Page 1

Allen-Bradley

IMC S Class

Compact Motion

Installation

Controller

(Cat. No. 4100-999-122)

and Setup

Manual

Page 2

Important User

Information

Because of the variety of uses for the products described in this

publication, those res ponsible for the application and use of thi s control

equipment must satisfy themselves that all necessary steps have been

taken to ass ure that each appli cation and use meets all performance and

safety requirem ents, inclu ding an y applicabl e laws, re gulatio ns, codes

and standards.

The illustrations, c harts, sample programs an d layout example s shown

in this guide ar e inte nded so le ly for purpos es of e xample . Si nce th ere

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellec tual property liabil ity) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanica l devices that should be taken into cons ideration when

applying products such as those described in this publication.

Reproduction of the content s of this copyright ed publication, in whole

or in part, without writte n permission of Allen-Bradle y Company , Inc.,

is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

identify a hazard

•

avoid the hazar d

•

recognize the consequences

•

Important: Identifies information that is critical for successful

GML, ULTRA, IMC, SCAN bus, Flex I/O, DTAM, PanelView, and SLC are trademarks; PLC is a registered

trademark of Allen-Bradley Company, Inc.

death, property damage or economic loss.

application and understanding of the product.

Page 3

Table of Contents

Preface

Who Should Use this Manual ........................ P-1

Purpose of this Manual .................................. P-1

Safety Precautions ..........................................P-1

Contents of this Manual .................................P-2

Related Documentation ...............................P-3

Product Receiving & Storage Responsibility. P-3

Allen-Bradley Support ...................................P-3

Local Product Support .................................P-4

Technical Product Assistance ...................... P-4

Chapter 1 – Safety

i

Read This Manual .......................................... 1-1

Chapter 2 – Introduction

IMC-S/23x Description.................................. 2-1

Features .......................................................... 2-2

Model Numbering System ............................. 2-4

Pre-Engineered Cable Assemblies ................. 2-4

Mechanical Specifications ............................. 2-5

Front Panel Layout ...................................... 2-5

Mounting and Clearance Dimensions .......... 2-6

General Specifications ................................... 2-6

Environmental Specifications....................... 2-7

Electrical Specifications ................................. 2-7

Encoder Input Specifications ......................... 2-7

Servo Output Specifications........................... 2-8

Dedicated Discrete I/O Specifications........... 2-8

Serial I/O Specifications ................................ 2-9

DH-485 Specifications ................................... 2-9

Flex I/O Compatibility Specifications ......... 2-10

Servo Performance Specifications ............... 2-10

Servo Gain Units ....................................... 2-11

Remote I/O Adapter Specifications ............. 2-11

AxisLink Specifications ............................... 2-13

Publication 999-122 January 1997

Page 4

ii

Table of Contents

Chapter 3 – Technical Overview

Digital Control Loop ...................................... 3-1

Encoders ......................................................... 3-2

Encoder Counter ............................................ 3-3

Software Feedback Calculations.................... 3-4

Servo Amplifiers and Motors ......................... 3-5

High Level Motion Functions........................ 3-6

Indexing and Jogging ................................... 3-7

Backlash Compensation .............................. 3-7

Electronic Cam ............................................ 3-7

Electronic Gearing....................................... 3-7

Interpolation ................................................. 3-8

Velocity Feedforward .................................... 3-8

CPU Watchdog .............................................. 3-9

Software Overtravel Limits............................ 3-9

Serial Communication .................................... 3-9

DH-485 Communication .............................. 3-10

Axis-Specific Discrete I/O ........................... 3-10

Home Limit Switch Input .......................... 3-10

Overtravel Limit Switch Inputs................. 3-10

Drive Fault Output ..................................... 3-11

Drive Enable Output .................................. 3-11

Position Registration Inputs ....................... 3-11

Status LEDs .................................................. 3-11

General Purpose Discrete I/O ......................3-12

The Imaginary Axis ..................................... 3-12

Remote I/O (Optional)................................. 3-12

AxisLink (Optional)..................................... 3-12

Publication 999-122 January 1997

Chapter 4 – Installation and Hookup

Introduction.................................................... 4-1

Complying with European Union Directives . 4-3

EMC Directive ............................................. 4-3

Low Voltage Directive................................. 4-3

Installing the IMC-S/23x ............................... 4-6

Configuring the IMC-S/23x........................... 4-7

Configure the Serial Ports ............................ 4-8

Select the Registration Input Voltage ........ 4-11

Select the Encoder Power Voltage ............. 4-12

Select the Servo Output Format................. 4-14

Serial Communications Devices.................. 4-15

Page 5

Table of Contents

Serial Communication Protocol ................. 4-15

Connecting RS-232 Devices ...................... 4-16

Connecting RS-422 Devices ...................... 4-18

Connecting Encoders ................................... 4-19

AB 1391B-ES & 1391-DES Drives .......... 4-20

AB 845F, 845H, & 845T Encoders ........... 4-20

AB 845K Encoders.................................... 4-21

AB 845P Encoders ..................................... 4-21

Other Encoders .......................................... 4-22

Connecting Servo Amplifiers ....................... 4-22

AB 1391B-ES & 1391-DES Drives .......... 4-23

Other Servo Amplifiers ............................. 4-23

Connecting Hydraulic Valves...................... 4-24

Connecting Axis-Specific Discrete I/O........ 4-25

The Drive Enable Outputs ......................... 4-26

The Drive Fault Inputs............................... 4-26

Connecting Registration Sensors ................. 4-27

Using the Registration Inputs .................... 4-28

Connecting the CPU Watchdog................... 4-29

Connecting Flex I/O .....................................4-30

Connect the I/O Power Supply ..................... 4-30

Connect the AC Power ................................. 4-31

Connecting Remote I/O (Optional) .............. 4-32

Connecting AxisLink (Optional) ................. 4-33

AxisLink for Standard Operation .............. 4-34

AxisLink for Extended Length Operation. 4-35

Connecting DH-485 (Optional) ................... 4-36

Chapter 5 – Understanding IMC-S/23x Setups

The Setup Menus ........................................... 5-1

Application Setup Menu .............................. 5-1

Machine Setup Menu ................................... 5-1

Hookup Diagnostics Menu.......................... 5-1

Servo Setup Menu ....................................... 5-2

Using the Setup Menus .................................. 5-2

Passwords .................................................... 5-2

Toggling ....................................................... 5-2

Disabling Feedback ..................................... 5-3

Disabling DH-485 ........................................ 5-3

Loading Setup Values.................................. 5-4

Selecting a Setup Menu ............................... 5-4

Selecting an Axis ......................................... 5-4

Editing Parameter Values ............................. 5-5

iii

Publication 999-122 January 1997

Page 6

iv

Table of Contents

Application Setup Menu ................................ 5-5

Upload Inhibit .............................................. 5-6

Editing the AxisLink Configuration .............. 5-6

Editing the DH-485 Configuration ................ 5-6

Maximum Node Address............................. 5-7

Network Node Address ...............................5-7

Baud Rate .................................................... 5-7

Token Hold Factor ....................................... 5-7

Editing the Axis Setup Parameters................. 5-8

Axis Configuration...................................... 5-8

Virtual Axes ................................................. 5-8

The Imaginary Axis................................... 5-10

Rotary Axes ............................................... 5-10

Position Units ............................................ 5-10

Display Fields ............................................ 5-11

Averaged Velocity Timebase ..................... 5-11

Move and Jog Profiles ............................... 5-12

Trapezoidal ................................................ 5-12

S Curve ......................................................5-13

Parabolic .................................................... 5-13

Backlash Compensation ............................ 5-14

Editing the Axis Fault Action Configuration 5-14

Editing the Direct Command Mode Configuration 5-16

Editing the Operator Interface Configuration 5-17

Editing the Runtime Display Configuration 5-18

Editing the Serial Port Configuration ........... 5-20

Editing the RIO Configuration ..................... 5-21

RIO Adapter Channel ................................ 5-21

