Page 1

Table of Contents

1 Introduction........................................................................................................1-1

What’s in the Manual...................................................................................................... 1-2

Conventions .............................................................................................................1-2

What is PLC-500™ A.I. Series™?.................................................................................. 1-4

Ladder Editing & Documentation Features............................................................... 1-4

Troubleshooting & Maintenance Functions............................................................... 1-5

What’s New in Version 8.04 ........................................................................................... 1-6

What’s New in Version 8.10 ........................................................................................... 1-6

Using PLC-500 A.I. ........................................................................................................ 1-7

Screen Layout........................................................................................................... 1-7

Starting PLC-500 A.I. .............................................................................................. 1-8

Selecting Menu Options ........................................................................................... 1-9

Using the Command Portal to Move Within PLC-500 A.I. ..................................... 1-10

Shortcut Keys......................................................................................................... 1-10

Context Sensitive Help ........................................................................................... 1-11

Exiting to DOS Temporarily................................................................................... 1-11

PLC-500 A.I. Optional Add-On Modules ...................................................................... 1-13

Other PLC-500 A.I. Compatible Products............................................................... 1-13

Complete A.I. Series Product Line .......................................................................... 1-14

Support for Your Rockwell Software Product................................................................. 1-15

Necessary Equipment.................................................................................................... 1-16

Basic Equipment .................................................................................................... 1-16

Optional Equipment ............................................................................................... 1-16

System Configuration.................................................................................................... 1-18

AUTOEXEC.BAT File........................................................................................... 1-18

CONFIG.SYS File.................................................................................................. 1-19

RAM Considerations.............................................................................................. 1-20

About Memory Managers.............................................................................................. 1-21

386MAX.SYS........................................................................................................ 1-21

QEMM.SYS........................................................................................................... 1-21

EMM386.EXE ....................................................................................................... 1-22

Communications Hardware ........................................................................................... 1-23

2 Handling Project Files........................................................................................2-1

Components of a Project File........................................................................................... 2-2

Program Files........................................................................................................... 2-3

Data Files................................................................................................................. 2-3

Page 2

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Database Files...........................................................................................................2-5

Processor Files..........................................................................................................2-5

Project ......................................................................................................................2-6

Creating a New Project....................................................................................................2-7

Modifying the SLC 500 Address...............................................................................2-9

Editing a New Project............................................................................................. 2-10

Selecting a Project File ..................................................................................................2-11

File List.................................................................................................................. 2-11

Search Specification................................................................................................2-12

Current Directory....................................................................................................2-13

Sorting the File List................................................................................................2-14

File Utilities...................................................................................................................2-15

Copying Files..........................................................................................................2-15

Renaming Files ....................................................................................................... 2-16

Deleting Files ......................................................................................................... 2-17

Backing Up Files ....................................................................................................2-17

Accessing the File Selector From the Offline Editor....................................................... 2-22

3 Configuring the SLC 500 CPU and I/O Modules.............................................. 3-1

CPU and I/O Configuration .............................................................................................3-2

Processor Type..........................................................................................................3-2

Rack Configuration...................................................................................................3-4

I/O Cards..................................................................................................................3-6

Exiting the Editor.....................................................................................................3-7

Processor Status Configuration ........................................................................................3-9

Fault Override at Powerup (S:1/8)........................................................................... 3-10

Load Memory Module on Memory Error (S:1/10)...................................................3-10

Load Memory Module Always (S:1/11)................................................................... 3-11

Load Memory Module and Run (S:1/12).................................................................3-11

Watchdog (S:3/8 - S:3/15) ...................................................................................... 3-12

I/O Slot Enables (S:11, S:12).................................................................................. 3-12

4 Data Table Addressing and Editing.................................................................. 4-1

Creating and Updating Data Table Files ..........................................................................4-2

Expanding a Data Table File.....................................................................................4-3

Adding a Data Table Address ...................................................................................4-3

Naming and Describing a Data Table File.................................................................4-4

Changing the File Access Mode................................................................................4-4

Protecting a Data Table File......................................................................................4-5

Deleting a Data Table File or Address .............................................................................4-7

Deleting All Program and Data Table Files...............................................................4-7

Clearing a Data Table File........................................................................................4-8

Clearing a Program File............................................................................................4-8

ii

Page 3

Table of Contents

Clearing All Program and Data Table Files.............................................................. 4-9

Monitoring Data Table Files.......................................................................................... 4-10

Monitoring Output and Input Files ......................................................................... 4-11

Monitoring the Processor Status File ...................................................................... 4-12

Monitoring the Global Status File ........................................................................... 4-14

Monitoring Binary Files ......................................................................................... 4-16

Monitoring Timer, Counter, and Control Files........................................................ 4-18

Monitoring Integer Files ......................................................................................... 4-19

Monitoring Floating Point Files .............................................................................. 4-21

Monitoring ASCII Files .......................................................................................... 4-21

Monitoring String Files.......................................................................................... 4-23

Multipoint Monitoring .................................................................................................. 4-25

Forcing................................................................................................................... 4-27

Selecting a SLC 500 Address or Operand...................................................................... 4-29

Addressing Modes.................................................................................................. 4-29

Symbolic Addressing.............................................................................................. 4-32

Short Addressing .................................................................................................... 4-33

Auto Addressing ........................................................................................................... 4-34

Attach Symbol to Existing Data File ....................................................................... 4-35

Attach Symbol to New Data File............................................................................. 4-36

Select Position........................................................................................................ 4-36

5 Ladder Program Basics .....................................................................................5-1

Ladder Programming ...................................................................................................... 5-2

A One-Rung Ladder Program.......................................................................................... 5-3

Logical State of Rungs..................................................................................................... 5-5

Series Logic (AND).................................................................................................. 5-6

Parallel Logic (OR) .................................................................................................. 5-6

A Four-Rung Ladder Program....................................................................................... 5-10

Operating Cycle (Simplified)......................................................................................... 5-13

6 Creating and Editing Ladder Logic...................................................................6-1

Creating Ladder Program Files........................................................................................ 6-2

Selecting a Program File to Edit...................................................................................... 6-5

Entering Instructions and Rungs ..................................................................................... 6-6

Moving the Cursor in the Ladder Logic.................................................................... 6-6

Select Mode (Append or Insert)................................................................................ 6-7

Enter the Instructions ............................................................................................... 6-8

Accept the Rung..................................................................................................... 6-10

Instruction Set Help ................................................................................................ 6-10

Changing a Rung .......................................................................................................... 6-12

Replace Mode ......................................................................................................... 6-12

Delete & Undelete Modes....................................................................................... 6-13

iii

Page 4

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Branching......................................................................................................................6-15

Creating Branches ..................................................................................................6-15

Adding Instructions to a Branch ............................................................................. 6-19

Extending Branches ................................................................................................ 6-20

Nesting Branches .................................................................................................... 6-21

Deleting a Branch...................................................................................................6-21

Undeleting a Branch...............................................................................................6-22

Re-using Blocks of Rungs (Libraries).............................................................................6-23

Block Copy and Cut................................................................................................6-23

Inserting a Block of Rungs ...................................................................................... 6-24

Saving a Block of Rungs.........................................................................................6-24

Loading a Saved Block of Rungs............................................................................. 6-26

Freeing the Scrap Buffer.........................................................................................6-31

Saving a Project File......................................................................................................6-32

Saving Your Project While Exiting.........................................................................6-32

Saving Your Project Within the Editor.................................................................... 6-39

Clearing and Deleting Program Files.............................................................................6-40

Clearing a Program File.......................................................................................... 6-40

Clearing a Data Table File......................................................................................6-40

Clearing All Program and Data Table Files.............................................................6-41

Deleting All Program and Data Table Files............................................................. 6-41

Resetting a Processor ..............................................................................................6-42

7 Changing Processor Modes ............................................................................. 7-1

Processor Modes..............................................................................................................7-2

Program Mode (SLC 5/03 and 5/04 only)..................................................................7-2

RemProg Mode.........................................................................................................7-2

