Page 1

Installation Instructions

IMPORTANT: SAVE THESE INSTRUCTIONS FOR FUTURE USE.

Yel low LED

Pushbutton

Green LED

42JT VisiSight™ Photoelectric Color Mark Sensors

Default Settings:

Output Mode: Light Operate (Output ON when the color mark is

detected after being taught)

Output Type: PNP or NPN (Push-Pull)

Sensor User Interface

LED Status

The table below provides LED status in the RUN mode i.e., during

operation, the sensor is always in RUN mode, except when being

taught.

OFF Power is OFF

Green

Yel l ow *

*LED status shown when the load is connected as PNP. The LED status reverses when the load is

connected as NPN. (e.g. LED is ON when the output is de-energized and OFF when is energized)

Mounting the Sensor

Securely mount the sensor on a firm, stable surface or support.

An application which is subject to excessive vibration or shifting

may cause intermittent operation. For installation convenience,

Rockwell Automation offers a wide range of mounting brackets

(see the Accessories section for more details).

ON Power is ON

Flashing (1.5 Hz)

Output short circuit protection

OFF Output de-energized

ON Output energized

active

General Specifications

42JT-F5LET1-

Environmental

Certifications cULus and CE Marked for all applicable directives

Operating Environment IP67, IP69K

Operating Temperature [C (F)] -20…+60° (-4…+140°)

Storage Temperature [C (F)] -20…+80° (-4…+179°)

Optical

Light Source Visible white LED

Sensing Range [mm (in.)] 12 (0.47)

Tolerance [mm (in.)] +/- 2.5 (+/- 0.1)

Spot Size [mm (in.)] 1 x 4 (0.4 x 0.15)

Adjustments Pushbutton

Electrical

Volt age 10… 30V DC

Current Consumption 25 mA max.

Sensor Protection Reverse polarity, short circuit protection

Outputs

Response Time 50 μs

Output Type PNP or NPN (Push-Pull)

Output Function Selectable light operate or dark operate

Output Current 100 mA max.

Output Leakage Current 10 μA max.

Mechanical

Housing Material ABS

Lens Material PMMA

Cover Material PMMA

Connection Types 2 m PUR cable, 4-pin DC micro (M12) QD on a 150 mm

PUR pigtail, 4-pin pico (M8) integral QD

Optional Accessories Mounting brackets, cordsets

Replace with A2 for 2 m (6.6 ft) cable, F4 for 4-pin DC micro (M12) QD, or P4 on 4-pin DC pico

(M8) QD

UL: -20…+50°C (-4…122°F)

