Page 1

Installation Instructions

Time

PHOTOSWITCH® Bulletin 45PVA Part Verification Array

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Description

The Allen-Bradley 45PVA is a photoelectric Parts Verification

Features

S Robust metal enclosure with super slim 13mm profile

Array designed for bin picking applications and object

detection in the parts assembly industry. When used as part of

a suitably configured bin-picking system, the 45PVA effectively

prevents mispicks to enhance efficiency and minimize down

time. It is also the ideal solution to address the “error proofing”

initiatives prevalent in the automotive industry.

The 45PVA uses an array of LEDs to create a light screen that

can be spanned across bins at an assembly station. By

mounting the sensors on parts bins and wiring them into a

controller programmed with the necessary logic, a virtually

error-free bin-picking process can be achieved. ‘Job lights’ on

the 45PVA will not only show the assembler the bins required

to complete the current process, but will also indicate the

correct picking sequence. In the event the assembler attempts

to pick an incorrect part, a selectable warning light on the

45PVA will illuminate to indicate the error; additional fault

enunciation can be achieved via controller logic in conjunction

with a tower light or audible alarm.

S Large highly-visible job indicator lights

S Optional Red warning light indicator to notify operator of

incorrect component selection

S Dip switch selectable lighting operation for job lights

S Transmitted beam or selectable retroreflective/diffuse

sensing modes

S NPN or PNP dip switch selectable output reduces inventory

S Two frequency dip switch selectable cross talk protection

S Different sizes are available for different component racks.

Transmitted beam models are available in four sizes (100

mm (4 in), 225 mm (9 in), 300 mm (12 in), and 375 mm (15

in)). Retroreflective/diffuse models are available in two

sizes (100 mm (4 in) and 225 mm (9 in)).

In addition to increasing efficiency and quality control by

preventing faults in the bin-picking process, the 45PVA is

instrumental in personnel stress reduction and the

simplification of personnel training—especially in multi-lingual

facilities.

