Page 1

937CU-AIHLP-DC1 Installation Instructions

HART Loop Converter

Page 2

Page 3

Symbols Used

Warn ing

Warn ing

Attention

Caution!

This symbol indicates a possible fault.

Non-observance could interrupt devices and any connected facilities or systems, or result in

their complete failure.

Bul. 937C HART Loop Converter Installation Instructions

Danger!

This symbol indicates an imminent danger.

Non-observance will result in personal injury or death.

This symbol warns of possible danger.

Failure to heed this warning may result in personal injury or death, or property

damage, including destruction.

Warning!

This symbol indicates a possible fault or danger.

Non-observance

This symbol warns the user of a possible f ault.

Failure to heed this warning can lead to total failure of the device and any other

connected equipment.

may cause personal injury or serious property damage.

Note

This symbol draws attention to important information.

1

Page 4

Safety Notes

Warn ing

Attention

Attention

Attention

Warn in g

Attention

Warn in g

Note

Note

Bul. 937C HART Loop Converter Installation Instructions

The HART Loop Converter must only be operated by trained personnel in

accordance with this handbook.

The protection of operating personnel and of the system is only ensured if the devices

are used in accordance with their intended purpose. Any other type of operation than

that described in this manual places the safety and functionality of the devices and

systems connected to them in question.

The devices may only be installed, connected, and adjusted by electrical professionals

outside the hazardous area.

If faults cannot be elimina ted, the devices must b e taken out of operation and protected

from being placed in service again inadvertently. Tampering with or making changes to

the devices is dangerous and therefore not permitted. They render the warranty void.

The responsibility for the adherence to local safety standards lies with the operator.

2

Page 5

Bul. 937C HART Loop Converter Installation Instructions

Reference to further documentation

Laws, standards, or directives applicable to the intended use must be observed. In

relation to hazardous areas, Directive 1999/92/EC must be observed.

The corresponding data sheets, declarations of conformity, EC-type-examination

certificates, certificates and Control Drawings if applicable (see data sheet) are

an integral part of this document. You can find this information under

www.ab.com.

Due to constant revisions, documentation is subject to permanent change. Please refer

only to the most up-to-date version, which can be found under www.ab.com.

Marking

HART Loop Converter

Certification under Pepperl+Fuchs GmbH

Lilienthalstrasse 200, 68307 Mannheim, Germany

KFD2-HLC-Ex1.D.2W (937CU-AIHLP-DC1)

BASEEFA 07 ATEX 0174 , for additional certifications, see www.ab.com

E II (1)GD [Ex ia] IIC, [Ex iaD]

Pepperl+Fuchs Statement of Conformity

E II 3G Ex nA II T4 X

Intended Use

The devices are only approved for appropriate and intended use. Ignoring these

instructions will void any warranty and absolve the manufacturer from any liability.

The device must only be operated in the ambient temperature range and at

the relative humidity (non-condensing) specified.

The de

vices are used in Control &Instrumentation (C&I) technology for the galvanic isolation

of C&I signals such as 20 mA and 10 V standard signals or alternatively for adapting or

standardizing signals. Devices that incorporate intrinsically safe circuit are used for

operating intrinsically safe field devices in hazardous areas.

3

Page 6

Improper Use

Protection of the operati

is not being used according to its intended purpose.

equipment is not suitable for isolating signals in high current

The

is noted

Mounting/Installation

Prior to mounting, installation, and commissioning o

familia

The device must not be installed at locations where corrosive vapors may be present. The

devices fulfill a degree of protection IP 20 according to IEC/EN 60529.

The devices are designed for use in pollution degree 2 and overvoltage category II as per

IEC/EN 60664-1.

If used in areas with higher pollution degree, the devices need to be protected accordingly.

Only use power supplies that provide protection against direct contact (e. g. SELV or

PELV) for the connection to power feed modules.

Observe the tightening torque of the terminal screws.

The installation instructions in accordance with IEC/EN 60079-14 must be observed.

Intrinsically safe circuits of associated apparatus (installed in safe areas) can be led into

hazardous areas, whereby special attention must be paid to maintain separation distances

to all non-intrinsically safe circuits according to the requirements in IEC/EN 60079-14.

All separation distances between two adjacent intrinsically safe circuits need to be

observed in accordance with IEC/EN 60079-14.

If "Ex i" protected circuits (intrinsically safe) were operated with non-intrinsically safe

circuits, they must no longer be used as "Ex i" protected circuits.

4

ng personnel and t

separately

r with the

corresponding dat

in the

device and carefully read the instruction manual.

h

7C HART Loop

Bul. 93

e overall system is not ensured if the product

asheet.

f the device you shou

ter

Conver

applications

Installation Instructions

unless

this

ld make

yourself

Page 7

Bul. 93

7C HART Loop

Converter Installation

Instructions

T

he respective

to e

devices with intrinsically safe circuits of associated apparatus (verification of intrinsic

safety). Make sure to observe IEC/EN 60079-14 and IEC/EN 60079-25.

If more channels of one

connection is made directly at the terminals of the device. When verifying the intrinsic

safety, the maximum values for the parallel connection must be considered.

peak values of the field device and the assoc

x

plosion protection should be considered when connecting intrinsically safe field

nected i

device are con

n parallel, make sure the parallel

iated apparatus with regard

Operation, Maintenance, Repair

he devices must not be repaired, changed or

T

product must always be replaced with an original device.

nipulated. If there

ma

Delivery, Transport, Disposal

C

heck the packaging and contents for damage.

Check if

Keep the original packaging. Always store and transport the

Alway

temperature (see data sheet) must be considered.

Disposing

in compliance with the applicable laws and guidelines of the respective country.

a

ve received every item and if the items received are the ones you ordered.

you h

n

s store the device in a clean a

of devices, packaging material, and possibly contained batteries must be

d dry environment. The permitted storage

device in the original packaging.

a defect, the

is

5

Page 8

Product Specifications

Function

The

HART Loop Converter is an isolated barrier suitable for intrinsically safe applications

The device supplies f

The device analyzes u

variables can be transformed into varying current signals from these four HART

variables. These signals are used to display the values via the analog inputs of the

process control system.

The device is easily configured by the use of key

software.

