Page 1

Installation Instructions

PHOTOSWITCHr Bulletin 45LST Optical Fork Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

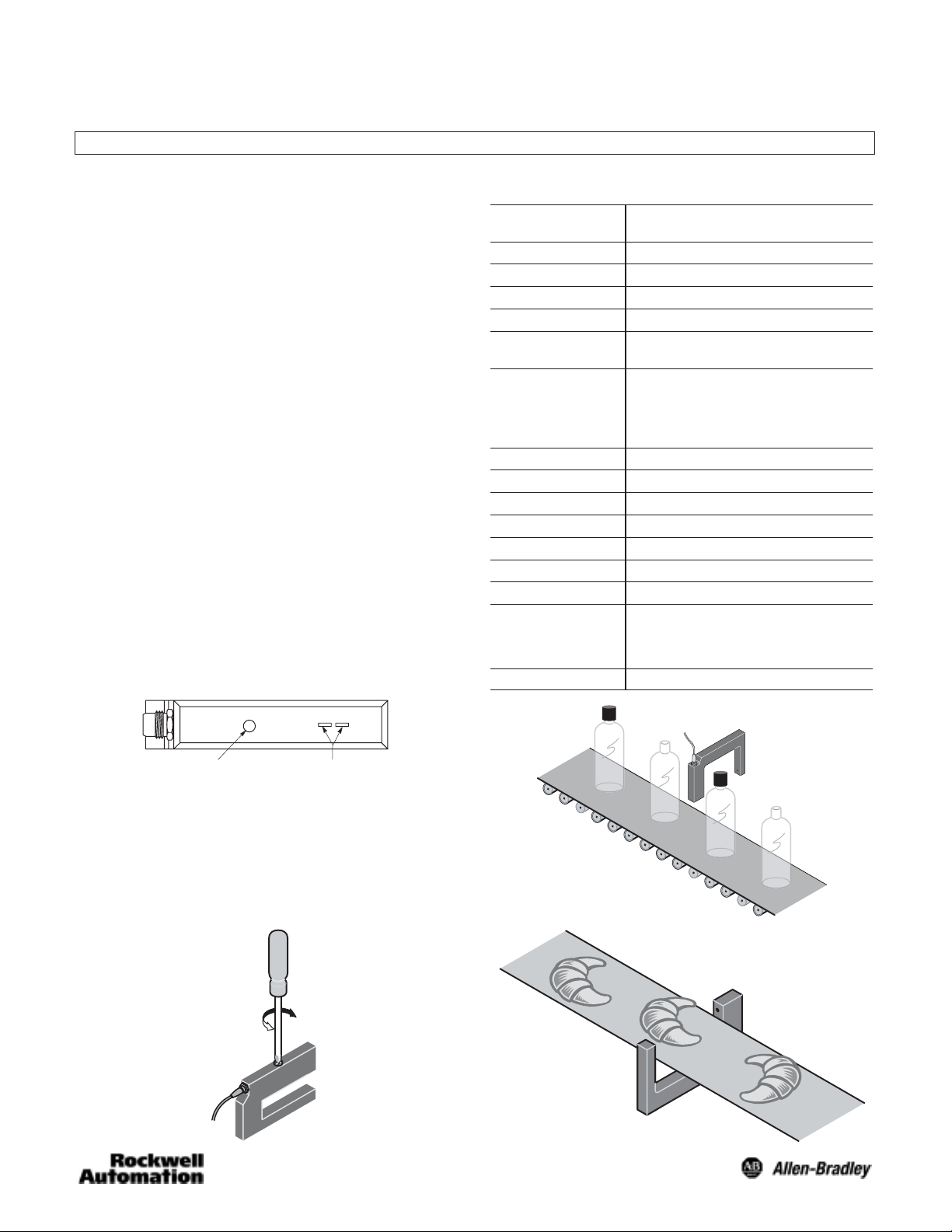

Description

The 45LST optical fork sensor is designed for small part

detection on machines and conveyors. With available slot

widths from 2mm to 225mm (0.08in to 8.86in), these sensors

feature adjustable sensitivity and selectable NPN/PNP with

LO/DO energized output in a heavy-duty IP65 aluminum

housing. Applications include label detection on clear

substrates, cap detection on bottles, and part sensing on

conveyers for the packaging and material handling industries.