Run Mode (SLC 5/03 and 5/04 only).........................................................................7-3

RemRun Mode ..........................................................................................................7-4

RemTest Mode..........................................................................................................7-5

Changing Remote Modes .................................................................................................7-6

Modifying a Windows 95 DOS Box..........................................................................7-8

8 Adding Descriptive Text to Ladder Logic ........................................................ 8-1

Describing Addresses.......................................................................................................8-3

Entering an Address Description While Defining an Instruction...............................8-4

Changing an Address Description .............................................................................8-5

Search for Undescribed Instructions..........................................................................8-6

Search and Replace Description Text........................................................................8-7

Describing Rungs ............................................................................................................8-9

Configuring the Rung Editor...................................................................................8-10

Creating Rung Descriptions with the Tags Feature..................................................8-11

Editing an Existing Rung Description ..................................................................... 8-13

iv

Page 5

Table of Contents

Describing Page Titles................................................................................................... 8-14

Creating a Page Title with the Tags Feature ........................................................... 8-14

Editing an Existing Page Title with the Tags Feature ............................................. 8-15

Revision History Display............................................................................................... 8-17

Device Code Assignment............................................................................................... 8-18

Program Note Editor ..................................................................................................... 8-19

9 Using the Database Editor.................................................................................9-1

The Databases................................................................................................................. 9-2

Address Descriptions................................................................................................ 9-2

Page Titles and Rung Descriptions ........................................................................... 9-3

Pseudo-addresses.............................................................................................................9-4

Instruction Addresses ............................................................................................... 9-4

Ladder Files ............................................................................................................. 9-4

Data Table Files ....................................................................................................... 9-4

Rung and Page Descriptions..................................................................................... 9-5

Editing Address Descriptions Using the Database Editor................................................. 9-6

Editing an Address Description................................................................................ 9-7

Using Wildcard Characters..................................................................................... 9-11

Search for Symbol or Address................................................................................. 9-11

Inserting an Address Record ................................................................................... 9-12

Deleting Address Records....................................................................................... 9-13

Copying Address Records....................................................................................... 9-15

Changing Addresses............................................................................................... 9-17

Editing Page Titles/Rung Descriptions Using the Database Editor................................. 9-19

Editing Page Titles/Rung Descriptions ................................................................... 9-20

Searching for a Page Title or Rung Description...................................................... 9-21

Inserting a Page Title or Rung Description............................................................. 9-22

Deleting a Page Title or Rung Description .............................................................. 9-22

Copying Page Titles/Rung Descriptions.................................................................. 9-25

Changing Page Title/Rung Description Addresses.................................................. 9-26

Configure Database Editor ............................................................................................ 9-28

10 Searching..........................................................................................................10-1

Accessing Search Functions .......................................................................................... 10-2

Search Parameters......................................................................................................... 10-3

Search for an Instruction Type, Address, Symbol, or Edit Zone..................................... 10-5

Search for a Rung Number............................................................................................ 10-8

Search by Cross Reference............................................................................................. 10-9

Search Using Page Titles (Advanced Diagnostics)........................................................10-11

Search and Replace Addresses and Instructions............................................................10-14

Search and Replace Description Text ...........................................................................10-17

v

Page 6

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

11 Creating and Printing Reports........................................................................ 11-1

Accessing the Reporting Options Menu .........................................................................11-2

Select Project for Reports...............................................................................................11-3

Generate Xref Data Base................................................................................................11-4

Configure Reports..........................................................................................................11-5

Margins..................................................................................................................11-7

Miscellaneous Options............................................................................................11-8

Select Printer Configuration....................................................................................11-9

Load or Save Report Configuration.......................................................................11-10

Select and Configure Report Types.............................................................................. 11-12

Ladder Report.......................................................................................................11-12

Cross Reference Report.........................................................................................11-21

Data Table Dump and Data Table Usage Reports..................................................11-25

Data Base Form.................................................................................................... 11-30

Unused Address Report......................................................................................... 11-31

Program File List Report....................................................................................... 11-31

Data File List Report............................................................................................. 11-32

Sequencer Data Report.......................................................................................... 11-33

Processor Config Report........................................................................................11-34

Rack Description Report....................................................................................... 11-35

I/O Parts List Report.............................................................................................11-37

Revision History ................................................................................................... 11-38

Table of Contents/Key...........................................................................................11-39

Configure Printer......................................................................................................... 11-40

Select a Printer Driver .......................................................................................... 11-40

Create a New Printer Driver.................................................................................. 11-40

Modify or Delete an Existing Printer Driver.......................................................... 11-44

HP LaserJet Information .......................................................................................11-45

Print Wire Labels.........................................................................................................11-48

Select Wire Label Type.........................................................................................11-48

Print Test Pattern .................................................................................................. 11-50

Print a Label Setup Pattern ................................................................................... 11-50

Print Labels for USED I/O Points..........................................................................11-51

Print Labels for ALL I/O Points............................................................................ 11-51

Edit and Print User Defined Labels.......................................................................11-51

Select Report Printing Order........................................................................................ 11-53

Print Reports ............................................................................................................... 11-55

Batch Printing .............................................................................................................11-56

12 Customizing PLC-500 A.I. ............................................................................... 12-1

User-Defined Help.........................................................................................................12-2

Accessing User-Defined Help..................................................................................12-2

vi

Page 7

Table of Contents

Adding Help Topics................................................................................................ 12-3

Keyboard Macros .......................................................................................................... 12-5

Defining a Macro ................................................................................................... 12-5

Using Macros......................................................................................................... 12-6

Deleting Macros..................................................................................................... 12-7

Loading a New Macro File ..................................................................................... 12-7

Changing a Macro’s Description ............................................................................ 12-8

Ladder Editor Configuration ......................................................................................... 12-9

Options................................................................................................................... 12-9

Configure Window Display ...................................................................................12-11

Function Key Text........................................................................................................12-14

Change Key Configuration...........................................................................................12-16

Programming Screen Size ............................................................................................12-18

Recommended Settings Under Windows................................................................12-19

Program Operational Parameters..................................................................................12-20

13 Program Compare............................................................................................ 13-1

Using the Compare Utility ............................................................................................. 13-2

14 Utility Options for Database Maintenance......................................................14-1

Rebuild Damaged Database........................................................................................... 14-2

Delete Unused Instruction Addresses ............................................................................. 14-3

Update Database to Current Revision ............................................................................ 14-5

Export Database............................................................................................................ 14-6

Export Descriptions and Symbols ........................................................................... 14-6

Export Rung Descriptions and Page Titles.............................................................. 14-8

Export Cross Reference Data.................................................................................. 14-9

Export to A-B Format ASCII Files ........................................................................14-10

Import Database...........................................................................................................14-11

Import Descriptions and Symbols ..........................................................................14-11

Import Rung Descriptions and Page Titles.............................................................14-11

Import Allen-Bradley Database..............................................................................14-12

Repair/Compact Database.............................................................................................14-14

15 Configuration for Online Communications .................................................... 15-1

A Network Example...................................................................................................... 15-2

Using WINtelligent LINX Drivers................................................................................. 15-5

Communication Device Configuration........................................................................... 15-6

Interface Hardware Type ............................................................................................... 15-8

Available Hardware Devices................................................................................... 15-9

Serial Port to A-B 1747-PIC Interface Converter ...................................................15-10

1784-KT/KT2 Communication Interface Modules.................................................15-11

1784-KL Interface Card.........................................................................................15-12

vii

Page 8

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

1784–KR Communication Board ..........................................................................15-13

1784-PCMK Interface Card ..................................................................................15-14

1784-KTX/KTXD Interface Card..........................................................................15-16

5/03, 5/04 CH0, 1770-KF3, 1747-KE.................................................................... 15-17

LINX Driver.........................................................................................................15-18

Serial Port to MicroLogix Controller..................................................................... 15-21

S-S Technologies, Inc. 5136-SD/SD2.................................................................... 15-22

A-B Ethernet DH+ to 1785-KA5........................................................................... 15-23

RSI LAN Logistics................................................................................................ 15-24

