Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

These devices are intended for object

recognition only and may not be used for

protection of humans (access protection).

AT T EN T I O N

45MLA Measuring Light Array Sensors

Description

The Allen-Bradley 45MLA measuring light array is a measurement

sensor that utilizes an array of transmitted beam photoelectric

sensor pairs to detect and measure objects. The array housing is

extremely compact, allowing for easy installation in a range of

applications.

The 45MLA are packaged as transmitted beam pairs—the emitter

and receiver arrays are both included. The system requires an

Allen-Bradley 45MLA controller, which must be ordered

separately.

The controller drives the photoelectric elements in the emitter

and reads out the receiver beam information. Use of one of these

external controllers allows the flexibility to:

• Output an analog signal (4…20 mA or 0…10V)

• Configure up to four separate sensing zones with independent

outputs, or

• Communicate individual beam status via serial protocols.

Additionally, the 45MLA can also be customized for application

specific overhang and over-height detection.

Features

• Height measuring capability

• Slim profile array (16 x 20 mm (0.6 x 0.8 in.))

• Beam spacing (pitch) of 10 mm (0.4 in.) or 25 mm (1.2 in.)

• Minimum detectable object is 18 mm (0.7 in.) or 33 mm (1.3 in.)

• Long operating range—4 m (13 ft)

• Fast reaction time and measurement speed

• Sensing array height of 300…1200 mm (11.8…47.2 in.)

•IP54

• Individual beam status available via controller (serial

communication models only)

• Same housing as Allen-Bradley GuardShield™ Micro 400

Specifications

Environmental

Certifications cULus and CE Marked for all applicable directives

Operating Enviroment IP54

Operating Temperature [C (F)] 0…+55° (+32…+131°)

Storage Temperature [C (F)] –20…+70° (–4…+158°)

Vibr ation

Shock

Relative Humidity 15…95%

Optical

Sensing Modes Transmitted beam pair

Sensing Range 0…4 m (0…13 ft)

Field of View 3.2°

Light Source 940 nm

Beam Spacing (pitch) 10 mm (0.4 in.) or 25 mm (1.2 in.)

Minimum Detectable Object Height 18 mm (0.7 in.) or 33 mm (0.3 in.)

LED Indicators

Mechanical

Housing Material Aluminum

Lens Material Polycarbonate

Cover Material Polycarbonate

Connection Types

Accessories

Supplied Accessories Adjustable mounting kit (445L-AF6143)

Required Accessories (Controller)

Required Accessories

(Light array to controller connecting

cable)

Optional Accessories

10…55 Hz; amplitude 0.35 mm (0.01 in.); meets

or exceeds IEC 60068-2-6

Acceleration 10 g, pulse duration 16 ms;10…55

Hz; amplitude 0.35 mm (0.01 in.); meets or

exceeds IEC 60068-2-29

Red: Status

Green: Alignment

8-pin DC micro (M12) female QD on 500mm (20

in.) cable pigtail (for connection to 45MLA

controller only)

Controller Analog Model:

45MLA-CTRL-ALG

Controller Basic Model: 45MLA-CTRL-BSC

Controller I/O Model: 45MLA-CTRL

Controller RS485: 45MLA-CTRL-485

Controller CAN: 45MLA-C TRL-CAN

3 m M12—RJ45: 445L-AC8RJ3

5 m M12—RJ45: 445L-AC8RJ5

8 m M12—RJ45: 445L-AC8RJ8

Max. system length cannot exceed 10 m (32.8 ft)

Adjustable flat mounting bracket:

445L-AF6149

Flat mounting kit: 445L-AF6145

Cascadable array extension patchcord,

M12 8-pin, 3M: 445L-AC8PC3

Page 2

Array LED Description Color Meaning

Red LED Off

Green LED On

Red LED On

45MLA

Not Aligned Aligned

Green LED Off

Green (also LED D1 on controller) Light array alignment

Red (also LED D2 on controller) Light array status

Off Target present or arrays not aligned

Green Target not present, arrays aligned and within range

Green (flashing) Light intensity inadequate

Off Target not present (and arrays aligned)

