Page 1

Smart Motor

Manager

Bulletin 825

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this publication, those responsible

for the application and use of this control equipment must satisfy themselves that all

necessary steps have been taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are

intended solely for purposes of example. Since there are many variables and requirements

associated with any particular installation, Allen-Bradley does not assume responsibility or

liability (to include intellectual property liability) for actual use based upon the examples

shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation and Maintenance

of Solid-State Control (available from your local Allen-Bradley office), describes some important

differences between solid-state equipment and electromechanical devices that should be taken

into consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or part, without

written permission of Rockwell Automation, is prohibited.

Page 3

Throughout this manual we use notes to make you aware of safety considerations:

ATTENTION

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage or economic loss

!

Attention statements help you to:

• identify a hazard

• avoid a hazard

• recognize the consequences

IMPORTANT

Allen-Bradley is a trademark of Rockwell Automation

European Communities (EC) Directive Compliance

If this product has the CE mark it is approved for installation within the European Union and

EEA regions. It has been designed and tested to meet the following directives.

EMC Directive

Identifies information that is critical for successful application and

understanding of the product.

This product is tested to meet the Council Directive 89/336/EC Electromagnetic

Compatibility (EMC) by applying the following standards, in whole or in part, documented in

a technical construction file:

• EN 50081-2 EMC — Generic Emission Standard, Part 2 — Industrial Environment

• EN 50082-2 EMC — Generic Immunity Standard, Part 2 — Industrial Environment

This product is intended for use in an industrial environment.

Page 4

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by applying the

safety requirements of EN 61131-2 Programmable Controllers, Part 2 - Equipment

Requirements and Tests. For specific information required by EN 61131-2, refer to the

appropriate sections in this publication, as well as the Allen-Bradley publication Industrial

Automation Wiring and Grounding Guidelines For Noise Immunity, publication 1770-4.1.

This equipment is classified as open equipment and must be mounted in an enclosure during

operation to provide safety protection.

ATTENTION

!

In order to achieve maximum performance from this product, correct

transport, proper and competent storage and installation, and careful

operation and maintenance must be observed.

• The power supply must be switched off prior to any intervention

in the electrical or mechanical part of the equipment!

• In accordance with applicable rules, work on electrical equipment

or means of production may only be carried out by competent

electricians or suitably trained persons guided and supervised by

a competent electrician.

• The electrical equipment of a machine/plant must be inspected/

tested. Deficiencies, such as loose connections or scorched

cables, must be eliminated immediately.

• The Bulletin 825 Smart Motor Manager features supervision and

protection functions that can automatically switch devices off,

bringing motors to a standstill. Motors can also be stopped by

mechanical blockage, as well as mains failures and voltage

fluctuations.

• In case of functional disturbances, the machine/plant must be

switched off and protected and the disturbance eliminated

immediately.

• The elimination of a disturbance may cause the motor to restart.

This may endanger persons or damage equipment. The user must

take the necessary safety measures to avoid this type of

occurrence.

• Sufficient safety distance must be maintained where wireless

equipment (walkie-talkies, cordless and mobile phones) is used.

Page 5

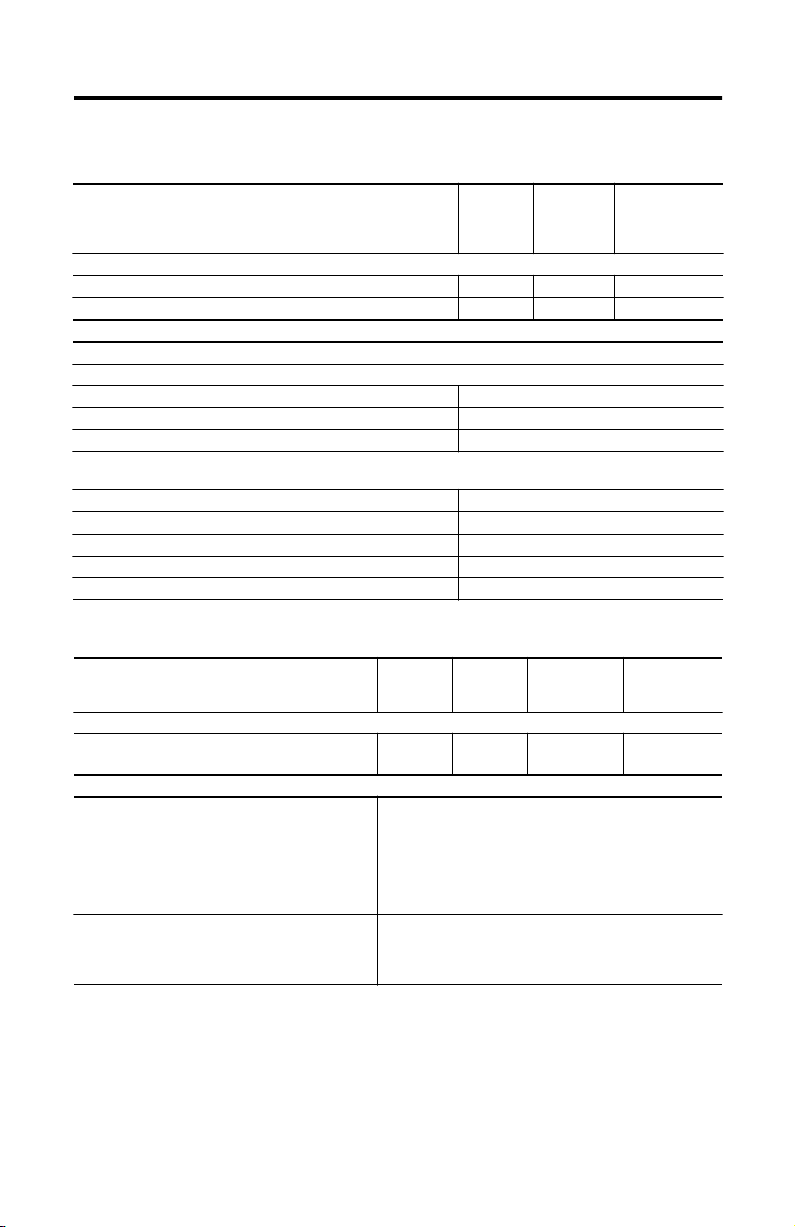

Table of Contents

Chapter 1 —

Why Have an Electronic Control and Protection System? . . . . . . . . . . . . 1-1

Operational Demands of the Motor/Drive . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Temperature Rise . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Motor Operating Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Current and Temperature Curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Limiting Temperatures, Insulation Classes . . . . . . . . . . . . . . . . . . . . . 1-4

Operational Requirements for Installation. . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Personnel and Installation Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Bulletin 825 Smart Motor Manager

as an Automation Component . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2 —

System Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

System Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Modular Design. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operating Elements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Specifications— Basic Unit and Converter Module . . . . . . . . . . . . . . . . . 2-5

Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Main Current Transformers for the Motor Circuit. . . . . . . . . . . . . . 2-10

Core Balance Current Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Short-Circuit Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Response Supply Voltage Failure. . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Automatic Recognition of Converter Module . . . . . . . . . . . . . . . . . . . . . 2-13

Introduction

Equipment Description

Chapter 3 —

Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Actual Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Set Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Recorded Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Functions

Publication 825-UM001B-EN-P January 2001

Page 6

ii Table of Contents

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Selecting the Setting/Display Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Setting the Operation Parameters (Set Values) . . . . . . . . . . . . . . . . . . 3-5

Indications of Actual Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Indications of Recorded Values (Statistics) . . . . . . . . . . . . . . . . . . . . . 3-8

Test Button. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Function Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Functions of the Basic Unit (Cat. No. 825-M…). . . . . . . . . . . . . . . . . . . 3-16

Thermal Overload. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Adjustable Ratio of Cooling Constants . . . . . . . . . . . . . . . . . . . . . . . 3-17

Indication of the Time to Tripping . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Indication of the Time until the Thermal Trip can be Reset . . . . . . 3-18

Adjustable Setting Characteristic . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Asymmetry (Phase Unbalance) and Phase Failure . . . . . . . . . . . . . . 3-22

High Overload and Jam . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Underload . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Earth (Ground) Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Limiting the Number of Starts per Hour (Start Lockout). . . . . . . . . 3-33

Monitoring the Starting Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34

Warm Start. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-35

Emergency Override of Thermal Trip (Emergency Start) . . . . . . . . 3-38

LED Alarm and Trip Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-39

Connection of the Main Relay (MR) . . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Connection of the Alarm Relay (AL). . . . . . . . . . . . . . . . . . . . . . . . . 3-40

Alarm Relay AL. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Function of the Cat. No. 825-MST Option Card. . . . . . . . . . . . . . . . . . . 3-42

Short-Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Earth (Ground) Fault Protection with a Core Balance Current

Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

Stalling During Start . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-44

PTC Thermistor Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Analog Output for Thermal Load or

Motor Temperature (PT100 Max.). . . . . . . . . . . . . . . . . . . . . . . . . . . 3-48

Analog Output for Motor Current. . . . . . . . . . . . . . . . . . . . . . . . . . . 3-50

Control Inputs #1 and #2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-51

Switching to a Second Rated Current . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Publication 825-UM001B-EN-P January 2001

Page 7

Table of Contents iii

Functions of the Cat. No. 825-MLV Option Card . . . . . . . . . . . . . . . . . 3-53

Phase Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-53

Phase Failure (Based on Voltage Measurement). . . . . . . . . . . . . . . . 3-54

Star-Delta (Wye-Delta) Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

Functions of the Cat. No. 825-MMV Option Card. . . . . . . . . . . . . . . . . 3-56

PT100 (100Ω Platinum) Temperature Sensor (RTD) . . . . . . . . . . . 3-56

PT100 #7 Temperature Sensor (RTD) . . . . . . . . . . . . . . . . . . . . . . . 3-57

Chapter 4 —

Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Flush Mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Mounting Position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Surface Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Converter Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Thermal Utilization Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Installation and Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Main Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Control Circuits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Chapter 5 —

Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Main Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Special Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Operating Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Chapter 6 —

Checking the Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Checking the Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Checking the Installation with the Control Voltage Applied. . . . . . . . . . . 6-2

Switching on the Control Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Checking the Set Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Motor Current. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Locked Rotor or Starting Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Locked Rotor Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Assembly and Installation

Setting the Operational Parameters

Commissioning and Operation

Publication 825-UM001B-EN-P January 2001

Page 8

iv Table of Contents

Programming, Setup, and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Starting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Operating. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Chapter 7 —

General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Checking without Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Functional Check with the Test Button . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Indication of Recorded Values. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Checking with Test Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Test Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Chapter 8 —

Alarm, Warning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Procedure when Alarm/Warning Picks Up. . . . . . . . . . . . . . . . . . . . . 8-1

Trip . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Procedure if “ALARM” does not Reset . . . . . . . . . . . . . . . . . . . . . . . 8-8

Procedure if “TRIP” cannot be Reset . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

Chapter 9 —

Bulletin 825 Smart Motor Manager with Contactors. . . . . . . . . . . . . . . . . 9-1

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Star-Delta Starter with Bulletin 825 Smart Motor Manager. . . . . . . . . . . . 9-3

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Short-Circuit Protection of Medium/High-Voltage Motors. . . . . . . . . . . 9-4

Main Circuit (with Cat. No. 825-MST Option Card) . . . . . . . . . . . . . 9-4

Control Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Two-Speed Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Two-Speed Motor: 0.5 A < Speed I < 20 A < Speed II < 180 A. . . . . . . 9-7

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Two-Speed Motors with Primary Current Transformer . . . . . . . . . . . . . . 9-8

Primary Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Separately Ventilated Motors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Testing and Maintenance

Error Diagnosis and Troubleshooting

Applications/Wiring

Publication 825-UM001B-EN-P January 2001

Page 9

Table of Contents v

Basic Unit and Converter Module with Primary Current Transformer

and Core Balance Current Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Basic Unit and Converter Module with Core Balance Current

Transformer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Motors with Low Idling Current (< 20%

Main Circuit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-11

Connecting the PT100 Temperature Sensors Using the

2/3/4-Conductor Technique. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-12

Basic Unit and Converter Module with Primary Current Transformer,

2-Phase Current Evaluation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-13

