Page 1

MultiSight™ Vision Sensors

USER MANUAL

48MS

Page 2

Important User Information

WARNING

ATTENTION

BURN HAZARD

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams. No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an

explosion in a hazardous environment, which may lead to personal injury or

death, property damage, or economic loss.

IMPORTANT

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead to

personal injury or death, property damage, or economic loss. Attentions

help you identify a hazard, avoid a hazard, and recognize the consequences.

SHOCK HAZARD

Labels may be on or inside the equipment (for example, drive or motor) to

alert people that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, drive or motor) to

alert people that surfaces may reach dangerous temperatures.

We recommend that you save this user manual for future use. The following symbols are used in this manual for clarification.

This symbol indicates supplemental sections of the text which contain useful

tips.

Identifies features and functions that are only available with EtherNet/IP

E

models. These features and functions are not available on the standard

MultiSight models.

Page 3

MultiSight™ User Manual

Important User Information

Table of Contents

Important User Information and Definition of Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Components Supplied. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Requirements for Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Performance Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Description of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Network Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Basic Settings for PC and MultiSight Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the IP Address of the PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Setting the IP Address of the MultiSight. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Firmware Update. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Program Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

File/Exit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Options/Language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Help/Help . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Help/About. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Program Interface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Commands . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Select Detector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Detector Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Detector Types—Detailed Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Image . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Pattern . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Setup—Quick Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Example Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

RESET/Power On. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Frequently Asked Questions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Technical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Use of Control Input IN2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Control Input: Activate 0 or 1 and Activate 0 to 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Control Input: Teach Temporary or Teach Permanent. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Trigger Mode Parameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Minimum Operating Distance and Field of View by Cat. No.. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Connector Pin Assignments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Dimensional Drawings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Mounting Setup Illustration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

10000000877(02) 3

Page 4

MultiSight™ User Manual

E

E

E

IMPORTANT

Components Supplied

Components Supplied

• Bulletin 48MS MultiSight vision sensor with integrated lighting

• Computer software on CD-ROM

• Installation instructions, mounting bracket 48MS-BKTDT with three screws, Allen wrench, screwdriver, and protective cap for

M12 Ethernet connector.

• Two PVC M12 QD covers (must be installed around the metal coupling nuts of both connection cables for ESD protection).

Typical Applications

The MultiSight is an optical multipixel sensor with a pass/fail PNP output. The MultiSight uses three ( four) different methods of

evaluation (pattern matching, contrast, brightness, and contour matching) to detect or differentiate objects by means of

previously defined optical characteristics, e.g. for separating “good” and “bad” parts. The main applications are in the field of

industrial automation for quality assurance purposes. The MultiSight can be used for detecting presence or absence, completeness,

position, markings, labeling, packaging, and components. The MultiSight is an economical alternative to conventional vision

systems.

Requirements for Use

To configure the MultiSight, the following items are required: PC or notebook with minimum Pentium III, 1 GHz, 256 MB RAM,

Microsoft Windows 98, 2000, XP™, or Vista™ network connection or network with TCP-IP protocol. Recommended screen resolution

1024 x 768 pixels. Basic knowledge of computing and electronics wiring is also essential. The IP address of the MultiSight is set by

the manufacturer to 192.168.100.100 with sub-net mask 255.255.255.0.

The operation of the MultiSight is independent of a computer or PLC. A PC or notebook is required only for configuring the sensor.

For reproducible results and avoidance of malfunctions, adequate and consistent object illumination is essential.

Reflections or varying incident light may affect detection results.

If necessary, use an external white-light source and/or light-

screening devices to exclude incident light.

4 10000000877(02)

Page 5

MultiSight™ User Manual

E

E

E

E

E

E

Description of Operation

Performance Features

• Vision sensor

• Easier handling and setup than traditional vision systems

• 640 x 480 resolution CCD chip

• Integrated white-light illumination

• Image display on computer using included software

• Standalone sensor function

• Compact, sturdy, industrial housing (IP67) with standard 8-pin micro (M12) QD connectors

• Detection distance adjustable from 20 mm to infinity (see “Minimum Operating Distance and Field of View by Cat. No.” on

page 63 for corresponding field of view)

• Four outputs (PNP type sourcing MOSFETs), two inputs (sinking)

• Short evaluation time

• Three (or four) evaluation methods: Pattern Matching, Brightness, Contrast, and Contour Matching

• Ten virtual detectors or 32 virtual detectors

• Individual virtual detectors can be logically linked or grouped for evaluation of different objects with several characteristics

for inspection

• Ethernet connection for setup

• EtherNet/IP connection for communication of I/O information

• RSLogix 5000 Add-on Profile for ease of integration into a Logix-based control system

Description of Operation

Basics

The image recorder of the MultiSight is a CCD chip with a resolution of 640 x 480 pixels. Evaluation is based on 320 x 240 scanning

points. The sensor is designed for inspection and cannot provide measurement information. To operate the MultiSight, at least one

virtual detector must be configured by designating a Region of Interest and teaching a sample image (see screen shot on page 20).

This virtual detector is stored in a non-volatile flash memory on the sensor and is re-activated for standalone operation after

switching off and on. Standalone operation is, therefore, possible with or without PC or PLC.

Evaluation Method

During operation, the MultiSight continuously compares the pattern of the detected image with that of the reference image. The

pixel grey-scale values of the sample are analyzed and a level of conformity to the original sample is determined. If this level falls

within the user adjustable threshold settings, the sensor turns the PNP output ON or OFF (i.e., the part passes or fail s the inspection).

The EtherNet/IP connection is capable of communicating additional data about the inspection.

10000000877(02) 5

Page 6

MultiSight™ User Manual

E

E

E

IMPORTANT

Installation Instructions

Setup

The PC must be connected to a MultiSight sensor via the Ethernet

port to load the configuration software. Also, Run mode of the

sensor is automatically stopped when the software connects to

the sensor. The software is tightly integrated with the firmware on

the sensor. As parameters are changed in the software they are

changed in the sensor. There is not a typical “download” or

“upload” process, but the “write to flash memory” button in the

software must be pushed to save the settings from the sensor’s

RAM to the sensor’s nonvolatile flash memory. The Teach

command is used only for teaching the pattern, contour, or

shutter speed (in automatic shutter adjustment mode). The active

detector in the software is the active detector in the sensor. This

means that if the sensor is switched to run mode, whatever

detector was most recently selected in the software will

determine the output of the sensor ( unless it is changed via

EtherNet/IP).

If an EtherNet/IP connection is established, the Logix add-on

profile output tag FirstDetector will control which detector is

active and override the configuration software setting. To give

control of which detector is active back to the configuration

software, set the FirstDetector tag value to -1.

Installation Instructions

Installation

To help provide maximum accuracy of detection, the MultiSight should be protected from vibration.

Secure the connection cables with cable binders to prevent

crushing or slipping.

Select a position for the MultiSight in which interfering factors

such as slight differences in the position of the object or

variations in lighting have little or no effect.

Attach the MultiSight onto the dovetail mounting bracket, 48MS-BKTDT (supplied with the unit) and then onto a suitable object

above the target. Use only the 48MS-BKTDT for mounting the unit (see “Approximate Dimensions—mm (in.)” on page 68).

6 10000000877(02)

Page 7

MultiSight™ User Manual

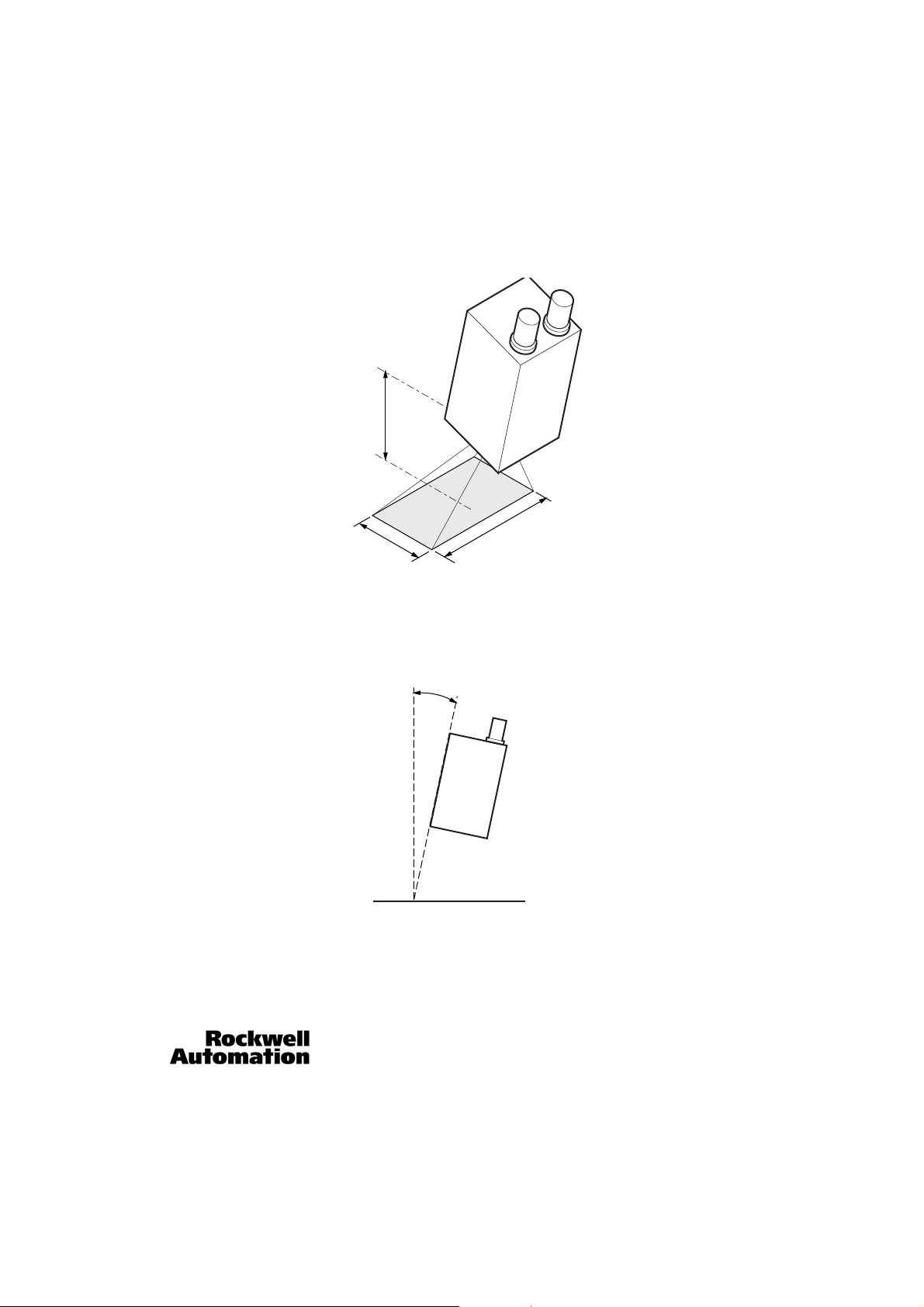

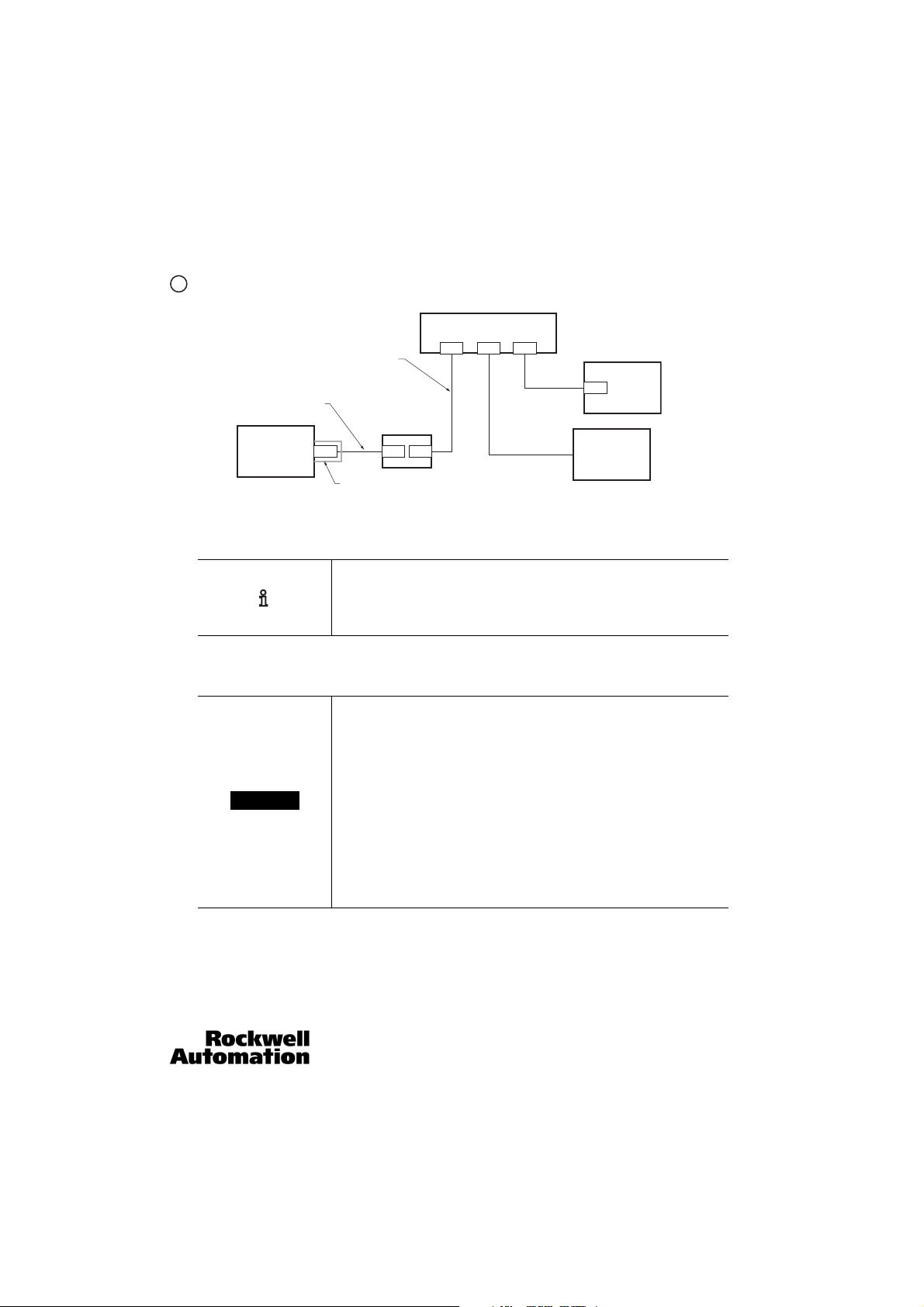

Operating

Distance

Height of

Field of View

Width of

Field of View

Approx. 10…15°

Target Surface

Installation Instructions

The height and width of the field of view is determined by the operating distance (see “Minimum Operating Distance and Field of

