Page 1

SAFEDGE

PRESSURE SENSITIVE

SAFETY EDGE SYSTEM

INSTALLATION

& USER MANUAL

READ THIS MANUAL IN FULL BEFORE INSTALLATION

After installation this manual should be

retained in a safe and accessible place

R

Drawing No: 31611

Issue 2

R

EO: 26630

Page 2

Guardmaster Safedge

Pressure sensitive safety edge system

Installation and user manual

SECTION 1 STORAGE AND HANDLING

SECTION 2 SYSTEM DESCRIPTION

SECTION 3 INSTALLATION & SPECIFICATIONS

SECTION 4 ELECTRICAL CONNECTIONS

SECTION 5 COMMISSIONING & USE

SECTION 6 MAINTENANCE & SERVICE

SURFACE MOUNTING DIN RAIL MOUNTING

SAFEDGE

EN 954-1 Cat. 3

pr EN 1760-2

A1 + Z 2 MC 13 23 31

A2

-- Z1 MC 14 24 32

STOP

RUN

OPEN

Control unit

Isolate before opening

Made in the UK

(A1/A2) 110/230VAC selectable

(+/-) 24V AC/DC

440F-C251D

A1 + Z 2 MC 13 23 31

A2

-- Z1 MC 14 24 32

R

SAFEDGE

RUN

STOP

OPEN

Safedge Pressure Sensitive Safety Edge System

Control Unit

Supply Voltage 230/110VAC (see selector)

50-60Hz 0r 24V AC/DC

IP65 Hoseproof, Dust tight

Safety Contacts 250V 2A N/O

Aux Contacts 250V 2A N/C

Safedge Profile Voltage 12Vdc

EN 954-1 Category 3, prEN 1760-2

System response time 13mS

See user manual for further information

ISOLATE POWER BEFORE OPENING

R

PRESSURE SENSITIVE EDGE SYSTEM

CONTROL UNIT Pt. No. 440F-C251P

MADE IN THE UK

Record of Thorough Inspection And Test

(see section 6.2.2 and 6.2.3)

Date Inspected By Comments

261

Page 3

225

Record of Routine Inspection And Test

(see section 6.2.2 and 6.2.3)

Date Inspected By Comments

INTRODUCTION

The Safedge sensitive edge sensing system is ideal as a safety sensor in applications such as

power operated doors, automated vehicles and moving machinery beds etc. It can provide a

continuous line of high sensitivity touch sensing along or around practically anything.

This manual covers the use of the parts of the Safedge system. If joints or corners are required,

contact your supplier. All installation work must be carried out by suitably trained and qualified personnel and should be in accordance with statutory requirements for safety. READ THIS MANUAL IN FULL

BEFORE INSTALLATION. After installation this manual should be retained in a safe and accessible

place. For any further assistance, please contact your supplier.

1.0 STORAGE & HANDLING

STORAGE

The Safedge control unit and Profiles should be stored within the temperature range of

- 10°C to + 55°C.

HANDLING AND TRANSPORT

The Safedge control unit and Profile should be transported within the temperature range of - 10°C

to + 55°C and should not be subjected to any impact or heavy loads. The original packaging should be

used to give protection from excessive flexing. Always unpack carefully and avoid damage by the use

of knives etc.

2.0 SYSTEM DESCRIPTION

The Safedge system comprises of up to 50 metres of Profile, cable connector, a terminating resistor,

“C” rail and a control unit. The control unit can monitor lengths of up to 50 metres. All Profiles have

the same principle of operation.