RIO Baud Rate ........................................... 5-22

RIO Rack Size ........................................... 5-22

RIO Rack Address ..................................... 5-23

RIO Starting Group ................................... 5-23

RunningApplication Program on Power-Up 5-23

Machine Setup Menu ................................... 5-24

Editing the Feedback Configuration ............ 5-25

Conversion Constant (K)........................... 5-25

Unwind ...................................................... 5-26

Unwind Reference Point............................ 5-26

Encoder Loss Detection............................. 5-27

Editing the Overtravel Configuration .......... 5-27

Overtravel Limit Switches ......................... 5-28

Software Travel Limits .............................. 5-28

Publication 999-122 January 1997

Page 7

Table of Contents

Editing the Homing Configuration .............. 5-29

Home Position ........................................... 5-29

Active Homing .......................................... 5-30

Homing Without a Limit Switch or Marker 5-30

Homing to an Encoder Marker.................. 5-30

Homing to a Limit Switch......................... 5-31

Homing to a Limit Switch and Marker...... 5-32

Limit Switch Contacts ............................... 5-32

Absolute Homing....................................... 5-33

Absolute_MV ............................................ 5-34

Absolute_Serial ......................................... 5-35

Passive Homing ......................................... 5-35

Editing the Servo Configuration.................. 5-36

Dual Loop Control ..................................... 5-36

Servo Output Limiting ............................... 5-39

Drive Fault Input ....................................... 5-40

Editing the Positioning Configuration ......... 5-40

Position Lock Tolerance ............................ 5-40

Backlash Offset.......................................... 5-41

Approach Direction ................................... 5-41

Hookup Diagnostics Menu ........................... 5-42

Checking Motors and Encoders ................... 5-43

Testing Encoders .......................................... 5-45

Editing the Motor/Encoder Polarity ............. 5-47

Tuning Velocity Loop Servo Drives ............ 5-47

Adjusting Offset .........................................5-47

Digital Battery Box .................................... 5-48

Checking Encoder Markers.......................... 5-50

Align Absolute Transducers ......................... 5-51

Checking The Discrete I/O .......................... 5-53

Checking the Dedicated Discrete Inputs ... 5-53

Checking the Dedicated Discrete Outputs . 5-54

Checking Flex I/O Discrete Inputs ............ 5-54

Checking Flex I/O Discrete Outputs ......... 5-55

Checking Flex I/O Analog Inputs .............. 5-56

Checking Flex I/O Analog Outputs ........... 5-57

Servo Setup Menu........................................ 5-58

The Servo Loop Gains ................................. 5-58

Velocity Gain ............................................. 5-59

Proportional Gain ...................................... 5-59

Integral Gain .............................................. 5-59

Feedforward Gain ...................................... 5-60

v

Publication 999-122 January 1997

Page 8

vi

Table of Contents

Self-Tuning the Servo Gains ........................ 5-60

Using the Position Error Integrator ........... 5-66

Using Velocity Feedforward ...................... 5-66

Tuning Faults ............................................... 5-67

Aborted by Escape! ...................................5-67

Encoder Fault! ........................................... 5-67

Hit Hardware Overtravel Limit! ................ 5-67

Position Error Tolerance Exceeded! .......... 5-68

Drive Fault Detected! ................................ 5-68

Manually Tuning the Loop Gains 5-68

Setting the Drive Offset & Deadband Comp 5-69

Setting the Velocity Gain ........................... 5-69

Setting the Proportional Gain .................... 5-70

Setting the Integral Gain ............................ 5-71

Setting the Feedforward Gain .................... 5-72

Setting the Position Error Tolerance.......... 5-72

Saving Setup Values .................................... 5-73

Setup Menu Reference ................................. 5-74

Chapter 6 – Setting Up Your IMC-S/23x Using GML

Chapter Objectives ......................................... 6-1

General Startup Precautions ........................... 6-1

Setting Up Your Compact.............................. 6-2

Before You Begin ........................................ 6-2

Preparing the System................................... 6-2

Getting Started ............................................. 6-3

Defining Preferences ................................. 6-3

Defining Your Controller and Its Options .... 6-4

Defining Your Axes................................... 6-5

Applying Power........................................... 6-6

Establishing Communication....................... 6-6

Downloading Your Diagram..................... 6-7

Testing Motor Connections & Defining Dir 6-7

Testing the Encoder Marker...................... 6-8

Tuning a Velocity Loop ............................. 6-8

Tuning Servo Parameters.......................... 6-9

Saving Your Parameters .......................... 6-10

Publication 999-122 January 1997

Chapter 7 – Troubleshooting

Chapter Objectives......................................... 7-1

Understanding How to Detect a Problem ...... 7-1

Replacing Modules ........................................ 7-2

Before You Begin ........................................7-2

Page 9

Table of Contents

Removing a CPU Module............................ 7-2

Installing a Replacement CPU Module ....... 7-3

Removing a Power Supply Module ............. 7-3

Installing a Replacement Power Supply ..... 7-4

Understanding Status LEDs ........................... 7-5

Understanding the System OKLED .............. 7-5

Understanding System Faults ......................... 7-6

Finding Faults.............................................. 7-6

Viewing Instantaneous Status.................... 7-6

Viewing Continuous Status ....................... 7-7

Troubleshooting General System Problems... 7-8

Appendix A – Cable Information

Introduction ................................................... A-1

4100-CCF1 or 4100-CCF3......................... A-2

4100-CCS15F ............................................. A-2

4100-CCA15F ............................................ A-3

4100-CCW15F ............................................ A-4

4100-RCS3T ............................................... A-4

4100-CCAQB ............................................. A-5

vii

Publication 999-122 January 1997

Page 10

viii

Table of Contents

Publication 999-122 January 1997

Page 11

Preface

P-1

Preface

Read this preface to familiarize yourself with the rest of the manual.

This preface covers the following topics:

who should use this manual

•

the purpose of this manual

•

general safety precautions

•

receiving and storage information

•

Allen-Bradley support

•

Who Should Use this

Manual

Purpose of this Manual

Safety Precautions

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting the Allen-Bradley IMC S Class

Compact.

If you do not have a bas ic understandi ng of the Compact, contact your

local Allen-Bradley representative for information on available training

courses before using this product.

This manual is a installa tion and set up guide for the Compact. It gi ves

you an over view of the Compact an d describes the procedures yo u use

to install, set up, use, and troubleshoot the Compact.

The following general precautions apply to the Compact:

ATTENTION:

and associated machinery shoul d pl an or im pl ement the

!

installation, startup, and subsequent maintenance of the

system. Failure to comply can result in personal injury

and/or equipment damage.

Only those familiar with the Compact

ATTENTION:

devices. To avoid hazar d of electrical shock, ver ify that

all voltage on the capacitors has been discha rged before

attempting to service, repair, or remove this unit. You

should only attempt the procedures in this manual if you

are qualified to do so and familiar with solid-state

control equipment and the safety procedures in

publication NFPA 70E.

ATTENTION:

for local safety and electrical codes.

This product contains stored energy

The system integrator is r esponsible

Publication 999-122 - January 1997

Page 12

P-2 Preface

Contents of this Manual

ATTENTION:

An incorrectly applied or installed

Compact can result in componen t damage or a reduction

!

in product life. Wiring or application errors, such as

undersizing the mot or, incorrect or in adequate AC supply ,

or excessive ambient temperatures can result in

malfunction of the product.

ATTENTION:

This product contains ESD

(Electrostatic Discharge) sensitive parts and

assemblies. Static control precautions are required

when installing, testing, servicing, or repairing this

assembly. Component damage can result if ESD

control procedures are not followed. If you are not

familiar with static control procedures, refer to

Allen-Bradley publication 8000-4.5.2, Guarding

Against Electrosta tic Dama ge or a ny other applic able

ESD Protection Handbook.

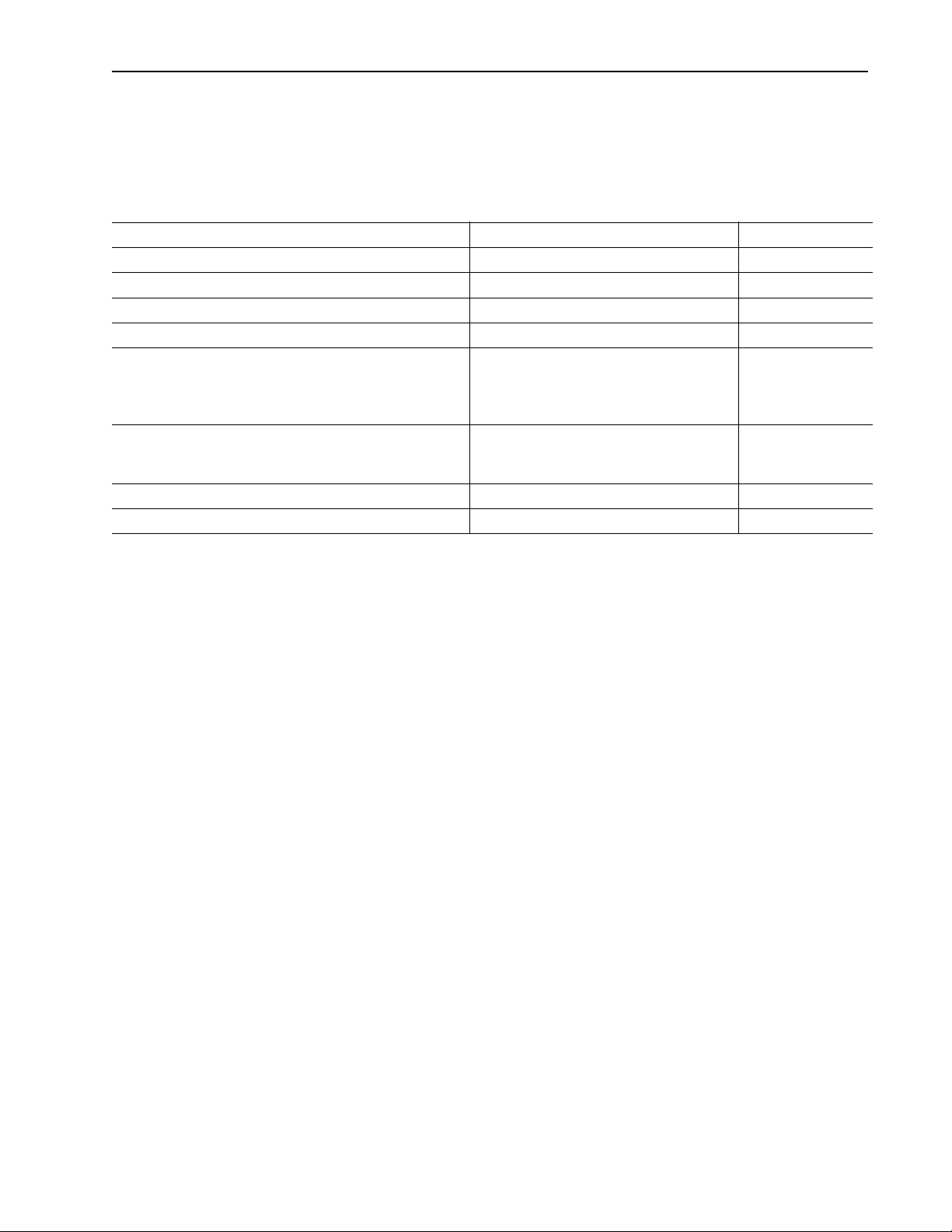

Chapter Title Contents

Describes the purpose, background, and scope

Preface

1 Safety Lists safety information regarding the Compact.

2 Introduction Provides a feature overview of the Compact.

3 Technical Overview Provides a technical overview of the Compact.

4

5

6

7 Troubleshooting

Appendix A Cable Information

Installation and

Hookup

Understanding the

IMC-S23x Setup

Setting Up your

Compact

of this manual. Also specifies the audience for

whom this manual is intended.