In addition to the current outputs, the device has two changeover contacts. These

changeover contacts can be programmed so that the changeover contacts function as

trip values for the HART variables

Bul. 937C HART Loop Converter Installation Instructions

ield devices and can be connected in parallel to existing HART circuits.

p to four HART variables (PV, SV, TV, QV). Three HART

pad or with the FDT configuration

6

Page 9

Product Specifications

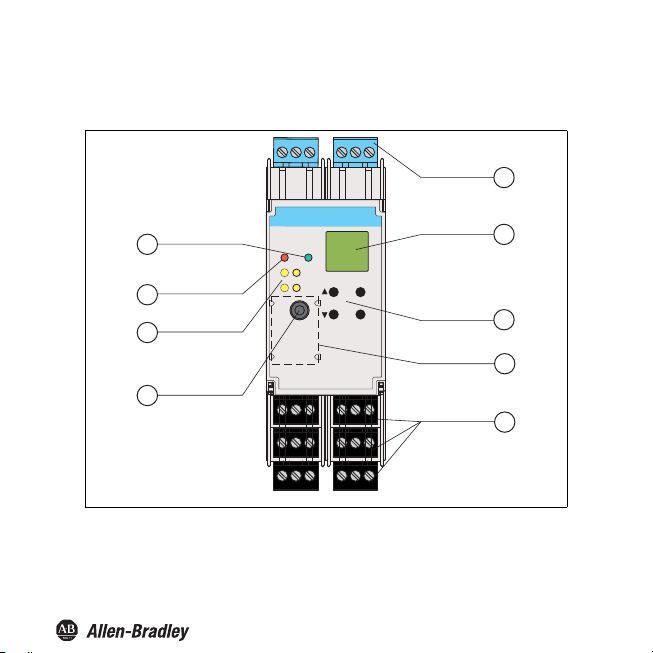

Assembly

Operating and indicating elements

9

8

7

6

OUT

RS232

1 2

ERR PWR

1 2

3 4

7 8 9

13

14 15

192021

Bul. 937C HART Loop Converter Installation Instructions

1

3

6

4 5

2

ESC

10 11 12

16

17 18

222324

OK

3

4

5

7

Page 10

Bul. 937C HART Loop Converter Installation Instructions

1 Removable terminals, blue

2

LC display Display for showing

3

Keypad

ESC

OK

4

Place for labeling

5

Removable terminals, green

6

Programming socket RS 232 serial interface for a connection to a PC for

7

yellow LEDs Outputs Out 1 ... 4, indicating relay status

8

red LEDs Indicating faults

9

green LEDs Indicating power supply

the measured values

the current output values

the fault messages

the parameterization mode

Four keys for selecting the displayed values,

output values and for setting the parameters of the

device Up

Down

Escape

Confirmation

setting parameters and diagnosis of the device using

FDT

the current

8

Page 11

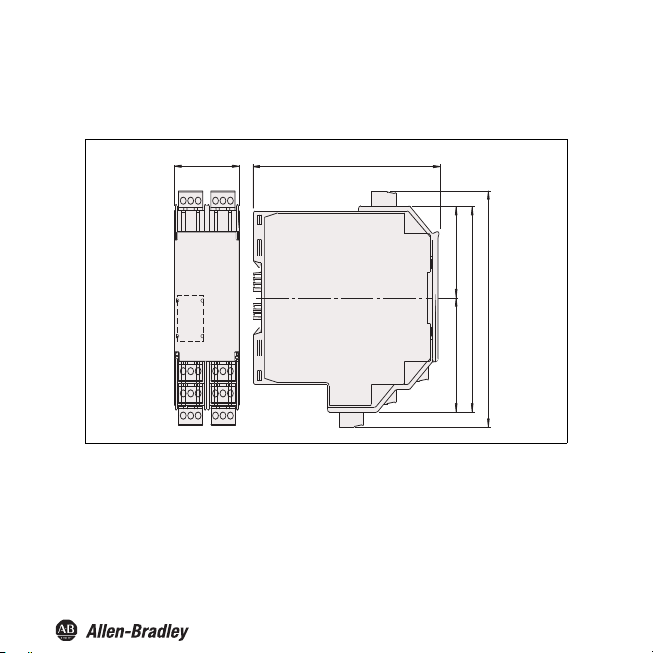

Product Specifications

Dimensions

Housi

Bul. 937C HART Loop Converter Installation Instructions

ng

40 mm

(1.6")

115 mm

(4.5'')

46 mm (1.82'')58 mm (2.28'')

104 mm (4.1'')

119 mm (4.7'')

Number of terminal blocks max. 10

Dimension drawing with screw terminals

When using screw terminals with test sockets the device is 124 mm (4.9 in) in height.

When using

spring terminals the device is 131 mm (5.16 in) in height.

9

Page 12

Bul. 937C HART Loop Converter Installation Instructions

Ins

tallation

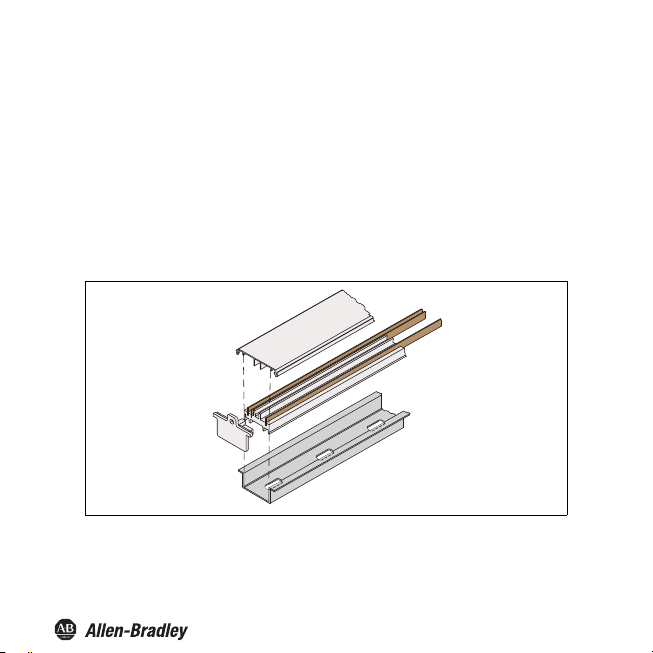

DIN Mounting Rail

The devices are mounted on a 35 mm DIN mounting rail according to EN 60715.

