Page 1

Rockwell Automation

AutoMax ControlNet

Communication Interface

Module

(Cat. No. O-58820-2)

Major Rev. 2

User Manual

Page 2

Page 2 AutoMax ControlNet Module

Important User Information

Solid state equipment has operational characteristics differing from those

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication SGI-

1.1) describes some important differences between solid state equipment

and hard–wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid state equipment, all

persons responsible for applying this equipment must satisfy themselves

that each intended application of this equipment is acceptable.

In no event will Rockwell Automation be responsible or liable for

indirect or consequential damages resulting from the use or application

of this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, Rockwell Automation cannot

assume responsibility or liability for actual use based on the examples

and diagrams.

Rockwell Automation assumes no patent liability with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss.

Attentions help you:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is especially important for

successful application and understanding of the product.

Microsoft is a registered trademark of Microsoft Corporation.

Windows, Windows 95 and Windows NT are trademarks of Microsoft Corporation.

ControlLogix and Data Highway Plus are trademarks of the Allen-Bradley Company, Inc.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 3

Page 4

INTRODUCTION 9

Who Should Use This Manual? 9

Purpose of this Manual 9

Conventions Used in this Manual 9

Getting Support 10

Reference Documents 10

Requirements 10

MBCN AUTOMAX CONTROLNET MODULE 11

Overview 11

Module Overview 11

Hardware Features 13

7-Segment Display 13

OK LED 14

MAC ID Thumbwheels 14

Serial Configuration Port 14

NAP Port 15

ControlNet Connectors 15

Network Status LEDs 15

7-Segment LED Codes 16

Communication Error 18

INSTALLATION 19

Prevent Electrostatic Discharge 19

Installation and Wiring 20

Connecting to the Network 21

Troubleshooting Wiring Problems 21

QUICK START 22

PROGRAMMING THE MBCN 23

Overview 23

Page 5

AutoMax ControlNet Module Page 5

Memory Overview 23

Configuring Scheduled Connections 24

Creating a Configuration 24

Configuring 1771 I/O 25

Configuring Flex I/O 26

Configuring Scheduled Data with Another MBCN 27

Configuring Scheduled Data with a PLC-5 28

Configuring Scheduled Data with a ControlLogix Processor 29

Setting the Network Properties 32

Downloading the Configuration 32

Putting the MBCN in Run Mode 32

Accessing I/O Data 32

Application Example 33

Multicast Connections 34

MONITORING MODULE OPERATION 35

Status of Each Connection 35

Operating Status 38

Summary of Registers for Monitoring Operation 39

UNSCHEDULED MESSAGING 41

Register Organization 41

AutoMax Application Programming 42

GATEWAY_CMD_OK@ Status Codes 51

Extended Status (EXT_STS) Codes for Command 0F 53

Commands from Remote Nodes 54

Differences from the M/N 57C442 Module Interface 56

VIEWING NETWORK PARAMETERS 57

Current Network Parameters 57

Pending Network Parameters 58

STATE REGISTERS 60

Module State 60

NAM State 60

Keeper State 61

Flash State 62

Serial CONFIG Port State 62

Channel State 63

DIAGNOSTIC COUNTERS 64

Publication number DSMBCN-UM001B-EN-P February 2003

Page 6

Page 6 AutoMax ControlNet Module

Standard ControlNet Counters 64

Module Specific Counters 65

The Error Log 66

ACTIVE NODE LIST 67

ID AREA 68

Vendor ID 68

Device Type 68

Product Code 68

Major Revision 68

Minor Revision 68

Status 68

Serial Number 69

Product Name Length 69

Product Name 69

Current Address 70

MAC ID Switches 70

Summary of ID Area Locations 70

FIRMWARE VERSION INFORMATION 71

USING THE HOST WATCHDOG 72

UPDATING THE FIRMWARE 73

CONVERTING FROM MAJOR REVISION 1 TO 2 76

If you have access to the Reliance MBCN hardware 76

If you have an offline configuration file (*.xc) 76

SPECIFICATIONS 78

SUPPORT 79

Publication number DSMBCN-UM001B-EN-P February 2003

Page 7

AutoMax ControlNet Module Page 7

Table of Figures

Figure 1 Serial Cable Wiring.......................................................................................................................14

Figure 2 LED Status Table..........................................................................................................................16

Figure 3 7-Segment LED Codes .................................................................................................................17

Figure 4 Memory Overview........................................................................................................................24

Figure 5 Connection Status Values .............................................................................................................38

Figure 6 Scanner State Table.......................................................................................................................39

Figure 7 – Adapter (Scheduled Produced Data) State Table.......................................................................39

Figure 8 Summary of Monitor Registers.....................................................................................................40

Figure 9 Summary of Unscheduled Message Registers..............................................................................41

Figure 10 Control and Status Registers.......................................................................................................42

Figure 11 Command Table..........................................................................................................................46

Figure 12 GATEWAY_CMD_OK Status Table.........................................................................................51

Figure 13 Local and Remote Status Table ..................................................................................................52

Figure 14 Extended Status Error Codes Table ............................................................................................54

Figure 15 Unsolicited PLC-5 Commands ...................................................................................................54

Figure 16 Unsolicited Basic Command Set Commands .............................................................................55

Figure 17 Current Network Parameters.......................................................................................................58

Figure 18 Pending Network Parameters......................................................................................................59

Figure 19 Module State Table.....................................................................................................................60

Figure 20 NAM State Table........................................................................................................................61

Figure 21 Keeper State Table......................................................................................................................62

Figure 22 Flash Memory State Table..........................................................................................................62

Figure 23 Serial Config State ......................................................................................................................62

Figure 24 Channel State Table....................................................................................................................63

Figure 25 Standard ControlNet Diagnostic Counters..................................................................................65

Figure 26 Module-Specific Diagnostic Counters........................................................................................66

Figure 27 Active Node Table......................................................................................................................67

Figure 28 Device Status Table ....................................................................................................................68

Figure 29 Device Status, Bits 4-7................................................................................................................69

Figure 30 ID Locations Table .....................................................................................................................70

Figure 31 Firmware Versions Table............................................................................................................71

Publication number DSMBCN-UM001B-EN-P February 2003

Page 8

Page 9

This introduction covers the following topics:

• who should use this manual

• the purpose of the manual

• contents of the manual

• conventions used in the manual

• getting support

Who Should Use This Manual?

Use this manual if you are responsible for designing, installing,

programming or troubleshooting systems that are based on AutoMax

Control using the MBCN ControlNet module (O-58820-2) with major

revision 2 firmware.

You should have a basic understanding of AutoMax products. You

should understand Allen Bradley PLC-5s and ControlLogix PLCs and be

familiar with using ControlNet I/O modules on the ControlNet network.

Introduction

Purpose of this Manual

This manual shows you how to install and use the MBCN ControlNet

module. It describes the procedures to install, configure, and operate the

MBCN ControlNet module.

Conventions Used in this Manual

The following conventions are used throughout this manual:

• bulleted lists, such as this one, provide information, not procedural

steps

• numbered lists provide sequential steps

• bold type is used for emphasis

courier font is used for text you should type

•

• hexadecimal numbers are shown with a trailing ‘h’, for example,

1234h

• titles for menu items, dialog boxes, etc. in software are shown in

italics

• addresses that refer to a single byte within an AutoMax register are

shown with a trailing ‘L’ or ‘H’ to indicate the low or high byte of

the register.

• T=>O means ControlNet target-to-originator; O=>T means

originator-to-target. The originator is the node that opens the

connection to the target.

• RSNetWorx means RSNetWorx for ControlNet

Page 10

Page 10 AutoMax ControlNet Module

Getting Support

Refer to page 79 for information on how to obtain support for the MBCN

module.

For support on the AutoMax processor or programming software, contact

Rockwell Automation or your local distributor.

Reference Documents

For information on using RSNetWorx, refer to:

• RSNetworx ControlNet Getting Results, Publication Number 9399CNETGR, Catalog number 9357-CNETL3

For information on ControlNet, refer to one of the following:

• ControlNet Specification, available from ControlNet International,

www.controlnet.org

• IEEE 518 Guide for the Installation of Electrical Equipment to

Minimize Electrical Noise Input to Controllers

• ControlNet user manual, publication 1786-2.12

, approximate cost US$350

Requirements

RSNetWork for ControlNet version 3.21 and above includes support for

configuring the MBCN.

MBCN firmware version 1.10 and above requires RSNetWorx for

ControlNet for configuration.

The MBCN must be running firmware version 1.10 or above to be used

with ControlFlash.

To use the connection status information, you need RSNetWork for

ControlNet version 4.11 or above and firmware version 2.1 or above on

the MBCN.

Refer to page 73 for information on updating the firmware in the MBCN.

Refer to page 76 for information on converting a revision 1 MBCN to a

revision 2 MBCN in RSNetWorx for ControlNet.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 11

Overview

Module Overview

AutoMax ControlNet Module Page 11

MBCN AutoMax ControlNet Module

This chapter contains the following information:

• module overview

• a summary of hardware features

• a description of how the hardware works

The MBCN module makes it possible for an application running in an

AutoMax Controller to communicate with and control ControlNet I/O

devices. The MBCN can also exchange data with other processors over

the ControlNet network using scheduled produced and consumed data.

The MBCN uses the standard AutoMax memory-mapped interface to the

host processor.

All I/O data is mapped into AutoMax registers 16384-32767. You can

select the register assignment for the data for each connection or have the

register assignment created automatically when you create the I/O

configuration.

The module:

• supports up to 127 scheduled connections, up to 480 words per

connection

• supports a maximum of 16 Kbytes total input data

• maps input data into AutoMax Processor registers 16384-24575

• supports a maximum of 16 Kbytes total output data

• maps output data into AutoMax Processor registers 24576-32767

• provides global status on all originator to target (O=>T) connections

and global status on all target to originator (T=>O) connections

• provides status on each connection, in AutoMax registers 1536215614, two 16-bit words per connection. You map the location of the

status information for a connection using RSNetWorx. This requires

major revision 2 of the MBCN firmware and RSNetWorx for

ControlNet 4.11 or later. Major revision 1 of the MBCN firmware

does not support status on individual connections

You use RSNetWorx for ControlNet to configure the I/O devices being

scanned and all scheduled produced and consumed connections.

