Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

ATTENTION

45LMS Laser Measurement Sensor

Description

The 45LMS family of long distance laser sensors is available in a

variety of measuring ranges. The 8 m diffuse and 50 m

retroreflective models use a Class 1 visible red laser and the

15 m diffuse models use a Class 2 visible red laser. The discrete

and analog outputs can be easily set using the 5-step rotary

switch and the push button. Potential applications include object

position (analog output) and object detection (background

suppression with discrete output).

This sensor utilizes the Time of Flight (ToF) principle and has a

relatively small beam spot even at 15 m away. The sensor is

completely self-contained and does not require any external

control devices which add cost and require additional mounting

space.

The 45LMS is easily set up by mounting the sensor such that the

target is within the operating range of the sensor and teaching in

the appropriate set-points required for the application. All

sensors in this family have one discrete output with one analog

output. The discrete output can be wired for either Light Operate

(L.O.) or Dark Operate (D.O.) and the analog output is

automatically scaled between the selected set-points with either

a positive or negative slope.

The 45LMS is an excellent solution for long range detection and

measurement applications including: distance measurement,

verifying material position, stack level, thickness measurement,

roll diameter, positioning fixtures, error proofing inspection, long

standoff distance, level monitoring, crane crash protection and

other difficult applications that exceed the capabilities of

standard diffuse or background suppression photosensors.

Features

• Eye Safe Class 1 or Class 2 laser (by model)

• 8 m (26 ft.), 15 m (49 ft.) or 50 m (164 ft.) sensing

range, dependent on model

• One discrete output (1 x NPN/PNP) and one analog

output (1 x 4…20 mA)

• Easy setup of switch points or analog scaling using

programming buttons

• IP65 enclosure

• Self-contained sensor

This installation instruction should be read and

understood before operating the sensor.

The 45LMS sensor should only be installed by

qualified personnel.

The 45LMS is not a safety component as described

by the EU machinery directives.

