upgrade, the

controllers in the redundant chassis pair must match for the system to

synchronize.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 23

Page 24

Chapter 2 Design a ControlLogix Redundancy System

Plan for Controller Connections

Consider these conditions when you plan controller connection use:

• ControlLogix 5560 controllers provide 250 total connections.

• ControlLogix 5570 controllers provide 500 total connections.

If you use the redundant controller at, or very near the connection limits, you can

experience difficulty synchronizing your chassis.

Redundancy Modules in Redundant Chassis

Two redundancy modules, one in each chassis of the redundant chassis pair,

jointly supervise the control system operating states and transitions, which

establishes the framework for system redundancy. This bridge between chassis

facilitates the exchange of control data and synchronization of operations.

The redundancy modules let you commission the redundant system in a plugand-play manner without any programming. You connect a redundancy module

pair with the default configuration in the redundant chassis pair and configure

the redundant system.

You can establish redundancy between chassis in either of these manners:

• Insert a redundancy module pair into two powered chassis that contain

redundancy-compliant components and redundancy-enabled application

programs, and then connect the redundancy modules.

• Insert and connect the redundancy modules in two chassis and then insert

redundancy-compliant components into each chassis.

IMPORTANT You are not required to develop any programming to migrate from a non-

redundant to a redundancy system if your application meets these

conditions:

• Your application meets the points that are listed in Restrictions on

page 19.

• The controller properties dialog box in your project has Redundancy

enabled.

Once the redundant chassis pair contains all desired components and is powered,

no further tasks are required in the redundancy modules to activate system

redundancy. The redundancy modules automatically determine the operational

state of each of the chassis pair and are ready to accept commands and provide

system monitoring.

24 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 25

Design a ControlLogix Redundancy System Chapter 2

Communication Modules in Redundant Chassis

Remember these points when placing ControlLogix ControlNet® and

EtherNet/IP™ communication modules in the redundant chassis pair:

• You must use enhanced communication modules in redundancy systems.

Enhanced communication modules contain a ‘2’ in their catalog number.

For example, the 1756-EN2T module.

•Standard ControlNet and EtherNet/IP communication modules are not

supported. Standard communication modules contain a 'B' in their catalog

number. For example, the 1756-ENBT module.

• You can use the 1756-EN2TR module only with a redundancy system,

revision 19.052 or later.

• You can use the 1756-EN2F module only with a redundancy system,

revision 20.054 or later.

• You can use the 1756-EN2TP module only with a redundancy system,

revision 31.052 or later.

• You can use any combination of up to seven enhanced communication

modules in each redundant chassis.

• If you use a ControlNet network in your redundant chassis pair, you must

have two ControlNet communication modules outside the redundant

chassis pair. When you assign node address numbers, assign the lowest

node number address to a ControlNet communication module outside the

redundant chassis pair.

For more information, see Use at Least Four ControlNet Network Nodes

on page 30 through Assign Lowest Node Numbers to Remote ControlNet

Modules on page 31.

• You cannot use Series A ControlNet communication modules in a

redundancy system.

• The Series for EtherNet/IP communication modules is not required to

match in a partnered set. However, the firmware levels must be the same in

a partnered set. Also, if your application requires a feature specific to a

module series level, you must use the same series level for each module in a

partnered set.

For example, only the 1756-EN2T/C communication module only offers

the double-data rate (DDR) feature. You must use 1756-EN2T/C

modules in each chassis of the redundant chassis pair to use DDR.

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 25

Page 26

Chapter 2 Design a ControlLogix Redundancy System

• Do not use the USB ports of communication modules to access the

redundant system network while the system is running, that is, online. Use

of the USB ports while online can result in a loss of communication after a

switchover.

Plan for Communication Module Connections

A CIP™ connection is a point-to-point communication mechanism that is used

to transfer data between a producer and a consumer. These mechanisms are

examples of CIP connections:

• Logix 5000™ controller message transfer to Logix 5000 controller

•I/O or produced tag

• Program upload

• RSLinx® DDE/OPC client

• PanelView™ polling of a Logix 5000 controller

ControlLogix ControlNet communication modules provide 131 total CIP

connections. Consider these points when using CIP connections with

ControlLogix ControlNet communication modules:

• Three of the 131 CIP connections are reserved for redundancy. The three

redundant-system CIP connections always appear to be in use, even when

no connections are open.

• You can use the remaining 128 CIP connections in any manner that your

application requires, such as the examples listed previously.

ControlLogix EtherNet/IP communication modules provide 259 total CIP

connections. Consider these points when using CIP connections with

ControlLogix EtherNet/IP communication modules:

• Three of the 259 CIP connections are reserved for redundancy.

• You can use the remaining 256 connections in any manner that your

application requires, such as the examples listed previously.