Example: DIN mounting rail(35 mm x 15 mm)

Power Rail

To reduce wiring and installation costs, Power Rail is the optimum solution. The

Rail is a DIN mounting rail with plastic insert, that delivers power to the devices (24 V

DC) and transfers bus signals and a collective error message.

The Power Rail is factory-equipped with cover

and open segments of the Power Rail. Thus, the Power Rail is protected from

contamination. Additionally the cover and end caps prevent that electrically conductive

parts come in contact with the Power Rail.

and end caps. These parts cover empty

Power

10

Page 13

Power Rail is available in two sizes:

Power Rail 937A-PR08 and 937A-PR20

Th

ree leads:

• two conductors for power

•

one conduct

or for collective error messaging

Power Rail

Bul. 937C HART Loop Converter Installation Instructions

11

Page 14

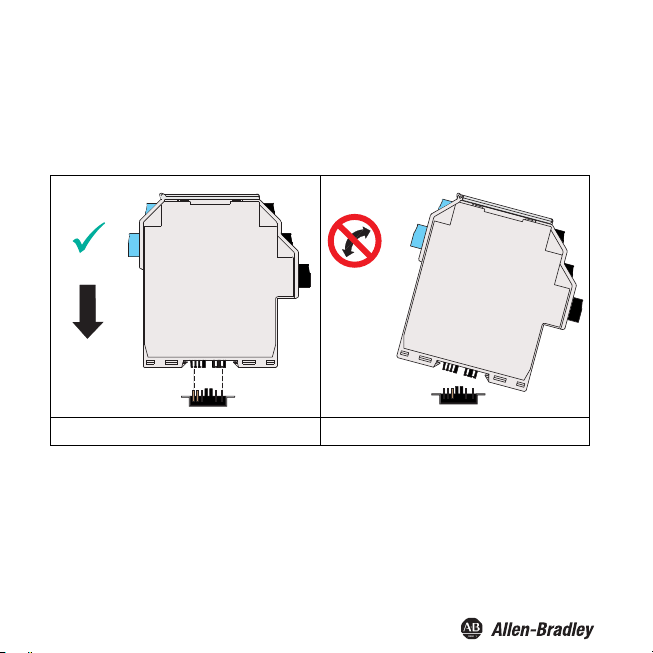

Mounting

Mounting the Isolated Barrier

Snap the device onto the DIN mounting rail in

figure below.

Bul. 937C HART Loop Converter Installation Instructions

a vertical downward movement. See

CORRECT: Device snapped on vertically.

Mounting the Terminal Blocks

The insulation o

replace the terminal blocks, observe the rated insulation voltage. If the rated voltage

greater than 50 V AC, proceed as follows:

1. Switch off

2. Connect the terminal blocks or disconnect the terminal blocks.

12

INCORRECT: Device snapped on from the side.

Can damage the contacts and cause the device to fail.

f the removable terminal blocks protect against direct contact. If you

the voltage.

Page 15

Bul. 937C HART Loop Converter Installation Instructions

Connection

The removable terminal blocks simplify connection and control cabinet construction

significantly. These

with core cross-sections of up to 2.5 mm² (14 AWG). The terminal blocks are coded

with red coding pins so misconnection of terminal blocks are eliminated.

terminal blocks offer adequate space for the connection of leads

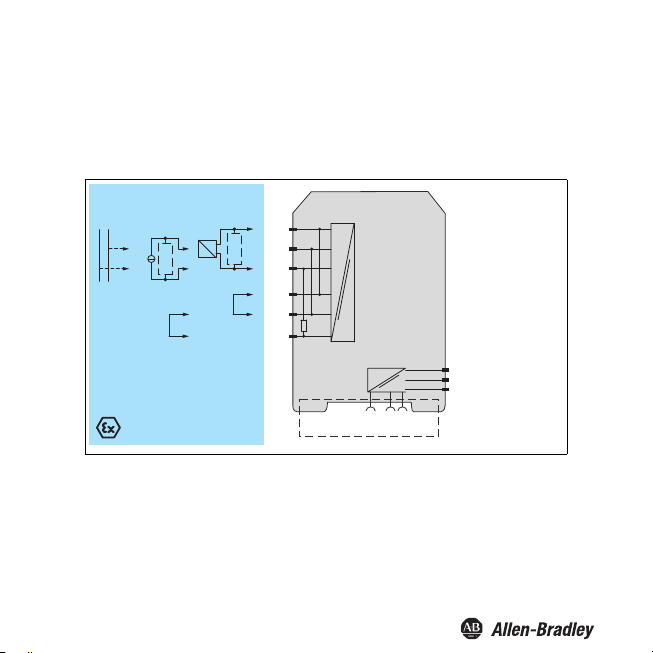

Input Connection (field circuit)

Connecting the Field Circuit

1. Connect the field circuit to the blue terminals.

2. Observe the tighteni

0.5Nm ...0.6Nm.

The intrinsically safe fie

lines in accordance with DIN EN 60079-14. You can connect the following field devices:

1.

any separately supplied HART current circuit with transmitter or positioner connected in

parallel

Connection to terminals 2 and 3

a HART-capable active curre

2.

transmitter

Connection to terminals 2 and 3 with bridge between terminals 5 and 6

3.

