Page 1

Installation Instructions

ControlNet Modular Repeater

Medium Distance Fiber Module

Cat. Nos. 9904-RPFM

Use this document as a guide when you install a ControlNet™ repeater fiber module for

medium distances. This document contains:

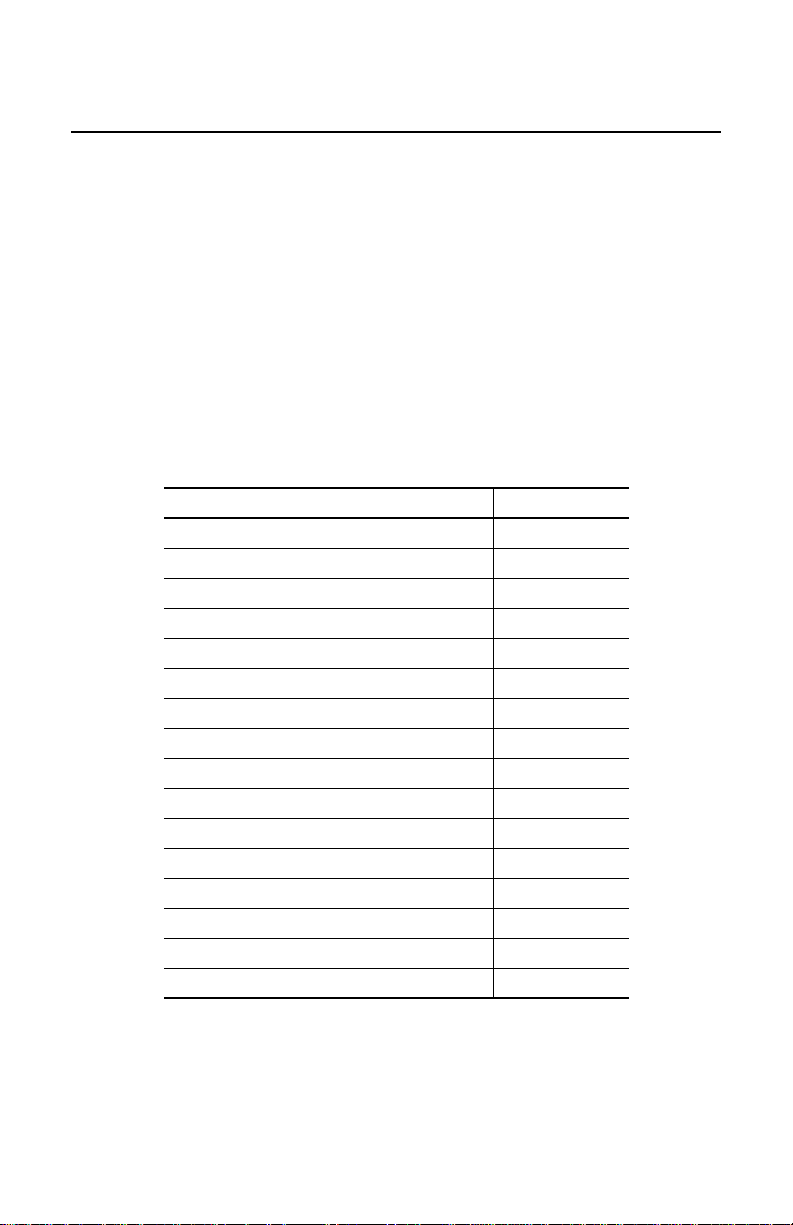

Topic: Page:

Important User Information 2

EMC Directive 3

Low Voltage Directive 3

Fiber Optic Safety Statements 3

About the Fiber Module 4

Mount the Fiber Module 5

Remove the Protective Caps 8

Choose Fiber Cable Types 9

Estimate Cable Lengths 9

Specifications for 9904-RPFM Fiber Optic Cable 10

Connect the Fiber Cable 11

Example Topology 12

Status Indicators 13

Mounting Dimensions 14

Specifications 15

Hazardous Location Approval 16

Publication 9904-IN011A-EN-P - October 2000

Page 2

2 ControlNet Modular Repeater Medium Distance Fiber Module

ATTENTION

!