The MBCN maintains standard ControlNet diagnostic counters, as well

as additional diagnostic counters, to monitor MBCN operation and to

diagnose problems.

The MBCN maintains an active node list.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 12

Page 12 AutoMax ControlNet Module

The MBCN can send unscheduled messages to other nodes on the

network, and receive and respond to unscheduled messages from other

nodes, using PLC-5 PCCC commands. The MBCN emulates the

AutoMax interface on the M/N 57C442 Data Highway Plus module.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 13

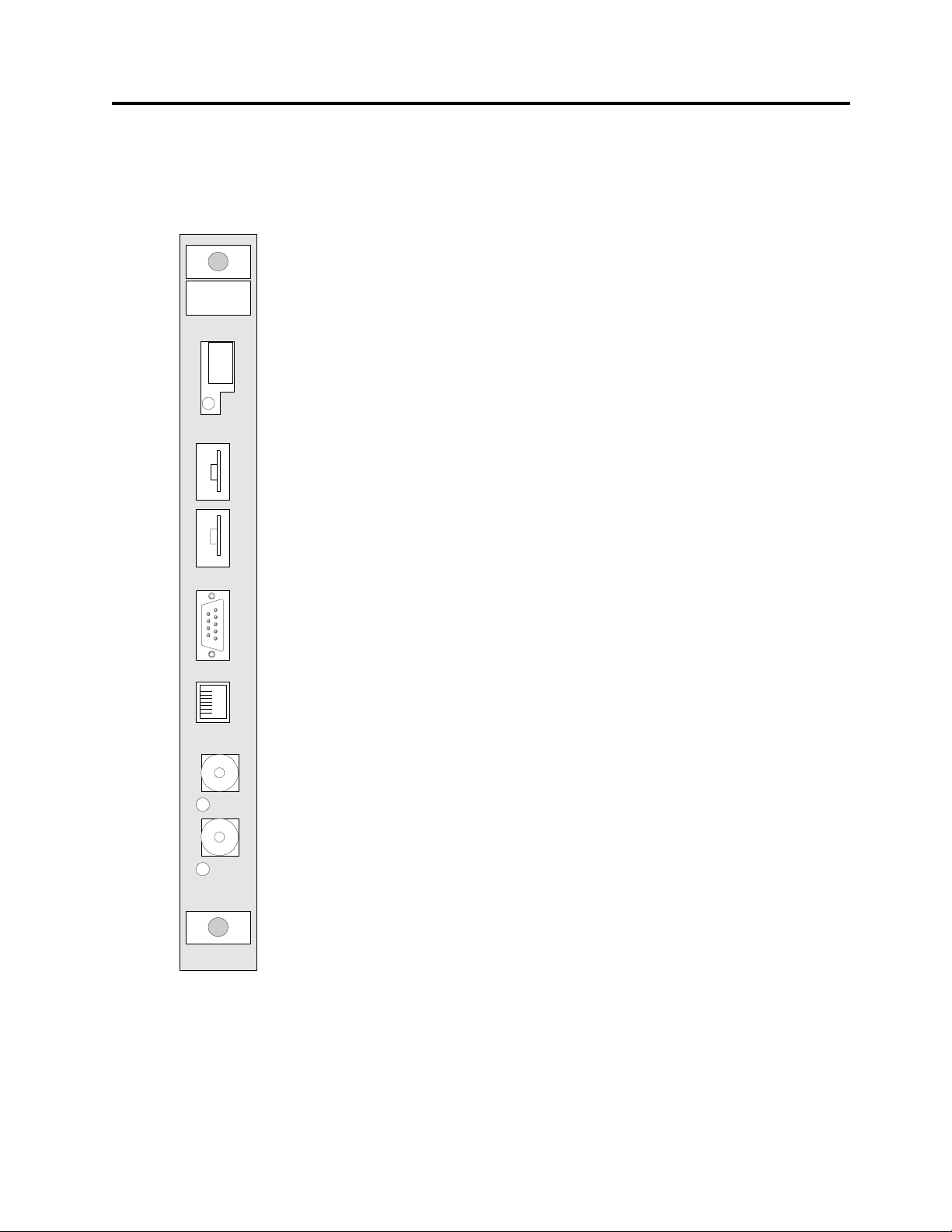

Hardware Features

AutoMax ControlNet Module Page 13

The main hardware features of the MBCN are:

• 7-segment display

MBCN

O-58820

Fault

Code

MAC ID

OK

• OK LED

• switches to set the MBCN’s ControlNet address

• serial config port for updating the MBCN firmware

• ControlNet NAP port

• ControlNet BNC connectors

• network status LEDs

10

These are described in detail in the following sections

1

Config NAP

A

COM

B

COM

7-Segment Display

The MBCN has a 7-segment LED to indicate status. Refer to page 16 for

a summary of 7-segment display codes.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 14

Page 14 AutoMax ControlNet Module

6

7

8

9

OK LED

The MBCN contains a hardware watchdog that monitors operation of the

MBCN hardware and software. The hardware watchdog times out only

when there is a catastrophic hardware or firmware failure on the MBCN.

The green OK LED is on when the hardware watchdog is OK and is off

if the watchdog times out.

NOTE: The hardware watchdog is NOT the same as the host watchdog.

See page 72 for information on using the host watchdog.

MAC ID Thumbwheels

Use the two thumbwheels labelled MAC ID to set the MBCN’s address

on ControlNet. The upper thumbwheel sets the most significant digit;

the lower thumbwheel sets the least significant digit.

To maximize network efficiency and reduce network overhead, you

usually assign ControlNet addresses consecutively, starting at 1.

NOTE: 0 is not a valid address.

The MBCN reads the thumbwheels only at power-up. You must power

down and power back up for changes in the thumbwheel settings to be

recognized.

Serial Configuration Port

The thumbwheel switches must be positioned in the center of the detent.

You can verify the switch settings by displaying register 32.

The serial CONFIG port on the front of the MBCN can be used to:

• update the firmware on the MBCN

• update the FPGA (field programmable gate array) configuration on

the MBCN

Note: you normally update both using ControlFlash over ControlNet.

The serial cable for a standard PC COM port must have lines 2 and 3

swapped. It does not require any handshaking. Pins 2 and 3 are wired

the same as a PC 9-pin COM port. A cable is provided with the MBCN

when shipped in the original packaging.

1

2

3

4

5

1

6

2

7

3

8

4

9

5

Figure 1 Serial Cable Wiring

Connect to the serial port using any communication software. For

example, you can use the HyperTerminal program supplied with

Windows. The MBCN serial port supports a baud rate of 57.6 Kbaud,

with no parity, 8 data bits and 1 stop bit.

Refer to page 73 for information on updating MBCN firmware.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 15

NAP Port

AutoMax ControlNet Module Page 15

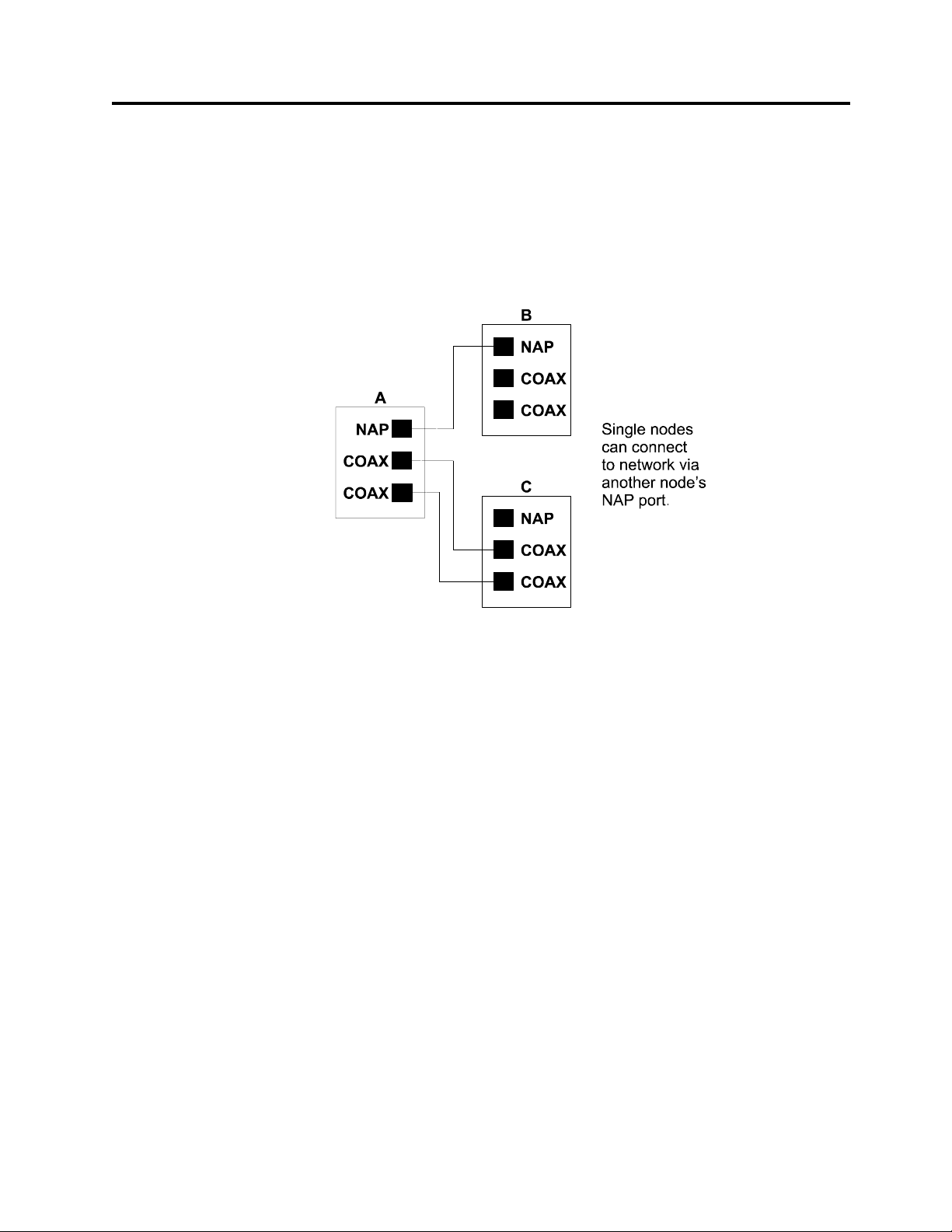

The MBCN has a standard ControlNet NAP port to allow a transient

node to connect to the ControlNet network.