a 2-wire HART measuring transmitter, e. g

output signal of 4 mA ... 20 mA

The HART measuring transmitter is supplied by the isolated barrier

Connection to terminals 1 and 3

ng torque of the terminal screws. The tightening torque is

ld circuit may be routed in the hazardous area with connection

nt source, e. g., a separately supplied HART measuring

., HART measuring transmitter with an analog

with bridge between terminals 4 and 5

13

Page 16

HART

Bul. 937C HART Loop Converter Installation Instructions

+

+

-

+

mA

-

HART

1+

2+

HART

3-

4

5

250 Ω

6

Zone 0, 1, 2

Div. 1, 2

Power Rail

ERR 24 V DC

14

Page 17

Bul. 937C HART Loop Converter Installation Instructions

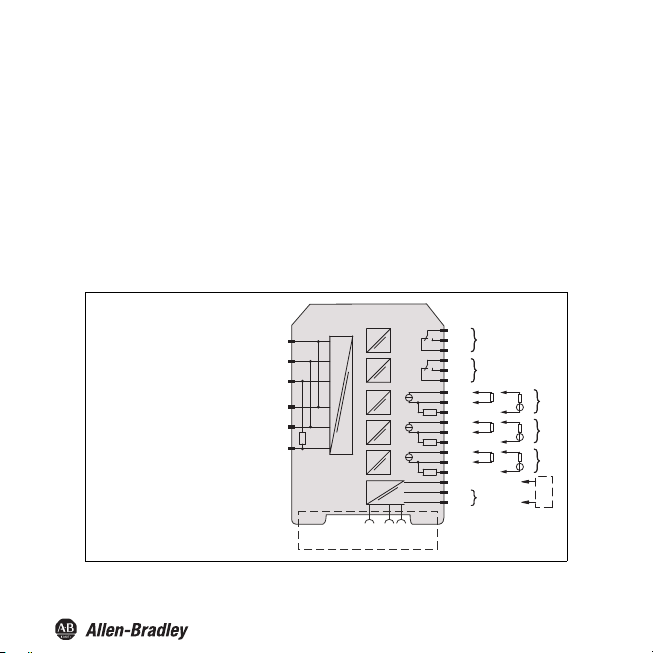

Connection

The following co

Connecting t

1. Connect the drive circuit to the green terminals.

2.

Terminals 10 ... 12: output I (relay 1 (change-over contact))

Terminals 16 ... 18: output II (relay 2 (change-over contact))

Terminals 7

Terminals 13 ... 15: output IV, current output as source (13/14) or

Terminals 19 .

Terminals 22/24: connection of HART handheld

Terminals 23/24: power supply 24 VDC

nnections are available:

he Drive Circuit

he tightening torque of the terminal screws. The tightening torque is 0.5 Nm...0.6 Nm

Note t

... 9: output III, current output as source (7/8) or sink (7/9)

.. 21: output V, current output as source (19/20) or sink (19/21)

250 ˜

ERR 24 V DC

Power Rail

sink (13/15)

10

I

11

12

16

17

II

18

7

13

14+

1519

20+

2122

23+

24-

8+

+

9-

+

+

24 V DC

mA

mA

mA

V

-

V

-

V

-

Zone 2

Div. 2

III

IV

V

HART

15

Page 18

Bul. 937C HART Loop Converter Installation Instructions

Connecting a HART Handheld to the Field Device

You have two options for connecting a HART handheld to

Connection to terminals 22/24 of the isolated barrier.

Connection to the field cables from the isolated barrier to the field

the field device:

device

Transmitting the HART signal using the

Description of HART Operations

Dynamic Query of Variables

Universal HART command 3 is used to query dynamic variables from the field device.

This quer

y is done either directly or by activating burst mode.

Burst Mode

Burst mode is the preferred method because this mode guarantees the fastest signal

transmission. The isolated barrier always tries to set the connected field device to

burst mode

The command for burst mode activation is sent to the field device under

following conditions:

after a restart or

after resetting the isolated barrier after restarting the field d

communication between the field device and isolated

been reestablished again after a time out.

16

current outputs of the isolated barrier is not possible.

the

evice. In the process,

barrier must have

Page 19

Bul. 937C HART Loop Converter Installation Instructions

Polling Mode (command and answer)

The isolated barrier deactivates the burst configuration of the field device. The

isolated barrier performs the field device query using HART command 3.

Procedure to Restore Burst Mode

ated barrier does not receive any more data from the field device in burst mode,

If the isol

the following actions are taken:

The isolated barrier switches to polling mode.

The isolated barrier checks whether another HART master has started in the query

signal circuit. If the

burst mode is interrupted.

If the iso

attempts to activate burst mode.

As soon as the isolated barrier receives a burs

isolated barrier switches from polling mode to burst

This process enables other HART masters to deactivate burst mode momentarily for

service work.

Time Out (communication loss)

When the tim

outputs switch to the defined safe state. Timeout can be adjusted.

isolated barrier has detected a HART master, the restoring of

lated barrier does not detect any other HART masters, the isolated barrier

t message from the field device, the

mode.

eout time has been exceeded in the absence of communication, all

17

Page 20

Bul. 937C HART Loop Converter Installation Instructions

Configuration

Caution!

Fault in the plant

Changing the device data changes the device function.

Before entering new device data, make sure the plant is not endangered by

Attention

changing the device data.

Configuring the Device

Configure the device using the buttons on

buttons for navigation. The following chapters contain more detailed information about

the menus.

The navigation principle is shown using the following example:

Iout1

OK →

← ESC

← ESC

← ESC

← ESC

← ESC

The menu items from the lowest menu level are outlined in bold.

the front side. Use the ,, ESC, and OK

Lowest menu level

Assignment

▼ ▲

Characteristic

▼ ▲

Start Value

▼ ▲

End Value

▼ ▲

OK →

← ESC

4 - 20 NE43

Fault Current

18

Page 21

Bul. 937C HART Loop Converter Installation Instructions

Parameterization Mode

After being switched on, the device is in display m

protection enabled, you must enter the password every time you transition from

display mode to parameterization mode.

Display mode

OK + ESC (simultaneously for 1 s) →

← ESC

Calling up Parameterization Mode

Press the OK and ESC buttons simultaneously for approx. 1

second.

The device changes from display mode to parameterization mode.

Exiting Parameterization Mode

1. Press the ESC once or multiple times.

level you are in.

The device changes from parameterization mode to display mode.

2. If you have not pressed a but

switches back automatically to display mode.

ton for 10 minutes in parameterization mode, the device

ode. If you have password

parameterization mode

▼ ▲

▼ ▲

▼

The number of times depends on which menu

Main menu

Unit

HARTcom

Output

Service

19

Page 22

Bul. 937C HART Loop Converter Installation Instructions

Password Protection

You can activate password protection to protect parameterization from unauthorized

s. Ifpassword protection is enabled, you can viewthe parameter settings but not

change

changethem. Password protection is deactivated during delivery.The passwordis preset

and cannotbechanged by the operator. The password is 1234. Information about enabling

password protection.

Entering the Password

1. As soon as you try to change th e parameterization, the device switches automat ically to

the input window for password access.

The first digit of the password flashes.

2. Set the first digit of the password using the and buttons.

3. Confirm your entry with OK.

The next digit flashes.

4. Repeat steps 2 and 3, until all digits have been entered.

5. Confirm your entry with OK.

If the password was correct, the device changes to parameterization mode. The

device can now be parameterized.