RSI LAN Logistics NETBIOS............................................................................... 15-25

Serial to 1770-KF2B.............................................................................................15-26

A-B Ethernet to DH+............................................................................................15-27

WinLinx Driver Ethernet to DH+ ......................................................................... 15-28

DH+ Direct Local/Remote Settings.............................................................................. 15-29

Find Baud, Parity, Protocol Settings.............................................................................15-32

Communications Port Considerations ................................................................... 15-32

Troubleshooting....................................................................................................15-33

Using Modems.............................................................................................................15-34

Modem Dialing..................................................................................................... 15-34

Terminal Utility Program...................................................................................... 15-39

Troubleshooting Communications ............................................................................... 15-41

Troubleshooting 1784-xx Communications...........................................................15-42

16 Channel Configuration.................................................................................... 16-1

Enabling/Disabling Channels ........................................................................................16-2

Channel 0’s Default Settings ......................................................................................... 16-4

Cable to Connect to Channel 0.......................................................................................16-5

Configuring Channel 0..................................................................................................16-6

System Mode Configuration.................................................................................... 16-9

User Mode Configuration...................................................................................... 16-15

Configuring Channel 1................................................................................................ 16-18

Parameters for DH-485 Master..............................................................................16-20

Parameters for DH+..............................................................................................16-20

17 Uploading and Downloading Ladder Programs............................................ 17-1

Downloading to a SLC 500 Processor............................................................................ 17-2

Checking for Errors................................................................................................ 17-2

Downloading ..........................................................................................................17-3

Upload Program from SLC 500 ..................................................................................... 17-4

Using Memory Modules (EEPROMs and UVPROMs)................................................... 17-6

Available PROMs................................................................................................... 17-6

Burning EEPROMs (Online Only) .......................................................................... 17-8

Read SLC-500 Program from EEPROM/UVPROM ..............................................17-11

viii

Page 9

Table of Contents

Translate from ACH to HEX .................................................................................17-11

18 Online Editing and Monitoring........................................................................18-1

Online Editing Modes ................................................................................................... 18-3

Online Editing Screen................................................................................................... 18-5

Edit Zone Markers.................................................................................................. 18-5

Status Line Display................................................................................................. 18-5

Effects of Online Editing on Your System ..................................................................... 18-7

System Impacts....................................................................................................... 18-7

Communication Break ............................................................................................ 18-7

Data Table Files ..................................................................................................... 18-7

Offline Editing of a Program Containing Edit Zones .............................................. 18-8

Performing an Online Edit ............................................................................................ 18-9

Accepting a Rung..................................................................................................18-11

Testing and Assembling Edits......................................................................................18-12

Testing Edits.........................................................................................................18-12

Untesting Edits ......................................................................................................18-14

Assembling Edits...................................................................................................18-14

Canceling Edits.....................................................................................................18-16

Effects of Online Editing on Your Project.....................................................................18-17

Run Mode Online Editing Effects..........................................................................18-17

Program Mode Online Editing Effects...................................................................18-19

Error Messages.............................................................................................................18-20

19 Troubleshooting and Diagnostics...................................................................19-1

Network Diagnostics (Who) .......................................................................................... 19-2

Who Listen............................................................................................................. 19-2

Who Active ............................................................................................................ 19-3

Processor Status ............................................................................................................ 19-6

Clearing a Faulted Processor ......................................................................................... 19-7

Cause and Effect Database............................................................................................. 19-8

Create Cause and Effect Database........................................................................... 19-8

Cross Reference Searching with a Cause and Effect Database................................. 19-9

Searching.....................................................................................................................19-11

Search Inputs Function..........................................................................................19-11

Cross Reference Search .........................................................................................19-13

Advanced Diagnostics..................................................................................................19-14

System Information......................................................................................................19-15

Verify Ladder Program and Data Table........................................................................19-17

I/O Forcing ..................................................................................................................19-18

Using Forces..........................................................................................................19-20

Entering Forces.....................................................................................................19-21

Force Table Monitor..............................................................................................19-26

ix

Page 10

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Toggle Bit Value ......................................................................................................... 19-28

Non-Sequential Rung Display ...................................................................................... 19-30

Histograms and Timing Charts....................................................................................19-32

Contact Histogram................................................................................................19-32

Timing Charts ...................................................................................................... 19-35

Special Instruction Display.......................................................................................... 19-37

Special Display: PID Instruction.......................................................................... 19-37

Special Display: MSG Instruction........................................................................ 19-39

Special Display: Sequencer Instructions...............................................................19-40

Instructions With Multiple Operands.................................................................... 19-42

Instructions With Single Operands........................................................................19-42

Custom Display ...........................................................................................................19-43

Custom Data Display Editing................................................................................ 19-44

Custom Data Display Monitoring.......................................................................... 19-47

Restore From Backups................................................................................................. 19-50

Restore Ladder Program ....................................................................................... 19-50

Restore Database................................................................................................... 19-51

Clean Directory/Remove Backups......................................................................... 19-52

20 Security System............................................................................................... 20-1

Security System Setup Options.......................................................................................20-3

Enabling the Security System.................................................................................. 20-4

Enabling User Logging...........................................................................................20-5

Printing the User Log..............................................................................................20-6

Clearing the User Log ............................................................................................. 20-6

Specifying the User Log Path..................................................................................20-6

Defining a New Master Password............................................................................20-7

User Setup Options........................................................................................................20-8

Adding a User Name and Rights.............................................................................20-9

Deleting a User.....................................................................................................20-11

Modifying Password and Rights For an Existing User ........................................... 20-11

Processor Security Options...........................................................................................20-13

Editing a Processor Password................................................................................ 20-13

Deleting a Processor Password..............................................................................20-14

Editing a Processor Master Password.................................................................... 20-14

Deleting a Processor Master Password .................................................................. 20-15

A PLC-500 A.I. File Extensions..............................................................................A-i

B Error Codes.........................................................................................................B-i

Types of Software Errors ................................................................................................ B-ii

Memory Errors................................................................................................................B-v

Checking the Amount of Memory Available .............................................................B-v

x

Page 11

Table of Contents

Freeing Base RAM..................................................................................................B-vi

Memory beyond 640K ...........................................................................................B-viii

DOS Errors....................................................................................................................B-ix

Error List .....................................................................................................................B-xiv

C ASCII Character Codes ......................................................................................C-i

ASCII Chart (character codes 0 - 127)..................................................................... C-ii

Extended ASCII Chart (character codes 128 - 255)................................................ C-iii

Glossary of ASCII Acronyms................................................................................... C-iv

D Bit & Word Mnemonics......................................................................................D-i

Address and Symbol Parsing........................................................................................... D-i

Sub-Element Word and Bit Mnemonics......................................................................... D-iii

xi

Page 12

1 Introduction

Welcome to Rockwell Software's PLC-500 A.I. Series or MicroLogix™ 1000 A.I.

Series software! You have acquired the most flexible and powerful DOS based

programming tool for the Allen-Bradley® MicroLogix™ 1000 controller and

SLC 500™ family of processors available. A.I. Series programs integrate

programming, documentation and troubleshooting in one package, making them a

complete solution for your PLC® programming needs.

This chapter explains the basic concept behind PLC-500 A.I. Series, and contains

information about:

• Using the manual

• Reaching Rockwell Software Tech Support

• Equipment you'll need to run the A.I. Series software

Page 13

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

What’s in the Manual?