Page 4

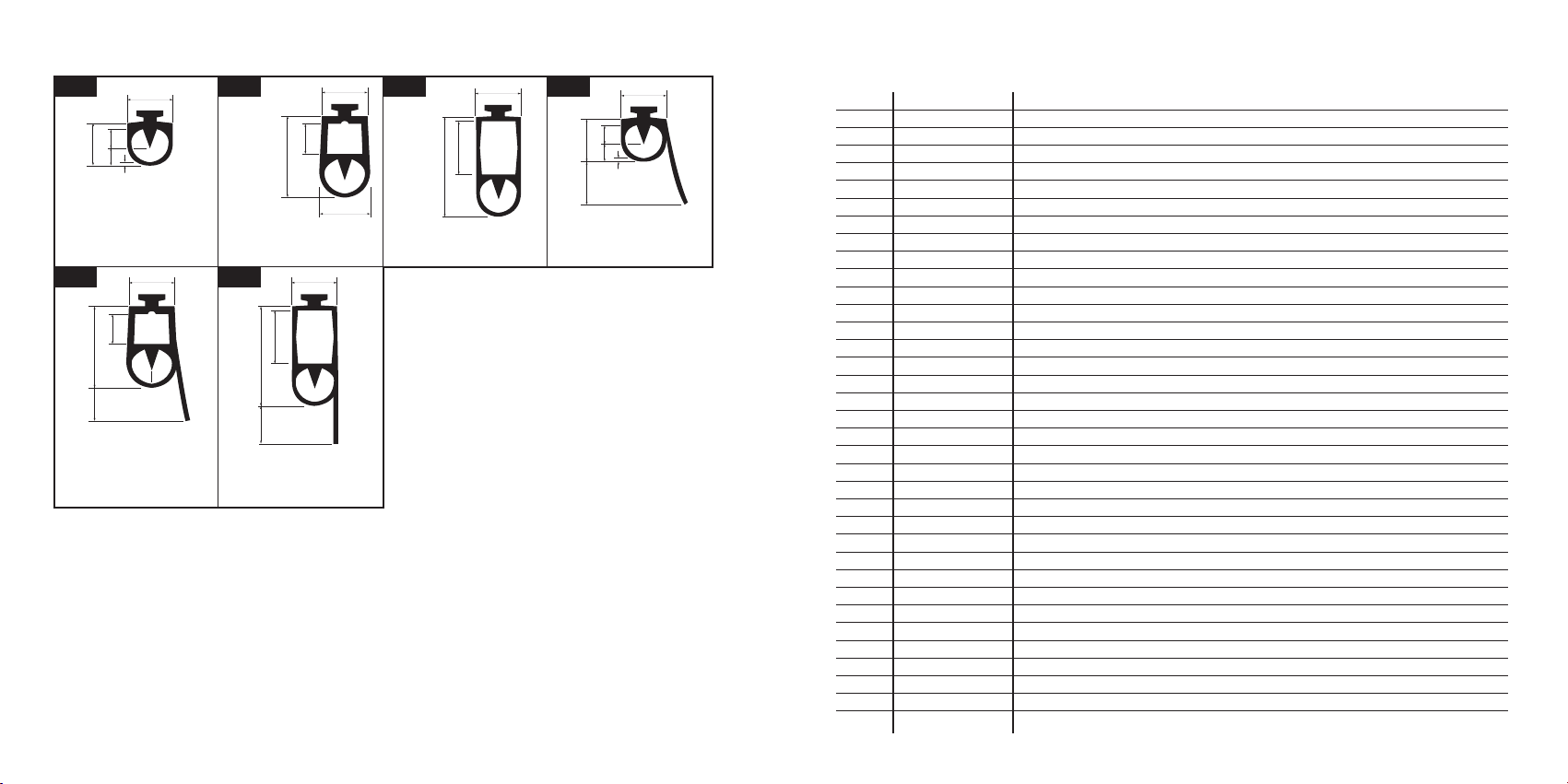

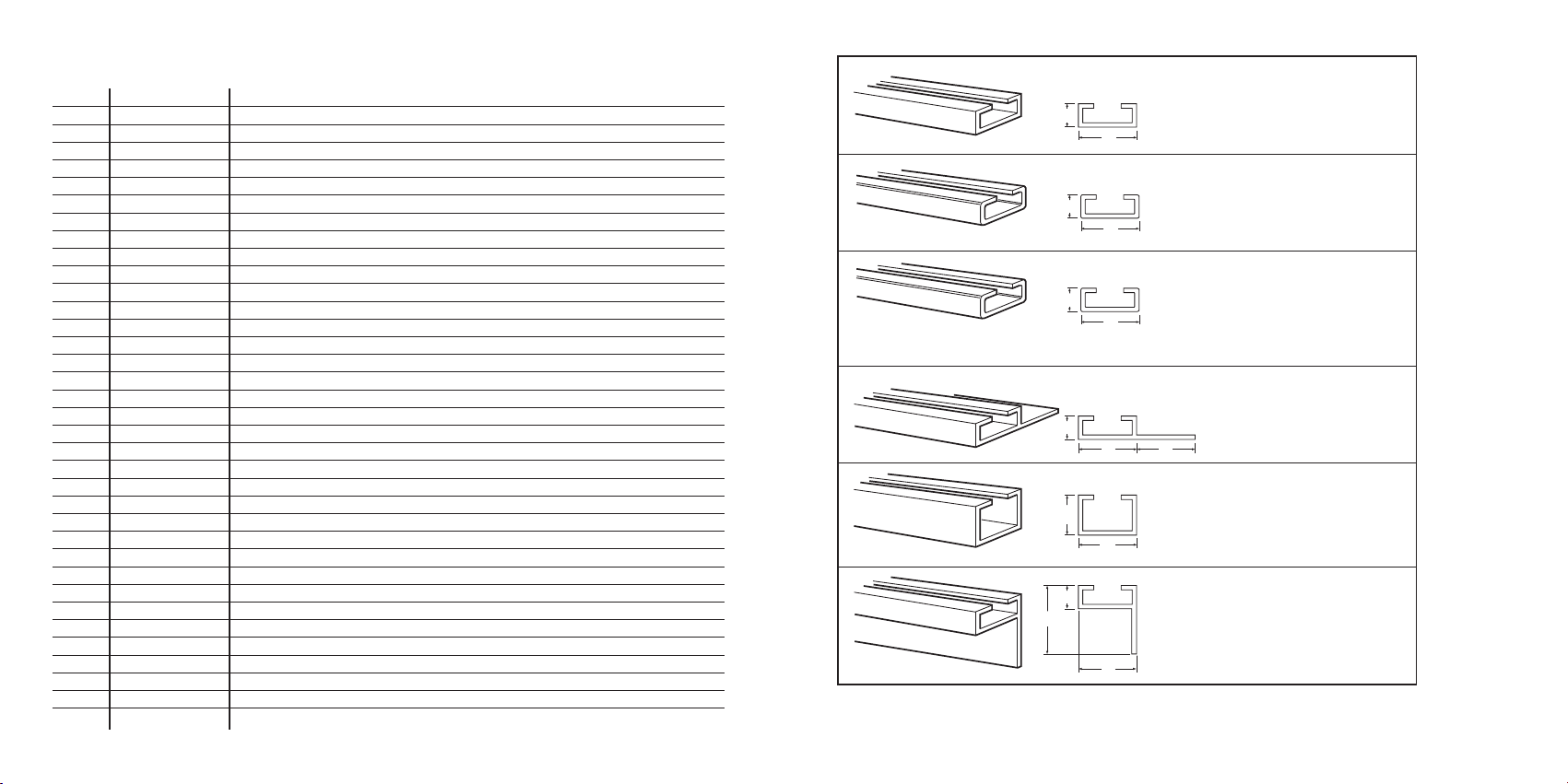

SAFEDGE PROFILES

30

36

68

28.5

12.59

24.5

2

28 - 30

25

14

43

17

30

36

6829

28.5

12.59

24.5

2

Cushion factor 5mm

440F-E0110S

440F-E0110R : Red profile

440F-E0110N : Increased resistance

to oil.

25

14

43

28.5

440F-E0310S

Cushion factor 41mm

440F-E0510S

Cushion factor 5mm

with sealing lip

440F-E0210S

Cushion factor 41mm

with sealing lip.

440F-E0804S

Cushion factor 19mm

with sealing lip

fig. 1 fig. 2 fig. 3 fig. 4

fig. 5 fig. 6

Cushion factor 19mm

440F-E1610S

440F-E1610N : Increased resistance

to oil.

FOR VARIOUS CONNECTION PIECES AND

ACCESSORIES, PLEASE REFER TO OUR

CATALOGUE

3 24

Record of Routine Inspection And Test

(see section 6.2.2 and 6.2.3)

Date Inspected By Comments

Page 5

ALL “C” RAILS ARE SUPPLIED WITHOUT FIXING HOLES

“C” Rail 440F-R1212 can be supplied curved to meet most applications

25 25

10

25

18

25

10

25

10

25

10

"C" rail-aluminium C112/A

440F-R1212

Suitable for the fixing of all the

Safedge Profiles.

"C" rail-zinc coated steel C112/S

440F-R1112

Suitable for the fixing of all the

Safedge Profiles.