Red Target present (or arrays not aligned)

Red (flashing) Height measurement error

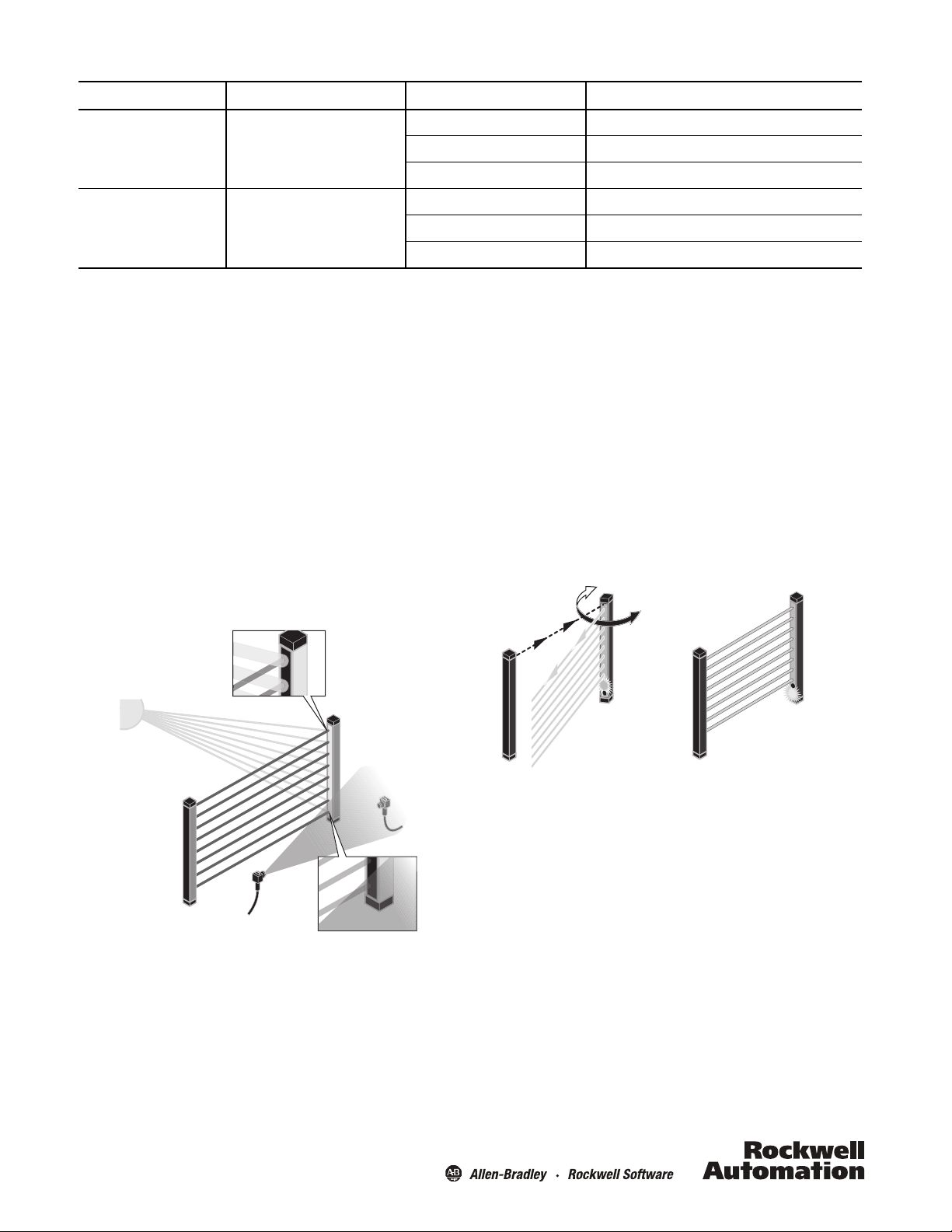

Mounting Instructions

1. Both the emitter and receiver profiles are lined with

continuous grooves to attach to the mounting brackets,

allowing these brackets to be attached at any position along

the length of the housing. Note: A flat mounting kit is also

available for purchase separately.