With the PLC-500 A.I. or MicroLogix 1000 A.I. software, you should find the

following manuals:

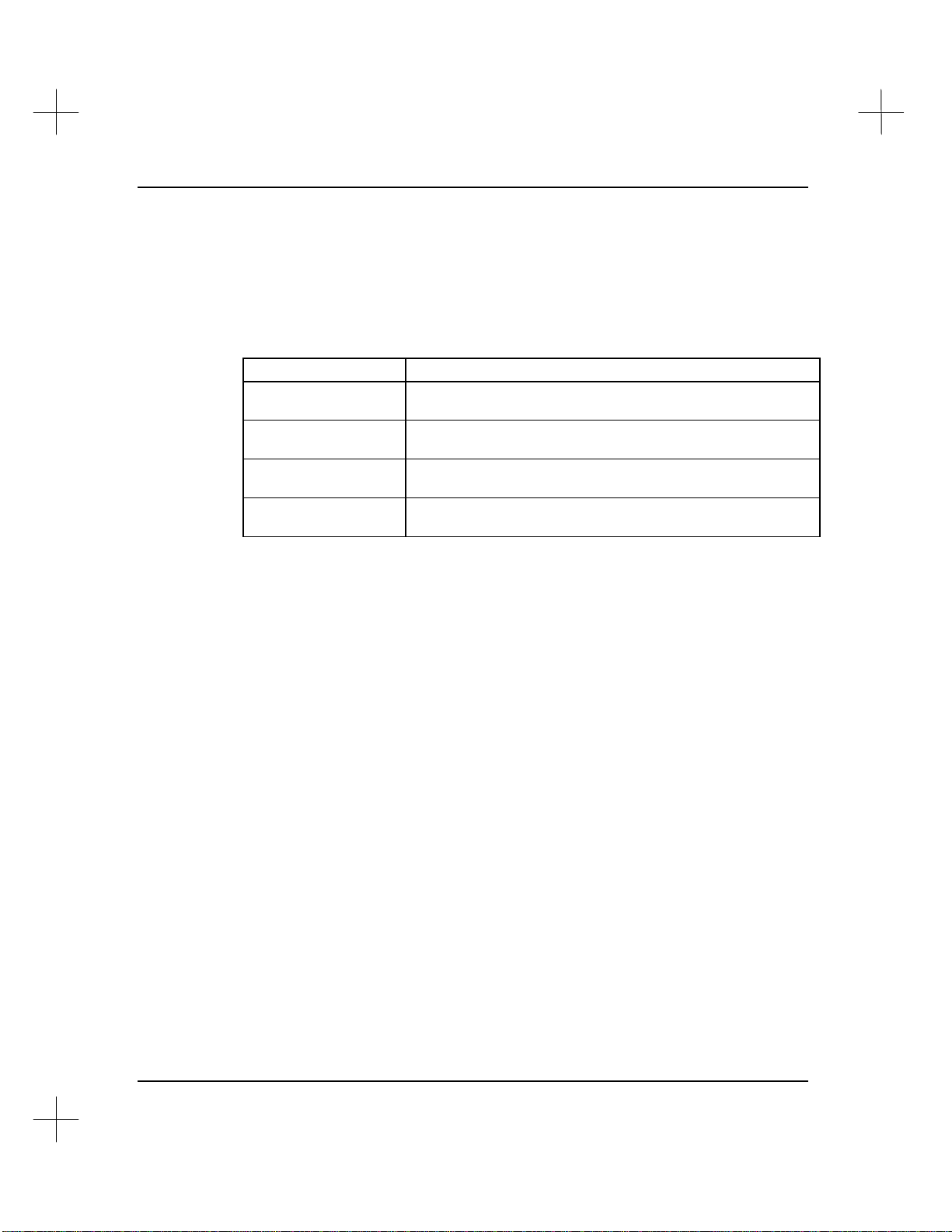

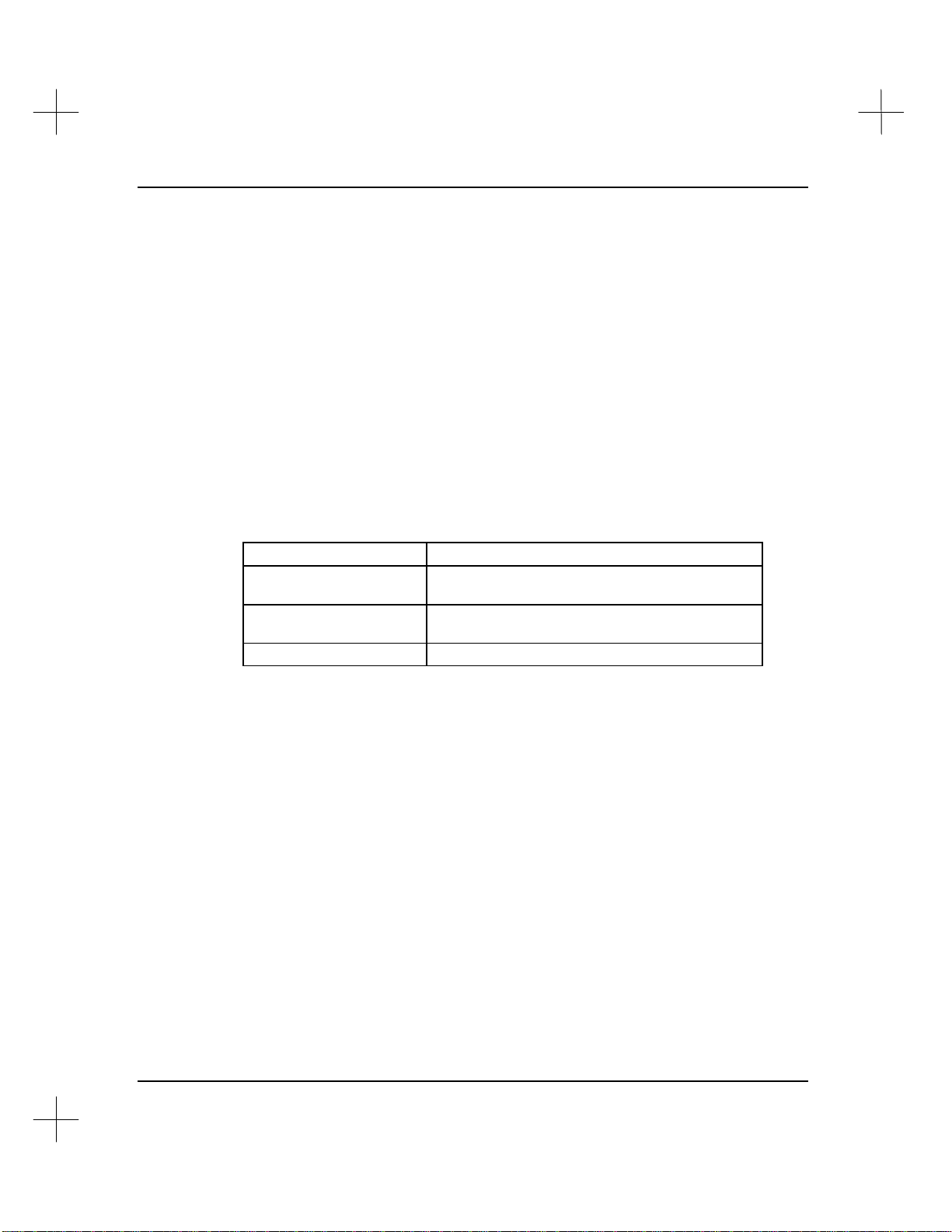

Manual: Content description:

Software Reference The manual you are reading now. Discusses the operation of

your Rockwell Software Inc. product.

Instruction Set

Reference

A.I. Series Installation

Guide

Product Support Guide Explains the various support options available from Rockwell

These manuals, along with the Allen-Bradley supplied SLC 500 Installation manual,

will describe the procedures for using your SLC 500 controller.

This manual provides you with the information you need to:

• use PLC-500 A.I. to create and edit projects

• download and run your programs on a SLC 500™ family or MicroLogix 1000™

processor

• use troubleshooting features of PLC-500 A.I.

• use passwords to secure your system

Discusses the functions of the SLC 500 ladder programming

instructions.

Explains how to install, move, update and remove your A.I.

Series software. Discusses copy protection considerations.

Software Inc. and how to access them.

Conventions

There are a few typographical conventions that can help you to better use this manual.

They are listed below.

• [BOLD] characters in brackets represent keystrokes used to execute a function.

• Bold characters represent menu choices.

• COURIER TEXT represents characters which you should type.

