Page 1

Installation Instructions

Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts

Catalog Numbers 2711P-RAK7, 2711P-RAT7, 2711P-RAK10, 2711P-RAT10,

2711P-RAK12S, 2711P-RAT12S

Language Page

English 3

Français 9

Deutsch 15

Español 21

Italiano 27

Português 33

Publication 2711P-IN010C-MU-P - March 2007

Page 2

2 Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you to identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Publication 2711P-IN010C-MU-P - March 2007

Page 3

Installation Instructions

Adapter Kit for PanelView Standard and

PanelView “e” Terminal Cutouts

Catalog Numbers 2711P-RAK7, 2711P-RAT7, 2711P-RAK10, 2711P-RAT10,

2711P-RAK12S, 2711P-RAT12S

English

Topic Page

About This Publication 4

Package Contents 4

Tools Required 4

Disconnect Power to the Terminal 5

Remove the Existing Terminal 5

Attach the Adapter Plates to the Panel 5

Attach the Terminal to the Adapter Plate 7

Publication 2711P-IN010C-MU-P - March 2007

Page 4

4 Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts

About This Publication

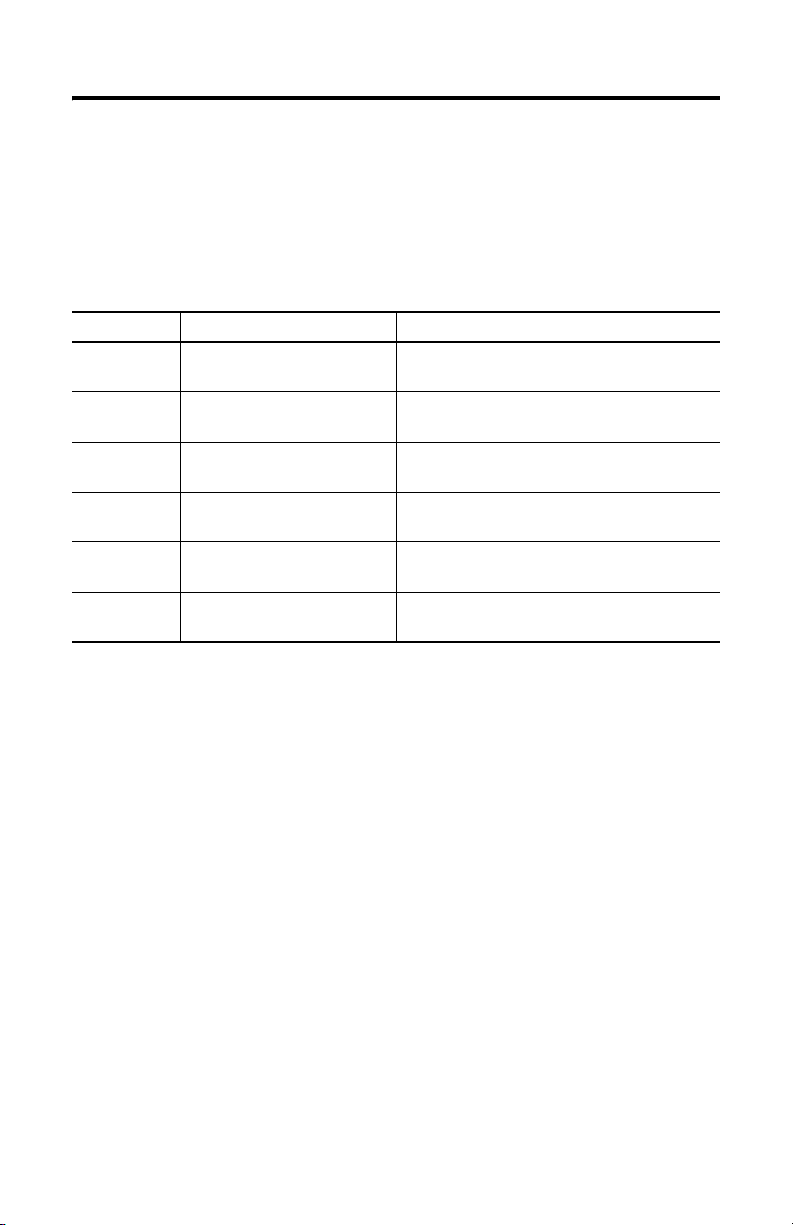

This document provides instructions on how to mount the following devices into

existing PanelView Standard and PanelView “e” terminal cutouts.

• PanelView Plus 700-1250

• PanelView Plus CE 700-1250

Cat. No. This Terminal: Fits into Existing Cutout for:

2711P-RAK7 PanelView Plus 700 Keypad

PanelView Plus CE 700 Keypad

2711P-RAT7 PanelView Plus 700 Touch

PanelView Plus CE 700 Touch

2711P-RAK10 PanelView Plus 1000 Keypad

PanelView Plus CE 1000 Keypad

2711P-RAT10 PanelView Plus 1000 Touch

PanelView Plus CE 1000 Touch

2711P-RAK12S PanelView Plus 1250 Keypad

PanelView Plus CE 1250 Keypad

2711P-RAT12S PanelView Plus 1250 Touch

PanelView Plus CE 1250 Touch

PanelView Standard 900 Keypad (2711-K9xxx)

PanelView Standard 900 Touch (2711-T9xxx)

PanelView Standard 1000 Keypad (2711-K10xxx)

PanelView 1000e Keypad (2711E-K10xxx)

PanelView Standard 1000 Touch (2711-T10xxx)

PanelView 1000e Touch (2711E-T10xxx)

PanelView Standard 1400 Keypad (2711-K14xxx)

PanelView Standard 1400 Touch (2711-T14xxx)

Package Contents

The cutout adapter kit includes:

• Cutout adapter plates with gasket and ball bearing spacers

• Adapter bars for plates with 3 or 4 holes

• 8 , 10, or 12, #10-32 nuts with flat washers, depending on number of studs in

adapter plate

Tools Required

The following tools are required for installation:

• Socket driver with 3/8 inch socket

• Slot or Phillips screwdriver

• Torque wrench capable of 17 lb-in

Publication 2711P-IN010C-MU-P - March 2007

Page 5

Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts 5

Disconnect Power to the Terminal

1. Disconnect power at the source and remove the power cord from the

PanelView terminal.

2. Disconnect all communication cables from the terminal.

ATTENTION

Make sure the power cord of the terminal is disconnected and that all cables

have been disconnected from the terminal.

Remove the Existing Terminal

1. Remove the mounting clips that secure the terminal in the panel.

TIP

2. Slide the existing terminal out from panel.

The PanelView Standard and PanelView “e” mounting clips are different than

the PanelView Plus mounting clips. Store the mounting clips separately to

avoid confusion later.