Time/Current Characteristic of Bulletin825 Smart Motor Manager . . . 9-14

) . . . . . . . . . . . . . . . . . . . . . . 9-11

e

Chapter 10 —

References

Figures

Figure 1.1Bulletin 825 Smart Motor Manager. . . . . . . . . . . . . . . . . 1-1

Figure 1.2Operating Characteristics of an AC Motor. . . . . . . . . . . 1-3

Figure 1.3 AC Current Profile of a Motor Starting

Direct-on-Line . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1.4 Temperature Rise Characteristics

of Motor Windings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Figure 1.5 Reduction in Average Life (EM) of a Motor

when Winding is Continuously Overheated. . . . . . . . . . 1-5

Figure 2.1 Modular Design of the Bulletin 825

Smart Motor Manager . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Figure 2.2Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Figure 2.3Front View with Operating Elements. . . . . . . . . . . . . . . 2-4

Figure3.1Setting Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure3.2Menu Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Figure3.3Entering a Data Value . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Figure3.4Selecting the Actual Values . . . . . . . . . . . . . . . . . . . . . . . 3-7

Figure3.5Selecting Recorded Data . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Figure3.6Basic Unit Test Button . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Figure 3.7 Two-Body Simulation of the Heating Up

of a Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Figure3.8Trip Characteristic (10…30s). . . . . . . . . . . . . . . . . . . . 3-19

Publication 825-UM001B-EN-P January 2001

Page 10

vi Table of Contents

Figure3.9Trip Characteristics (40…100 s) . . . . . . . . . . . . . . . . . . 3-20

Figure 3.10 Reduction in Permissible Motor Output

Due to Voltage Asymmetry per IEC and NEMA . . . . 3-23

Figure3.11Function of High Overload and Jam Protection . . . . . 3-24

Figure3.12Function of Underload Protection . . . . . . . . . . . . . . . . 3-26

Figure3.133-Phase Current Detection . . . . . . . . . . . . . . . . . . . . . . 3-27

Figure3.14Example of 2-Phase Current Sensing . . . . . . . . . . . . . . 3-28

Figure 3.15 Isolated Network: Earth Fault

on the Network Side . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-31

Figure 3.16 Network Earthed through a High Impedance

Earth Fault on the Network Side . . . . . . . . . . . . . . . . . 3-31

Figure 3.17 Isolated network: Earth (Ground) Fault on the Leads

on the Motor Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Figure 3.18 Network Earthed through a High Impedance:

Earth (Ground) Fault on the Motor Leads. . . . . . . . . . 3-32

Figure 3.19 Isolated Network: Earth (Ground) Fault

in the Motor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-32

Figure 3.20 Network Earthed through a High Impedance:

Earth (Ground) Fault on the Motor. . . . . . . . . . . . . . . 3-32

Figure3.21Limiting the Number of Starts per Hour . . . . . . . . . . . 3-33

Figure3.22Monitoring Starting Time . . . . . . . . . . . . . . . . . . . . . . . 3-34

Figure 3.23 Current and Temperature Curves for Warm and

Cold Motor Starts and the Smart Motor Manager

Tripping Limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-36

Figure 3.24 Example for t6x

= 10 s and

e

Warm Trip Time= 70% . . . . . . . . . . . . . . . . . . . . . . . . 3-37

Figure3.25Interruption of a Short-Circuit . . . . . . . . . . . . . . . . . . . 3-43

Figure3.26Stalling During Starting . . . . . . . . . . . . . . . . . . . . . . . . . 3-45

Figure3.27Characteristic of PTC Sensors as per IEC 34-11-2 . . . 3-48

Figure3.28Analog Output for Motor Temperature Rise. . . . . . . . 3-49

Figure3.29Analog Output for Motor Temperature. . . . . . . . . . . . 3-50

Figure3.30Analog Output for Motor Current . . . . . . . . . . . . . . . . 3-50

Figure3.31Operating Diagram for Timer Functions . . . . . . . . . . . 3-52

Figure3.32Diagram of Star-Delta (Wye-Delta) Starting. . . . . . . . . 3-55

Figure 4.1Basic Unit Mounted in an Enclosure . . . . . . . . . . . . . . . 4-1

Figure 4.2Mounting Position. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Figure 4.3 Basic Unit Mounted into Panel Mounting Frame

(Cat. No. 825-FPM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Publication 825-UM001B-EN-P January 2001

Page 11

Table of Contents vii

Figure 4.4Cat. Nos. 825 MCM2, 825-MCM-20, 825-MCM180. . . 4-3

Figure 4.5Cat. Nos. 825-MCM630, 825-MCM630N . . . . . . . . . . . 4-3

Figure 4.6Cat. No. 825-MTUM Thermal Utilization Indicator . . . 4-4

Figure 4.7Basic Unit Housing with Option Cards . . . . . . . . . . . . . 4-5

Figure 4.8Basic Unit with Converter Module . . . . . . . . . . . . . . . . . 4-6

Figure 4.93-Phase Current Evaluation. . . . . . . . . . . . . . . . . . . . . . . 4-6

Figure 4.102-Phase Current Evaluation. . . . . . . . . . . . . . . . . . . . . . . 4-7

Figure 4.11Smart Motor Manager Basic Unit . . . . . . . . . . . . . . . . . . 4-8

Figure 4.12Cat. No. 825-MST Option Card . . . . . . . . . . . . . . . . . . . 4-9

Figure 4.13Cat. No. 825-MLV Option Card. . . . . . . . . . . . . . . . . . 4-10

Figure 4.14Cat. No. 825-MMV Option Card . . . . . . . . . . . . . . . . . 4-11

Figure 6.1 Range of Starting Currents of Standard Motors

Expressed as Multiple of the Rated Service

Current . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

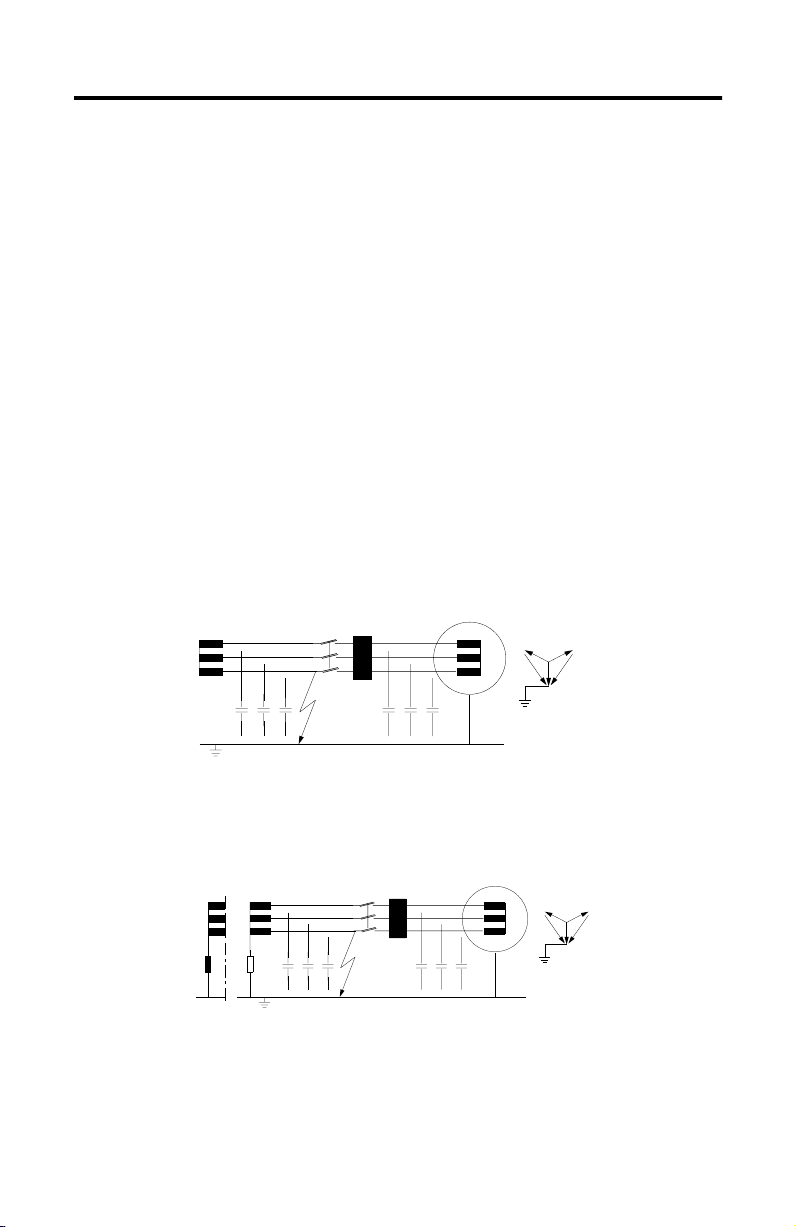

Figure 7.1Test with a 3-Phase Current Source . . . . . . . . . . . . . . . . 7-5

Figure 7.2Test with a Single-Phase Current Source . . . . . . . . . . . . 7-6

Figure 9.1Basic Unit and Converter Module. . . . . . . . . . . . . . . . . . 9-1

Figure 9.2Control by Momentary Contact . . . . . . . . . . . . . . . . . . . 9-2

Figure 9.3Basic Unit and Converter Module. . . . . . . . . . . . . . . . . . 9-3

Figure 9.4Control by Momentary Contact . . . . . . . . . . . . . . . . . . . 9-3

Figure 9.5Basic Unit for Short-Circuit Protection . . . . . . . . . . . . . 9-4

Figure 9.6Control by Momentary Contact . . . . . . . . . . . . . . . . . . . 9-5

Figure 9.7Two-Speed Application Utilizing One 825-MCM* . . . . 9-6

Figure 9.8Two-Speed Application Utilizing 825-MCM180 . . . . . . 9-7

Figure 9.9 Two-Speed Application Utilizing Primary Current

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Figure 9.10 Typical Application Utilizing Primary Current

Transformers and Core Balance Current

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-9

Figure 9.11 Typical Application Utilizing Core Balance Current

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-10

Figure 9.12Application with Low Idling Current . . . . . . . . . . . . . . 9-11

Figure 9.132/3/4 Conductor Technique for PT100 Wiring . . . . . 9-12

Figure 9.14 Typical Application Utilizing 2-Phase Current

Evaluation with Primary Current Transformers. . . . . . 9-13

Figure 9.15Trip Characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-14

Publication 825-UM001B-EN-P January 2001

Page 12

viii Table of Contents

Tables

Table 2.AEnvironmental Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Table 2.B Nominal Rated Voltages Ue . . . . . . . . . . . . . . . . . . . . . . 2-6

Table 2.CElectrical Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Table 2.DSupply Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Table 2.ERelay Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Table 2.FTerminals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Table 2.GMain Current Transformer Ratings. . . . . . . . . . . . . . . . 2-10

Table 2.H Recommended Data for Core Balance Current

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Table 2.IConverter Module — Related Error Messages. . . . . . . 2-13

Table 3.AActual Values Overview. . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Table 3.BSet Values Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Table 3.CRecorded Values Overview. . . . . . . . . . . . . . . . . . . . . . . 3-3

Table 3.DDisplay Example of Set Values Menu. . . . . . . . . . . . . . . 3-6

Table 3.EDisplay Example of Actual Values Menu. . . . . . . . . . . . 3-7

Table 3.FDisplay Example of Recorded Values. . . . . . . . . . . . . . . 3-9

Table 3.GProtective Functions Summary. . . . . . . . . . . . . . . . . . . 3-13

Table 3.HWarning Functions Summary . . . . . . . . . . . . . . . . . . . . 3-14

Table 3.IControl Functions Summary. . . . . . . . . . . . . . . . . . . . . 3-15

Table 3.JThermal Overload Setting Parameters . . . . . . . . . . . . . 3-21

Table 3.KProtection Against Thermal Overload . . . . . . . . . . . . . 3-22

Table 3.L Asymmetry (Phase Unbalance)

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-23

Table 3.MHigh Overload and Jam Setting Parameters. . . . . . . . . 3-24

Table 3.NUnderload Setting Parameters. . . . . . . . . . . . . . . . . . . . 3-26

Table 3.O Earth (Ground) Fault — Holmgreen/Residual

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Table 3.P Core Balance Current Transformer

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Table 3.Q Earth (Ground) Fault Core Balance

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Table 3.RStarts per Hour Setting Parameters. . . . . . . . . . . . . . . . 3-33

Table 3.SMonitoring Start Time Setting Parameters. . . . . . . . . . 3-35

Table 3.TWarm Start Setting Parameters . . . . . . . . . . . . . . . . . . . 3-38

Table 3.UAlarm Examples. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-41

Table 3.VReset Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . 3-42

Table 3.WShort Circuit Setting Parameters. . . . . . . . . . . . . . . . . . 3-44

Publication 825-UM001B-EN-P January 2001

Page 13

Table of Contents ix

Table 3.XStalling during Start Setting Parameters . . . . . . . . . . . . 3-45

Table 3.YPTC Setting Parameters. . . . . . . . . . . . . . . . . . . . . . . . . 3-46

Table 3.ZSensor Measuring Circuit Specifications. . . . . . . . . . . . 3-47

Table 3.AAPhase Sequence Setting Parameters. . . . . . . . . . . . . . . . 3-54

Table 3.ABPhase Failure Setting Parameters. . . . . . . . . . . . . . . . . . 3-54

Table 3.AC Star-Delta (Wye-Delta) Starting

Setting Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-55

Table 3.AD PT100 Temperature Detector Resistance

per IEC 751 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-56

Table 3.AEPT100 (RTD) Setting Parameters . . . . . . . . . . . . . . . . . 3-57

Table 3.AFMotor Insulation Class Setting Parameters. . . . . . . . . . 3-58

Table 4.ACat. Nos. 825 MCM2, 825-MCM-20, 825-MCM180. . . 4-3

Table 4.BCat. Nos. 825-MCM630, 825-MCM630N . . . . . . . . . . . 4-4

Table 4.CSpecifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Table 5.AMain Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Table 5.BSpecial Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Table 5.CCommunication Settings . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Table 5.DCat. No. 825-M… Operating Parameters. . . . . . . . . . . . 5-4

Table 6.AChecking the Actual Values. . . . . . . . . . . . . . . . . . . . . . . 6-6

Table 7.AList of Recorded Values. . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Table 8.APossible Causes and Actions. . . . . . . . . . . . . . . . . . . . . . 8-3

Publication 825-UM001B-EN-P January 2001

Page 14

x Table of Contents

Notes:

Publication 825-UM001B-EN-P January 2001

Page 15

Chapter

1

Introduction

Why Have an Electronic Control and Protection System?