If the password was not correct, cancel password access and begin password entry

again using step 1.

Canceling Password Entry

You can cancel password entry at any time.

Press the ESC button.

The device switches to display mode.

20

Page 23

Entering Numbers

At the lowest menu level of the Parameter menu,

or entering a numerical value.

Parameter Current value, flashing

Selecting a Numerical Va

1. Select the para

the OK button.

2. Press

The current value flas

Select a value from the list of values using the and

3.

buttons.

The new value flashes. The value is not stored.

4. Confirm your sel

The new value does not flash. The

Entering a Numerical Value

1. Select the parameter where you want to ente

2. Press t

he OK button.

The current value flashes.

3.

To change the value in steps, press the or button. or

To change the value

button.

The new value flashes. The value is not stored.

4. Confirm your

The new value is stored.

lue

meter for which you want to change the numerical value.

ection with OK.

selection with OK.

Bul. 937C HART Loop Converter Installation Instructions

you have the option of selecting

OK →

← ESC

← ESC

← ESC

hes.

more quickly, press and hold the or

▼ ▲ ↓

New value, flashing,

not stored

OK ↓

New value, not flashing,

stored

value is stored.

r the numerical value.

21

Page 24

Entering Floating Point Figures

Bul. 937C HART Loop Converter Installation Instructions

At the lowest me

point figures.

The floating point figures can have the following structure:

nu level of the Parameter menu, you have the option of entering floating

Positive number Input Negative number Input

43210000 43.21 E06 -3210000 -3.21 E06

4321000 4321 E03 -321000 -321 E03

432100 432.1 E03 -32100 -32.1 E03

43210 43.21 E03 -3210 -3.21 E03

4321 432 1 E00 -321 -321 E00

432.1 432.1 E00 -32.1 -32.1 E00

43.21 43.21 E00 -3.21 -3.21 E00

1.234 1.234 E00

0.1234 123.4 E-03 -0.123 -123 E-03

0.01234

0.001234 1.234 E-03 -0.00123 -1.23 E-03

0.0001234 123.4 E-06 -0.000123 -123 E-06

loating point figure, you must enter the following parameters:

For a f

four digits of the mantissa (decimals) for

a minus sign and three digits for t

the position of t

the exponents

12.34 E-03 -0.0123 -12.3 E-03

positive numbers

he decimal point in or after the mantissa

he mantissa for negative numbers

22

Page 25

Bul. 937C HART Loop Converter Installation Instructions

Entering a Numerical Value

1. Select the parameter for which you want to enter the numerical value.

2. Press t

3. Press t

4.

5. Confir

6. Repeat steps 4 and 5, until all dig

7. Confirm your entry with OK.

8.

9. Confirm your entry with OK.

10.

11. Confirm your entry with OK.

he OK button.

The cur

rent value from the mantissa and exponent flashes.

he OK button.

With positive numbers, the first digit of the mantissa

flashes. With

To change the value in steps from 0 to 9, press the or button.

To enter a minus sign, press the until the f

Press t

point.

To specify the value of the exponent, press the or

the exponents from E-33 to E33 in increments of three.

negative numbers, the minus sign flashes.

irst digit is less than 0.

m your selection with OK.

The nex

t digit of the mantissa flashes.

its have been entered.

The position of the decimal point flashes.

he or button to specify the position of the decimal

The exponent flashes.

The new value is stored.

button. You can select

23

Page 26

Unit

Bul. 937C HART Loop Converter Installation Instructions

At the lowest men

for the HART variables.

auto

The device displays the unit which is

devices for the HART variables PV, SV, TV, QV.

custom

The device displays the unit which was defined by you for the HART variables PV,

SV, TV, QV in the Cu

u level of the Unit menu, you have the option of selecting the unit type

transferred from connected HART field

stom Tag menu.

Unit

OK →

← ESC

OK →

PV

▼

← ESC

▼ ▼

Ty p e

OK →

← ESC

auto

custom

OK →

← ESC

see below

← ESC

← ESC

← ESC

Custom Tag

OK →

SV

▼

TV

▼

QV

← ESC

OK →

← ESC

OK →

← ESC

same as PV

same as PV

same as PV

24

Page 27

Bul. 937C HART Loop Converter Installation Instructions

Changing the Custom Tag of HART Variables

1. Select the HART variable for which you wou

2. Press the

3. Select the Custom Tag menu.

4.

5. Confirm y

6.

7. Confirm your entry with OK.

8. Repeat steps

9.

10. Confirm your entry with OK.

Canceling the Value Input for HART Variables You

ca

n cancel the value entry at any time.

Press the ESC button.

OK button.

The device displays:

if a value has not be

If a value is defined: the insert mark on the first character, the following character,

and the symbol

To select one of eight possi

, press the or button.

The insert mark flashes.

To select a character, press

spaces.

To select the s

The new value for Custom Tag has been

en defined: the insert mark and the symbol

ble positions for the insert mark before the symbol

our selection with OK.

the or button.

4 and 7, until all characters have been entered. You can also define

ymbol , press the or button.

ld like to change the custom tag.

stored.

25

Page 28

HARTcom

Bul. 937C HART Loop Converter Installation Instructions

The HARTcom menu offers the

between device and field device. If available, the device activates burst mode of the

HART field device for the fastest possible communication. To query variables (PV, SV,

TV, QV, if present) the device uses the universal HART command 3.

HARTcom

option of specifying the method for communication

OK →

← ESC

Mode

▼

OK →

← ESC

secondary

▲▼

primary

TimeOut

← ESC

▼ ▲

ComControl auto detect

← ESC

OK →

5 s ... 60 s

← ESC

OK →

← ESC

▲▼

▼

▲▼

polling

burst

OK →

OK →

▼

0 ... 15

fixed

← ESC

← ESC

ShortAddress

LocateMethod

▲▼

▲▼

← ESC

← ESC

search

OK →

← ESC

Rebuild

← ESC

On Rebuild

▲▼

OFF Rebuild

26

Page 29

Bul. 937C HART Loop Converter Installation Instructions

Selecting a

Mode

The device functions as primary or secondary HART master according to the

HART standard. The device is compatible with each HART handheld and for every

other HART master.

1.

Use the or buttons to select whether the device should operate as a primary or

secondary HART master.