"C" rail-aluminium C112/A3

440F-R1215

Ideal when external fixings of "C" rail is

required. Accepts all profiles.

25

10

30

"C" rail-aluminium C112/A2

440F-R1214

Ideal when external fixings of "C" rail is

required. Accepts all profiles.

"C" rail-aluminium C112/A4

440F-R1216

Deeper rail allows cables to be run through

channel under safedge profile. Accepts all

profiles.

"C" rail PVC

C112/PB = Black 440F-R1212PB

C112/PR = Red 440F-R1212PR

C112/PY = Yellow 440F-R1212PY

Suitable for the fixing of all the Safedge

Profiles. 3 colours available.

423

Record of Routine Inspection And Test

(see section 6.2.2 and 6.2.3)

Date Inspected By Comments

Page 6

Each Profile uses a combination of non-conductive rubber and a flexible wire cored conductive rubber,

bonded together to form a variety of energy absorbing Profiles. The Profile has no rigid internal parts

which can “break through” or cause fatigue failures after prolonged use. The maximum operating

voltage of the Profile is 12 VDC so no dangerous voltage is exposed if the Profile is accidentally cut or

sheared. The copper wire core throughout the length of the Profile ensures that there is no significant

build up of resistance over long lengths.

The circuit through the Profile is monitored by the Safedge control unit which, when a 6KΩ resistance

is present (i.e. normal run conditions), produces a signal to the machine control circuit.

When the Profile is pressed, from any direction through 90° as shown above, the top conductive

rubber strip compresses and touches the middle conductive rubber so creating a “short circuit” and the

overall resistance drops. This is monitored by the control unit which initiates the machine shutdown.

Any single fault in the Profile or the wiring connections to the Profile will be detected and the control

unit outputs will go to a safe (OFF) state.

Individual Profiles connect to each other by wires, axial connectors or standard 90° connectors. The

Profiles are connected to the control units by two wires. The control unit has fully cross monitored

safety relays and it is possible to configure the unit so that an external contactor fault will be detected.

Compliance with the requirements of EN 954-1 Category 3 and pr EN 1760-2 is achieved for the

control unit regarding electrical faults and can be met for the associated part of the machine control

system. Compliance with the requirements of EN 954-1 Category 1 is achieved for the Profile.

The Safedge system complies with the requirements of the European EMC Directive. Normal operation

under interference conditions likely in industrial environments is assured as it has been tested and certified.

NOTE:- Special measures may be required in the presence of abnormally high levels of EMI e.g. near

to welding or induction heating equipment or near to radio transmitters / transceivers.

Conductive

Rubber

Non Conductive Rubber

Flexible Wire

Cores

Flexible copper

cores send the

signal to the

Evaluator

90°

45°

45°

'Contact'

Zone

5 22

Record of Routine Inspection And Test

(see section 6.2.2 and 6.2.3)

Date Inspected By Comments

Page 7

3.0 INSTALLATION OF THE SAFEDGE SYSTEM

ONLY USE 440F-A0020 CYANOACRYLATE.

The cyanoacrylate adhesive ensuring a lasting sealing and high protection to IP65.

3.1 INSTALLATION OF “C” RAIL

"C" RAIL

CABLE CONNECTOR

CLOSING CAP

TO CONTROL UNIT

OR NEXT PIECE

OF PROFILE

CONNECTOR

WITH RESISTOR

621

6.2.4 Repair

Prior to working on a Safedge system or machine control system, isolate the power source to the

machine and Safedge system. Observe electrical safety precautions.

User repairs are limited to replacement with new Safedge system parts. In the event of any problems,

the units should be returned to the supplier.

Any repairs to the connecting wires should be made using heat shrink butt splice connectors.

After replacing any parts the inspection and test shown at 6.2.2 & 6.2.3, must be carried out with

special attention given to those parts replaced.

TAMPERING WITH COMPONENT PARTS WILL INVALIDATE WARRANTY.

WARRANTY INVALID IF QUALITY SEAL IS BROKEN ON THE DIN RAIL (440F-C251D) CONTROL

UNIT

WARNING

After maintenance or repair operations it is important that all fastenings, cable protection etc, are

correctly refitted. Failure to do this or the use of non approved parts may result in the Safedge system

failing to achieve its specified performance.