2. Align the emitter and receiver such that the two units are

parallel to each other and the sides with the photosensor

elements (and the clear plastic lenses) are facing each other.

3. Please note that the receiver (blue connector) can be sensitive

to interference light. No other source of external light,

including the emitters of any photoelectric sensor, array, or

reflective surface, should be directed towards the receiver

housing. Although the 45MLA is tolerant of bright sunlight, it is

better practice to mount the receiver housing such that no sun

light shines directly into the curved front area of the receiver

lens.

In addition, the connectors cables are offered with both blue and

white rings attached to each end of each cable. Remove the blue

markers from the emitter's cable and the white ones from the

receiver's cable so that the cables are marked appropriately for

future use.

The individual light arrays are powered through this connection

to the controller. Please refer to the Installation Instructions

corresponding to the specific controller that you are using for

further details on wiring and connecting the controller.

Alignment

This is a crucial step in the setup since sensor operation is

dependent on correct alignment of the emitter and receiver. This

process is simplified by using the green LED on the receiver unit

to serve as an indication of proper alignment.

Electrical Installation

Both light arrays must be connected to the controller through the

RJ45 connectors. For ease of connection, the pigtail connector for

the emitter has a white marker, and the receiver has a blue

marker. Be sure to connect the emitter to the plug connection on

the controller with the white marker, and the receiver to the plug

connection with a blue marker.

2

Horizontal Alignment

1. Aim the receiver 90° away from the emitter (light source) and

verify that the red status LEDs on both the receiver and emitter

are ON.

2. Slowly rotate the receiver to face the emitter and note the

point at which these red LEDs turn OFF and the green

alignment LED turns ON.

3. Continue to rotate the receiver away from the emitter until the

green LED turns OFF again, and the red LEDs turn ON. Note the

point at which this happens.

4. For horizontal centering, rotate the array halfway between the

two points at which the red LEDs turn OFF.

Page 3

3.2° 3.2°

The field of view of the 45MLA is 3.2°

Receiver Array

Emitter Array

45MLA Controller

Emitter connecting cable

Receiver connecting cable

For use in NFPA 79 applications only.IMPORTANT

32 (1.26)

28 (1.10)

M4

20

(0.79)

4.8

(0.19)

dia.

1.9

(0.08)

4.9

(0.19)

12.7

(0.50)

8.9

(0.35)

30

(1.18)

25.5

(1.00)

M4 x 16

3.3

(0.13)

3

(0.12)

Vertical Alignment

1. Beginning with the two arrays parallel to each other, slide the

receiver down and note the point at which the red LEDs turn

ON on both arrays. This indicates that the receiver is no longer

in line with the emitter.

2. Slide the receiver back upwards until the red LEDs turn OFF

and the green LED on the receiver turns ON. This indicates that

the two arrays are aligned.

3. Continue to slide the receiver upwards, noting the point at

which the green LED turns OFF, and the two red LEDs turn ON,

again indicating misalignment.

4. For vertical centering, position the receiver halfway between

the two points at which the red LEDs turn OFF.

Wiring Diagram

The 45MLA is a “Three Box System”—every setup consists of an

emitter array, a receiver array, and an external controller.

All electrical connections are made via the 45MLA-CTRL

controller.

Note: Cascading light array systems can consist of two or three

light array pairs. The last pair must be a standard array pair

and the first (and middle) pairs must be cascadable. A

total system can be no more than 10 m (32.8 ft) in length

from the controller to the end of the last array and cannot

exceed 254 total beams.

Adjustable Bracket 445L-AF6143

(4 pieces included) [mm (in.)]

