Page 1

937CU-AISTR-DC1 Installation Instructions

Strain Gauge Converter

Page 2

Page 3

Symbols Used

Warn ing

Warn ing

Attention

Note

Bul. 937C Strain Gauge Converter Installation Instructions

This symbol warns of possible danger.

Failure to heed this warning may result in personal injury or death, or property

damage, including destruction.

This symbol warns the user of a possible f ault.

Failure to heed this warning can lead to total failure of the device and any other

connected equipment.

This symbol draws attention to important information.

1

Page 4

Safety Notes

Warn ing

Attention

Attention

Attention

Warn in g

Attention

Warn in g

Note

Note

2

Bul. 937C Strain Gauge Converter Installation Instructions

The Frequency Converter with Trip Values must only be operated by trained personnel

in accordance with this handbook.

The protection of operating personnel and of the system is only ensured if the devices

are used in accordance with their intended purpose. Any other type of operation than

that described in this manual places the safety and functionality of the devices and

systems connected to them in question.

The devices may only be installed, connected, and adjusted by electrical professionals

outside the hazardous area.

If faults cannot be elimina ted, the devices must b e taken out of operation and protected

from being placed in service again inadvertently. Tampering with or making changes to

the devices is dangerous and therefore not permitted. They render the warranty void.

The responsibility for the adherence to local safety standards lies with the operator.

Page 5

Overview

Bul. 937C Strain Gauge Converter Installation Instructions

The devices of the Bul. 937C IS Barriers, Isolators and Converters are used to transmit signals

between field

937 products ar

circuits of these devices are intrinsically safe and are galvanically isolated from the not intrinsically

safe circuits. The devices thus represent an electrical isolation between the hazardous area and

the secure area.

Devices can be used

process control system or the control.

Two different, freely parameterisable trip values

Further information (e. g.

instructions for the Bul. 937 family) can be found on our Internet page www.ab.com.

devices and the process control system or control.

e suitable for connection to field devices in the hazardous area. The field current

for signal transmission between field devices in the secure area and the

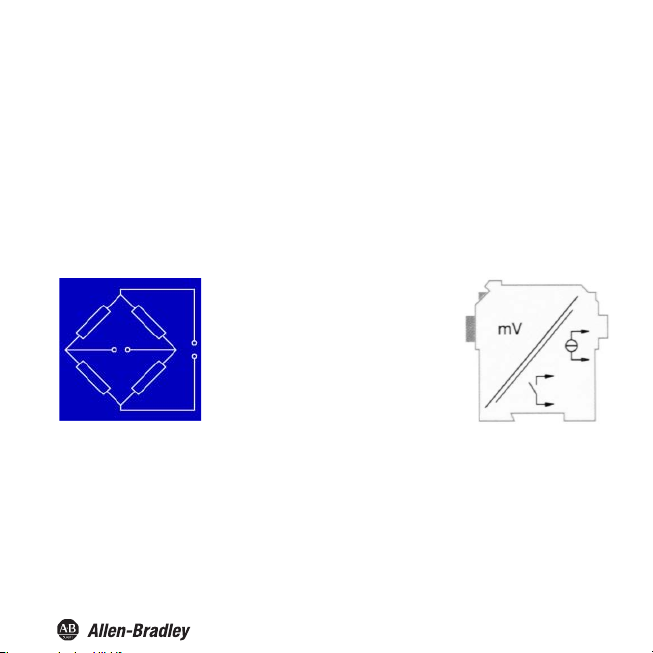

Resistance bridges, i. e. strain gauges,

load cells, force transducers, pressure

transducers, torque shafts or similar

devices, can be connected to the input of

the converters .

The 937CU-AISTR-DC1 converts the

input signal into a proportional output

current, which can be forwarded e. g. to a

display unit or an analog input of the

process control system or control. By

means of the two relay outputs.

of the input signal can be monitored.

certificates and the 937CU-AISTR-DC1 data sheet and the operating

3

Page 6

Bul. 937C Strain Gauge Converter Installation Instructions

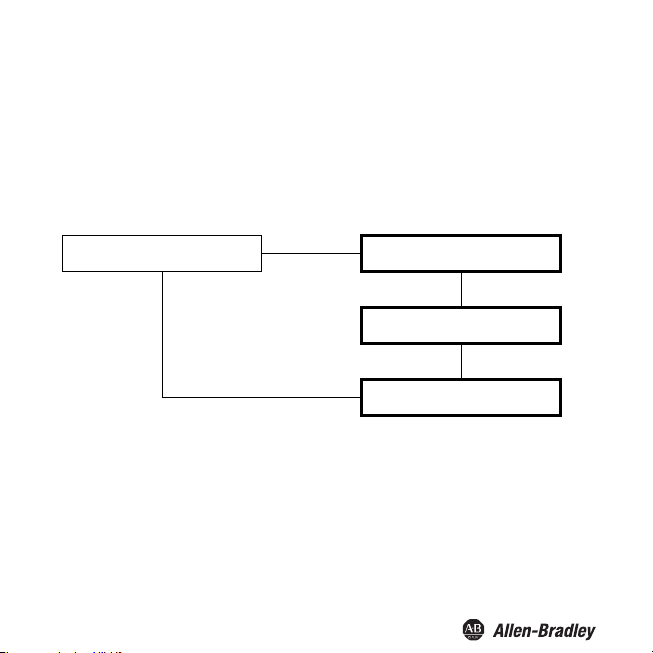

Mounting and Connection

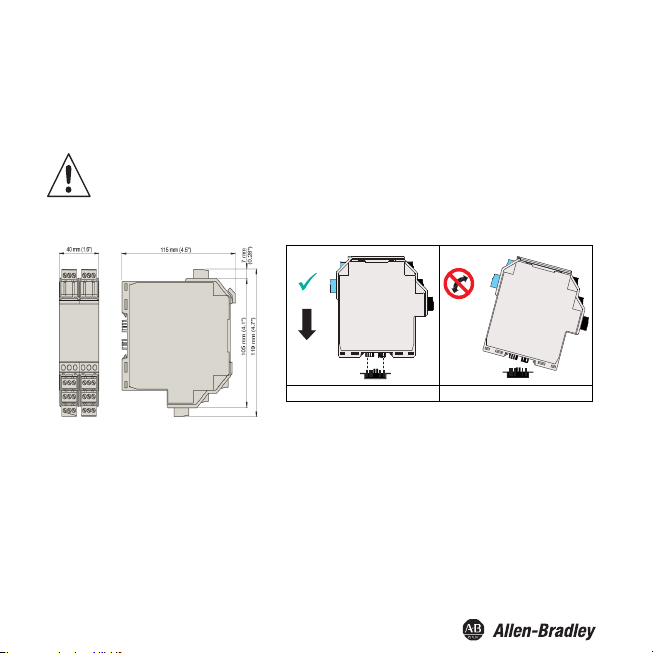

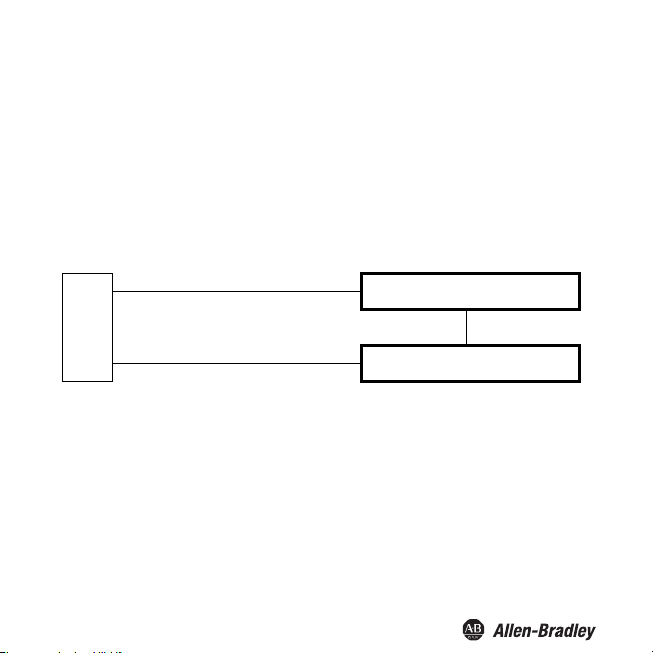

The Strain Gauge Converter can be mounted on a 35 mm standard rail corresponding to DIN EN

60175. The devices must be snapped onto the rail vertically, and never slanted or tipped to the side.

The Strain Gauge Converters are constructed in protection class IP20 and must

therefore be protected from undesirable environmental conditions (water, small

foreign objects).

