Page 1

Installation Instructions

PHOTOSWITCHr Bulletin 45LFM Label Sensor

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Description

The Rockwell Automation 45LFM–CMBA1–D5 Label Sensor

is an innovative electronic sensor used to sense and/or count

labels. A signal is generated as the edge of the label passes

through the sensor. It can be configured to sense the leading

or trailing edge.

Features

S Consistently senses the presence of most labels on a web

S Clear labels on clear backing

S Clear labels on opaque backing

S Opaque labels on clear backing

S Opaque labels on opaque backing

S Count 50,000 labels per minute with registration error less

than 0.01 inch

S Heavy-duty metal housing

S Ideal for label counting and label registering applications

Specifications

Supply Voltage &

Current

Power-Up or Reset

Leakage Current 5µA

Output Configuration Complimentary: NPN and PNP

Output Rating 150mA max

Short Circuit Protection Yes

Reverse Polarity

Protection

Output Invert Control Yes

Registration Accuracy 0.025mm (0.01in)

Response Time 10microseconds

Maximum Switching

Minimum Gap or

Label Size

Indicators Edge, zero

Construction Anodized aluminum

Environmental Rating IP54

Connections 5Ćpin micro QD

Operating Conditions

Approvals CE marked for all applicable directives

11 to 30V DC @ 50 mA max

10microseconds

Delay

Yes

10KHz

Speed

0.76mm (0.03in)

4_C to 50_C (40_F to 120_F)

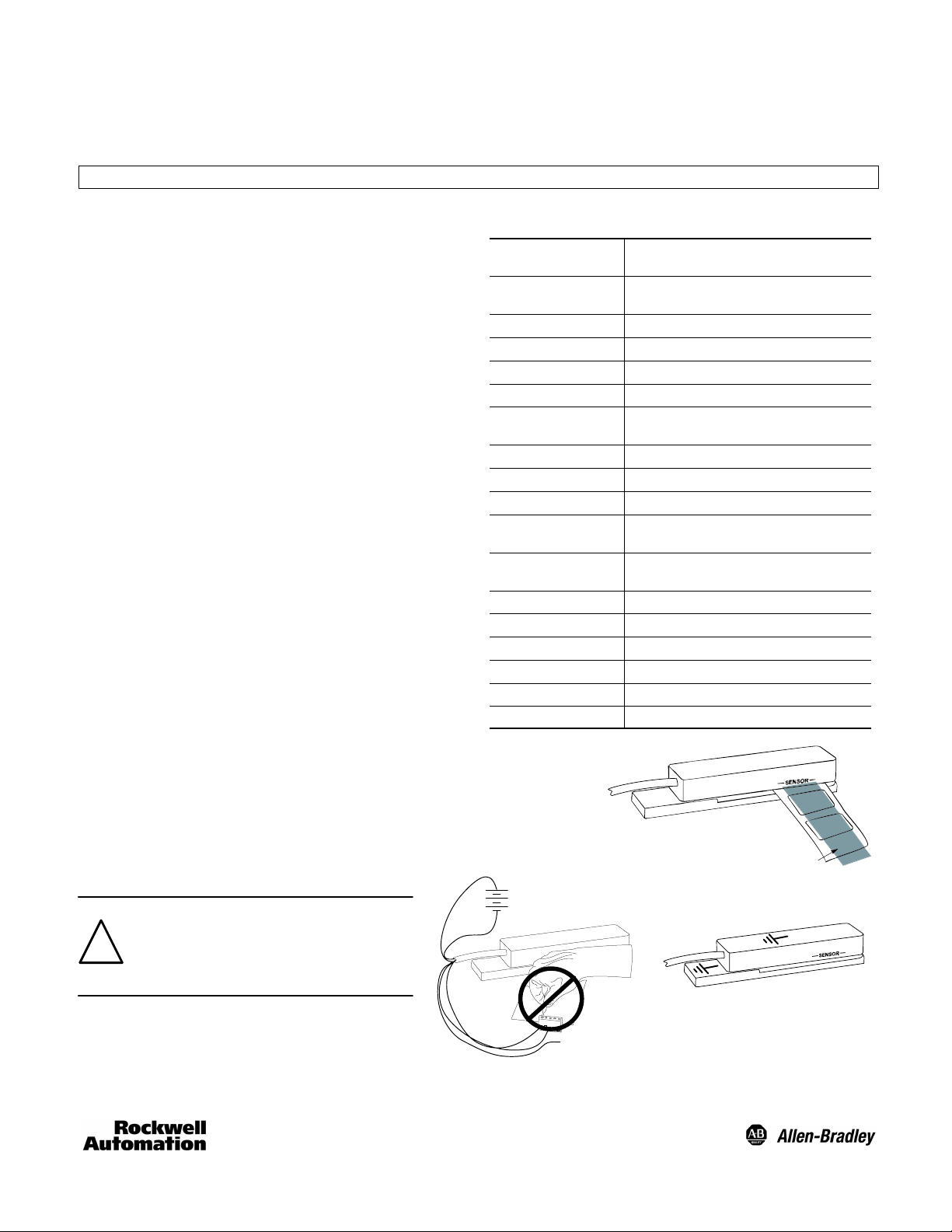

Mounting the Sensor

Mount the sensor perpendicular to the web so the web

passes through the sensor gap. The back of the web should

contact the mounting plate. Labels must pass under sensing

area marked [––SENSOR––]. Small labels (38.1mm (1.5in))