Page 2

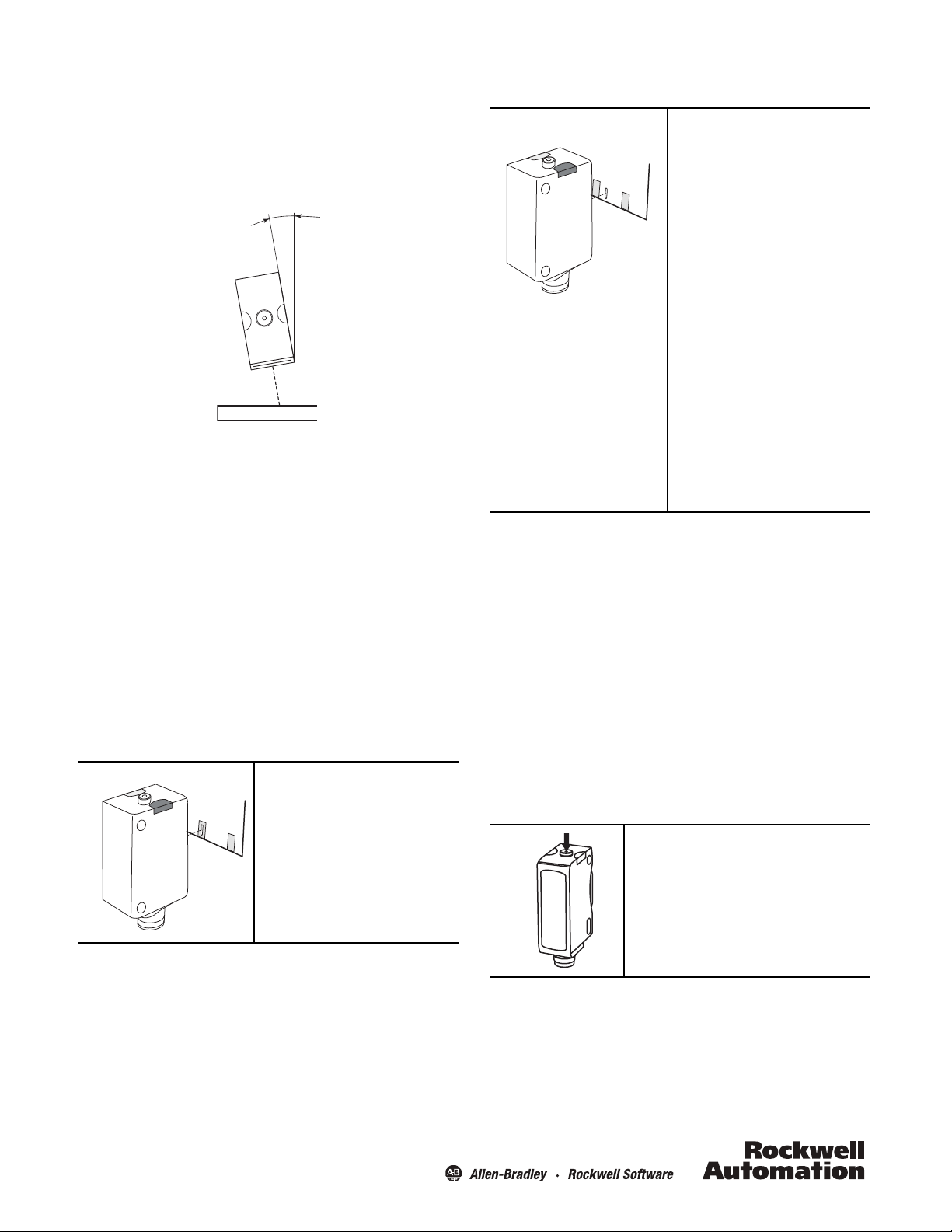

Sensor Alignment

10º

t > 3 s

t < 0.5 s

t > 6 s

Position the 42JT VisiSight contrast sensor so that the distance

from the object to the sensor is 12 mm. High reflectivity surfaces

can impact the reliability of the color mark detection. We

recommend that you angle the sensor 10° to help improve the

color mark detection as shown below.

VisiSight™ Configuration

The 42JT VisiSight is configured using the pushbutton (or Remote

Teach) and the LED indicators on the sensor. There are four

features that can be configured:

• Static Teach

• Dynamic Teach (running process)

• Light operate (LO) or dark operate (DO) output

• Pushbutton lock/unlock

The sensor output is disabled during Teach.

2. Teach the background (second condition).

Present the background to the sensor. Press and

release the button. The teach process is complete.

If the push button is not pressed within 30 seconds,

the sensor exits teach mode and returns to RUN

mode without learning the new setting.

However, if the contrast of the color mark vs. the

background is not sufficient (e.g., a yellow mark on a

white background) the sensor is unable to detect the

color mark. If that is the case, the white LED (light

spot) flashes 10 times.

A flashing white LED (light spot) indicates the

following:

Flashes (10 times): insufficient contrast level

Flashes (3 times): small contrast level

No flashing: good contrast level

If the white LED flashes, angle the sensor 10° (see

“Sensor Alignment,” at left), and repeat the teach

process.

If the sensor is still unable to detect the color mark

and indicates “insufficient contrast level,” a higher

end sensor may be necessary, such as the 45CRM

color mark sensor.

Dynamic Teach (Running Process)

If the targets to be detected are moving with the sensor aimed at

the running process, press and hold the button for three seconds,

until the yellow LED starts flashing. The color mark will

automatically be taught in the next 30 seconds provided the

sensor sees two cycles of mark and background.

Te ac h

Teaching the color mark is a two step process:

1. Teach the color mark (first condition).

Place the sensor 12 mm (0.47 in.) from the color

mark and aim it at the mark. Press and hold the

button for three seconds, until the yellow LED starts

flashing. Release the button.

Although the sensor will operate within a tolerance

of +/-2.5 mm (0.1 in.) from the focal distance, the

sensor should be installed at 12 mm (0.47 in.) for

optimal performance.