The need to optimize production facilities requires enhanced control, monitoring, and

protection systems.

Motor and installation use must be maximized while minimizing both the downtime required

for maintenance and that caused by motor failures; these requirements are easily met by the

microprocessor-based Bulletin 825 Smart Motor Manager.

The Bulletin 825 Smart Motor Manager has a modular design and is easily programmed. Its

attributes enable an optimum fit to a wide variety of motor and installation requirements.

The Bulletin 825 Smart Motor Manager provides continuous monitoring of motor operating

data in one of two ways. The data can be viewed directly on the unit or it can be monitored

remotely via a network by using a PC or process computer. The main statistical data can also

be accessed at any time.

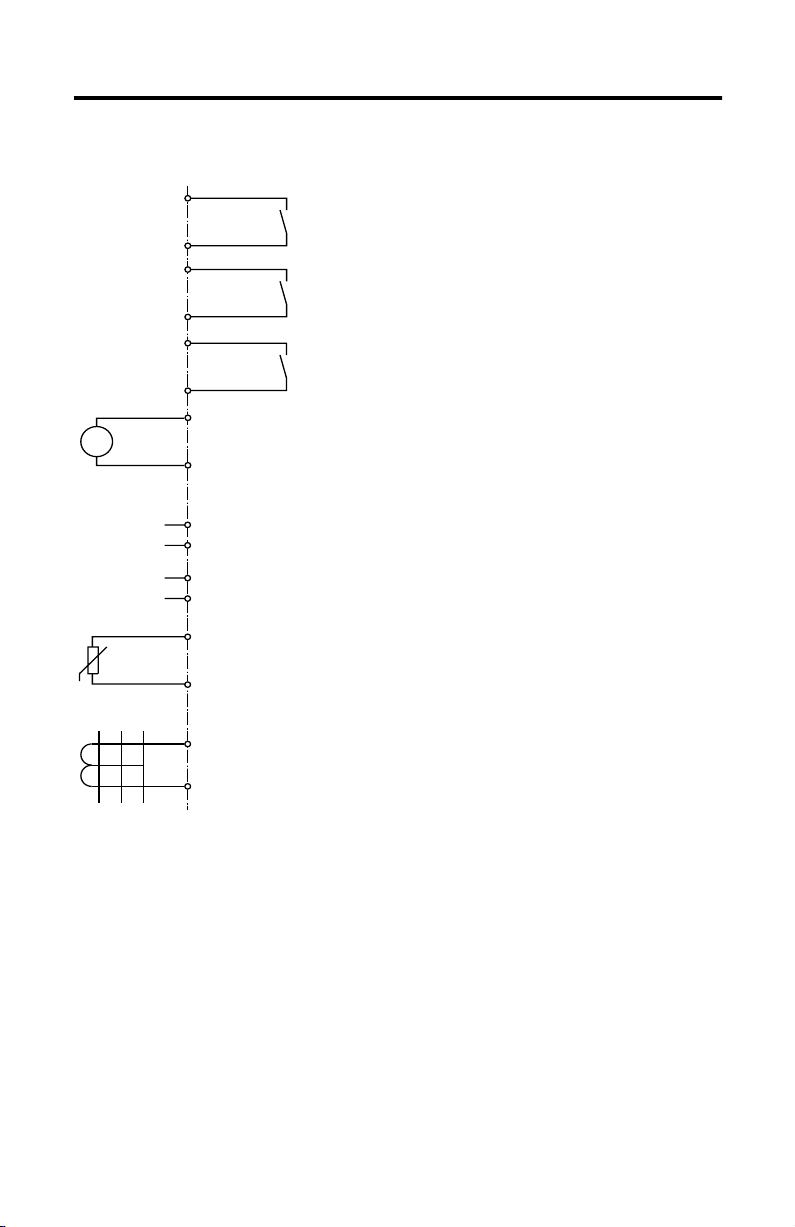

Figure 1.1 Bulletin 825 Smart Motor Manager

Publication 825-UM001B-EN-P January 2001

Page 16

1-2 Introduction

Operational Demands of the Motor/Drive

Temperature Rise

Motor designs and applicable standards require that, when a motor is operated under

specified loads and ambient conditions, the critical parts of the motor will remain within an

allowable temperature range and short-term overloads will not harm the motor.

The device protecting the motor must permit full use of the motor and its economical

operation. At the same time, the protective device must switch off rapidly if an overload

occurs.

Motor Operating Characteristics

Electric motors absorb electrical energy and supply mechanical energy. During this energy

conversion, losses are produced in the form of heat. The total loss consists of the following

separate losses:

• Losses independent of the current (these losses are virtually constant i.e., they also

occur at no load)

• Iron losses caused by remagnetization and eddy currents

• Mechanical losses caused by friction and ventilation

• Losses dependent on the current (these losses increase with load i.e., with the current

consumed by the motor)

• Heat losses caused by the current in the stator

• Heat losses caused by the current in the rotor

• Increased temperature rise caused by poor cooling (e.g., cooling fins are dusty or

damaged, coolant temperature is too high)

Publication 825-UM001B-EN-P January 2001

Page 17

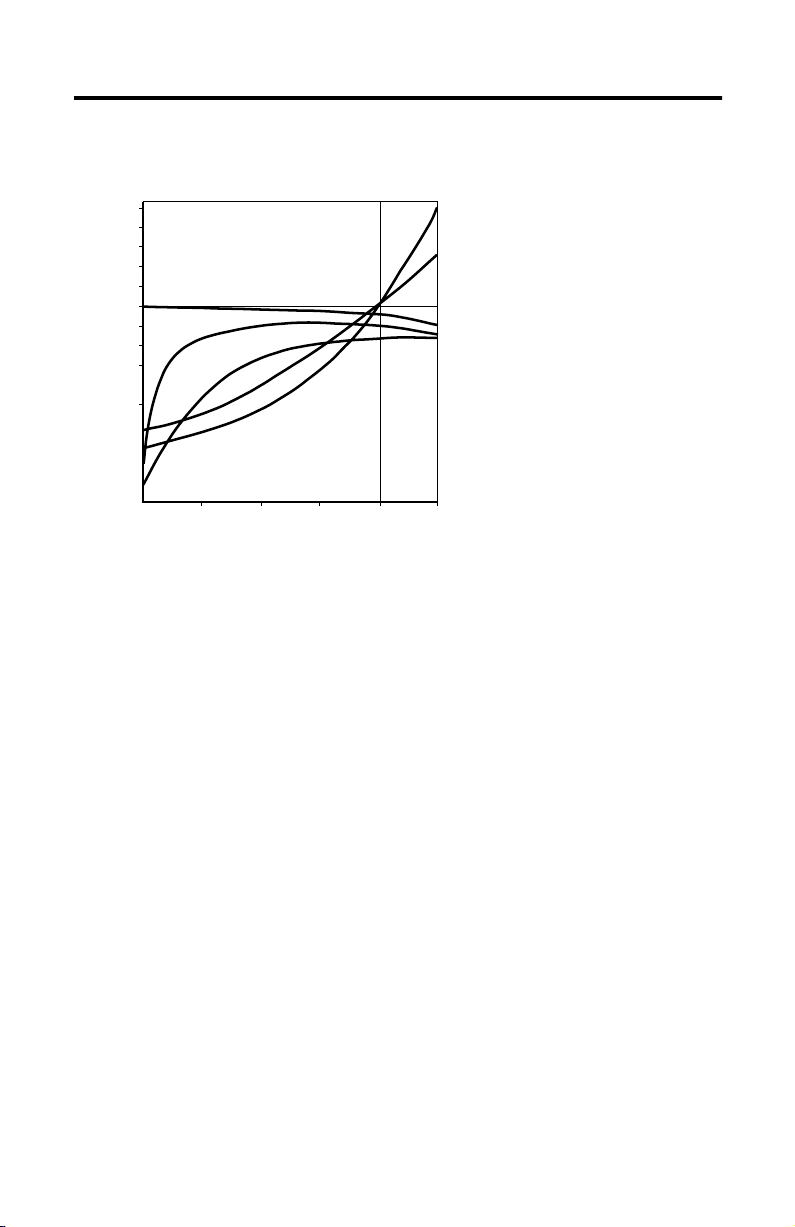

Figure 1.2 Operating Characteristics of an AC Motor

s

Introduction 1-3

ve

1.5

Pv

P

1.4

e,

I

I

1.3

e,

n

n

1.2

1.1

1.0

cos ϕ, η,

0.9

0.8

0.7

0.5

Operating characteristics of an AC motor as a function of load. Between no load and half load, the losses increase only slightly

with rising load. Between half load and rated load, the change in efficiency is minimal, and the power factor approaches its

maximum. The losses increase approximately proportional to the load. Above rated load, the losses increase more rapidly than

the load.

n

η

cos ϕ

I

P

v

25 50 75 100 125

n

I

s

e

P Power

Pe Rated operational power

Pv Power losses

Pve Power losses under rated condition

Operational current

Rated service current

e

n Speed

n

Rated operational speed

e

n

Synchronous speed

s

cos ϕ Power factor

η Efficiency

P

[%]

P

e

Current and Temperature Curves

Power loss is approximately proportional to the square of the motor current. The potential

for motor hazards exists mainly during starting and in a locked rotor condition. When a

locked rotor condition exists, the maximum value of the starting current flows (approximately

4…8 times the rated service current I

As the motor speed increases, the power converted into heat decreases. But if the rotor

remains locked, the temperature of the stator and rotor windings rises considerably, caused by

the high losses and the short time that heat can flow into the laminated core. If the motor is

not switched off quickly, the stator or rotor winding can burn out.

After startup, the temperature of the winding rises according to the load and cooling of the

motor. In time, the winding reaches its steady-state value.

A high current results in a correspondingly high operating temperature.