Page 8

3.1.1 MOUNTING THE “C” RAIL

3.2 ASSEMBLY & INSTALLATION OF THE SAFEDGE PROFILE

3.2.1 Cut the Safedge Profile to length.

Profiles without coasting chamber should

be cut with rubber shears.

Profiles with coasting chamber should be

cut with a fine tooth saw.

Holes drilled on

installation

(Fasteners not

supplied)

20

6.2.1 Profile Cleaning

The Profiles should be kept clean of deposits such as swarf and other materials to prevent damage or

dead-zones. It is permissible to use warm water and a mild detergent to clean the surface area.

DO NOT USE SOLVENTS.

6.2.2 Routine maintenance inspection and test - (

recommended weekly or after repair

)

Stop the machine, clean the Profile(s) and allow to dry off. Inspect the surface of the Profile for

damage. Any damage that punctures the profile could let material or liquid in. It must be dealt with

immediately. Check that all end caps, corners and joints are secure and free from damage. Damaged

parts must be replaced immediately.

Test the Profile operation. Two people may be required, one to press the Profile and one to observe the

operation of the control unit. On systems using Manual reset mode, the reset button must be

continuously pressed. Check that the RUN “Green” LED is illuminated when the profile is not pressed

and that the STOP “Red” LED is illuminated when it is. Start the machine, press the Profile and check

that the machine stops immediately.

If these checks reveal any problems, do not allow use of the machine until they are rectified. Record all

inspections and tests in a written log.

6.2.3 Thorough examination and test - (

twice yearly or after repair

)

To be undertaken by a person competent in electrical and mechanical engineering.

a) Carry out tests at 6.2.2

b) Isolate the power source to the machine and Safedge system. Observe electrical safety

precautions.

c) Inspect the Profile and components thoroughly for mechanical damage.

d) Disconnect the wires to the Profile at terminals Z1-Z2.

e) Connect the wires from the Profile to the input of an ohmmeter. One person should now press the

Profile with one hand at every point on the strip. The resistance should measure 6K +/- 10% when

the profile is not pressed and no greater than 1K when it is.

If these checks reveal any problems, do not allow the use of the machine until they are rectified.

Record the inspection and test in a written log.

7

Page 9

6.0 MAINTENANCE AND SERVICE

6.1 FAULT FINDING GUIDE

Symptom Probable Cause Check

“Yellow” LED Open circuit in profile or Z1-Z2 Terminals are secure.

Illuminates. connecting wiring. Cable for breaks

Profile for damage.

No LED’s illuminate even if Supply failure. Voltage selector switch is set correctly.

Profile is pressed. Supply fuse.

Supply voltage is present.

No LED’s illuminate unless Failure to reset. If using contactor monitoring, check

Profile is pressed and then each contactor is functioning correctly.

the stop “Red” LED MC-MC terminals are secure.

illuminates. Link is in place or Reset button

functions correctly.

Unit appears to work Blown fuse. Output fuses.

correctly but there is no Damaged or incorrect wiring. All wiring for damage.

output.

Fault on Safedge causing Movement on any internal relays.

the Outputs to fail safe REPLACE CONTROLLER.

Machine does not stop if Incorrect external connections All wiring to contactors for mistakes.

Profile pressed.

Run “Green” LED goes off.

Machine does not stop if DO NOT ALLOW THE USE OF THE MACHINE

Profile pressed.

REPLACE CONTROLLER.

Run “Green” LED stays on.

6.2 MAINTENANCE

This section should be read in full before any maintenance work is attempted.

Attention is drawn to regulations for planned preventative maintenance under E.U. Directive

89/655/EEC (Implemented in Great Britain as the Provision and Use of Work Equipment Regulations

1992).

During maintenance operations, disconnect the machine’s prime mover before working on the

Safedge system. Observe electrical safety precautions.

19

3.2.2 When using the closing cap 440F-A1302 with

sealing lip, the profile base has to be cut

back to a length of 12mm. The cut must

be made carefully to ensure that the profile

base is completely trimmed off, leaving a

flush surface.

3.2.3 The shaded areas must be roughened

with emery paper

3.2.4 The closing caps are moulded with 4

grommets, each with a rubber plug. When

fitting a resistor, leave the plugs intact. When

making a cable connection, select the

required cable exit and remove the plug from

the grommet with a hole punch.

3.2.5 Pull the connecting cable through the

hole.