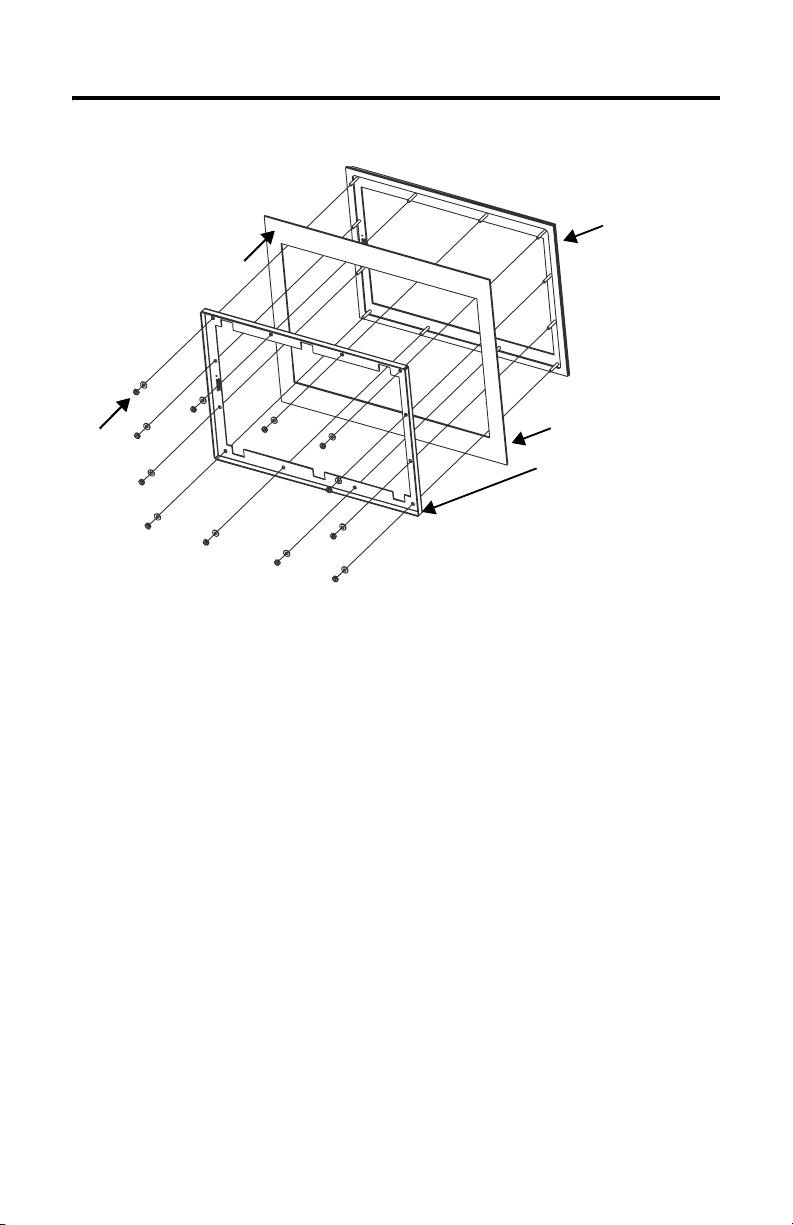

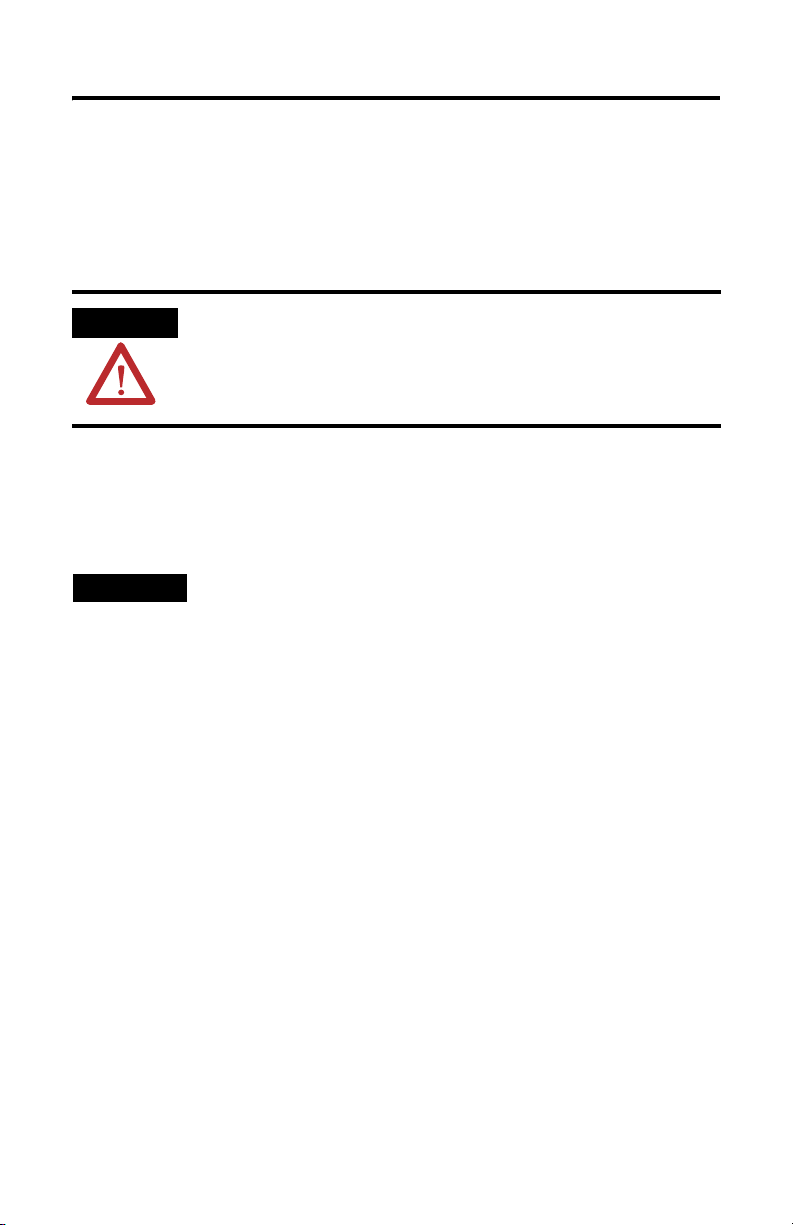

Attach the Adapter Plates to the Panel

The studs on the front adapter plate fit within the cutout of the terminal.

1. Place the front adapter plate into the panel cutout until the sealing gasket

material is firmly against the front of the panel.

Publication 2711P-IN010C-MU-P - March 2007

Page 6

6 Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts

Inside of Panel or Enclosure

Front Adapter Plate

Nut and

Washer

Front of Panel or Enclosure

Rear Adapter Plate

with 12 holes

2. Mount the rear adapter plate to the front adapter plate studs from the back

of the panel, flat side of rear adapter plate towards back of enclosure.