2. Confirm your selection with OK.

Defining TimeOut

If the device does not receive a valid HART message within the specified

time, the communication fault fault message is output.

1.

To change the time in steps, press the or buttons.

Set the time from 5 s ... 60 s in increments of 5 seconds.

2. Confirm your entry with OK.

Defining ComControl

You can specify the communication type between isolated barrier and field device. The

change in communication type is effective immediately. It is not necessary to restart the

isolated barrier.

1.

Select the type of communication using the or buttons.

2. Select auto detect.

If you select this type of communication, the burst configuration of the field

device is not changed.

3. Choose polling.

If you select this type of communication, the isolated barrier deactivates the

burst configuration of the field device. The isolated barrier performs the field device

query using HART command 3.

4. Choose burst.

If you choose this type of communication, the isolated barrier activates the

burst configuration of the field device for HART command 3.

5. Confirm your entry with OK.

27

Page 30

Editing device data: Input

Note!

Note that the field device can be put into burst mode, in accordance to the isolated

barrier configuration. This also applies when a different HART master is in the HART

circuit. If a different HART master changes the burst configuration of the field device, the

isolated barrier waits until the other HART master logs out of the HART circuit. The

isolated barrier assumes that the other HART master is logged off when it does not

send a message for approximately 60 s. After this period of time, the isolated barrier

activates the burst configuration of the field device.

Defining ShortAddress

The defined short address is needed for identification of the field device during

the localization phase.

1.

To enter a short address between 0 ... 15, press the or buttons.

2. Confirm your entry with OK.

Selecting LocateMethod

According to the HART standard, more than one HART field device can be present in a

HART circuit. But the device can communicate only with a single HART field device.

This HART field device is identified during the localization phase.

1.

Select the localization method with the or buttons.

2. Select fixed.

The device communicates with the field device that has a short address

defined under ShortAddress.

3. Choose search.

During booting, the device searches for the field device with the smallest short

address, beginning with the short address defined under ShortAdress. The address

of the field device found is stored by the device under ShortAddress. This

accelerates the device starting when it boots again.

4. Confirm your entry with OK.

28

Bul. 937C HART Loop Converter Installation Instructions

Page 31

Activating Rebuild

Bul. 937C HART Loop Converter Installation Instructions

If the connection to the field device has been lost, the localization phase can be

performed with Rebuild without switching the device off and on again.

1.

Select On

2. Conf

Rebuild with the or buttons.

irm your selection with OK.

The display On Rebuild flashes.

3. Pres

s the OK button.

The device searches for c

4. Pres

s the ESC button once or multiple times to switch to display mode.

onnected field devices when booting.

Current Outputs

In the Output menu, you have the option of defining current outputs 1 to 3 of the device.

The menu structure is identical for the three current outputs. Current output 1 is described

as an example. For information on relay contact outputs.

OK →

Output Assignment

← ESC

▼

Iout1

OK →

← ESC

Characteristic

Start Value see section

OK →

← ESC

▲▼ ▼

OK →

← ESC

▲▼

OK →

← ESC

▲▼

disabled

PV

▼

SV

▼

TV

▼

QV

4 - 20

unlimited

4 - 20 NE43

▲▼

29

Page 32

Editing device data: Input

Bul. 937C HART Loop Converter Installation Instructions

End Value see section

Fault Current

OK →

Iout2

▼

Iout3

▼

Rel1

▼

← ESC

OK →

← ESC

same as Iout1

same as Iout1

OK →

← ESC

▲▼

OK →

down

← ESC

▼

up

▼

hold

Rel2

cting an Assignment

Sele

The values of th

output. The number of available variables depends on the HART field device. When

selecting disabled, the downscale fault current of 0 mA or 2 mA is constantly present at

the current output, depending on the characteristic.

1.

2. Conf

e selected HART variable (PV, SV, TV, QV) are shown on the current

Select the desired HART variable using t

he or buttons.

irm your selection with OK.

30

Page 33

Editing device data: Input

Bul. 937C HART Loop Converter Installation Instructions

Defining a Characteristic

The choice of characteristic defines th

Measuring underranges or overranges outside the specified range cannot be analyzed.

If measuring ranges are undercut or exceeded, the minimum or maximum value is

issued constantly.

1.

Sele

ct the characteristic using the or buttons.

2. Select the characteristic 4 - 20 unlim

For the characteristic 4 - 20 unlimited, measuring underranges are

analyzed linearly up to 0

up to approx. 23 mA by the device.

3. Select the characteristic 4 - 20 NE43.

For the characteristic 4 - 20 NE43

up to 3.8 mA, and measuring overranges are analyzed linearly up to 20.5 mA by the

device.

4. Confirm your entry with OK.

e limits for measuring underrange and overrange.

ited.

mA, and measuring overranges are analyzed linearly

, measuring underranges are analyzed linearly

Defining the Start Value

Make sure during configuration that the start value is at l

If the start value does not meet this requirement, the start value will not be accepted by

the device.

1. Enter the start value as

"Entering Floating Point Figures" . The defined unit from the Unit

menu is used as the unit.

2. Confirm your entry with OK.

a floating point figure. For entering floating point figures, see

east 1% less than the end value.

Defining the End Value

Make sure during configuration that the end value is at least 1 % greater than the start value.

1. Enter the end value

see "Entering Floating Point Figures" . The defined unit from the Unit menu

is used as the unit.

2. Confirm your entry with OK.

as a floating point figure. For entering floating point figures,

31

Page 34

Bul. 937C HART Loop Converter Installation Instructions

Example

Characteristic 4 - 20 NE43, start value 2 bar, end value 10 bar

mA

20.5

20.0

4.0

3.8

0

1.9

2 10 bar

Defining the Fault Current (fault message)

The type of fault current chosen will define how the current output transmits the

fault message to the controller.

1.

Select the type of fault current using the

2. Select the fault current down.

The fault message is indicated by a low current value.

3. Select the fault current up.

The fault message is indicated by a high current value.

4. Select the fault current hold.

The last measured value before the fault occurred is stored.

5. Confirm your entry with OK.

or buttons.

10.25

32

Page 35

Bul. 937C HART Loop Converter Installation Instructions

Relay Contact Outputs

In the Output menu, you have the option of defining relay contact outputs 1 to 2 of the

device. The menu structure of the four relay contact outputs is identical. Relay contact

output 1 is described as an example.