View by Cat. No.” on page 63).

For most applications, it is recommended to align the MultiSight at an angl e of approximately 10…15° with reference to the optical

axis in order to avoid interfering reflections from the inspection target.

10000000877(02) 7

Page 8

MultiSight™ User Manual

IMPORTANT

ATTENTION

E

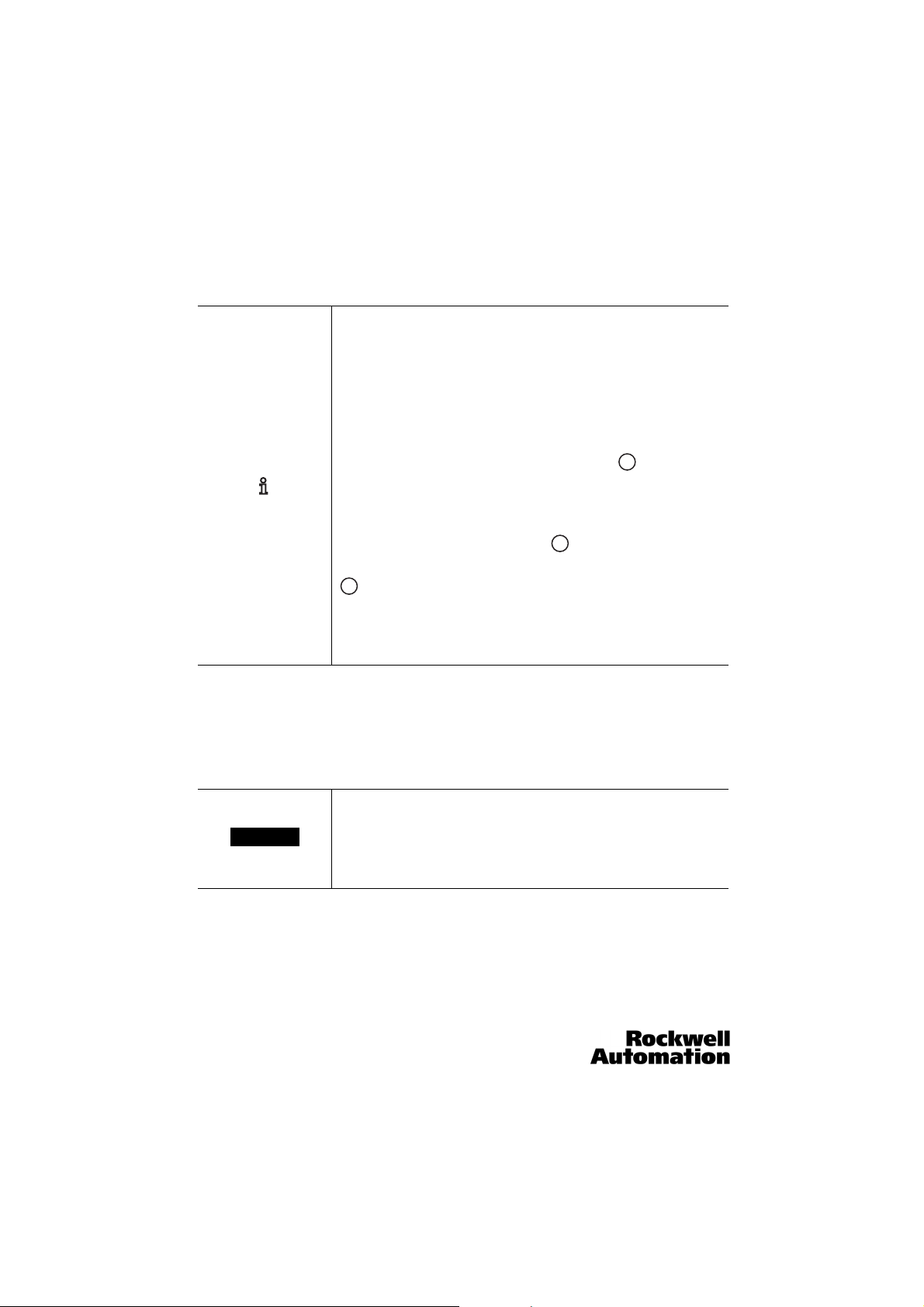

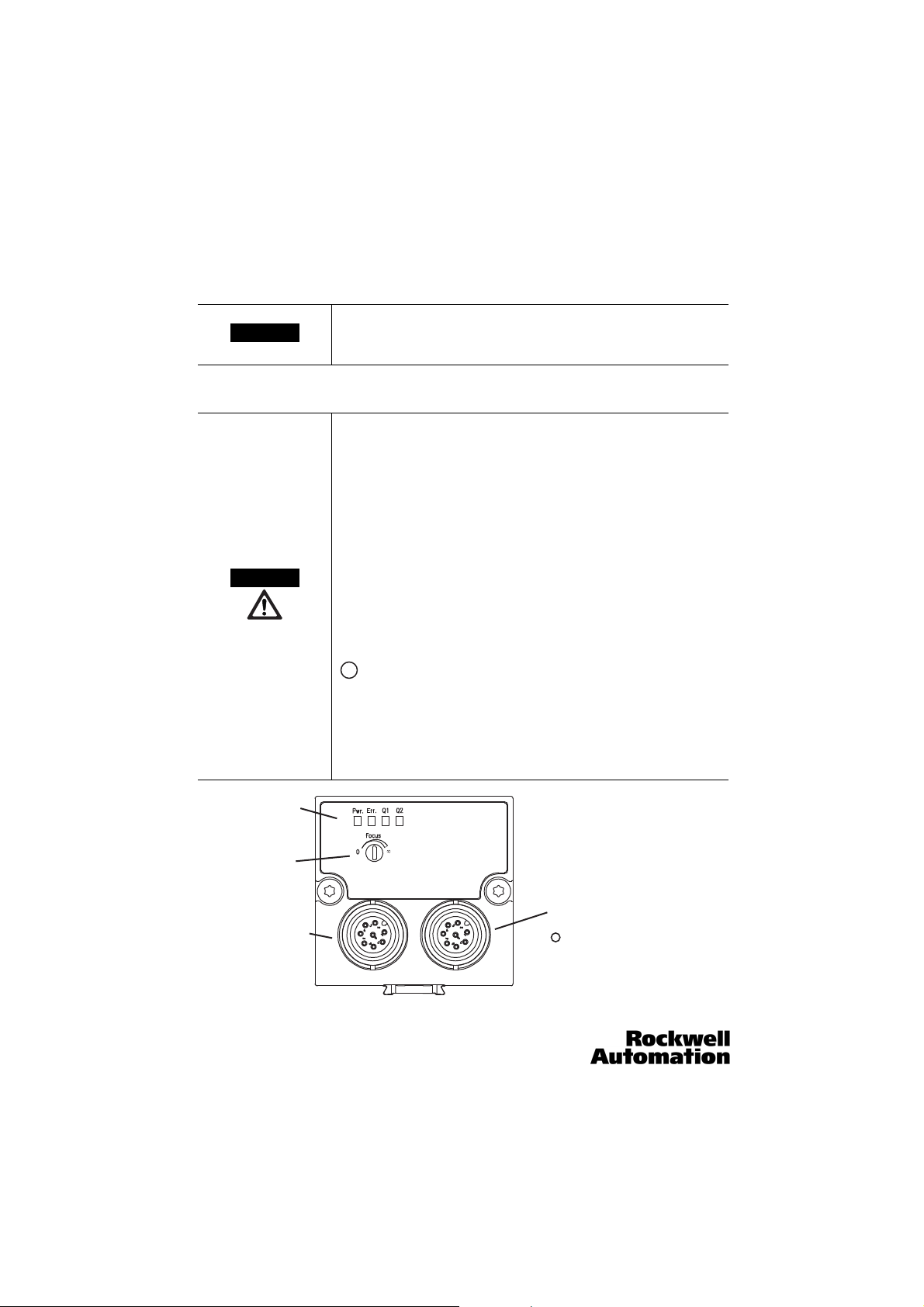

Focus Adjustment

LED Indicators

M12 Connection Socket

24 V DC and I/O

M12 Connection Socket ENET

(8-pin on standard models,

4-pin D-code on EtherNet/IP models)

PWR-I/O ENET

E

Installation Instructions

Fine Adjustment

Electrical Installation

Fine adjustment of the MultiSight should not be carried out until

after electrical connection and start-up (PC software installation)

(see “Start-up” on page 18).

The electrical installation of the MultiSight must be carried out by

a qualified electrician.

When installing the MultiSight disconnect all electrical

components from the power supply.

When the unit is used on a network, make sure that the network

address (IP address) of the MultiSight set by the manufacturer at

192.168.100.100 is still free and is not in use by any other unit

connected to the system.

If necessary, reset the IP address of the MultiSight as described in

“Network Settings” on page 11.

When the MultiSight is in use, the protective caps supplied must

be covering the M12 socket (Ethernet) if it is not in use. Failure to

do this may cause malfunction.

EtherNet/IP models only:

The supplied black PVC M12 covers must be installed around the

coupling nut of each connection cable (Power-I/O and ethernet)

to protect from ESD when using standard cables. (There is a

plastic nut on the MultiSight specific cables to provide this ESD

protection, so the PVC cover is not required for 48MS-CS-2 and

48MS-ECSCROSS-3.)