Use the 8, 10 or 12 nuts and flat washers to fasten the rear adapter plate to

the studs.

3. Using the torque wrench, tighten the nuts to not more than 1.92 Nm

(17 lb-in) to maintain a NEMA Type 4X rating.

Do not overtighten.

Publication 2711P-IN010C-MU-P - March 2007

Page 7

Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts 7

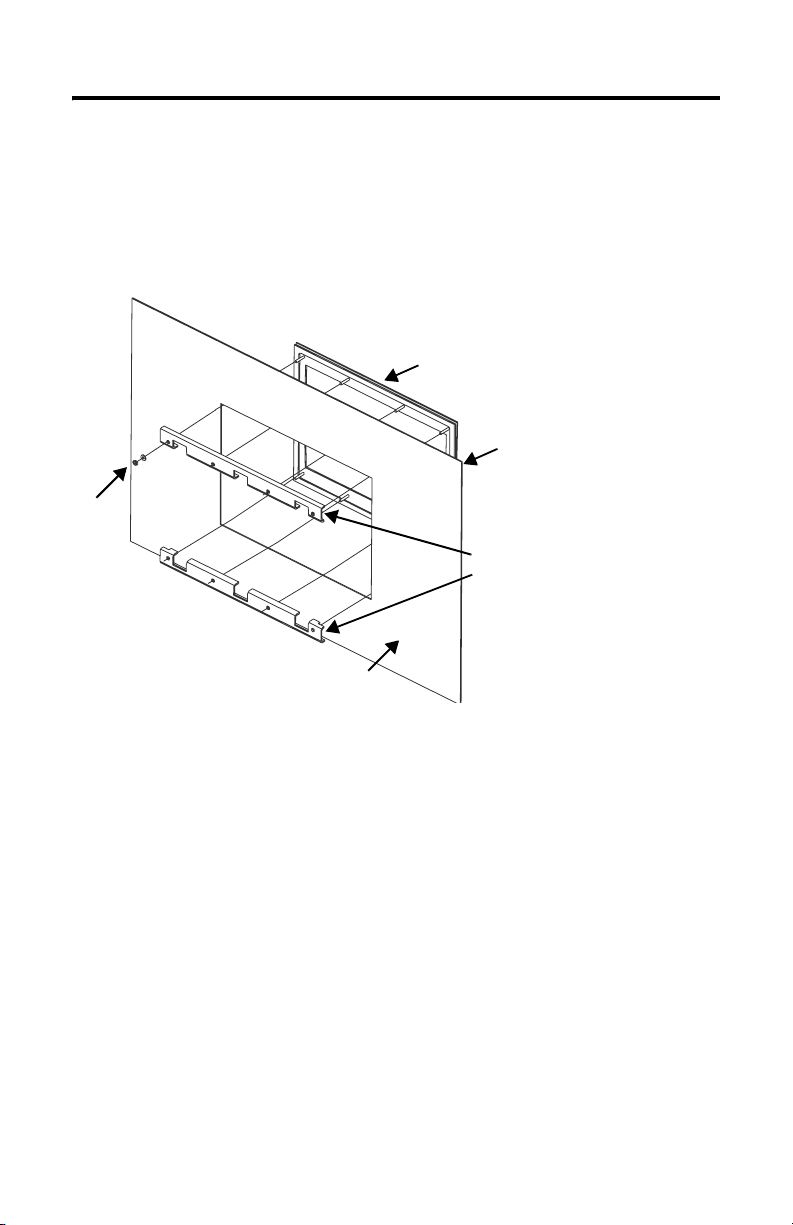

1000 Keypad Only

The studs on the adapter plate fit within the cutout of the terminal.

1. Place the adapter plate into the panel cutout until the sealing gasket material

is firmly against the front of the panel.

Adapter Plate

Front of Panel or Enclosure

Nut and

Washer

Adapter Bars

with 4 Holes

Inside of Panel or Enclosure

2. Mount the adapter bar to the adapter plate studs from the back of the panel,

flat side of bar towards back of enclosure.

Use the 8 nuts and flat washers to fasten the adapter bar to the studs.

3. Using the torque wrench, tighten the nuts to no more than 1.13 Nm

(10 lb-in) to maintain a NEMA Type 4X rating.

Do not overtighten.