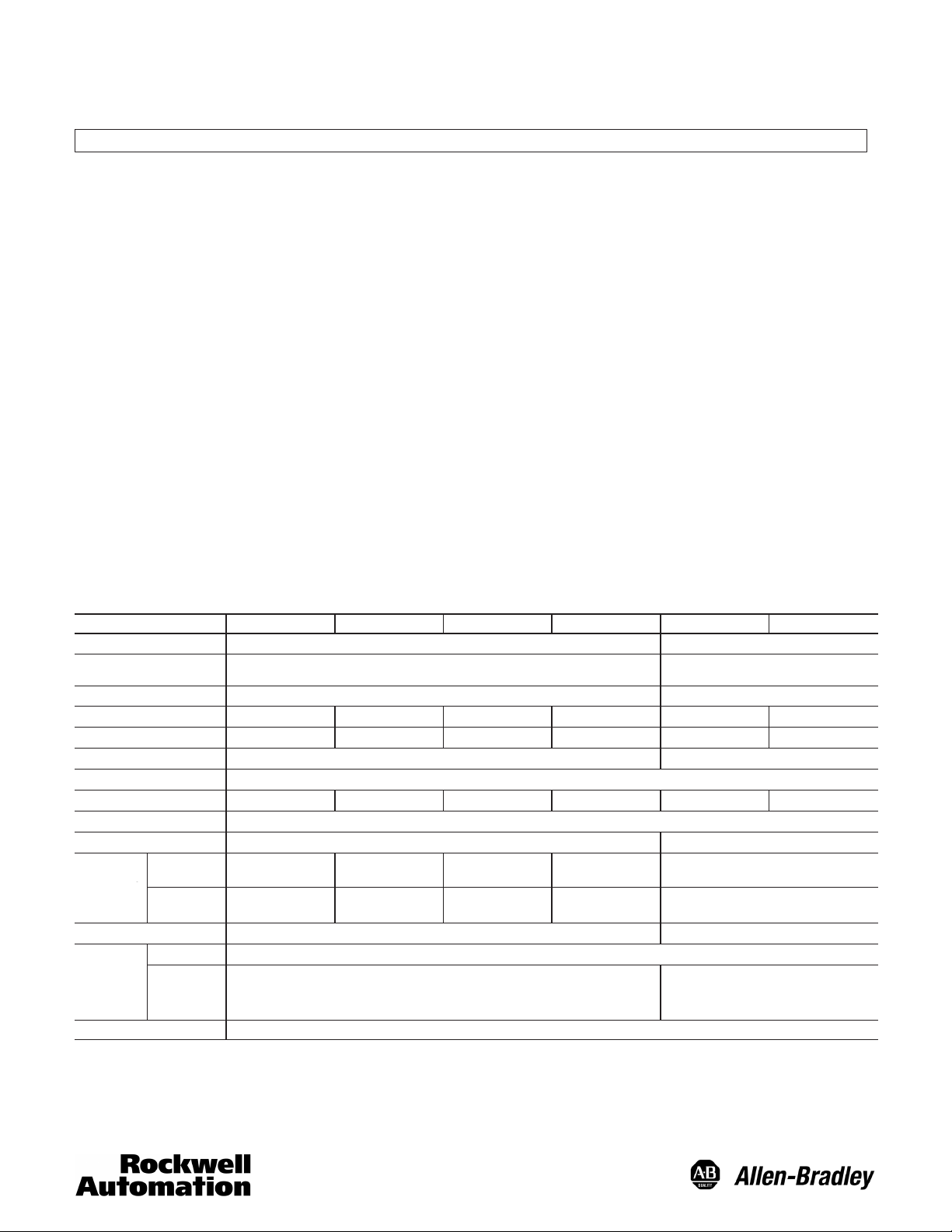

General Specifications

Description 45PVA–1LEB1–F4 45PVA–1LEB2–F4 45PVA–1LEB3–F4 45PVA–1LEB4–F4 45PVA–2LEA1–F4 45PVA–2LEA2–F4

Detection

Range

Detection Object

No. of Optical Axis

Detection Width

Optical Axis Pitch

Power Supply

Current Consumption (Max)

Output Mode

Operation Mode

Response

Time

Indicator Job/Warning

Short Circuit Protection

Standard

Interference

Protection

Light Source

Power and

Output

5 10 13 16 4 8

100 mm 225 mm 300 mm 375 mm 100 mm 225 mm

130 mA 140 mA 150 mA 155 mA 68 mA 78 mA

NPN/PNP Output Selectable; Rating: Current 50mA (30VDC) Max. Residual Voltage 2V or less

Light on: 35 ms

Dark on: 25 ms

Light on: 45 ms

Dark on: 28 ms

Power Indicator—Small Green LED; Receiver Light on Indicator—Small Green LED;

Receiver Dark on Indicator—Small Orange LED

Transmitted–Beam Retroreflective/Diffuse

2m (Max.)

35 mm (Min.) Opaque Object Varies with distance (see chart)

25 mm 29 mm

12 to 26V DC, Ripple 10% (Max.)

Light-on/Dark-on Selectable Target Present = Output On

Light on: 68 ms

Dark on: 42 ms

Light on: 84 ms

Dark on: 52 ms

Infrared LED, Wave-length 880 nm Visible Red LED, 640 nm

Light on: 70 ms

Dark on: 42 ms

Light on: 88 ms

Dark on: 54 ms

Large Green/Red

Light on: 94 ms

Dark on: 58 ms

Light on: 116 ms

Dark on: 72 ms

Built-in

2 m (Retro Mode)/400 mm Gray Paper

Power Indicator—Small Green LED (blinks

orange during power up sensitivity

adjustment). Output Indicators—Small

(Diffuse)

120 ms

120 ms

Orange LED.