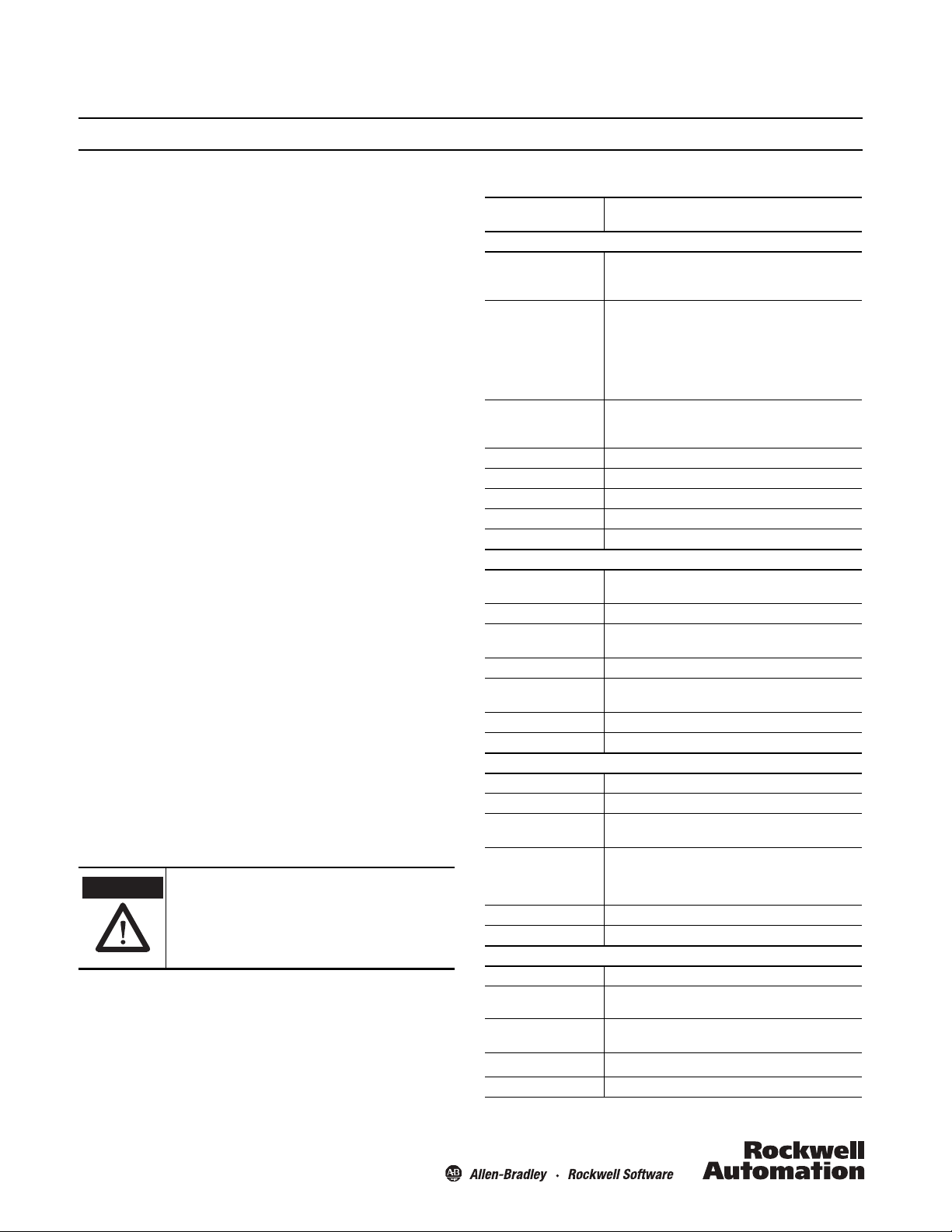

General Specifications

Certifications

Operation

Sensing Beam

Spot Size

Sensing Distance

Absolute Accuracy ± 25 mm (± 0.98 in.)

Repeatability < 5 mm (0.20 in.)

Angle Deviation ± 2° max.

Reference Target Kodak white (90%)

Temperature Influence ≤ 0.25 mm/K typ.

Electrical

Operating Voltage

Current Consumption ≤70 mA @ 24V DC

Discrete Output Type

Discrete Output Rating 30V DC max. / 100 mA max.

Analog Output Type

Switching Frequency 50 Hz

Response Time 10 ms

Mechanical

Housing Material Plastic ABS

Optical Face Material Plastic pane

Control Inputs

LED Indicators

Connection Type 4-Pin DC Micro (M12)

Supplied Accessories None

Environmental

Operating Environment IP65

Vibration

Shock

Operating Temperature

Storage Temperature -30…70°C (-22…158°F)

UL, cULus, and CE marked for all applicable

directives

Class 1 laser, visible red 660 nm (for 8 m & 50 m

models)

Class 2 laser, visible red 660 nm (for 15 m model)

< 10 mm (0.39 in.) at a distance of 8 m (26 ft)

°

at 20

C (68°F)

< 15 mm (0.59 in.) at a distance of 15 m (49 ft)

°

at 20

C (68°F)

< 50 mm (2 in.) at a distance of 50 m (164 ft)

°

C (68°F)

at 20

0.2…8 m (0.66…26.25 ft) diffuse

0.2…15 m (0.66…49.21 ft) diffuse

0.2…50 m (0.66…164.04 ft) retroreflective

10…30V DC

(18…30V DC when operating in IO-Link mode)

1 NPN/PNP output, short-circuit protected, reverse

polarity protected

1 analog output 4…20 mA, short-circuit/overload

protected

5-step rotary switch for operating modes selection

Push button for set-point teach

Green: Power

Yellow: Output switching states

Green/Yellow Flashing 2.5 Hz: Teach indication

Green/Yellow Flashing 8.0 Hz: Teach error

10…55 Hz, 0.5 mm amplitude; 3 planes; meets or

exceeds IEC 60068-2-6

30 g; 11 ms: 3 planes: meets or exceeds

IEC 60068-2-27

°

C (-22…122°F)