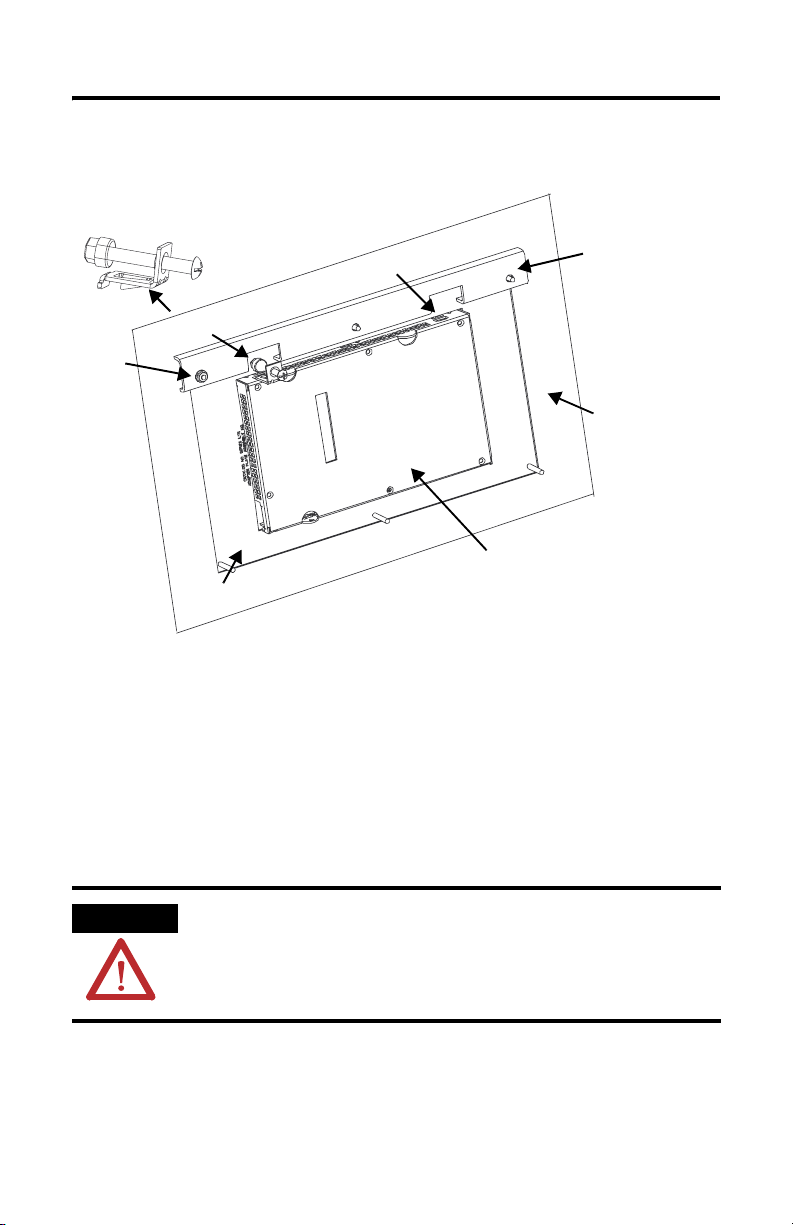

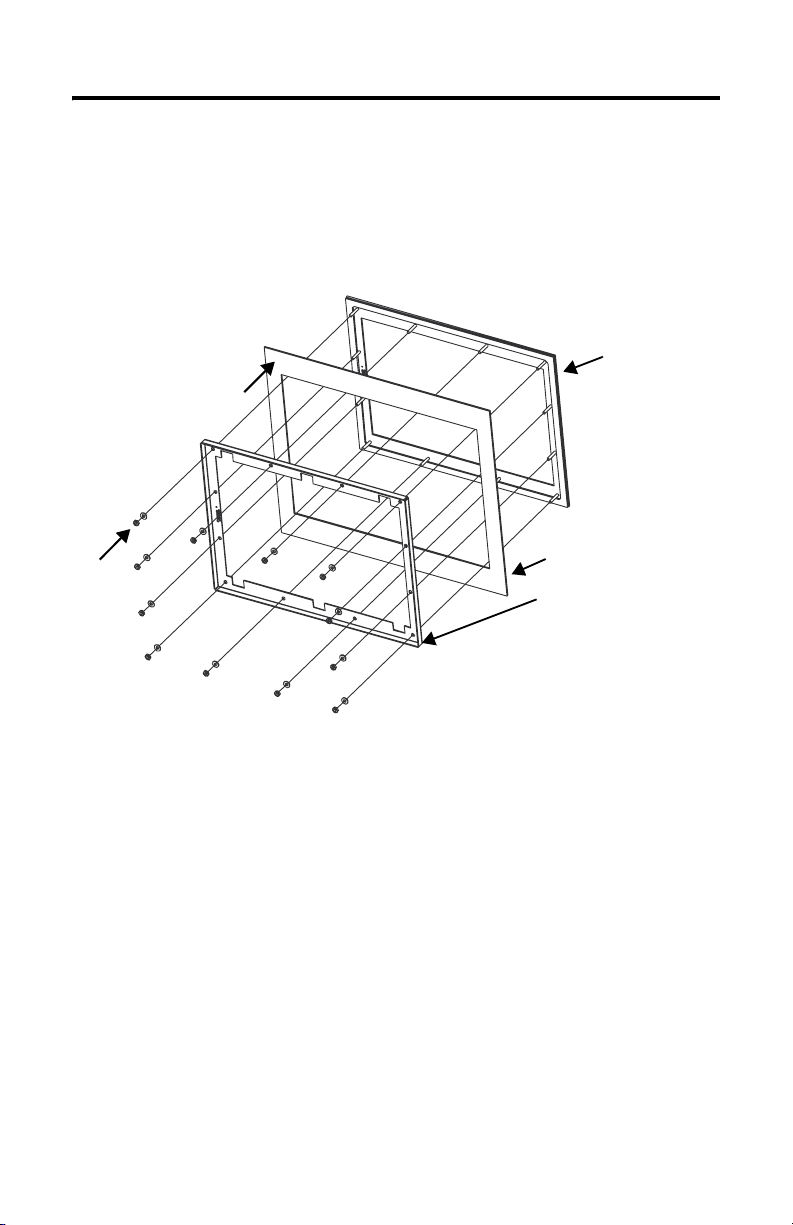

Attach the Terminal to the Adapter Plate

1. Insert the new terminal into the front of the enclosure until the terminal

gasket is flush with the adapter plate.

2. Install the mounting clips.

The number of clips varies depending on terminal type. The ends of the

mounting clips slide into the slots on the terminal.

Publication 2711P-IN010C-MU-P - March 2007

Page 8

8 Adapter Kit for PanelView Standard and PanelView “e” Terminal Cutouts

The illustration is a view from inside the enclosure. The top or bottom clips

tighten directly to the adapter plate.

Mounting Clip Slot

Mounting Clip

Nut

and

Washer

Back of Terminal

Adapter Plate

Adapter Bar

Panel or Enclosure

3. Tighten the screws on the mounting clips by hand until the gasket seal

contacts the mounting surface uniformly.

4. Using the torque wrench, tighten the screws on the mounting clips to the

specified torque rating provided in the installation instructions for the new

terminal.

This is necessary to maintain a NEMA Type 4X rating. Do not overtighten.

ATTENTION Tighten the mounting clips to the specified torque to provide a proper seal and

to prevent potential damage to the terminal. Allen-Bradley assumes no

responsibility for water or chemical damage to the product or other equipment

within the enclosure because of improper installation.

Publication 2711P-IN010C-MU-P - March 2007

Page 9

Notice d’installation

Kit d’adaptation pour découpe de terminal

PanelView Standard et PanelView « e »

Réf. 2711P-RAK7, 2711P-RAT7, 2711P-RAK10, 2711P-RAT10,

2711P-RAK12S, 2711P-RAT12S

Français

Pour les informations suivantes Voir page

Description 10

Contenu du kit 10

Outils nécessaires 10

Déconnexion du terminal 11

Retrait du terminal existant 11

Fixation des plaques d’adaptation sur le panneau 12

Fixation du terminal à la plaque d’adaptation 13

Publication 2711P-IN010C-MU-P - March 2007

Page 10

10 Kit d’adaptation pour découpe de terminal PanelView Standard et PanelView « e »

Description

Ce document indique comment monter les équipements suivants dans une

découpe existante prévue pour les PanelView Standard et les PanelView « e ».

• PanelView Plus 700 à 1250 ;

• PanelView Plus CE 700 à 1250.

Réf. Ce nouveau terminal S’insère dans une découpe prévue pour un

2711P-RAK7 PanelView Plus 700 à clavier

2711P-RAT7 PanelView Plus 700 à dalle tactile

2711P-RAK10 PanelView Plus 1000 à clavier

2711P-RAT10 PanelView Plus 1000 à dalle tactile

2711P-RAK12S PanelView Plus 1250 à clavier

2711P-RAT12S PanelView Plus 1250 à dalle tactile

PanelView Plus CE 700 à clavier

PanelView Plus CE 700 à dalle tactile

PanelView Plus CE 1000 à clavier

PanelView Plus CE 1000 à dalle tactile

PanelView Plus CE 1250 à clavier

PanelView Plus CE 1250 à dalle tactile

PanelView Standard 900 à clavier (2711-K9xxx)

PanelView Standard 900 à dalle tactile (2711-T9xxx)

PanelView Standard 1000 à clavier (2711-K10xxx)

PanelView 1000e à clavier (2711E-K10xxx)

PanelView Standard 1000 à dalle tactile

(2711-T10xxx)

PanelView 1000e à dalle tactile (2711E-T10xxx)

PanelView Standard 1400 à clavier (2711-K14xxx)

PanelView Standard 1400 à dalle tactile

(2711-T14xxx)

Contenu du kit

Le kit d’adaptation pour découpe contient les éléments suivants :

• plaques d’adaptation pour découpe avec joint d’étanchéité et espaceurs à

roulement à billes ;

• barres d’adaptation pour plaques à 3 ou 4 trous ;

• 8, 10 ou 12 écrous n° 10-32 avec rondelles plates (selon le nombre de

goujons de la plaque d’adaptation).