1

Page 2

General Specifications (continued)

Description 45PVA–1LEB1–F4 45PVA–1LEB2–F4 45PVA–1LEB3–F4 45PVA–1LEB4–F4 45PVA–2LEA1–F4 45PVA–2LEA2–F4

Cross Talk Elimination

Material

Wiring

Environmental Characteristics

Selectable Frequency

Enclosure: Aluminum, Lens: Polycarbonate, End plate: Resin

4-Pin DC Micro Connection with 2m pigtail

Ambient Light

Operating TemperatureĊC (F)

Storage TemperatureĊC (F)

Operating Humidity

Enclosure Protection

Vibration Resistance

Shock Resistance

Dielectric Strength

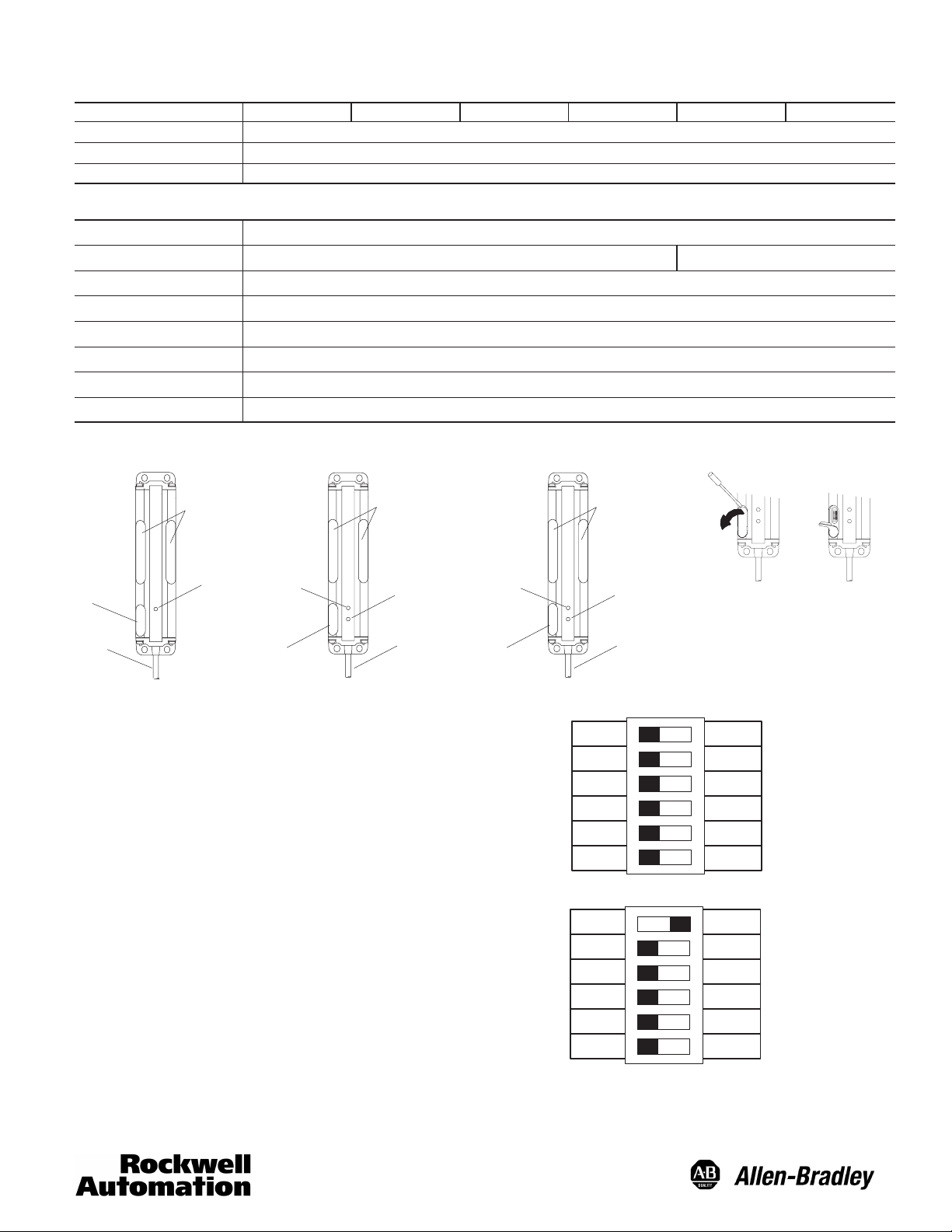

Description

Transmitter Receiver

Job Indicator

(Green)