must be centered under the sensing area.

Electrical Connections

ATTENTION: Unused wires must be

insulated from contact with other

objects. All power must be off when

!

installing the sensor. DC ground is

connected to sensor body.

No power during

connection.

Labels must pass under Sensor.

Sensing Area

Sensor case is

grounded

Page 2

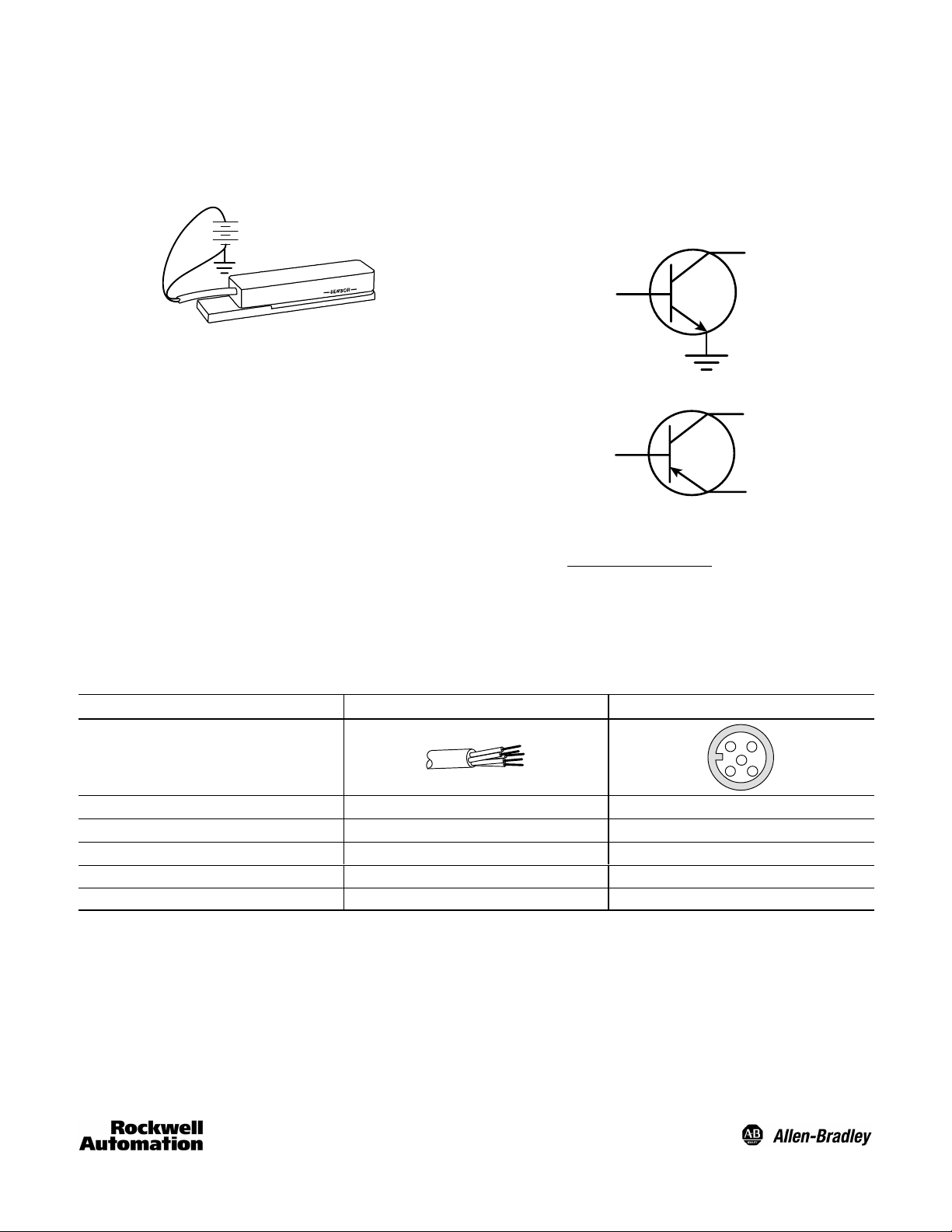

Power

Sensor can be powered with 11–30V DC but optimum

performance is obtained with 24V DC. The negative side of

the power supply is grounded to the sensor body.