Attention

CORRECT: Device

snapped on vertically.

INCORRECT: Device snapped

on from the side. Can damage

the contacts and cause the

device to fail.

4

Page 7

Bul. 937C Strain Gauge Converter Installation Instructions

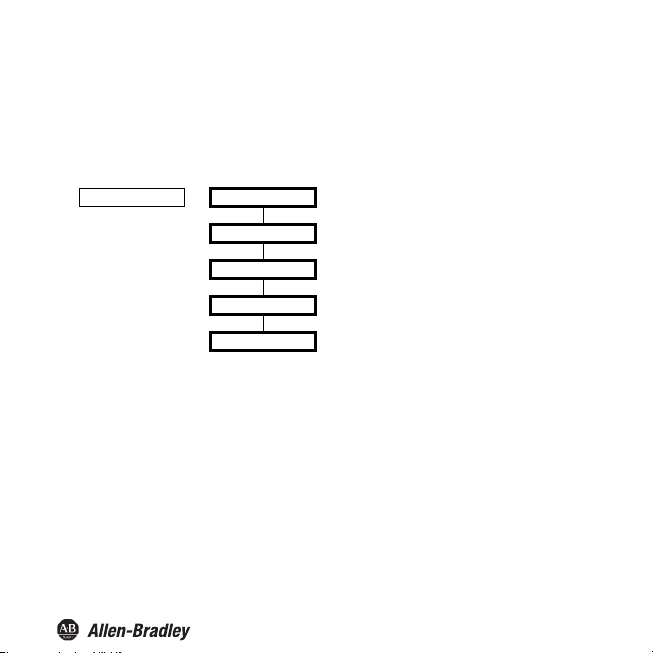

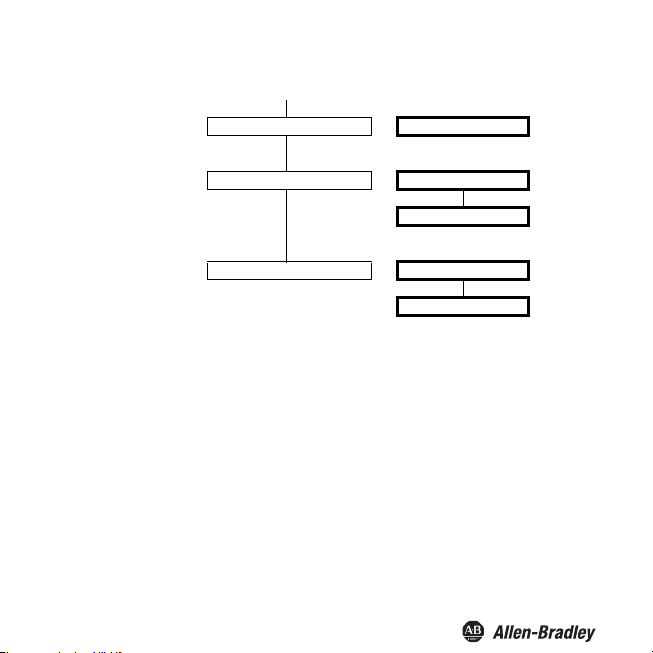

Connection

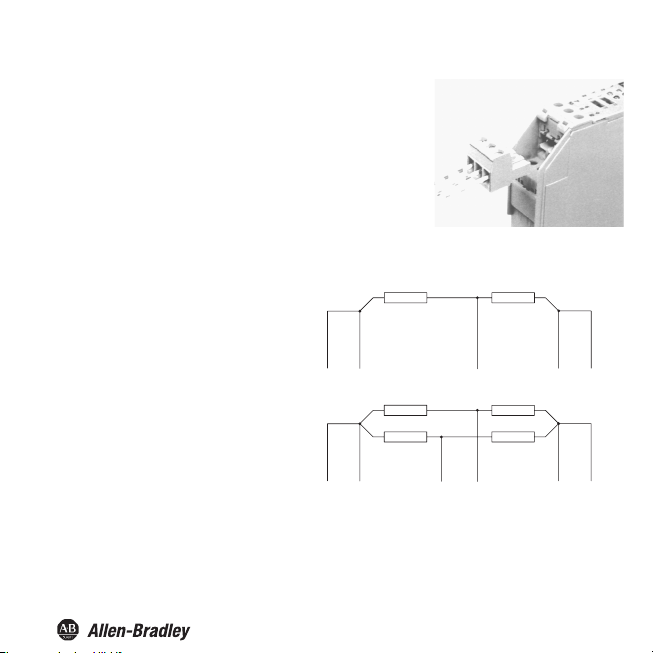

The Bul. 937 series' slip-off terminals significantly simplify

connection and co

quick and error-free exchange of the unit when service is

needed.

The terminals can be screwed on, are self-opening, and have

generous connection room for a wire diameter of up to 2.5 mm²

and coded plugs, so that leads cannot be confused.

The intrinsically safe field circuit is connected

to

the blue terminals 1 to 6 of the Strain

. auge Converters. This may be conducted

into the hazardous area using DIN EN

60079-14-compliant leads.

The non-intrinsically safe field circuit is

connected to the black terminals 1 to 6 of

the Strain Gauge Converters.

In both cases you can connect:

• a half bridge (terminals 1, 3, 4, 5, 6)

• a full bridge (terminals 1 to 6)

nstruction of switching cabinets. They allow

5

Page 8

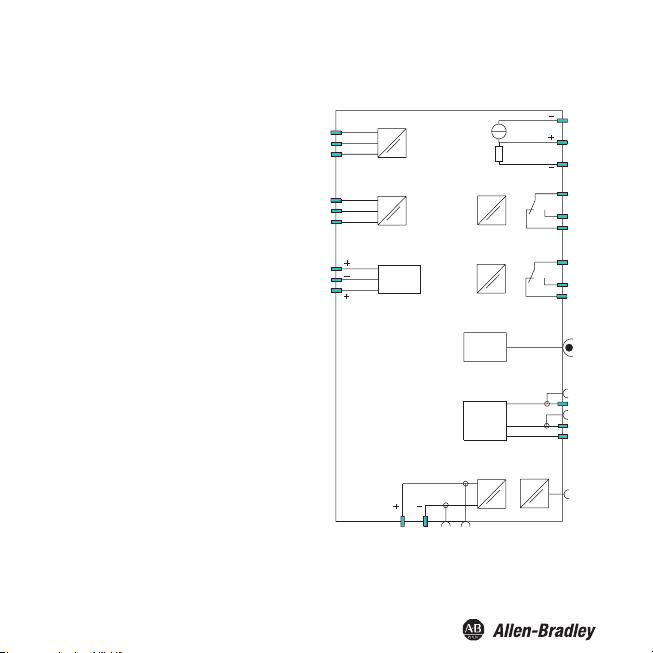

Terminals

Bul. 937C Strain Gauge Converter Installation Instructions

The remaining green terminals have the

following functions:

• Terminals 7/8: current output

• Terminal 9: only for voltage output (see

below.)