Power Indicator

Switch Cover

Cable (Gray)

(Green)

Dark Indicator

(Orange)

Switch Cover

10,000 lx (Max.)

0…50_ (32…122_) -10…50_ (14…122_)

–25…70_ (–13…158_)

35% to 85 %RH

IP 62

10Hz to 55Hz, 1.5mm Amplitude, 2 hours, X,Y and Z directions

500 m/s2 3 times X,Y and Z directions

1,000VAC for 1 minute

Job Indicator (Green)

Warning Indicator (Red)

(optional functionality)

Light Status Indicator

(Green/Orange)

Cable (Black)

Retroreflective/Diffuse

Output Indicator

(Orange)

Switch Cover

Job Indicator (Green)

Warning Indicator (Red)

(optional functionality)

Power Indicator (Green)

(Blinks orange during

power up sensitivity

adjustment)

Cable (Black)

Mode Selection Switches

Mode Selection Switches

Transmitted Beam

1. Job indicator mode

2. Job indicator speed control for flashing

3. Selectable operation mode (receiver only)

4. Selectable warning indicator (receiver only)

5. NPN/PNP selectable switch

6. Selectable frequency

Retroreflective/Diffuse

1. Operating mode selection

2. Automatic sensitivity adjustment ON/OFF

3. Output Normally Open/Normally Closed

4. Selectable warning indicator

5. NPN/PNP selectable switch

6. Selectable frequency

Note: Only operate the mode selection switches with the power supply turned off.

Factory Default Settings

1

Flash

2

Fast

PNP

A

Diffuse

N.O.

PNP

Freq A

3

4

5

6

1

2

3

4

5

6

Dark_on

Warning_on

Auto Adjust

Warning_on

Light

Slow

Light_on

Warning_off

NPN

B

Retro

Auto Adj Off

N.C.

Warning_off

NPN

Freq B

2

Page 3

1. Job indicator mode (transmitted beam)

Either a steady light or flashing light mode can be selected.

Operating mode selection (retro/diffuse)

Retroreflective or diffuse operating mode can be selected

2. Job indicator speed control for flashing (transmitted beam)

The flashing speed can be selected as slow or fast.

Automatic sensitivity adjustment ON/OFF (retro/diffuse)

The automatic sensitivity adjustment can be turned on or off. (Regardless of this setting, sensitivity is always adjusted when

the power is turned on.)

3. Selectable operation mode (transmitted beam receiver)

The output mode of the receiver can be selected for light or dark operate.

Output Normally Open/Normally Closed (retro/diffuse)

The output mode can be selected for Normally Open or Normally Closed.

4. Selectable warning indicator

Select the warning indicator mode.

5. NPN/PNP selectable switch

Select the transistor mode for the output and the job indicator input.

NPN Output (PNP Input)

PNP Output (NPN Input)

6. Selectable frequency

The frequency can be switched to eliminate crosstalk.