), and all of the power absorbed is converted into heat.

e

Publication 825-UM001B-EN-P January 2001

Page 18

1-4 Introduction

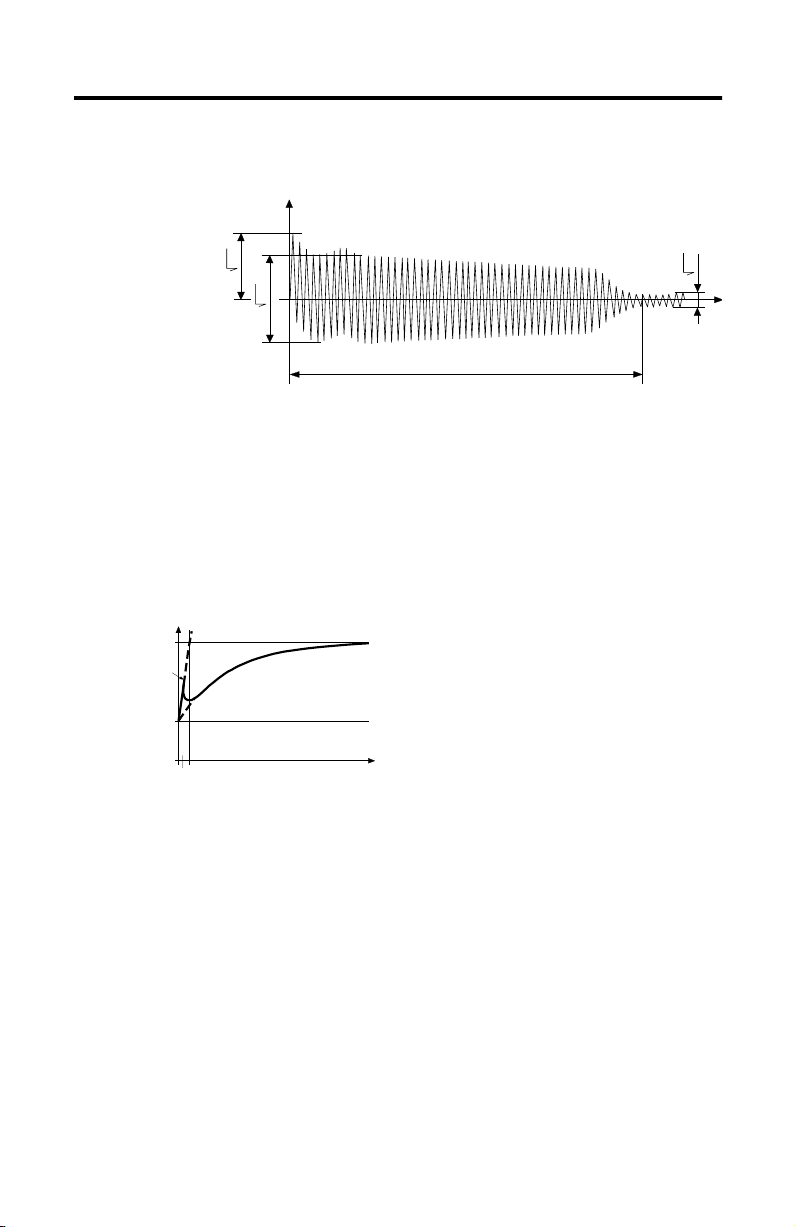

Figure 1.3 AC Current Profile of a Motor Starting Direct-on-Line

Starting current

A

Starting time

t

A

Rated service

e

current

t Time

Oscillogram of switching on a squirrel-cage induction motor by direct-on-line starting. The high motor starting current A flows

during the starting time (t

cause an excessive temperature rise. The brief, asymmetrical peak when switching on can be ignored.

). If this is less than the limit specified by the manufacturer (usually 10 s), the starting current does not

A

I

A

1.6 2 I

A

2 2 I

t

A

e

2 2 I

Motors are not thermally homogeneous. The winding, stator iron, and rotor have different

heat capacities and conductivities. Following unduly heavy loads, e.g., during starting,

temperature equalization occurs between the various parts of the machine (heat flows from

the warmer winding into the cooler iron until the temperature difference is minimal).

Figure 1.4 Temperature Rise Characteristics of Motor Windings

ϑ

ϑ

G

ϑ

ϑ

K

ϑ

s

0

e

t

t

B

A

ϑ

Temperature limit of the insulation

G

ϑ

Coolant temperature

K

ϑ

Temperature rise at start

s

ϑ

Temperature rise when operated

e

continuously at rated current

t

Starting time

A

t

Permitted stalling time

t

B

Temperature rise in a motor winding. During the starting time (tA), the temperature of the winding rises very rapidly; at the end of

startup, the temperature drops temporarily because heat is transferred to the laminated core.

Limiting Temperatures, Insulation Classes

The permissible temperature limit for a winding — and thus the load-bearing capacity — of

the motor is primarily a function of the motor's insulation. Applicable standards (UL, CSA,

IEC, and NEMA) distinguish between different classes of insulation and corresponding

temperature limits.

Publication 825-UM001B-EN-P January 2001

Page 19

Introduction 1-5

Insulation Aging

The aging of insulation material is a chemical process that is accelerated by continuous

overtemperature. It may be assumed that a winding temperature that is constantly 10 K

higher than the temperature limit reduces the motor life by half. This “life law” shows that

particular attention must be paid to adhering to the permitted operating temperature for long

periods of time. (Note that overtemperatures of short duration and infrequent occurrence do

not seriously affect the life of the machine.)

The Bulletin 825 Smart Motor Manager's ability to accurately limit excessive current

conditions greatly aids in extending motor life. In practice, it may be expected that there will

be reduced loads and pauses, so that when the temperature limit is reached, the motor life will

not be impaired.

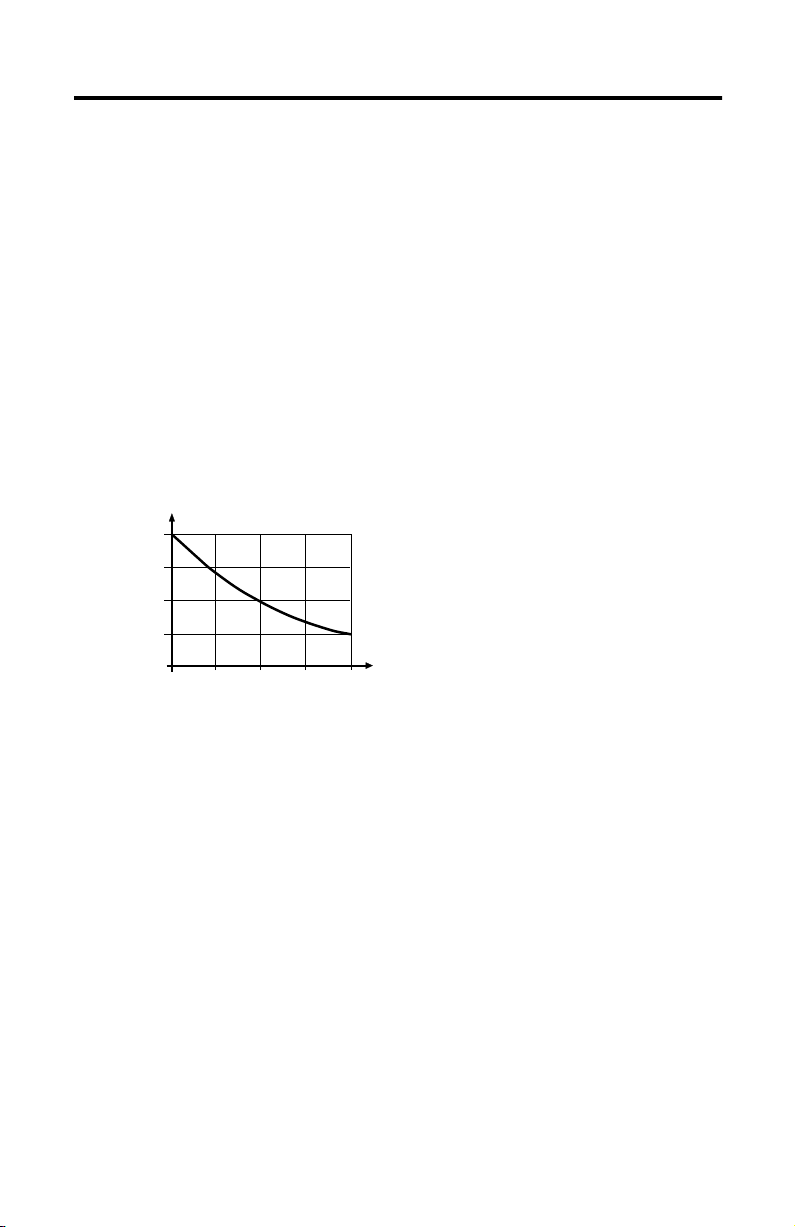

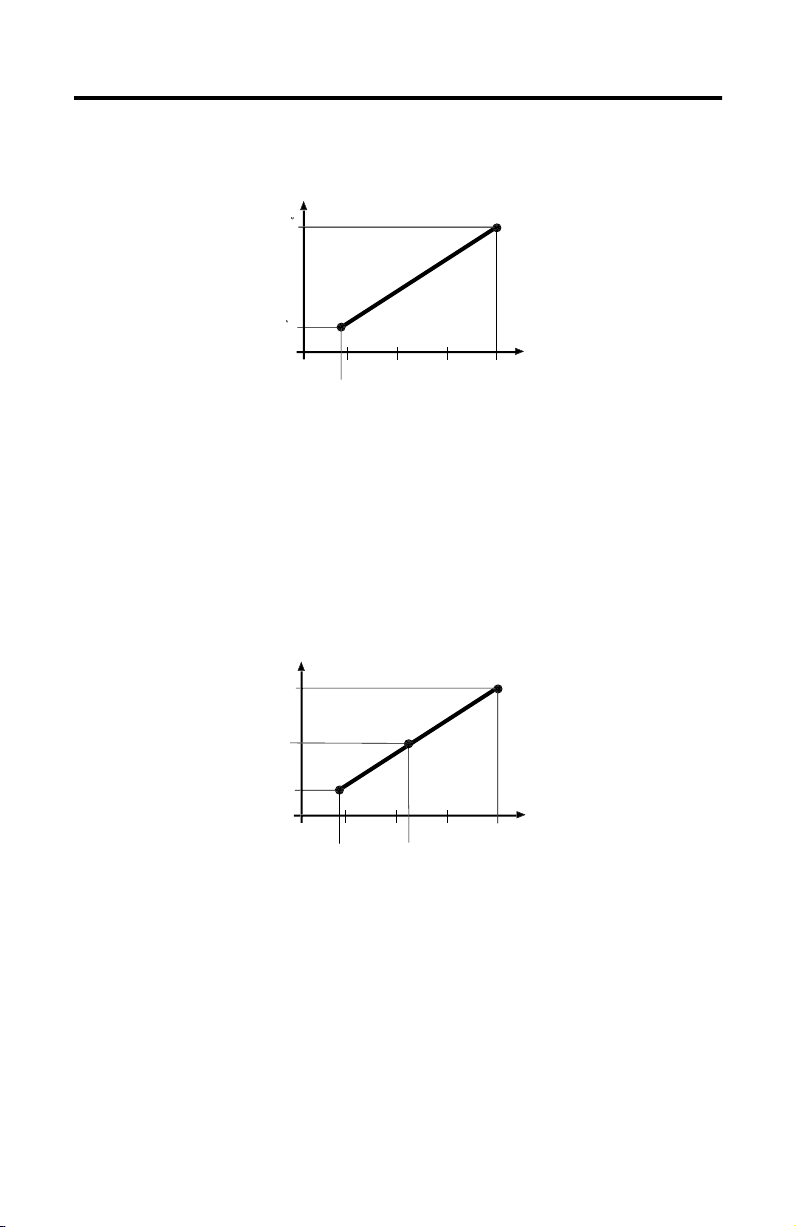

Figure 1.5 Reduction in Average Life (EM) of a Motor when Winding is

Continuously Overheated

E

Average motor life

M

ϑ

Temperature limit of the insulation

G

100

E

M

%

70

50

25

0

+5K +10K +15K +20K

ϑ

G

Rotor Temperature

The rotors of squirrel-cage induction motors with simple construction (no insulation) may

continuously attain higher temperatures than rotors in motors with insulated windings.

However, in larger motors, the concentration of the rotor losses during starting is higher than

the concentrations of losses in other parts of the motor. The starting time of such motors is

therefore limited by the thermal capacity of the rotor. These types of motors are commonly

referred to as “rotor-critical” motors. Critical to the rotor are the mechanical stresses caused

by the temperature rise, unsoldering of the rotor bars, and, for EExe motors (motors for use

in the chemical industry), the high temperature as a source of ignition.

Operational Requirements for Installation

Monitoring the application parameters and process data of an installation can be very

important. Even a slight change in the starting and operating behavior of the motor can

indicate an impending fault. The Smart Motor Manager helps eliminate potential trouble

before major repairs are necessary and loss of production occurs.

Publication 825-UM001B-EN-P January 2001

Page 20

1-6 Introduction

The Smart Motor Manager fulfils these requirements by providing protection against the

following:

• high overload, stalling and jam

• underload

• phase sequence

Personnel and Installation Safety

Personnel protection in the vicinity of control equipment is of primary importance. The

corresponding requirements of regulatory agencies are therefore becoming increasingly

severe. The Smart Motor Manager reflects this by providing the following protection:

• equipment construction

• touch protection

• insulated housing

• motor protective functions:

• Earth (ground) fault

• High overload, stalling and jam

• Wrong direction of rotation

Bulletin 825 Smart Motor Manager as an Automation Component

The Bulletin 825 Smart Motor Manager detects abnormal operating conditions and faults in

motor branch circuits. The data made available by the Smart Motor Manager can be used for

operational control and optimization of the installation.