Important User Information

Because of the variety of uses for the products described in this publication, those

responsible for the application and use of this control equipment must satisfy

themselves that all necessary steps have been taken to assure that each application

and use meets all performance and safety requirements, including and applicable

laws, regulations codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide

are intended solely for purposes of example. Since there are many variables and

requirements associated with any particular installation we do not assume

responsibility or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

NEMA Standards Publication No. ICS 1.1-1987, Safety Guidelines for the Application,

Installation, and Maintenance of Solid State Control, describes some important

differences between solid-state equipment and electromechanical devices that

should be taken into consideration when applying products such as those

described in this publication.

Throughout this document we use notes to make you aware of safety

considerations:

Identifies information about practices or

circumstances that can lead to personal

injury or death, property damage or

economic loss.

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Publication 9904-IN011A-EN-P - October 2000

Identifies information that is critical for successful application

and understanding of the product.

Page 3

ControlNet Modular Repeater Medium Distance Fiber Module 3

ATTENTION

!

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the European

Union and EEA regions. It has been designed and tested to meet the following

directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part,

documented in a technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial

Environment

• EN 5001082-2 EMC — Generic Immunity Standard, Part 2 — Industrial

Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers, Part 2 Equipment Requirements and Tests. This equipment is classified as open

equipment and must be mounted in an enclosure during operation to provide

safety protection.

Fiber Optic Safety Statements

Do not look directly into the fiber ports. Light levels will cause

damage to your eyesight.

Publication 9904-IN011A-EN-P - October 2000

Page 4

4 ControlNet Modular Repeater Medium Distance Fiber Module

About the Fiber Module

Use this module when a medium-distance (distances of 3000m/ 9843ft) fiber link is

required between two ControlNet products. This fiber link provides ground

isolation between nodes and is less susceptible to noisy environments than

traditional copper media.

IMPORTANT

The distance that can be supported is dependent on the quality

of the fiber, number of splices, and connectors. The total loss of

the fiber link must be less than 13.3 dB.

The module provides:

• two fiber channels

• activity LED indicators for each fiber channel

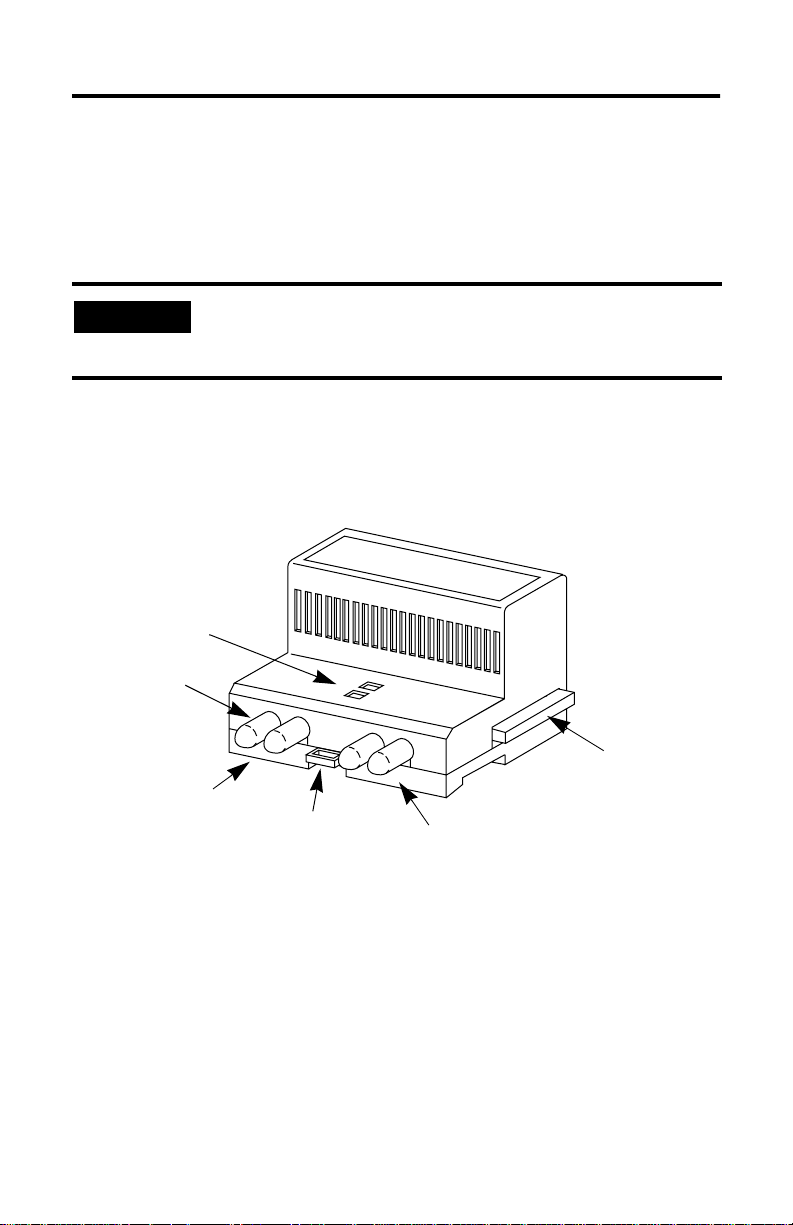

Figure 1 Components of the Module

Indicators

Protective caps

Channel 1 fiber port

Module locking tab

The left side of the modules (not shown here) also contains a backplane connector

Channel 2 fiber port

Right-side

backplane

connector with

protective cover

Publication 9904-IN011A-EN-P - October 2000

Page 5

ControlNet Modular Repeater Medium Distance Fiber Module 5

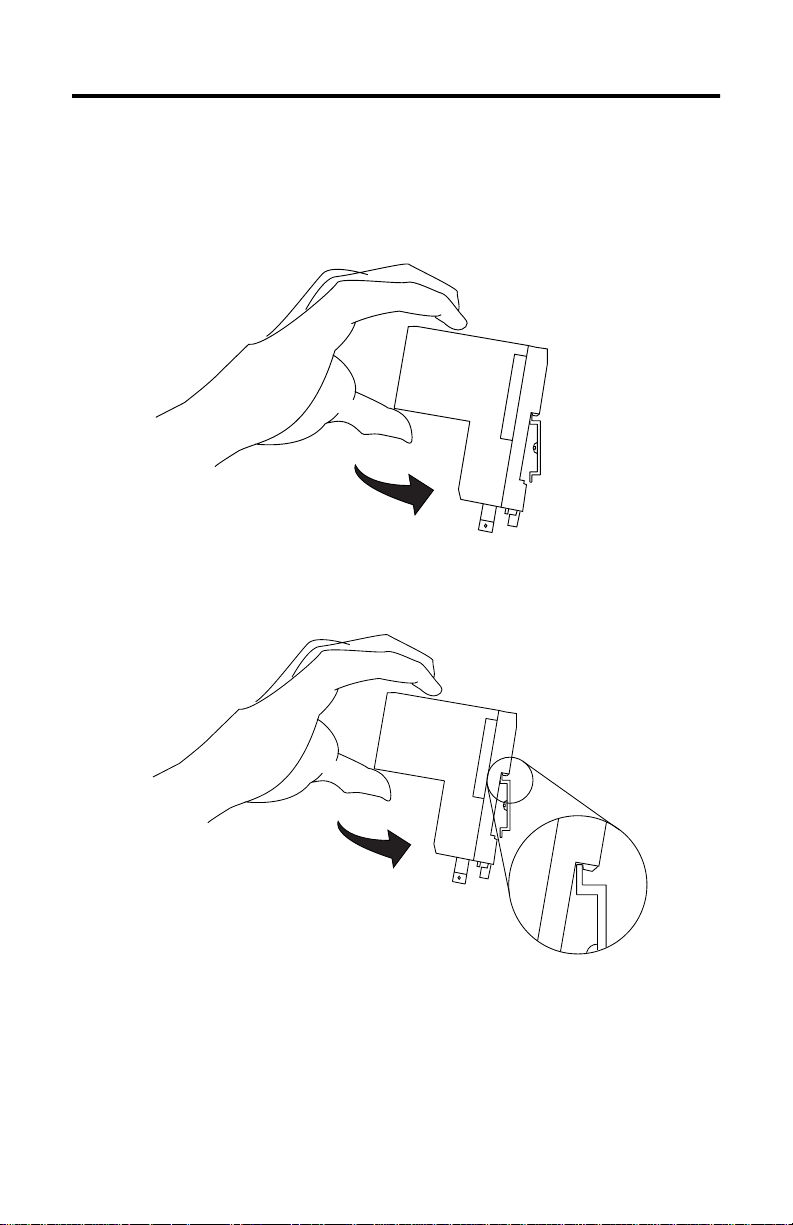

Mount the Fiber Module

To mount the module on the DIN rail:

o

1. Position the module on a 35 x 7.5mm DIN rail at a 30

2. Hook the lip on the rear of the module onto the top of the DIN rail, and

rotate the module onto the rail.

angle.