The 45LST sensors are also ideal for the automotive, paper,

and food industries.

The 45LST optical fork sensor maintains all ratings that are

necessary for all applicable industries today: IP65, cULus and

CE marked for all applicable directives.

Features

S 10 to 30V DC operation

S Fast 30µsec response time

S NPN/PNP output

S IP65 Housing

S Industrial aluminum housing

S cULus listed and CE marked for all applicable directives

User Interface

Green LED = Power ON/

Unblocked light path

Red & Green LED blink =

Short circuit mode

Red LED = Output energized

Specifications

Approvals UL, cULus and CE marked for all applicable

Sensing Beam Pulsed (modulated) or nonpulsed (continuous) IR

Sensing Gap 2mm (0.08in) to 225mm (8.86in)

Supply Voltage 10-30V DC

Current Consumption 30mA maximum (45LST-1LEA1-P4 = 40mA)

Circuitry Protection Reverse polarity, transient, overload, short circuit

Output Configuration NPN (current sinking) or PNP (current sourcing)

Output Rating 100mA (NPN or PNP)

Response Time 30 microseconds or 1 millisecond

Adjustments Sensitivity (25 turn adjustable screw)

Housing Material Anodized aluminum

Environmental Ratings IP65

Connections 4Ćpin DC pico (M8) connector

Operating Temperature

Leakage Current 12V Supply: 0.78mA @ 10mA load, 6.9mA @

PowerĆon Delay 129ms

directives

protection

Light Operate: Normally open circuits that conduct

with target present

Dark Operate: Normally closed circuits that

conduct with target absent

-20_C to +60_C (-4_F to 140_F)

100mA load

24V Supply: 0.30mA @ 10mA load, 3.0mA @

100mA load

Sensitivity Adjustment LEDs

Sensor Setup

Initial setup includes mounting the sensor securely and then

providing power through a 4-pin pico cordset. The initial

factory settings have the threshold on the sensor preset so

that most opaque objects may be sensed. To adjust sensitivity

turn adjustment screw clockwise to increase or

counterclockwise to decrease.