1-2

When more than one key is to be pressed at a time, the keys are separated by a

dash. For example, [Ctrl-F10] means hold down the [Ctrl] key and press the

[F10] key.

Page 14

Introduction

Advisory Messages

Note Note statements contain additional information that you may find valuable or should

pay special attention to.

Information in this format may be critical to the proper operation of the system.

Actions that may result in death, personal injury, or damage to equipment are noted

!

in this format.

1-3

Page 15

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

What is PLC-500 A.I. Series?

PLC-500 A.I. is a software program designed to create, edit, document, and

troubleshoot ladder logic programs for SLC 500 and MicroLogix processors.

PLC-500 A.I. contains many advanced editing, documentation, and troubleshooting

features. Also, PLC-500 A.I. is part of Rockwell Software's A.I. (Advanced Interface)

Series of programming software for the Allen-Bradley SLC 500, MicroLogix, and

PLC-2, 3, 5, and 5/250 platforms. All of these software packages have similar

interfaces; once you learn one package, you'll know them all!

Ladder Editing & Documentation Features

Ladder logic editing and documentation are the two primary functions of the

PLC-500 A.I. Series software. All SLC 500 processor functions are supported (e.g.,

ladder and data table creation, and monitoring functions). The PLC-500 A.I. software

enhances program development through the following features.

• auto-addressing and symbolic programming

• automatic program backup and revision history

• I/O module and rack configuration

• block of rung options: cut, copy, paste, read or write to disk, and indexed loading

• rung or instruction delete/undelete

• search and replace addresses or documentation text

• verify ladder program (detects programming and addressing errors)

• intelligent program and/or data table comparison

• 75 character instruction descriptions with 15 character symbol names

• 64K rung descriptions (approximately 16 pages per rung) and page titles

• full-screen database editor

• database import/export functions

• flexible program reporting options

• I/O wire label printing

• user configurable security system

• extensive context sensitive help database with information on both the

PLC-500 A.I. software and the SLC 500 Instruction Set

1-4

Page 16

• user-configurable help system allowing you to add your own help screens

Troubleshooting & Maintenance Functions

The PLC-500 A.I. Series software incorporates powerful diagnostic and troubleshooting

features to facilitate start-up and maintenance. These features include the following.

• DH-485, DH+, and station diagnostics

• program upload and download

• configurable search parameters and cross reference searching

• advanced diagnostics (section header) searching

• I/O forcing functions

• non-sequential rung display

• contact histograms

• timing charts

• custom display and data entry screens

Introduction

1-5

Page 17

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

What’s New in Version 8.04

PLC-500 A.I. version 8.04 adds the following features.

• Support for SLC 5/03 enhanced (OS301) and SLC 5/04 (OS400) processors

• MicroLogix 1000 controller programming

• ASCII, string and floating point data types

• Extended memory use

• Support for Allen-Bradley Ethernet, 1784 KTX/KTXD, and DH+ communications

• New driver added for 1784-PCMK card allowing you to use almost any vendor’s

card services and socket services

• Support for RSI LAN Logistics, 1770-KF2B communications

• Support for WinLinx Ethernet to DH+ communications (v8.05)

• Local/remote settings for DH+ devices (v8.05)

• I/O bit display mode can be set to either include or exclude the word number

• Custom display screens are stored in one file, *.CDL, and get backed up with the

project in the .IB1 file. Comments can be entered on custom display screens.

What’s New in Version 8.10

PLC-500 A.I. version 8.10 adds the following features.

• Support for SLC 5/03 OS302 and SLC 5/04 OS401 processors

• Indirect addressing (SLC 5/03 OS302 and SLC 5/04 OS401 processors only)

• Global Status File containing Global Status Words from each processor on the

DH+ network

• Short addresses

• New instructions including trigonometric and logarithmic instructions and

compute expressions

• Output cross referencing on selected instructions

• Multipoint monitoring and editing

• Configuration for SLC 5/03 and 5/04 DF1 Master

1-6

Page 18

Using PLC-500 A.I.

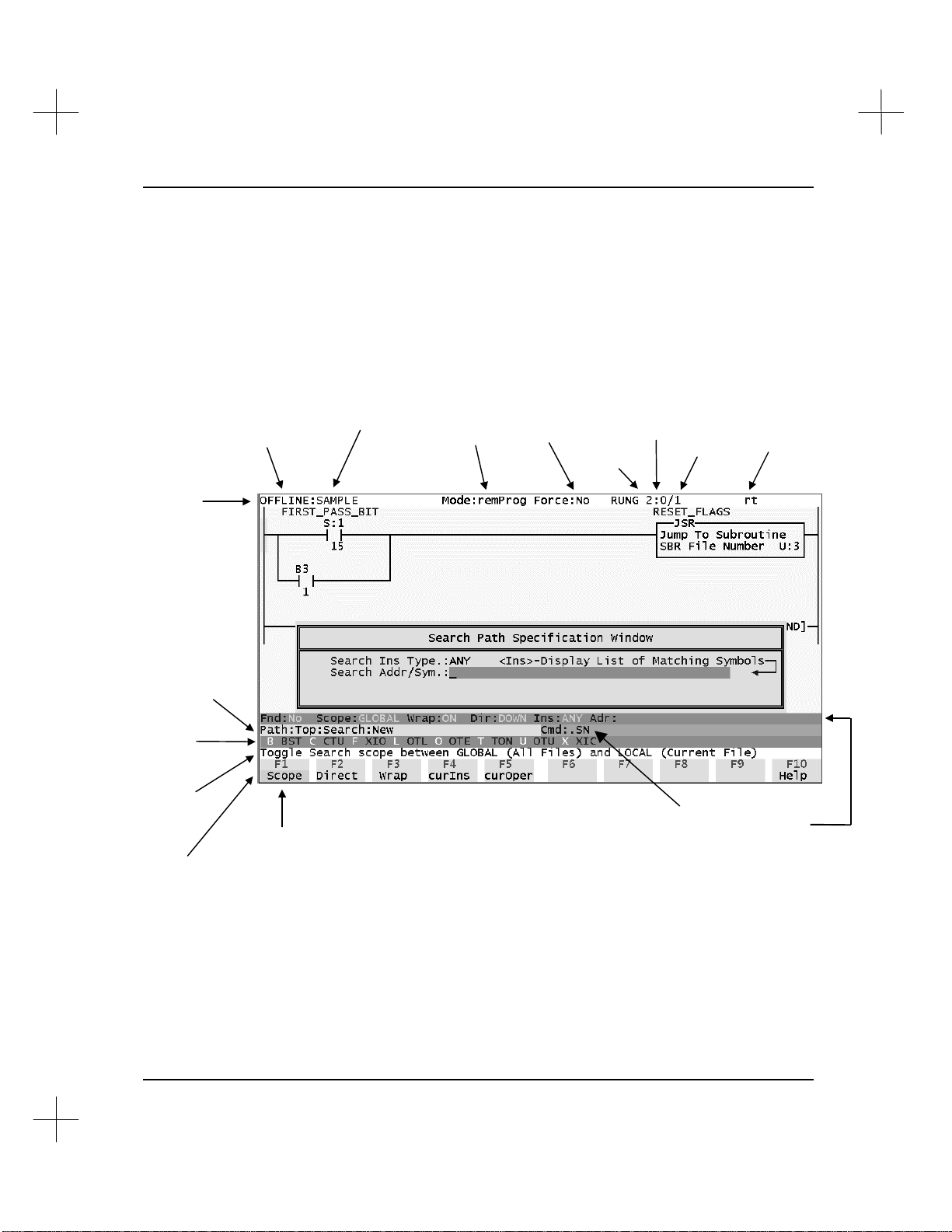

Menu Bar

Status Line

“New.”

rung

screen

This section presents the information available on a typical screen and explains how to

navigate within the software.