Provides information that allows you to install and

hook up your Compact.

Provides information that allows you to

understand the setup procedures for the

Compact.

Provides setup procedures for the Compact.

Explains how to interpret and correct problems

with your Compact.

Provides information about the cables used with

the Compact.

Publication 999-122 - January 1997

Page 13

Preface P-3

Related Documentation

The following documents contain additional information concerning

related Allen-Bradley products. To obtain a copy, contact your local

Allen-Bradley office or distributor.

For Read This Document Document Number

A description and specifications for the Compact Compact Motion Controller Product Data 4100-2.3

A user guide for GML programming to be used with the Compact. GML Programming Manual GML-DOC-S

An overview of the Flex I/O products Flex I/O Product Profile 1794-1.14

Specifications for the Flex I/O products Flex I/O Product Data 1794-2.1

Published by the

An article on wire sizes and types for grounding electrical equipment National Electrical Code

A complete listing of current Allen-Bradley documentation, including

ordering instructions. Also indicates whether the documents are

available on CD-ROM or in multi-languages

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Schematics related to the Compact. Schematics 4100-5.0.01

Allen-Bradley Publication Index SD499

National Fire

Protection Association

of Boston, MA.

Compact Prod uc t

Receiving and Storage

Responsibility

Allen-Bradle y Support

You, the customer, are responsible for thoroughly inspecting the

equipment before accepting the shipment from the freight company.

Check the item(s) you r eceive aga inst your purchase or der. If any items

are obviously damaged, it is your responsibility to refuse delivery until

the freight agent ha s n oted the damage on the freight bil l. Shoul d you

discover an y concealed damage during unpacking, you are responsible

for notifying t he freight agent. Lea ve t he shipping container i ntact and

request that the freight agent make a vi sual inspection of the equipment.

Leave the pro duct in its shi pping contai ner prior to instal lation. If you

are not going to use the equipment for a period of time, store it:

in a clean, dry location

•

within an ambient temperat ure range of -40 to 70 ° C (-40 to 158° F)

•

within a relative humidity range of 5% to 95%, non-condensing

•

in an area where it cannot be exposed to a corrosive atmosphere

•

in a non-construction area

•

Allen-Bradley offers support services worldwide, with over 75

Sales/Support Of fices, 512 auth orized Distrib utors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Publication 999-122 - January 1997

Page 14

P-4 Preface

Local Product Support

Contact your local Allen-Bradley representative for:

sales and order support

•

product technical training

•

warranty support

•

support service agreemen ts

•

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the

your local Allen-Bradley representative. For the quickest possible

response, we recommend that you have the catalog numbers of your

products av ailable when you call . The Rockwell Automation T echnical

Support number is (

603) 443-5419

Troubleshooting

.

chapter first. Then call

Publication 999-122 - January 1997

Page 15

Safety

Chapter

1

Read This Manual

Read and understand this instruction manual. It pr ovides the nece ssary

information to allo w you to install, connect, and se t up your IMCñS/23x

for safe, reliable operation.

ATTENTION: DANGEROUS MACHINERY!

Operation and maintenance of automatic equipment

!

!

involves potential hazards. Control Operators, Setup

Personnel, and Programmers should each take

precautions to avoid injury.

Injury and entanglement may occur if hands and limbs

come in contact wit h moving machinery . KEEP HANDS

CLEAR of dangerous moving machinery. Loose fitting

clothing or ties ca n become entangled in the machinery.

These items should not be worn while operating,

servicing, or programming the machine.

ATTENTION: HIGH VOLTAGES!

Electric shock can ki ll. Be sure the con troller is safely

installed in accordance with the Installation and

Hookup Section of this manual. Avoid contact with

electrical wires and cabling while power is on. The

electrical cabinet should be opened only by trained

service personnel.

ATTENTION: STATIC CONTROL!

The internal modules of the IMC S Class Compact motion

!

controller contain staticñsensitive electronic

components. Remove and handle the internal modules

only at a staticñsafeguarded work area. Failure to do so

may result in a dra st ica lly shortened life of your moti on

controller.

A disposable wristñstrap for grounding yourself is

included with this product. Please follow the directions

for use of this strap when removing and handling the

motion controller s internal modules.

Publication 999-122 - January 1997

Page 16

1-2 Safety

Publication 999-122 - January 1997

Page 17

Introduction

Chapter

2

IMC-S/23x Description

The IMC-S/23x is a compact, rugged, microprocessor-based two- or

four-axis servo motion controller. By including the logic and field

power supplies, t he IMC-S/23x pro vides a comp letely programmabl e,

stand-alone motion and logic controller suitable for a wide variety of

industrial applications.

The IMC-S/23x, in conjunction with external drive systems and

feedback encoders, provides two or four axes of closed-loop

point-to-point positioning with profile (trapezoidal, parabolic, or

S-curve), velocity, acceleration, and deceleration control as well as

multi-axis linear, circular, or helical interpolation. The electronic

gearing feature allows any axis to be slaved to another at a

programmable ratio. The electronic cam feature allows coordinated

motion profiles which are functions of ti me or position of another axis.

Sophisticated phase shift, auto-registration, and auto-correction

capabilities allow many complex motions and synchronizations to be

easily programmed. General-purpose discrete I/O, analog inputs,

analog outputs, et c. are provided by dire ct connection of Allen-Bradl ey

Flex I/O modules. Up to eight Fle x I/O modules–pro viding a total of

128 discrete I/O poi nts –may be connected directly to the IMC-S/23x.

Analog inputs and outputs can be substituted for discrete I/O blocks

for increased I/O flexibility.

Application programming of the IMC-S/23x for any application is

accomplished with GML, the exclusive Graphical Motion Control

Language from Allen-Bradley. Using GML, over 100 different

commands are available to completely customize operation of the

IMC-S/23x for your specific application. Complete application

programs are downloaded to the IMC-S/23x via a field-configurable

RS-232C or RS-422 port where they are store d in non-volati le memory

(write-protected battery-backed RAM).

A prompted, English-language machine setup procedure, complete

hookup diagnostics, an d improved Automatic Servo Setup routines for

self-tuning the se rvo paramet ers make setti ng up the IMC-S/23x q uick

and easy.

Publication 999-122 - January 1997

Page 18

2-2 Introduction

Features

A dedicated serial port–which can be field-configured for RS-232,

RS-422, or Allen-Bradley DH-485 communications–is prov ided for the

man-machine interface (MMI). Connection of the MMI device is via

an AT-compatible DB-9 connector (RS-232 or RS-422) or RJ-45

connector (DH-485), both locate d on the f ront pan el. If DH-485 is not

used, a multi-unit addressing scheme (Multidrop) allows up to eight

IMC-S/23x motion controll ers to share a single RS-422 communication

channel in sophisticated multi-axis systems. The address of each unit

is set by a recessed front panel rotary switch.

The Remote I/O option allows the IMC-S/23x to communicate directly

with an A-B PLC® via Remote I/O using both discrete and block

transfers. The AxisLink option allows axes on other IMC S Class

controllers or ALECs (AxisLink Encoder Converter modules) to be

used as master axes for electronic gearing and cams. This ability

provides real-time coordination for distributed, multi-axis systems in

electronic gearing, cam, lineshaft, and synchronization applications.

Powerful graphical software development system (GML) makes

•

application programming easy and fun.

State-of-the-art Intel i960 RISC microprocessor.

•

Fast application program execution (most commands executed in

•

less than 1 µs) ensures highest machine performance and

productivity.

Completely digital–no potentiometers or other adjustments

•

required; wi ll not drift with time temperature or humidity.

Multitasking operating sy stem allows simult aneous execution of up

•

to 10 tasks for efficient utilization.

Electronic gearing for synchronization of any axis to another at a

•

programmable ratio. Ratio may be specified as a floating-point

number of integer fraction (1/3, 3/10 etc.).

Electronic cam for co ordinated motion profil es on one or more axes.

•

Profiles may be position versus time or slave axis position versus

master axi s position.

Sophistic ated phase shift and advance/r etard capabilities for

•

electronic gears and cams allows complex motions to be easily

programmed.

Auto-registr ation and auto-corr ection make high-spe ed registratio n

•

applications easy.

Exclusive Imaginary Axi s provi des addit ional command-onl y axis

•

for precise generat ion of master motion in master-sl ave applications

or correction moves in registration and synchronization

applications.

Concurrent, independent, or synchronous motion on all axes.

•

Interpolated motion on up to three axes.

Publication 999-122 - January 1997

Page 19

Introduction 2-3

Wide position, speed, acceleration, and deceleration ranges for

•

precise control.

Separately programmable acceleration and deceleration rates for

•

maximum versatility.

Trapezoidal, parabolic, and S-curve velocity profiles.

•

Rotary mode with electronic unwind allows unlimited position

•

range for rotary axes.

Merge motion functi on allows seamless trans ition between all types

•

of motion.

Most motion parameter s (including master axis for electr onic gears

•

and cams) can be changed on-the-fly with no delays.

Powerful floa ting-poi nt math ca pabilitie s includi ng trans cendental

•

functions (sin, cos, log, etc.).

Sophisticated Nested Digital Servo Control Loop with automatic

•

servo setup for quick and easy servo tuning.