• Terminals 10 ... 12: relay 1

• Terminals 13/14: binary input 1

• Terminals 15/14: binary input 2

• Terminals 16 ... 18: relay 2

• Terminals 19 ... 21: RS 485 interface

(deactivated if plug is in RS 232 interface)

• Terminal 22: not used

• Terminals 23/24: power supply 24 V DC

If you connect terminals 7 and 9 by means of a

bridge, a voltage output of - 10 V ... + 10 V

results between this bridge and terminal 8. The

built-in shunt resistance is 500 Ω.

The RS 485 interface is galvanically isolated

from other circuits. It is deacti vated if you plug a

connector into the socket of the RS 232

interface on the front panel of the Strain

Gauge Converters.

Further information on connecting the Strain

Gauge Converters (e. g. on using the Power

Rail) can be found in the data sheet and in the

operating instructions for the Bul. 937 system

on our Internet page www.ab.com.

6

GND

7

8

9

1100

1111

1122

1166

1177

1188

P

21+

N

1920

1

2

3

4

5

6

1133

1144

1155

Binary

inputs

2233

RS 232

RS 485

2244

Page 9

Bul. 937C Strain Gauge Converter Installation Instructions

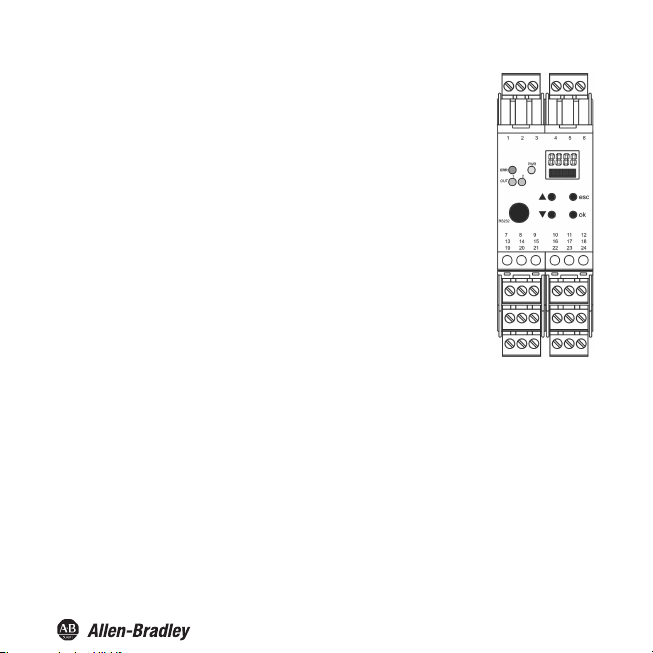

Front panel

On the front panel of the

• LED ERR (red) to indicate

a sensor fault (flashes red)

−

− the simulation mode (only when using FDT flashes red)− a

device fault (steady red)

• PWR LED (green), to indicate the presence of the supply voltage

• LED OUT 1 (yellow), to indicate that relay 1 is active

• LED OUT 2 (yellow), to indicate that relay 2 is active

• serial RS 232 interface to connect to a PC for parameterisation and

diagnosis of the Strain Gauge Converter using FDT.

• a display for measured value and error message display and for

display during parameterisation mode

•

four buttons for parameterisation of the Strain Gauge Converters

− S (Up)

− T (Down)

− ESC (Escape)

− OK

Strain Gauge Converters you will find:

Display mode and error messages

Meas

ured value display

• In normal operation, the current net value is indicated on the display in the selected unit.

• If you hold down the T key, the current gross value is indicated on the display in the selected unit.

•

If you hold down the S key, the mV value actually measured by the Strain Gauge Converters on

th

e terminals 1 and 2 is indicated on the display.

• As usual, the following applies: net value = gross value - tare

7

Page 10

Bul. 937C Strain Gauge Converter Installation Instructions

Messages during operation

• Alarm freeze

• Hold on error

messages

Error

•

Err INT: error

sensor is connected

•

Err MEM: error in the memory of the Strain Gauge Converters

•

Err SIM: Strain Gauge Converter in simulation mode (only when using FDT.

• Err CELL: cell breakage or no cell connected; for information on selecting the check for sensor

breakage

If you cannot solve the problem by checking the cell and the cell cables and by switching the Strain

Gauge Converters off/on, please contact

In the case of a fault, the relays switch into a state with no current, unless you have selected the

function Hold on error .

in the internal communication of the Strain Gauge Converters; may also occur if no

Rockwell Automation.

Editing device data

WARNING: A change in device data will change the operation of the device!

WARNING: Before entering new

installation will result.

FDT Interface

This manual describes Parameterization mode of the universal frequency converter using the control panel. parameterization mode

for the universal frequency converter is more convenient with a PC using Field Device Tool (FDT) software.

Some specialized functions can only be selected using the FDT , for instance, pulse suppression as an alternative to the start-up

override.

The FDT interface is the specification describing the standardized data exchange between devices and control system or engineering

or asset management tools. Examples include: PACTware

FDT frame software can be downloaded from the web: www.pactware.com www.fdtgroup.org.

TM

PACTware

is trademark of PACTware Consortium

data into the device, you should therefore as certain that no danger to the

TM

, FieldCare, FactoryTalk AssetCentre, and Process Device Configuration.

8

Page 11

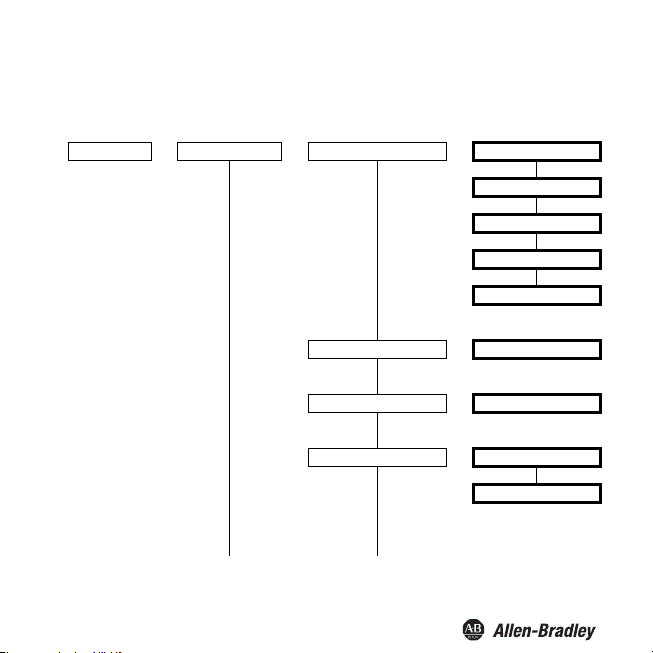

Parameterization mode control panel

Programming

Bul. 937C Strain Gauge Converter Installation Instructions

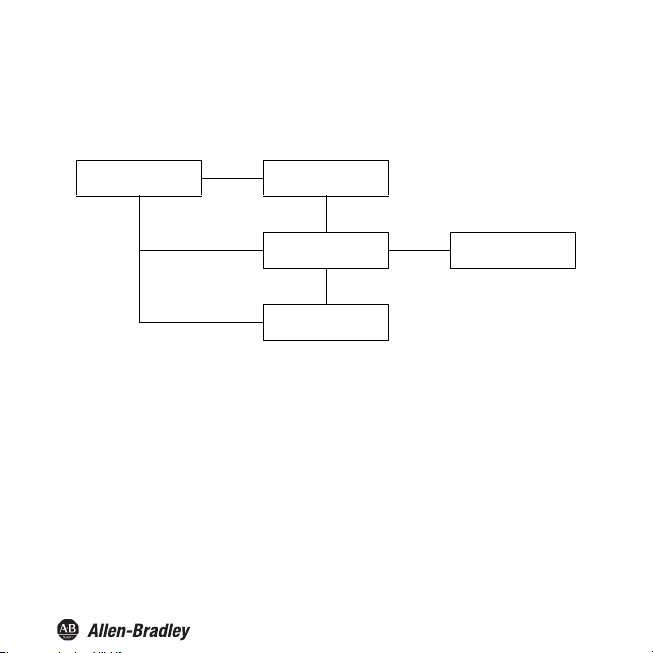

Main menu parameterization mode

Display mode

You can return to display mode from any point in the menu in parameterization mode by pressing the ESC

key (possibly multiple times). If you do not press any key for 10 minutes in parameterization mode, the

device automatically switches back into display mode.