12

8

Page 10

3.2.6 Prick each of the copper wires with one of

the needles. Press the needle contacts of

the connector in the direction shown:

(wedge outwards), straight into the copper

wires.

3.2.7 CAUTION

The narrow side (wedge) of the connector

must show outwards.

3.2.8 Fold back the sealing lip of the cap;

a) Apply adhesive to shaded area of closing

cap as illustrated then affix to edge of

profile, applying pressure for 10 seconds

to ensure adhesion.

b) Apply adhesive to remainder of shaded area

and allow sealing lip to make contact with profile.

IMPORTANT: Spread the adhesive evenly over the

shaded area! Do not allow adhesive to enter inside

the profile.

5.3 APPLICATIONS

Z1

Z2

+

-

Brown

White

L

6K

RESISTOR

STOP

START

110/230V AC SUPPLY

110/230V AC Application with 2 contactors, contactor monitoring

and START/STOP circuit. (Shown with profile pressed)

MOMENTARY

PUSH BUTTON

EXTERNAL FUSE

+ve Z1 Z2 13 23 31

NE

-ve MC MC 14 24 32

SAFEDGE

PROFILE

SAFEDGE

CONTROL

UNIT

K1

K1

K2

K2

K1

K2

(A1)

(A2)

L

6K

RESISTOR

K1

EXTERNAL FUSE

110/230V AC Application with 1 contactor.

(Shown with profile pressed).

+ve Z1 Z2 13 23 31

NE

-ve MC MC 14 24 32

SAFEDGE

PROFILE

SAFEDGE

CONTROL

UNIT

(A2)

(A1)

189

Page 11

3.2.9 To ensure complete seal apply more

adhesive on the Safedge Profile around

grommet/cable exit and sealing lip of the

closing cap.

3.2.10 Axial profile connector 440F-A0061S is used

for extensions and repairs (see steps 1, 2, 3,

6 and 7) for the 440F-E0110 series of profiles

only. For other types, use straight pin connectors.

3.3 CONTROL UNIT

3.3.1 TECHNICAL SPECIFICA

TION

440F-C251P Surface mount 440F-C251D DIN rail

Conformity: prEN 1760-2, EN 954-1: CATEGORY 3

Power Supply - user select: 110/230V AC (50-60Hz) and 24V AC/DC +10% -15%

System response time: 13mS

Environmental protection: IP65. Enclosure IP40 DIN0470

Terminals IP20 DIN0470

Max. Safedge profile voltage: 12V DC (open circuit).

Nominal operating voltage: 4V (run condition).

Max. output fuse: 2A quick acting 5A quick acting

Impulse withstand voltage: 2500V.

Over voltage: Category 2

Contamination level: III

Min. switched current/voltage: 10mA/10V

Power consumption: <6 VA

10

5.2 AUTOMATIC RESET MODE

1) Turn the power on

a) Run “Green” LED illuminates.

b) Safety contacts close.

c) Auxiliary contacts open.

d) Contactors energise.

2) Press the Profile

a) Run “Green” LED extinguishes.

b) Stop “Red” LED illuminates.

c) Safety contacts open.

d) Auxiliary contacts close.

e) Contactors de-energise.

3) Release the Profile

a) System has returned to step 1a.

Comparative properties

Profiles Profiles

440F-E0110N 440F-E0110S 440F-E0110R 440F-E0510S

440F-E1610N 440F-E1610S 440F-E0804S 440F-E0310S

440F-E0210S

Tensile strength (reinforced) MPa 26 20

Resilience (20°C) F G

Low temperature flexibility F G

Resistance to sunlight G G

Resistance to heat ageing G G

Resistance to oxidation F G

Resistance to ozone F G

Resistance to H

2OGG

Resistance to dilute acids F G

Resistance to concentrated acids F G

Resistance to oils & greases G P

Key:- G = Good F = Fair P = Poor

17

440F-A0061S

Terminal block tightening torque rating 7 in/lbs,

suitable for wire sizes 16AWG.

Use 16AWG minimum.

Use Copper Conductors Only.

Temperature rating of field wiring shall not be

less than ambient.

Page 12

5.0 COMMISSIONING & USE SEQUENCE OF OPERATION

When the unit is installed, check the following sequence of operation.

5.1 Manual reset mode.

1) Turn the Power on

a) No LED’s illuminate.