Isolation of all e xternal connections fr om the microproces sor logic

•

for reliable performance.

4 MHz maximum feedback count rate allo ws high s peed opera tion

•

without sacrificing resolution.

Encoder loss detection protects operators and machinery from

•

damage in the event of encoder feedback failure.

Isolated 16-bit DA Cs for smooth motion. Software offset correction

•

eliminates drift with analog servo drives.

Field-configurable servo outputs allow independent selection of

•

±10V or ±150 µΑ signal format for each axis.

Programmable position lock and posit ion error toler ances for serv o

•

fault protection.

Programmable directional software travel limits for enhanced

•

overtravel protection.

Vel ocity Feedforward to reduce following error.

•

Four optically isolated limit switch inputs for a home switch,

•

positive and negative overtravel switches, and a drive fault signal

for each axis.

Relay-contact drive enable output for each axis.

•

Optically isolated high-speed position registration input for each

•

axis for position synchronization and registration applications.

CPU Watchdog with front-panel LED indicator for fail-safe

•

protection.

Publication 999-122 - January 1997

Page 20

2-4 Introduction

AxisLink option allows real-time axis coordination between

•

controllers for distributed, multi-axis systems.

Non-volatile storage (write-locked battery-backed RAM) of

•

application program, setup parameter and default variable values.

Memory Lock keyswitch on front panel prevents accidental or

•

unauthorized changes to application program, default setup

parameters, and default variable values.

Model Numbering System

The IMC-S/23x is available as a two- or four-axis motion controller

with optional Remote I /O Adapter and AxisLin k. The complete model

number is specified as shown below:

IMC-S/

Platform

2 = Stand Alone

Packaging

3 = Compact Package

Number of Axes

2 =Two Axes

4 = Four Axes

2

3

-

Pre-Engineered Cable

Assemblies

Remote I/O Option

R = Remote I/O Adapter

AxisLink Option

L = AxisLink Multi-Axis Synchronization Link

Pre-engineered cable assemblie s are used for connec ting the Fl ex I/ O,

servo amplifiers, feedback devices, axis-specific (dedicated) I/O, and

the CPU watchdog. The table below shows the available cable

assemblies.

ATTENTION:

connections to the IMC-S/23x while the power is on!

!

Doing so risks damage to the IMC-S/23x, external

components, and your health!

Do not attempt to make any electrical

Publication 999-122 - January 1997

Page 21

IMC S/23x Pre-Engineered Cable Assemblies

Catalog Number Used to Connect. . . Length

(ft) (m)

4100-CCF1

4100-CCF3

4100-CCS15F

4100-CCAQB

4100-CCA15F

4100-CCW15F

4100-RCS3T

or

Flex I/O

Servo and Feedback

1391B-ES or 1391-DES

Dedicated Discrete I/O

CPU Watchdog

REC Interface

10.3

31

15 4.5

-15 4.5

15 4.5

31

Introduction 2-5

Number

Required

1 per S Class

1 per Axis

1 per Axis

1 per Axis

1 per S Class

1 per Axis

Mechanical Specifications

Front Panel Layout

(IMC-S/23x-RL model shown.)

Publication 999-122 - January 1997

Page 22

2-6 Introduction

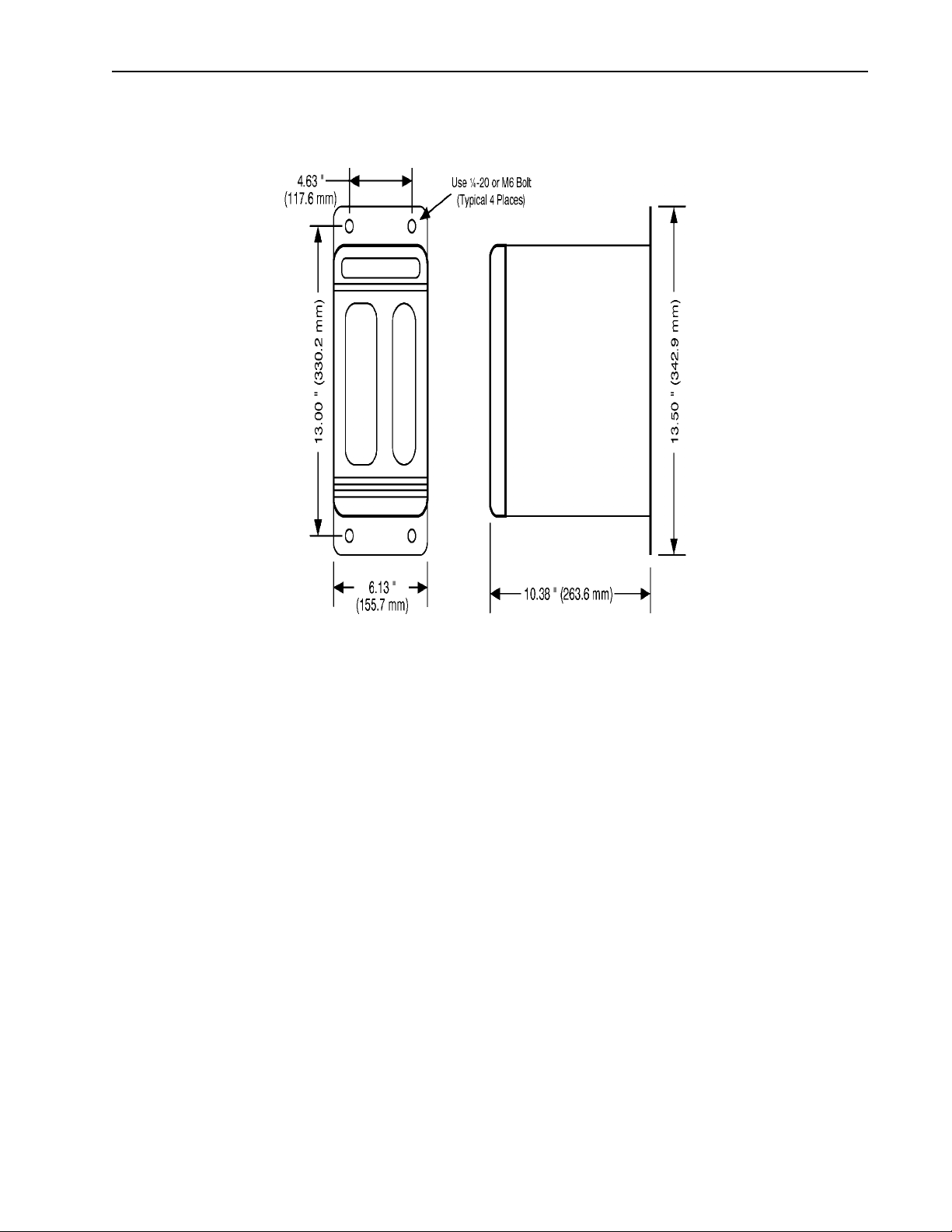

Mounting and Clearance Dimensions

General Specifications

Motion Control

Microprocessor

Number of

Controlled Axes

Application

Storage

Data Storage

Number of User

Variables

Number of Electronic

Cam Poi n ts

Intel 80960SB @ 16 MHz.

2 (Axis 0 and Axis 1) IMC-S/232...models.

4 (Axis 0, 1, 2, and 3) IMC-S/234...models.

Write-lockable batt ery-backed RAM (Ran dom-Access Memory) with 10

year (minimum) battery life for application program (32K) and setup

parameter values.

Write-lockable batt ery-backed RAM (Ran dom-Access Memory) with 10

year (minimum) battery life for cam table and default user variable values.

2,000 user-definable; values stored as 64-bit floating-point numbers.

26,000 total.

Publication 999-122 - January 1997

Page 23

Envir onmental Specifications

Storage

Temperature -40°C to 70°C (-40°F to 158°F).

Operating

Temperature 0°C to 50°C (32°F to 122°F).

Maximum

Humidity 95% non-condensing.

Electrical Specifications

AC Power Input 90 - 132 or 175 - 264 Volts AC,

AC Fuse 3A Dual Element Time Delay (Slow Blow) 1/4 x 11/4

I/O Power Input 18 - 36V DC,

I/O Fuse 3A Dual Element Time Delay (Slow Blow) 1/4 x 11/4

Introduction 2-7

47 - 63 Hz,

3 Amperes maximum.

3A maximum (24V nominal).

Encoder Input Specifications

Number of

Encoder Inputs

Type of

Encoder Input

Encoder

Interface IC AM26LS32 or equivalent.

Compatible

Encoder Types

Decode Modes 4X Quadrature, Step/Direction, Count Up/Count Down.

Maximum Encoder

Frequency

Input

Impedance 7 kΩ minimum (each input).

Encoder

Power

2 (Axis 0 and Axis 1) IMC-S/232...models.

4 (Axis 0, 1, 2, and 3) IMC-S/234...models.

Incremental AB quadrature; optically isolated, differential with marker

channel.

Differential, TTL-Level (5V DC) line driver outputs, with or without

marker; including the following Allen-Bradley devices:

845F-SJxZ14-xxYx...

845F-SJxZ24-xxYx...

845H-SJxx14xxYx...

845H-SJxx24xxYx...

845K-SAxZ14-xxY3

845K-SAxZ24-xxY3

845P-SHC14-xx3

845T-xx12Exx...

845T-xx13Exx...

845T-xx42Exx...

845T-xx43Exx...

4,000,000 counts per second (4 MHz). This is equivalent to a channel

frequency of 1 MHz in 4X quadrature decode mode.

5 or 12 Volts DC at 1 Ampere (tot al) a v a ilable f rom IMC-S/23x . Voltage

selection by internal sw itch.