(0.95)

18.9

(0.74)

15

6

(0.59)

(0.24)

5.5 (0.22)

38.7

(1.53)

18.7

(0.73)

24

M4 x 16

(0.11)

2.8

52

(2.05)

30

(1.18)

(0.84)

18.7

(0.73)

21.4

The 45MLA arrays feature an M12, 8-pin female QD which

connects to the connecting cable 445L-AC9RJx (x = 3, 5, or 8

meter length). The other end of the 445L connecting cable has an

RJ45 connector which plugs into the ports on the controller. The

emitter plugs into the top port, marked with the white dot. The

receiver plugs into the lower port, marked with the blue dot. The

445L connecting cable comes with both blue and white markers

at each end. It is recommended to remove the markers that do

not correspond to the array pigtail marker.

3

Flat Bracket 445L-AF6145 (sold separately) [mm (in.)]

Cascadable Array Extension Patchcord 445L-AC8PCx

Length, 1 or 3 m (3.28 or 9.8 ft); tolerance 0/+50 mm

80

50.2

(1.98)

17

(0.67)

Dia.

32.2

(1.27)

(3.15)

51.3

(2.02)

15 (0.59)

Dia.

Page 4

Dimensions [mm (in.)]

B

A

C

8-pin female

M12 (micro) QD

Cable clip 6 mm

White (emitter)

Blue (receiver)

0.75

(0.03)

18.5

(0.73)

8.1

(0.32)

500

(19.7)

0.75

(0.03)

1.5

(0.06)

20

(0.79)

15.8

(0.62)

B

A

C

8-pin female

M12 (micro) QD

Cable clip 6 mm

White (emitter)

Blue (receiver)

0.75

(0.03)

18.5

(0.73)

8.1

(0.32)

500

(19.7)

0.75

(0.03)

14.2

(0.56)

50

(1.97)

32.5

(1.28)

18.5

(0.73)

8.1

(0.32)

500

(19.7)

8-pin male

M12 (micro) QD

Cable clip 6 mm

White (emitter)

Blue (receiver)

Standard Array

Cascadable Array

Standard Array

A

Sensing Height [mm (in.)]

Housing Height [mm (in.)] Beam Spacing [mm (in.)] No. of Beams Cat. No.

C

300 (11.8) 322 (12.7) 25 (0.98) 12 45MLA-AT0300P25

600 (23.6) 622 (24.5) 25 (0.98) 24 45MLA-AT0600P25

900 (35.4) 922 (36.3) 25 (0.98) 36 45MLA-AT0900P25

1200 (47.2) 1222 (48.1) 25 (0.98) 48 45MLA-AT1200P25

300 (11.8) 322 (12.7) 10 (0.39) 30 45MLA-AT0300P10

600 (23.6) 622 (24.5) 10 (0.39) 60 45MLA-AT0600P10

900 (35.4) 922 (36.3) 10 (0.39) 90 45MLA-AT0900P10

1200 (47.2) 1222 (48.1) 10 (0.39) 120 45MLA-AT1200P10

Cascadable Array

A

Sensing Height [mm (in.)]

Housing Height [mm (in.)] Beam Spacing [mm (in.)] No. of Beams Cat. No.

C

300 (11.8) 339 (13.3) 25 (0.98) 12 45MLA-CT0300P25

600 (23.6) 639 (25.2) 25 (0.98) 24 45MLA-CT0600P25

900 (35.4) 939 (37.0) 25 (0.98) 36 45MLA-CT0900P25

1200 (47.2) 1239 (48.8) 25 (0.98) 48 45MLA-CT1200P25

300 (11.8) 339 (13.3) 10 (0.39) 30 45MLA-CT0300P10

600 (23.6) 639 (25.2) 10 (0.39) 60 45MLA-CT0600P10

900 (35.4) 939 (37.0) 10 (0.39) 90 45MLA-CT0900P10

1200 (47.2) 1239 (48.8) 10 (0.39) 120 45MLA-CT1200P10

Note: The 45MLA ships as a transmitted beam pair—both the emitter and receiver arrays are in one package. The “T” in the cat. no.

represents the transmitted beam pair. For individual parts, replace the “T” with an “E” for emitter or “R” for receiver, for example,

45MLA-AR0300P10.

August 2010, Printed in Switzerland

10000035051

107 863

Loading...

Loading...