8 10000000877(02)

Page 9

Sensor Display LED Description

48MS

ENET

PC

PWR

I/O

PLC

ENET (a)

PWR and I/O (b)

E

IMPORTANT

E

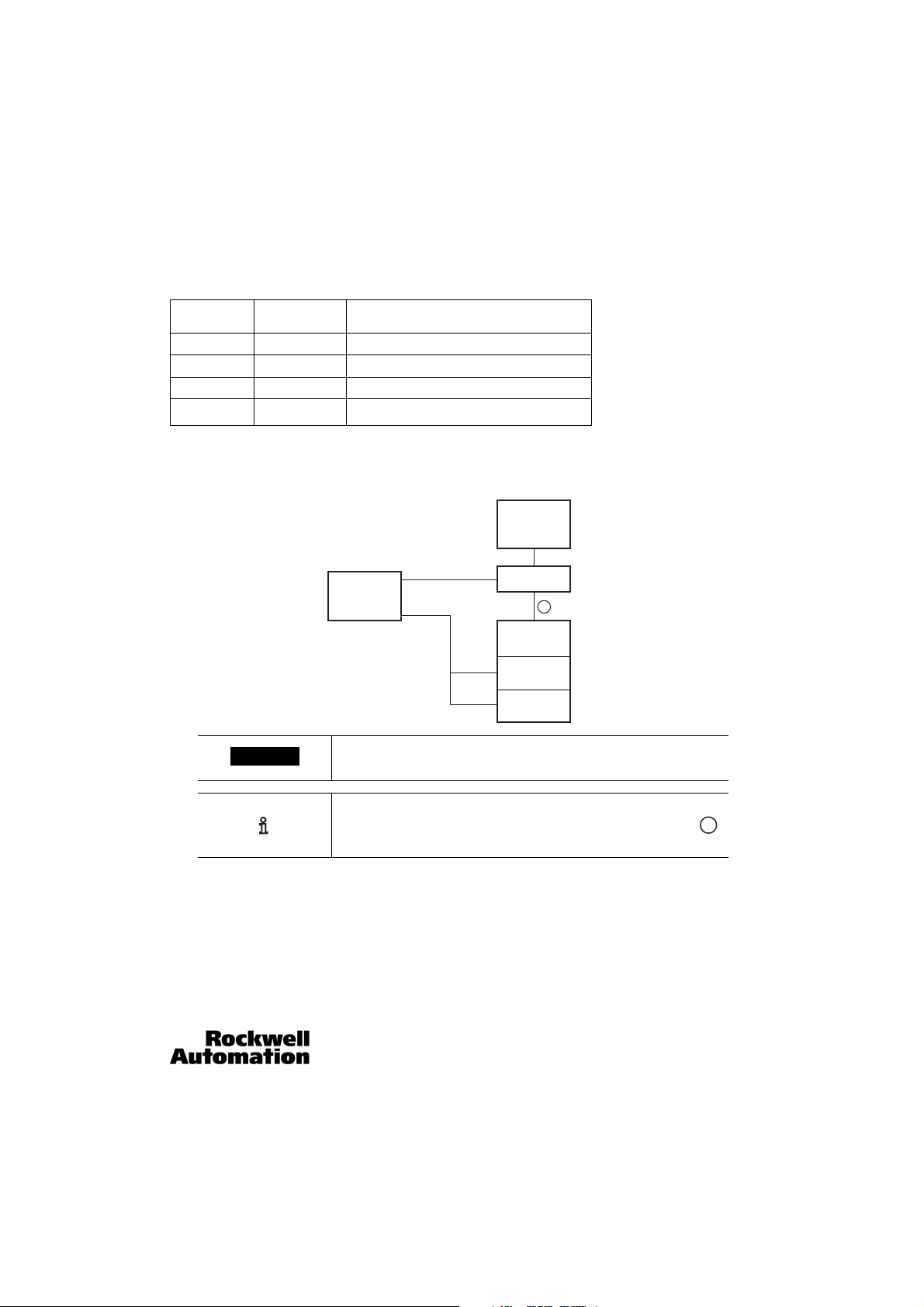

Name Color Meaning

Pwr. green

Err. red

Q1 yellow

Q2 yellow

Operating voltage

Error

Result 1 (pass/fail = OUT1)

Result 2 (position = OUT2)

Tab le 1 : Tabl e Dis pla y LE Ds

For electrical installation, connect the MultiSight as shown:

MultiSight™ User Manual

Installation Instructions

Use only the correct connection cables as listed below (see

“Accessories” on page 67).

The Ethernet connection is only required for setup. During normal

operation, only the PWR and I/O cable needs to be connected (

unless using the EtherNet/IP functionality).

10000000877(02) 9

Page 10

MultiSight™ User Manual

48MS PC

Ethernet Cable

48MS-ECS-3

Network

e.g. Switch, Hub, etc

Standard

Network Cable

M12

RJ45 RJ45

RJ45

E

E

48MS

48MS-M12CVR

PC

Ethernet

Connector

1585A-DD4JD

Ethernet

Cross Cable

48MS-ECROSS

M12 M12 RJ45 RJ45

Ethernet Cordset

(1585D-M4TBDM-2*)

Installation Instructions

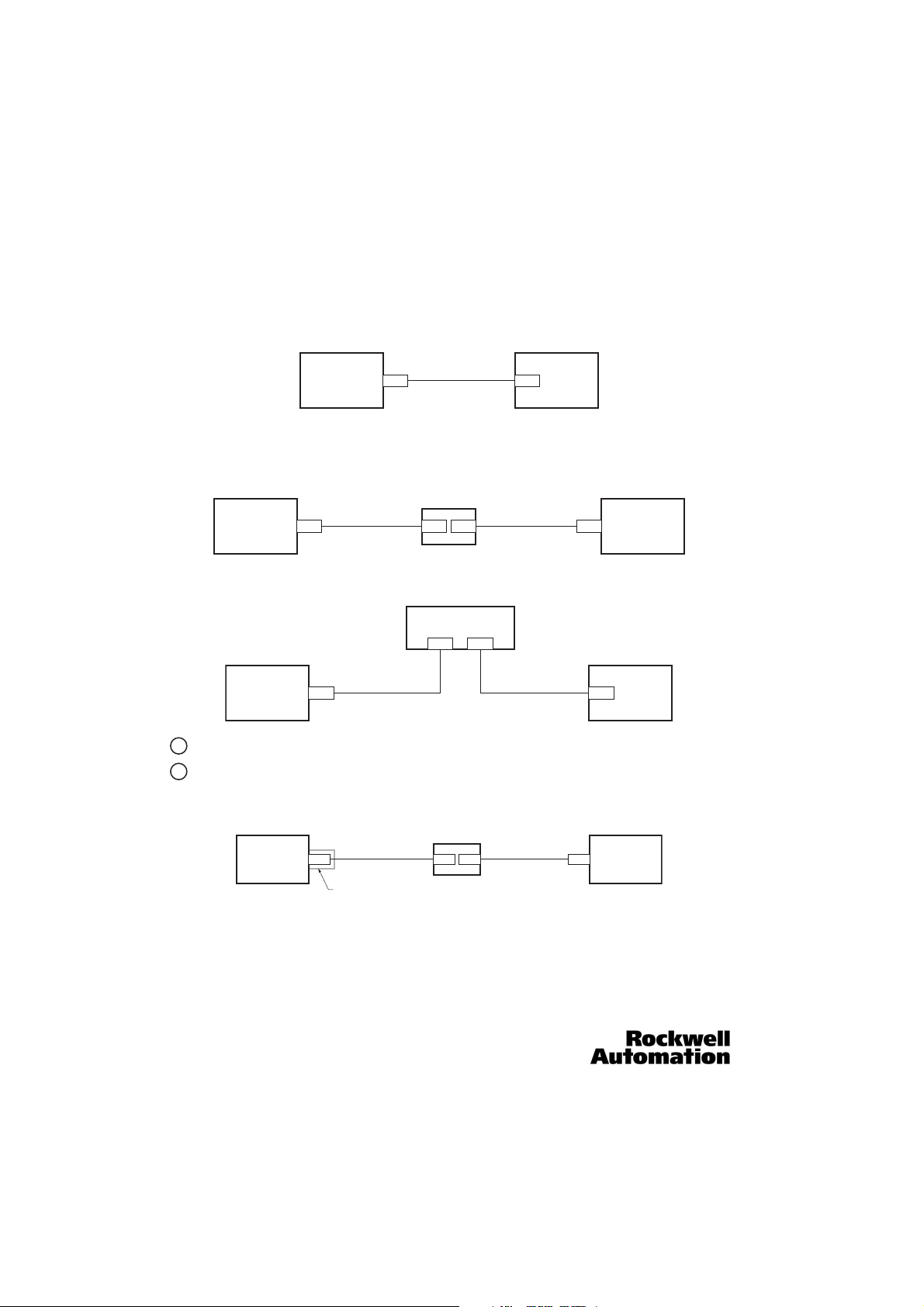

Network Connection (a) for standard models

Direct connection of the MultiSight to a PC with a single crossover cable (recommended):

Ethernet

Cross-over Cable

48MS-ECSCROSS-3

48MS PC

Direct connection of the MultiSight to a PC with an industrial ethernet cable and a separate standard RJ-45 crossover cable:

Ethernet Cable

48MS PC

Connection of the MultiSight to a PC via a network:

M12 RJ45

Ethernet

Connector

48MS-RJ45Conn

48MS-ECS-3

RJ45M12 RJ45 RJ45

Ethernet

Cross Cable

48MS-Ecross

Network Connection (a) for EtherNet/IP Models

Direct connection of the MultiSight with EtherNet/IP to a PC with an industrial ethernet cable and a separate standard RJ-45

crossover cable:

10 10000000877(02)

Page 11

MultiSight™ User Manual

E

48MS

PC

Ethernet Cable

1585J-M8TBJM-2*

Ethernet Cable

1585J-M8TBJM-2*

Network

e.g. Switch, Hub, etc

Standard

Network

Cable

RJ45 RJ45RJ45

RJ45

Ethernet

Connector

1585A-DD4JD

EtherNet Cable

1585D-M4TBDM-2*

M12 RJ45

PLC EtherNet/

IP Scanner

48MS-M12CVR

M12

IMPORTANT

Network Settings

Connection of the MultiSight with EtherNet/IP to a PC and PLC via a network:

Power and I/O Connection (b)

Connector pinouts and a detailed wiring diagram are shown in the “Connector Pin Assignments” section on page 66.

If the “Control Input” parameter of the active detector is set to

“Enable” (the default setting), the control input (IN2) must be

connected to V+ (24V DC) in order to operate the sensor with an

external trigger (input IN1) (see page 66).

Network Settings

The following instructions indicate how to change the network

configuration of the PC and the MultiSight. If incorrect settings

are used, the network links in the computer may be lost. Note the

current settings for later use before making any changes.

It may be necessary to re-start the system during this procedure.

In order to determine which IP addresses are allowed in your

network or locally in your PC, and to carry out the necessary

settings on your PC, contact your system administrator.

The illustrations, dialogues and menus originate from the

TM

operating system Microsoft Windows XP

. The illustrations are

similar in other operating systems.

10000000877(02) 11

Page 12

MultiSight™ User Manual

IMPORTANT

IMPORTANT

Network Settings

Basic Settings for PC and MultiSight

To configure the MultiSight Sensor with a PC it is essential that Ethernet capability is installed in the PC and the LAN connection on

the PC is active with a TCP/IP protocol. This also applies when the PC is not connected to a network (see “Network Connection” on

page 8). In addition, every machine in the network must be allocated a unique IP address.

For the MultiSight Sensor Finder software to detect a MultiSight

via Ethernet, all wireless Ethernet connections from the PC must

be disabled. Also, deselect “Check Point SecuRemote” in the Local

Area Connection Properties and disable any firewalls.

The IP address consists of four decimal blocks in the for mat aaa.bbb.ccc.ddd where each block may have a value from 0-255. The first

three decimal blocks (aaa.bbb.ccc) form the address area.

In order to use the configuration software, the address area of the PC and the MultiSight must be identical. The fourth decimal block

(ddd) must be different.

The sensor finder tool (Connect/Find) can be used to change the IP address of the MultiSight, even if the address area of the PC and

MultiSight are different.

Example:

If the IP address of the PC is 192.168.2.67, any address between 192.168.2.1 and 192.168.2.254 can be selected for (with selected

subnet mask 255.255.255.0) the MultiSight, with the exception of the IP address of the PC (192.168.2.67) and the IP addresses of

any other machines in the network.

The IP address of the MultiSight is set by the manufacturer to 192.168.100.100. In the above example, the IP address of the

MultiSight therefore has to be reset to the address range of the PC (see “Setting the IP Address of the MultiSight” on page 15).

Setting the IP Address of the PC

Contact your system administrator to determine which IP

addresses are allowed in your network or locally in your PC, and to

carry out the necessary settings on your PC.

The IP address of the computer needs to be set when the MultiSight is directly connected with the computer (see “Electrical

Installation” on page 8) and only if the computer has no IP address. In all other cases, the IP address of the MultiSight has to be

adjusted to that of the computer (see “Electrical Installation” on page 8).