Publication 999-122 - January 1997

Page 24

2-8 Introduction

Servo Output Specifications

Number of

Servo Drive Outputs

Type of Output Isolated analog voltage or current; individually field-configurable via

Output Range ±10 Volts DC or ±150 µA (minimum).

Resolution 16 bits, 305 µV or 4.58 µA per bit.

Output Impedance 220Ω resistive for voltage output; 56Ω maximum load impedance for

Output Offset ±80 µV maximum. Compensated to 0 volts via soft ware setup pr ocedure.

Dedicated Discrete I/O

Specifications

Number of

Dedicated Discrete

Inputs

Dedicated

Discrete Input

Functions

Input Type Optically isolated.

Operating

Voltage

Input ON

Current

Impedance

Input Response

Number of

Dedicated

Discrete Outputs

Dedicated Discrete

Output Function

Output Type Normally-open relay contacts (Drive Enable);

Operating

Voltage

Output

Current

Input

Time

2 (Axis 0 and Axis 1) IMC-S/232...models.

4 (Axis 0, 1, 2, and 3) IMC-S/234...models.

internal switch for each axis.

current output.

10 (5 each for Axis 0 and 1) IMC-S/232...models.

20 (5 each for Axis 0, 1, 2, and 3) IMC-S/234...models

Home Limit Switch,

Positive Overtravel Limit S witch,

Negative Overtravel Limit Switch,

Drive (Amplifier) Fault,

Position Registration.

24 Volts DC nominal; 28V DC maximum.

24 Volts DC nominal; 28V DC maximum or 5 Volts DC nominal;

10V DC maximum for position registration inputs.

12 µΑ per input (nominal);

2.5 µΑ for position registration inputs.

2 kΩ (resistive) per input;

8.8 kΩ (resistive) for 24V position registration inputs.

5 µs maximum;

1 µs maximum for pos ition registration i nputs.

4 (2 each for Axis 0 and 1)IMC-S/232...models.

8 (2 each for Axis 0, 1, 2, and 3)IMC-S/234...models.

Drive (Amplifier) Enable.

Absolute Position Strobe.

Optically isolated, floating, solid-state relay (Position Strobe).

0.010 - 40 Volts DC; 24V DC nominal for drive enable outputs,

5.10± 0.10 Volts DC for position strobe outputs.

1 Ampere per output maximum for drive enable outputs;

10 µΑ per output maximum for position strobe outputs.

Publication 999-122 - January 1997

Page 25

Serial I/O Specifications

Number of

Serial Channels 2 (Serial Port A and Serial Port B).

Channel Type Optically isolated RS-232C or RS-422; each channel individually

Information Code ASCII (American Standard Code for Info rmation Interchange).

Baud Rate User-selectable up to 128k Baud (RS-422).

Number of

Start Bits 1.

Number of

Stop Bits 1.

Word Length 8 bits total; 7 data bits plus 1 parity bit.

Parity Space parity transmitte d;

Duplex Full or half (user-selectable).

Data

Synchronization XON (Control-Q)/XOFF (Control-S).

Front-Panel

Connectors IBM-PC /AT compatible 9-pin D-type female.

RS-422

Termination User-selectable 220Ω resistor via internal switch.

Introduction 2-9

configurable via internal s witch.

User-selectable up to 115.2k Baud (RS-232C).

Receive parity ignored (may be Mark, Space, Even, or Odd).

DH-485 Specifications

Number of

DH-485 Channels 1; replaces Serial port B when used.

Channel Type Optically isolated half-duplex RS-485.

Baud Rate 9,600 or 19.2k Baud (user-selectable).

Front-Panel

Connectors Two RJ-45 jacks (+24V is not provided).

RS-485

Termination User-selectable 220Ω resistor via internal switch.

Node Address User-selectable between 0 and 31 inclusive.

Node Type Token-passing master.

Accessible Data

Files

1 Binary file (B3) for up to 16,384 bits

1 Integer file (N7) for up to 1,024 16-bit values

1 Floating-point file (F8) for up to 512 32-bit values

1 ASCII string file (A) for up to 2, 048 characters

9 user-configurable files; each can be individually configured as any of

the above types or as a BCD file for floating point simulation (required

for certain A-B MMI devices).

Publication 999-122 - January 1997

Page 26

2-10 Introduction

Flex I/O Compatibility

Specifications

Maximum Number of

Flex I/O Modules 8.

Compatible

Modules

S Class Interface Direct-no 1794-ASB or other adapter required.

Servo Performance

Specifications

Servo Loop

Sample and Update

Maximum Feedback

Frequency 4 MHz (4,000,000 feedback counts per second).

Absolute

Position Range

Absolute Position

Resolution

Speed Range 0.00001 feedback counts per servo update to 4,000,000 feedbac k counts

Speed Resolution 15 position unit digits or

Acceleration/

Deceleration Range

Acceleration/Deceleration

Resolution

Electronic Gearing

Gear Ratio Range 0.00001:1 to 9.99999:1 (slave counts : master counts).

Electronic Gearing

Gear Ratio Resolution 8 position unit digits or 32 feedback count bits.

Servo Gain Resolution 32 bit floating point.

Servo Output Limit

Servo Output Limit

Resolution 305 µ (voltage output); 4.58µΑ (current output).

1794-IB16 16 24V DC Discrete Inputs

1794-IA8 8 115V AC Discrete Inputs

1794-IE8 8 Current/Voltage Analog Inputs

1794-OB16 16 24V DC Discrete Outputs

1794-OA8 8 115V AC Discrete Outputs

1794-OE4 4 Current/Voltage Analog Outputs

1794-IE4XOE2 4 Current/Voltage Analog Inputs

2 Current/Voltage Analog Outputs

Rate 250 Hz to 2 kHz for each of 2 or 4 axes.

± 1,000,000,000 feedback counts for Linear AxisAxi s:Lin earli near ax es ;

R for rotary a xes.

15 position unit digits or

32 feedback count bits, whichever is less.

per second.

15 feedback count bits, whichever is less.

0.00001 feedback counts per servo update2 to 4,000,000,000 feedback

counts per second2.

15 position unit digits or

15 feedback count bits, whichever is less.

Range 0 to 100%.

Publication 999-122 - January 1997

Page 27

Servo Gain Units

IMC-S/23x Servo Gain Units

Gain Description Units

P

I

V

F

Proportional Gain

Integral Gain

Velocity Gain

Feedforward Gain

Deadband Compensation

Offset Compensation

Introduction 2-11

Counts per Millisecond

Count of Error

Counts per Millisec ond2

Count of Error

Millivol ts

Count per Mi llisecond

Counts per Millisecond

Count per Mi llisecond

Volts

Volts

Remote I/O Adapter

Specifications

Baud Rate

Rack Address

Rack Width

I/O Group Address

IMC-S/23x-R and IMC-S/23x-RL models only.

57.6K, 115.2K or 230.4K (User-selectable).

User-selectable between 0 and 31 decimal.

User-selectab le in quarter-rack increment s (1/4, 1/2, 3/4, Full).

User selectable as shown below:

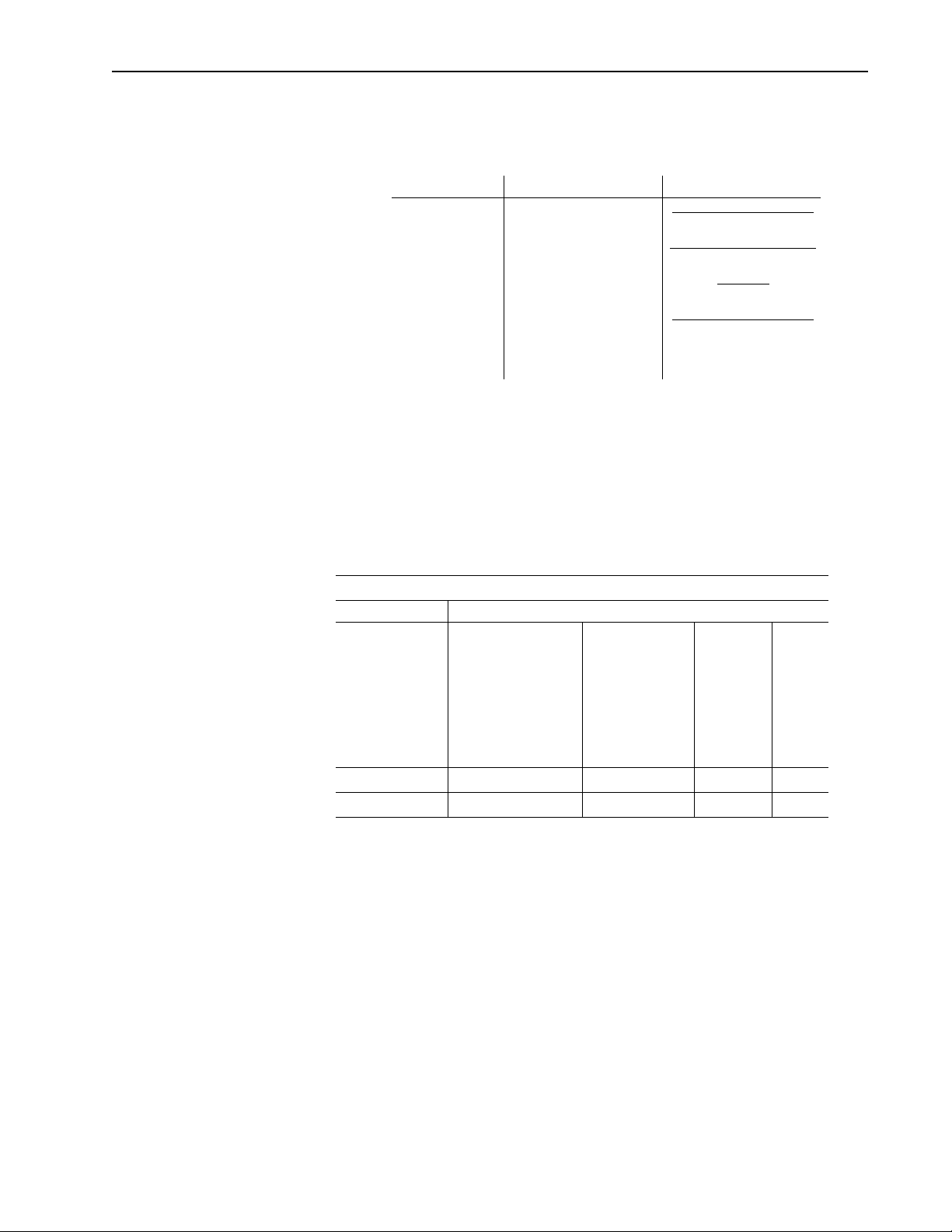

IMC-S/23x Remote I/O Adapter Addressing

Type of Transfer I/O Group

Block

Discrete

Discrete

Discrete

Discrete

Discrete

Discrete

Discrete

Starting I/O Group 0246 024 02 0

Rack Width

0246

1357

1/4 1/2 3/4 Full

024

135

246

357

02

13

24

35

46

57

0

1

2

3

4

5

6

7

Publication 999-122 - January 1997

Page 28

2-12 Introduction

Number of

Discrete I/O Bits

12 dedicated inputs,

12 dedicated outputs,

User-defined as shown below:

IMC-S/23x Remote I/O Adapter

Number of User-Defined Discrete I/O Bits

Rack Width Inputs Outputs

1/4

1/2

3/4

Full

Maximum Block

Transf er Length 64 words (128 bytes).

Block Transfer

Data Types

User Variable values,

Axis Data Parameter value,

Axis Data Bit state,

Master Cam Posi tion Point values,

Master Cam Time Point values,

Slave Cam Position Point values,

Axis or System Variable value.

Block Transfer

Data Formats

32-bit (double-word) 2s complement integer,

16-bit (single-word) 2s complement integer,

32-bit (8-digit) signed BCD,

32-bit IEEE floating-point,

Word-swapped 32-bit (double-word) 2s complement integer,

Word-swapped 32-bit (8-digit) signed BCD,

Word-swapped 32-bit IEEE floating-point.

36

68

100

4

4

36

68

100

Publication 999-122 - January 1997

Page 29

Introduction 2-13

AxisLink Specifications

Baud Rate Standard and extended

Cable Type Standard and extended

Cable Length Standard and extended

Number of

Motion Controll ers

Addressing Standard and extended

Number of Virtual

Master Axes

Type of Virtual

Master Axes

Slave Axes Standard and extended

IMC-S/23x-L and IMC-S/23x-RL models only.

1 megabit per second.

node configurations

Extended length

500 kilobit per second.

configuration

Allen-Bradley 1770-CD RIO cable (Belden 9463 or

node configurations

Extended length

equivalent).

Belden 9182, Carol C8014 or equivalent.

configuration

25 meters (82 feet) maximum total. Minimum of 1

node configurations

Extended length

configuration

Standard and extended

meter (3 feet) between controllers.

125 meters (410 feet) maximum total. Minimum of 1

meter (3 feet) between controllers.

8 maximum for a total of 32 possible axes.

length configurations

Extended node

16 maximum for a total of 64 possible axes.

configuration

User-selectable address via rotary selector switch on

length configurations

Extended node

front panel.

User-selectable address via GML.

configuration

Standard configuration 4 maximum total; 1 per motion controller maximum.

Any axis on any motion controller can be a virtual

master axis to any ot her motion controller . Each motion

controller can de fine a total of tw o separate axes on an y

other motion control lers as virtual master axes, b ut only

one can be active at any time. A tot al of f our di fferent

axes can be active as virtual master axes at any time.

Extended length and

extended node

configurations

2 maximum total; 1 per motion controller maximum.

Any axis on any motion controller can be a virtual

master axis to any ot her motion controller . Each motion

controller can de fine a total of tw o separate axes on an y

other motion control lers as virtual master axes, b ut only

one can be active at any time. A total of two different

axes can be active as virtual master axes at any time.

All configurations 2: Command and Actual. Each virtual mast er axis may

be defined to report its command or actual position.

31 maximum total per virtual master axis (3 local + 4

length configurations

Extended node

configuration

x 7 other motion controllers = 31).

63 maximum total per virtual master axis (3 local + 4

x 15 other motion controllers = 63).

Publication 999-122 - January 1997

Page 30

2-14 Introduction

Number of

Discrete I/O

Discrete I/O

Response

All configurations 112 inputs maximum total and 16 user-definable

outputs per motion controller. Any motion controller

can read the 16 discrete outputs of any other motion

controller, giving a maximum total of 7 x 16 = 112

discrete inputs per motion controller. For extended

node configuration, discrete I/O can still only be

obtained from a maximum of 7 other controllers (112

inputs maximum total), n ot from all 15 other controllers

available in a 16 node maximum extended node

configuration.

All configurations ≤1 millisecond.

Publication 999-122 - January 1997

Page 31

Technical Overview

Chapter

3

Digital Control Loop

Each axis of the IMC-S/23x utilizes a powerful Nested Digital Servo

Control Loop to provide servo positioning control and compensation

of a servo actua tor. The servo actuator can be a DC motor, a brushless

DC motor, an AC motor (with the appropriate drive electronics), or a

hydraulic cylinder or motor.

The Nested Digital Serv o Control Lo op utilizes s tate-of-the- art digital

hardware and sof tware to perfo rm the func tions nec essary to e stablis h

a closed l oop servo system. The only external elements neede d to

complete the servo loop are:

Actuator (Brushless DC Motor, Hydraulic Cylinder, etc.)

•

Servo Amplifier for Actuator

•

Digital Incremental Encoder (Quadrature type)

•

The digital approach t o motion cont rol has numerous adv antages o v er

conventional analog servo control techniques. Digital feedback

eliminate s the need for potentiometers in the control loop with their

associated adjustmen t labor and dr ift. Furthe rmore, the Nested Di gital

Servo Loop is microprocessor-based. Microprocessor design reduces

the system parts count, increases system reliability, and greatly

increases the flexibility of the control.

The Nested Digital Servo Loop synthesizes a velocity (rate) loop as

well as the required position loop in software using only the position

information provided by the encoder (or other feedback device). No

analog tachometer is required to provide complete stabilization and

positioning control of the motor and load. In addition, velocity

feedforward is provided to reduce the intrinsic following error of the

position loop when the motor is moving.

Publication 999-122 - Janua ry 1997

Page 32

3-2 Technical Overview

A functional block diagram of the Nested Digital Servo Loop is shown

below. The following sections discuss, in detail, each block in this

diagram.

Encoders

The IMC-S/23x interfaces to rotary or linear quadrature-type

incremental encoders to provide both position and velocity feedback.

The most common type of such encoders are optical; they utilize a light

source and an alternately clear and opaque disc or scale to generate

their output.

When operating at a f ixed speed, quadrat ure-type incremental enco ders

generate two squar e wave outputs , usually referred to as Channel A and

Channel B, which are approx imately 90° out of phase with one a nother.

Proper phasing of these two channels can be checked by driving the

encoder at a fixed speed and displaying the two encoder outputs on a

dual channel oscilloscope.

Encoders are available with a variety of different output driver

configurations. The IMC-S/23x interfaces directly to differential line

driver encoders providing TTL (5V) level signals. In addition, the

encoder inputs ar e optically isolated and po wered from a separate po wer

supply contained withi n the IMC-S/23x. Encoder loss circuitry dete cts

when any of the encoder connections have broken.

Publication 999-122 - Janua ry 1997

Page 33

Technical Overview 3-3

Often a third output channel is available from the encoder. This

so-called "marker" output is also known as Channel Z, 0, or C. The

marker output from an encoder is a pulse that occurs at one specific

point on the encoder disc (rotary encoders) or slide (linear encoders).

Therefore, the marker may be used to establish a precise absolute

position reference. Note that for rotary encoders, the marker provides

a position referenc e within one revolution of the encoder. F or multi-turn

applications, othe r means must be us ed in conjunct ion with the mark er

pulse to determine the absolute position. The IMC-S/23x can interface

to encoders with marker pulse outputs of either active-high or

active-low polarity.

Encoder Counter

The encoder counter circuitry is identical for all axes and consists of

optically-isolated AM26LS32 input buffers, programmable decode

logic, and 16-bit encoder counters contained within the CX2216.

Once buffered and isolated, the two TTL-level encoder signals

(Channel A and B) are c onnecte d to the CX22 16 which de codes them

using 4X quadrat ure logic (4 cou nts per e ncoder lin e). Afte r decoding,

the count signals are sent to the encod er counter in the CX2216 , which

keeps a record of the number of counts and the direction of encoder

motion. The IMC-S/23x software extends the encoder counters to 32

bits giving a total position range of ±1,000,000,000 encoder counts.

A quadrature type enc oder generates four counts for every line on the

encoder disc or s lide. The sequenc e in whi ch th e co unts a re gen era ted

is determined by the direction that the encoder is moving, and the

encoder counter increments or decrements accordingly.

The maximum encoder rate for any digital control is determined by

many factors, i ncluding t he sample r ate of the c ontrol lo op, the siz e of

the encoder counters , and pulse ra te limitati ons of the digit al circuit ry .

The maximum encoder count rate, or

encoder bandwidth

, for the

IMC-S/23x , is 4.0 Megahert z.