26 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 27

Design a ControlLogix Redundancy System Chapter 2

1756-PA75R or 1756-PB75R Power Supplies

Annunciator Wiring (optional)

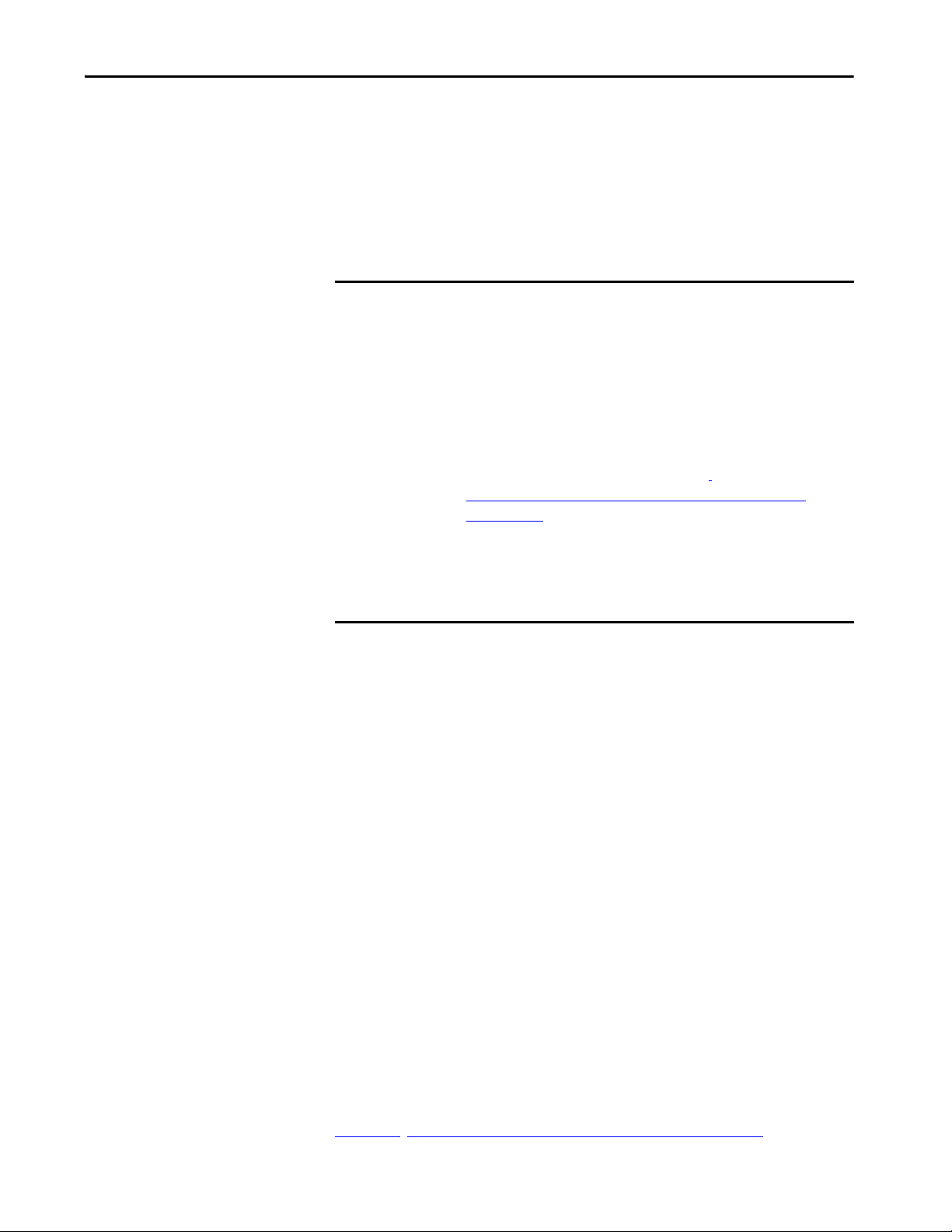

Power Supplies and Redundant Power Supplies in Redundancy Systems

Redundancy systems can use standard power supplies. You can choose to use

redundant power supplies to maintain power to a ControlLogix chassis if one of

the supplies loses power. Use these hardware components to connect redundant

power supplies:

• Two redundant power supplies for each chassis

• One 1756-PSCA chassis adapter for each redundant chassis

• Two 1756-CPR cables for each redundant chassis to connect the power

supplies to the 1756-PSCA adapter

• Optional, user-supplied annunciator wiring to connect the power supplies

to remote input modules

Figure 3 - Redundant Power Supplies with Redundant Chassis

For more information about redundant power supplies, see the ControlLogix

System Selection Guide, publication 1756-SG001

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 27

.

Page 28

Chapter 2 Design a ControlLogix Redundancy System

EtherNet/IP Networks with Redundant Systems

The use of EtherNet/IP networks in a redundancy system is primarily dependent

on your system revision.

IMPORTANT A remote chassis can be accessed over an EtherNet/IP network by using any

EtherNet/IP module that works in a non-redundant chassis with no

additional firmware requirement with the following exception. If the remote

chassis contains a controller that consumes a tag that is produced in the

redundant chassis pair, it can only consume the tag with the required

firmware revisions.

For more information on how to use an EtherNet/IP network in your

redundancy system, see Configure the EtherNet/IP Network on page 65

.