OK + ESC (simultaneously, 1 sec)

ESC

Unit ()

Input ()

Output

Service

9

Page 12

Bul. 937C Strain Gauge Converter Installation Instructions

Password

You can protect the current configuration from unauthorized changes by using a password (See Service;

inactive when Strain Gauge Converter is delivered).

If password protection is active, the various settings in parameterization mode are visible before entry of the

password, but may not be changed. The first time an attempt is made to change a setting, the device

automatically displays a window for entering the password.

• You must enter the password once each time after switching from display mode to parameterization

mode.

• Th

e password cannot be changed and is 1234.

How to enter the password:

automatic switch to password entry

Parameters still protected ESC

Change

attempt

Parameters released OK, value 1234

*If the or keys are pressed, the value changes stepwise ; if the or keys are held down for a longer

period, the value "rolls" to higher or lower values.

Value 0, flashing

, *:

new value, flashing

ESC

OK, wrong value

10

Page 13

Bul. 937C Strain Gauge Converter Installation Instructions

Navigation Method

The following illustration shows the navigation method in parameterization mode using the , , OK, and

ESC keys:

Output

OK →

← ESC

← ESC ← ESC

← ESC

Relay 1

Relay 2

I

out

ST

OK →

ST

Mode of operation

11

Page 14

Lowest menu level

Choose Values, Enter Numbers

At the lowest level of t. e menus, you can

individual parameters, or enter a numeric value.

either choose between particular possible values for

Bul. 937C Strain Gauge Converter Installation Instructions

Lowest menu level

Parameters

When entering numeric values, p

•

o

u press the or key, the value changes stepwise.

If y

•

If you hold the or key

• The sign

switches automatically.

• The d

ecimal point is moved automatically.

Units are automatically converted to higher units, e. g. kg to t, or a factor is displayed, e. g. factor 10

for numbers ≥ 10000.

lease note:

for a longer time, the value "rolls" to higher or lower values.

OK

ESC

ESC

current value, flashing

, : ESC

new value, flashing

OK

new value, saved, not flashing

12

Page 15

Bul. 937C Strain Gauge Converter Installation Instructions

Unit

The following figure shows the menu for the unit. The menu options of the lowest menu level are

surrounded by a bold box. The unit is used for the measured value display (net and gross) and for all

respective settings in the parameterisation mode.

Unit —— kg*

N

%

cbm (m³)

pcs (pieces)

* If more than 9999 kg are entered, the unit changes automatically from kg on t!

The Strain Gauge Converter makes measurements in mV.

13

Page 16

Bul. 937C Strain Gauge Converter Installation Instructions

Sensor

The following figures show the menus for the input parameters. The menu options of the lowest menu

level are surrounded by a bold box. Menu options that are only displayed if you have selected certain

parameter values elsewhere are highlighted in grey.

Input —— Sensor ——

Excitation

—— 1 V

2 V

3 V

4 V

5 V

Sensitivity

Cell rating

Rate

continued on next page continued on next page

—— 0.001 to 60.00 mV/V

—— 0.001 kg to 999.9 t

—— normal

fast

Edition 06/2008 182694

14

Page 17

Bul. 937C Strain Gauge Converter Installation Instructions

Calibrati

Trigger 1

Trigger 2

on

Cell detect

Smoothing

—— On

Off

—— 0 sec to 10 sec

15

Page 18

Bul. 937C Strain Gauge Converter Installation Instructions

Excitation, Sensitivity, Cell rating

• For the values of these parameters, please refer to the technical data of the sensor.

• The supply voltage exists between terminals 3 and 4.

• When connecting several measuring cells in parallel, the supply voltage and sensitivity must be

transferred, the cell data are to be totalled. Only cells of the same design and with identical cell

data may be connected in parallel.

• For a resulting total sensor resistance of R < 100 Ω the supply voltage 5V must not be selected.

The maximum permitted supply voltage is calculated as follows:

Supply voltage = 49 mA x total resistance of the measuring cells

•For th eCell data parameter, the maximum cell load must be set in kg (even if a different unit has

been selected).

The cell data can be set up without a measuring cell being connected. The Strain Gauge

Converter can then be connected

voltage created by the weighing cell due to the load is converted linear into the corresponding

gross weight.

nt to use the Strain Gauge Converter without calibration yet take into account

If you wa

an existing empty weight (e. g. an empty tank or a weighing platform) when

measuring, do not use the function "Zero point" but the function "Tare".

Note

Please note that mechanical influences have not yet been taken into account (e. g. acting of forces on

the weighing cell other than perfectly vertically) so that the weighing device does not achieve its

optimum accuracy.

To take into account mechanical influences a calibration of the fully

device using defined loads is unavoidable.

Note

to the weighing cell and is basically ready for operation. The

installed weighing

16

Page 19

Bul. 937C Strain Gauge Converter Installation Instructions

Without adjustment , the gross value is calculated as follows:

e in

----M---e-----a---s---ur-----ed------ v------a--lu---------

Gross value

This results in the following assignment: 0 mV is converted into 0 unit, the maximum sensor signal (=

sensitivity x excitation voltage) is converted into the maximum cell load of the selected unit, interim

values are converted proportionally.

Maximum cell load

= Cell rating/(kg/unit)

---------- -----------

=

Sensitivity × Excitation voltage

Unit

--------

mV

------

ll ra

-----Ce--------

------ti-----ng-- -

×

kg/unit

0

0

Maximum sensor signal

= Sensitivity x Excitation voltage

Rate, Cell error, Smoothing

• If you have selected the fast setting for Rate, the Sensor failure and Smoothing menu options are

not displayed. In this case, a check for sensor breakage and smoothing is not possible.

Note

• If you have selected the On setting for Sensor failure, a check for sensor breakage is performed

after each measurement (terminals 1 and 2). Possibly, the Strain Gauge Converter returns the

error message Err CELL. Unless this check is enabled the Strain Gauge Converter might

process uncontrolled input values until the sensor failure has been detected.

mV

17

Page 20

Bul. 937C Strain Gauge Converter Installation Instructions

• The settings influence the measuring cycle time:

• By means of Smoothing, you influence the reaction of the Strain Gauge Converter to strongly

fluctuating measured values.

The Strain Gauge Converter processes the smoothed value instead of the current measured

value. With an adjusted smoothing time of 0 sec, the input value is processed directly. The

largest smoothing is reached with the attitude 10 sec. Note please that with increasing smoothing

also the response time of the Strain Gauge Converter is reduced.

Smoothing is designed as a first-order low-pass filter. The smoothing time is the time required by

the output signal to get from 10 % to 90 % after a jump stimulation.

18

Page 21

Bul. 937C Strain Gauge Converter Installation Instructions

Calibration

The following figure shows the menu levels following the Calibration menu option. The menu options

of the lowest menu level are surrounded by a bold box. Menu options that are only displayed if you

have selected certain parameter values elsewhere are highlighted in grey.

Calibration ——

Zero

—— Set

—— -100 to +100 mV

Adjust

Range

kg/unit

Execute

—— Weight

Execute

—— Set

Execute

—— 0.001 kg/unit to 999.9 t/unit

—— yes

—— 0.001 kg to 999.9 t

—— yes

—— see zero point & adjust

—— yes

no

no

no

19

Page 22

Bul. 937C Strain Gauge Converter Installation Instructions

Zero point

For installations where a signal of 0 mV does not correspond to the measured value 0 in the selected

unit, a zero offset can be stored.