Every servo sample period, the microprocessor reads the encoder

counter for each axis and computes a count increment by subtracting

the previ ous counter value from the present counter value . Thi s c ount

increment repres ents the distanc e the axis has tr aveled i n the precedin g

millisecond. This v alue is then us ed to update the 32- bit actual position.

Publication 999-122 - Janua ry 1997

Page 34

3-4 Technical Overview

Software Feedback

Calculations

Every servo sample period, the IMC-S/23x microprocessor also does

a complete position feedback calculation for each axis by first

computing the dif ference between the actual positi on and the command

position. This quantity is called the Position Error. The intent of every

closed loop position se rvo syst em is to driv e this position error to zero.

T o accompl ish this, the position erro r is mult iplied by a pro grammable

P (Proportional) Gain term and used to generate a velocity command.

In addition, when the axis is not moving, po sition error i s accumulated

(integrated) and multiplied by the I (Integral) Gain term and added into

the velocity command. This allows the IMC-S/23x to compensate for

static disturbances that would otherwise keep the position error from

becoming zero. Such static disturbances include static friction

(so-called Sticktion) and gravity effects on vertical axes.

Integral Gain is also effective in reducing the tracking erro r between

the master and slave axis when the electronic gearing feature is used.

The integral term is deactivated, however, when performing

commande d motion (moves an d jogs) to improve servo stability and

decrease overshoot.

To create a stable position servo loop without using an analog

tachometer, damping is provided by synthesizing a tachometer in

software. This is accomplished by calculating the rate of change of

encoder position to generate the actual velocity. The actual velocity is

compared to (subtracted from) the command velocity to generate the

velocity error. This velocity error is then multiplied by the

programmable V (Velocity) Gain and used to dri ve the mot or to reduce

the velocity error (an d thus t he positi on error al so) to zer o. W ith serv o

drive s incorporatin g a true tachomet er loop, the so ftware v elocity loop

is disabled.

After being mult iplied by the V gai n, the veloci ty error is range l imited

and then se nt out to a 16-bit DAC (Digital-to-Anal og Converter to

generate the ±10 volt or ±150 mA signal for use by the drives.

In use, the servo output ranges between ±10 volts or ±150 mA,

depending on the settin g of the drive out put type switch. The maximum

output can also be cla mped to less than the abo ve full scale v alues. This

servo output limit is fully programmable.

In addition, deadband compensation is provided to compensate for

friction effects when using current-loop servo amplifiers. Deadband

compensation adds a programmable valu e to the magnitude of t he servo

output signal (i.e. when the velocity error is positive, the DB

compensation value is added, and when the velocity error is negative,

the DB compensation value i s subtracted) .

Publication 999-122 - Janua ry 1997

Page 35

Technical Overview 3-5

Finally, drive offset compensation is provided to allow compensating

for the inevi table offset and drift in anal og servo amplifiers. Dri ve offset

compensation adds a programmable valu e to the magnitude of t he servo

output signal.

Each of the gain terms me ntioned abo v e has a u nique influe nce on th e

closed loop dynamics of t he system. By adjust ing the P, I, and V gains,

it is easy to tailor the syst em dynamics to meet specific needs. The three

programmable control ga ins influence t he closed loop dynamics i n the

following wa y:

Servo Amplifiers and

Motors

Proportional Gain

Integral Gain

Vel ocity Gain

⇒

⇒

⇒

Elastic Stiffnes s

Static Disturbance Compensation

Damping

Each axis of the IM C-S/23x can inter face to a sta ndard serv o amplif ier

operating in current (torque) or velocity (tach) mode which accepts a

±10V DC command. Servo ampli fiers are availabl e from Allen-Bradley

as well as other manufactur ers to drive DC, brushless DC or AC motors

in a wide range of powers. The IMC-S/23x can also interface to

hydraulic serv o and proportional v alves which acce pt ±150 mA signals.

Publication 999-122 - Janua ry 1997

Page 36

3-6 Technical Overview

High Level Motion

Functions

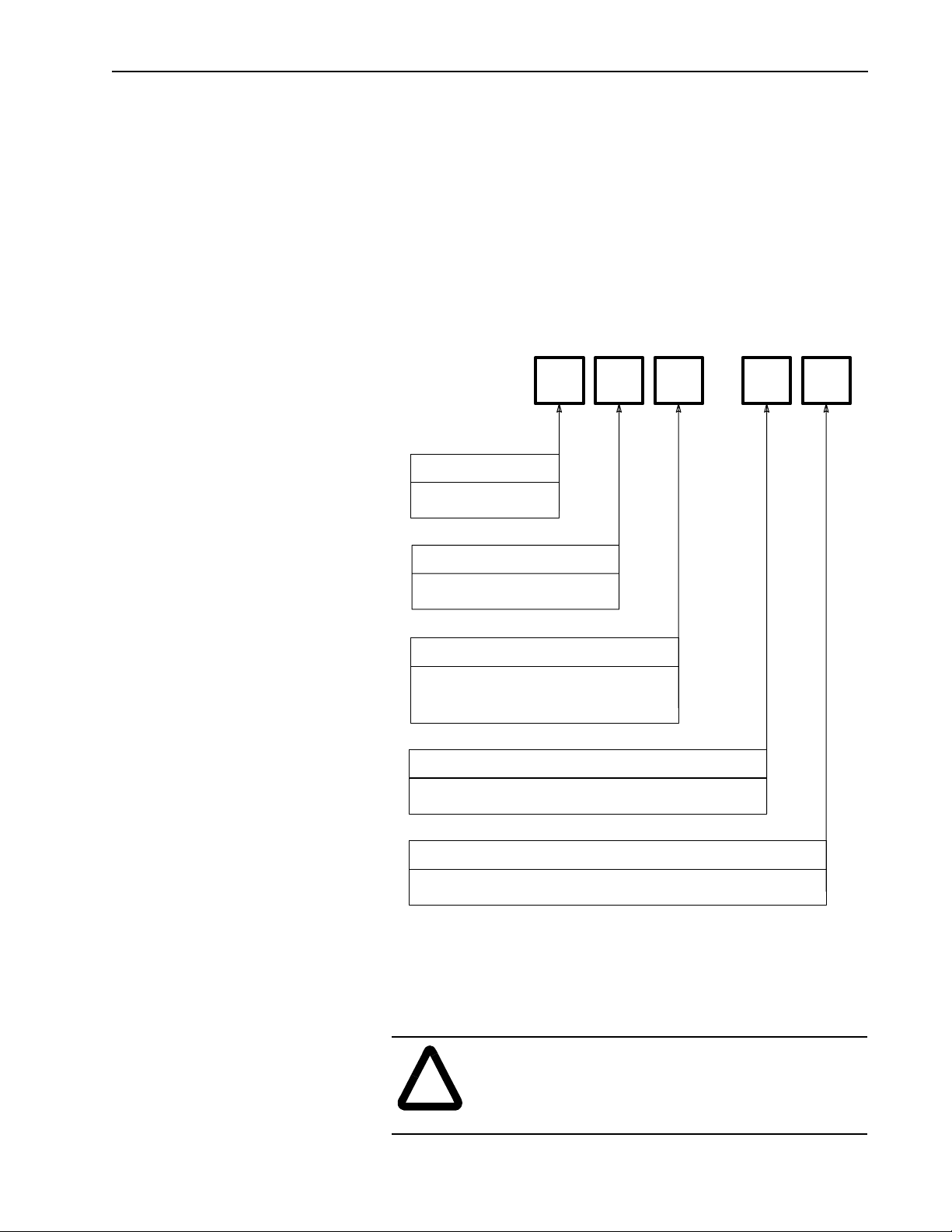

Destination

Position

Because servo action forces the actual position to track the command

position, sophisticated indexing, jogging, and electronic gearing

functions are easily implemented through software control of the

command position. These high le vel motion functions are sho wn below

and explained in the following paragraphs.

Trapezoidal,

Backlash

Compensation

Parabolic,

S-Curve,

Indexed

Ramp Up/Ramp Down

Jogger

Time-Lock Cam

Master Axis

Command

Position

Master Axis

Actual Position

Time

Position-Lock Cam

Master Position

Electronic Gearing

M

Interpolator 0

Interpolator 1

S

Command

Position

Σ

Publication 999-122 - Janua ry 1997

Page 37

Technical Overview 3-7

Indexing and Jogging

The indexer moves the axis using either a trapezoidal, parabolic, or

S-Curve (controlled jerk) velocity profile. Axis velocity, acceleration,

and deceleration are completely programmable. The trapezoida l profile

is the most common type of mov e and resul ts in a smooth acc eleration

to the desired sp eed and a smooth deceleration to th e desired destination

position. Parabolic and S-curve profiles are provided for use where

minimum stress on the mechanics is more important than minimum

index time.

The jogger produces constant speed motion of the axis in either

direction. The v elocity and the acceleration ra te are programmable. The

indexer an d jogger also pro vide th e ability to cha nge speeds and inde x

positions while the axis is mo v ing . The jogger also allows changes in

the acceleration or deceleration ramp while jogging. Furthermore,

electronic gearing may be combined with ind ex and jog motion to create

complex motion profiles and synchronizations.

Backlash Compensation

Another high level motion function is Backlash Compensation. This

technique–called Unidirectional Approach–overcomes mechanical

backlash by alw ays approaching the dest ination position from the same

direction. When ap proaching the destinat ion position from the opp osite

direction, the axis moves past the destination position by a

programmable Backlash Offset, reverses, and then moves back to the

destination positi on. Since the axi s al ways approa ches th e desti nati on

position from the same direction, the mechanical backlash is always

taken up in the same direction ensuring accurate positioning.