-30…50

Page 2

Interface

8 m & 50 m MODELS

Laser Class 1

15 m MODELS

Laser Class 2

DO NOT STARE INTO BEAM

88

(3.47)

102

(4.02)

11

(.43)

6

(0.24)

62

(2.44)

93

(3.66)

10

(.39)

54.6

(2.15)

Ø5.2

(Ø0.205)

14.8

(0.58)

8

(0.32)

CLASS 1

LASER PRODUCT

Complies with 21 CFR

dated June 24, 2007

1040.10 and 1040.11 except

for deviations pursuant to

Laser Notice No. 50,

IEC 60825-1: 2007 certified

2

(0.08)

25.8

(1.02)

9

(0.36)

9.8

(0.39)

M12

23.8

(0.94)

12

(0.47)

18

(0.71)

54.9

(2.16)

7

(0.28)

A

Laser output

1

3

4

2

3

4

2

1

Blue

Black

White

Brown

+

ANALOG

LOAD

−

(Q2)

(Q1)

Yellow LEDs - Signal indicators

SET button

Rotary Switch

Laser output

Green LED

Operating indicator

Interface type IO-Link

Protocol IO-Link V1.0

Cycle time Min. 2.3 ms

Mode COM 2 (38.4 kBaud)

Process data width 16 bit

SIO mode support Yes

The 8 m & 50 m models of the 45LMS are Class 1 laser products.

A Class 1 laser is safe under all conditions of normal use. This

means the maximum permissible exposure (MPE) is impossible

to exceed.

The 15 m models of the 45LMS are Class 2 laser products. A

Class 2 laser is not safe to stare at continuously; however, the

blink reflex of the human eye will prevent eye damage, unless the

person deliberately stares into the beam for an extended period

of time.

Dimensions [mm (in.)]

A

45LMS-BKT1 mounting bracket [mm (in.)]

35

)

15

(0.59

62

(4.41)

43

3

(2.44)

5.3

(1.69)

(0.12)

20

(0.787)

(0.21)

60°

5.3

(0.21)

5°

5°

(1.38)

30

(1.18)

112

(1.38)

5°

5°

5.3

(0.21)

5.3

(0.21)

43

(1.69)

50

(1.97)

35

35

(1.38)

0.14

R3.5

Wiring

NPN or PNP (Push-Pull)

The 45LMS photoelectric sensor is available with a micro quickdisconnect for ease of installation and maintenance.

Rockwell Automation recommends the use of the 889 Series of

cordsets and patchcords for quick-disconnect model sensors. All

external wiring should conform to the National Electric Code and

all applicable local codes.

The 45LMS features a Push-Pull discrete output. This means the

outputs always drive either 24V or 0V and can therefore be wired

like either an NPN or a PNP sensor.

Mounting

Securely mount the sensor on a firm, stable surface or support for

reliable operation. A mounting subject to excessive vibration or

shifting may cause intermittent operation. The 45LMS-BKT1

mounting bracket is available for installation convenience. Once

securely mounted, the sensor can be wired per the wiring

instructions in the next section.

2

Controls and indicators

SET

A

Q1

B

RUN

A

Q2

B

Setting the sensor

The 45LMS is set up using the Rotary Switch and the SET button,

and it displays feedback via the Yellow and Green LED indicators

on the top of the sensor.

Upon completion of any set-point Teach, both LEDs flash

simultaneously, followed by alternating flashing of the LEDs.

• A successful Teach is indicated by a slower alternating

flashing (2.5 Hz).

• An unsuccessful Teach is indicated by a faster alternating

flashing (8 Hz). After an unsuccessful Teach, the sensor

continues to operate with the previous valid setting.