• If the zero offset is known from the data of the installation, please enter the value under Set

displays.

• If you select (after appropriate measures in the installation, e. g. removing all weights) Execute and

then Yes, the current mV measured value is stored as zero point. The gross value, the net value

and the tare are set to 0.

For storing the zero point by means of the triggers, i. e. without using the control panel keys.

Adjust without mechanical load

The easiest calibration method. However, not all links in the measuring chain will be considered

resulting in some inaccuracies.

• A trigger input must be parameterized as zare

• After installation and connection of the Strain Gauge Converter the corresponding input must be

short-circuited with the measuring cell free from loads.

Adjust with mechanical load

This is the more accurate calibration method because the whole measuring chain is included. It does,

however, require a high effort.

Adjust

The adjust is an exact defined excitation of the cell, e. g. by an exactly known weight. The Strain

Gauge Converter requires both the value of the adjust in the selected unit and the

generated input signal in mV:

• First enter the adjust value in the selected unit kg, N, cbm or pcs under Weight. If you have selected

the unit %, the adjust value must be entered in the unit that was selected before the unit was set

to %.

• After excitation of the sensor (applying the weight), select Execute and then Yes. This determines

the adjust value in mV. The tare is set to 0, gross value and net value correspond to the adjust

value in the selected unit.

For determining the adjust value in mV by means of the triggers, i. e. without using the control

panel keys, see Triggers section.

20

Page 23

Bul. 937C Strain Gauge Converter Installation Instructions

Notes on Zero point and Adjust

• For the result of the adjust it does not matter whether you determine the zero point or the

adjust value first.

• Zero point and adjust value must be determined in the same unit (do not change the unit before

both operations have been performed).

•

If you perform the adjust in a unit

kg/unit .

• If you change one of the Excitation voltage, Sensitivity or Cell rating parameters, a new adjust is

required.

After an adjust, the gross value is calculated as follows:

Gross value =

This results in the following assignment: The zero point (in mV) is converted into 0 unit, the adjust

value in mV is converted into the adjust value of the selected unit, intermediate values and values

beyond the adjust value are converted proportionally:

Unit

Adjust

other than kg, a new adjust is required after changing the value

easu

ed

val

u

e

i

V

–

Zer

o

--M---------

-----Ad---r------

---

-----

just in

------

--

---

---n---–--- m-----

------

m

V

Ze

ro

t

-----

---

------

----- p---o---i---n--

× Adjust in unit

po

int

0

0

Zero point Adjust

mV

21

Page 24

Bul. 937C Strain Gauge Converter Installation Instructions

Range

This parameter is required for evaluations in the unit %.

Under Set displays, enter the value that is to correspond to the gross value 100 % in the (before

•

selecting %) selected unit kg, N, cbm

cell load are possible.

• Alternatively, you can select Execute and then Yes after excitation of the cell (e. g. after applying

a corresponding weight). This stores the current measured value as Range.

After a change to the unit %, the gross value is calculated as follows:

Gross value in %

or pcs (see section 7.2). Values between 0 and the maximum

oss va

ue

t ch

ang

---Gr-----------

-----------l------

-----wi------th------ou-------Range

-----------

------e --------

to %

------

× 100 %=

kg/unit

• This menu option is only displayed if N, cbm or pcs has been selected as unit (see section 7.2) or

if % has been selected as unit and N, cbm or pcs has been selected previously.

• The entered value determines the conversion of kg into

− N (approx. 1/9.81 = 0.102)

− cbm (known from the application or to be determined by weighing)

− pcs (known from the application or to be determined by weighing).

• If % has been selected as unit, the factor for converting kg into the previously selected unit must

be entered.

• If an adjust into a unit other than kg is performed, the value kg/unit must be entered before the

adjust. After changing the value kg/unit, a new adjust is required.

22

Page 25

Bul. 937C Strain Gauge Converter Installation Instructions

7.5 Triggers

The following figure shows the menus for trigger 1 and trigger 2. The menu options of the lowest menu

surrounded by a bold box. For information on the binary inputs, see Connection section.

level are

Trigger 1 —— Tare Trigger 2 —— Tare

Adjust Adjust

Zero Zero

Binary input for trigger 1: terminals 13/14 Binary input for trigger 2: terminals 15/14

•

In the case of the Tare setting, a signal of at least 100 ms at the binary input results in the

current meas

tare. As usual, the following applies:

net value = gross value - tare

• In the case of the Adjust setting, a signal of at least 100 ms at the binary input results in the current

measured value of the Strain Gauge Converter being adopted as the value for the adjust.

• In the case of the Zero setting, a signal of at least 100 ms at the binary input results in the current

measured va

Storing the adjust and the zero point by means of the triggers only makes sense, for example, if you

want to avoid operational actions on

ured value of the Strain Gauge Converter being stored as the (new) value for the

lue of the Strain Gauge Converter being adopted as the value for the zero point.

the Strain Gauge Converter.

23

Page 26

Bul. 937C Strain Gauge Converter

Relays

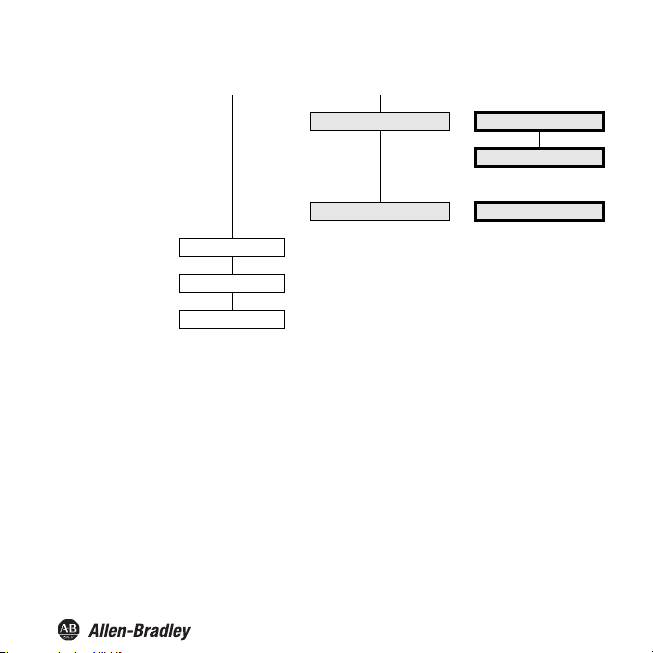

The following figure shows the menus for the output parameters.

Output —— Relay 1 ——

Installation Instructions

Trip alarm

Fault indication

Relay 2 ——

I

out

From the Relay 1 and Relay 2 menu options, you can use the OK key to get to a menu in which you

can enter individual parameters for the selected relay. Both menus are structured in the same way and

are thus only described once.

The activated function of a relay (Trip alarm or Fault indication) is marked by On. If you want to activate

a different function, first call this function using the S and T keys. Then press the OK key twice. After

the first OK you can cancel with ESC.

Trip alarm

Fault indication

24

Page 27

Bul. 937C Strain Gauge Converter Installation Instructions

Trip alarm

The following figures show the menu levels following the Trip alarm menu option. The menu options

of the lowest menu level are surrounded by a bold box.

If the Trip alarm function is activated (On), use the OK key to get from the Trip alarm menu option to

the Min/Max menu option. If you reactivate the Trip alarm function, pressing the OK key twice takes

you directly to the Min/Max menu option.

Trip alarm (On) —— Min/Max —— Min

Max

Trip —— Trip point & Hysteresis

Hysteresis ——

Mode —— Passive

Gross/Net —— Gross

continued on next page

Trip point & Hysteresis

Active

Net

25

Page 28

Bul. 937C Strain Gauge Converter Installation Instructions

Delay

Alarm freeze

Hold on error

—— 0 sec. to 250 sec.