Page 2

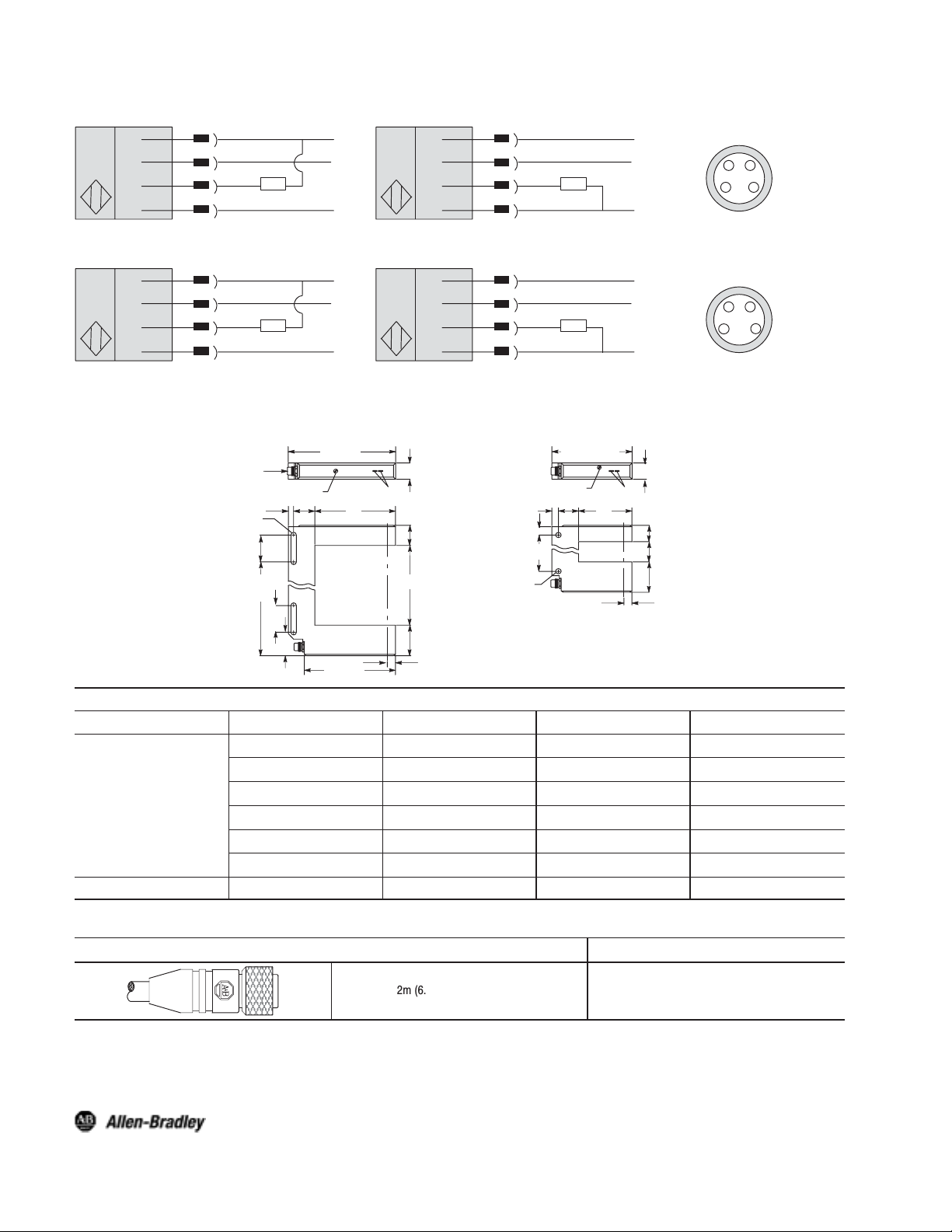

Wiring Diagrams

2 to 120

NPN (Light Operate)

3

2

4

1

Blue

White

Black

Brown

Load

PNP (Light Operate)

+

Ê

–

+

–

Brown

1

White

2

Black

4

3

Load

Blue

+

Ê

–

Pico

24

13

NPN (Dark Operate)

Brown

1

White

2

Black

4

Blue

3

Ê White Wire not used.

Dimensions—mm (inches)

M8 Plug

Sensitivity Adjustment

4 (0.16)

R = 2.2

20 (0.79)

233

(9.17)

Fork Size A B C D

2 to 120

(0.08 to 4.72)

225 (8.86) 225 (8.86) 60 (2.36) Ċ Ċ

PNP (Dark Operate)

Blue

Load

+

Ê

–

+

–

3

White

2

Black

4

1

Load

Brown

+

Ê

–

225mm 2mm to 120mm

20

(0.79)

(0.77)

19.5

16

(0.63)

80 (3.15)

68 (2.68)

B

Optical

Axis

LEDs

12 (0.47)

15

(0.59)

A

22.5

(0.88)

6

(0.24)

Sensitivity Adjustment

5 (0.20)

4.2 (0.16) Dia.

2 Places

D

C

20 (0.79) + B

15

(0.59)

B

Optical

Axis

LEDs

6

(0.24)

12 (0.47)

12.25 (0.48)

A

22.75

(0.89)

Dimensions—mm (inches)

2 (0.08) 40 (1.57) 14 (0.55) 6.25 (0.25)

15 (0.59) 40 (1.57) 27 (1.06) 6.25 (0.25)

30 (1.18) 40 (1.57) 42 (1.65) 6.25 (0.25)

50 (1.97) 57 (2.24) 40 (1.57) 17.25 (0.68)

80 (3.15) 57 (2.24) 70 (2.75) 17.25 (0.68)

120 (4.72) 57 (2.24) 110 (4.33) 17.25 (0.68)

Pico

24

13

Accessories

Description Catalog Number

2m (6.5ft) pico QD Cordset 889P-F4AB-2

PHOTOSWITCHR is a registered trademark of

Rockwell Automation.

Publication 75009–204–01(A)

2

June 2003

Printed in USA

Loading...

Loading...