A large number of supervisory, protective, and control functions improve operational control

and avoid unnecessary downtime. This maximizes your motor investment, making the Smart

Motor Manager a valuable component in modern automation systems.

Publication 825-UM001B-EN-P January 2001

Page 21

Chapter

2

Equipment Description

System Structure

The Bulletin 825 Smart Motor Manager is a microprocessor-based protection and control

system for motors. For the AC motor and the operated installation this means:

• Maximum utilization

• Continuous supervision

• Reliable protection

The modular structure of the system and all of its possible functions enable the Bulletin 825

Smart Motor Manager to be economically and optimally adapted to any installation.

System Components

The motor protection system consists of:

• The basic control and protection unit

• Current converter modules for 0.5…630 A

• Cable for connecting between the basic unit and the current converter module

• Optional plug-in printed circuit boards

• Thermal utilization meter to indicate the thermal load

Installation

The Smart Motor Manager can be either flush mounted in an enclosure door, or surface

mounted to the enclosure mounting plate using a panel mounting frame.

Current converter modules can be surface mounted.

Publication 825-UM001B-EN-P January 2001

Page 22

2-2 Equipment Description

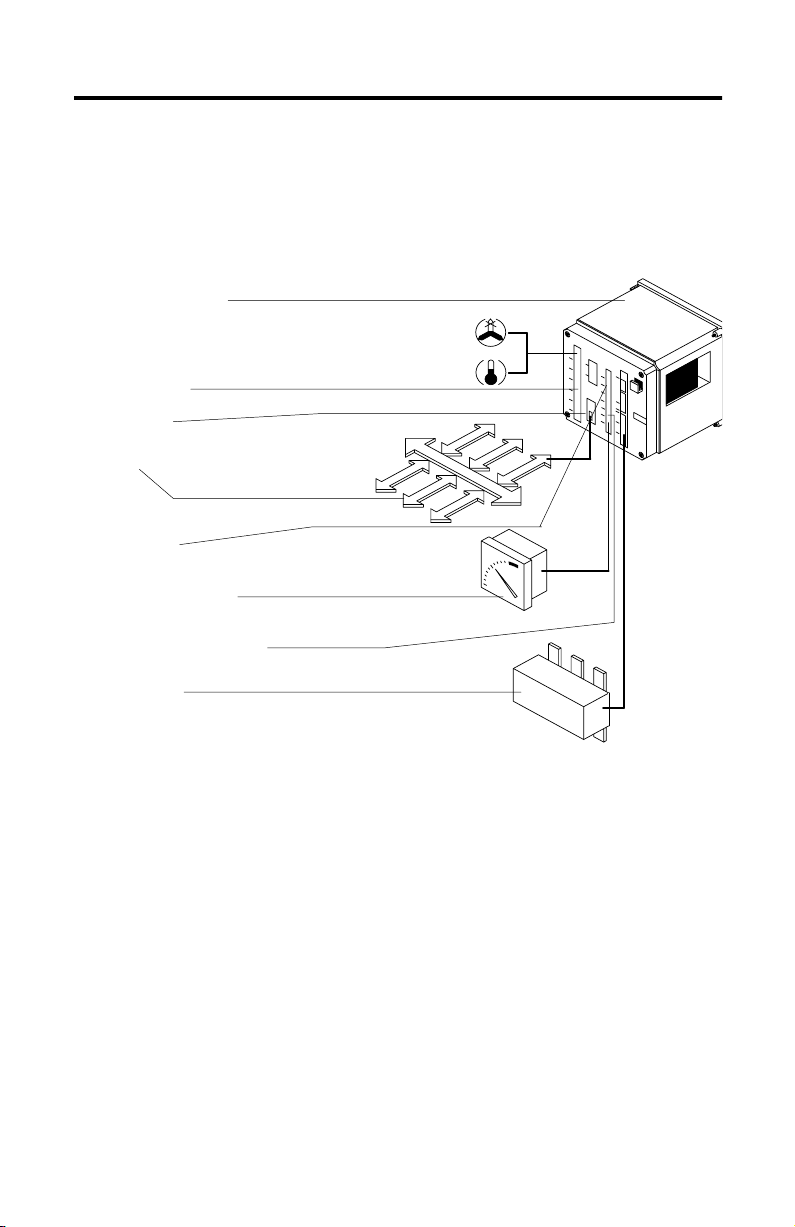

Modular Design

The Cat. No. 825-M basic unit can be fitted with additional option (function) cards to suit the

requirements.

Figure 2.1 Modular Design of the Bulletin 825 Smart Motor Manager

Basic unit, Cat. No. 825-M…

Option:

Cat. No. 825-MLV

Cat. No. 825-MMV

Communication

Communication

Network

Cat. No. 825-MST

Thermal utilization module

Core Balance Current Transformer

PT100

4...20 mA

Converter module

Available Communications Cards

Cat. No. 825-MDN: DeviceNet

Cat. No. 3600-RIO: Remote I/O ➊

Cat. No. 3600-MBS: Modbus ➊

Cat. No. 825-MPB: PROFIBUS FMS

➊ Available from Prosoft Technology, Inc. (not an Allen-Bradley product). References to third-part products are

provided for informational purposes only. Prosoft Technology, Inc., is solely responsible for the accuracy of

information, supply, and support of this product. For further information regarding this particular referenced

product, please contact Prosoft Technology, Inc., in the U.S. at (661) 664-7208 or your local Prosoft

Technology, Inc. distributor.

Publication 825-UM001B-EN-P January 2001

Page 23

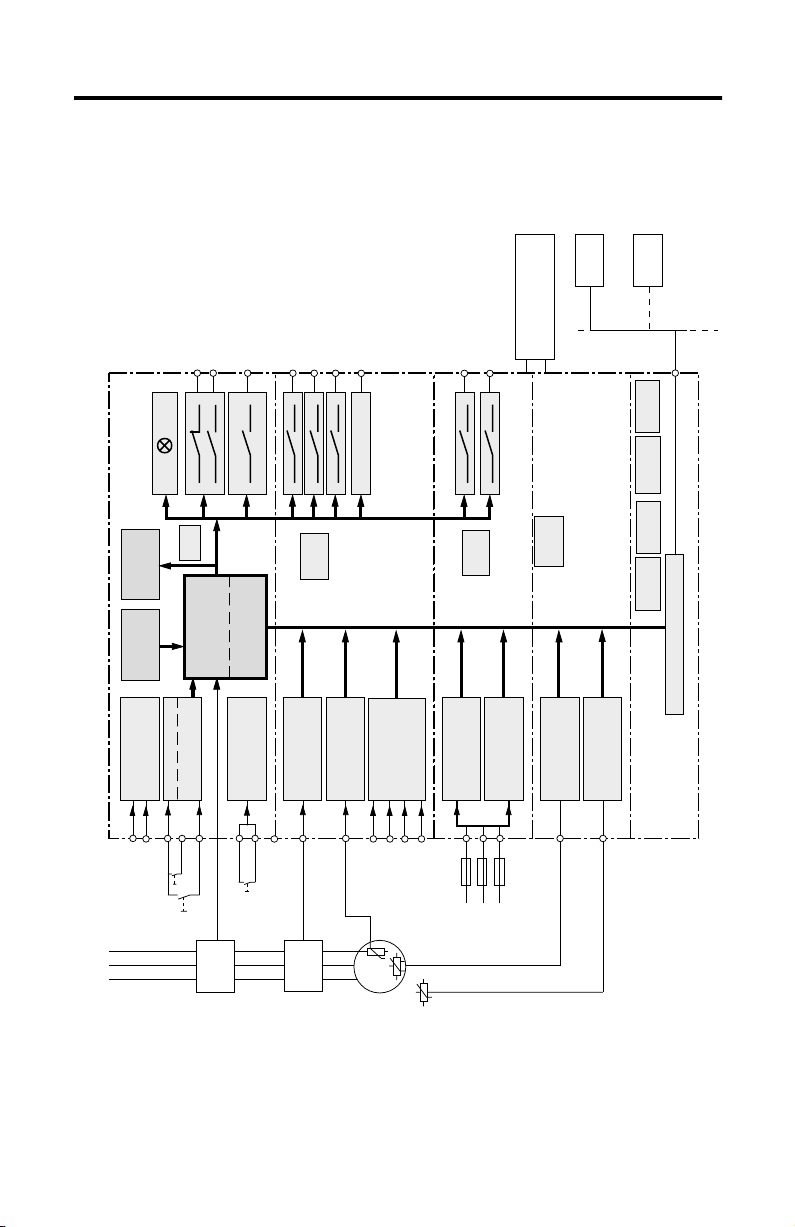

Block Diagram

Figure 2.2 Block Diagram

Equipment Description 2-3

PC

PLC

LCD

Operation

Supply

-

+

Y11

A1 (-)

A2 (+)

Warning/Trip

Main relay MR

Alarm relay AL

95/96

97/98

13/14

825-M

Basic unit

Controller

Y13

Remote reset

Y22

Y21

Disable settings

Emergency start

Y12

Auxiliary relay #1

23/24

825-M

k, l

Auxiliary relay #2

Auxiliary relay #3

Analog output

33/34

43/44

I+ / I-

4…20 mA

825-MST

overload

Earth fault

Thermistor

T1, T2

Y31

#1

24 V AC/DC

Control

Y32

inputs

#2

Y41

Y42

24 V AC/DC

Auxiliary relay #4

Auxiliary relay #5

53/54

63/64

825-MLV

Phase

sequence

Phase failure

L1

L3

L2

F

L1L3L2

Choice

825-MLV or 825-MMV

825-MMV

Stator /

Ambient temperature

bearing temperature

PT100 #7

(RTD)

PT100 #1…#6

(RTD)

1T1/1T2/1T3

7T1/7T2/7T3

…6T1/6T2/6T3

Network

825-MPB

3600-MBS

3600-RIO

825-MDN

Communication Interface

825-

L1 L2 L3

MCM

∑

M

3 ~

amb

ϑ

Publication 825-UM001B-EN-P January 2001

Page 24

2-4 Equipment Description

Operating Elements

The Smart Motor Manager is very easy to operate. All functions, data, and tests can be

entered, executed, or displayed using the six membrane keys and the single-line LCD, which

displays all available data and functions.

Figure 2.3 Front View with Operating Elements

➊

➋

➏

➎

➍

➌

➊ Fault indicator (LED)

Flashing: warning

Steady state: trip

➋ LCD: Single line (two lines of text are displayed alternately)

➌ Values: Selection of mode

Actual: Indication of actual operational data

Set: Setting mode (set/modify, store parameters)

Recorded: Indication of statistical data

➍ Select: Select function and enter/change operating parameter

➎ Settings: Enable entry (Change) and memorize (Enter)

➏ Test: Verifies operation of Smart Motor Manager.

➐ Reset: Enables the Smart Motor Manager after a trip.