Unicast Functionality

Redundancy systems support unicast produced tags. Unicast consumed tags are

not supported in redundancy systems. Unicast I/O is not supported in a

redundancy system.

Possible Communication Delays on EtherNet/IP and ControlNet Networks

The connection between a component and the redundant chassis pair can

experience brief communication delays during a switchover. After the switchover

is complete, communication resumes automatically.

These connection types can experience the communication delay when the

switchover occurs:

• HMI to redundant chassis pair

• FactoryTalk® Batch server to redundant chassis pair

• FactoryTalk Alarms and Events Service to redundant chassis pair

IMPORTANT • Prior to firmware revision 30.051, the communication delays apply only

when communication is exclusively over EtherNet/IP networks.

• With fir mware revision 30.051 or later, the communication delays apply to

both EtherNet/IP and ControlNet networks.

28 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 29

Design a ControlLogix Redundancy System Chapter 2

ControlNe t

EtherNet/IP

HMI

Redundant Chassis Pair

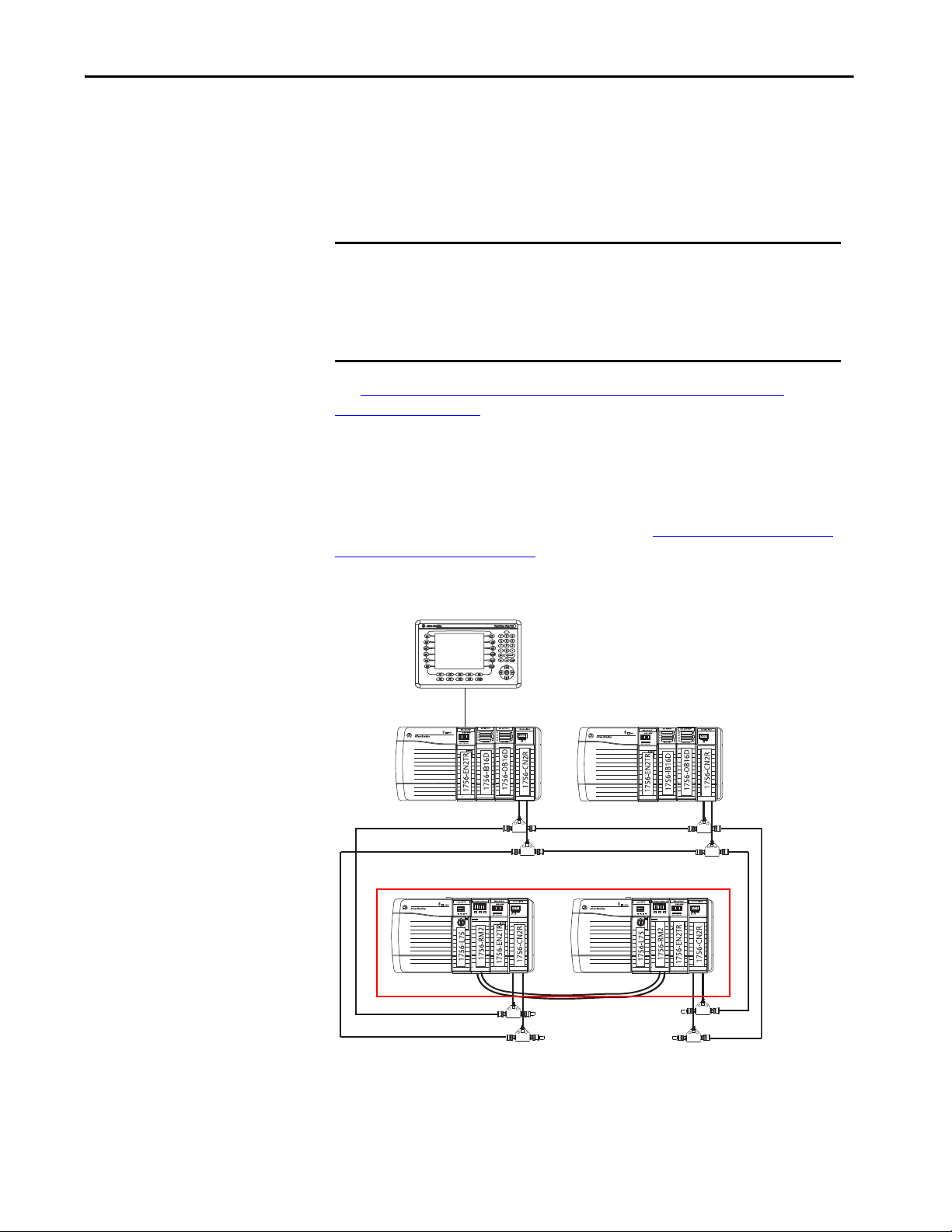

Bridge from an EtherNet/IP Network to a ControlNet Network

Bridge from an EtherNet/IP network to a ControlNet network if you must

maintain the connection between the component and a redundant chassis pair

during a switchover.

IMPORTANT You can bridge from an EtherNet/IP network to a ControlNet network to

maintain the connection between the component and a redundant chassis

only in redundancy firmware revisions prior to revision 30.051.