12 10000000877(02)

Page 13

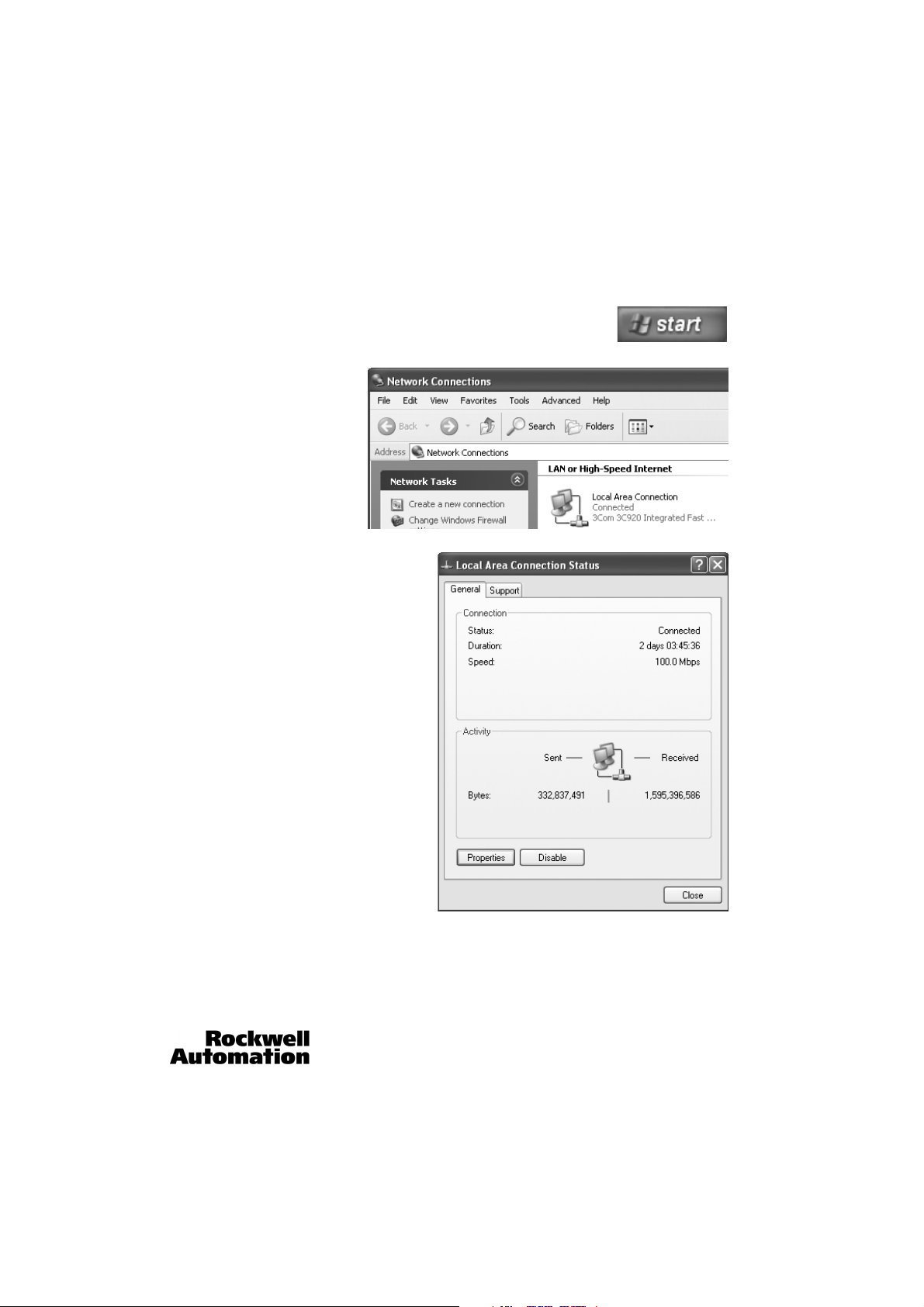

To set the IP address of the computer carry out the following procedure in the operating system:

1. Click on the “Start” button on your computer.

2. Click on “Settings”

3. Click on “Network Connections”

4. Double click on “Local Area Connection”

MultiSight™ User Manual

Network Settings

10000000877(02) 13

Page 14

MultiSight™ User Manual

Network Settings

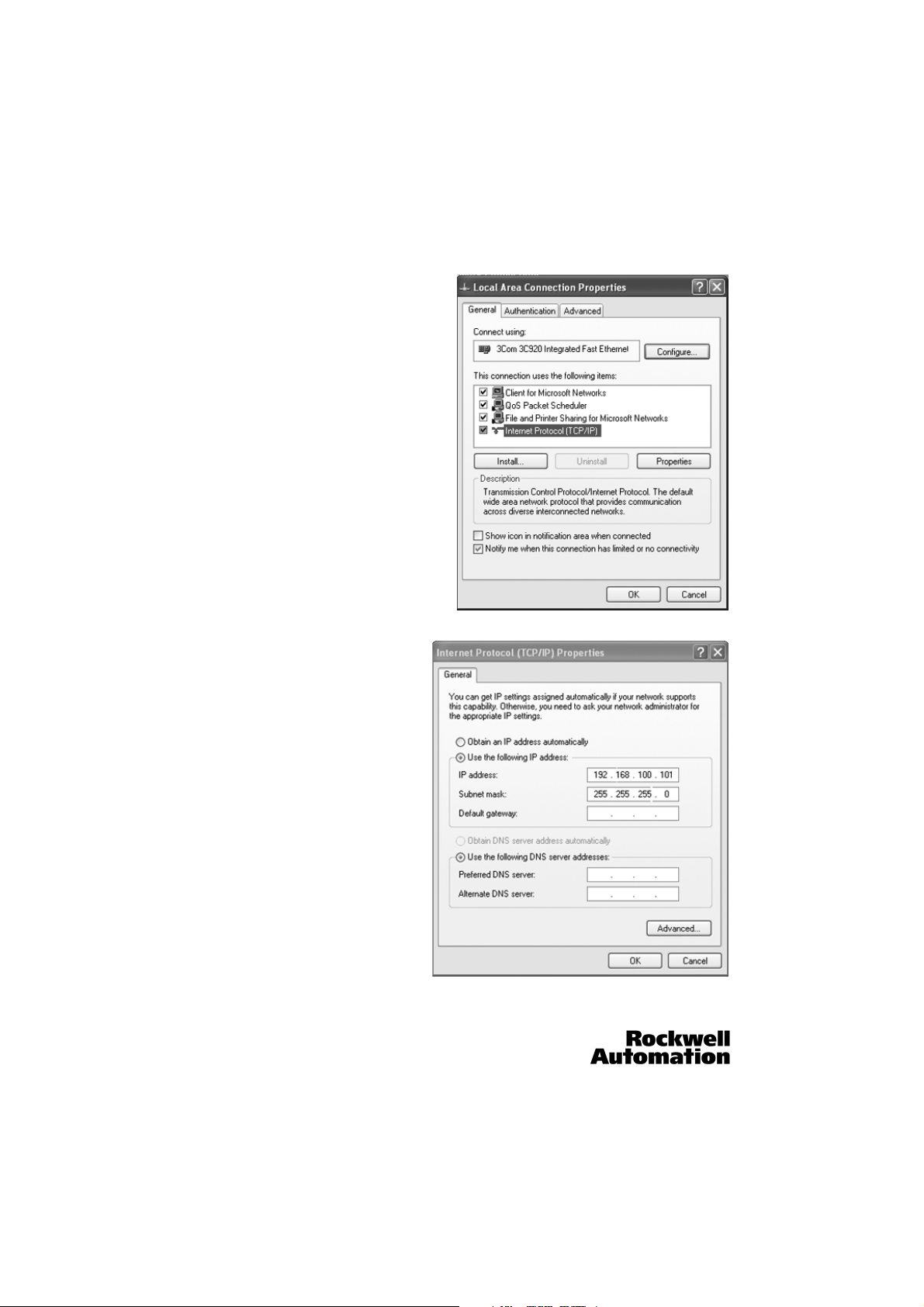

5. Click on “Properties”

6. Click on “Internet Protocol TCP/IP” properties

7. Set the IP address and Subnet mask per the

previous page

14 10000000877(02)

Page 15

MultiSight™ User Manual

IMPORTANT

IMPORTANT

Network Settings

Setting the IP Address of the MultiSight

Contact the system administrator to determine which IP

addresses are allowed on your network for the MultiSight. The IP

address set for the MultiSight should be marked on the enclosed

label. After installation, stick the label on the sensor in a clearly

visible position.

Before setting the IP address, make sure that the computer is connected as described in “Electrical Installation” and “Basic Computer

Settings” (see “Electrical Installation” on page 8 and “Basic Settings for PC and MultiSight” on page 12).

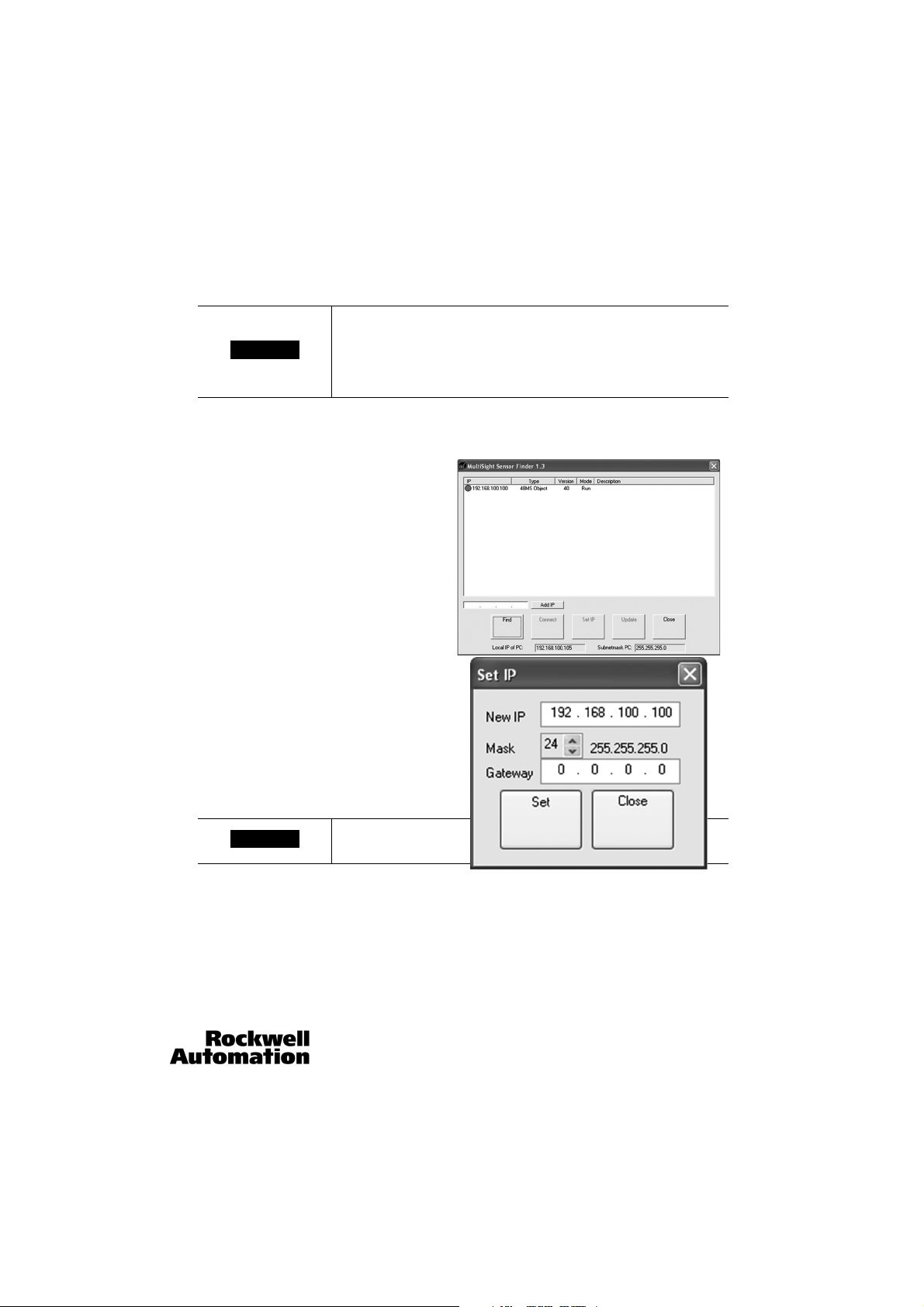

To set the IP address on the MultiSight, proceed as follows in

the PC software:

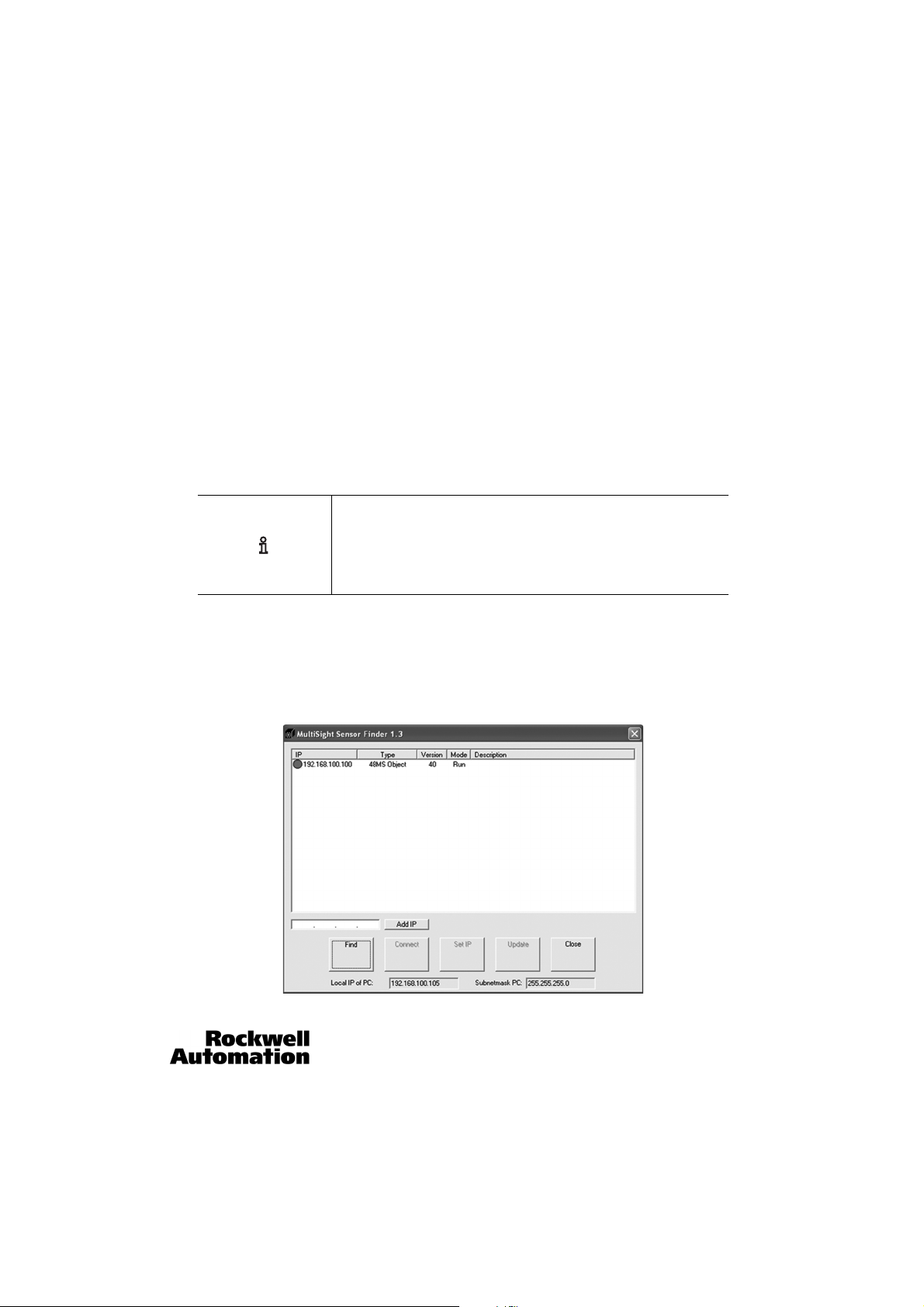

1. Open the MultiSight software.

2. Click on the “Find” button. After a few seconds, a list of

sensors in the network appears. If this does not happen,

repeat the Find process.