Outils nécessaires

Les outils suivants sont nécessaires pour monter les plaques d’adaptation :

• une clé à douille avec douille de 3/8 pouce ;

• un tournevis plat ou cruciforme ;

• une clé dynamométrique.

Publication 2711P-IN010C-MU-P - March 2007

Page 11

Kit d’adaptation pour découpe de terminal PanelView Standard et PanelView « e » 11

Déconnexion du terminal

1. Déconnectez l’alimentation à la source et débranchez le cordon

d’alimentation du terminal PanelView.

2. Déconnectez tous les câbles de communication du terminal.

ATTENTION

Assurez-vous que le cordon d’alimentation du terminal PanelView est

déconnecté et que tous les autres câbles sont déconnectés du terminal.

Retrait du terminal existant

1. Retirez les colliers de fixation qui maintiennent le terminal sur le panneau.

TIP

2. Retirez le terminal du panneau.

Les colliers de fixation des PanelView Standard/ PanelView « e » sont

différents des colliers des PanelView Plus. Rangez les colliers séparément pour

éviter toute erreur par la suite.

Publication 2711P-IN010C-MU-P - March 2007

Page 12

12 Kit d’adaptation pour découpe de terminal PanelView Standard et PanelView « e »

Fixation des plaques d’adaptation sur le panneau

Les goujons de la plaque d’adaptation avant s’insèrent dans la découpe prévue

pour le terminal.

1. Placez la plaque d’adaptation avant dans la découpe du panneau de manière

à bien positionner le joint d'étanchéité contre l’avant du panneau.

Plaque d’adaptation

Intérieur du panneau ou de

l’armoire

Ecrou et

rondelle

Plaque d’adaptation arrière à

12 trous

avant

Avant du panneau ou de

l’armoire

2. Montez la plaque d’adaptation arrière sur les goujons de la plaque avant, par

l’arrière du panneau (le côté plat de la plaque d’adaptation arrière orienté

vers l’arrière du panneau).

Fixez la plaque d’adaptation arrière sur les goujons à l’aide des écrous et des

rondelles plates (8, 10 ou 12).

3. Utilisez la clé dynamométrique pour serrer les écrous avec un couple

d’1,92 Nm maximum, afin de conserver une classification NEMA type 4X.

Veillez à ne pas trop les serrer.

Publication 2711P-IN010C-MU-P - March 2007

Page 13

Kit d’adaptation pour découpe de terminal PanelView Standard et PanelView « e » 13

Terminaux 1000 à clavier uniquement

Les goujons de la plaque d’adaptation s’insèrent dans la découpe prévue pour le

terminal.

1. Placez la plaque d’adaptation dans la découpe du panneau de manière à

bien positionner le joint d’étanchéité contre l’avant du panneau.

Plaque d’adaptation

Avant du panneau ou de l’armoire

Ecrou et

rondelle

Barres d’adaptation

à 4 trous

Intérieur du panneau ou de l’armoire

2. Fixez la barre d’adaptation sur les goujons de la plaque par l’arrière du

panneau (le côté plat de la barre orienté vers l’arrière du panneau) à l’aide

des 8 écrous et des 8 rondelles plates.

3. Utilisez la clé dynamométrique pour serrer les écrous avec un couple

d’1,13 Nm maximum, afin de conserver une classification NEMA type 4X.

Veillez à ne pas trop les serrer.

Fixation du terminal à la plaque d’adaptation

1. Placez le nouveau terminal dans l’ouverture de manière à ce que son joint

affleure la plaque d’adaptation.

2. Mettez les colliers de fixation en place.

Publication 2711P-IN010C-MU-P - March 2007

Page 14

14 Kit d’adaptation pour découpe de terminal PanelView Standard et PanelView « e »

Le nombre de colliers à utiliser varie suivant le type de terminal. Les

extrémités des colliers s’insèrent dans les encoches situées sur le terminal.

L’illustration suivante est une vue de l’arrière du panneau ou de l’intérieur de

l’armoire. Les colliers supérieurs et inférieurs se serrent directement sur la

plaque d’adaptation.

Encoche pour collier de fixation

Barre d’adaptation

Collier de fixation

Ecrou et

rondelle

Panneau ou armoire

Arrière du terminal

Plaque d’adaptation

3. Serrez les vis des colliers de fixation à la main jusqu’à ce que le joint

d’étanchéité soit positionné uniformément sur la surface de montage.

4. Utilisez la clé dynamométrique pour serrer les vis sur les colliers de fixation,

en respectant le couple de serrage indiqué dans la notice d’installation du

terminal.

Le couple de serrage doit être respecté pour conserver une classification

NEMA type 4X. Veillez à ne pas trop les serrer.

ATTENTION

Serrez les colliers de fixation avec le couple de serrage qui convient pour

obtenir une bonne étanchéité et éviter d’endommager le terminal.

Allen-Bradley ne saurait être tenu pour responsable des dégâts causés par une

infiltration d’eau ou de produit chimique dans le terminal ou dans tout autre

équipement présent dans l’armoire, suite à une installation incorrecte.

Publication 2711P-IN010C-MU-P - March 2007

Page 15

Installationsanleitung

Adapter-Kit für Ausschnitte für Terminals des

Typs PanelView Standard und PanelView „e“

Bestellnummern 2711P-RAK7, 2711P-RAT7, 2711P-RAK10, 2711P-RAT10,

2711P-RAK12S, 2711P-RAT12S

Deutsch

Thema Seite

Beschreibung 15

Lieferumfang 16

Erforderliche Werkzeuge 16

Abklemmen des Terminals 16

Ausbau eines vorhandenen Terminals 17

Befestigen der Adapterplatten am Schaltschrank 17

Befestigen des Terminals an der Adapterplatte 20

Publication 2711P-IN010C-MU-P - March 2007

Page 16

16 Adapter-Kit für Ausschnitte für Terminals des Typs PanelView Standard und PanelView „e“

Beschreibung

In dem vorliegenden Dokument wird der Einbau folgender Geräte in einem

vorhandenen Ausschnitt für ein Terminal des Typs PanelView Standard und

PanelView „e“ beschrieben.