—— On

Off

—— On

Off

Operating behavior

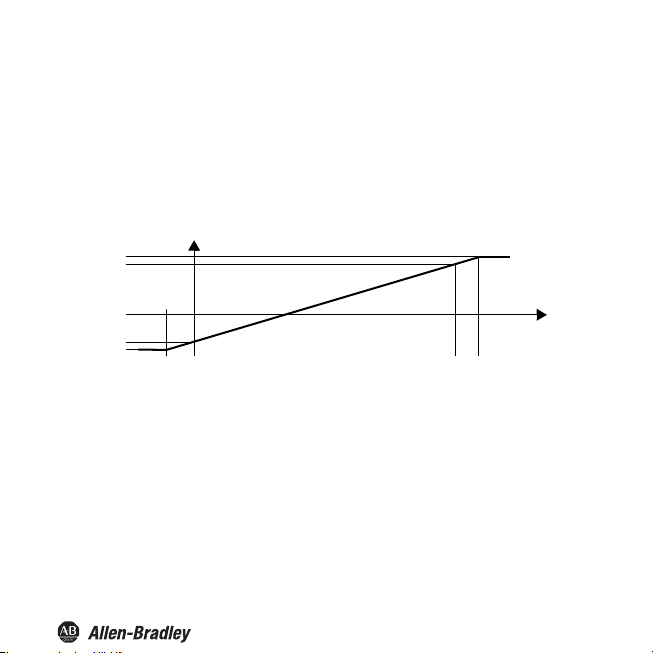

As the trip mode Max or Min are possible, as the operating mode Active or Passive are possible.

Areas of application:

• Trip mode Max, operating mode Active: alarm if the signal is above the trip value, e. g. horn on;

protection against overfilling, e. g. open drain in capacity tank

• Trip mode Max, operating mode Passive: protection against overfilling, e. g. conveyor belt/pump

off; for a large hysteresis Min-Max operation, e. g. conveyor belt/pump on/off

• Trip mode Min, operating mode Active: alarm if the signal is below the trip value, e. g. horn on;

protection against shortfalls in security reserves, e. g. conveyor belt/pump on

• Trip mode Min, operating mode Passive: Protection against shortfalls in security reserves, e. g.

pumping out off; for a large hysteresis Min-Max operation

The exact operating behavior of the Strain Gauge Converter is illustrated in the following figure:

26

Page 29

Measured value

Max - hysteresis

Min + hysteresis

Max

Min

Bul. 937C Strain Gauge Converter Installation Instructions

Trip mode Min, operating mode Active:

energized

de-energized

Trip mode Min, operating mode Passive:

energized

de-energized

Trip mode Min, operating mode Active:

energized

de-energized

Trip mode Min, operating mode Passive:

energized

de-energized

Time

Trip point and Hysteresis

When entering the values for the trip point and hysteresis, please observe the following:

• By means of the Gross/Net parameter, you determine whether the value for the trip point is a gross

value or a net value (gross value minus current tare).

• The trip point and hysteresis must be entered in the selected unit.

− The minimum value for the trip point is 0, the minimum value for the hysteresis is 0.1.

− If you have selected Gross, the maximum ce ll load is the maximum value for

the trip point and hysteresis.

− If you have selected Net, the value of the maximum cell load minus the current tare

is the maximum value for the trip point and hysteresis.

27

Page 30

Bul. 937C Strain Gauge Converter Installation Instructions

As the representation of the operating behavior

•

− for the trip mode Max: trip point - hysteresis ≥ 0

− for the trip mode Min: trip point + hysteresis ≤ upper limit of the trip point

in section 7.6.2 shows, the following must apply:

The limits are automatically determined by the Strain Gauge Converter being.

• The hysteresis should be > 1 % of the trip point in order to prevent rapid switching of the relay.

Delay

If you set a time > 0 sec, you prevent short-time violations of the trip value from triggering an alarm.

• The relay only switches if the trip point is exceeded/fallen short of for a period that is longer than

the delay time.

• The relay only switches back if the trip point -/+ hysteresis is fallen short of/exceeded for a period

that is longer than the delay time.

• If the trip point is exceeded/fallen short of for a short time, this does not have any effects.

The following figure shows the operating behavior for the trip mode Max, operating mode Active.

Measured

value

Max

Max - hysteresis

Trip mode Max, operating mode Active, with delay

energised

de-energised

Delay Delay

Time

28

Page 31

Bul. 937C Strain Gauge Converter Installation Instructions

Alarm freeze and Hold on error

• By means of the Alarm freeze you ensure that the operating personnel notices if the trip value is

temporarily violated.

If Alarm freeze On has been selected, the new condition is maintained after switching the relay,

until the ESC key is pressed or the device is restarted. These actions reset the relay, unless the

trip value is still exceeded.

• The Hold on error function prevents the relay from de-energising in the case of a fault.

If Hold on error On has been selected, the condition of the relay is maintained in the case of a

fault , until the error message is cleared. Afterwards, the relay takes up its normal function again.

Fault indication

The following figure shows the menu levels following the Fault indication menu option. The menu

options of the lowest menu level are surrounded by a bold box.

If the Fault indication function is activated (On), use the OK key to get from the Fault indication menu

option to the Alarm freeze menu option. If you reactivate the Fault indication function, pressing the OK

key twice takes you directly to the Alarm freeze menu option.

Fault indication (On) —— Alarm freeze —— On

Off

A relay with the function Fault indication is energised in normal operation. If the device detects a

fault , the relay is de-energised.

29

Page 32

Current output

The following figures show the menu levels following the I

lowest menu level are surrounded by a bold box.

I

—— Characteristic —— 20.20 -/+mA

out

Gross/Net —— Gross

Span —— Gross/Net,Span,Inv

continued on next page

Bul. 937C Strain Gauge Converter Installation Instructions

menu option. The menu options of the

out

4 - 20 NE 43

12.20 -/+mA

0 - 20 mA (b)

Net

30

Page 33

Bul. 937C Strain Gauge Converter Installation Instructions

Fault current

Inverted

—— Min

Max

Hold

Up/down

—— Normal

Inverted

Gross/Net, Span, Inverted

•

By means of the Gross/Net parameter, you determine whether the value for the Span is a gross

value or a net value (gross value minus current tare).

•

By means of the Span parameter, you determine the measured value range which is represented

by the current output.

− The span must be entered in the selected unit.

ave selected Gross, you can enter values between 1 % and 100 % of the maximum cell

− If you h

load.

− If you have selected Net, you can enter values between 1 % of the maximum cell load and the

value of the maximum cell load minus the current tare.

•

If you select Inve

current output and the Span is converted into the end value (for the Strain Gauge Converter

always +20 mA). If you select Inverted → inverted, the Span is converted into the start value of

the current output and the measured value 0 is converted into the end value.

rted → normal, the measured value 0 is converted into the start value of the

31

Page 34

Bul. 937C Strain Gauge Converter Installation Instructions

Characteristic

The settings have the following meaning (for Inverted → normal)

Selected setting 20.20 -/+mA

+ 20.5

+ 20.0

mA

0

- 20.0

- 20.5

- 1.25 % 0 100 % = span 101.25 %

This setting converts the measured value 0 into -20 mA (i. e. into 20 mA in the case of changed polarity

at the terminals 7 and 8), the

(terminal 7 -, terminal 8 +), interim values are calculated proportionally.