I/O connections are not supported in any bridge configurations in any

version.

See Data Server Communication Recovery Time Reduction During a

Switchover on page 17.

This example graphic shows the recommended method to connect an HMI to a

redundant chassis pair if connection drops are a concern in your application. In

this graphic, the remote chassis contains I/O modules and the EtherNet/IP and

ControlNet communication modules. The I/O modules are not required and are

shown for example only. For all requirements, see ControlNet Networks with

Redundant Systems on page 30.

Figure 4 - Configuration Used to Eliminate Communication Delays on Switchover

CH2 CH1 OK

CH2 CH1 OK

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 29

Page 30

Chapter 2 Design a ControlLogix Redundancy System

ControlNet Networks with Redundant Systems

ControlNet networks are used to connect redundant controller chassis to remote

I/O and to other devices in the system.

IMPORTANT A remote chassis can be accessed over a ControlNet network that uses any

ControlNet module that works in a non-redundant chassis with no

additional firmware requirement.

ControlNet Network Requirements

If you use a ControlNet network in your redundancy system, you must

consider the following:

• Use at Least Four ControlNet Network Nodes

• Assign Lowest Node Numbers to Remote ControlNet Modules

• Set Partnered ControlNet Module Switches to the Same Address

• Reserve Consecutive Node Addresses for Partner Modules

Use at Least Four ControlNet Network Nodes

With redundant systems, at least four ControlNet network nodes are required

per ControlNet network. This configuration is required because two or more

ControlNet nodes must be used with the two ControlNet modules that are used

in the redundant chassis. One of the two nodes outside of the redundant chassis

must be at a lower node address than the ControlNet modules in the redundant

chassis.

If your ControlNet uses fewer than four nodes, and a switchover occurs,

connections can drop and outputs connected to that node can change state

during the switchover.

You can include these ControlNet modules and redundant ControlNet nodes:

• ControlNet bridges in remote chassis

• Any other ControlNet devices on the ControlNet network

• A workstation running RSLinx Classic communication software that is

connected via a ControlNet network

For more information, see Knowledgebase Article ControlNet Network Keeper

and ControlLogix Redundancy.

30 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 31

Design a ControlLogix Redundancy System Chapter 2

ControlNet Module Switches

Assign Lowest Node Numbers to Remote ControlNet Modules

Do not assign the lowest ControlNet node addresses to ControlNet modules in

the redundant chassis pair.

If you assign the lowest ControlNet node addresses to ControlNet modules in

the redundant chassis pair, you can experience these system behaviors:

• Upon a switchover, you can lose communication with I/O modules,

produced tags, and consumed tags.

• If you remove a ControlNet module from the redundant chassis, it can

result in lost communication with I/O modules, produced tags, and

consumed tags.

• If the entire system loses power, you can be required to cycle power to the

primary chassis to restore communication.

Set Partnered ControlNet Module Switches to the Same Address

Where ControlNet modules are used as partners in a redundant chassis pair, you

must set the node address switches to the same node address. The primary

ControlNet modules can be at even or odd node addresses.

For example, if partnered ControlNet modules are assigned to nodes 12 and 13

of the ControlNet network, set the node address switches of the modules to the

same address of 12.

Figure 5 - Example of Switch Address for Partnered ControlNet Modules

CH2 CH1 OK

1756-L64

CH2 CH1 OK

1756-L64

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 31

Page 32

Chapter 2 Design a ControlLogix Redundancy System

CH2 CH1 OK

CH2 CH1 OK

1756-L64

1756-L64

Node 12 Node 13

ControlNet Module Switches

Primary Chassis Secondary Chassis

Reserve Consecutive Node Addresses for Partner Modules

Where ControlNet modules are used as partners in redundant chassis, plan

consecutive node numbers for those partnered modules. Plan for consecutive

node addresses because the redundant system automatically assigns the

consecutive node address to the secondary ControlNet module.

For example, partnered ControlNet modules with address switches set at 12 are

assigned ControlNet node numbers 12 and 13 by the system.

TIP The primary chassis always assumes the lower of the two node

addresses.

Figure 6 - Example of Redundant ControlNet Modules at Consecutive Addresses

32 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 33

Design a ControlLogix Redundancy System Chapter 2

Redundant ControlLogix Chassis with

1756-CN2R Modules

Redundant Trunk Lines

Work stati on wi th Con trolN et

Interface Card

Redundant ControlNet Media

The use of redundant ControlNet media helps to prevent a loss of

communication if a trunkline or tap is severed or disconnected. A system that

uses redundant ControlNet media uses these components:

• 1756-CN2R, series B or later, communication modules in each redundant

chassis

• ControlNet modules that are designed for redundant media at each

ControlNet node on the network

• Redundant trunk cabling

• Redundant tap connections for each ControlNet module connected

Figure 7 - Redundant ControlNet Media with Redundant ControlLogix Chassis

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 33

Page 34

Chapter 2 Design a ControlLogix Redundancy System

Secondary Chassis

Chassis Bridge from EtherNet/IP

to Remote I/O Net works

Primary Chassis

Other Communication Networks

You can use only EtherNet/IP and ControlNet networks, and corresponding

modules, in the local chassis for redundancy systems.