Electronic Cam

The electronic cam f eature pr ovide s the IMC-S/ 23x with t he abilit y to

execute coordinated motion profiles. This is accomplished by

programming a table of position values which describe the desired

profile, and then e xec uting the tab le as required. Ele ctronic ca ms may

be defined in terms of axis pos ition(s) v ersus time (time-lo ck cams) or

position of the slave axis versus position of the master axis

(position-lock cams).

Electronic Gearing

Electronic gearing allo ws an y ax is to be progr ammed to t rack another

axis at a specif ied ratio. By con vention, the axis that is tracking i s called

the

the master axis is equi v alent to the inpu t shaft, a nd the s lav e axis t o the

output shaft in a mechanical transmission.

, while the axis that is bein g tracked is called the

slave

Publication 999-122 - Janua ry 1997

master

. Thus,

Page 38

3-8 Technical Overview

Electronic gearing is accomplished by first reading the master axis’

actual position an d computing the distance increment fro m the previous

reading. This increment is then multiplied by a programmable gear ratio

and added to the slave axis’ command position. In this way the slave

axis is forced to track the master axis according to the specified gear

ratio. The slave axis may be programmed to move in the same or the

opposite direction from the master axis.

Electronic gearing ratios may be specified as a number between

0.00001:1 and 9.99999:1 . Alt er nat el y, the gear ratio may be specified

as a pair of intege r values–a numera tor and denominator– r epresenting

the exact ratio of slave axis feedback counts to master axis feedback

counts. The ability to s pecify numerator/denominator gear rati os makes

it possible to perform electronic gearing using an irrational gear ratio

such as 1/3 with no accumulated error.

By combining the jog and electronic gearing capabilities of the

IMC-S/23x, the slav e axis may be smoothly accelerated and dec elerated

into and out of electronic gearing motion. This merged motion

capability is equivalent to a software clutch.

Velocity Feedforward

Interpolation

T wo independent interpolators for all axes allow any two or three axes

to be moved as a group along a linear , circular , or helical path. Motions

from the two interpolators may be combined with each other or with

other types of motio n. Motion segments may be blended to one another

to accomplish continuous path motion as long as they are tangent at

their intersection.

The IMC-S/23x is capable of pro viding velocity fe edforward to reduce

following error. Following error is the servo position error that is

present when the axis is moving at a commanded speed. Without

velocity fe edforward, a fo llowing err or necessary to pr oduce suff icient

output to drive the motor at the comman ded speed will always exist.

Many applicatio ns require that the following error be near zero over

the entire speed range of the motor . Velocity feedfor ward may be used

to satisfy this requirement.

Velocity feedforward is provided by pre-computing the command

velocity as the rate of change with respect to time of the command

position. The command velocity is then scaled by the F Gain

(Feedforward Gai n) and added to the v elocity command. By adjusti ng

the F Gain it is poss ib le to produce, from the feedforward term alone,

the required ve locity command to d riv e the motor at the de sired speed.

Thus, only a little position error is needed to " fine tune" the motor spe ed

and position.

Publication 999-122 - Janua ry 1997

Page 39

Technical Overview 3-9

Velocity feedforward is v ery usef ul in el ectroni c gearing a pplicat ions,

since no position error between the master and slave axes exists with

mechanical gears. Using velocity feedforward also allows the position

loop integrator (I Gain) to respond more quickly to changes in speed.

CPU Watchdog

Software Overtravel Limits

Serial Communication

The IMC-S/23x pro vides a CPU Watchdog that monitors the he alth of

the motion control microprocessor. In the event of a processor

malfunction or other f ault, the CPU watchdog is im mediately disabled.

T o reset the Watchdog, the IMC-S/23x must be reset, either by cy cling

power, or by pressing the Reset button on the front panel.

An LED labeled "System OK" is provided on the IMC-S/23x front

panel to visually monitor the state of the CPU watchdog. This green

LED is lit under normal operation, and goe s out when the watchdog is

deactivated. A relay driven by the CPU watchdog provides normally

open and normally closed contacts on the Watchdog connector for

wiring into the machine’s E-Stop string or other fail-safe circuit.

The IMC-S/23x can be configured to range check the command

position of each axi s to ensure that the axis is oper ating within its limits.

These software travel limit values are fully programmable. When an

overtravel condition occurs, the IMC-S/23x either disables the

feedback loop and disables the amplifier, or decelerates the axis to a

stop. In either case, further motion in the offending direction is

inhibited.

Serial communicat ion with the IMC-S/23x is v ia either an RS-232C or

RS-422 serial link to one of two ports. If configured for RS-232C,

operation up to 19.2K baud is possible, while ports configured for

RS-422 can operate at up to 128K baud. A PC/AT-compatible 9-pin

D-type connector is pr ovided for each serial po rt on the fron t panel. In

general, the GML software development system for application

programming is connected to serial port A while a serial operator

interface device or runtime display is connected to serial port B.

The IMC-S/23x can be configured to operate in Multidrop Mode

allowing up to eight con trols to share a single RS-422 communicati ons

link. This is ac complished by using two special non- echoed commands

to activate individual units to respond to commands issued by the

operator interf ace device or host computer . Each IMC-S/23x is assigned

its own uniq ue address via a recesse d front-panel rotary sel ector switch.

Publication 999-122 - Janua ry 1997

Page 40

3-10 Technical Overview

DH-485 Communication

Axis-Specific Discrete I/O

The IMC-S/23x communicates with other devices over DH-485 by

reading and writing data i nto and out of data file s. Data from local fil es

(in the motion controller) is transferred to and from remote files (in

other devices ). In the motion contr oller , up to 13 dif ferent local f iles of

five different types can be used. Each type of file contains a different

number of elements and is equivalent to a different SLC file type as

shown belo w.

IMC S Class DH-485 Local File Types

S Class

File Type

Binary

Integer

Floating

ASCII

BCD

Elements Element

W ords/Bits

16-bit Values

Floating Point Values

Characte rs

BDC Values

Numbers

0 - 1023

0 - 1023

0 - 511

0 - 2047

0 - 1023

Equivalent to

SLC File T y pe

B

N

F

A

D

Each axis of the IMC-S/23x has associated with it four

optically-isolated inputs which provide a direct interface for a home

switch, overtravel (positive and negative) switches, and a drive fault

signal (usually an output from the amplifier). In addition, a relaycontact drive enable output is provided for each axis to enable and

disable the amplifier under program control. The four discrete inputs

are completely de-bounced and can be connected directly to limit

switches which operate on 24V DC. Inputs can be from mechanical

limit switches, proximity switches, or PLC outputs.

Each axis of the IMC- S/23x can be individuall y programmed to operate

with or without t hese discre te inputs e nabled. If enabled, each discr ete

input can be individually programmed to operate with normally open

(NO) or normally closed (NC) limit switch contacts.

Home Limit Switch Input

Home limit switches are used in conjunction with two of the four

programmable homing sequences. When a homing sequence is

enabled, the IMC-S/23x executes it under program control. See the

Setup section of this manual fo r a complete de scription of the avai lable

homing sequences.

Overtravel Limit Switch Inputs

Overtravel limit switches can be used to enforce the mechanical safe

travel limits during machine operation. Assuming that the overtravel

function is enabled, the IMC-S/23x may be programmed to either

provide a status, disable the feedback loop, and deactivate the drive

enable output of the affected axis, or stop motion and decelerate the

axis to a stop when an overtravel limit switch is tripped.

Publication 999-122 - Janua ry 1997

Page 41

Technical Overview 3-11

Drive Fault Output

The driv e fault inputs may be connected to the fault outputs (if provided )

on the amplifiers for each axis. This al lows the IMC-S/23x to re act to

a fault in the amplifiers themselves . Lik e t he othe r disc re te inp uts, th e

drive fault input may be enabled and disabled from the application

program, and may be configured to operate with active-high or

active-low drive fault outputs. When a drive fault input is activated,

assuming the function is enabled, the IMC-S/23x stops all motion on

the particular a xis and de acti v ates t he approp riate dri v e enabl e output .

Drive Enable Output

The driv e enable outp ut for each axis al lows t he IMC-S/23x to di sable

the axis amplif iers in the e vent of a motion f ault. Since it uses a fl oating

normally-open rel ay contact, the dri ve enable outp ut can be connected

to amplifier s ha ving ei ther ac tive-high or acti v e -lo w ena ble o r disab le

inputs.

Status LEDs

Position Registration Inputs

Special, high-speed, optically-isolated inputs on the IMC-S/23x (one

per axis) provi de a direct interface for position registration s ensors. The

position registration inputs are unfiltered to minimize propagation

delay for speed-critical position registration applications and can be

directly connected to sensors (or enco der markers) oper ating on 5V or

24V DC.

When a position registration input is activated, assuming the position

registration feature is enabled, the current actual position of the axis is

immediately latched in hardware into a special registration latch. The

latched registration position is then available within the application

program for calculations.

Three general purp ose status LEDs are provided on the front panel of

the IMC-S/23x. Labeled St atus 0, 1, 2, thes e LEDs are used to indicate

the results of the power-up diagnostics performed whenever power is

applied to the IMC-S/23x. If the IMC-S/23x passes its power-up

diagnostics, all th ree status LEDs are turn ed off and the CPU w atchdog

LED (System OK) is turned on. At this point, the three status LEDs

may be used by the application program for any desired purpose.

If all three status LEDs are not off after power -up, the IMC-S/23x d id

not pass its power-up diagnostics, and the CPU watchdog is not

activ ated. In this case, the code sho wn on the three status LEDs indicate s

the specific tes t wh ic h fa il ed.

Publication 999-122 - Janua ry 1997

Page 42

3-12 Technical Overview

General

Purpose

Discrete I/O

The IMC-S/23x provide s a direct connection to Allen-Bradley Flex I/ O