Introduction

Screen Layout

Command/Menu

Level. Current

position in menu

structure. The path

shown on this

screen indicates that

from the top menu

bar, “Search” was

selected and then

Instruction

Shortcut Key

Assignments

(Key List)

Function Key

Help (description

of highlighted

menu item)

offline or online

operation

highlighted

menu item

current project

processor

mode

forcing

status

current

program

Command Portal

keys to reach this

total

number of

rungs

Rung

comment and

page title

attached to

current rung

Search Mode

Configuration

(only appears

when searching)

Items in bold type may be moved or removed from the screen. Refer to Configure

Window Display in Chapter 12 - Customizing PLC-500 A.I.

1-7

Page 19

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

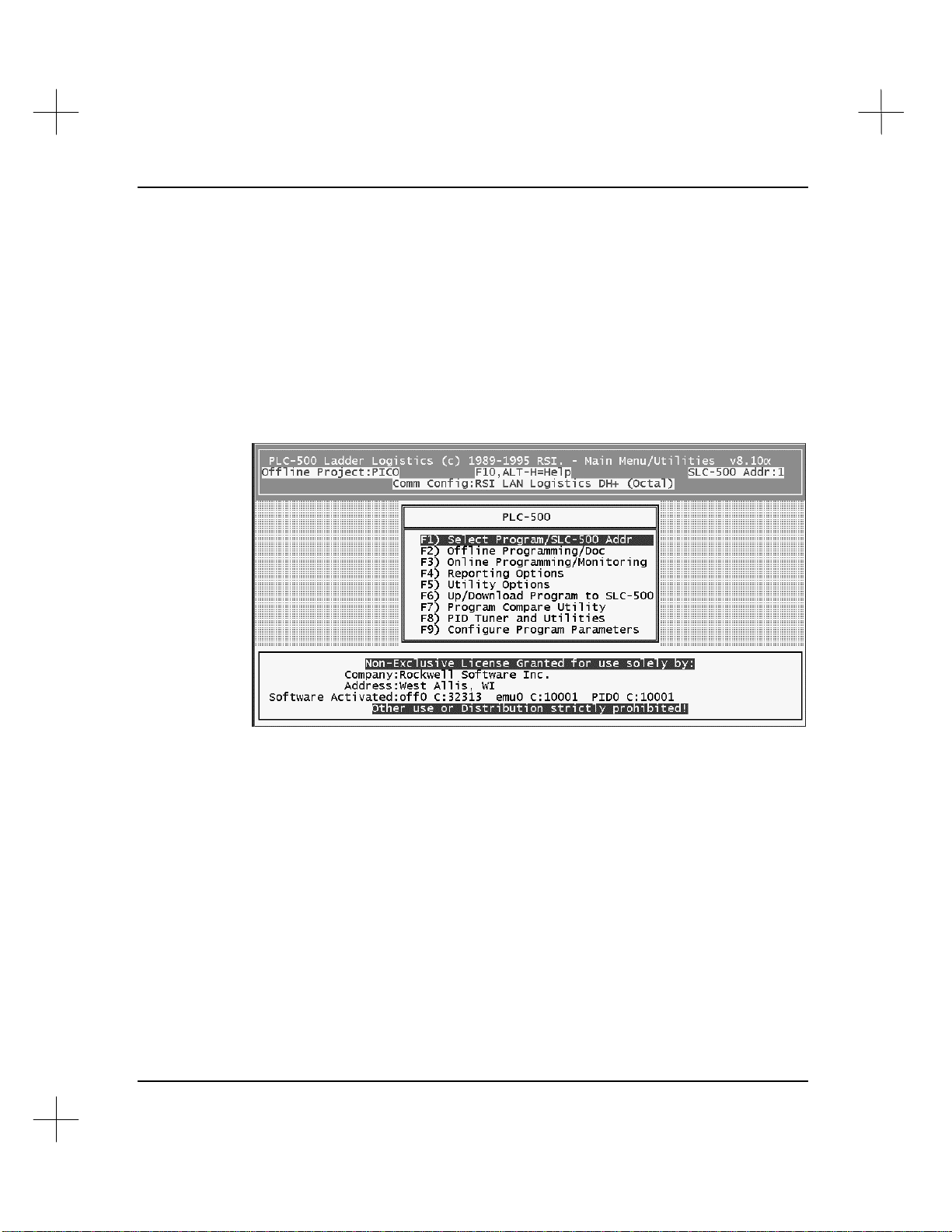

Starting PLC-500 A.I.

To run PLC-500 A.I.:

1. Change to the directory where PLC-500 A.I. has been installed. The default

directory is C:\SLC500. To change the directory, type

CD \SLC500 [Enter]

2. Enter the command to run the software. At the DOS prompt, type

AB500

The Main Menu will appear.

1-8

The second line from the top of the screen identifies the currently selected Project, on

the left, and the default network address for the processor, on the right.

The third line from the top of the screen displays the currently selected communication

device followed by the addressing mode of the processor station address on the DH+

(octal), DH-485 (decimal), or Ethernet (decimal) network.

The large box across the lower part of the screen shows your Company name and

Address (city and state or province). The currently activated software modules, the

drives they are installed on, and their serial numbers are displayed immediately below

those lines if the activation files are found on a local or network hard drive. For more

information on installing the software and on activation files, refer to the A.I. Series

Installation Guide.

Page 20

Introduction

Note Company name and address information is taken directly from our customer database.

Please contact Rockwell Software Technical Support at (414) 321-4266 to correct

spelling errors or incorrect registration information.

Selecting Menu Options

Menus in PLC-500 A.I. are displayed in a bar along the bottom of the screen as shown

under Screen Layout on page 1-7, or as a list in a box as seen on the Main Menu.

From a menu box, you can select an option in one of two ways:

• Press the function key associated with the desired option. For example, to select

Reporting Options from the menu above, press [F4].

• Use the arrow keys on your keyboard to move the highlighting to the desired

option, then press [Enter].

From a menu bar at the bottom of the screen, you can select an option in one of two

ways:

• Press the function key associated with the desired option. For example, to select

Help from the screen on the previous page, press [F10].

• Use the tab key on your keyboard to move the highlighting to the desired option,

then press [Enter].

To exit a menu (and move backwards through the menu structure) press [Esc].

1-9

Page 21

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Using the Command Portal to Move Within PLC-500 A.I.

The Command Portal provides a quick way of moving around within the PLC-500 A.I.

ladder editor. Notice on the screen on page 1-7 that each item on the function key

menu bar is in lower case except for one letter. This letter can be used in the Command

Portal to access that menu option.

Press [.] to access the Command Portal. A box will appear on the screen in which you

can type the letters corresponding to the menu bar items you want to select. Press

[Enter] to issue the command.

For example, you can access the data table memory map function any time you are

editing a project by typing .UM [Enter].

The Key Command Guide supplied with PLC-500 A.I. details the Command Portal

keys.