OK →

← ESC

Iout1

▼ ▲

Iout2

▼ ▲

Iout3

▼ ▲

Rel1

▼ ▲

Rel2

OK →

← ESC

OK →

← ESC

Tr i p

▼ ▲

Faul t

same as Rel1

Output

33

Page 36

Bul. 937C HART Loop Converter Installation Instructions

Selecting Relay Contact Output Me

1.

Select the desired relay contact output using the or

Confirm your entry with OK.

2.

The relay contact output me

The active menu is marked as On.

3.

If you would li

4. Press

the OK button twice.

The active menu is marked as O

5. If you wo

34

uld like to cancel activation, press the ESC button after the first OK.

nus

buttons.

nus trip value and fault signal are displayed.

ke to activate the other menu, select this menu with or .

n. The submenu is displayed.

Page 37

Trip Value

Calling up a Trip Value

1.

Select the Tr

2. If th

3. If the trip value menu is not activated,

is marked as On.

ip value menu with the or buttons.

e trip value menu is activated, press the OK button once.

The Assignment submenu is dis

The Assignment submenu is displayed. T

Trip (On) disabled

Bul. 937C HART Loop Converter Installation Instructions

played.

press the OK button twice.

he trip value menu is activated and

OK → OK →

Assignment

← ESC ← ESC

▼ ▲ ▼

Min/Max

Tr i p see section

Hyteresis see section

OK →

← ESC

▲▼

OK →

← ESC

▲▼

OK →

← ESC

▲▼

PV

▼

SV

▼

TV

▼

QV

min

▼

max

35

Page 38

Bul. 937C HART Loop Converter Installation Instructions

OK →

Mode

▼ ▼

Restart Inhibit

▲▼

Delay

cting an Assignment

Sele

The values of the H

relay contact output. The number of available variables depends on the HART field

device. When disabled is selected, the relay remains constant in a de-energized state.

ART variables selected here (PV, SV, TV, QV) are monitored using a

← ESC

OK →

← ESC

OK →

← ESC

passive

active

On

▼

OFF

0 s ... 250 s

1.

Select the desired HART variable using the

irm your selection with OK.

2. Conf

or buttons.

Selecting the switching characteristics defines the switching direction and the direction

of operation. See applications.

1.

Select the switching direction mi

irm your selection with OK.

2. Conf

3.

ct the direction of operation passive or active with the or buttons.

Sele

irm your selection with OK.

4. Conf

n or max with the or buttons.

36

Page 39

Bul. 937C HART Loop Converter Installation Instructions

implement the following applications:

You can

Switching direction m

range, e. g., sounder on

over

Switching direction m

overrange, e

(pump, heater, ... on/off)

Switching direction min

underrange, e. g., sounder is on.

Switching direction min

underrange, e. g., pump, heating,

p, heater, ... off/on)

(pum

The exact switching characteristics of the device are shown in the following illustration:

Max – hysteresis

Min + hysteresis

ax, direction of operation active: alarm if there is a trip value

ax, direction of operation passive: switch off during trip value

. g., pump, heating, ... off, for larger hysteresis Min-Max operation

, direction of operation active: alarm if there is a trip value

, direction of operation passive: switch off during trip value

... off, for larger hysteresis Min-Max operation

Val ue

Max

Min

Switching direction max, mode active:

energized

de-energized

Switching direction max, mode passive:

energized

de-energized

Switching direction min, mode active:

energized

de-energized

Switching direction min, mode passive:

energized

de-energized

Time

37

Page 40

Bul. 937C HART Loop Converter Installation Instructions

Defining the Tr

1. Enter the starting point as a

2. Confirm your entry with OK.

ip Point

chap

ter 3.5.4. The defined unit from the Unit menu is used as the

unit. See chapter 3.5.5.

Defining Hysteresis

Make sure during input that the hysteresis is at least 1 %

This avoids "fluttering" of the relay.

1. Enter the hysteresis as a floating point figure. For en

chap

ter 3.5.4. The defined unit from the Unit menu is used as the

unit. See chapter 3.5.5.

2. Confirm your entry with OK.

Activating the Restart Inhibit

The restart inhibit is used to prevent momentary trip value violations from not being

noticed by operating personnel.

1.

Use the

2. Confi

rm your selection with OK.

The relay status is retained after switching the relay.

3. If you would like to reset the relay status, press the ESC

or button or re

The r

Defining the Response Delay

Inputting a response delay > 0 s prevents momentary trip value violations from triggering

an alarm.

1.

To change the time i

0 s ... 250 s in increments of 5 seconds.

2. Confirm your entry with OK.

38

floating point figure. For entering floating point figures, see

greater than the trip point.

tering floating point figures, see

or buttons to select On.

start the device.

elay is reset. Exception: there is a trip value violation.

n steps, press the or buttons. Set the time from

Page 41

Bul. 937C HART Loop Converter Installation Instructions

onse delay has the following effects:

Resp

When the value of the trip point is out

of time longer th

When the value of the trip point ± hysteresis is in range (not reached or exceeded) for a

period of time longer

Shorter overranges/underranges do not

The following illustration shows an example of switching

Max – hysteresis

an the delay time, the relay switches.

than the delay time, the relay switches back.

Val ue

Max

of range (exceeded or not reached) for a period

have an effect.

characteristics with response delay

Switching direction max, mode active, with delay:

energized

de-energized

Delay Delay

Time

39

Page 42

Bul. 937C HART Loop Converter Installation Instructions

Fault Message

Calling up a Fault Message

1.

2. If the fault message menu i

3. If the fault message menu i

or buttons to select the Fault message menu.

Use the

The Restart inhibit submenu is disp

s activated, press the OK button once.

layed.

s not activated, press the OK button twice.

The Restart inhibit submenu is displayed. The Fault

activated and is marked as On.

OK →

Restart InhibitFault (On)

← ESC

message menu is

OK →

← ESC

▼

Activating the Restart Inhibit

The restart inhibit is used to prevent momentary trip value violations from not being

noticed by operating personnel.

1.

2. Conf

3. If you would like to reset the relay status, press the ESC or

or buttons to select On.

Use the

irm your selection with OK.

The relay status is retained after switching the relay.

on or restart the device.

butt

y is reset. Exception: there is a fault message.