• PanelView Plus 700-1250

• PanelView Plus CE 700-1250

Bestell-Nr. Neues Terminal: Vorhandener Ausschnitt für:

2711P-RAK7 PanelView Plus 700 Tastatur

PanelView Plus CE 700 Tastatur

2711P-RAT7 PanelView Plus 700 Touchscreen

PanelView Plus CE 700 Touchscreen

2711P-RAK10 PanelView Plus 1000 Tastatur

PanelView Plus CE 1000 Tastatur

2711P-RAT10 PanelView Plus 1000 Touchscreen

PanelView Plus CE 1000 Touchscreen

2711P-RAK12S PanelView Plus 1250 Tastatur

PanelView Plus CE 1250 Tastatur

2711P-RAT12S PanelView Plus 1250 Touchscreen

PanelView Plus CE 1250 Touchscreen

PanelView Standard 900 Tastatur (2711-K9xxx)

PanelView Standard 900 Touchscreen (2711-T9xxx)

PanelView Standard 1000 Tastatur (2711-K10xxx)

PanelView 1000e Tastatur (2711E-K10xxx)

PanelView Standard 1000 Touchscreen

(2711-T10xxx)

PanelView 1000e Touchscreen (2711E-T10xxx)

PanelView Standard 1400 Tastatur (2711-K14xxx)

PanelView Standard 1400 Touchscreen

(2711-T14xxx)

Lieferumfang

Das Ausschnittadapter-Kit enthält:

• Ausschnittadapterplatten mit Dichtung und Distanzblöcken mit Kugellager

• Adapterleisten für Platten mit 3 oder 4 Löchern

• 8, 10 oder 12 Muttern #10–32 mit Unterlegscheiben (je nach Anzahl der Stifte

an der Adapterplatte)

Erforderliche Werkzeuge

Folgende Werkzeuge werden für die Installation benötigt:

• Steckschlüssel mit 3/8-Zoll-Einsatz

• Schlitz- oder Kreuzschlitz-Schraubendreher

• Drehmomentschlüssel für 1,92 Nm

Publication 2711P-IN010C-MU-P - March 2007

Page 17

Adapter-Kit für Ausschnitte für Terminals des Typs PanelView Standard und PanelView „e“ 17

Abklemmen des Terminals

1. Unterbrechen Sie die Stromversorgung an der Quelle und ziehen Sie das

Netzkabel vom PanelView-Terminal ab.

2. Ziehen Sie alle Kommunikationskabel vom Terminal ab.

ACHTUNG

Vergewissern Sie sich, dass das Netzkabel sowie alle anderen Kabel vom

PanelView-Terminal abgezogen sind.

Ausbau eines vorhandenen Terminals

1. Entfernen Sie die Montageklammern, mit denen das Terminal im

Schaltschrank gesichert ist.

TIPP

2. Ziehen Sie das vorhandene Terminal aus dem Schaltschrank.

Die Montageklammern für Terminals des Typs PanelView Standard/PanelView

„e“ unterscheiden sich von den Klammern für Terminals des Typs PanelView

Plus. Zur Vermeidung von Verwechslungen sollten die Montageklammern

daher separat aufbewahrt werden.

Publication 2711P-IN010C-MU-P - March 2007

Page 18

18 Adapter-Kit für Ausschnitte für Terminals des Typs PanelView Standard und PanelView „e“

Befestigen der Adapterplatten am Schaltschrank

Die Stifte auf der vorderen Adapterplatte passen in den Ausschnitt des vorhandenen

Terminals.

1. Setzen Sie die vordere Adapterplatte auf den Schaltschrankausschnitt auf,

sodass die Dichtung gleichmäßig an der Vorderseite des Schaltschranks

anliegt.

Vordere

Innenseite des

Schaltschranks oder

Gehäuses

Mutter

und

Unterleg

-scheibe

Hintere Adapterplatte

mit 12 Löchern

Adapterplatte

Vorderseite des

Schaltschranks oder

Gehäuses

2. Befestigen Sie die hintere Adapterplatte von der Rückseite des

Schaltschranks her an den Stiften der vorderen Adapterplatte; dabei muss die

flache Seite der hinteren Adapterplatte zur Rückwand des Gehäuses

ausgerichtet sein.

Befestigen Sie die hintere Adapterplatte unter Verwendung der (8, 10 oder

12) Muttern und Unterlegscheiben an den Stiften.

3. Ziehen Sie die Muttern mit Hilfe des Drehmomentschlüssels bis zu einem

maximalen Drehmoment von 1,92 Nm an; dies ist das für die

NEMA-Kategorie 4X vorgesehene Drehmoment.

Ziehen Sie die Schrauben nicht zu fest an.

Publication 2711P-IN010C-MU-P - March 2007

Page 19

Adapter-Kit für Ausschnitte für Terminals des Typs PanelView Standard und PanelView „e“ 19

Nur Tastatur 1000

Die Stifte auf der Adapterplatte passen in den Ausschnitt des vorhandenen

Terminals.

1. Setzen Sie die Adapterplatte auf den Schaltschrankausschnitt auf, sodass die

Dichtung gleichmäßig an der Vorderseite des Schaltschranks anliegt.

Adapterplatte

Vorderseite des Schaltschranks

oder Gehäuses

Mutter

und

Unterleg

-scheibe

Adapterleisten

mit 4 Löchern

Innenseite des Schaltschranks oder

Gehäuses

2. Befestigen Sie die Adapterleiste von der Rückseite des Schaltschranks her an

den Stiften der Adapterplatte; dabei muss die flache Seite der Adapterleiste

zur Rückwand des Gehäuses ausgerichtet sein.

Befestigen Sie die Adapterleiste unter Verwendung der acht Muttern und

Unterlegscheiben an den Stiften.

3. Ziehen Sie die Muttern mit Hilfe des Drehmomentschlüssels bis zu einem

maximalen Drehmoment von 1,13 Nm an; dies ist das für die

NEMA-Kategorie 4X vorgesehene Drehmoment.

Ziehen Sie die Schrauben nicht zu fest an.

Befestigen des Terminals an der Adapterplatte

1. Setzen Sie das neue Terminal an der Vorderseite des Gehäuse an, bis die

Dichtung des Terminals bündig mit der Adapterplatte ist.

Publication 2711P-IN010C-MU-P - March 2007

Page 20

20 Adapter-Kit für Ausschnitte für Terminals des Typs PanelView Standard und PanelView „e“

2. Bringen Sie die Montageklammern an.

Die Anzahl der Klammern variiert je nach Terminaltyp. Die Enden der

Klammern lassen sich in die Schlitze am Terminal schieben.

Die nachfolgende Abbildung zeigt die Innenansicht des Gehäuses. Die

oberen und die unteren Montageklammern sind direkt mit der Adapterplatte

verbunden.