Teach Light Operate (L.O.) or Dark Operate (D.O.)

The default setting of the output is Light Operate (L.O.: output ON

when the color mark is detected after being taught.)

If the application requires the output to turn OFF when the color

mark is detected, the setting may be changed to Dark Operate

(D.O.)

1. To access the teach output mode setting:

Press and hold button for six seconds, until green LED starts

flashing. Release the button. The current setting is indicated by

the yellow LED:

L.O.: Yellow LED ON

D.O.: Yello w LED OFF

2

Page 3

2. To change the sensor output mode setting:

M12 Male M8 Male

Output (PNP or NPN) (Push-Pull)

Remote Teach/Lock

+V

-V

?

Brown (1)

White (2)

Black (4)

Blue (3)

t < 0.5 s

Press and release the button within ten seconds to toggle from

L.O. to D.O. , the sele cti on in dica ted by the y ello w LED.

The sensor retains the setting per the last button depression and

returns to the RUN mode ten seconds after the last button is

depressed.

Wiring Diagrams

The quick-disconnect connector is shown in the following

diagrams. The pin numbers correspond to male connectors on

the sensor.

Micro (M12) Male QD on Pigtail and

Integral Pico (M8) Male QD

1

4

2

4

Pushbutton Lock/Unlock

The pushbutton or remote teach (RT) can be used to prevent

unauthorized users from changing teach settings.

To lock th e pushbutton: press and release the button three

times within three seconds. Both LEDs flash synchronously for

three seconds indicating that the pushbutton is now locked.

To unlock the pushbutton: press and release the button three

times within three seconds. Both LEDs flash asynchronously for

three seconds indicating that the pushbutton is now unlocked.

Permanent Lock: The pushbutton may be permanently locked

by connecting the white wire (pin 2) to –V.

Remote Teach (RT)

The sensor can be taught remotely via the white wire (pin 2).

Connection to +V acts the same as the button being pressed and

no connection is the same as the button not being pressed. The

sensor can be taught by following the same teach/timing

sequence as used in the pushbutton teach. For example, connect

to the +V for more than three seconds to align and install the

reflector, disconnect from the +V; while the reflector is in the

sensor’s field of view and there is no target, connect to the +V for

less than one second to complete the teach process. All

pushbutton functions can also be carried out via RT.

1

2

3

Output Wiring

?

Normal operation: no connection.

Remote Teach: connect to +V. Refer to the Remote Teach section.

Pushbutton lock: connect to -V. Refer to the Pushbutton Lock/Unlock section.

Margin Curve

120

100

80

Signal [%]

60

3

3

0

7171615141312111098

Distance [mm]

Page 4

Power, Control and Information Solutions Headquarters

Americas: Rockwell Automation, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414.382.2000, Fax: (1) 414.382.4444

Europe/Middle East/Africa: Rockwell Automation NV, Pegasus Park, De Kleetlaan 12a, 1831 Diegem, Belgium, Tel: (32) 2 663 0600, Fax: (32) 2 663 0640

Asia Pacic: Rockwell Automation, Level 14, Core F, Cyberport 3, 100 Cyberport Road, Hong Kong, Tel: (852) 2887 4788, Fax: (852) 2508 1846

www.rockwel lautomation.com

Approximate Dimensions [mm (in.)]

12

(0.47)

M8 x 1

34

(1.34)

22.9

(0.90)

25.4

(1.0)

2.6

(0.10)

20

(0.79)

12

(0.47)

34

(1.34)

22.9

(0.90)

25.4

(1.0)

2.6

(0.10)

20

(0.79)

2.8

(0.11)

Clearance for

M3 or #4-40 screw

(2 places)

Clearance for

M3 or #4-40 screw

(2 places)

Accessories

Stainless Steel Mounting Brackets

60-BJS-L1

°

15

8 (0.32)

24

(0.95)

60-BJT-L2

14

(0.55)

30°

12

(0.47)

R 25.4

(R 1.0)

18.6

(0.73)

33

(1.3)

63.5

(2.5)

8

(0.32)

14

(0.55)

20°

R 25.4

(1.0)

10°

12

(0.47)

18.6

(0.73)

33

(1.3)

Copyright © 2012 Rockwell Automation, Inc. All Rights Reserved. 10000234774 Ver 01

December 2012

Printed in Germany

068-14494

Loading...

Loading...