Page 3

After the LEDs flash simultaneously, they flash alternately to

indicate whether the Teach was successful:

Successful: slower alternating flashing (2.5 Hz)

Unsuccessful: faster alternating flashing (8 Hz).

¹

Set-points can be independently taught. For example, set-point

IMPORTANT

IMPORTANT

24 V

0 V

0.2 m Q1B

MAX

24 V

0 V

0.2 m Q1A MAX

Q1-B can be set/re-taught without changing set-point Q1-A.

By pressing the SET button for >5 s when Q1-A, Q1-B or Q2-A is

selected with the Rotary Switch, the taught value for that set-point

is deleted, leaving the sensor with no value for the set-point that

was selected. When you delete Q2-A, the analog output changes

to Zero Point mode (see “Zero Point (Positive Slope)” on page 4

for details). Note that the value for Q2-B cannot be deleted, it can

only be overwritten.

When switching between discrete sensing modes, it is necessary

to delete or teach the set-points for both Q1-A and Q1-B.

The remainder of these instructions refer to the 24V

state as ON and the 0V state as OFF (PNP). If wired

as NPN, the logic is inverted.

Setting the discrete output: Q1

The discrete NPN/PNP output can be set as a switchpoint or

switching window as described below.

These instructions were made with the assumption that the

sensor is being used for Light Operate and that a PNP output is

desired. If the required output is NPN, then refer to the rotary

positions listed in the parentheses () throughout the Discrete

Output instructions.

Switch-point and farther

In this mode, the sensor output will turn on if it detects an object

at the Teach-point or at any distance farther than the Teach-point

up to the maximum range of the sensor. For example, if the

Teach-point is at 2 m, the output will turn on if the sensor detects

an object anywhere from 2 m to the maximum range.

1. Place a target at the desired Teach-point, move the Rotary

Switch to position Q1-A (Q1-B for NPN).

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3. If the Teach is successful, move the Rotary Switch to RUN.

Switching window

24 V

0 V

0.2 m

Q1A

Q1B

MAX

Please note that when you use the sensor for an

NPN output, the Yellow LED will behave opposite to

the sensor output.

For example, when the NPN output is ON, the

Yellow LED will be OFF.

Switch-point and closer

This is the most commonly used mode for object detection with

background suppression. If using the sensor for this type of

application set the Teach-point at the farthest distance from the

sensor that the target will pass.

When using this mode, the sensor output will turn on if it detects

an object between 200 mm (8 in.) from the sensor face and up to

the Teach-point. For example, if the Teach-point is set at 2 m (6.6

ft), the output would turn on if the sensor detects an object

anywhere between 200 mm and 2 m.

1. Place a target at the desired Teach-point, move the Rotary

Switch to position Q1-B (Q1-A for NPN).

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3. If the Teach is successful, move the Rotary Switch to RUN.

When setting the sensor this way, the output will turn on when it

detects an object within a window created between two Teachpoints. For example, if the Teach-point for Q1-A is set at 2 m, and

the Teach-point for Q1-B is set at 3 m, the sensor will turn the

output on if it detects an object between 2 and 3 m.

1. Place a target at the closer (relative to the sensor) desired

Teach-point, move the Rotary Switch to position Q1-A

(Q1-B for NPN).

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3. Place a target at the farther (relative to the sensor) desired

Teach-point, move the Rotary Switch to position Q1-B

(Q1-A for NPN).

4. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

5. If the Teach is successful, move the Rotary Switch to RUN

Switching window (inverted)

24 V

0 V

0.2 m

Q1B

Q1A

MAX

When setting the sensor this way, the output will turn on when

there is no object detected within the defined window created

between 2 Teach-points. For example, if the Teach-point for Q1-B

is set at 2 m, and the Teach-point for Q1-A is set at 3 m, the

sensor will remain on as long as there is no object detected

between 2 and 3 m.

1. Place a target at the closer (relative to the sensor) desired

Teach-point, and move the Rotary Switch to position Q1-B

(Q1-A for NPN).