Mutter

und

Unterleg

-scheibe

Montageklammer

Adapterplatte

Schlitz für Montageklammer

Rückseite des

Ter mi na l

Adapterleiste

Schaltschrank oder

Gehäuse

3. Ziehen Sie die Schrauben der Montageklammern von Hand an, bis die

Dichtung die Montagefläche überall gleichmäßig berührt.

4. Ziehen Sie die Schrauben der Montageklammern mit Hilfe des

Drehmomentschlüssels bis zu dem Drehmoment an, das in der

Installationsanleitung des neuen Terminals angegeben ist.

Dies ist für die Einhaltung der Anforderungen gemäß NEMA-Kategorie 4X

erforderlich. Ziehen Sie die Schrauben nicht zu fest an.

ACHTUNG

Ziehen Sie die Schrauben der Montageklammern mit dem korrekten

Drehmoment an, um eine ordnungsgemäße Dichtung zu gewährleisten und

eine mögliche Beschädigung des Terminals zu vermeiden. Rockwell

Automation übernimmt keine Haftung für Schäden, die durch Wasser oder

Chemikalien am Terminal oder an anderen Geräten innerhalb des Gehäuses

entstehen und auf eine unsachgemäße Installation zurückzuführen sind.

Publication 2711P-IN010C-MU-P - March 2007

Page 21

Instrucciones de instalación

Juego adaptador para cortes de terminal

PanelView Estándar y PanelView “e”

Números de catálogo 2711P-RAK7, 2711P-RAT7, 2711P-RAK10,

2711P-RAT10, 2711P-RAK12S, 2711P-RAT12S

Español

Para consultar Vea la página

Descripción 21

Contenido del paquete 22

Herramientas requeridas 22

Desconecte el terminal 22

Extraiga el terminal existente 23

Acople las placas adaptadoras al panel 23

Acople el terminal a la placa adaptadora 25

Publication 2711P-IN010BC-MU-P - March 2007

Page 22

22 Juego adaptador para cortes de terminal PanelView Estándar y PanelView “e”

Descripción

Este documento proporciona instrucciones para montar los siguientes dispositivos

en cortes existentes para terminal PanelView Estándar y PanelView “e”.

• PanelView Plus 700-1250

• PanelView Plus CE 700-1250

No. de cat. Este nuevo terminal: Cabe en este corte existente para:

2711P-RAK7 Teclado PanelView Plus 700

2711P-RAT7 Pantalla táctil PanelView Plus 700

2711P-RAK10 Teclado PanelView Plus 1000

2711P-RAT10 Pantalla táctil PanelView Plus 1000

2711P-RAK12S Teclado PanelView Plus 1250

2711P-RAT12S Pantalla táctil PanelView Plus 1250

Teclado PanelView Plus CE 700

Pantalla táctil PanelView Plus CE 700

Teclado PanelView Plus CE 1000

Pantalla táctil PanelView Plus CE 1000

Teclado PanelView Plus CE 1250

Pantalla táctil PanelView Plus CE 1250

Teclado PanelView Estándar 900 (2711-K9xxx)

Pantalla táctil PanelView Estándar 900 (2711-T9xxx)

Teclado PanelView Estándar 1000 (2711-K10xxx)

Teclado PanelView 1000e (2711E-K10xxx)

Pantalla táctil PanelView Estándar 1000

(2711-T10xxx)

Pantalla táctil PanelView 1000e (2711E-T10xxx)

Teclado PanelView Estándar 1400 (2711-K14xxx)

Pantalla táctil PanelView Estándar 1400

(2711-T14xxx)

Contenido del paquete

El juego adaptador de corte incluye:

• placas adaptadoras de corte con empaquetadura y separadores de cojinetes

de bolas

• barras adaptadoras para placas con 3 ó 4 orificios

• 8, 10 ó 12 tuercas #10-32 con arandelas planas (dependiendo del número de

pernos de la placa adaptadora)

Herramientas requeridas

Se requieren las siguientes herramientas para la instalación:

• llave de cubo con casquillo de 3/8 pulg.

• destornillador plano o Phillips

• llave dinamométrica con capacidad de 17 pulg.-libras

Publication 2711P-IN010BC-MU-P - March 2007

Page 23

Juego adaptador para cortes de terminal PanelView Estándar y PanelView “e” 23

Desconecte el terminal

1. Desconecte la alimentación en la fuente y extraiga el cable de alimentación

del terminal PanelView.

2. Desconecte todos los cables de alimentación del terminal.

ATENCIÓN

Asegúrese de que el cable de alimentación del terminal PanelView esté

desconectado y que todos los cables hayan sido desconectados del terminal.

Extraiga el terminal existente

1. Quite las abrazaderas de montaje que fijan el terminal al panel.

TIP

2. Deslice el terminal existente fuera del panel.

Las abrazaderas de montaje del PanelView Estándar/PanelView “e” son

diferentes de las abrazaderas de montaje del PanelView Plus. Guarde las

abrazaderas de montaje por separado para evitar confusión posteriormente.

Publication 2711P-IN010BC-MU-P - March 2007

Page 24

24 Juego adaptador para cortes de terminal PanelView Estándar y PanelView “e”

Acople las placas adaptadoras al panel

Los pernos ubicados en la placa adaptadora frontal encajan dentro del corte del

terminal.

1. Coloque la placa adaptadora frontal dentro del corte de panel hasta que el

material de la empaquetadura selladora esté ubicado firmemente contra la

parte frontal del panel.

Placa adaptadora

Parte interior del panel o

envolvente

Tuerca y

arandela

frontal

Parte frontal del panel o

envolvente

Placa adaptadora trasera con

12 orificios

2. Monte la placa adaptadora trasera en los pernos de la placa adaptadora

frontal desde la parte posterior del panel (el lado plano de la placa

adaptadora trasera hacia la parte posterior del envolvente).

Con las (8, 10 ó 12) tuercas y arandelas planas, fije la placa adaptadora

trasera a los pernos.

3. Con la llave dinamométrica, apriete las tuercas a un par no mayor de

1,92 Nm (17 pulg.-lbs) para mantener la clasificación NEMA Tipo 4X.

No apriete demasiado.

Publication 2711P-IN010BC-MU-P - March 2007

Page 25

Juego adaptador para cortes de terminal PanelView Estándar y PanelView “e” 25

Teclado 1000 solamente

Los pernos ubicados en la placa adaptadora encajan dentro del corte del terminal.

1. Coloque la placa adaptadora dentro del corte de panel hasta que el material

de la empaquetadura selladora esté ubicada firmemente contra la parte

frontal del panel.

Placa adaptadora

Parte frontal del panel o envolvente

Tue rc a y

arandela

Barras adaptadoras

con 4 orificios

Parte interior del panel o envolvente

2. Monte la barra adaptadora en los pernos de la placa adaptadora desde la

parte posterior del panel (el lado plano de la barra hacia la parte posterior

del envolvente).