3. Select the desired sensor by clicking on it.

4. Click on the “Set IP” button and enter the desired IP

address for the MultiSight (same as the IP address of the

PC except for the last block, see “Basic Settings for PC and

MultiSight” on page 12). Click Set to accept.

It is possible to adjust the subnet mask and standard

gateway using the set IP function. It is recommended to

not change these settings unless necessary.

It is not possible to see a MultiSight on a different standard

gateway than your PC using the sensor finder function.

5. Switch the power to MultiSight off and on again, and

click on Find again to locate the sensor with the newly assigned address.

Note: the period between the sensor re-start and successful Find is approx. 6 sec. If necessary, repeat Find operation.

The MultiSight is now ready for operation at the newly-assigned IP address.

For network operation use only IP addresses which have not already been assigned.

10000000877(02) 15

Page 16

MultiSight™ User Manual

Network Settings

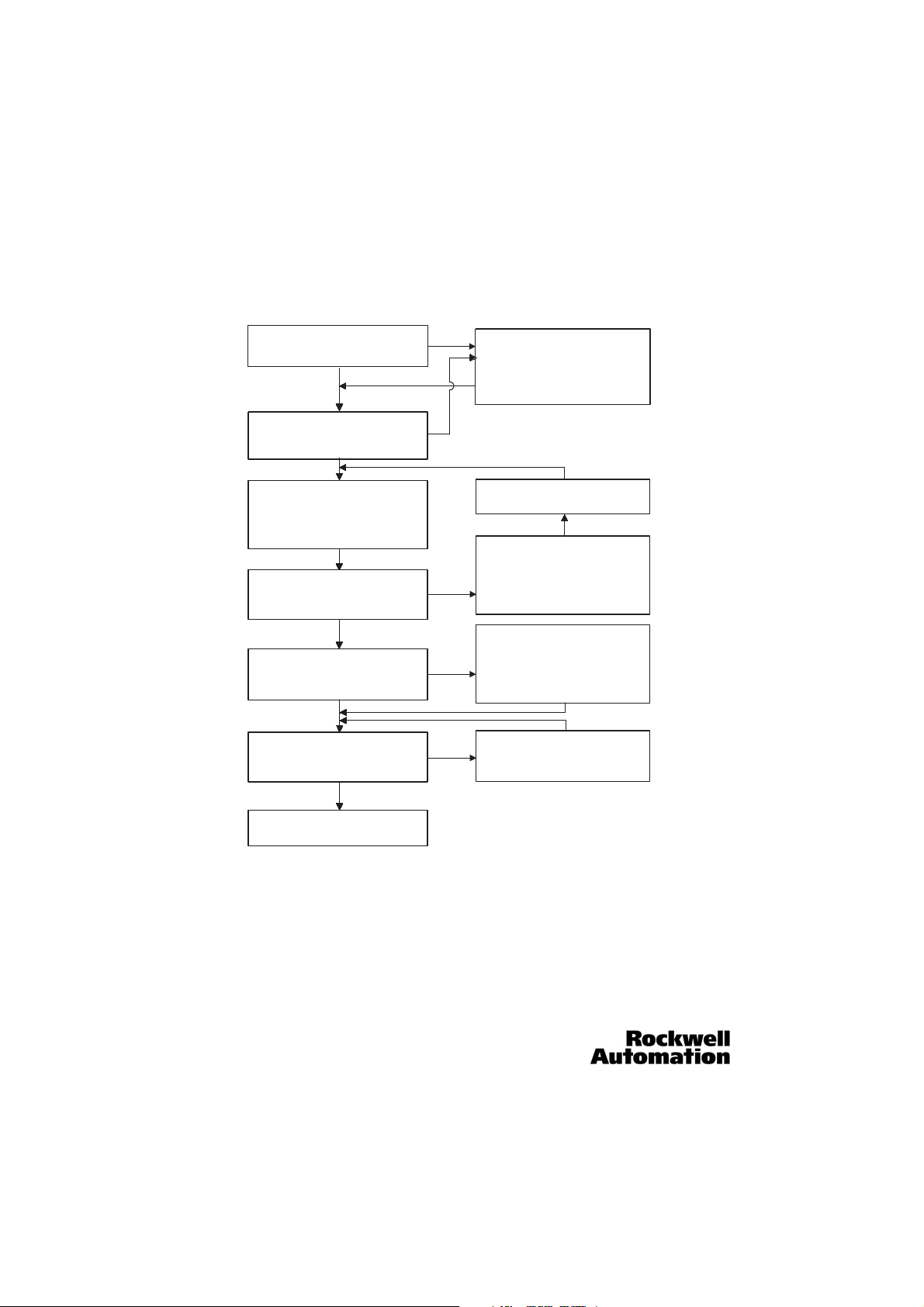

Creating a Functioning Ethernet Connection Between a PC and a MultiSight

1. Direct connection (see “Electrical Installation” on page 8)

All cables correctly connected?

24V DC Power Supply?

yes

Electrical connection ok?

MultiSight Pwr LED on

Network: Start/Settings/Network connections

No red X on Local Area Connection

Set IP address of PC to xed address.

Start/settings/network connections/

(right click) local area connection/

Internet Protocol (TCP/IP)/Properties/

IP address = 192.168.100.101/255.255.255.0

Click Connect/Find in MultiSight PC Software

IP Address area of sensor and PC identical?

Click Connect/Find in MultiSight PC software

and make connection with "Connect"

yes

Contact system administrator

Sensor is listed with IP

Success

i.e., IP aaa.bbb.ccc = identical

yes

no

no

Failure

no

Failure

Connect all cables correctly

1. Power and I/O cable

2. Ethernet crossover cable

Check settings, adjust if necessary

Conrm (via LAN properties) that rewalls,

wireless networks, and check point

secure remote are disabled.

After second attempt

Execute "Ipcong"

Start/run/cmd: input. "ipcong"

Execute "ARP"

Start/run/arp -a -d

Reset IP address of sensor

i.e., aaa.bbb.ccc. = identical to PC IP

address area

.ddd = dierent

Execute "Ping"

Start/run/cmd/ping "IP-Adr.Sensor"

e.g., "192.168.100.100"

Check software and sensor version?

Success

Done

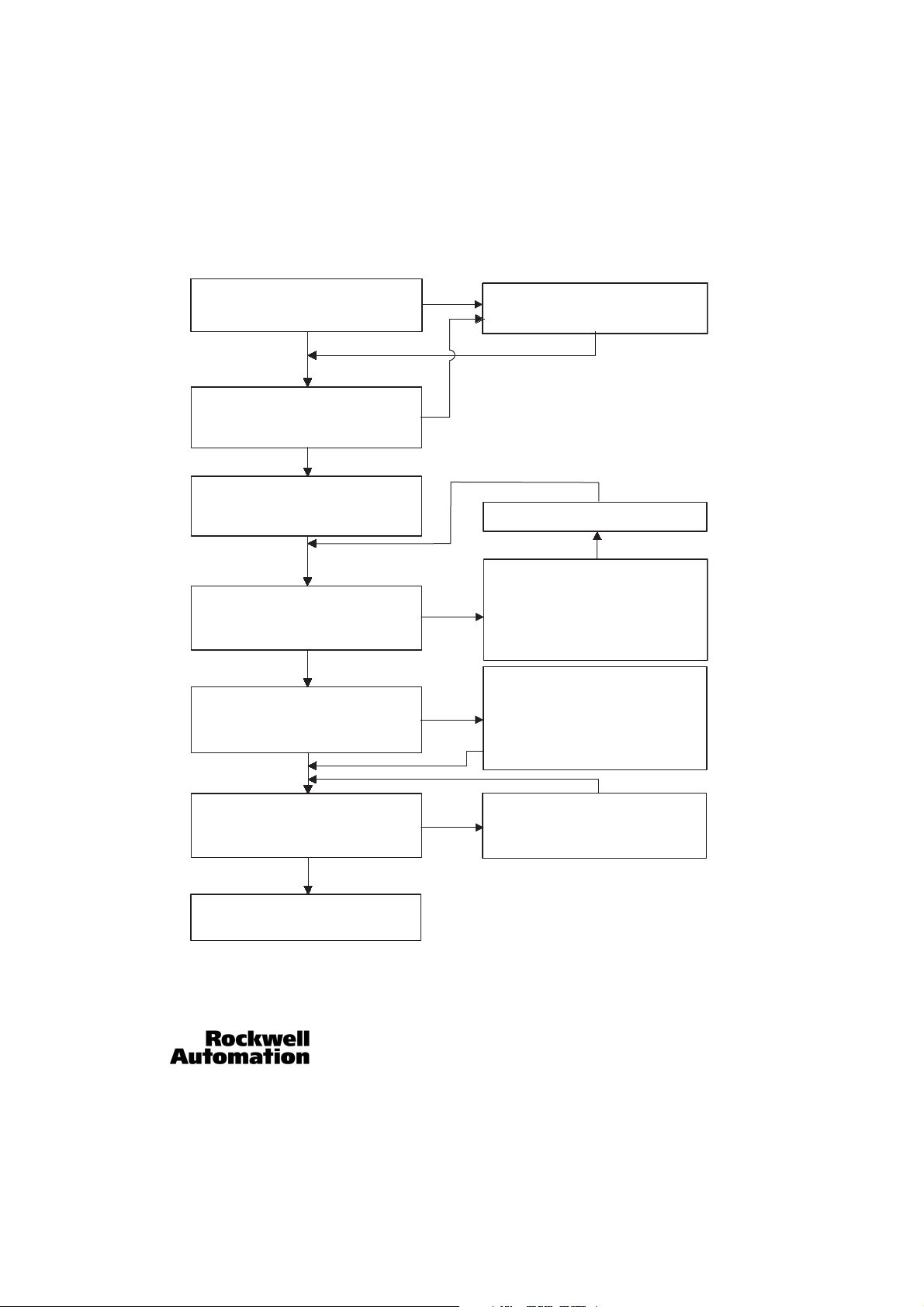

2. Network connection (see “Network Connection (a) for standard models” on page 10)

16 10000000877(02)

Page 17

MultiSight™ User Manual

Connect all cables correctly

1. Connecting cable

2. Ethernet cable (straight)

Obtain IP address for sensor

from system administrator

If necessary execute IPCong.

Determine IP of PC and note

yes

no

no

Failure

Failure

All cables correctly connected?

Check settings, adjust if necessary

Success

Success

no

Done

yes

yes

Electrical connection ok?

MultiSight Pwr LED on

Network: Start/Settings/Network connections

No red X on Local Area Connection

Click Connect/Find in MultiSight PC Software

Sensor is listed with IP

Click Connect/Find in MultiSight PC software

and make connection with "Connect"

IP Address area of sensor and PC identical?

i.e., IP aaa.bbb.ccc = identical

Check software and sensor version?

Execute "ARP"

Start/run/arp -a -d

Conrm (via LAN properties) that rewalls,

wireless networks, and check point

secure remote are disabled

Execute "Ipcong"

Start/run/cmd: input. "ipcong"

Reset IP address of sensor

i.e., aaa.bbb.ccc. = identical to PC IP

address area

.ddd = dierent

Execute "Ping"

Start/run/cmd/ping "IP-Adr.Sensor"

e.g., "192.168.100.100"

Network Settings

10000000877(02) 17

Page 18

MultiSight™ User Manual

IMPORTANT

IMPORTANT

Start-up

Firmware Update

Before using the Update function, consult your Support group

and use only the original update files from the manufacturer. The

execution of the function must not be interrupted as this may

cause failure of the MultiSight. The stored detector configurations

are deleted by the update and must be redefined when the

function is concluded.