For values below the measured value 0, the output current decreases linearly to a minimum of

-20.5 mA (-1.25 % of the measurement range). Further underflows cannot be evaluated (output

-20.5 mA). If the span is exceeded, the output current increases linearly to a maximum of +20.5 mA

(101.25 % of the measurement range). Further increases cannot be evaluated (output +20.5 mA).

span is converted into +20 mA

Selected setting 4 - 20 NE 43

20.5

20.0

4.0

3.8

0

- 1.25 %

mA

0 100 % = span ≈ 103 %

32

Measured

value

Measured

value

Page 35

Bul. 937C Strain Gauge Converter Installation Instructions

This setting converts the measured value 0 into 4 mA, the span is co

are calculat

values

For values below the measured value 0, the output current decreases linearly to a minimum of 3.8 mA

(-1.25 % of the measurement range). Further underflows cannot be evaluated (output 3.8 mA). If the

span is exceeded, the output current increases linearly to a maximum of 20.5 mA (approx. 103 % of

the measurement range). Further increases cannot be evaluated (output 20.5 mA).

proportionally.

ed

nverted into 20 mA, interim

Selected setting 12.20 -/+mA

+ 20.5

+ 20.0

0

- 12.0

- 12.5

≈ - 1.6 % 0 100 % = span ≈ 102 %

T

his setting conve

at the terminals 7 and 8), the span is converted into +20 mA

(terminal 7 -, terminal 8 +), interim values are calculated proportionally.

For values below the measured value 0, the output current decreases linearly to a minimum of

-12.5 mA (approx. -1.6 % of the measurement rang e). Further underflows cannot be evaluated (outpu t

12.5 mA). If the span is exceeded, the output current increases linearly to a maximum of 20.5 mA

(approx. 102 % of the measurement range). Further increases cannot be evaluated (output 20.5 mA).

mA

rts the measured value 0 into -12 mA (i. e. into 12 mA in

Measured

value

the case of changed polarity

33

Page 36

Bul. 937C Strain Gauge Converter Installation Instructions

Selected setting 0 - 20 mA (b)

20.5

20.0

0

This setting converts the measured value 0 into 0, the span (see section 7.7.1) is converted into

20 mA, interim values are calculated proportionally.

Values below the measured value 0 cannot be evaluated (output 0 mA). If the span is exceeded, the

output current increases linearly to a maximum of 20.5 mA (102.5 % of the measurement range).

Further increases cannot be evaluated (output 20.5 mA).

Fault curr

ent

The following table shows what the current output is during a fault, depending on the selected setting:

mA

0 100 % = span 102.5 %

Measured

value

Setting

Min

(downscale)

Max

(upscale)

Hold last value before the fault

Up/down in the case of Err Cell: downscale; in all other cases: upscale

Characteristic

20.20 -/+mA

-21.5 mA 2.0 mA -21.5 mA

+21.5 mA 21.5 mA +21.5 mA 21.5 mA

Characteristic

4 - 20 NE 43

Characteristic

12.20 -/+mA

34

Characteristic

0 - 20 mA (b)

0 mA

(cannot be

distinguished from

measurement ≤ 0)

Page 37

Bul. 937C Strain Gauge Converter Installation Instructions

Service

The following figure shows the menus for the service parameters. The menu options of the lowest

menu level are surrounded by a bold box.

Service ——

RS 485: Set the address of the Strain Gauge Converter for communication via the RS 485

interface here.

Reset: If yes is flashing and you press the OK key, all settings of the Strain Gauge Converter will be

reset to factory settings (see exceptions: language and password activation). All entries which you

have ever made in parameterisation mode and the adjust will be lost.

Password

Language —— Eng (English)

RS 485 (see below) —— 0 to 31

Reset (see below.) —— yes

—— On

Off

De (German)

no

35

Page 38

Bul. 937C Strain Gauge Converter Installation Instructions

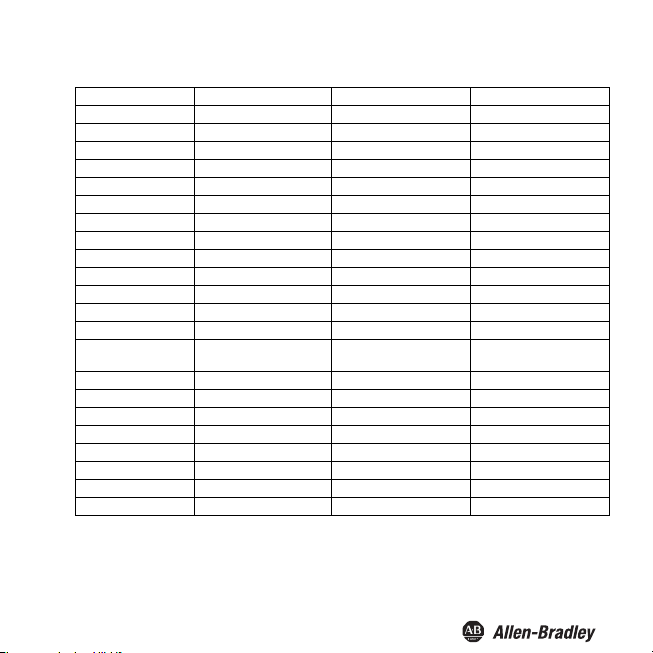

Factory settings

Menu Parameter Factory setting Local setting

Main menu Unit kg

Input sensor Excitation voltage 5 V

Input adjustment Zero point 0.000 mV

Input Trigger 1 Zero

Output relay 1 Trip alarm On (= selected)

Sensitivity 2,000 mV/V

Cell rating 1000 kg

Rate Normal

Cell error On

Smoothing 0 sec.

Adjust 1000 kg

Range 1000 kg

Tr i g g e r 2 Ze ro

MIN/Max

(= Trip mode)

Trip point 10.00 kg

Hysteresis 10.00 kg

Mode Passive

Net/Gross Net

Delay 0 sec.

Alarm freeze Off

Hold on error Off

Fault indication not selected

Max

36

Page 39

Bul. 937C Strain Gauge Converter Installation Instructions

Parameter Parameter Factory setting Local setting

Output relay 2 Trip alarm On (= selected)

Output I

out

Service Password Off

MIN/Max

(= Trip mode)

Trip point 10.00 kg

Hysteresis 10.00 kg

Mode Passive

Net/Gross Net

Delay 0 sec.

Alarm freeze Off

Hold on error Off

Fault indication not selected

Characteristic 20.20 -/+mA

Net/Gross Net

Span 20.00 kg

Fault current Max

Inverted Normal

Language Eng

RS 485 1

Reset no

Max

37

Page 40

Bul. 937C Strain Gauge Converter Installation Instructions

RS 485 interface

The Strain Gauge Converter can be connected to an RS 485 2-wire bus via the terminals 19 ... 21 or

via the Power Rail. In principle, such a bus is structured as follows:

390 Ω

+ 5 V

B line/+

Strain Gauge

Converter

21

Connection cable 5 m max.

19

220 Ω

390 Ω

Attention

Characteristics of the RS 485 interface of the Strain Gauge Converter:

• Baud rate 9600

• 1 start bit, 8 data bits, no parity bit, 1 stop bit

Bus cable 500 m max.

A line/-

Ensure that the polarity of the connection is correct!

An incorrect polarity causes inverted data signals and thus prevents the bus from

working properly.

38

220 Ω

Connection cable 5 m max.

RS 485 device(up to 31 RS 485 devices)

Page 41

Bul. 937C Strain Gauge Converter Installation Instructions

Requests via the RS 485 interface are not suitable for time-critical or safety-critical

applications.

Warning

The Strain Gauge Converter can request the following information via the RS 485 interface e. g.

from a PC

or a PLC (with 3 decimal places each):

Net measured value (in the set unit)

•

Gross measured value (in the set unit)

•

mV measured value (in the set unit)

•

Output value current output (in mA)

•

The following commands are available for the requests:

• Null: delete the receive buffer of the requesting device

Check_1: checks whether Strain Gauge Converter (with the respective address) is connected

•

• Get_value_ch1: requests the net measured value

• Get_value_ch2: requests the gross measured value

• Get_value_ch3: requests the mV measured value

• Get_current: requests the output value current output

Note

At the beginning of each RS 485 communication, send the re

The RS 485 interface is deactivated if a connector is plugged into the programming

jack (RS 232 interface).