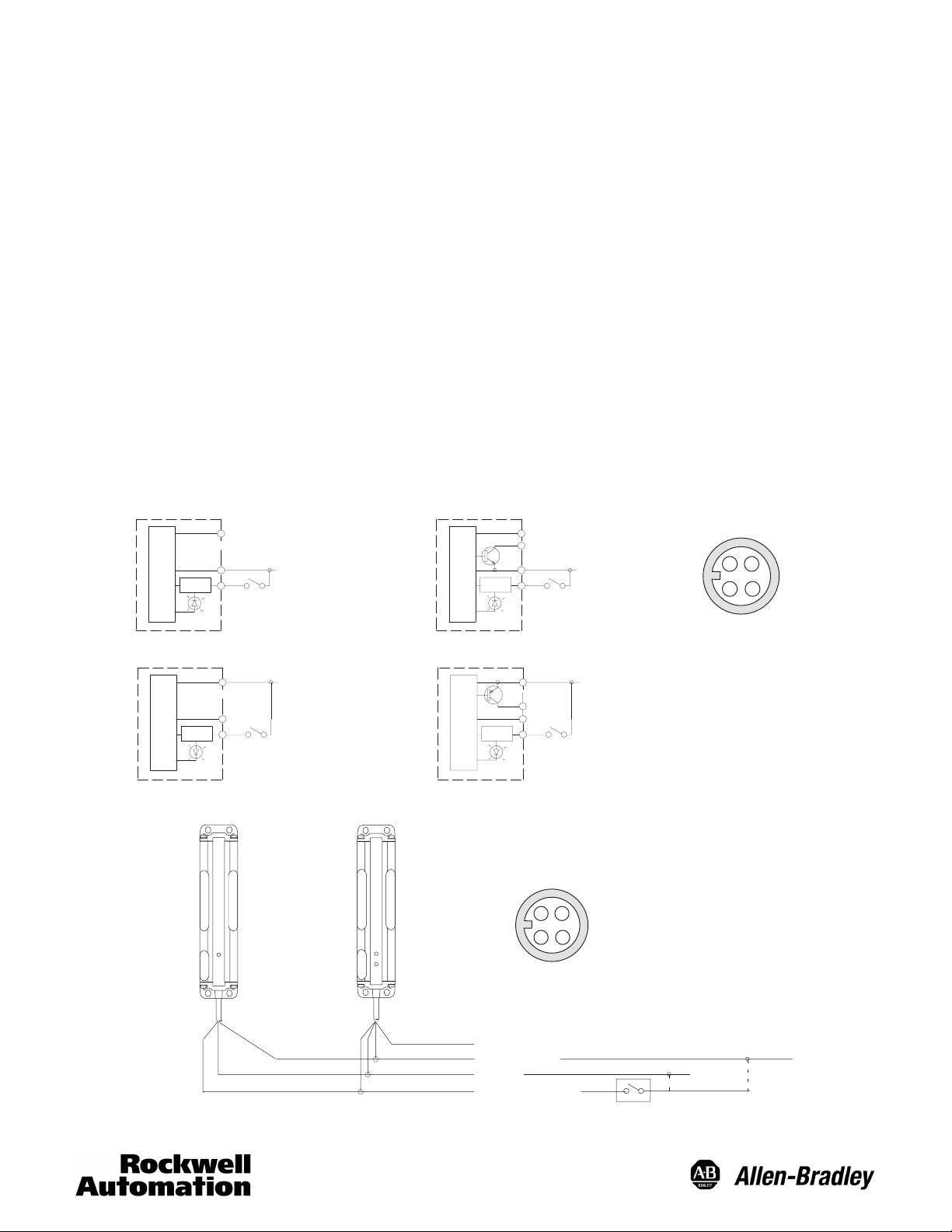

Input/Output Circuit and Wiring

The NPN/PNP input of the job indicator and the NPN/PNP output are selected by mode switch.