This function allows you to update the software of the MultiSight.

To update the software of the MultiSight proceed as follows:

Open the MultiSight software.

“Find” and select the desired sensor.

Click on the button “Update” and select the desired update file.

Switch the MultiSight Sensor off and on again.

Reconfigure the MultiSight Sensor with the PC software.

Start-up

Rockwell Automation supplies defect-free software for

installation in the customer‘s plant and integration in the

customer‘s computing system. Rockwell Automation is not liable

for any interference, failure or damage to the customer‘s system

caused by the installation or integration of this software.

These conditions are accepted by the customer without

reservation by clicking the button at the start of the softwareinstallation process.

The MultiSight functions only with software supplied. Software

updates are available online at www.ab.com/go/multisight.

The PC Software must always match the corresponding sensor

firmware.

Installation of older versions of the software using Windows 98,

2000 and XP™, requires administration rights. Please download

the latest version of the software from the above location.

18 10000000877(02)

Page 19

MultiSight™ User Manual

Start-up

To start the MultiSight, proceed as follows:

1. Switch on the power supply (24V DC) for the MultiSight. If necessary, connect the control input (IN2) with V+ (24V DC) (see

note on page 11).

2. For the first start-up of the MultiSight, install the supplied software on the computer that will be used for configuring the

sensor. When the CD is inserted, the installation program starts automatically or can be started using the setup program /

Software/ MultiSight.exe. Then follow the instructions on the screen.

3. During installation, the file MultiSight Sensor Finder.EXE is created (standard folder: C:\Program Files\Rockwell

Automation\MultiSight\…), a link is added to the start menu (standard location: Start\Programs\Rockwell

Automation\MultiS ight\…), and an icon is added to the desktop (icon “MultiSight Sensor Finder”). This User Manual can also

be read directly from the CD-ROM (supplied).

Un-install Procedure

The software can be un-installed by using the operating system

(Windows 2000 and XP™) under Start/Settings/Control Panel/Add

or Remove Programs. Scroll down and select “MultiSight Sensor,”

then click the “Remove” button.

4. Configure the network settings according to the instructions in the “Network Settings” section on page 11.

5. Start the PC sof tware by double-clicking the “MultiSight Sensor Finder” icon.

After the installation of the PC software, only one related icon (MultiSight Sensor Finder) is visible on the desktop. Double

click on this icon to open the software which then executes one find loop and shows the list of all MultiSight sensors found on

the local ethernet network. The IP address of the computer is shown at the bottom of the window.

10000000877(02) 19

Page 20

MultiSight™ User Manual

Start-up

6. Click the desired sensor to select it in order to Connect, SetIP, or Update. Click the Connect button in order to establish a

network connection with the sensor and start the configuration software.

If no sensor can be found with the Find command, it is possible to connect manually with function “Add IP” by filling in the

known IP-address of the sensor.

7. Click “Yes” to stop Run mode of the MultiSight and connect to the sensor.

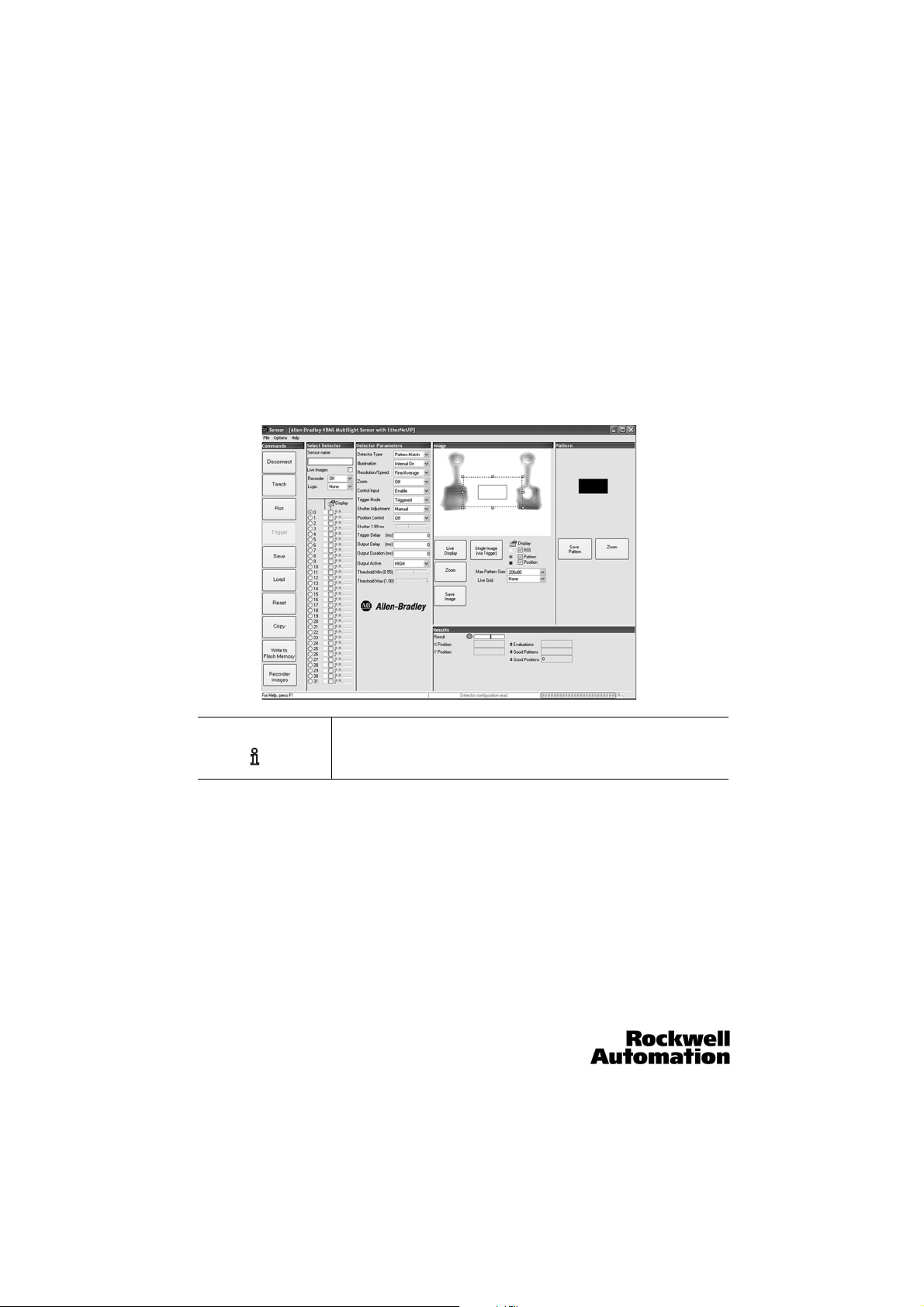

8. The configuration software looks like this:

The configuration software can only be opened when the

computer is connected to a powered and functional MultiSight.

9. If the software was able to make a connection with the MultiSight, all the buttons are activated after a few seconds and the

image currently “seen” by the sensor is displayed in the Image window.

If the buttons are not activated, (i.e., greyed out) the software was not able to connect with the MultiSight.

• Check cable connections and IP address of both the MultiSight and the computer. If necessary, set the IP address of the

PC and/or the sensor as described in the “Network Settings” section on page 11. Use the MultiSight Sensor Finder software to attempt to reconnec t. If unable to connect, read the “Network settings” section on page 11 and make the necessary settings to the PC and/or sensor.

10. Click the “Live Display” button in the Image window. After a moment the image in the window begins to be repeatedly

refreshe d.

20 10000000877(02)

Page 21

MultiSight™ User Manual

IMPORTANT

Start-up

11. If no live image appears, check to confirm the following:

a. No obstruction in front of the lens.

b. Sufficient lighting. Detector Parameter “Illumination” should be “Internal ON” or sufficient external lighting provided.

c. Correct shutter settings (under Detector Parameters—see screen shot). Increase shutter time to brighten the image.

d. Correct focus—focus screw on back of MultiSight.

5. Adjusting image focus: To adjust image definition, turn the focusing screw on the back of the housing (see the illustration in

“Electrical Installation” on page 8) in clockwise direction (increase the focusing distance) or counterclockwise direction

(decrease the focusing distance). Check the position of the MultiSight and adjust if necessary.

Make fine adjustments to shutter speed and focus using “GOOD”

parts to enable optimal configuration.

The basic setup of the MultiSight is complete. To differentiate between “GOOD” and “BAD” parts, use the software to configure the

MultiSight. The next sec tion describes the configuration software.

10000000877(02) 21

Page 22

MultiSight™ User Manual

IMPORTANT

Start-up

Program Description

Menu

The menu for the PC program has main and subsections. These are selec ted by clicking the desired menu item or by pressing the ALT

key and the first letter of the menu item at the same time.

File/Exit

Exit program.

Options/Language

Select language. The new language does not take effect until the software is restarted. (Currently English is the only available

language.)

Options/Result Display

(Keyboard Locked)

The “Result” window is shown enlarged in a pop-up window. This mode locks the keyboard and limits the mouse pointer to the popup window.

This mode can only be de-activated by placing the mouse pointer

over the Result indicator (the grey, green, or red circle next to the

top bar graph) and pressing the key combination ALT + B at the

same time.

Help/Help

Display the help file (a pdf of the User Manual).

Help/About

Displays software version number.

22 10000000877(02)

Page 23

MultiSight™ User Manual

Program Interface

The program interface is entirely displayed on one screen. It is arranged into six windows as follows:

Commands

Select Detector

Detector Parameters

Image

Patte rn

Results

Start-up

10000000877(02) 23

Page 24

MultiSight™ User Manual

E

Start-up

Commands

The buttons shown along the left hand side of the screen are for the general operation of the MultiSight, administration of detector

configuration and displaying other information on the program.

If a button is not active (i.e., greyed out) then that command is not

available in the current mode.

Command Description

Connect/Disconnect Connect to or disconnect from MultiSight (see Setup).

Conne ct:

Last IP—connects to the most recent IP address used

Default IP—connects to the default IP address 192.168.100.1 00

New IP—type in IP address to connect to

Find—Opens sensor finder (use when IP address of MultiSight is unknown)

Listed IP addresses—recently used IP addresses. Connect to an address by clicking on it.

Disconnect:

Existing connection to MultiSight is disconnected. MultiSight goes into run mode.

Tea c h

Teach the pattern ( or contour) currently in the red pattern box in the image window.

Also used to determine th e shutter speed (when Shutter Adjustment param eter is set to

Automatic).

The Teach command does not affect other configuration

parameters. Other configuration parameters are changed on

the MultiSight as soon as they are changed in the software.

Teach from MultiSight image—the MultiSight will take a new picture and learn the pattern

or contour in the red pattern frame. Note: this image could be different than what is

currently displayed, if the part has moved or a setting has been changed.

Teach from PC image—[Recommended method] the MultiSight will learn the pattern or

contour in the red pattern frame of the image currently displayed in the image section of the

software.

24 10000000877(02)

Page 25

MultiSight™ User Manual

Start-up

Command Description

Run/Stop Run Evaluation mode (MultiSight is automatically in Run mode when not connected to

Trigger Manual triggering of MultiSight image evaluation (active only in “Run” mode and if Trigger

Save Save the detector configuration for one detector or all detectors.

Load Load previously saved detector configuration(s).

Reset The configuration parameters for a single detector or for all detectors are reset to the default

Copy Copy the configuration of one or many parameters from one Source Detector Configuration

Write to Flash Memory Writes all detector parameter settings to nonvolatile flash memory so that they are

the software)

Stop Configuration mode. Configuration parameters can only be changed in this mode.

parameter is set to “tri ggered” (see “Detector Parameters” on page 32) or when triggered

image button in image section is pushed).

settings.

to other detector s.

Logically linked or grouped detectors must have identical settings for certain parameters

(see page 28). Recommended procedure:

1. Set the parameters of one detector to the desired configuration

2. Press the Copy button

3. In the Copy command pop-up window, select the configured detector from the

Source Detector Configuration drop-down list.

4. Selec t the detectors along the left side of the window that need to match the Source

Detector Configuration (e.g., detectors that are logically linked or grouped with the

source detector).

5. Selec t Default Par. at the bottom right of the window. This automatically selects all

the parameters that n eed to match for logically linked or grouped detec tors.

6. Press the OK button to copy the Source Detector Configuration to the other selected

detectors.

maintained if the sensor loses power.

10000000877(02) 25

Page 26

MultiSight™ User Manual

E

E

E

Start-up

Command Description

Recorder Images Transfers the images saved on the MultiSight to the computer.

The MultiSight can save up to 30 images on its local memory. To save images, the Recorder

parameter in the Sele ct Detector window must be turned on (see page 27). Based on the

setting of that parameter, the MultiSight can save either the last 30 images or the last 30

images of inspections that resulted in an output of FAIL.

When the images are transferred to the computer, they are deleted from the MultiSight

memory. In order to keep the image, it must be saved to the computer using the Save button

on the Saved Pics pop-up window that opens when the images are transferred.