When the connector is removed, the request Check_1 is

communication.

quest Check_1.

required to switch to RS 485

39

Page 42

Bul. 937C Strain Gauge Converter Installation Instructions

The commands must be encoded as follows:

Command 1st byte 2nd byte 3rd byte 4th byte 5th byte 6th byte

Null 00 0 00 0

Check_1 Address 1 Checksum

Get_value_ch1 Address

Get_value_ch2 Address

Get_value_ch3 Address

Get_current Address

The S

train Gauge Converter return

Command 1

st

byte 2

Check_1 Address 9 Checksum

Get_value_ch1 Address Value Checksum

Get_value_ch2 Address Value Checksum

Get_value_ch3 Address Value Checksum

Get_current Address Value Checksum

Explanations:

• Address: The address must be calculated as follows: 128 + setting under Service → RS 485 (see

section 7.8). Values from 128 + 0 to 128 + 31, i. e. from 10000000

• Checksum: The checksum is calculated as follows: 100

code), e. g. for Check_1 for address 17: 100

The figure

•

9 in the response to Check_1 refers to the device type Strain Gauge Converter.

• Value: in the signed long data format (4 bytes or 2 bytes)

B

Checksum

Hex

C

Checksum

Hex

10

Checksum

Hex

D

Checksum

Hex

s the following responses:

nd

byte 3

rd

Hex

byte 4

- (91

Hex

Hex

th

- (1st byte + ... + penultimate byte of the

+ 1) = 6E

byte 5

to 10011111

Bin

= 01101110

Hex

th

byte 6

th

, are possible.

Bin

Bin

byte

40

Page 43

Bul. 937C Strain Gauge Converter Installation Instructions

Example

The weight of a truck load is to be calculated. The empty weight of the truck can be between 7.5 t

and 15 t, the load to be measured can be up to 20 t

alarm is to be triggered at a weight above 20.5 t.

The truck rests on 4 weighing cells which have been connected in parallel at the input of the Strain

Gauge Converter. Each weighing cell ha

• Supply voltage 5 V

• Sensitivity 2 mV/V

• Maximum load: 15 t

• Internal resistance: 350 Ω

The mass of the truck weighing scales is 10 t.

s the following data:

. To prevent an overloading of the truck an

Unit

The weight is to be displayed in the unit tons. In the menu Unit kg must be set. If the weight reaches

1000 kg the device automatically switches to t.

41

Page 44

Bul. 937C Strain Gauge Converter Installation Instructions

Sensor data

Because the truck scale rests on 4 measuring cells the parameters of each individual measuring

cell must be combined: The following entries must

• Supply voltage:

Here the resulting total resistance of the parallel connection of the 4 sensors must be taken into

account. If the resulting resistance of the sensors connected in parallel falls below 100 Ω, a lower

supply voltage must be selected due to the maximum available current. The maximum permitted

supply voltage is calculated as follows:

Total resistance x 49 mA = maximum supply voltage

− 4 measuring cells with each 350 Ω = 87.5 Ω

− 87.5 Ω x 49 mA = 4.2875 V

Set the supply voltage to 4 V.

The maximum permitted total resistance of the sensors is 10 kΩ.

• Sensitivity:

The sensitivity of the individual cells can be accepted 1:1.

Example:

4 cells with 2 mV/V each, entry in Sensitivity = 2 mV/V

• Cell data:

Max. cell load: The cell load of the individual sensor must be multiplied by the number of sensors.

Example:

4 sensors with 15 t each, entry in Cell load = 60 tons).

Explanation:

If e. g. only one cell is loaded at its individual maximum load it will output its maximum voltage. The

other 3 senso

voltage source and results in a voltage drop. Only if all 4 cells are loaded at their respective

maximum loads will they output their respective maximum voltages equally which is then measured

in parallel by the Strain Gauge Converter. All uneven loads between those two extremes behave

linear, therefore the parallel connection can be considered as a single measuring cell.

rs are connected to this voltage and become consumers; this puts a load on the

be made in the menu Sensor:

42

Page 45

Bul. 937C Strain Gauge Converter Installation Instructions

Trigger inputs

One trigger input must be parameterized as "Tare" to enable a subsequent zero point setup.

Calibration

The calibration can be carried out offline or online.

Offline

Calibration without mechanical load is the simplest way of calibrating the Strain Gauge Converter.

However, inaccuracies are to be expected because the whole measuring chain is not included in the

calibration process.

With an empty weighing device setting a zero point for the whole system is possible via the input

parameterized as tare

only the origin is adjusted.

The Strain Gauge Converter is then calibrated. Because the measuring cells are normally calibrated

at factory and are very str

Online

The online calibration is more accurate than the offline calibration because it involves the whole

measuring chain 100%. The measuring cell is put under a defined load and the Strain Gauge

Con

verter calibrated to these points.

The cell returns with an empty weighing platform 1.43 mV. In t

Adjust > Zero point > Execute a zero point calibration is carried out, i. e. the 1.43 mV are allocated

to 0 kg which is now also displayed by the Strain Gauge Converter.

A defined weight must then be placed on the cell, e. g. 5 t.

Under the menu item Input > Calibration > Adjust > Weight the applied weight must now be entered

(5

t) and the calibration be carried out via Execute. The Strain Gauge Converter now displays 5 t.

The processes Zero point calibration and Adjust must always be carried out together, but the

sequence described above does not have to be adhered to (it is possible to calibrate Adjust and then

Zero point.

under "Trigger input". The characteristic of the weighing cell is retained and

ongly linear, the measuring values are calculated with great accuracy.

he menu item Input > Calibration >

43

Page 46

Bul. 937C Strain Gauge Converter Installation Instructions

However, because the total mass to be measured is greater, the range must also be entered|.

Under Input > Calibration > Range > Set the weight to be measured must be entered, in the example

35 t. With this setting the value 100 % will be displayed at 35 t if the unit is changed to %.

The

Strain Gauge Converter has now been calibrated including the whole measur

ing chain.

Outputs

Current output

The current output must only represent the net value (the weight of the load). In the menu Output >

I

> Gross/Net the option

out

The adjustable range relates to the maximum cell load. Because the maximum cell load is not

reached with a full tank (full truck = 20 t, maximum cell load = 60 t) the value 20 t must be

entered here.

Relay outputs

To prevent overloading a relay must be trigge

means that the relay must be parameterized as a limit value switch with the switching direction "Max";

swi

ching point the 20.5 t must be entered. As hysteresis a value of approx. 1 % of the range is

as a

t

recommended, i. e. 250 kg (0.25 t). The relay must energise once the switching point has been

exceeded, the direction of action must therefore be entered as "active".

To prevent the relay from switching during the tru

entered under the menu item Relay > Trip alarm > Delay. Limit overruns of less than 60 s duration

will then be ignored.

Net

must therefore be selected.

red as a limit value relay if 20.5 t is exceeded. This

c

k entering the scales a time of 60 s can be

Operation

An empty truck enters the scales. After short-circuiting the inputs of the trigger input previously

p

arameterized as "Tare" a zero point calibration is carried out. The truck is then loaded and the Strain

auge Converter displays only the weight of the load.

G

At the current output the weight of the

fully loaded truck.

for the

Via the RS 485 interface the weight of the load (net weight) can be queried by a PLS via the

command Get_value_ch_1 and be processed numerically.

load is represented by 4 m

A for the empty truck and 20 m

A

44

Page 47

Page 48

Publication 937-IN004A-EN-P - April 2014 (DIR 10001099008)

(DIR 10001176475)

Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A .

Loading...

Loading...