Publication 9904-IN011A-EN-P - October 2000

Page 6

6 ControlNet Modular Repeater Medium Distance Fiber Module

3. Press the module down onto the DIN rail until flush.

The locking tab should snap into position and lock

the module to the DIN rail.

4. If the module does not snap into position, use a screwdriver or similar

device to move the locking tab down while pressing the module flush onto

the DIN rail. Release the locking tab to lock the module in place. If

necessary, push up on the locking tab to lock.

Publication 9904-IN011A-EN-P - October 2000

Page 7

ControlNet Modular Repeater Medium Distance Fiber Module 7

ATTENTION

!

5. Remove the protective backplane cap as shown in “Remove the Protective

Caps” on page 8.

6. Once attached to the DIN rail, slide modules to the left to mate with the

repeater adapter or another repeater module.

30043-M

Be certain that the adapter and repeater modules are secured

together with DIN rail anchors. Failure to do so may result in

the loss of communications and/ or cause damage to the

modules. The total number of modules that can be attached to

the repeater adapter can not exceed four or the total power

consumption of the modules can not exceed 1.6A @ 5VDC,

whichever comes first.

IMPORTANT

IMPORTANT

7. Connect the fiber cable as shown in “Connect the Fiber Cable” on page 11.

If you exceed the module or power limit, you may cause damage

to the repeater adapter and modules.

If this is the right–most module, a DIN rail latch must be used on

the right side of the fiber module.

Publication 9904-IN011A-EN-P - October 2000

Page 8

8 ControlNet Modular Repeater Medium Distance Fiber Module

Remove the Protective Caps

1. Remove the protective caps from the fiber ports that you are going to use.

2. Save the caps for future use.

Figure 2 Protective Caps

Protective

backplane cap

DIN rail

Protective cap

The left side of the module (not shown here) also

contains a backplane connector

If you plan: Then:

to place the module in storage keep the protective caps on the channels to protect

not to use channel(s) keep the protective caps on the channels to protect

to connect another module to the right

backplane connector

not to connect to the right backplane connector leave the backplane cap on.

the unit from dust.

the unit from dust.

remove the protective backplane cap and save cap

or future use.

Publication 9904-IN011A-EN-P - October 2000

Page 9

ControlNet Modular Repeater Medium Distance Fiber Module 9

IMPORTANT

Choose Fiber Cable Types

Multi-fiber cables for backbone use are available with a wide range of fiber counts;

between 2 and 216 fibers. The following figure shows an example of a multi-fiber

backbone cable and two fiber interconnect cable.

The type of fiber cable you choose to use depends on the network environment.

Consult your installation professional to determine

the best type of cable to use for your environmental

conditions.

multi-fiber

backbone cable

30689-M

Estimate Cable Lengths

The maximum length of a fiber cable section for the

9904-RPFM is dependent on the quality of the fiber,

number of splices, and the number of connectors.

The total attenuation for a cable section must be

less than 13.3dB.

Typically cable attenuation for a wavelength of 1300nm is less than 1.5dB/km.

zipcord

Each fiber system has different constraints, therefore determining maximum fiber

optic cable lengths differs for each system. The 9904-RPFM is designed to solve

medium distance applications that require 3km (9843ft) between two ControlNet

products. We guarantee up to 3km, but you can achieve greater distances by

increasing the quality of the fiber cable and termination connector media. The

medium distance module provides ground isolation between nodes and is not

disrupted by the noise that affects traditional copper media.

Avoid splicing your cable. Connectors can cause considerable

attenuation and limit the maximum length of your system. Be

certain to check the attenuation of different cable sections

after the cable is installed.