IMPORTANT Do not use the redundant chassis to bridge between networks. Bridging

through the redundant chassis to the same or different networks, or

routing messages through redundant chassis is not supported.

You can bridge to other communication networks outside of the redundant

chassis. You can bridge these networks via a remote chassis:

• DeviceNet

•Universal remote I/O

•Data Highway Plus™

Figure 8 - Example of Bridging to Remote I/O on Various Networks

34 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 35

Design a ControlLogix Redundancy System Chapter 2

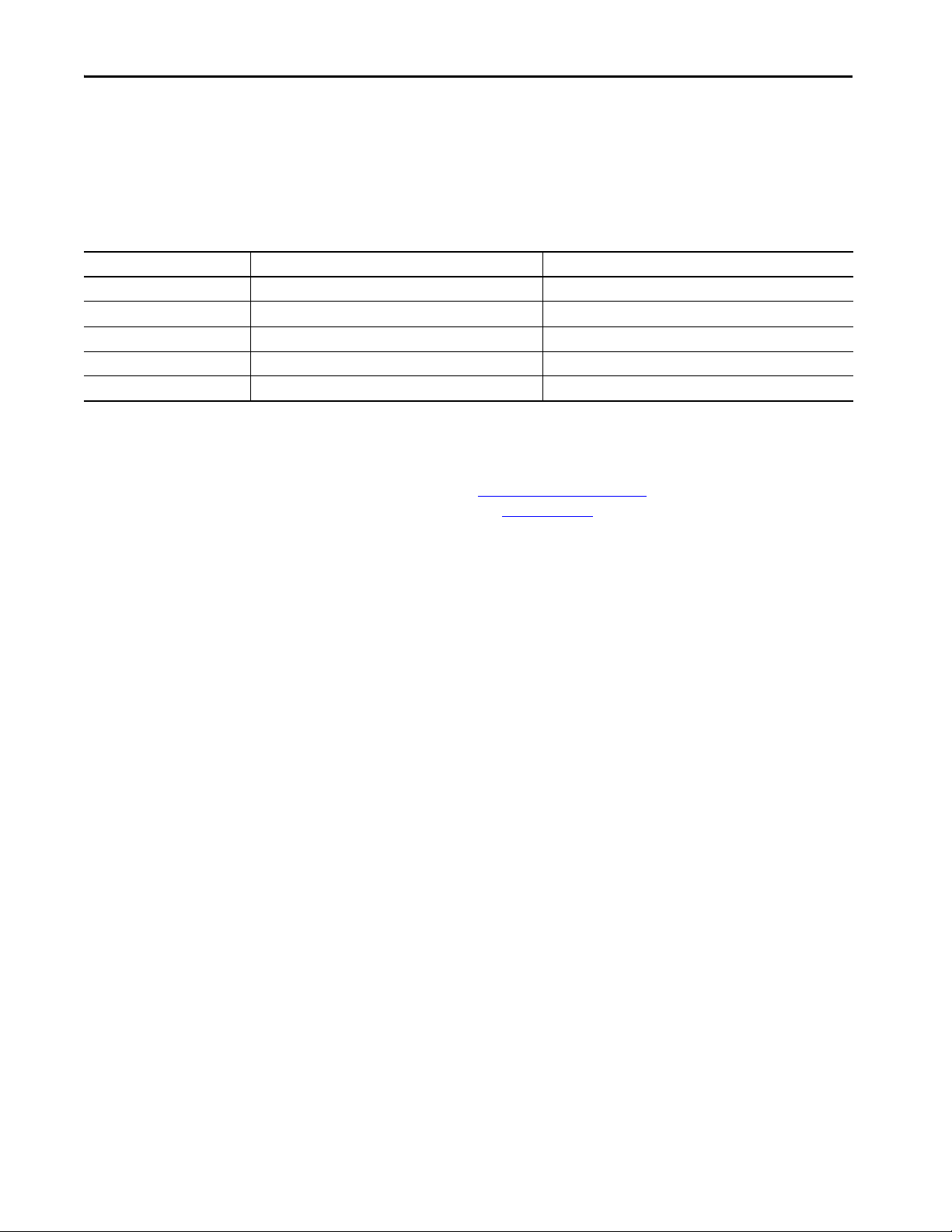

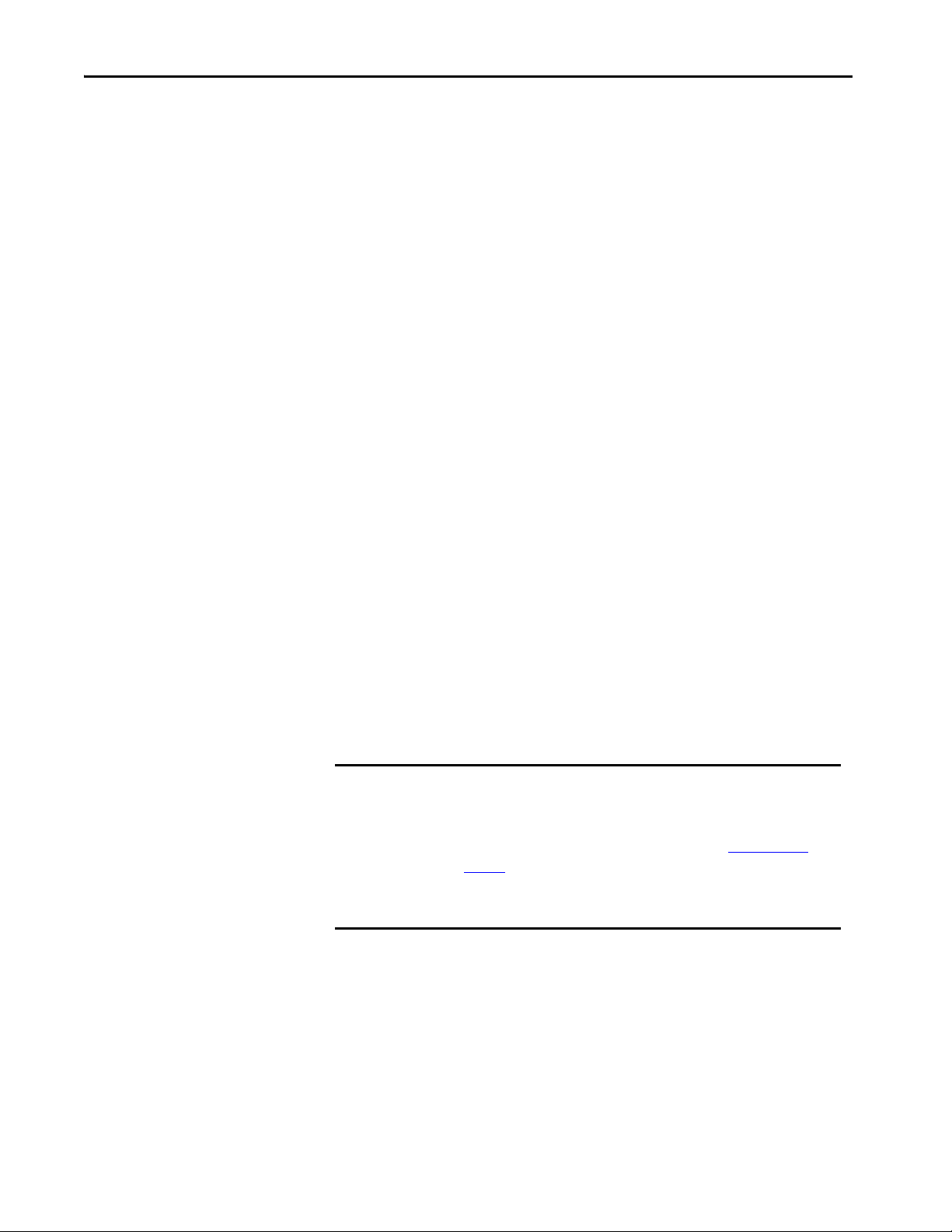

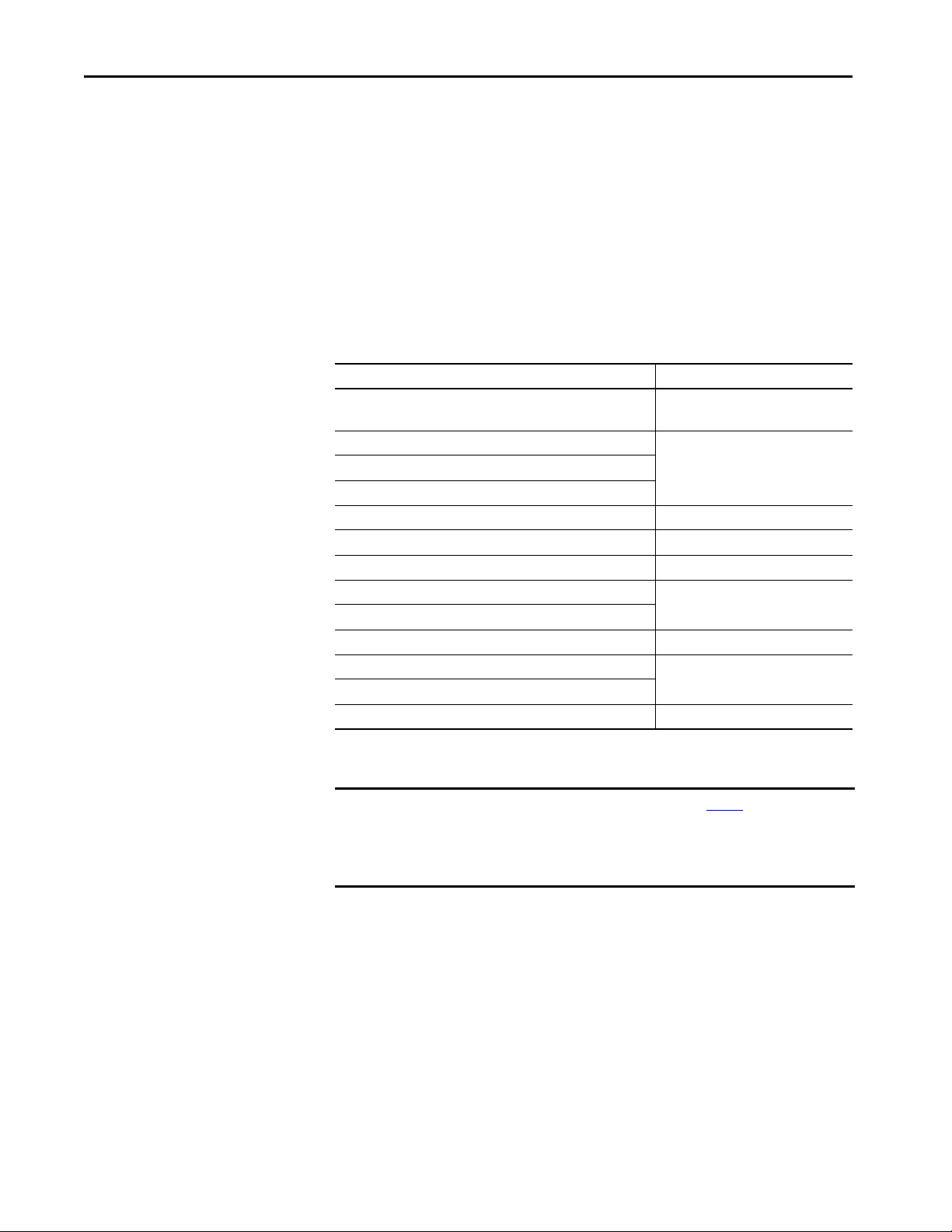

This table indicates what system components to use with each network that is

connected to a redundant system.

Table 1 - Communication Networks Available for Use with Redundancy Systems

Network Connection to Redundant System Component

I/O HMI

ControlNet Directly to redundant chassis Yes Yes

Via a bridge No Yes

DeviceNet Via a bridge Yes Yes

EtherNet/IP Directly to redundant chassis Yes - Redundancy System,

Revision 19.052 or later

Via a bridge No Yes

Universal remote I/O Via a bridge Yes Yes

Data Highway Plus Via a bridge Yes Yes

(1) Prior to redundancy firmware revision 30.051, you can connect the HMI to the redundant chassis pair via a bridge

from an EtherNet/IP network to a ControlNet network to help prevent a brief loss of communication with the

redundant chassis pair if a switchover occurs. For more information, see Possible Communication Delays on

EtherNet/IP and ControlNet Networks on page 28.

Yes

(1)