The rela

On

OFF

40

Page 43

Bul. 937C HART Loop Converter Installation Instructions

Service

Sele

In t

he Service menu, you have the option of specifying basic device parameters.

OK → OK →

Service ENG

Language

← ESC ← ESC

▼ ▲

▼

DE

← ESC

Passw ord

OK →

On Password

← ESC

▲▼

▲▼

OFF Password

← ESC

Reset

▼

OK →

← ESC

On Reset

▲▼

OFF Reset

OK →

← ESC

Ver si on

← ESC

Version No.

ct language

1.

2. Select EN

3. Conf

4. Select DE

5. Conf

or buttons to select which language is used by the device display.

Use the

G for English.

irm your selection with OK.

for German.

irm your selection with OK.

41

Page 44

Bul. 937C HART Loop Converter Installation Instructions

Activating Password Protection

To protect parameterization from unauthorized changes, you can enable

password protection. Information about password protection see chapter 3.5.2.

1.

Use the

2. To enable password protection,

3. Conf

4. To disable password protection, select Off Password.

5. Conf

Resetting the Device to

1.

2. Conf

or buttons to select the desired setting.

irm your selection with OK.

irm your selection with OK.

select On Password.

Factory Settings

the

or buttons to select On Reset.

Use

On Res

et flashes.

irm your selection with OK.

The device is reset to factory settings. All entries yo

in parameterization mode will be lost.

Displaying the Software Version

Use the or buttons to display the

version.

The software version of the de

vice software is displayed.

u have defined

42

Page 45

Editing device data: Default settings

Bul. 937C HART Loop Converter Installation Instructions

Operation

ators during Operation

Indic

The isolated barrier displays the following operating modes and fault messages

during operation.

LED Indicators

LED Status Description

Green LED O No power supply

Red LED Flashes briey Displays a single HART fault message received by the eld device

Yellow

LEDs

Flashes regularly Start-up phase, self-test

On Normal function

Flashes regularly Invalid HART data (missing commun ication or fault in the eld

On Device self-test of isolated barrier detected a fault

On Isolated barrier is in reset state, all other LEDs are o

On

device)

Output Out 1, relay energized

Output Out 2, relay energized

43

Page 46

Display Indicators

In normal operation, the display shows:

the current values of the HART

resent current output values for the three current outputs in mA

the p

urrent device status

the c

This display shows information about the device status of the field device (1 byte) and

t the response code (1 byte) of the field device. These two bytes are displayed in

abou

the first line of the display in hexadecimal form with the code RC on the left side.

In the ev

44

rrent setting of the type of communication

the cu

LOOP

•

he isolated ba

T

performs the field device query using the HART command 3.

• LOOP

The isolated barrier performs the field

•

LOOP

The iso

• LOOP Mixed

The isolated barrier performs the field

3 (polling). The field device is in burst mode, however it references a different

HART command than 3.

ent of a fault, the display shows:

Err Device Fault

Displays a device fault in

Err Communication

Displays a communication fault – r

Err Field Device Malfunction

Displays a field device failure – red LED

lashes.

f

Bul. 937C HART Loop Converter Installation Instructions

variables PV, SV, TV, QV in the selected unit

Locate

rrier reestablishes the HART circuit. The isolated barrier

Poll

device query using the HART command 3.

Burst

lated barrier receives the HART command 3 of the field device.

device query using the HART command

the isolated barrier – red LED lights up.

ed LED flashes.

Page 47

Bul. 937C HART Loop Converter Installation Instructions

Display Options for Current Output Values and HART Variables

To select the displayed measured

buttons.

To select units for measured values, use the Unit menu.

Every time the isolated barrier receives a HART command 3 message from the field

he display is updated.

device, t

The isolated barrier displays the current output values as a four-digit number. The

decimal point is set to provide the best possible resolution.

The isolated barrier shows the floating point value for HART variables as follows:

• If possible, as a fo

Negative values are shown on the device with three digits because of the

minus sign.

t is rounded as necessary. For example, the number 0.3456 is shown as

• A digi

0.346.

isolated barrier cannot show the floating point value, the mantissa and

• If the

exponent are shown in alternation.

values or current output values, use the and

ur-digit number with decimal point and without exponent.

Fault Message

The following table shows which fault message the current outputs send

based on the characteristic

Setting 4 - 20 unlimited 4 - 20 NE43

down 0 mA

up approx. 23 mA

hold Last measured value before the fault

Cannot be distinguished from falling

below the start value

Cannot be distinguished from the e nd

value being exceeded

2.0 mA

21.5 mA

to the controller,

45

Page 48

Bul. 937C HART Loop Converter Installation Instructions

Technical Specifications

Default Settings

The following table provides an overview of the default settings. Information about

resetting the device to the default setting see Service.

Tip

If the device parameters have changed, enter these changes in the "Custom Value"

column. This provides an overview of your individual device settings.

Menu Parameters Default setting Custom value

Unit

HARTcom Mode secondary

Output --- Iout1

Output --- Iout2

PV --- Type

SV --- Type auto

TV --- Type auto

QV ---Type

TimeOut 10 s

ComControl auto detect

ShortAddress 0

LocateMethod search

Assignment disabled

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

Assignment disabled

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

auto

auto

46

Page 49

Editing device data: Default settings

Menu Parameters Default setting Custom value

Output --- Iout3

Output --- Rel1 *

Output --- Rel2 *

Service Language ENG

Assignment disabled

Characteristic 4 - 20 NE43

Start value 0.000

End value 100.0

Fault current down

Trip value On (selected)

Trip value --- Assignment

Trip value --- Min/Max

Trip value --- Trip point

Trip value --- Hysteresis

Trip value --- Operating mode

Trip value --- Restart inhibit

Trip value --- Response delay

Fault message not selected

Trip value On (selected)

Trip value --- Assignment

Trip value --- Min/Max

Trip value --- Trip point

Trip value --- Hysteresis

Trip value --- Operating mode

Trip value --- Restart inhibit

Trip value --- Response delay

Fault message

Password OFF

Bul. 937C HART Loop Converter Installation Instructions

disabled

min

80.00

10.00

passive

OFF

0 s

disabled

min

80.00

10.00

passive

OFF

0 s

not selected

47

Page 50

Page 51

Page 52

Publication 937-IN003A-EN-P - April 2014 (DIR 10001099005) 814570

(DIR 10001176476)

Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A .

Loading...

Loading...