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3

Page 4

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

After the LEDs flash simultaneously, they flash alternately to

indicate whether the Teach was successful:

Successful: slower alternating flashing (2.5 Hz)

Unsuccessful: faster alternating flashing (8 Hz).

¹

3. Place a target at the farther (relative to the sensor) desired

20 mA

4 mA

~3.9 mA

0.2 m Q2A MAXQ2B

20 mA

4 mA

~3.9 mA

0.2 m Q2B MAXQ2A

Teach-point, move the Rotary Switch to position Q1-A

(Q1-B for NPN).

4. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

5. If the Teach is successful, move the Rotary Switch to RUN.

Setting the analog output: Q2

The 4…20 mA output can be defined as any range within 200 mm

to the maximum range of the sensor, as either a rising or falling

slope, as described below. The default analog output setting for

Q2 is A = 200 mm (8 in.) and B = 5,000 mm (16 ft) for all sensor

models. Minimum window for setting the analog span is 21 mm

(0.83 in.)

Positive Slope

In the Positive Slope mode (also called Rising Slope) a target

positioned at the closer set-point results in an analog output of

4 mA while a target at the farther set-point results in an output of

20 mA, with the analog output scaled linearly in between. In this

mode, the sensor will output 20 mA when the target is outside of

the operating range, which is 0…200 mm (0…8 in.) and anything

greater than the maximum sensing range.

1. Place a target at the minimum Teach-point.

2. Move the Rotary Switch to position Q2-A.

3. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

4. Place a target at the maximum Teach-point.

5. Move the Rotary Switch to position Q2-B.

6. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

7. If the Teach is successful, move the Rotary Switch to RUN.

Negative Slope

1

.

1

.

20 mA, with the analog output scaled linearly in between. In this

mode, the sensor will output 3.9 mA when the target is outside of

the operating range, which is 0…200 mm (0…8 in.) and anything

greater than the maximum sensing range.

1. Place a target at the maximum Teach-point, and move the

Rotary Switch to position Q2-A.

2. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

3. Place a target at the minimum Teach-point, move the Rotary

Switch to position Q2-B.

4. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

5. If the Teach is successful, move the Rotary Switch to RUN.

Zero Point (Positive Slope)

20 mA

<3.9 mA

<0.2 m MAXQ2B

In the Zero Point (Positive Slope) mode a target positioned at the

farther set-point (Q2-B) results in an analog output of 20 mA and

the analog signal is scaled linearly between 0.0 mm and (Q2-B).

This is useful for simplifying the scaling within the PLC or control

device. For example, the following equation can be used:

D = (D

Max

/ I

Max) * Ii

where

D = Current distance of target

D

= set-point distance

Max

I

= analog range (which is always 20 for the 45LMS)

Max

I

= current analog output from sensor.

i

However, even though the analog signal is scaled linearly from

0.0 mm to (Q2-B) it will still provide an analog output of 20 mA

when the target is outside of the operating range, which is

0…200 mm (0…8 in.) and anything greater than the maximum

sensing range. (This is due to the fact that the 45LMS cannot

detect objects between 0…200 mm.)

1. Place a target at the maximum Teach-point.

2. Move the Rotary Switch to position Q2-B.

3. Press and hold the SET button until the Green and Yellow

LEDs flash simultaneously

1

.

4. Move the Rotary Switch to position Q2-A, and delete the setpoint [factory default is 200 mm (8 in.)] by pressing and holding

the SET button for >5 s. Successful completion is indicated by

both LEDs turning off.

5. If the Teach is successful, move the Rotary Switch to RUN.

In the Negative Slope mode (also called Falling Slope) a target

positioned at the farther set-point results in an analog output of

4 mA while a target at the closer set-point results in an output of

10000237459 Ver 00 Copyright ©2012 Rockwell Automation, Inc. All Rights Reserved.

March 2012

Loading...

Loading...