2) Press the reset switch

a) Run “Green” LED illuminates.

b) Safety contacts close.

c) Auxiliary contacts open.

d) Contactors energise.

3) Press the Profile

a) Run “Green” LED extinguishes.

b) Stop “Red” LED illuminates.

c) Safety contacts open.

d) Auxiliary contacts close.

e) Contactors de-energise.

4) Release the Profile

a) Stop “Red” LED extinguishes.

b) System has returned to step 1a.

5) If Profile is pressed before reset

a) Stop “Red” LED will illuminate each time the

Profile is pressed but the safety contacts will not energise.

440F-C251P Surface mount 440F-C251D DIN rail

Relay outputs: 2 x independant volt free N/O safety contacts

1 x volt free N/C auxiliary contact

NOTE: Auxiliary should not be used for safety

Utilisation category: AC - 15; 2A / 250V DC

DC - 13; 2A / 30V DC

Safety inputs: Safedge profile (open resistance 6KΩ)

Indication LED 1: Green: Run.

LED 2: Yellow: Open.

LED 3: Red: Stop.

Internal controls: AC voltage selector

Internal fuses: 2A safety fuses replaceable (2 off) 500mAT supply fuse replaceable (1 off)

500mAT supply fuse replaceable (1 off)

Max. output fuse: N/A 4A on AC / 2A on DC

Ambient temp. range - control unit -10°C to + 55°C.

Ambient temp. range - profile -5°C to +55°C excluding 110N & 01610N (0°C to 55°C)

Humidity: Up to 90% RH at + 55°C.

Vibration: Tested in accordance with IEC 68-2-6, frequency range

10 - 55Hz, displacement 0.15mm

10 cycles per axis, sweep rate, 1 octave per minute

MC-MC contactor monitor loop: N/C (normally closed) contactor loop

Max. conductor size: 1 x 1 mm2stranded with sleeves stripped 1x2.5 mm2stranded with sleeves stripped

5mm, 1 x 1.5mm2solid conductor. 8mm, 1 x 4 mm2solid conductor

Terminals: Minus terminal screws Plus-minus terminal screws M3.5 with

M2 spring action. self lifting connection, washer terminal

boards separately removable.

Installation group: C in accordance with VDE 0110.

Material: Polycarbonate

Fixing details: 4 x M4 holes 35 mm DIN Rail

Housing: D=75mm, H=130mm, W=130mm D=120mm, H=73mm, W=45.5mm, 16 way

Weight: 650g 450g

Miscellaneous: The Safedge Profile must be terminated with a 6KΩ resistor.

11 16

Page 13

440F-E0110N 440F-E0110S 440F-E0310S 440F-E1610N 440F-E1610S

actuating distance: 6.4mm 6.6mm 8.0mm 7.8mm 9.4mm

response distance: 1.2mm 1.9mm 27.2mm 8.4mm 5.0mm

• max. speed: 100 mm/s

• suitable for the detection of fingers

The control unit must not be mounted inside the hazard zone. Access to the control unit is required for

manual reset or for routine indicator observation so it must be able to be seen operating. The control

unit can be mounted on either side of power doors, as long as the only hazard is the actual doors.

In all other cases the control unit can be mounted anywhere convenient outside the hazard zone,

taking into account the access requirements for test and maintenance.

3.3.2 MOUNTING

440F-C251P (Surface Mounted)

440F-C251D (Din Rail Mounted)

35MM DIN RAIL MOUNTING

45.5

73

120

A1 + Z2 M C 13 23 31

A2

-- Z 1 MC 14 24 32

115mm

130mm

115mm

130mm

4 x M4 Fixing Holes

Pg16/21

Pg16/21

75mm

4.6 Reset terminal MC-MC

These terminals are used for a number of different functions (surface mount supplied jumpered,

DIN rail supplied without jumper). Without the jumper the terminals can be connected to positively

guided normally closed auxiliary contacts on the machine contactors to provide monitoring of the

contactors in dual channel control systems. If one contactor fails to isolate the power at

de-energisation of its control coil, the Safedge system will not allow the other contactor to be

energised until the fault has been rectified. Fit a jumper between these terminals on the DIN rail

unit if this function is not required.This terminal is also used for auto/manual reset. If the MC-MC

terminal is left jumpered or connected up to the contactors normally closed contact only, the unit

is in automatic reset mode. In automatic reset mode the output is achieved solely by removal of

the actuating force. The out put is also achieved at power up of the actuator (when there is no

actuation force present). If a spontaneous restart may generate a risk, based on the result of a

risk assessment to EN1050, then this mode must not be used. See EN 60204 Pt.1 and EN954

Pt.1. For manual reset mode a normally open spring return (not latching) push button must be

connected across the MC-MC terminals or in series with the contactors normally closed. When

the actuating force is removed, the unit will not operate until the button is pressed. The button

will also have to be pressed after power up of the control unit.