It is possible to save either the current image or all the images by using the Save or Save All

buttons. The images are stored as bitmap files (.bmp).

Images are saved in dynamic memory and are, therefore, lost if the sensor loses power or is

turned off.

Select Detector

The MultiSight can be configured with up to ten ( 32) vi rtual detectors (i.e. inspection of ten ( 32) different characteristics).

In order to configure one of the ten ( 32) detectors, select the appropriate numbered radio button in the Select Detector

window. The current configuration of that detector appears and can be edited in the Detector Parameters section. (If that detector

on the MultiSight has not been previously configured, the default values appear.) Parameters that are changed in the software are

immediately changed on the MultiSight in dynamic memory. In order to permanently save changes in Flash memory on the

MultiSight, click the Write to Flash button in commands window..

When the sensor is in run mode, each detector is independently evaluated. The results of these evaluations are indicated to the right

of the radio buttons for each detector. The small grey dots change color to represent the results of the individual detector evaluation,

with green indicating PASS and red indicating FAIL. The first dot is for inspection (pass/fail) OUT1 (LED Q1) and the second dot is for

position OUT2 (LED Q2). While in run mode, a green (or blue) line on the bar graph indicates the degree of similarity to the pattern or

contour the sensor has been taught for that detector. When using contrast or brightness detector types, the bar graph indicates the

level of contrast or brightness. The black line on the bar graph represents the threshold (configured in the “Detector Parameters” on

page 34).

Detectors can be logically linked together. For example, the sensor can be set up to inspect multiple components on a product. Each

component is inspected by a single detector. The evaluation result of each detector is then logically combined with the evaluation

results of all the other detectors, resulting in a single output (OUT1/LED Q1). If the AND (All) logic is selected, all selected detectors

must pass evaluation for the pass/fail output OUT1 to give a PASS output. (If any one detector fails its evaluation output OUT1 gives

a FAIL output.) I f the OR (Search) logic is select ed, OUT1 gives a PASS output if any one of the detectors passes its evaluation. See the

parameter descriptions below for an explanation of how to logically link detectors.

Detectors can also be grouped. The grouping of detectors makes it possible to check several characteristics on different parts without

reconnecting the software during part changes. For example, during the first production shift of the day Part A is inspected for

several characteristics, then during the second production shift Part B is inspected for different characteristics. The sensor can be

changed via the Control Input on the PWR and I/O connector from Part A to Part B without having to reconnect to the software via

the Ethernet port. See “Use of Control Input IN2” section on page 58.

26 10000000877(02)

Page 27

MultiSight™ User Manual

IMPORTANT

Parameter Description Screen Shot

Sensor name Assign a name for the connected MultiSight. This name appears in

Live Images When this checkbox is selected, the live image is displayed in the

Recorder Off No images are recorded on the sensor

the MultiSight Sensor Finder software and allows for easier

identification of the correct sensor when multiple MultiSight

sensors are on a single network.

Image window of the software during Run mode.

Selecting this mode increases evaluation

cycle time (whether the sensor is connected

to the software or not). Deselect this option

for the faster evaluation time.

Failed images The MultiSight records up to the last 30 images

of evaluations that FAIL

All images The MultiSight records up to the last 30 images

(both PASS and FAIL)

See Commands/Recorder Images on page 24 for instructions on

transferring the images from the MultiSight to the computer

Start-up

10000000877(02) 27

Page 28

MultiSight™ User Manual

IMPORTANT

Start-up

Parameter Description Screen Shot

Logic The Logic field allows the user to define how the detectors are

linked together to determine the single OUT1 (pass/fail) output. A

detector can be standalone (inspection of a single characteristic),

logically linked (multiple inspections on a single part), or grouped

(multiple inspections on different parts). ( The concept is more

thoroughly described in the above general description of the Select

Detector window.) The state of the inspection output OUT1

(passes/fails)/LED Q1 is determined by how the individual detec tor

evaluation results are linked in the Logic field.

The evaluation of logically linked detectors is

based on a single image. This means that

certain detector parameters must be the

same for all detectors that are logically

linked together (see the chart below). The

recommended procedure is to set the first

detector in the group to the desired settings,

then use the Copy command in the

Commands window (on the left of the

software screen, see page 24) to copy the

configuration of that detector to the other

detectors that will be logically linked.

The software will give the error message

“group parameter check failed” when the

sensor is put into run mode if detectors that

are linked together have nonmatching

parameters that should match.

28 10000000877(02)

Page 29

MultiSight™ User Manual

E

Parameter Description Screen Shot

Logic (con tinued)

Select radio buttons 0-9 ( 0-31) in order to configure the

parameters for that detec tor. Detectors that are logical ly linked

should follow these guidelines for the Detector Parameter

configurations:

Detector Type any

Illumination identical

Resolution/Speed any

Zoom identical

Control Input identical

Trigger Mode identical

Shutter Adjustment manual

Posit ion Contro l any

Shutter identical

Trigger Delay identical

Output Delay identical

Output Duration identical

Output Active identical

Threshold

Min any

Threshold Max any

The Logic field has the following options:

None—No logical link or grouping, i.e. only the selected detector

determines the output.

AND (All) and OR (Search)—The inspection output OUT1 (pass/

fail) is based on the evaluation of all detectors selected via the lefthand check box. (In the screen shot, detectors 1-6 are logically

linked.)

AND (All)—OUT1 is active if ALL selected detectors pass

evaluation

OR (Search)—OUT1 is active if ANY of the selected detectors

passes evaluation

AND and OR (group)—The group functionality allows the

MultiSight to make several different inspections on multiple parts

without reconnecting to the software to change between the

parts. (This functionality is described more thoroughly above in the

general description of the Select Detector window.)

Start-up

10000000877(02) 29

Page 30

MultiSight™ User Manual

IMPORTANT

Start-up

Parameter Description Screen Shot

Logic (continued) In order to use the grouping functionality,

It is not possible to logically link groups with one another.

The functionality of the left-hand check box is different for

grouping than for the logical linking previously described. The

evaluation of a group begins with the detector last selected via the

Control Input (IN2). (When the sensor is connected to the

computer for configuration, the radio button currently selected will

determine which detector the sensor begins the group evaluation

with.) The sensor evaluates each detector that has a check in the

left hand box. The next detector that does NOT have a check is the

last detector in the group. If detectors 1-3 have a check and 4 does

not, Group A is detectors 1-4. See the screen shot to the right.

The detectors in different groups do not have to have matching

parameters; however, those within the same group must follow

the matching parameter guidelines listed above.

Detector Parameter Control Input must be

set to “Activate 031” for ALL active

detectors.

The same Logic is applied to each Group of

detectors. Example: if the detectors in Group

A are logically linked with AND, the detectors

in Group B will be logically linked with AND.

It is not possible to link Group A with AND

and Group B with OR.

}

Group AGroup B

}

30 10000000877(02)

Page 31

MultiSight™ User Manual

E

Parameter Description Screen Shot

Radio buttons

0…9

0…31)

(

Display icon Checking this box indicates whether the yellow Region of Interest

Designates the active detector—by clicking one of the ten radio

buttons, the corresponding detector is selected and its parameters

can be configured. The parameters are displayed in the Detector

Parameters window in the middle of the screen. Only one detector

can be configured at a time. After restart, the most recently

selected detector is active. The selected detector evaluates a

Region of Interest (ROI) which is configured in the Image window.

If a certain de tector is to be tested, select that detec tor and click

the Run command button to the left.

(ROI) and red pattern frames should be shown on the Image during

Run mode even if the detector is not selected with the radio

button. The Region of Interest (ROI) and pattern frames of the

detector selected with the radio button are automatically

displayed during Run mode; other detectors with a check in the

display icon box are shown but greyed out. This function does not

affect the performance; it is just included to ease the setup process.

Logical link—The time required for execution increases with the

number of logically linked active detectors.

The evaluation with logical linking affects both the primary

inspection pass/fail output OUT1 and the secondary position

result OUT2.

Start-up

10000000877(02) 31

Page 32

MultiSight™ User Manual

E

E

Start-up

Detector Parameters

To configure a detector, select the appropriate radio button in the Select Detector window and then set the parameters in the

Detector Parameters and Image windows. Each detector is configured independently. (Detector parameter configurations can be

copied into other detector parameters using the Copy command, see page 24.)

Parameter Description

Detector Type

Illumination Internal On Internal lighting is on for image exposure. Trigger

There are 3 ( 4) different methods of evaluation:

Pattern Matching (page 35)

Contrast (page 36)

Brightness (page 35)

Contour Matching (page 37)

These detector types are described in detail starting on page 35.

Each of the 10 detectors can have a different detector type (e.g.

Detector 1 = Pattern Match, Detec tor 2 = Contrast, etc.). This is

true even if the detectors are logically linked or grouped together.

for external lighting is generated.

Internal Off Inter nal lig hting i s off for image exposure. Trigger

for external lighting is generated.

External Constant Internal lighting is off for image exposure.

External lighting trigger is on constantly while the sensor is in Run

mode (or the Live Display in the Image window is selected during

configuration), i.e., the external light is always on; it does not

strobe with each image exposure. Use this setting to help reduce

annoyance from constantly strobing light.

Resolution/Speed Changes the resolution and therefore also the speed

Zoom Zoom function: On/Off (digital zoom 2:1)

Normal/Faster

Fine/Average

Rough/Fastest

Use this setting to improve cycle time

32 10000000877(02)

Page 33

Paramete r Descri ption

E

Control Input The settings for the Control Input are described in detail on page 58)

Enable

Teach temporary

Activate 0 or 1

Activate 0 to 31

Tea ch per man en t

If this parameter is set to Enable (the default setting), the I/O control input IN2 must be

connected to V+ (24V DC). (This is in addition to a trigger input on IN1 (external trigger)). If

the control input IN2 is not connected to V+, the MultiSight is in standby mode and will not

execute evaluations unless the trigger mode is continuous (see page 58 for more details.)

MultiSight™ User Manual

Start-up

Trigger Mode Triggered External trigger signal (IN1) or the software command button “Trigger” initiates image exposure

Shutter Adjustment Manual Manual setting of the shutter speed (recommended).

Position Control Activate evaluation of position deviation X and/or Y (pass/fail output only; positional information not available as a

and evaluation.

Continuous A new evaluation is started as soon as the previous evaluation completes.

Automatic Teach The shutter value is set automatically by the MultiSight when the Teach command is

executed.

discrete output. position data is available via EtherNet/IP.)

Off Position evaluation de-activated

Only X Evaluation direction X

Only Y Evaluation direction Y

X/Y rectangle Evaluation direction X and Y with rectangular deviation area (blue frame)

X/Y ellipse Evaluation direction X and Y with elliptical deviation area (blue frame)

Position Control is only used with Detector Types Pattern Match and Contour Match. When the pattern or contour is

successfully detected (i.e., OUT1 is active), the Position Control analyzes whether the pattern is within the blue

position frame. The Position Output OUT2 is active when the pattern is detected and the center of the pattern (the

green cross in the center of the green “detected pattern” frame) is inside the blue position frame.

The area for the position evaluation can be marked by double clicking the blue frame and adjusting the position

and shape using the mouse. Approach the line with the mouse pointer until it changes to a horizontal or vertical

double arrow. Keeping the left-hand mouse button pressed, the line can now be moved to the desired position.

10000000877(02) 33

Page 34

MultiSight™ User Manual

Start-up

Paramete r Descri ption

Shutter x.xx ms Exposure time: slide for se tting shutter value manually. Increase to brighten image; dec rease to darken image. The

Trigger Delay (ms) Time between trigger and exposure/evaluation in 0-3000 ms (see “Configurable Delays” on page 40).

Output Delay (ms) Time between trigger and availability of result on OUT1 and OUT2 in 0-3000 ms.

Output Duration (ms) Time in 0-3000 ms that the output state is maintained. Please review the notes in the Configurable Delays section

Output Active HIGH or LOW = inverting of OUT1 and OUT2.

Threshold Min. and Max. Threshold values define the minimum and/or maximum evaluation score for the inspection to pass. Can be

Threshold Min. and Max.

(cont.)

shutter speed can also be adjusted by clicking on the number and typing a new value into the pop-up window.

on page 40).

HIGH Passing evaluation results in the PNP output turning ON (sourcing current). Failing evaluation results in

the output turning OFF (normally open).

LOW Passing evaluation results in the PNP output turning OFF. Failing evaluation results in the output turning

ON (normally closed).

The result indicators in the software do not change with this parameter (i.e., green dot always indicates passing

evaluation).

adjusted by the sliders or by clicking on the threshold number and typing a new value into the pop-up window.

Values = 0.00…1.00 in 0.05 increments (35% conformity threshold would be entered as ‘0.35’). The threshold

values are depicted by small vertical black lines on the detector results bar graph when the sensor is in run mode.

Both thresholds can be used at the same time and in this case a section in the middle of the results bar graph can

be defined as the “Good zone.” (PASS output when Threshold Min. is exceeded AND Threshold Max. is not

exceeded.)