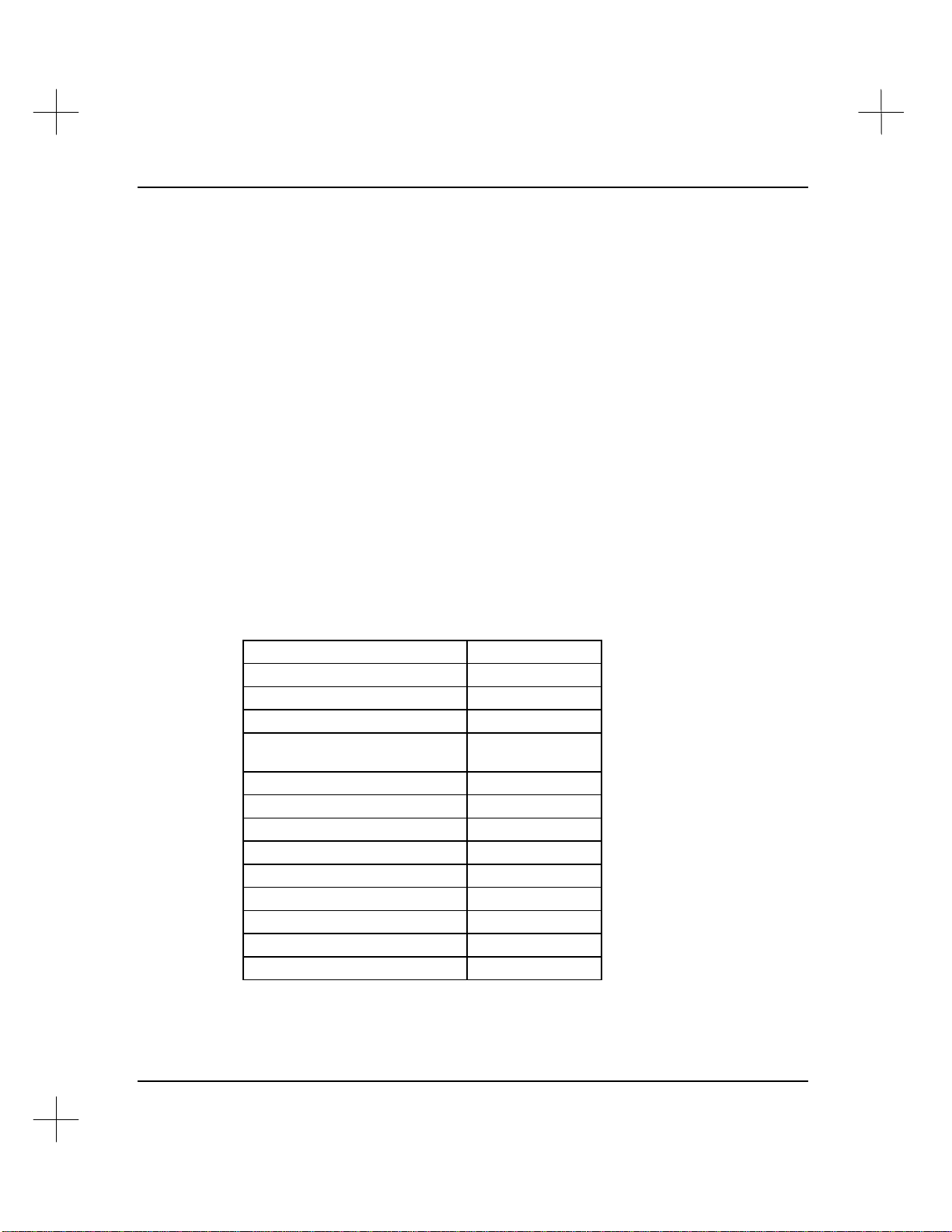

Shortcut Keys

Several key combinations allow you to move quickly from one feature of PLC-500 A.I.

to another.

1-10

Function Key Combination

display Program File list

display Data Table File list

toggle bit on/off

program key assignments (also

obtain instruction help)

display previous program file

change processor mode

access Display menu

access Note editor

force monitor

access user defined help

system information screen

display next program file

access Tag functions

[Shift-F1]

[Shift-F2]

[Shift-F5]

[Shift-F10]

[Alt- –] (dash)

[Alt-C]

[Alt-D]

[Alt-E]

[Alt-F]

[Alt-H]

[Alt-I]

[Alt-N]

[Alt-T]

Page 22

Context Sensitive Help

!

When you are using any Rockwell Software A.I. series product and wonder what to do

next, try pressing [F10]. The Context Sensitive Help system will display information

about where you are in the software and what your options are.

In some parts of the software, [F10] is used for some other function. In those

situations, [Ctrl-F10] is the help key.

When Help is displayed, use the [PgUp] and [PgDn] keys to move through the pages.

Press [Esc] to exit from the help system.

Exiting to DOS Temporarily

You can temporarily leave PLC-500 A.I. to go into DOS. This allows you to run other

DOS applications and utilities without closing PLC-500 A.I.

To shell into DOS:

1. From the Main Menu, select [F5] Utility Options. The system displays the Utility

Options menu.

Introduction

2. From this menu, select 12 Exit to DOS Temporarily. The system goes into DOS,

keeping PLC-500 A.I. resident.

Note To select menu options beyond [F9], use the cursor motion keys to highlight the option,

and press [Enter].

To return to PLC-500 A.I., type exit and press [Enter] at any DOS prompt.

Note You can also shell out to DOS while in the Offline or Online editor by selecting [F6]

Utility, [F9] Util2, [F1] Exit or by using the Command Portal keys .UUE.

Do not load any Terminate and Stay Resident programs (TSRs) while in the

temporary DOS session. This includes network shells.

Do not modify or delete any PLC-500 A.I. files during the temporary DOS session.

Do not turn off or reboot the computer during the temporary DOS session.

1-11

Page 23

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

You can prevent users from exiting temporarily to DOS by setting the NOEXITTODOS

environment variable. See the A.I. Series Installation Guide for a complete list of

environment variables.

Add the following line to a batch file that starts PLC-500 A.I. or to the

AUTOEXEC.BAT file. If you only want to prevent exiting to DOS for one use, type

the line at the DOS prompt before starting PLC-500 A.I.

SET NOEXITTODOS=1

You can also use the security system to prevent users from exiting temporarily to DOS.

See Chapter 20 - Security System.

1-12

Page 24

PLC-500 A.I. Optional Add-On Modules

Rockwell Software produces the following software packages that operate in

conjunction with PLC-500 A.I. series software. For more information about these

products, contact Rockwell Software or your Rockwell Software distributor.

PID Loop Tuner and Data Acquisition/Monitoring

Tune your SLC 5/02, 5/03, and 5/04 PID loops quickly and easily! The PID Tuner

collects and analyzes data from PID loops, and suggests optimum tuning parameters for

the loops. You can directly download the suggested parameters to the SLC 500

processor. The PID Tuner is available either as an add-on to the SLC 500 software, or

as a stand-alone system with its own menu and database import functions. (Not

available for the MicroLogix 1000 controllers.)

Processor Emulation Module

Run and test your ladder logic without going online! The Processor Emulation module

allows your computer to run the ladder logic without a programmable controller. (Not

available for the MicroLogix 1000 controllers.)

Introduction

Other PLC-500 A.I. Compatible Products

The following Rockwell Software products may be used with the PLC-500 A.I. software

or by themselves to simplify operations with the SLC 500. For more information on

these products, call Rockwell Software or your Rockwell Software distributor.

WINtelligent LINX™

Use Windows applications to monitor and write data to the SLC 500 data table!

WINtelligent LINX uses the Windows Dynamic Data Exchange (DDE) to transfer data

between SLC 500's (or PLC-5's, PLC-2's and PLC-3's) and DDE compatible Windows

applications, such as Microsoft Excel.

1-13

Page 25

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Complete A.I. Series Product Line

Do you use other Allen-Bradley PLC platforms? Rockwell Software produces versions

of the A.I. Series software for PLC-2 & 1774-PLC, PLC-3 & 3/10, PLC-5, and PLC5/250, each with the same features as the SLC 500 product. Contact your Rockwell

Software distributor or Rockwell Software Inc. for more information.

1-14

Page 26

Support for Your Rockwell Software Product

When you purchase a software package from Rockwell Software, you also purchase the

support services of the entire Rockwell Software staff. We understand the expense of

"down time," and we'll do whatever we can to solve any software (and yes, sometimes

hardware) problems you might encounter.

For information on product support and updates, please refer to the Product Support

Guide or call the Rockwell Software Support Information Line at (414) 321-4266.

Introduction

1-15

Page 27

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

Necessary Equipment

The following equipment is necessary to run the PLC-500 A.I. Series Ladder Logistics

Software. This information is written for running your A.I. Series software in DOS.

Exceptions and considerations for running under Windows™ operating systems

(Windows, Windows 95, and Windows NT™) are noted.

Basic Equipment

• IBM 386, 486, Pentium, or compatible

• DOS 5.0 or greater

• 4 M of RAM (16 M of RAM under Windows 95)

• One floppy and one hard disk drive

• Monochrome, EGA or VGA display

Note To run PLC-500 A.I. version 8.xx in monochrome, you must set an environment

variable. Add the following command to your autoexec.bat file or to a batch file that

starts PLC-500 A.I.

SET FORCEMONO=1

At least 3 M of Extended Memory must be available after loading all TSR’s and

device drivers, otherwise PLC-500 A.I. will run extremely slowly and some modules

!