Use the NAP port on the MBCN if you want to attach a transient node to

the network and you do not want to rewire the network. Do not connect

any node to the network using both the NAP port and a coax path at the

same time. The following figure shows how to correctly connect a

transient node.

ControlNet Connectors

Network Status LEDs

NAP Connection 1

You can also use the NAP port on the MBCN to attach the MBCN to an

existing network, by connecting to the NAP port on a node on the

existing network.

The NAP cable has 8 conductors and a shield, with RJ-45 connectors at

each end. The cables are reversed from one end of the cable to the other,

so that 1->8, 2->7, etc. Maximum cable length is 10 m.

Connect the MBCN to the ControlNet network using the standard

ControlNet BNC connectors.

There is one network status (COM) LED for each network connector.

The network status LEDs display the following states, using the priority

scheme shown. If more than one condition exists, the LEDs display the

state with the highest priority.

When using redundant cabling, both LEDs should be green. One will be

brighter; this is the active channel.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 16

Page 16 AutoMax ControlNet Module

The LEDs do not reflect the state of the NAP port. If you connect the

MBCN to the network via the NAP port, the two network status LEDs

flash red together.

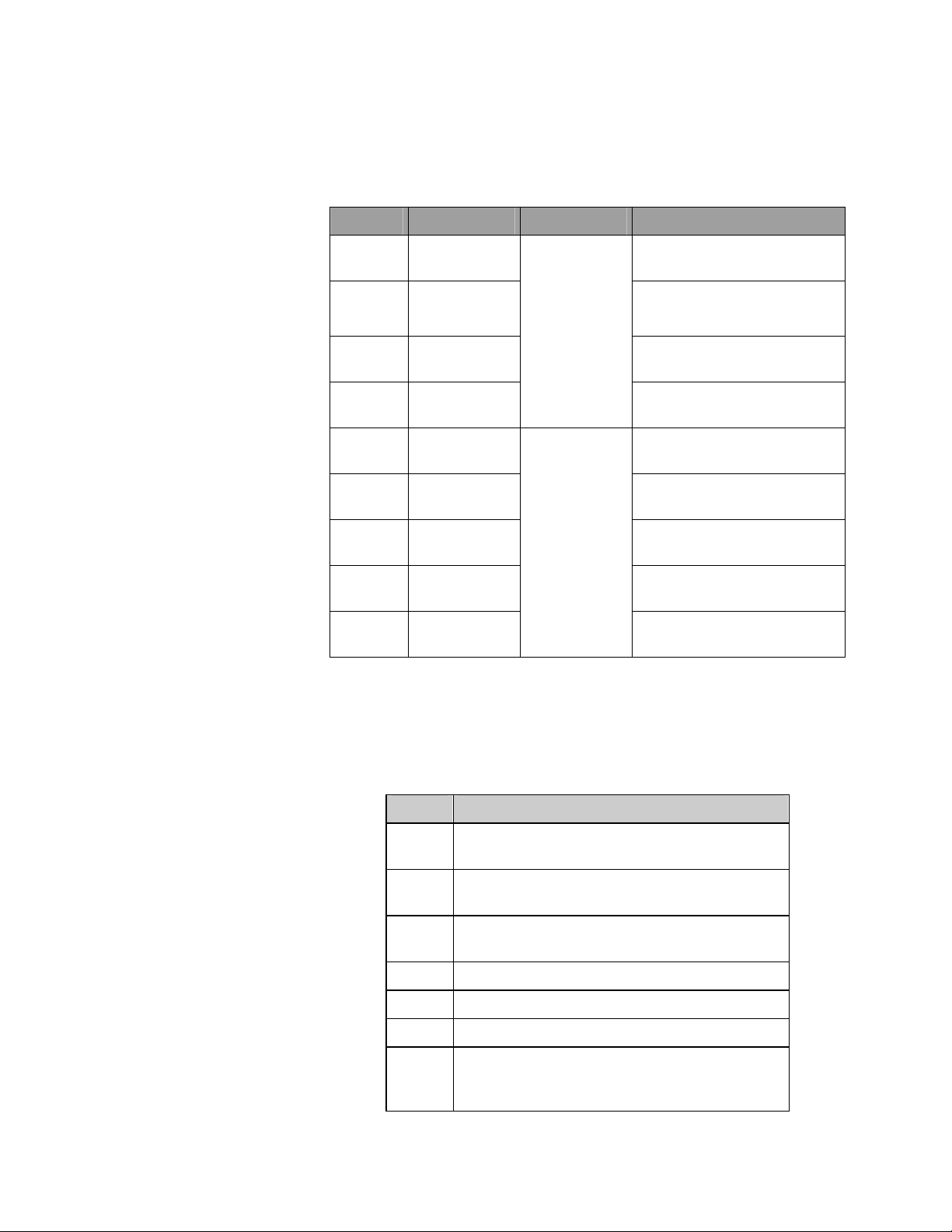

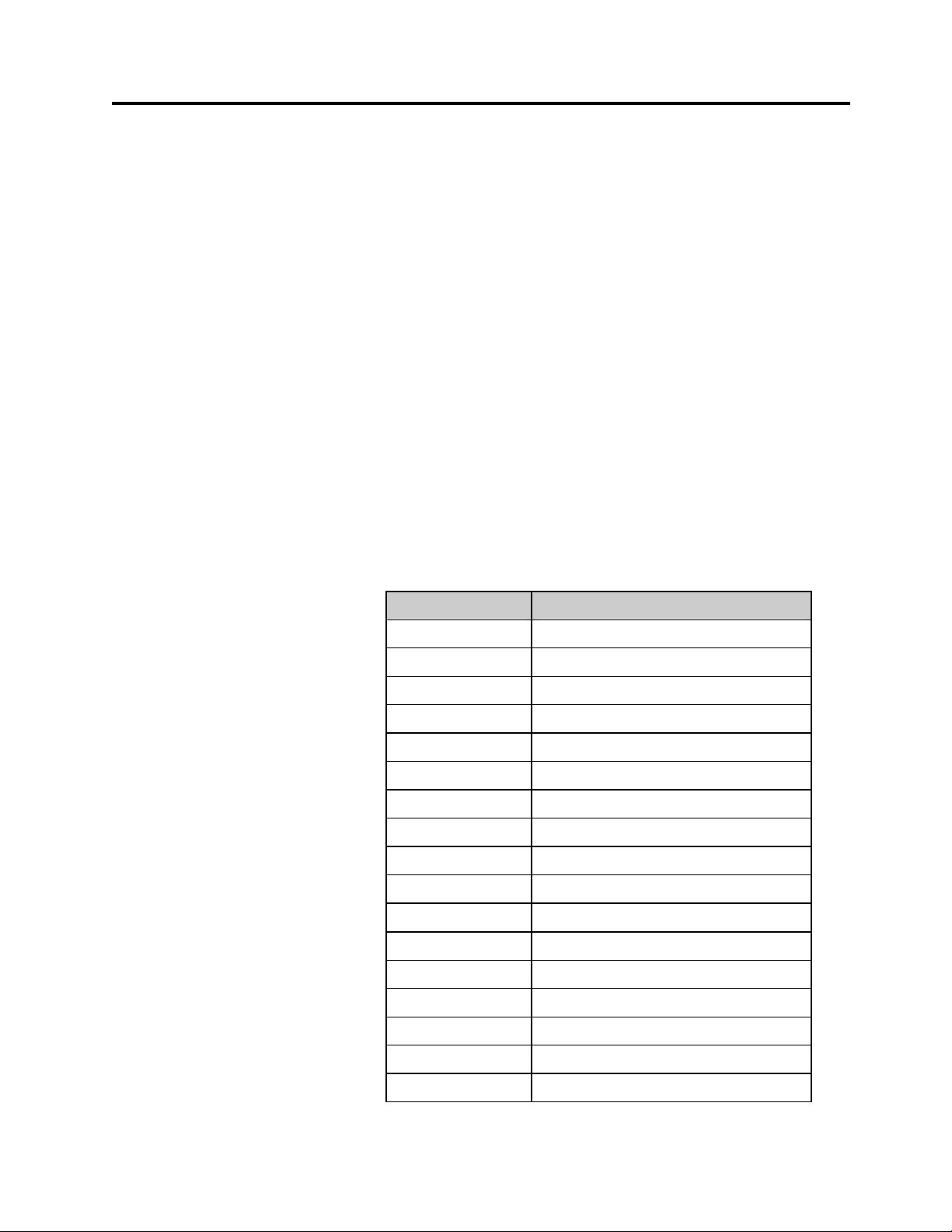

Priority State How to view Cause

1

(highest)

2 Both steady

3 Alternating

4 Alternating

5 Steady off Channel disabled or channel

6 Flashing

7 Flashing

8 Flashing

9

(lowest)