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 35

Page 36

Chapter 2 Design a ControlLogix Redundancy System

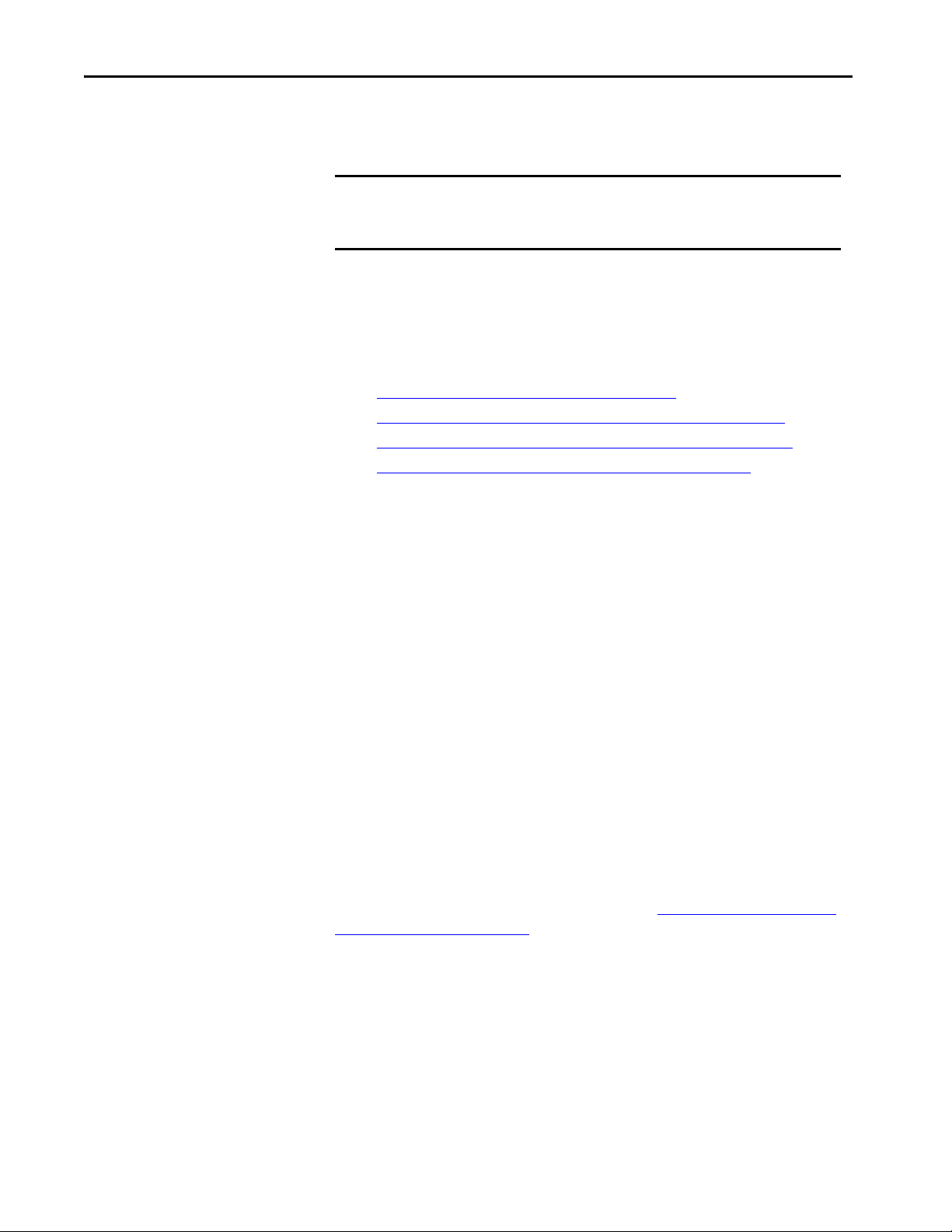

I/O Placement

In a redundancy system, you can place I/O modules in these locations:

• Same ControlNet network as redundant controllers and communication

modules

• Same EtherNet/IP network as redundant controllers and communication

modules

• DeviceNet network that is connected via a bridge

• Universal remote I/O network that is connected via a bridge

IMPORTANT You cannot install I/O modules in the redundant chassis pair. You can only

install I/O modules in remote locations that are accessed over the networks

in this list.

You can connect to remote I/O modules over an EtherNet/IP network in a

redundancy system, revision 19.052 or later.

1715 Redundant I/O Systems

With a redundancy system revision 19.052 or greater, you can connect to 1715

Redundant I/O systems over an EtherNet/IP network.

The 1715 Redundant I/O system provides high availability and redundancy for

critical processes by using a redundant adapter pair and multiple I/O modules

that have diagnostics and are easily replaceable.

The 1715 Redundant I/O system consists of one, two-slot, adapter base unit that

houses a redundant adapter pair. The adapter base unit is connected to up to 8,

three-slot, I/O base units, which can hold up to 24 fully configurable digital and

analog I/O modules. You can configure a 1715 Redundant I/O system in a Ring

or Star topology.

Each 1715 Redundant I/O system uses one IP address as the primary IP address

for all communication. The redundant adapter pair consists of two active

modules, a primary adapter and its partner, a secondary module.

For more information about the 1715 Redundant I/O system, see the Redundant

I/O System User Manual, publication 1715-UM001

.

36 Rockwell Automation Publication 1756-UM535I-EN-P - October 2020

Page 37

CH2 CH1 OK

CH2 CH1 OK

EIP Mod

EIP Net

Setup

GPS

TimeCD

3 1

4 2

Out

1 2

Speed

Duplex

PRP

DLR

PoE

Alarms PSU

1234567891011122526

13

1458912

10/100/1000 PoE+

100/1000 SFP

100/1000 SFP+

GPS ANT. DIG.TimeCode ANA.TimeCode

Console Alarm

TOD

16 17 20 21 24

25

OUTINOUT

IN

28

27242122 23201718 191613 1415 28

Express

Setup

Disp.

Mode

EIP Mod

EIP Net

Setup

GPS

TimeCD

3 1

4 2

Out

1 2

Speed

Duplex

PRP

DLR

PoE

Alarms PSU

1234567891011122526

13

1458912

10/100/1000 PoE+

100/1000 SFP

100/1000 SFP+

GPS ANT. DIG.TimeCode ANA.TimeCode

Console Alarm

TOD

16 17 20 21 24

25

OUTINOUT

IN

28

27242122 23201718 191613 1415 28

Express

Setup

Disp.

Mode

Bridging Chassis

1771 Chassis with

1771-ASB

Universal remote I/O

DeviceNet

DeviceNet Device

Control Tower™

Primary Chassis

Secondary Chassis

1715 Redundant I/O

EtherNet/IP Switches

Wor kst ati on

EtherNet/IP

ControlNe t

1734 POINT I/O™

EtherNet/IP

EtherNet/IP

Design a ControlLogix Redundancy System Chapter 2

Figure 9 - Example of I/O Placement Options

Rockwell Automation Publication 1756-UM535I-EN-P - October 2020 37

Page 38

Chapter 2 Design a ControlLogix Redundancy System

In this module Reserve

Controller 5 connections

1756-EN2T 5 connections

Using HMI

Depending on the network that is used to connect the redundant system to

HMIs, plan for certain placement and configuration requirements. You can