Setting the Threshold Max below the Threshold Min is not possible.

In practice, “Good” parts are not 100% identical with the pattern taught. Slight differences

in position or fluctuations in light level mean that they do not conform completely to the

reference pattern. “Bad” parts should differ from “Good” parts in as many characteristics or

as large a part of the pattern area as possible. If a pattern has been taught using a “Good”

part, it must first be established what degree of conformity with the pattern is achieved

with various “Bad” parts (reference the length of bar graph for results). The degrees of

conformity with the pattern achieved with various “Good” and “Bad” parts should be as far

apart as possible. The threshold value should be set approximately at the center of this

difference between the “Good” and “Bad” parts.

34 10000000877(02)

Page 35

MultiSight™ User Manual

E

Start-up

Detector Types—Detailed Description

The following detector types are available: Pattern Matching, Brightness, and Contrast.

The EtherNet/IP model also has a Contour Matching detector type.

Pattern Matching

With this method, the detector looks for a pattern in a defined Region of Interest (ROI). By defining this ROI as larger than the

pattern there is some tolerance in positioning of the inspected part. The ROI is the yellow frame on the image and the pattern is

defined by the red frame. In run mode, the sensor evaluates the ROI on the current image to see if the pattern is present. The

evaluated pattern must match the taught pattern to a degree of conformity greater than the minimum threshold value (and less

than the maximum threshold value).

Example: The sensor is taught the following pattern:

In the next row of three patterns, each pattern is recognized with 100% conformity

because the evaluated pattern is exactly the same as the taught pattern even

though it is in a different position in the Region of Interest (ROI). It differs only in

direction X and Y and is not rotated.

In the next row of three patterns, each pattern is recognized but with less than

100% conformity. Pass or Fail result is dependant on the threshold settings (degree

of conformity).

Pattern detection is also tolerant of up to ± 5° of rotation. The next two images

would be recognized. Due to the slightly rotated orientation of the pattern, the

conformity would be less than 100% even though there is 100% pixel conformity.

(Patterns with more than 5° of rotation are not recognized.)

Brightness

The MultiSight uses an 8 bit grey-scale CCD chip to capture images. The chip assigns each pixel a value of 0 (black) to 255 (white).

The Brightness Detector Type evaluates all pixels that are darker than grey-scale value 128 as black. The detector examines the

Region of Interest (ROI) and determines the “Brightness” level (White = 100%, Black = 0%). If this level is between the configured

threshold minimum and maximum, the detector passes the evaluation.

The shutter speed has a significant effect on the number of pixels which are evaluated as black and thus which images pass or fail

this inspection.

10000000877(02) 35

Page 36

MultiSight™ User Manual

Region of Interest:

Shutter setting:

=

=

=

=

=

= 100%

=0%

5%

=

Detector Type

ROI Image

Brightness

bar graph

Contrast

bar graph

100% <10%

50% >90%

0% <10%

Start-up

For example, here is the same image with three different shutter speeds:

The setting of the threshold determines the maximum number of pixels detected as being dark which is required to pass the

evaluation. The position of each dark pixel within the ROI does not affect the evaluation.

Example:

These two images produce exactly the same result in the brightness evaluation because

in each case 9 of the 25 pixels are detected as dark.

Contrast

The Contrast Detector Type evaluates the difference between the brightness levels of the pixels in the ROI. An image that is all one

shade of one color has low contrast. An image that is half white and half black has very high contrast.

Example:

Summary of Brightness and Contrast Detector Types

For Contrast and Brightness Detector Types, the teach function is only used for Automatic Shutter Adjustment. It is recommended

that the Shutter Adjustment parameter is set to Ma nual, in which case the Teach command has no effect.

36 10000000877(02)

Page 37

MultiSight™ User Manual

Start-up

Contour Matching

The Contour Matching detector type is essentially a simplified pattern matching algorithm. Instead of the fully detailed pattern with

relative grey scale levels and complex area evaluation used for comparison in the Pattern Matching detector type, the Contour

Matching detector type compares simple line contours and shapes. In contour mode, the teach process identifies the borders

between dark and bright areas on the image. These borders between dark and light are highlighted with a blue line and

subsequently represent what the MultiSight looks for in run mode. When the MultiS ight performs an inspection in run mode, it

identifies these line shapes and determines if they match the taught line contour. The threshold settings affect how closely the

found line shapes match the taught line shape.

As an example, a solid black circle on a white background would cause a single circular contour line. A black ring on a white

background would cause a large circular contour line (at the outer diameter) and within it a smaller circular contour line (the inner

diameter). There is a contour line tracing border between black and white.

The primary advantage of Contour Matching (in comparison to Pattern Matching) is that this detector type is fully tolerant of shape

rotation, i.e. the object may appear in any angular position and still be detected. Another advantage is that the taught contour can

be edited by the user to remove parts of the contour that are not to be used for the inspection. The primary disadvantage of Contour

Matching (in comparison to Pattern Matching) is that it cannot detect as complex a pattern. Contour Matching is also typically

slower.

To edit the taught line contour, place the cursor over the pattern in the Pattern section of the software on the right hand side of the

screen. The cursor becomes an eraser. The size of the eraser is determined by the Eraser Size parameter under the pattern. It is

recommended to use the Zoom button (in the Pattern section) to work with a larger image. This eraser can be used to eliminate

portions of the taught line contour (depicted as a blue line) that should not be included in the inspection. For example, another

component near the part to be inspected, or even a shadow, may cause a contour shape in the taught image. The blue contour lines

created by these conditions can be eliminated by placing the cursor-eraser over those sections and clicking the mouse button. If a

desired blue contour line is accidentally deleted, the entire contour must be re-taught.

For a repeatable inspection results using the Contour Matching

detector type, a high-contrast image is essential.

There are several additional parameters that appear when the Contour Matching detector type is used. These parameters affect

either the teach process or the inspection process. They are described in more detail below. For most applications these can remain

in their default states.

10000000877(02) 37

Page 38

MultiSight™ User Manual

Start-up

Parameter Description Screen Shot

Edge con trast

1

Edge gradient

Min. edge length

Search mode

Edge width

2

2

1

Difference in grey-scale value.

Minimum difference in grey scale value to define a line

contour, i.e. the min. difference between bright and

dark areas to get a blue contour line.

Defined in terms of 8 bit grey scale value

Value range = 7…128, default = 50.

Edge steepness.

Maximum number of pixels for the edge width, within

which the above edge contrast difference should take

place.

Value range = 6…19, default = 12.

1

Minimum length of a contour element.

For rem oving or allowing small contour lines.

Value range = 4…24, default = 8

Complete search = Searches the entire ROI for the

contour with the best match. If multiple matches are

found, the best match is identified.

st

good = Stops search as soon as first contour

Until 1

match is found. Results in faster application speed but

risks matching similar line contours in the ROI.

This parameter gives the user the capability to improve

the speed of the application at the expense of accuracy.

Posit ion tole rance.

Allows for more or less tolerance in matching a contour

to the taught contour. Defined in number of pixels.

Used for deviations in shape.

Value options = 3, 5, 7, 9, default = 5

38 10000000877(02)

Page 39

MultiSight™ User Manual

Parameter Description Screen Shot

2

Min. scaling

Max. scaling

Starting angle

Tot al ang le

Threshold Contour

2

2

2

Minimum factor for scaling the size of the contour.

Values = 0.5 … 1.0, default = 1.0

Maximum factor for scaling the size of the contour.

Values = 1.0 … 1.5, default = 1.0

Angle at which the search starts. Search in clockwise

direction.

Valu es = - 180° … 179°, default = -10°

0° = 12:00am on a clock

Maximum search angle. Used to reduce the angular

positions that are inspected, so that only a contour

with minimal displacement from the original angular

position is matched. E.G. – The application is to

confirm that a part is in the correct orientation, so

reduce the Total angle. If the part is not in the correct

orientation, the contour will not be found.

2

Threshold Contour defines the minimum evaluation

score for the inspection to pass. Threshold is adjusted

by the slider.

Values = 0.00 … 1.00 in increments of 0.05

The threshold value is depicted by a small vertic al black

line on the detector results bar graph when the sensor

is in run mode.

Start-up

Note: The default settings for all Contour Matching parameters can be used for most

applications

1

Parameter for teaching

2

Parameter for evaluation

The angle information displayed in the Results area and available via the EtherNet/IP connection is only a rough estimation. To help

improve the precision of angle data, the Contour Matching parameters should use the following settings:

Edge contrast: set value as high as possible

Edge gradient: set value as low as possible

Min. edge length: set value as high as possible

Search mode: Complete Search

Edge width: set value as low as possible

10000000877(02) 39

Page 40

MultiSight™ User Manual

IN1

(Trigger)

Evaluation Time of Sensor

Ready On

"

Ouput Valid

OUT4

(Ready/Busy)

OUT 1+2

(Pass/Fail)

IN1

(Trigger)

Evaluation

Time

Trigger

Delay

Ready On

"

Ouput Valid

OUT4

(Ready/Busy)

OUT 1+2

(Pass/Fail)

Start-up

Configurable Delays

There are three timing mechanisms that can be used: Trigger Delay, Output Delay, and Output Duration. Each has a range of

0…3000 ms. The following timing diagrams show the behavior of the outputs for each timing mechanism condition.

Case 1: No delay timers used (default state)

Case 2) Trigger Delay = Time (in ms) between the Trigger Input turning on (rising edge) and the image exposure

40 10000000877(02)

Page 41

MultiSight™ User Manual

IN1

(Trigger)

Output Delay

(Includes Evaluation Time)

Ready On

"

Ouput Valid

OUT4

(Ready/Busy)

OUT 1+2

(Pass/Fail)

IN1

(Trigger)

Evaluation Time

+ Output Duration

Ready ON

"

Output NOT Valid

(Output OFF)

Output

Duration

(Output Valid)

OUT4

(Ready/Busy)

OUT 1+2

(Pass/Fail)

Evaluation

Time

Start-up

Case 3) Output Delay = Time (in ms) between the Trigger and the availability of results from Output 1+2 (Pass/Fail). Note that the

Output Delay must be longer than the evaluation time.

Case 4) Output Duration = Duration (in ms) of the result output on Outputs 1+2. The outputs will turn OFF once the Output Duration

is complete (unle ss the Output Active parameter is set to LOW/Normally Closed, in which case the outputs will turn ON once the

Output Duration is complete)

When the configurable delays are used, the minimum total cycle

time will be at least as long as the sum of the delay times. This will

reduce the number of inspections that can be made in a given

period of time.

A new part cannot initiate a trigger signal until the previous

evaluation, timing delays, and output duration are complete.

10000000877(02) 41

Page 42

MultiSight™ User Manual

Start-up

Special Case: Control of Outputs with Use of Output Duration Parameter

Output Behavior with 0 ms Output Duration (default setting) Behavior with > 0 ms Output Duration

OUT4 (Ready) This output shows when the sensor is ready to make an

OUT1 (pass/fail) and

OUT2 (position)

evaluation and when the results of the previous

evaluation are valid.

Turned ON while sensor is waiting for an external

trigger. Turned OFF when an evaluation is initiated

(either with the external trigger or Trigger Delay after

the external trigger). Turned ON again when the result

outputs (OUT1 and OUT2) are valid.

Output state is held until the next evaluation is

complete

Image

The Image section contains the current camera image as well as the Region of Interest (ROI), Pattern, and Position frames for the

detector currently selected via the radio buttons in the Select Detector window (and other detectors selected with the Display Icon

check box in the Select Detector window).

This output shows when the sensor is ready to make an

evaluation but DOES NOT show when the results of the

previous evaluation are valid.

Turned ON while sensor is waiting for an external

trigger. Turned OFF when an evaluation is initiated

(either with the external trigger or Trigger Delay after

the external trigger). Turned ON again after the

evaluation is processed AND the Output Duration has

elapsed. OUT1 and OUT2 are reset (outlined below) at

the same time as OUT4 is turned ON.

This means that there is no output to confirm OUT1 and

OUT2 data validity. The PLC must account for the

evaluation time before reading the output results.

Output state is de-activated after the Output Duration

time elapses. (Output ON or OFF based on setting of

parameter Output Active.)

42 10000000877(02)

Page 43

MultiSight™ User Manual

Screen Shot Field name Description

Region of Interest (ROI) –

Yellow frame with a

number

Frames: Region of

Interest (ROI - Yellow),

Patter n (Red) ,

Posit ion (Bl ue), and

Match (Green)

Live Display Displays the current live image of the MultiSight and

Zoom Magnifies the ima ge with a digital zoom (2:1 ratio).

Save image Saves the current image as a bitmap file (.bmp) with or

Max. Pattern Size Select a maximum pattern size of 400 x 160, 160 x 400,

When a detector is selected (radio buttons in Select

Detector window) its ROI appears as a yellow frame

with a number on the image. The ROI can be selected

by double clicking anywhere inside it. A dot will be

displayed just outside each corner and along each side

to indicate that it is selected. When the ROI frame is

selected, it can be moved by clicking and dragging

inside the frame and it can be resized by placing the

cursor on the side or corner and then clicking and

dragging.