Both steady

off

red

red/green

red/off

red/green

red/off

green/off

Steady green

Viewed

together

Viewed

Independently

Reset or no power

Failed link interface

Fatal error on MBCN

Self test

Bad node configuration, such

as duplicate address

not supported

Invalid link configuration,

such as address > UMAX

Link fault or no MAC frames

received

Temporary channel error, or

listen only

Normal operation

Figure 2 LED Status Table

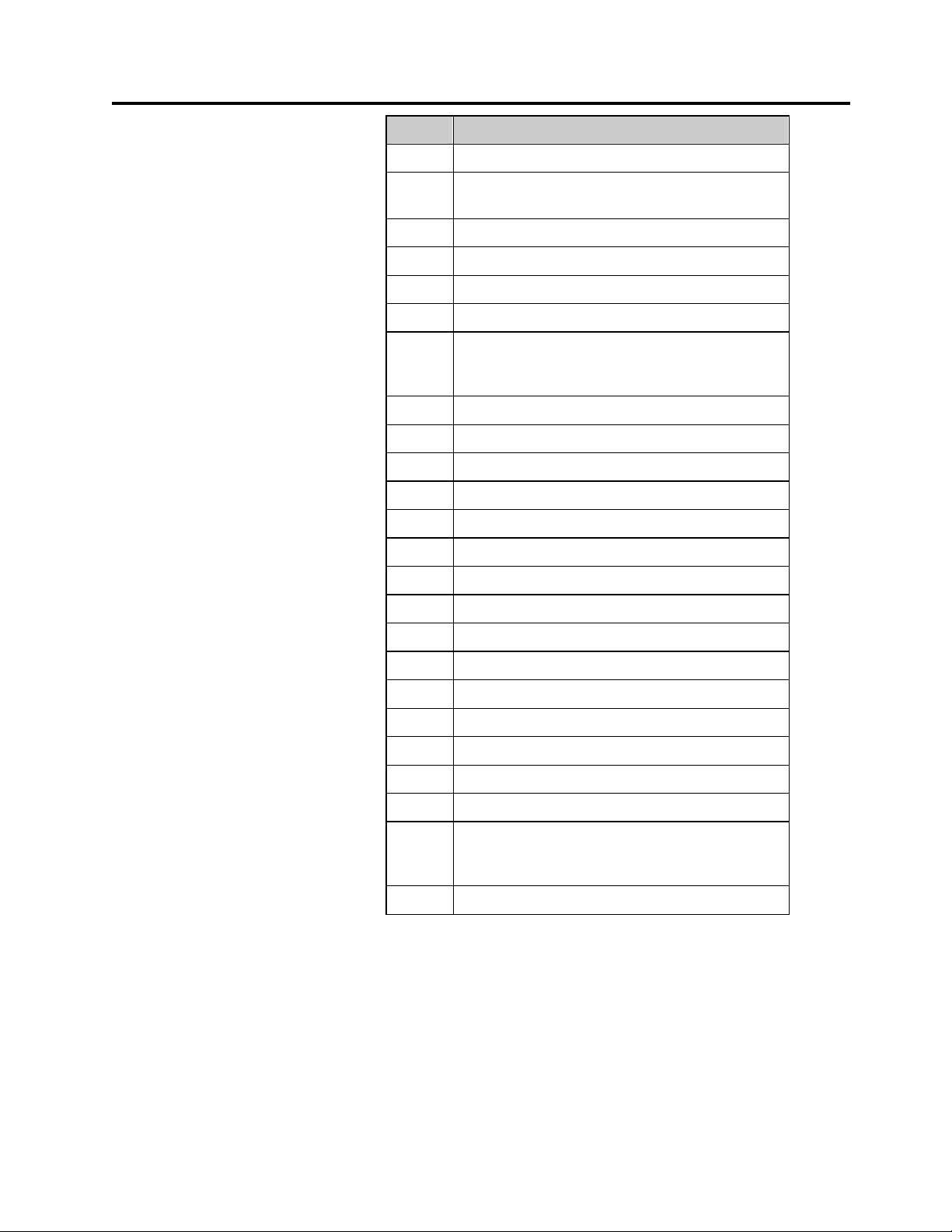

7-Segment LED Codes

Value Meaning

1 NAM not attached. There are no other nodes

on the network.

2 Keeper faulted master. The MBCN schedule

needs to be updated using RSNetWorx.

3 Keeper faulted backup. The MBCN schedule

needs to be updated using RSNetWorx.

4 Keeper change

5 Keeper faulted change

6 Keeper temporary state

b Inactive. The MBCN is online but has no

scheduled connections and is not sending or

receiving messages.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 17

AutoMax ControlNet Module Page 17

Value Meaning

C Communication error

d One or more connections requires a schedule.

Use RSNetWorx to schedule all connections.

E Bad thumbwheel value

P Scanning in program mode

U Firmware on the MBCN is being updated

H Hardware on the MBCN is being updated.

r Module requires reset, usually after an update.

Cycle power to the rack that contains the

MBCN.

.0 Module checksum failure

.1 Local RAM data failure

.2 Local RAM address failure

.3 Local RAM FF fill failure

.4 Local RAM 00 fill failure

.5 Code copy failure

.6 Shared RAM failure

.7 Shared RAM address failure

.8 Shared RAM FF fill failure

.9 Shared RAM 00 fill failure

.A Module startup failure

.b Bootup shell activate prompt

.C Board reset failure

.d AutoMax watchdog failure

.E Power fail

.F Module hardware failure (jabber inhibit, host

watchdog). Cycle power to see if the problem

disappears. If it does not, replace the MBCN.

Off Scanning OK in run mode

Figure 3 7-Segment LED Codes

LED codes that start with a dot are hardware failures and usually indicate

that the MBCN has suffered a fatal hardware or firmware failure.

Contact technical support.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 18

Page 18 AutoMax ControlNet Module

Communication Error

The following are common causes for communication error ( C ) to be

displayed on the 7-segment LED:

• The MBCN couldn’t open one or more connections. Look at the

status for each connection in RSNetWorx or on the MBCN

• The MBCN has refused a connection or has returned an error to an

unscheduled message. Look at the status for each connection using

RSNetWorx or the status registers on the MBCN or look at the status

of the connections on other nodes that have connections to the

MBCN.

• The MBCN is sending unscheduled messages that are failing.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 19

Prevent Electrostatic Discharge

The MBCN is sensitive to electrostatic discharge.

ATTENTION: Electrostatic discharge can damage integrated circuits

or semiconductors if you touch backplane connector pins. Follow these

guidelines when you handle the module:

• Touch a grounded object to discharge static potential

AutoMax ControlNet Module Page 19

Installation

• Wear an approved wrist-strap grounding device

• Do not touch the backplane connector or connector pins

• Do not touch circuit components inside the module

• If available, use a static-safe work station

• When not in use, keep the module in its static-shield packaging

This chapter contains the information necessary to:

• install the MBCN in the AutoMax rack

• connect the MBCN to the ControlNet network

• use the MBCN serial port

• understand the MBCN LEDs

Publication number DSMBCN-UM001B-EN-P February 2003

Page 20

Page 20 AutoMax ControlNet Module

Installation and Wiring

The user is responsible for conforming to all applicable local, national,

and international codes. Wiring practices, grounding, disconnects, and

over-current protection are of particular importance. Failure to observe

this precaution could result in severe bodily injury or loss of life.

To reduce the possibility of electrical noise interfering with the operation

of the control system, exercise care when installing the wiring from the

control system to the external devices. For detailed recommendations,

refer to IEEE 518.

Step 1. Stop any application tasks that may be running.

This equipment is at line voltage when AC power is connected.

Disconnect and lock out all ungrounded conductors of the AC power

line. Failure to observe this precaution could result in severe bodily

injury or loss of life.

DANGER

DANGER

WARNING

Inserting or removing a module may result in unexpected machine

motion. Power to the machine should be turned off before inserting or

removing a module. Failure to observe these precautions could result in

bodily injury.

Step 2. Turn off all power to the rack. All power to the rack as well as

all power leading to the rack should be off.

CAUTION

This module contains static sensitive components. Careless handling

can cause severe damage. Do not touch the connectors on the back of

the module. When not in use, the module should be stored in an antistatic bag. The plastic cover should not be removed. Failure to observe

this precaution could result in damage to or destruction of the

equipment.

Step 3. Take the MBCN out of its shipping container. Take it out of the

anti-static bag, being careful not to touch the connectors on the back of

the MBCN.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 21

Step 4. Set the MBCN’s address on the network using the thumbwheels.

Make sure the thumbwheels are centered on the detents.

Step 5. Insert the MBCN in the desired slot in the rack, making sure that

it is well seated in the rack. Use a screwdriver to secure the MBCN in

the rack.

Step 6. Connect the MBCN to the ControlNet network using the BNC

connectors on the front of the MBCN.

Step 7. Turn on power to the rack.

Connecting to the Network

Connect the MBCN to the ControlNet network like any other ControlNet

node, using a ControlNet tap to connect to the network trunkline. The

drop cable from the tap to the MBCN should be 1 m long. The

recommended trunk cable type is RG6. (It is recommended that you use

standard ControlNet network taps available through Allen-Bradley.)

The physical ends of the network trunkline should be terminated with

75-ohm terminators. There should be two and only two terminators on

the network.

AutoMax ControlNet Module Page 21

The MBCN supports redundant cabling.

Ensure that the address for the MBCN is less than or equal to the

maximum unscheduled address (UMAX) configured on the network.

NOTE: 0 is not a valid address.

If the MBCN is being used as a scanner or for scheduled I/O, make sure

the address is less than or equal to the maximum scheduled address

(SMAX) configured on the network.

To maximize efficiency on the ControlNet network, assign consecutive

node addresses to nodes on the network, with the nodes exchanging

scheduled data at the lowest addresses.

Troubleshooting Wiring Problems

If the MBCN does not go active on the network:

• Check cabling for correct wiring to the MBCN.

• Check network termination. Only the two nodes at the physical ends

of the network should have terminating resistors. There should be

two and only two terminators on the network.

• Check the network configuration. Make sure UMAX is high enough

to include this node.

• Check that you haven’t duplicated the address of another node on the

network.

• Check that the thumbwheels have been read correctly by displaying

register 32.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 22

Page 22 AutoMax ControlNet Module

The following steps describe the procedure for using the MBCN as a

scanner. The sections that follow describe the procedures and registers

in more detail.