4.7 Profile connection to control units

These terminals are used to connect the Profile to the:-

Z1 = Brown (inner conductor).

Z2 = White (outer connector).

Refer to 5.3 APPLICATIONS.

NOTE: Profile must be terminated with a 6KΩ Resistor (yellow) for series connection. When two

profiles are connected directly to Z1 and Z2 (parallel) then each profile should be terminated with

a 15K resistor (blue).

Connection in Parallel & Series

ALTERNATIVE CONNECTION METHOD

CONNECTING IN PARALLEL

A maximum of two profiles can be connected in parallel to

assist in ease of wiring in certain applications.

Uses 15K resistor (blue)

CONNECTING IN SERIES

If more than one profile is to be used they are normally connected

in series as shown.

Uses 6K8 resistor (yellow)

15 12

Page 14

4.0 ELECTRICAL CONNECTIONS - Safedge control unit

440F-C251P (Surface Mounted)

440F-C251D (Din Rail Mounted)

A1 + Z 2 MC 13 23 31

A2

-- Z1 MC 14 24 32

4.3

4.14.2

4.7

4.6

4.5

4.4

SUPPLY

FUSE

500mA

110V

230V

STOP (RED)

OPEN (YELLOW)

RUN (GREEN)

4.1

SUPPLY FUSE

500mA

SAFETY FUSES

2A

4.2

L

110V

230V

N

ve ve

+--

31 32 13 14 23

24

4.3 4.4 4.5

4.6

4.7

STOP

RED

OPEN

YELLOW

LED INDICATION

RUN

GREEN

Z1 Z2 MC MC

CONTROL UNIT INSTALLATION AND WIRING - (Follow steps 4.1 to 4.7 for correct installation)

IMPORTANT: Wiring must be in accordance with the National Electric Code and applicable local codes

and ordinances

4.1 Mains selector switch

If using a 110V AC or a 230V AC supply, the voltage selector switch should be set as appropriate

before turning the power on. The unit is set to 230V AC when manufactured.

4.2 Mains input terminal LN (A1, A2, )

If a 110V AC or 230V AC supply is used it should be wired, together with a protective earth

(ground) to the terminals shown. The size of the protective earth (ground) wire should be at least

equal to that of the supply wire. Also check (4.1). If these terminals are used, ignore (4.3).

4.3 24V AC/DC input terminal +ve and -ve

If a 24V AC/DC supply is being used, the supply should be connected to these terminals,

ensuring that the correct polarity is observed. Do not make any connections to the terminals

of (4.2). Where a 24V AC or DC supply is used, it must be isolated from the mains supply in

accordance with international electrical safety pratice (IEC 364-4-41). One pole should be

earthed. For 24V DC the negative pole should be earthed (grounded). With 24V AC the earthed

(grounded) pole of the power supply should be connected to the -ve terminal.

4.4 Aux Output terminal 31 and 32

This terminal provides an auxiliary normally closed contact (i.e. closed when the green “Run”

light is off) which is suitable for indication or for alarm devices. As this is an auxiliary, it must not

be connected to the safety circuit.

4.5 Safety Output terminal 13, 14, 23 and 24

These are volt free contacts for connection to the machine safety circuits i.e, they are connected

in series with the machine contactor control circuit. (Max. rating 2A at 250V AC). Both of these

safety circuits are internally fused but must also be externally protected with a 2A quick acting fuse.

If one contactor is being used, terminals 13 and 24 are required and terminals 14 and 23 should

be jumpered together. For 2 contactors with 2 independent control circuits (i.e. a dual channel

system), use 13-14 for one contactor and 23-24 for the other. For 2 contactors, also see (5.3).

13 14

Loading...

Loading...