NPN Output

(selected)

Transmitter

1

4

Job

2

Pin 1 (Brown): 12 to 24V DC

Pin 3 (Blue): 0V

Pin 2 (Pink or White):

Job Indicator Input

Transmitted Beam Receiver and

Retroreflective/Diffuse

1

Pin 1 (Brown): 12 to 24V DC

4

Pin 4 (Black): Output (NPN)

Pin 3 (Blue): 0V

Job

2

Pin 2 (Pink or White):

Job Indicator Input

Face View Male Receptacle (Sensor)

DC Micro

1324

PNP Output

(selected)

Transmitter Receiver

1

Pin 1 (Brown): 12 to 24V DC

Pin 3 (Blue): 0V

4

Job

2

Pin 2 (Pink or White):

Job Indicator Input

Transmitter (not required for

Retroreflective/Diffuse models)

Transmitted Beam Receiver

and Retroreflective/Diffuse

4

1

3

2

1

Pin 1 (Brown): 12 to 24V DC

4

Pin 4 (Black): Output (PNP)

3

Pin 3 (Blue): 0V

Job

2

Pin 2 (Pink or White):

Job Indicator Input

Face View Male Receptacle (Sensor)

DC Micro

1324

Black: Out

Brown: 12 to 24V DC

Blue: 0V

White: Job Indicator Input

(NPN Output

Selected)

(PNP Output

Selected)

Note: Warning light requires no wiring. It is triggered using internal logic when the input is off (low) and the target is present.

3

Page 4

Installation

Cable

Cable

Cable

Cross-Talk Elimination

When two or more sensors are installed close together the sensors may interfere with each other and not operate correctly. In that

case, flip the frequency switch on one set of sensors. For transmitted beam, transmitter and receiver pairs must be set to the

same frequency.

1

2

3

4

5

6

Select switch for frequency

1

2

3

4

5

6

Transmitted Beam Models

Transmitter Receiver

Transmitter Receiver

1

2

3

4

5

6

Select switch for frequency

1

2

3

4

5

6

Retroreflective/Diffuse Models

1

2

3

4

5

6

1

2

3

4

5

6

Bin #1

Bin #2

An additional method for dealing with sensor cross talk interference is by alternating the direction of transmitter/receiver pairs. The

same effect can be achieved with the retro/diffuse model by setting the units up back to back.

Transmitted Beam Models Retroreflective/Diffuse Models

Transmitter Receiver

Bin #1 Bin #2

TransmitterReceiver

4

Page 5

Minimum Detectable Object Size

Retroreflective Mode

90

80

70

60

50

40

30

Minimum Object SizeĊmm

20

10

Operating Indicator

Transmitter Receiver

Retroreflective/Diffuse

Power Indicator

(Green)

Output Indicator (Orange)

Power Indicator (Green)

Blinks orange & green during power up sensitivity

adjustment

Dark Indicator (Orange)

Lights when the beam is interrupted

Light Status Indicator (Green/Orange)

Green: Stable light condition (>1.5 x gain).

Orange: Misaligned or interrupted beam.

0

0 0.5

(1.6 ft)

1

(3.3 ft)

DistanceĊm (ft)

1.5

(4.9 ft)

TypicalSpecified

2

(6.6 ft)

Job Indicator & Warning Indicator

The green job indicator LED is on when the input to the PVA is on. The output signal is turned on when the target is present

(when in Dark On or Normally Open mode). For example, when the operator’s hand is in the bin. The red warning indicator is on

when the target is present and the input is off.

OFF ON OFF

Input

Green Job Indicator (determined by input)

Target Present (operator hand in bin)

Output (determined by target present)

Red Warning Indicator

ON

ON

ON

ON

ON

ON

Light Margin and Operating Indicators (transmitted beam receiver only)

x1.5

x1.0

Dark Indicator

(Orange)

Light status

Indicator

Note: Use a dry, soft cloth for cleaning the lens and case. Lightly wipe it off. Never use solvents such as thinner.

Light

Orange

Operating Level

Green

Orange

5

Stable light

area

Unstable light

area

Dark area

Light

Page 6

Dimensions—mm (inches)

Switch Cover

4.0 (0.15)

Cat. No.

45PVA-1LEB1-F4

45PVA-1LEB2-F4

45PVA-1LEB3-F4

45PVA-1LEB4-F4

45PVA-2LEA1-F4

45PVA-2LEA2-F4

Ê N = Number of optical axis.