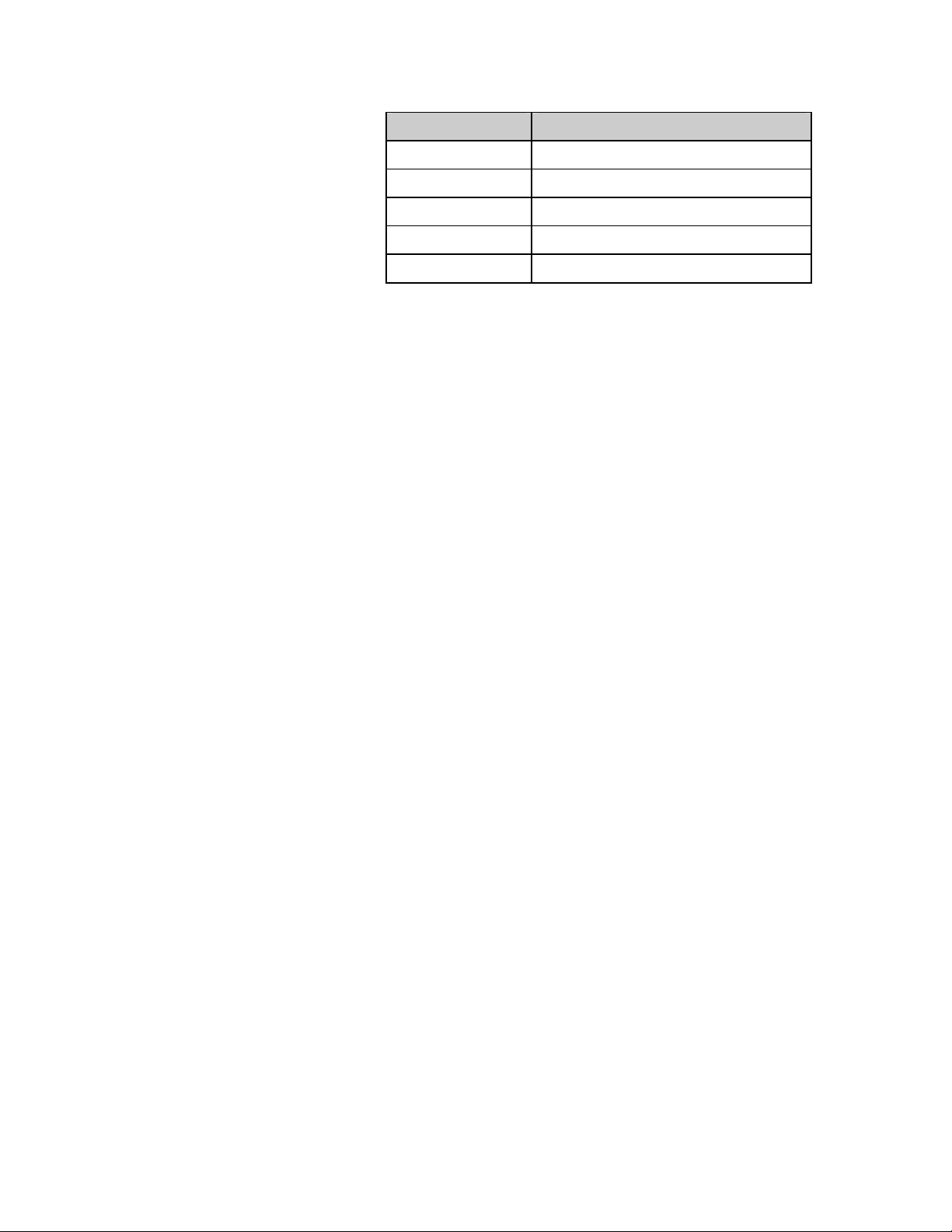

Step Description Refer to

Quick Start

page:

Step 1. Use RSNetWorx to create a configuration that

contains the I/O devices the MBCN is to scan

and the scheduled produced and consumed

connections for the MBCN.

Step 2. Download the configuration to the MBCN. 32

Step 3. Check the NAM state for online. 60

Step 4. Put the MBCN in run mode. 32

Step 5. Verify you can read input data and set output

data, check connection status, and so on.

24

32,35

Publication number DSMBCN-UM001B-EN-P February 2003

Page 23

Overview

Memory Overview

AutoMax ControlNet Module Page 23

Programming the MBCN

This section is a guide for configuring and programming the MBCN.

Configure the scheduled connections using RSNetWorx. The

configuration you create contains all the I/O devices to be scanned, and

all the scheduled produced and consumed connections on the MBCN, the

network parameters and the schedule for all updates.

This section starts with some general information, then describes the

MBCN memory layout in detail, with information about the interface

between your application and the MBCN, and the organization of the

tables on the MBCN.

The MBCN contains 64 Kbytes (32768 16-bit registers) of shared

memory that can be accessed through the AutoMax rack backplane by

application tasks running on an AutoMax processor. The following table

shows the general organization of the shared memory.

AutoMax Registers Description

0-63 Status and control

5 Module control register

64-7383 Unscheduled data

9216-9245 ID area

9247 Channel state

9248-9263 Active node list

9280-9292 Pending network parameters

9304-9316 Current network parameters

9336-9339 Error log

9344-9401 Diagnostic counters

9466 Serial port state

9468-9471 Revision information

9472 Module state

9473 NAM state

9474-9475 Host watchdog

9476 Keeper state

9477 Flash state

Publication number DSMBCN-UM001B-EN-P February 2003

Page 24

Page 24 AutoMax ControlNet Module

AutoMax Registers Description

9478 Link timeout

15362-15614 Status for each connection

15744-15760 Overall status information

16384-24575 Scheduled receive data

24576-32767 Scheduled transmit data

Figure 4 Memory Overview

Configuring Scheduled Connections

The MBCN can act as a ControlNet scanner to scan I/O modules. As

well, scheduled connections can be configured to exchange data with

other scanner nodes on the network.

You use RSNetWorx to configure your network. The following sections

briefly describe how to configure commonly occurring devices. For

detailed information, refer to the RSNetWorx documentation and online

help.

Creating a Configuration

You can use RSNetWorx as an offline or online configuration tool. In

most cases you will use it online. The instructions that follow describe

using RSNetWorx online. They assume that RSNetWorx and RSLinx

have been installed, along with any hardware required to communicate

with the ControlNet network.

1. Run RSNetWorx.

2. Create a new configuration using the File/New command.

3. Put RSNetWorx online using the Network/Online command.

4. Select a path to the network. RSNetWorx should go online and

display the devices it finds on the network.

5. Click on the MBCN you are configuring to select it, right click on it

and select Scanlist Configuration from the menu that appears.

RSNetWorx asks whether you want to switch to Edit Mode. Click

Yes.

6. The MBCN Scanlist Configuration Tool opens. There are two tabs –

the Connection Configuration tab, which shows all the connections

for the device you are configuring, and the Connection Status tab,

which shows the status of those connections.

7. Select the Connection Configuration tab to create connections.

The device you are configuring, in this case the MBCN, is shown

highlighted. The other devices are shown as a list.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 25

Configuring 1771 I/O

AutoMax ControlNet Module Page 25

8. To create a connection to another device, right click on that device in

the list and select Insert Connection from the menu that appears.

9. To create a target on the MBCN to which another device can

connect, right click on the MBCN and select Insert Target for

Connections from the menu.

The following sections provide simple examples of how to create

connections for specific types of devices. For deatiled information, refer

to the online help for RSNetWorx for ControlNet and the documentation

for the devives you are connecting.

Adding Analog Modules

When RSNetWorx goes online, it scans the network and finds 1771

adapters and chassis but it cannot detect analog modules in those chassis.

If you want to create connections to those devices, you must first add

them to the chassis before you start the MBCN Scanlist Configuration.

You do not have to add discrete modules.

To add analog modules:

1. From the main RSNetWorx window, double click on the 1771

chassis. The View Chassis window appears. Drag modules from the

Hardware list to the appropriate 1771 chassis slot. When you have

added all required modules, click OK.

2. Right click on the MBCN you are configuring and select Scanlist

Configuration to start the Scanlist Configuration tool.

Creating the Connection to Discrete I/O

To create a connection to the 1771 discrete data:

1. Right click on the adapter and select Insert Connection. The

Connection Properties dialog box opens.

2. Set the Connection Name to Discrete Exclusive Owner.

3. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

This time will be the update time for all the discrete modules in the

rack. The default values for the RPIs is the network update time

(NUT).

4. Set the Input and Output sizes to the desired values.

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

6. Click OK to complete the configuration.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 26

Page 26 AutoMax ControlNet Module

Creating Connections to Analog I/O Modules

Note: You must always create a connection to the discrete I/O in the

chassis, even if you are interested only in the analog modules in the

chassis.

1. Right click on the analog module and select Insert Connection.

2. Set the Connection Name to Discrete Exclusive Owner.

3. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

4. Set the Input, Output and Configuration sizes to the desired values.

Refer to the documentation for the module for details. Most modules

can be configured in more than one way – the values you choose

here depend on the type of module and how you want to configure it.

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

6. If the module has a Configuration Setting tab, select it and enter

appropriate values for the configuration data. Refer to the module

documentation for details.

Configuring Flex I/O

7. Click OK to complete the configuration.

You create a single connection for all the discrete modules in a Flex rack,

and individual connections to the analog modules.

You do not have to create a connection to the discrete modules to create

a connection to an analog module.

When you put RSNetWorx online, it should find and display the modules

in the Flex rack.

Discrete Connection

To create the connection to the discrete I/O in the MBCN Scanlist

Configuration:

1. Right click on the Flex ControlNet adapter and select Insert

Connection. The Connection Properties dialog opens.

2. Set the Connection Name to Exclusive owner.

3. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

This time will be the update time for all the discrete modules in the

rack.

4. RSNetWorx automatically sets the Input and Output sizes to the

maximum values. You can reduce these sizes if the higher slots are

Publication number DSMBCN-UM001B-EN-P February 2003

Page 27

AutoMax ControlNet Module Page 27

not occupied by discrete modules. For example, if the highest slot

occupied by an output module is slot 7, you can reduce the output

size from 8 to 7.