Note If you are running under a Windows operating systems, be sure to shell to DOS to

(Online and Reporting) will return errors.

check your free memory.

Optional Equipment

• Printer (Epson compatibles and PCL laser printers, such as the HP Laserjet, are

recommended)

• Special video cards. Video drivers are supplied to take advantage of specific video

hardware for enhanced ladder logic display. These include:

§ EVEREX Micro Enhancer Deluxe EGA

§ Video 7 VGA

§ Paradise/ALR VGA Professional Card

1-16

Page 28

§ ATI VGA WONDER

§ ATI Graphic Solution Card - Hercules Mode

§ Orchid ProDesigner VGA/Plus

Introduction

1-17

Page 29

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

System Configuration

The following sections discuss the steps necessary to assure smooth software start-up

and operation. This information is written for running your A.I. Series software in

DOS. Exceptions and considerations for running under Windows™ operating systems

(Windows, Windows 95, and Windows NT™) are noted.

AUTOEXEC.BAT File

There are no required statements in the AUTOEXEC.BAT file. If you want to start the

PLC-500 A.I. software automatically when your computer is restarted, or to start the

software from a different batch file, make sure you include the following statements in

the batch file:

Statement Function

c:

CD\SLC500

AB500

Change to the drive where PLC-500 A.I. is

installed

Change to the directory where PLC-500 A.I. is

installed

Start PLC-500 A.I. (at the main menu)

1-18

You can also include a statement in the batch file that sets an environment variable

which places user configuration files in a directory other than the SLC500 directory.

This statement is required in multi-user and network installations.

The statement is:

SET PLCLL=C:\USER1

where C:\USER1 is an existing subdirectory. If you use the environment variable,

copy the file SLC5LL.DEF from the product directory (usually \SLC500) to the

specified directory. This loads the default status file word/bit descriptions

automatically when a new database is loaded. Refer to the A.I. Series Installation

Guide for more information on network and multi-user installation.

Page 30

If your system has 4 M of RAM (at least 8 M if using a Windows operating system),

you can add the following line to your AUTOEXEC.BAT file to improve software

performance.

C:\DOS\SMARTDRV.EXE 1024

Once you have added this line and rebooted your computer, check to make sure that at

least 3M of RAM is free. Type MEM [Enter] at the DOS prompt. Look at the number

under the “Free” column for “Extended (XMS)” memory; it should be greater than or

equal to 3072. If it is less than 3072, decrease the RAM that is being allocated to

SMARTDRV.EXE, reboot, and check again. (For additional information on

SMARTDRV.EXE, see your DOS manual or type help smartdrv.exe at the DOS

prompt.)

CONFIG.SYS File

This file must be in the root directory of the drive that your computer boots from

(typically drive “C” for a hard disk based system). This file is not needed if you are

using Windows 95 or NT.

The CONFIG.SYS file should contain the following statements:

Introduction

DEVICE=C:\DOS\HIMEM.SYS

DEVICE=C:\DOS\EMM386.EXE NOEMS

DOS=HIGH

FILES=40

BUFFERS=30

Note The path in your DEVICE statements may be slightly different if you are running

Windows, for example, C:\WINDOWS\HIMEM.SYS or C:\WFW\HIMEM.SYS.

Specifying quantities greater than those listed above are generally acceptable, but

additional buffers will subtract from your available RAM. Use a text editor to modify

or create the CONFIG.SYS file if necessary.

Note If the CONFIG.SYS file is added or edited, you will need to “warm boot” your

computer (press [Ctrl-Alt-Del]) before the changes take effect.

1-19

Page 31

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

RAM Considerations

PLC-500 A.I. requires an 80386 or faster processor and at least 3 M of extended

memory (XMS) free. If your system has less than 3 M of available RAM, the software

will be forced to use a swap file on your hard drive, which slows down many software

operations considerably.

Note If you are running under Windows, be sure to shell to DOS to check your free memory.

An ideal system would contain at least 8 M of RAM, where at least 3 M of RAM is

available after allocating some memory to a disk cache (such as MS-DOS’s Smartdrv).

The version of MS-DOS on your system also affects the amount of available RAM.

Although the software can run on MS-DOS 4.01 and 5.0, consider MS-DOS 6.0 as the

minimum version due to its advanced memory management features.

PLC-500 A.I. no longer has a minimum conventional RAM requirement of about

580K. As long as you have more than 500K free conventional memory (and at least 3

M of XMS memory free), you will be able to run the software without memory errors.

1-20

Page 32

About Memory Managers

A memory manager is a software program that manages the use of memory in your

computer. If your computer has any expanded memory (EMS) or extended memory

(XMS) installed, you may be using some sort of memory manager.

In certain configurations, some memory managers may conflict with the following DH-

485 and DH+ network interface cards.

• Allen-Bradley 1784-KT

• Allen-Bradley 1784-KTX

• Allen-Bradley 1784-KL

• Allen-Bradley 1784-KT2

• Allen-Bradley 1784-KR

• Allen-Bradley 1784-PCMK

• S-S Technologies, Inc. 5136-SD

• S-S Technologies, Inc. 5136-SD2

Introduction

This section describes how to avoid these conflicts.

386MAX.SYS

386MAX.SYS is a memory manager produced by Qualitas, Inc.

There is an easy method to avoiding 386MAX conflicts with the interface cards.

386MAX is shipped with a program called MAXIMIZE.EXE. This program examines

your computer and makes certain that it won’t create memory conflicts with your

existing hardware. If you use MAXIMIZE.EXE to configure 386MAX, you should

have no conflicts with your interface. See the 386MAX User’s Guide for more details.

QEMM.SYS

QEMM.SYS is a memory manager produced by Quarterdeck, Inc.

1-21

Page 33

MicroLogix 1000 and PLC-500 A.I. Series Software Reference

The command line in your CONFIG.SYS file which starts QEMM.SYS can be

modified to avoid your DH-485 and DH+ interface cards. Use the “EXCLUDE”

statement to tell QEMM.SYS which addresses to avoid. An example of a command

which avoids an Allen-Bradley 1784-KT with a memory address of D800 is shown

below.

DEVICE=C:\QEMM\QEMM.SYS EXCLUDE=DB00-DBFF

A second example shows a command which avoids the Allen-Bradley 1784-KL in the

A-B T47 Programming Terminal.

DEVICE=C:\QEMM\QEMM.SYS EXCLUDE=E000-E0FF

EMM386.EXE

EMM386.EXE is a memory manager provided with MS-DOS.

The command line in your CONFIG.SYS file which starts EMM386.EXE can be

modified to avoid your DH-485 and DH+ interface cards. Use the “EXCLUDE”

statement to tell EMM386.EXE which addresses to avoid. An example of a command

which avoids an Allen-Bradley 1784-KT with a memory address of D800 is shown

below.

1-22

DEVICE=C:\DOS\EMM386.EXE EXCLUDE=DB00-DBFF

A second example shows a command which avoids the Allen-Bradley 1784-KL in the

A-B T47 Programming Terminal.

DEVICE=C:\DOS\EMM386.EXE EXCLUDE=E000-E0FF

Page 34

Communications Hardware

You can transfer programs to and from the SLC 500 and monitor online operations

using a Rockwell Software product and one of the following protocols depending on

your SLC 500 processor: DH-485, DH+, or RS-232. Refer to Allen-Bradley’s data

sheets or hardware manuals to determine valid network configurations.

For information on configuring communications hardware to operate with

PLC-500 A.I., refer to Chapter 15 - Configuration for Online Communications.

NT Users: Only serial drivers (except the 1747-PIC) will work when running PLC-

500 A.I. under Windows NT. RSI is working on a version of the software that will

contain special drivers to communicate through RSLinx™. This will allow you to

communicate using any of the drivers available with RSLinx.

Introduction

1-23

Page 35

2 Handling Project Files

There is a specific order of events to follow when you create a ladder logic program

using PLC-500 A.I. This chapter will tell you how to accomplish step 1 below.