13

(0.51)

Light Status Indicator,

Green/Orange (Receiver)

Power, Green (Retro/Diffuse)

N Ê

5 100 (3.9) 130 (5.1) 140 (5.5) 25 (1.0)

10 225 (8.9) 255 (10.0) 265 (10.4) 25 (1.0)

13 300 (11.8) 330 (13.0) 340 (13.4) 25 (1.0)

16 375 (14.8) 405 (16.0) 415 (16.3) 25 (1.0)

4 87 (3.4) 130 (5.1) 140 (5.5) 29 (1.1)

8 203 (8.0) 255 (10.0) 265 (10.4) 29 (1.1)

L1

M

P

18

(0.7)

57 (2.24) 51 (2.0)

L2

Dark Indicator, Orange (Receiver)

Power Indicator, Green (Transmitter)

Output ON Indicator, Orange (Retro/Diffuse)

45PVR-1LEB1-F4 Ser A

Dimensions—mm (inches)

M L1 L2 P

Job

Indicator

32

(1.25)

4.5 (0.17) Dia.

Accessories

Mounting Brackets

#60-2773 (2 brackets)

(included)

20

(0.78)

(0.91)

16

(0.63)

23

40 (1.57)

18

(0.7)

(0.39)

2 (0.07)

10

4.6

(0.18) Dia.

10

(0.39)

4.6

(0.18) Dia.

6

(0.23)

11

(0.43)

6

Page 7

Optional Mounting Brackets

Mounting brackets available as an option (not included with sensor).

Plastic Bracket

#60-2779 (2 brackets)

Metal Bracket

#60-2772 (2 brackets)

17.0 (0.67)

7.6 (0.30)

18.0

(0.71)

2 x M5 x 0.8

7.4 (0.29)

18.8 (0.74)

34.0 (1.34)

20.1

(0.79)

4.4 (0.17)

(1.06) Dia.

51.8 (2.04)

26.9

18.0

(0.71)

66

(2.60)

28.0 (1.10)

Dia.

2 x 16.0

(0.63)

18.0 (0.71)

68.3 (2.69)

28.0 (1.10)

7.4 (0.29)

5.2 (0.20)

Dia.

7.0 (0.27)

2.5

(0.10)

4 x M4 x 0.7

16.0

(0.63)

9.2 (0.36)

32.0

(1.26)

7

Page 8

Protective Metal Bracket

4

97

(0

08)

Galvanized

#60-277x-1 (2 brackets for transmitted beam models)

#60-278x-1 (1 bracket for retro/diffuse models)

L1

10.0

7.01

(0.27)

(0.39)

17.5

(0.689)

L2

R 3.05

(0.12)

111.3 (4.38)

68.3 (2.69)

51.3 (2.02)

Reflective Tape (included with retroreflective/diffuse models)

Dimensions'mm (inches)

Cat. No. For use with

92-122 45PVA-2LEA1-F4

92-123 45PVA-2LEA2-F4

W L

50 (2) 120 (4.7)

50 (2) 245 (9.6)

(0.196) Dia.

(0.354) Ref.

12.34

(0.486)

27.3 (1.07)

16.3 (0.64)

4 x R 5.08

4 x 4.97

x 4.

2 x R 2.03

.

(0.709)

8.99

(0.20)

Cat. No.

(2 brackets)

60-2775-1 60-2785-1

60-2776-1 60-2786-1

2 x 18

60-2777-1 NA

60-2778-1 NA

(1 bracket)

13.99

(0.55)

R.02Ref.

Internal Radii

Cat. No.

9.5 (0.37)

L1 L2 Material

10.0

(0.39)

130.0

(5.11)

254

(10.03)

330

(12.99)

405

(15.94)

148.36

273.35

(10.76)

348.36

(13.71)

423.34

(196.6)

External Radii

32.5 (1.28)

(5.84)

35_

R08Ref.

Galvanized

Steel

L

W

Publication 75009–203(05)

December 2006

Printed in USA

8

Loading...

Loading...