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values

6. You can set how output modules behave on lost communications or

in program mode on a slot by slot basis. First click the Rack

Specifications tab and make sure that Include in Output is Yes for the

module. Click the Advanced tab and set the parameters to the

desired values.

7. Click OK to accept the connection.

Analog Connection

You do not need to create a connection to the discrete I/O in the Flex

rack to create a connection to analog modules in the rack.

1. Set the Connection Name to Discrete Exclusive Owner.

2. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

3. Refer to the documentation for the individual module for detailed

information on possible values for the Input, Output and

Configuration sizes.

4. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values

5. Click on the Configuration Setting tab to set module configuration

data such as input or output range, safe state data, etc.

6. You can set how the outputs behave on lost communications or in

program mode on a slot by slot basis. First click the Rack

Specifications tab and make sure that Include in Output is Yes for

the module. Click the Advanced tab and set the parameters to the

desired values.

7. Click OK to accept the connection.

Configuring Scheduled Data with Another MBCN

1. Right click on the MBCN from which you want to obtain scheduled

data and select Insert Connection from the menu.

2. The Connection Name should be Consume Data From

Publication number DSMBCN-UM001B-EN-P February 2003

Page 28

Page 28 AutoMax ControlNet Module

3. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

4. Set the input size to the number of words of data you want to receive

from the destination MBCN.

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign the addresses, enter the

values.

6. Click OK to accept the settings you have entered.

RSNetWorx automatically creates a matching Produce Data target on the

destination MBCN.

Configuring Scheduled Data with a PLC-5

Produced Data on the PLC-5, Consumed on the MBCN

In the Scanlist Configuration for the MBCN:

1. Right click on the PLC-5 from which the MBCN is obtaining data

and select Insert Connection. If necessary, switch to Edit Mode.

The Connection Properties dialog opens.

2. Set the Connection Name to Receive Data From.

3. RSNetWorx automatically assigns the Consume Buffer ID. If the

automatic value is incorrect, change it to the correct value.

4. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

5. Set the Input Size to the number of words of data you wish the

PLC-5 to produce.

6. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

7. Click OK to accept the settings.

RSNetWorx automatically creates a matching produce target in the

PLC-5. Start the Scanlist Configuration tool for the PLC-5 and confirm

that this is so.

Produced Data on the MBCN, Consumed on the PLC-5

1. In the main RSNetWorx window, right click on the PLC-5 and select

Scanlist Configuration. The Scanlist Configuration tool for the

PLC-5 opens.

2. Right click on the MBCN from which you want the PLC-5 to obtain

scheduled data and select Insert Connection.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 29

AutoMax ControlNet Module Page 29

3. Set the Connection Name to Consume Data From.

4. RSNetWorx assigns the Producer ID automatically. If necessary,

change the value.

5. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

6. Set the Input Size to the number of words of data you wish the

MBCN to produce.

7. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

8. Click OK to accept the settings.

RSNetWorx automatically creates a matching produce target in the

MBCN. Start the Scanlist Configuration tool for the MBCN and confirm

that this is so.

Configuring Scheduled Data with a ControlLogix Processor

To exchange scheduled data with a ControlLogix processor, you must

first create user-defined data types for the data in the ControlLogix, then

create tags of the types you have created. This must be done offline in

RSLogix 5000.

Produced Data on the ControlLogix, Consumed on the MBCN

Use the following steps to create a produced tag in RSLogix 5000:

1. Expand the Data Types item in the tree, right click on User-Defined,

and select New Data Type...

In the dialog box that appears:

2. Give the new type a name, for example, ProdTagType, and

optionally a Description.

3. Create a member for the data type. This member should be an array

of INTs of the size of data that you want to transfer. The maximum

size is 240 words, but this may be further restricted by the network

schedule.

4. Click OK to accept the data type.

5. Expand the Controller in the tree. Right click on Controller Tags

and select Edit Tags. RSLogix 5000 displays a list of the existing

controller tags

6. Right click on an empty entry in the list and select Edit Tag

Properties.

In the dialog box that appears:

7. Give the tag a Name and optionally a description.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 30

Page 30 AutoMax ControlNet Module

8. For the Data Type, select the user-defined data type you created

earlier.

9. For Tag Type, check Produced and set the number of consumers to

an appropriate value (at least 1 but more if other nodes will be

consuming this data).

10. Click the OK button.

Save your program and download it to the ControlLogix processor.

In the RSNetWorx Scanlist Configuration for the MBCN:

1. Right click on the ControlLogix processor and select Insert

Connection.

2. In the Communication Parameters area, enter the name of the

produced tag (not the user defined data type) in the Value field.

3. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

4. Set the input size to the number of words of data in the produced tag.

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

6. Click OK to accept the settings.

Produced Data on the MBCN, Consumed on the ControlLogix

To have the ControlLogix processor consume data from the MBCN, you

must first add the MBCN to the I/O Configuration in the ControlLogix.

This must be done offline.

1. Right click on I/O Configuration in the tree and select New Module.

2. Select the appropriate ControlNet bridge module to match the

hardware in the ControlLogix chassis and click OK.

3. Give the ControlNet bridge module a Name and optionally a

Description.

4. Set the slot to the slot the bridge module occupies in the ControlNet

chassis.

5. Set the Node to match the switch settings on the bridge module.

6. Click Finish to accept the bridge module.

7. Right click on the ControlNet bridge module you just created and

select New Module.

8. Select 1785-PLC5C (the MBCN emulates a PLC-5) and click OK,

9. Give the module a Name and optionally a Description.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 31

AutoMax ControlNet Module Page 31

10. Set the Node to the MBCN address on the ControlNet network.

11. Click Finish.

Use the following steps to create a consumed tag in RSLogix 5000:

1. Expand the Data Types item in the tree, right click on User-Defined,

and select New Data Type... In the dialog box that appears:

2. Give the new type a name, for example, ConsTagType, and

optionally a Description.

3. Create members for the data type. The first member should be a

DINT (this entry contains status information). The other member

should be an array of INTs of the size of data that you want to

transfer. The maximum size is 240 words, but this may be further

restricted by the network schedule.

4. Click OK to accept the data type.

5. Expand the Controller in the tree. Right click on Controller Tags

and select Edit Tags. RSLogix 5000 displays a list of the existing

controller tags

6. Right click on an empty entry in the list and select Edit Tag

Properties. In the dialog box that appears:

7. Give the tag a Name and optionally a description.

8. For Tag Type, check Consumed.

9. For Producer, select the MBCN from the list.

10. Set the Remote Instance to match the value in the MBCN (see

below).

11. Set the Requested Packet Interval to the desired update rate. The RPI

must be greater than or equal to the network update time (NUT).

12. For the Data Type, select the user-defined consumed data type you

created earlier.

13. Click the OK button to accept the tag.

14. Save your program and download it to the ControlLogix processor.

In RSNetWorx you must create a target produced connection on the

MBCN. In the Scanlist Configuration:

1. Right click on the MBCN and select Insert Target for Connections.

2. Set the Connection Name to Produce Data.

3. Set the Producer ID to match the Remote Instance in the

ControlLogix.

4. Set the Output Size to match the data size (size of the data array, not

including the DINT) in the consumed tag in the ControlLogix.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 32

Page 32 AutoMax ControlNet Module

5. RSNetWorx assigns the Input Address, Output Address and Status

Address automatically if Enable automatic addressing on insert is

turned on. If you want to manually assign these addresses, enter the

values.

6. Click OK to accept the connection.

Example:

To produce 120 words of data on the MCN and consume them on the

ControlLogix, create a produce connection of size 120 on the MBCN,

then create a consumeddata type in the ControlLogix that consists of a

DINT and an array of 120 INTs. Create a tag in the ControlLogix that

uses this data type.

Setting the Network Properties

From the main RSNetWorx window, select Network/Properties… Set

the Network Update Time (NUT) in ms, the Max. Scheduled Address

(SMAX), the Max. Unscheduled Address (UMAX), and the Media

Redundancy. If necessary, you can select the Media Configuration tab

and add any repeaters, etc. on your network.

Downloading the Configuration

When all the configuration information has been entered into

RSNetWorx, select Save to save and download the configuration. The

Save Configuration dialog box appears. Select Optimize and re-write

schedule for all connections and click OK. Answer Yes to break

connections and download.

Putting the MBCN in Run Mode

Before you put the MBCN in run mode, your program should check the

NAM (network attachment monitor) state to confirm that the MBCN is

online. Refer to page 60 for information on how to do this.

Put the MBCN in run mode by setting bit 1 in register 5.

The MBCN goes out of run mode when you do a stop all in the AutoMax

or when you clear bit 1 in register 5.

Accessing I/O Data

You assign the location for the data for each connection either manually

or automatically in the Scanlist Configuration tool. If you assign

locations manually, RSNetWorx checks that there are no overlaps.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 33

Application Example

AutoMax ControlNet Module Page 33

There is usually some header information included with the data for each

connection. The amount varies with the type of device the MBCN is

connected to. RSNetWorx displays input and output sizes in the form

9(6). This means that the connection uses 9 words in total, with 6 words

of data and 3 words of header. If the address assigned to the connection

is 16384, this means that addresses 16384, 16385 and 16386 contain the

header, and that addresses 16387-16392 contain the 6 words of data.

Use this information to obtain the data addresses to use in your AutoMax

program.

In the following example, the MBCN occupies slot 9 in an AutoMax

rack.

In AutoMax Programming Executive Version 3.0 and later, you define

these registers using the Variable Configurator.

If you are using AutoMax Programming Executive Version 2.1 or earlier,

you define these registers using IODEF statements in the rack

configuration task.