Publication 9904-IN011A-EN-P - October 2000

Page 10

10 ControlNet Modular Repeater Medium Distance Fiber Module

Specifications for 9904-RPFM Fiber Optic Cable

The quality of the fiber cable determines the distance you can achieve. Consult

your local distributor for attenuation specifications prior to purchasing your fiber

media components. The table below provides specifications for fiber optic cable:

Item Description

Fiber Type 62.5/125 micron

Fiber Termination Type

Fiber Operating Wavelength 1300 nm

Optical Power Budget

1

This includes all loss associated with the fiber link, including: splices, fiber attenuation, bulkhead

connectors, and the 9904–RPFM ST terminations.

The medium-distance fiber module (9904-RPFM) is designed for use with 62.5/

125µm multi-mode optic fiber and plastic or ceramic ST type connectors. The

wavelength used is 1300 nm.

Termination is simply the process of attaching a connector to the ends of our fiber

cable. We recommend that you use a quality kit such as the Corning Cable Systems

Termination Kit with the unicam ST connectors. The Corning Cable Systems

Termination Kit has proven to be a simple and reliable method to terminate fiber

cable.

(Plastic or ceramic)

ST

1

13.3

Publication 9904-IN011A-EN-P - October 2000

Page 11

ControlNet Modular Repeater Medium Distance Fiber Module 11

Connect the Fiber Cable

If you are going to use only one channel, use either Channel 1 or Channel 2.

To connect the cable for Channel 1:

1. Connect to Channel 1 Receive (RX).

a. Align the knob of the cable connector with the groove of the module

connector, and insert the connector into Channel 1 RX.

Figure 3 Connect the Fiber Cable

9

9

0

4

-

R

P

F

M

30044-M

b. Twist the Receive connector until the bayonet lug is locked into place

2. Connect to Channel 1 Transmit (TX), repeat Step 1.

To connect the fiber cable to Channel 2:

3. Repeat the steps for Channel 1 and refer to the following figure.

Publication 9904-IN011A-EN-P - October 2000

Page 12

12 ControlNet Modular Repeater Medium Distance Fiber Module

Example Topology

Figure 4 This topology is for example purposes only.

Create a new segment with a fiber repeater.

T

N

coax segment

T

N

trunk-cable section

T

T

N

fiber segment

FR

T

FR

coax segment

N

trunk-cable section

T

TT

NN

41327

When you insert a fiber repeater into your media system, you create a new segment

or link. The same restrictions on the number of taps and cable length apply to this

new segment.

Figure 5 Basic fiber topology

coax segment 1

fiber repeater

adapter

9904-RPA

9904-RPFM

CH 1 CH2

RX TX

RX TX

fiber repeater

module

T

N

9904-RPA

RX TX

coax segment 2

terminator

tap

Publication 9904-IN011A-EN-P - October 2000

9904-RPFM

CH 1 CH2

RX TX

Page 13

ControlNet Modular Repeater Medium Distance Fiber Module 13

IMPORTANT

IMPORTANT

Be certain that the fiber cable you connect to Channel 1 (RX)

on one 9904-RPFM repeater to Channel 1 (TX) on the other

9904-RPFM repeater. You can use Channel 1 or Channel 2 on

either module.

The total number of fiber repeaters (9904-RPFS, RPFM)

between any two nodes (path) is limited to 5 repeaters and 6

segments. You may have many repeaters in a system, but a

maximum of five repeaters between any two nodes.

Status Indicators

The figure below identifies the LEDs on the module.

Figure 6 Status Indicators:

Channel 1 LED

Channel 2 LED

Status Indicator (LEDs): Probable Cause:

Off Repeater not connected to power supply

Green Repeater is running without errors. The received data frames

Flashing Green/Off No data activity on network.

are within specification for bit width distortion.

Publication 9904-IN011A-EN-P - October 2000

Page 14

14 ControlNet Modular Repeater Medium Distance Fiber Module

Mounting Dimensions

Figure 7 Mounting Dimensions

4.44 in.

(111 mm)

4.0 in.

(100 mm)

4.048 in.

(101.2 mm)

3.6 in.

(90 mm)

2.76 in.