Publication 825-UM001B-EN-P January 2001

➐

Page 25

Equipment Description 2-5

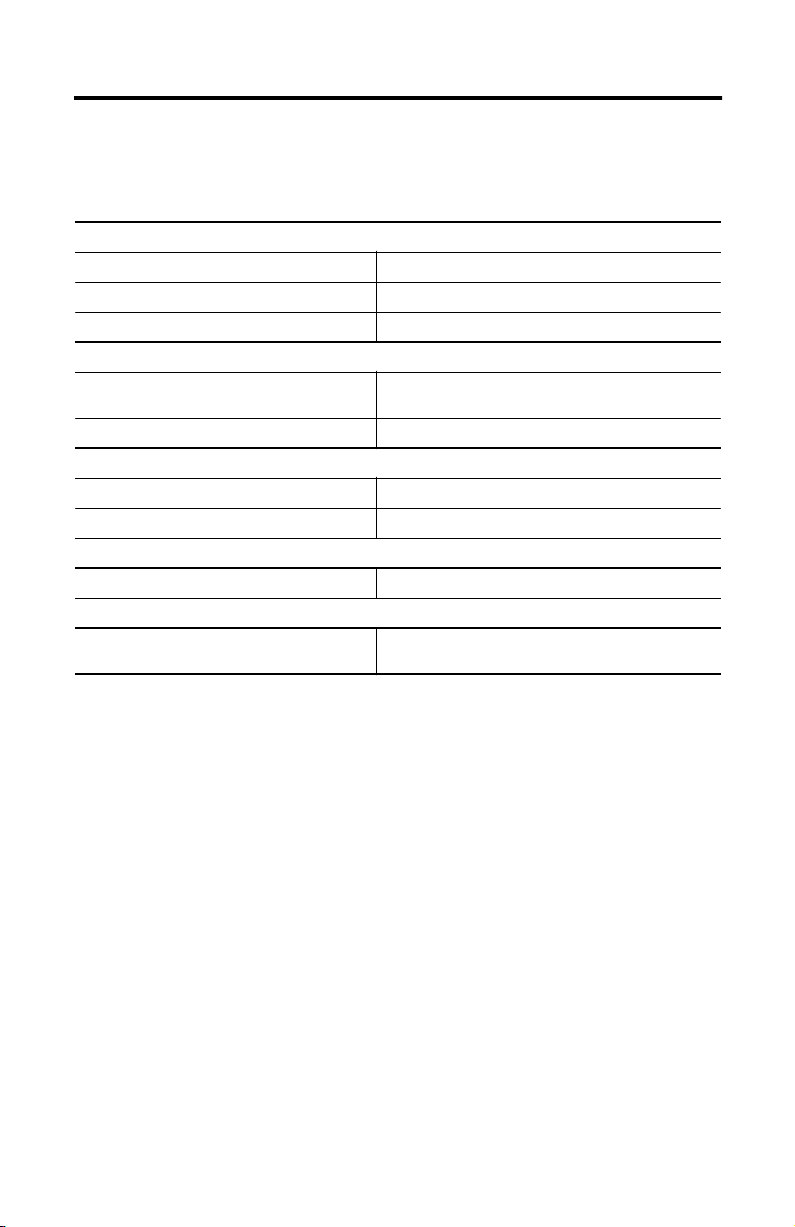

Specifications — Basic Unit and Converter Module

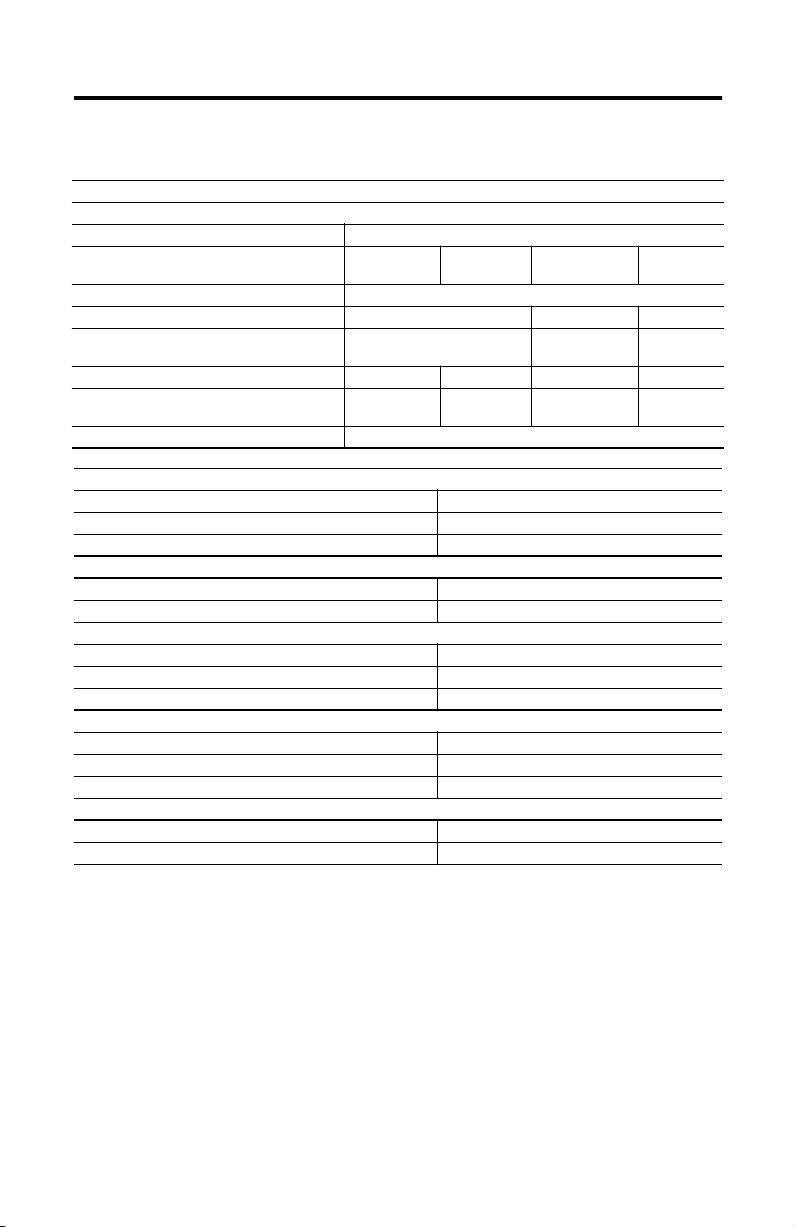

Table 2.A Environmental Ratings

Temperature

Operation -5…+ 60 °C (23…140 °F)

Storage -40…+ 60 °C (-40…140 °F)

Transport -40…+ 85 °C (-40…185 °F)

Climatic Withstand

Damp heat IEC 68-2-3

Climatic cycling IEC 68-2-30 25/40 °C (77/104 °F), 21 cycles

Enclosure Protection Class

825-M, enclosed in panel IP65

Terminals IP20

as per IEC 68-2-6 10…150 Hz, 3 G

as per IEC 68-2-27

40 °C (104 °F), 92%

relative humidity, 56 days

Resistance to Vibration

Resistance to Shock

30 G, shock duration 18 ms, half a sine wave in x, y, z

directions

Publication 825-UM001B-EN-P January 2001

Page 26

2-6 Equipment Description

Table 2.B Nominal Rated Voltages U

Primary Detection Circuit

as per IEC, SEV, VDE 0660 400V AC 660V AC 1 000V AC

as per CSA, UL 240V AC 600V AC 600V AC

Main relay (MR) 95…98, supply A1, A2

Phase sequence protection L1, L2, L3

as per IEC 947 400V AC

as per SEV 380V AC

as per UL, CSA 240V AC

Alarm relay (AL) 13/14

Auxiliary relay #1, #4, #5

as per IEC 947 400V AC

as per SEV 250V AC

as per UL, CSA 240V AC

Auxiliary relays #2, #3 50V AC/30V AC

Control inputs #1, #2 24V AC/DC

e

Motor Circuit

Control Circuit

825-

MCM2

825-

MCM20

825MCM180

MCM630

MCM630N

Table 2.C Electrical Ratings

Test V olt age

as per IEC 947-1

Control Circuit

Between control circuits and to all other circuits ➊

Main relay (MR) 95…98,

supply A1, A2

Phase sequence protection

L1, L2, L3

Alarm relay (AL), auxiliary relay

#1, #4, #5 as per IEC 947-4

Core balance current transformer k, I

Control inputs #1, #2

Auxiliary relays #2, #3

as per IEC 947-4

825-

MCM2

Motor Circuit

U

imp

2.5 kV

825-

MCM20

U

imp

6 kV

MCM180

MCM630

U

imp

4 kV

U

imp

2.5 kV

825-

U

imp

8 kV

825-MCM630N

12 kV

U

imp

➊ The measuring inputs for PT100 and PTC, the 4…20 mA output, and the communication interface are not

isolated from one another.

Publication 825-UM001B-EN-P January 2001

Page 27

Equipment Description 2-7

Standards

EMC

Noise emission as per EN 50 081-1 and as per EN 50 081-2

Noise proof as per EN 50 082-1 and as per EN 50 082-2

Standards: IEC 947-4, CSA C22.2 No. 14, UL 508

Approvals: CE, UL-Listed, CSA, PTB: Physkalisch-Technische Bundesanstalt (Germany):

Certification required for motor protection in explosion hazard area (e.g., Chemical,

Petrochemical Installations).

Table 2.D Supply Ratings

50/60 Hz, 22…24, 33…36, 44…48, 110…120, 220…240,

Nominal supply voltage U

Permissible voltage fluctuation

Power consumption AC 13 VA, DC 10 W max.

Short-circuit protection

s

380…415, 440V AC

24…48, 72…120, 220V DC

AC 0.85…1.10 U

DC 0.80…1.10 US for 24…48V DC

DC 0.80…1.20 U

DC 0.80…1.15 U

With the appropriate supply cable rating, the supply module is

short-circuit proof.

S

for 72…120V DC

S

for 220V DC

S

Publication 825-UM001B-EN-P January 2001

Page 28

2-8 Equipment Description

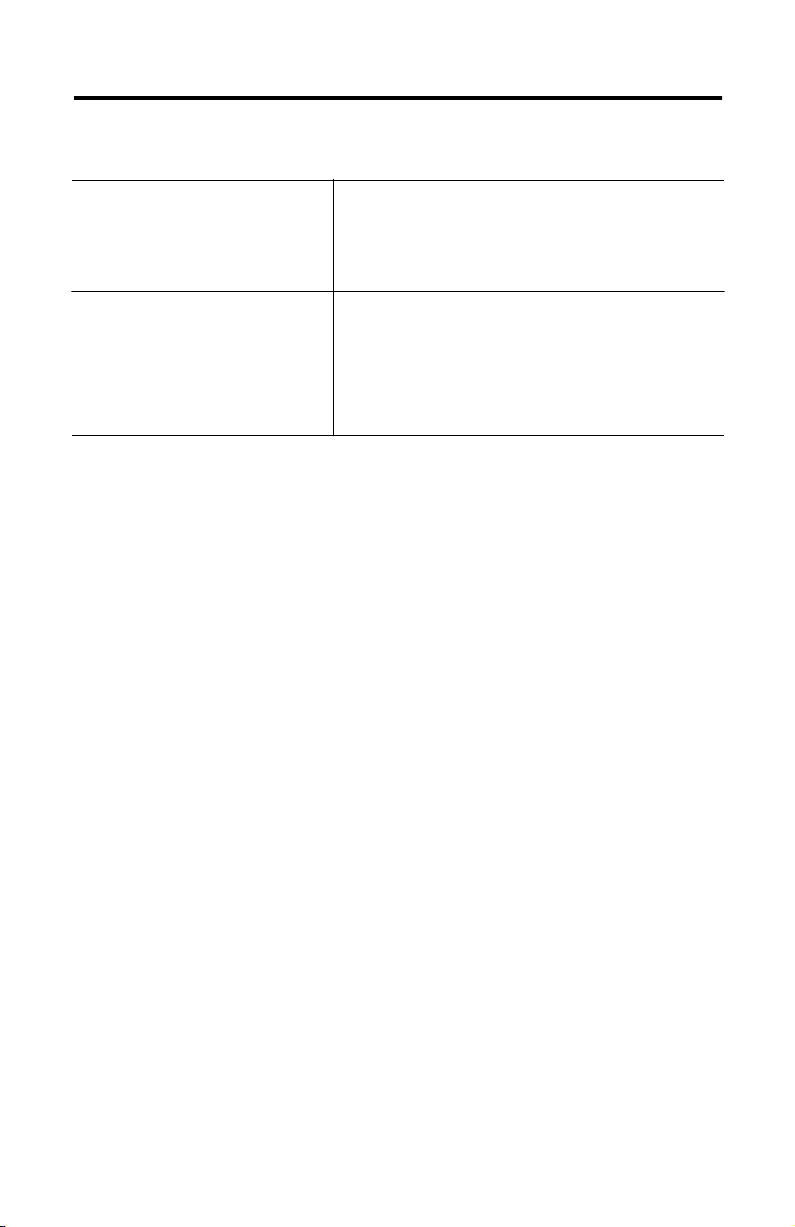

Table 2.E Relay Ratings

Contact Data of Output Relays

Main Relay (MR) 95…96

Contacts fitted 1 N/C and 1 N/O contact, galvanically separated

Nominal operating voltage

as per UL, CSA: pilot duty 240 V

Continuous thermal current [A] 4

Rated operating current for AC-15 [A] 3 3 1.2

Max. permissible switching current

(cos ϕ = 0.3) AC-15

Rated operating current for DC-13

without prot. network,

L/R = 300 ms

Max. rated current of back-up fuse: [A] 10 A, 500V AC, Type gG

Contacts fitted 1 N/O contact each

Continuous thermal current 4 A

Max. permissible switching voltage 400V AC, 125 VDC

cos ϕ = 1 4 A at 250V AC or 30V DC

cos ϕ = 0.4, L/R = 7 ms 2 A at 250 VAC or 30V DC

cos ϕ = 1 1 250 VA, 150 W

cos ϕ = 0.4, L/R = 7 ms 500 VA, 60 W

as per UL/CSA 240 V, 1 A pilot duty

Contacts fitted 1 N/O contact each

Continuous thermal current 4 A

Max. permissible switching voltage 48 VAC, 30 VDC

cos ϕ = 1 150 W

cos ϕ = 0.4, L/R = 7 ms 60 W

[V] 24 110…125 220…250 380…440

[A] 30 30 12

[A] 2 0.3 0.2 –

Alarm Relay (AL), Auxiliary Relays #1, #4, #5

Nominal Operating Current

Max. Switching Power

Auxiliary Relays #2, #3

Max. Switching Power

Publication 825-UM001B-EN-P January 2001

Page 29

Equipment Description 2-9

Table 2.F Terminals

Range of gauges:

Cat. No. 825-M plug-in terminals

as per UL AWG No. 22…14

as per VDE

Main circuit

825-MCM2/

825-MCM20

825-MCM180

825-MCM630(N) Bus bars: 25 x 8 mm

0.5…2.5 m2, single wire (AWG No. 20…14)

0.5…1.5 m

2

double wire (AWG No. 20…16)

nominal gauge 1.5 mm

Terminals: 2 x 2.5 mm

(2 x 0.0039 in

2 x AWG No. 20…14/1 x AWG No. 20…12

Aperture or busbars:

Wire ∅ 19 mm max. 20/16 x 4 mm

2

/1 x 4 mm2

2

/1 x 0.006 in2)

2

Publication 825-UM001B-EN-P January 2001

Page 30

2-10 Equipment Description

Main Current Transformers for the Motor Circuit

When the Cat. No. 825-M Control and Protection Unit is used as a secondary relay with Cat.