0100 TASK CNSCAN[TYPE=BASIC, PRIORITY=11, SLOT=0, CRITICAL=FALSE]

0110 IODEF CN_RUN@[SLOT=9, REGISTER=5, BIT=1]

0120 IODEF NAMSTATE%[SLOT=9, REGISTER=9473]

0300 IODEF INP_WRD_0%[SLOT=9, REGISTER=16393]

0310 IODEF INP_WRD_1%[SLOT=9, REGISTER=16394]

0400 IODEF OUT_WRD_0%[SLOT=9, REGISTER=24588]

0410 IODEF OUT_WRD_1%[SLOT=9, REGISTER=24589]

32767 END

The following BASIC program checks the NAM state for the attached

state before it puts the MBCN in run mode and starts accessing data, then

copies an input word to an output, and increments another output word.

0001 REM SAMPLE PROGRAM

0100 COMMON CN_RUN@

0110 COMMON NAMSTATE%

0120 COMMON INP_WRD_0%

0130 COMMON INP_WRD_1%

0140 COMMON OUT_WRD_0%

0150 COMMON OUT_WRD_1%

0160 COMMON REC_STAT1%

Publication number DSMBCN-UM001B-EN-P February 2003

Page 34

Page 34 AutoMax ControlNet Module

0200 IF NAMSTATE% = 12 THEN GOTO 300 \!ATTACHED

0210 DELAY 1 TICKS

0220 GOTO 200 \! WAIT FOR ONLINE

0300 CN_RUN@ = 1 \! PUT THE MBCN IN RUN

0400 OUT_WRD_0% = INP_WRD_0% \!COPY INPUT WORD

0410 IF OUT_WRD_1% > 10000 THEN OUT_WRD_1%=0\!LOOP

0420 OUT_WRD_1% = OUT_WRD_1% + 1 \!INCREMENT OUTPUT

0430 DELAY 1 TICKS

0500 GOTO 400

32767 END

Multicast Connections

To create listen-only or input-only connections to devices to consumed

data, use the previous procedures but set the Connection Name to Listen

Only or Input Only.

RSNetWorx automatically sets the output size to 0 for these connections.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 35

There are various registers on the MBCN that can be used to monitor the

operating status.

Status of Each Connection

You can use RSNetWorx to view the status of each connection.

Start the Scanlist Configuration for the MBCN and click on the

Connection Status tab. RSNetWorx displays Success for connections

that are operating correctly or gives an explanation for connections that

are not.

The MBCN also contains a status table that shows the status of each

connection, in registers 15362 to 15615.

Each entry consists of two 16-bit registers. The first is the General

Status, the second is the Extended Status. You assign the location of the

entry for a connection in RSNetWorx.

The following table shows possible status values.

AutoMax ControlNet Module Page 35

Monitoring Module Operation

General

Status,

hex

00 Service completed successfully.

01 0100 Connection in Use or Duplicate Forward Open.

01 0103 Transport Class and Trigger combination not

01 0106 Ownership Conflict

01 0107 Connection not found at target application. Could

01 0108 Invalid Connection Type. Indicates a problem with

01 0109 Invalid Connection Size. Check the sizes of

01 0110 Device not configured

01 0111 RPI not supported. May also indicate problem with

Extended

Status,

hex

Explanation

supported

be a buffer ID mismatch for scheduled produced and

consumed connections.

either the Connection Type or Priority of the

Connection.

scheduled produced and consumed connections.

the connection time-out multiplier.

01 0113 Connection Manager cannot support any more

connections

01 0114 Either the Vendor Id or the Product Code in the key

segment did not match the device

Publication number DSMBCN-UM001B-EN-P February 2003

Page 36

Page 36 AutoMax ControlNet Module

General

Status,

hex

Extended

Status,

hex

Explanation

01 0115 Product Type in the key segment did not match the

device

01 0116 Major or Minor Revision information in the key

segment did not match the device

01 0117 Invalid Connection Point. Could be the wrong

device type, device mismatches with scheduled

produced and consumed connections, etc.

01 0118 Invalid Configuration Format

01 0119 Connection request fails since there is no controlling

connection currently open.

01 011A Target Application cannot support any more

connections

01 0203 Connection cannot be closed since the connection

has timed out

01 0204 Unconnected Send timed out waiting for a response.

The destination device doesn’t exist (invalid

address, device turned off, etc.)

01 0205 Parameter Error in Unconnected Send Service

01 0206 Message too large for Unconnected message

service

01 0301 No buffer memory available

01 0302 Network Bandwidth not available for data

01 0303 No Tag filters available

01 0304 Not Configured to send real-time data

01 0311 Port specified in Path Segment Not Available

01 0312 Link Address specified in Path Segment Not

Available

01 0315 Invalid Segment Type or Segment Value in Path

01 0316 Path and Connection not equal in close

01 0317 Either Segment not present or Encoded Value in

Network Segment is invalid. The connection hasn’t

been scheduled. Run RS NetWorx.

01 0318 Link Address to Self Invalid

01 0319 Resources on Secondary Unavailable

02 n/a Connection Manager resources are unavailable to

handle service request

Publication number DSMBCN-UM001B-EN-P February 2003

Page 37

AutoMax ControlNet Module Page 37

General

Status,

hex

03* n/a Invalid connection number specified by the

04 Zero

05 Zero

07 n/a Connection has been lost. This is used by the

08 n/a Connection Manager does not support the

Extended

Status,

hex

Based

Word

Offset

Based

Word

Offset

Explanation

Get_Connection_Data service. This is also returned

by the Search_Connection_Data service if the

specified connection is not found.

Segment Type in path is invalid. The Extended

Status shall be the word offset (0 based) to the word

in the path where the error occurred. The offset

starts at the first word after the path size. This error

shall not be returned if an error occurs when parsing

the Connection Path.

Destination in path is invalid. The Extended Status

shall be the word offset (0 based) to the word in the

path where the error occurred. The offset starts at

the first word after the path size. This error shall not

be returned if an error occurs when parsing the

Connection Path.

Get/Set Services when they are made through a

connection.

requested Service.

09 Index to

Element

0C Optional Service cannot be performed while Object is in

10 Optional Service cannot be performed while Device is in

11 n/a Response data too large. This is used by the get

13 n/a Not enough data was received.

14 Attribute Id Attribute specified in FIND service is not supported

Error in Data Segment. Extended Status shall be

index to where the error was encountered in the

Data Segment. The Configuration Revision Number

if present in the Data Segment shall always be index

1. If the error occurs with the Get/Set Services, then

the extended status indicates the attribute number

that failed.

current state. The 1st word of Extended Status may

optionally contain the object’s current state.

This could occur if you are making changes while in

run mode.

current state. The 1st word of Extended Status may

optionally contain the device’s current state.

This could be caused by an offline unscheduled

device, or the keeper is in a faulted state.

services to indicate the amount of data requested

was too large to fit into the response buffer.

by Connection Manager

Publication number DSMBCN-UM001B-EN-P February 2003

Page 38

Page 38 AutoMax ControlNet Module

General

Status,

hex

15 n/a Too much data was received.

25 0114 Either the Vendor Id or the Product Code in the key

25 0115 Product Type in the key segment did not match the

25 0116 Major or Minor Revision information in the key

26 n/a Invalid path size

D0 01 Connection is closed or stopped

D0 02 Connection open is pending.

D0 03 Connection close is pending

Extended

Status,

hex

Explanation

segment did not match the device. Used if the Key

Segment was contained in the path.

device. Used if the Key Segment was contained in

the path.

segment did not match the device. Used if the Key

Segment was contained in the path.

(Target connection) Nothing is talking to this

connection.

Figure 5 Connection Status Values

Operating Status

The following registers contain information about the operation of the

MBCN.

Number of Instances

Register 15748 contains the number of connections currently configured.

This includes both originator-to-target (O=>T) and target-to-originator

(T=>O) connections.

Register 15751 contains the number of originator instances.

Overall Status

Register 15745 contains the overall status. You can use bits in this

register to quickly determine the overall status of MBCN operations.

If bit 0 is set, all I/O and scheduled consume and scanner (originator)

connections are operating with no errors.

If bit 8 is set, all scheduled produced (target) connections are operating

with no errors.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 39

AutoMax ControlNet Module Page 39

If bit 3 is set, one or more originator instances does not have a schedule.

Run RSNetWorx and schedule the network by enabling edits and doing a

save.

Scanner State

Register 15754 shows the current scanner state.

Value Scanner State

0 Idle

1 Active, in program mode

2 Active, in run mode

Figure 6 Scanner State Table

This register is read-only. The state is Idle only when you are

downloading a configuration.

Adapter State

Register 15755 shows the current state of scheduled produced data

connections.

Value State

0 Idle

1 Enabled

Figure 7 – Adapter (Scheduled Produced Data) State Table

This register is read-only.

Summary of Registers for Monitoring Operation

Refer to the preceding sections for detailed information on each of these

registers.

AutoMax

Registers

15362 -

15615

15745 Status Overall status

15748 NumInstances Number of instances currently

Name Description

Connection

status

Status of each connection

configured

15751 NumOrigInsts Number of originator instances

15754 ScanState Current scanner state

Publication number DSMBCN-UM001B-EN-P February 2003

Page 40

Page 40 AutoMax ControlNet Module

AutoMax

Registers

15755 AdapState Current adapter state

Name Description

Figure 8 Summary of Monitor Registers

Publication number DSMBCN-UM001B-EN-P February 2003

Page 41

Register Organization

AutoMax ControlNet Module Page 41

Unscheduled Messaging

The MBCN supports unscheduled messaging to other nodes on the

ControlNet network. It emulates the interface of the M/N 57C442 Data

Highway Plus module. It uses PCCC commands to communicate with

other nodes on the network.

This section describes how the messaging interface is organized in the

MBCN and provides examples of how the MBCN is accessed by the

application software. For more detailed information on programming,

refer to the AutoMax Programming Language manuals.

The MBCN supports sending messages on the local network only, not

through bridge modules.

The following table shows the memory organization. The following

sections describe the different register areas in more detail.