(69 mm)

Publication 9904-IN011A-EN-P - October 2000

Page 15

ControlNet Modular Repeater Medium Distance Fiber Module 15

Specifications

Communication Rate 5M bits/s

Operation Voltage

Class 2 operational power is provided from 9904-RPA at 5 V dc

Backplane Power Requirements 400 mA maximum

Indicators Channel 1 Status - Green

Channel 2 Status - Green

Environmental Conditions This product must be mounted within a suitable system enclosure to

prevent personal injury resulting from accessibility to live parts. The

interior of this enclosure must be accessible only by the use of a tool.

Operating Temperature

Storage Temperature

0 to 60

-40 to 85

o

C (32 to 125o F)

o

C (-40 to 185o F)

Pollution This industrial control equipment is intended to operate in a Pollution

Degree 2 environment, in overvoltage category II applications, (as

defined in IEC publication 664A) at altitudes up to 2000 meters without

derating.

Relative Humidity 5 to 95% non-condensing

Shock Operating

Non-operating

30 g peak acceleration, 11(

50 g peak acceleration, 11(

± 1)ms pulse width

± 1)ms pulse width

Vibration Tested 5 g @ 10-500Hz per IEC 68-2-6

Fiber Type 62.5/125 micron

Fiber Termination TypeST

Fiber Operating Wavelength 1300 nm

Optical Power Budget 13.3 dB

LED Light Output

Agency Certification

(when product or package marked)

2

(plastic or ceramic)

(1)

<5 mW/mm

Listed Industrial Control Equipment

(2)

Certified Process Control Equipment

Certified Class 1, Division 2, Groups A, B, C, D

Marked for all applicable directives

Marked for all applicable acts

N223

1

This includes all loss associated with the fiber link, including: splices, fiber attenuation, bulkhead connectors,

and the ST terminations.

2

Power to operate this equipment must be supplied from a source compliant with "Class 2" as defined in the

National Electrical Code ANSI/NFPA 70, or the Canadian Electrical Code - Part 1, C22

(1)

(2)

Publication 9904-IN011A-EN-P - October 2000

Page 16

Hazardous Location Approval

The following information applies when operating

this equipment in hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in Class I

Division 2 Groups A, B, C, D, Hazardous Locations and nonhazardous locations

only. Each product is supplied with markings on the rating nameplate indicating

the hazardous location temperature code. When combining products within a

system, the most adverse temperature code (lowest “T” number) may be used to

help determine the overall temperature code of the system. Combinations of

equipment in your system are subject to investigation by the local authority that

has jurisdiction at the time of installation.

EXPLOSION HAZARD –

• Do not disconnect equipment unless power has been removed or the area is

known to be nonhazardous.

• Do not disconnect connections to this equipment unless power has been removed

or the area is known to be nonhazardous. Secure any external connections that

mate to this equipment by using screws, sliding latches, threaded connectors, or

other means provided with this product.

• Substitution of components may impair suitability for Class I, Division 2.

• If this product contains batteries, they must only be changed in an area known to

be nonhazardous.

Informations sur l’utilisation de cet équipement

en environnements dangereux:

Les produits marqués « CL I, DIV 2, GP A, B, C, D » ne conviennent qu’à une

utilisation en environnements de Classe I Division 2 Groupes A, B, C, D

dangereux et non dangereux. Chaque produit est livré avec des marquages sur sa

plaque d’identification qui indiquent le code de température pour les

environnements dangereux. Lorsque plusieurs produits sont combinés dans un

système, le code de température le plus défavorable (code de température le plus

faible) peut être utilisé pour déterminer le code de température global du

système. Les combinaisons d’équipements dans le système sont sujettes à

inspection par les autorités locales qualifiées au moment de l’installation.

RISQUE D’EXPLOSION –

• Couper le courant ou s’assurer que l’environnement est classé non dangereux

avant de débrancher l'équipement.

• Couper le courant ou s'assurer que l’environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer tous les connecteurs externes reliés à

cet équipement à l'aide de vis, loquets coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de composants peut rendre cet équipement inadapté à une

utilisation en environnement de Classe 1, Division 2.

• S’assurer que l’environnement est classé non dangereux avant de changer les

piles.

Publication 9904-IN011A-EN-P - October 2000 PN 957400-94

Loading...

Loading...