Nos. 825-MCM2 and 825-MCM20, the following specifications apply:

Table 2.G Main Current Transformer Ratings

Minimum nominal operating voltage Nominal operating voltage of motor

Minimum rated primary current

Rated secondary current 1 A or 5 A

Class and nominal

overcurrent factor

Power rating

Rated frequency 50/60 Hz

Burden:

Power consumption at max. rated current

Continuous thermal current 3 A 24 A

Thermal current, 1 s duration 250 A 600A

Frequency of input current 50/60 Hz 50/60 Hz

No-load

➊ Designation according to IEC 60044 part 2:

5 Total measurement error (percentage):

±5% within range up to rated nominal overcurrent (10X)

±1% at rated nominal primary current

P For protection purposes

10 Rated nominal overcurrent factor: 10X rated nominal primary current

ext.

Extended rated thermal current: 120% of rated nominal primary current (if

120%

rated nominal transformer current)

With starting current 10

The current transformer error in addition to the basic unit error

➋ 2.5 A with Cat. No. 825-MCM2, 20 A with Cat. No. 825-MCM20

1n

➋

General Notes on 825-MCM…

: class 5 P 20

e

Nominal operating current of motor

5 P 10 ext. 120% ➊

According to power consumption in leads

and measuring circuits

825-M +

825-MCM2

0.1 VA/phase 0.4 VA/phase

An open-circuit secondary is permitted, as the burden is

installed in the detection module

825-M +

825-MCM20

motor > 87% of

e

Publication 825-UM001B-EN-P January 2001

Page 31

Equipment Description 2-11

Core Balance Current Transformer

Table 2.H Recommended Data for Core Balance Current Transformer

Nominal ratio Kn =

Burden: Measuring circuit 825-M…

Power consumption at max. rated current 0.4 VA

Continuous thermal current 0.5 A

Thermal current, 1 s duration 25 A

Frequency of input current 50/60 Hz

A core balance current transformer, current ratio = 100:1, is available, and might suit most

applications. (Max. earth (ground) fault current = 30 A.

minimum detectable earth (ground) fault

Pickup current of basic unit earth (ground) fault protection

Short-Circuit Protection

Choosing a Circuit Breaker or Fuse and Associated Contactor

The branch circuit short-circuit protective device series (circuit breaker or fuse) must assure

that the motor can start while interrupting short-circuit currents rapidly enough to prevent

damage to the installation. To aid in the latter, the fuse rating should be as low as possible.

The lowest possible fuse rating depends on the starting current of the motor and the tripping

time set on the Smart Motor Manager.

The Short-Circuit Coordination of the Starter Must Always be Taken into Account

The contactor receives its tripping signal when the Smart Motor Manager basic unit trips. The

basic unit interrupts all current up to the point of intersection with the time/current

characteristics of the circuit breaker or fuse.

When starting large motors, the main contacts on the contactor are subjected to high thermal

loads. If the motor starting time exceeds a certain limit, the maximum permissible current has

to be reduced.

The rating of the fuse or contactor must also allow for the prospective short-circuit current.

The Bulletin 825 converter modules are short-circuit proof.

The coordination (grading) diagrams for contactors are available on request.

Publication 825-UM001B-EN-P January 2001

Page 32

2-12 Equipment Description

Response Supply Voltage Failure

If the supply voltage fails, the setting data are retained.

Failure of Supply Voltage > 30 ms

• All energized output relays drop out

• The LED extinguishes

• The timer for “duration of supply failure” starts (maximum 8 h)

• The instantaneous set and statistical data are recorded

• The LCD extinguishes

Recovery of the Supply Voltage

• Initialization routine is started

• The time of occurrence and the duration of the supply failure are entered into

memory

• The thermal image is calculated and updated

• All output relays return to the state before the supply failure, except for relay #2 and

#3, when control is executed via communication

• LCD and LED activate

Publication 825-UM001B-EN-P January 2001

Page 33

Equipment Description 2-13

Automatic Recognition of Converter Module

The Bulletin 825 regularly checks:

• The link between the basic unit and the converter module

• Verifies that the full load current set on the basic unit is within the range of the

converter module

• The supervisory circuits

In the event of a fault, the output relay MR trips and the type of fault is displayed on the LCD.

Table 2.I Converter Module — Related Error Messages

Verify Sequence Display

• After switching on supply

• Supervision while motor is stationary

• When running, as soon as the link is

Link between basic unit and

converter module

Verification that FLC on basic

unit is within range of converter

module

Supervisory circuits

interrupted the basic unit will trip and

display one or more of the following

causes:

• short circuit, thermal, earth fault

(Holmgreen = residual),

asymmetry, overcurrent

• After switching on supply

• After each change in setting of rated

current

• Continuous monitoring (hardware

errors, supply, etc.)

825-MCM NOT CON

Ie OUT OF RANGE

ERROR 825-MCM

Publication 825-UM001B-EN-P January 2001

Page 34

Chapter

Functions

Menu Overview

Actual Values

In “Actual Values” mode, all operating parameters can be selected and read from the LCD.

Table 3.A Actual Values Overview

3

%

e

%

e

%

e

%

e

Option Card

Cat. No.

— 6-5 I earth - C mA — 6-7

— 6-6 Tambient ºC 825-MMV 6-7

— 6-6 PT100 #1(…6) ºC 825-MMV 6-7

— 6-6 PROBUS — 825-MPB 6-7

Page Display List

Display List

I MOTOR A — 6-6 I earth - H %I — 6-7

I MOTOR

I 1

I 2

I 3

TRIP IN s — 6-6 RIO — 3600-RIO 6-7

RESET IN s — 6-7 MODBUS — 3600-MBS 6-7

ASYM % — 6-7 DevNet — 825-MDN 6-7

Option Card

Cat. No.

Page

Publication 825-UM001B-EN-P January 2001

Page 35

Functions 3-2

Set Values

The parameters “Main Settings” and “Special Settings” must be programmed for every

application. The other parameters (e.g., “High Overload”, “Asymmetry”) have factory-set

values, which are correct for most applications.

Table 3.B Set Values Overview

Parameter List

THERMAL TRIP — 5-4 THERMAL RESET LEVEL — 5-10

THERMAL WARNING — 5-4 COOLING CONSTANT RATIO — 5-10

ASYMMETRY TRIP — 5-5 PTC TRIP 825-MST 5-10

ASYMMETRY WARNING — 5-5 PTC RESET 825-MST 5-10

OVERCURRENT TRIP — 5-5 CONTROL INPUT #1 5-10

OVERCURRENT WARNING — 5-5 DELAY AUX REL # 2

EARTH FAULT PROTECTION — 5-6 SPEED SWITCH 5-11

EARTH FAULT HOLMGREEN TRIP — 5-6 DISABLE FUNCTION 5-11

EARTH FAULT CORE TRIP 825-MST 5-7 CONTROL INPUT #2 5-12

EARTH FAULT CORE WARNING 825-MST 5-7 DELAY AUX REL #3 825-MST 5-12

SHORT CIRCUIT PROTECTION 825-MST 5-7 NEW FULL LOAD CURRENT 5-12

UNDERLOAD TRIP — 5-8 PHASE REVERSAL TRIP

UNDERLOAD WARNING — 5-8 PHASE LOSS TRIP 5-13

STAR DELTA STARTING 825-MLV 5-8 PT100 PROTECTION

WARM STARTING — 5-9 PT100 RESET/WARNING

START INHIBIT — 5-11 OUTPUT 4…20 mA 825-MST 5-15

START CONTROL — 5-9 STATION NUMBER — 5-16

MAIN RELAY CONNECTION — 5-10 REL #2-3 VIA COM — 5-16

ALARM RELAY CONNECTION — 5-10 CLEAR RECORDED VALUES — 5-16

THERMAL RESET — 5-10 FACTORY SETTINGS — 5-16

Option

Card

Cat. No.

Page Parameter List

Option

Card

Cat. No.

825-MST

825-MLV

825-MMV 5-13

Page

5-10

5-13

ATTENTION

!

All parameters can be set, including those functions associated with

option boards that have not been mounted in the device. However,

these warning and trip functions are not operational unless the

corresponding option board is installed.

Publication 825-UM001B-EN-P January 2001

Page 36

3-3 Functions

Recorded Values

In “Recorded values” mode, all recorded data can be selected and read from the LCD.

Table 3.C Recorded Values Overview

Display List

825-M MAIN TIME h min. — 7-2 CAUSE 2PRV TRIP — — 7-3

MOTOR RUNNING HR h min. — 7-2 CAUSE 3PRV TRIP — — 7-3

SINCE LAST START h min. — 7-2 CAUSE 4PRV TRIP — — 7-3

SINCE 1PRV START h min. — 7-2 SINCE EMG START h min. — 7-3

SINCE 2PRV START h min. — 7-2 SINCE POWER OFF h min. — 7-3

SINCE 3PRV START h min. — 7-2 DURATION POW OFF h min. — 7-3

SINCE 4PRV START h min. — 7-2 I BEF LAST TRIP

SINCE LAST TRIP h min. — 7-2 AS BEF LAST TRIP % — 7-3

SINCE 1PRV TRIP h min. — 7-3 EF BEF LAST TRIP

SINCE 2PRV TRIP h min. — 7-3 MAX T BEF LAST TRIP ºC 825-MMV 7-4

SINCE 3PRV TRIP h min. — 7-3 TH BEF LAST TRIP % — 7-4

SINCE 4PRV TRIP h min. — 7-3 NUMBER START — — 7-4

CAUSE LAST TRIP — — 7-3 NUMBER TRIP (TH,

CAUSE 1PRV TRIP — — 7-3

Option

Card

Cat. No.

Page Display List

AS, OC, EF, SC, UL,

PTC, PR, PL, PT100)

Option

Card

Cat. No.

%

e

mA,

%

e

——7-4

Page

—7-3

—7-3

Publication 825-UM001B-EN-P January 2001

Page 37

Operation

Selecting the Setting/Display Mode

Actual

Change mode by

pressing

Recorded

Functions 3-4

SET

Set

Values

ACTUAL VALUES

Indication of actual

operational data

SET VALUES

ChangeActual

Setting mode

(set/vary, store parameters)

ChangeActual

RECORDED VALUES

ChangeActual

Indication of

statistical data

Publication 825-UM001B-EN-P January 2001

Page 38

3-5 Functions

Setting the Operation Parameters (Set Values)

Text and data are indicated alternately (approximately 2 s text and 1 s data). On the “second

line,” the data that is factory set or subsequently modified is displayed. Functions not

activated (OFF) are not indicated.

1. To set the operation parameters, repeatedly press the Va lu es button until “SET

VALUES” appears on the display.