Registers Description

4 – 63 Status and control registers

64 – 1063 Binary file B3

1088 – 2087 Binary file B4

2088 – 3087 Binary file B5

4384 – 5383 Integer file N7

5384 – 6383 Integer file N8

6384 – 7383 Integer file N9

Figure 9 Summary of Unscheduled Message Registers

WARNING

REGISTERS AND BITS THAT ARE DESCRIBED AS "READ

ONLY" OR FOR "SYSTEM USE" ONLY MUST NOT BE WRITTEN

TO BY THE USER. WRITING TO THESE REGISTERS AND BITS

MAY RESULT IN IMPROPER SYSTEM OPERATION. FAILURE

TO OBSERVE THIS PRECAUTION COULD RESULT IN BODILY

INJURY.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 42

Page 42 AutoMax ControlNet Module

R/W Register Description

R/W 22 Response Poll period, in units of 1/8 second. This

R/O 32 Node address (1-99). The value comes from the

R/O 33 Extended Status (EXT STS) error code.

R/O 61 Module Software Revision Level. A value of 100

register is used by the GATEWAY_CMD_OK@

function to compute the time interval to poll for

command complete. The default value is 1, which

corresponds to a response polling period of 0.125

seconds.

thumbwheel switches on the faceplate and is updated

only on power-up. The MBCN will not begin to

communicate on the network until the node address is

properly set.

NOTE: The on-line Monitor function in the AutoMax

Programming Executive software can display the node

address in either decimal or hexadecimal notation.

indicates version 1.00, and so on. This is the same as

the version that scrolls on the 7-segment LED at

power-up.

R/O 62-63 Interface module ID (ASCII 'GTWY').

AutoMax Application Programming

The sections that follow describe how to configure registers in the

MBCN's shared memory and how to initiate commands from the MBCN.

Link configuration and application programming examples are provided.

Variable Configuration AutoMax application tasks communicate with

the Interface module by referencing registers in the shared memory.

These registers must first be configured using the AutoMax

Programming Executive software.

In AutoMax Programming Executive Version 3.0 and later, you define

these registers using the Variable Configurator.

If you are using AutoMax Programming Executive Version 2.1 or earlier,

you define these registers using IODEF statements in the rack

configuration task.

Figure 10 Control and Status Registers

Publication number DSMBCN-UM001B-EN-P February 2003

Page 43

AutoMax ControlNet Module Page 43

The format for the IODEF statement (used only in V2.1 and earlier) is as

follows:

nnnn IODEF variable_name [SLOT=slot number, &

REGISTER=register number, BIT=bit number]

where:

• nnnn = configuration task line number

• variable_ name = integer or boolean variable. Double integer

variables can be used but should be avoided because of the

possibility that all 32 bits will not transfer in one operation.

WARNING

IF YOU USE DOUBLE INTEGER VARIABLES IN THIS

INSTANCE, YOU MUST IMPLEMENT A SOFTWARE

HANDSHAKE BETWEEN THE TRANSMITTER AND RECEIVER

TO ENSURE THAT BOTH THE LEAST SIGNIFICANT AND MOST

SIGNIFICANT 16 BITS HAVE BEEN TRANSMITTED BEFORE

THEY ARE READ BY THE RECEIVING APPLICATION

PROGRAM. FAILURE TO OBSERVE THIS PRECAUTION COULD

RESULT IN BODILY INJURY.

• slot number = slot number of the module in the rack. This number

may range from 0 to 15.

• register number = AutoMax register number on the module. Register

numbers correspond to 16-bit words on the module.

• bit number = bit number of the I/O point in the register. Bit numbers

range from 0 to 15. Bit numbers are specified for Boolean variables

only.

Any variables contained in the rack configuration are accessible by any

task on any AutoMax Processor in the rack. When AutoMax variables

are referenced in AutoMax tasks, the data is directly obtained from or

written to the register image on the module. The data storage for an

AutoMax variable mapped to an A-B register will always exist in the

module's shared memory.

The registers in the MBCN's register image may be displayed using the

AutoMax Programming Executive Monitor I/O function.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 44

Page 44 AutoMax ControlNet Module

Application Programming

Read and write commands from the MBCN are initiated from a BASIC

application task by executing the GATEWAY_CMD_OK@ function:

GATEWAY_CMD_OK@(status%, cmd_code%, slave_node%, &

slave_reg$, master_var!, num_regs%)

where:

• status is an integer variable representing the location where the status

resulting from the operation is stored. Refer to page 51 for a list of

status values.

• cmd_code is a variable name or expression of type integer

representing the PCCC command sent by the module. The

commands are described on page 46.

Any other commands result in a status of 1 (invalid operation) being

returned.

slave_node is variable name or expression of type integer containing the

destination address (in decimal or hexadecimal). This is the address on

your network.

slave_reg is a variable name or expression of type string that specifies

the starting register number an the target device. For commands 3, 4, 5,

6, and 7, this is a logical address represented as an ASCII string for

PLC-5 controllers. For commands 1 and 2, this argument contains 4

octal digits, for example, "0200" (word offset). For command 5 (ReadModify-Write), this argument can contain up to ten ASCII addresses

separated by commas. The address must exist at the target node.

master_var is a variable name or expression (usually via the BASIC

language

The VARPTR! Function, of type double integer, represents the physical

address of the starting register on the module to be read from/written to.

num_regs is a variable name or expression of type integer that defines:

• for Word Range Read/Write (command 3 or 4) or for Typed

Read/Write (commands 6 or 7), the number of registers to be

transferred, from 1 to 1000;

• for Read-Modify-Write (command 5), the number of addresses to be

written, in the range 1 to 10;

• for Unprotected Read/Write (command 1 or 2), the number of

registers to be transferred, from 1 to 100.

The GATEWAY_CMD_OK@ function returns true if the command was

successfully completed. If the function returns false, the returned status is

an error code. Refer to page 51 for the error codes returned by the

GATEWAY_CMD_OK@ function.

Multiple tasks can access the MBCN.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 45

AutoMax ControlNet Module Page 45

NOTE: If more than four tasks try to initiate messages at the same time,

error code '22' is returned to the additional tasks attempting accesses.

If you are using AutoMax Programming Executive software version 2.1

or earlier, any required registers must be defined using IODEFs in the

configuration task. If you are using AutoMax Programming Executive

software version 3.0 or later, these registers are defined using the

Variable Configurator within the Programming Executive. The following

example illustrates one method of enabling the MBCN.

Example:

In the configuration, define the following registers:

RESP_TIME% [SLOT=4, REGISTER=22]

The application could initialize the MBCN as follows:

30 RESP_TIME%=2\!GATEWAY_CMD_OK@ should poll for

response every 250 ms.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 46

Page 46 AutoMax ControlNet Module

Commands Initiated by the Module

The commands described in figure 13 can be used by the AutoMax

Processor in the GATEWAY_CMD_OK@ function to initiate a

command on the MBCN.

GATEWAY_CMD_OK@

Command Code

1 Unprotected Read CMD = 01, FNC = n/a

2 Unprotected Write CMD = 08, FNC = n/a

3 Word Range Read CMD = 0F, FNC = 01

4 Word Range W rite CMD = 0F, FNC = 00

5 Read-Modify-Write CMD = 0F, FNC = 26

6 PLC-5 Typed Read CMD = 0F, FNC = 68

7 PLC-5 Typed Write CMD = 0F, FNC = 67

Description PCCC Function

Figure 11 Command Table

Commands 1 and 2 come from the basic command set and are accepted

by all Allen-Bradley processors. For PLC-5 processors, compatibility

files must exist. Refer to Allen-Bradley documentation for more

information. Command 1, Unprotected Read, transfers a block of data

from the target registers at the remote address to the specified AutoMax

registers on the module. Data can be transferred to any file in the PLC-5

data image area. The data is stored in the specified registers on the

module. A maximum of 100 registers can be transferred in a single

request. The transfer cannot cross file boundaries.

Command 2, Unprotected Write, transfers a block of data from the

specified AutoMax registers on the module to the target registers at the

destination address. The data must already exist in the registers on the

module. Data can be transferred from any file in the PLC-5 data image

area. A maximum of 100 registers can be transferred in a single request.

The transfer cannot cross file boundaries.

Commands 3, 4, 5, 6 and 7 come from the PLC-5 command set.

Commands 3, 4, 5, 6 and 7 are accepted by PLC-5 processors. For

commands 3, 4, 5, 6, and 7, only logical addresses represented as ASCII

strings are supported.

Command 3, Word Range Read, transfers a block of data from the target

registers at the remote address to the specified AutoMax registers on the

module. Data can be transferred to any file in the PLC-5 data image area.

The data is stored in the specified registers on the module. A maximum

of one file (1000 registers) can be transferred in a single request. The

transfer cannot cross file boundaries.

Publication number DSMBCN-UM001B-EN-P February 2003

Page 47

AutoMax ControlNet Module Page 47

Command 4, Word Range Write, transfers a block of data from the

specified AutoMax registers on the module to the target registers at the

destination address. The data must already exist in the registers on the

module. Data can be transferred from any file in the PLC-5 data image

area. The data is stored in the specified registers on the module. A

maximum of one file (1000 registers) can be transferred in a single

request. The transfer cannot cross file boundaries.

Command 5, Read-Modify-Write, sets or resets specified bits in

specified registers in the data table at the remote address. The data (AND

and OR masks) must already exist in the registers on the module. A

maximum of ten registers can be modified in a single request.

NOTE: The A-B controller at the remote address may change the states

of the original bits in memory before this command (command 5) can

write the word back to memory. Therefore, some bits may

unintentionally be overwritten. To help prevent this, we suggest that you

use this command to write into the storage area of a programmable

controller's data table, and have the controller read the word only, not

control it.

Command 6, Typed Read, transfers a block of data from the target

registers at the remote address to the specified AutoMax registers on the

module. Data can be transferred to any file in the PLC-5 data image area.

The data is stored in the specified registers on the module. A maximum

of one file (1000 registers) can be transferred in a single request. The

transfer cannot cross file boundaries.

Command 7, Typed Write, transfers a block of data from the specified

AutoMax registers on the module to the target registers at the destination

address. The data must already exist in the registers on the module. Data

can be transferred from any file in the PLC-5 data image area. The data