+Vin 24V DC

(11-30V DC)

50mA

Outputs

The NPN and PNP outputs are open-collector outputs. The

NPN output can sink up to 150mA and the PNP output can

source up to 150mA. Outputs are short circuit protected by

self-resetting internal fuses. These fuses will activate if the

outputs are connected directly to ground or power. Repeated

shorting will eventually cause the sensor to fail.

NPN Output

150mA maximum

PNP Output

150mA maximum

PNP Power In

+Vin maximum

(+30V DC)

The PNP POWER IN voltage must be connected to a supply

voltage and must not exceed +Vin

(+30V DC).

Output Polarity

Output polarity determines whether the output signal will go low or high on the label edge.

Note: Output polarity also depends on the direction of label movement through the sensor (see figure on page 4).

Wiring Table

Designation Lead Color (Cordset) 5ĆPin Micro QD Pin Assignment

Termination

V+ Brown 1

0V Blue 2

PNP Output/150mA maximum Black 3

NPN Output/+30V DC/150mA maximum White 4

Output Polarity/Ground or +Vin Grey 5

4

2

5

3

1

2

Page 3

Adjusting Gain and Zero

These sensors are extremely stable and should not require adjustment after the initial setup. Adjustment will only be required

for significant changes in label shape or thickness, or changes in power supply voltage.

1. Remove all material from sensor.

2. Center GAIN ADJUST

Turn GAIN ADJUST four

(4) turns counter clockwise.

Turn GAIN ADJUST two

(2) turns clockwise.

3. Set ZERO ADJUST

Set ZERO ADJUST to the

point where the ZERO light

starts to come on.

4. Set GAIN ADJUST

Insert material into sensor.

While moving labels through

Flash start plus 1/2 turn

the sensor, Set GAIN ADJUST

to the point where the EDGE

light starts to flash. Then

continue turning 1/2 turn

clockwise.

5. Sensor is now ready for use.

How GAIN and ZERO adjustments affect the 45LFM–CMBA1–D5

The 45LFM–CMBA1–D5 is a dual capacitor type sensor.

Labels pass or move in the direction from C1 to C2 or vise

versa. The common plate of both capacitors is the base plate

that makes up the c-frame of the sensor. The electronics in

the sensor measure the difference between C1 and C2,

analog voltage = C1 – C2, which makes this sensor a

differential type sensor.

C1 C2

Base plate of

45LFM-CMBA1-D5

When common material, web and label, is under both plates

C1 = C2 and the internal analog signal is 0 Volts. Also when

nothing is place in the sensor C1 = C2. When you press on

the BASE PLATE of 45LFM–CMBA1–D5 sensor and change

the gap of the sensor C1, for the most part, = C2. As material,

web and labels, pass through the sensor, it is the fact that the

gap of the label goes under C1 first that causes the analog

voltage to increase. Once the gap of the label is between C1

and C2 and common material is again under both capacitors,

the analog voltage returns to 0V. As the gap of the label

passes under C2, the analog voltage decreases. As common

material returns under both capacitors the analog voltage

returns to 0V. This 0V is the internal supply voltage and is not

the 0V supplying the power to the sensor.

3

Page 4

The gain adjustment is required in order to be sure the analog

)

3

A

voltage goes beyond two trip points. The first trip point is a

positive voltage point and turns the output on when the

analog voltage exceeds the trip voltage. While the second trip

point is a negative voltage point and turns the output off when

the analog voltage goes below the negative trip voltage.

Things that affect gain are: size of labels, both thickness and

width, and power supply voltage. Powering the sensor with

12V requires increased gain than when powering the sensor

with 24V. Thinner labels also require more gain for proper

detection. Too much gain can cause the sensor to pick up

certain types of ink on the label and cause false detection.

Output Polarity and Signal Waveforms

Output polarity is effected by the direction of label movement. Waveforms shown are for label movement shown in diagram.

Reversing label direction will invert waveforms.

Output Output Polarity

NPN Ground

NPN +Vin

PNP Ground

PNP +Vin

Dimensions—mm (inches)

M4 x 17.7

(0.7) (x4)

20.3

(0.8)

5.1

(0.2)

7.6

(0.3)

25.4

(1.0)

15.2

(0.6)

140 (5.5)

30.5

(1.2)

SENSOR

31.8

(1.25)

24.1

(0.95)

15.2

(0.6)

Gap 0.76 (0.03)

(Adjustable)

PHOTOSWITCHR is a registered trademark of

Rockwell Automation.

4

Publication 75009–193–01(A

January 200

Printed in US

Loading...

Loading...