Figure 3.1 Setting Mode

SET VALUES

Actual

Recorded

Values

Set

Select Settings

Change

Enter

2. Press Select (Up or Down) until the desired parameter (e.g., “FULL LOAD CURR”

and “35 Amp”) appears (display alternates between text and data).

Figure 3.2 Menu Selection

35 AMP

FULL LOAD CURR

Actual

Set

Recorded

Values

Select Settings

3. Press the Settings (Change) button once. The set value begins to flash. A new set value

can now be entered by means of the Select keys (Up or Down). The entry is completed

by pressing Settings (Enter).

Change

Enter

Publication 825-UM001B-EN-P January 2001

Page 39

Figure3.3 Entering a Data Value

Functions 3-6

35 AMP

Actual

Recorded

Values

Set

Select Settings

Change

Enter

Note: Hold down the Select button to change the values more quickly.

Table 3.D Display Example of Set Values Menu

LCD Range Description

SET VALUES

FULL LOAD CURR

20 A

PRIMARY C.T.

NO

PRIMARY C.T. RATIO

1

LOCKED ROT CURR

6 x Ie

LOCKED ROT TIME

10 sec

— Mode: setting parameters

0.5…2 000 Rated motor current in A

No/Yes Primary current transformer in use

1…2 000 Primary current transformer ratio

2.5…12

1…600

Maximum permitted time for the rotor to be stalled

Locked rotor current as

___

from cold

e

Note:For a complete list of parameters, refer to Chapter5.

Publication 825-UM001B-EN-P January 2001

Page 40

3-7 Functions

Indications of Actual Values

In “Actual Values” mode, all operating parameters can be selected and read from the LCD.

1. Press Values until “ACTUAL VALUES” appears on the display.

2. Press Select (Up or Down) until the desired information is displayed.

Figure 3.4 Selecting the Actual Values

ACTUAL VALUES

Actual

Recorded

Values

Set

Select Settings

Change

Enter

I MOTOR 00 %Ie

Actual

Set

Recorded

Values

Select Settings

Table 3.E Display Example of Actual Values Menu

LCD Range Description

ACTUAL VALUES

I MOTOR…A

TH UTILIZ…%

I MOTOR…% Ie

—

0.00… 49.99

50…24 000

0…100 Thermal utilization

0/20…999 Motor current as percent of rated current

Change

Enter

Display of the actual

values

Motor current in A

Note:For a complete list of parameters, refer to Chapter6.

Publication 825-UM001B-EN-P January 2001

Page 41

Functions 3-8

Applications

The “Actual Values” mode provides:

• Assistance during programming and setup

• Verification after maintenance or production change

• Continuous operational supervision

Indications of Recorded Values (Statistics)

In “Recorded Values” mode, all recorded data can be selected and read from the LCD.

1. Press Values until “RECORDED VALUES” appears on the display.

2. Press Select (Up or Down) until the desired statistical information is displayed.

Figure 3.5 Selecting Recorded Data

RECORDED VAL

Actual

Set

Recorded

Values

Select Settings

2 h 28 min

SINCE LAST TRIP

Actual

Recorded

Values

Set

Select Settings

Change

Enter

Publication 825-UM001B-EN-P January 2001

Change

Enter

Page 42

3-9 Functions

Table 3.F Display Example of Recorded Values

LCD Description

RECORDED VALUES

825-M MAIN TIME

_ _ _ H_ _ _MIN

MOTOR RUNNING TIME

_ _ _h_ _ _min

Bulletin 825-M* running time (including interruption ≤ 8 hour of control

Display of the statistical data

voltage in hours, minutes)

Total motor running time in hours, minutes

Note:For a complete list of parameters, refer to Chapter7.

Applications

The “Recorded Values” mode provides:

• Analysis of motor faults and production interruptions

• Analysis of premature motor failures

• A means of determining maintenance jobs on the switchgear, motor, and installation

Tes t Button

When the motor is at standstill, the alarms, trips, and tripping times of the protective

functions can be checked without external aids by pressing the Test button.

Figure 3.6 Basic Unit Test Button

Change

Enter

Settings

Publication 825-UM001B-EN-P January 2001

SMART MOTOR

MANAGER

Test

Reset

Page 43

Testing the Thermal Trip

1. Press the Test button.

LCD:

TEST THERMAL ON

2. After the set blocking time has expired, the basic unit must trip.

LCD:

LOCK ROT TIME

_ _ _sec

3. The LED lights.

4. The selected output relay picks up (MR, main relay, on trip).

LCD:

THERMAL TRIP

Resetting

Functions 3-10

Automatic: The trip becomes inactive when the Test button is no longer pressed.

Manual: Reset the trip with the Reset button.

Note: After the test, the thermal image resumes its correct state. Simulation of the motor

cooling is not affected by the test.

Testing the Trips (Asymmetry/Unbalance, Underload, etc.)

Example: Asymmetry

1. When in “Set Values mode”, access the selected output relay:

LCD:

ASYMMETR Y TRIP

AUX RELAY #2

Publication 825-UM001B-EN-P January 2001

Page 44

3-11 Functions

2. If no output is assigned the following readout appears:

LCD:

ASYMMETR Y TRIP

NO OUTPUT RELAY

3. Press the Test button.

LCD:

TEST

4. After the set trip delay expires, the basic unit must trip.

LCD:

AS TRIP TIME

_ _ _sec

5. The LED lights.

6. The selected output relay picks up.

LCD:

ASYMMETR Y TRIP

Resetting

Cancel the trip by pressing Reset.

Testing the Warning Functions

Example: Asymmetry warning

1. When in “Set Values” mode, access the selected output relay:

LCD:

AS WARNING

ALARM R ELAY

Publication 825-UM001B-EN-P January 2001

Page 45

Functions 3-12

2. Press the Test button.

LCD:

TEST

3. The LED flashes and the selected output relay picks up immediately.

4. LCD flashes

LCD:

TEST

AS WARNING

Resetting

As soon as the Test button is no longer pressed, the unit will automatically reset.

Publication 825-UM001B-EN-P January 2001

Page 46

3-13 Functions

Function Summary

Table 3.G Protective Functions Summary

Functions

Factory

Setting

Thermal overload On 100% — — MR, No MR

Asymmetry (phase failure) On 5…80% 35% 1…25 s 2.5 s All MR

High overloading/jam On

Underload Off 25…100% 75% 1…60 s 10 s All MR

Underload delayed enable On — — 0…240 s 0 s — —

Earth (ground) fault (residual) On 10…100% 50% 0.1…5 s 0.5 s All MR

Starting time monitor Off — — 1…240 s 10 s All MR

Limited starts per hour Off 1…10 2 — — All MR

Short-circuit Off

Earth (ground) fault

(core balance c.t.)

Stalling during start Off — ➊➊—All ➊ MR ➊

Thermistor input (PTC) Off — — — 800 ms All MR

Phase sequence (motor supply) Off — — — 1 s All MR

Phase failure (motor supply) Off — — — 2 s All MR

PT100 input #1…#6 (RTD)

(stator, bearings)

PT100 input #7 (RTD) ➋ Off——————

➊ Via external speedometer (control input #1), output and trip relays as for high overload.

➋ Allowing for the ambient temperature in the thermal image.

➌ Only one relay per function can be selected: MR = main relay, AL = alarm relay, auxiliary relay #1…#5 (if

auxiliary relays #2 and #3 are assigned to the communication [refer to page 5-16] they cannot be selected

here).

Setting

Range

Bulletin 825-M… Basic Unit

1…6

Bulletin 825-MST Option Card

4…12

Off 5 mA…50 A 1 A 0.1…5 s 0.5 s All MR

Bulletin 825-MLV Option Card

Bulletin 825-MMV Option Card

Off 50…200 °C 50 °C— <8 s

e

e

Factory

Setting

Tr ip pi ng

Delay

Range

2.4

0.1…5 s 0.5 s All MR

e

10

20…990 ms 50 ms #1, No #1

e

Factory

Setting

Relays ➌

Selection

MR, AL

#1…#3

Factory

Setting

MR

ATTENTION

Warning function settings must be such that associated alarms are

actuated before a trip occurs.

!

Publication 825-UM001B-EN-P January 2001

Page 47

Table 3.H Warning Functions Summary

Functions 3-14

Functions

Factory

Setting

Thermal utilization

(%∆ϑ load)

Asymmetry (%

High overloading (x

Underload Off 25…100%➋ 75%➋ — — AL, #1…5 AL

Earth (ground) fault

(core balance c.t.)

PT100 input #1…#6 (RTD)

(stator, bearings)

➊ Only one relay per function can be selected: MR = main relay, AL = alarm relay, auxiliary relay #1…#5 (if

auxiliary relays #2 and #3 are assigned to the communication [refer to page 5-16] they cannot be selected

here).

➋ Same setting as for the Underload Trip function.

)

e

e

Off 50…99% 75% — — AL, #1…5 AL

Off 5…80% 20% — — AL, #1…5 AL

)

Off

Off 5 mA…50 A 500 mA — — AL, #1…5 AL

Off 50…200 °C 50 °C — — AL, #1…3 AL

Setting

Range

Bulletin 825-M… Basic Unit

1…6

Bulletin 825-MST Option Card

Bulletin 825-MMV Option Card

Factory

Setting

e

Tri p pi ng

Delay

Range

2

e

Factory

Setting

— — AL, #1…5 AL

Relays ➊

Selection

Factory

Setting

Publication 825-UM001B-EN-P January 2001

Page 48

3-15 Functions

Table 3.I Control Functions Summary

Functions

Factory

Setting

Warm start (% of “cold”

trip)

Emergency override of

thermal trip ➊

Analog output assigned

to:

thermal utilization

PT100 max.

temperature

Motor

Bulletin 825-MST Option Card, Control Input #1: (24V AC/DC; 8 mA)

One of 3 functions can be selected:

1) Pickup delay, relay #2 Off — — 0…240 s 1 s — #2

1) Dropout delay, relay #2 — — — 0…240 s 2 s — #2

2) Speed switch Off — — — — —

3) Disable protective functions:

Asymmetry/phase failure Off — — — — — —

High overload/jam Off — — — — — —

Earth (ground) fault Off — — — — — —

Short-circuit Off — — — — — —

Underload Off — — — — — —

Limiting starts/hour Off — — — — — —

PTC Off — — — — — —

PT100 (RTD) Off — — — — — —

➊ Terminals Y11…Y12 must be jumpered.

➋ Minimum waiting time between two warm starts.

Setting

Range

Bulletin 825-M… Basic Unit

Off 50…100% 70% 4…60 min. ➋

—— — — ———

Bulletin 825-MST Option Card

4…20 mA

0…100%

On

50…200 °C

0…200%

Factory

Setting

—————

e

Tri p pi ng

Delay

Range

Factory

Setting

60 min.

➋

Relays

Selection

Factory

Setting

——

high overload relay

Publication 825-UM001B-EN-P January 2001

Page 49

Table 3.I Control Functions Summary (Continued)

Functions 3-16

Functions

Factory

Setting

Bulletin 825-MST Option Card, Control Input #2: (24V AC/DC; 8 mA)

One of three functions can be selected:

1) Pickup delay, relay

#3

1) Dropout delay, relay

#3

2) Set second rated

current ➊

3) Disable protective functions:

Asymmetry/phase

failure

High overload/jam Off — — — — — —

Earth (ground) fault Off — — — — — —

Short-circuit Off — — — — — —

Underload Off — — — — — —

Limiting starts/hour Off — — — — — —

PTC Off — — — — — —

PT100 (RTD) Off — — — — — —

Star-delta starting Off —

➊ For example, when used with two-speed motors

Setting

Range

Off — — 0…240 s 1 s — #3

—— —0…240 s2 s—#3

Off

Off — — — — — —

0.5…

2 000 A

Bulletin 825-MLV Option Card

Factory

Setting

20 A — — — —

Y-∆ at 1.1

Tri p pi ng

Delay

Range

Y-∆ at 1…240 s 10 s — Y: #4/∆:#5

e

Factory

Setting

Relays

Selection

Functions of the Basic Unit (Cat. No. 825-M…)

Factory

Setting

Thermal Overload

The Smart Motor Manager accurately simulates thermal conditions in the motor for all

operating modes. This permits maximum utilization of an installation and assures safe

protection of the motor.

The basic unit uses a two-body simulation to calculate a more precise representation of a

motor’s thermal condition during all modes of operation. A two-body simulation incorporates

the temperature rise characteristics of both the stator windings and the iron mass of the

motor into the thermal image.

The simulation of the Smart Motor Manager accurately represents the conditions in the

motor at all times.

Publication 825-UM001B-EN-P January 2001