Con las (8) tuercas y arandelas planas, fije la barra adaptadora en los pernos.

3. Con la llave dinamométrica, apriete las tuercas a un par no mayor de

1,13 Nm (10 pulg.-lbs) para mantener la clasificación NEMA Tipo 4X.

No apriete demasiado.

Acople el terminal a la placa adaptadora

1. Inserte el nuevo terminal en la parte frontal del envolvente hasta que la

empaquetadura del terminal quede al ras con la placa adaptadora.

2. Instale las abrazaderas de montaje.

Publication 2711P-IN010BC-MU-P - March 2007

Page 26

26 Juego adaptador para cortes de terminal PanelView Estándar y PanelView “e”

El número de abrazaderas varía dependiendo del tipo de terminal. Los

extremos de las abrazaderas se deslizan dentro de las ranuras en el terminal.

La siguiente ilustración es una vista del interior del envolvente. Las

abrazaderas superiores o inferiores se aprietan directamente en la placa

adaptadora.

Ranura para la abrazadera de

Abrazadera de montaje

Tue rc a y

arandela

Placa adaptadora

montaje

Parte posterior del

terminal

Barra adaptadora

Panel o envolvente

3. Apriete manualmente los tornillos de las abrazaderas de montaje hasta que

el sello de la empaquetadura haga contacto con la superficie de montaje de

manera uniforme.

4. Con la llave dinamométrica, apriete los tornillos de las abrazaderas de

montaje según la especificación de par apropiada proporcionada en las

instrucciones de instalación del nuevo terminal.

Esto es necesario para mantener la clasificación NEMA Tipo 4X. No apriete

demasiado.

ATENCIÓN

Apriete las abrazaderas de montaje según la especificación de par indicada

para proporcionar un sello adecuado y para evitar un daño potencial al

dispositivo. Allen-Bradley no asumirá responsabilidad alguna por daños

ocasionados por agua o productos químicos al terminal u otros equipos dentro

del

Publication 2711P-IN010BC-MU-P - March 2007

Page 27

Istruzioni per l’installazione

Kit adattatore per finestrature dei terminali

PanelView standard e PanelView “e”

Numero di catalogo 2711P-RAK7, 2711P-RAT7, 2711P-RAK10,

2711P-RAT10, 2711P-RAK12S, 2711P-RAT12S

Italiano

Per: Vedere pagina

Descrizione 27

Contenuto dell'imballaggio 28

Attrezzi necessari 28

Scollegare il terminale 28

Rimuovere il terminale esistente 29

Fissare le piastre adattatrici al pannello 29

Fissare il terminale alla cornice adattatrice 32

Publication 2711P-IN010C-MU-P - March 2007

Page 28

28 Kit adattatore per finestrature dei terminali PanelView standard e PanelView “e”

Descrizione

Questo documento contiene le istruzioni su come montare i seguenti dispositivi

nelle aperture esistenti per terminali PanelView standard e PanelView “e”.

• PanelView Plus 700-1250

• PanelView Plus CE 700-1250

Num. di cat. Questo nuovo terminale: Si adatta alla finestratura esistente di:

2711P-RAK7 PanelView Plus 700 con Tastierino

2711P-RAT7 PanelView Plus 700 Touchscreen

2711P-RAK10 PanelView Plus 1000 con Tastierino

2711P-RAT10 PanelView Plus 1000 Touchscreen

2711P-RAK12S PanelView Plus 1250 con con Tastierino

2711P-RAT12S PanelView Plus 1250 Touchscreen

PanelView Plus CE 700 con Tastierino

PanelView Plus CE 700 Touchscreen

PanelView Plus CE 1000 con Tastierino

PanelView Plus CE 1000 Touchscreen

PanelView Plus CE 1250 con Tastierino

PanelView Plus CE 1250 Touchscreen

PanelView Standard 900 con

Tastierino(2711-K9xxx)

PanelView Standard 900 Touchscreen

(2711-T9xxx)

PanelView Standard 1000 con con

Tastierino(2711-K10xxx)

PanelView 1000e con Tastierino(2711E-K10xxx)

PanelView Standard 1000 Touchscreen

(2711-T10xxx)

PanelView 1000e Touchscreen (2711E-T10xxx)

PanelView Standard 1400 con

Tastierino(2711-K14xxx)

PanelView Standard 1400 Touchscreen

(2711-T14xxx)

Contenuto dell'imballaggio

Il kit adattatore per la finestratura contiene:

• cornice adattatrice per l’apertura con guarnizione e distanziatori

• barre adattatrici per piastre con 3 o 4 fori

• 8 , 10 o 12 dadi #10-32 con rondelle piatte (in base al numero di perni della

cornice adattatrice)

Attrezzi necessari

Per l'installazione sono richiesti i seguenti attrezzi:

• operatore per chiave a bussola con chiave da 3/8 di pollice

• cacciavite a lama piatta o a croce

• chiave dinamometrica da 17 pollici-libbra

Publication 2711P-IN010C-MU-P - March 2007

Page 29

Kit adattatore per finestrature dei terminali PanelView standard e PanelView “e” 29

Scollegare il terminale

1. Scollegare l'alimentazione e rimuovere il cavo di alimentazione dal terminale

PanelView.

2. Scollegare tutti i cavi di comunicazione dal terminale.

AVVERTENZA

Assicurarsi che il cavo di alimentazione del terminale PanelView sia scollegato

e che tutti i cavi del terminale siano stati scollegati.

Rimuovere il terminale esistente

1. Rimuovere le clip di montaggio che fissare il terminale al pannello.

TIP

2. Estrarre il terminale esistente dal pannello.

Le clip di montaggio del terminal PanelView Standard/PanelView “e” sono

diverse da quelle del terminale PanelView Plus. Conservare separatamente le

clip di montaggio per evitare confusione successivamente.

Fissare le piastre adattatrici al pannello

I perni posti sulla cornice adattatrice anteriore si inseriscono all'interno dell’apertura

del terminale.

1. Inserire la cornice adattatrice anteriore nell’apertura del pannello fino a

quando la guarnizione di tenuta non tocca il pannello.

Publication 2711P-IN010C-MU-P - March 2007

Page 30

30 Kit adattatore per finestrature dei terminali PanelView standard e PanelView “e”

Cornice adattatrice

Interno del pannello o della

custodia

Dado e

rondella

Cornice adattatrice

posteriore con 12 fori

anteriore

Frontale del pannello o della

custodia

2. Da dietro il pannello (con il lato liscio della cornice posteriore rivolto verso

l'interno della custodia), montare la cornice adattatrice posteriore sui perni

della cornice anteriore.

Stringere la cornice adattatrice posteriore sui perni, utilizzando i dadi e le

rondelle (8, 10 o 12).

3. Utilizzando la chiave dinamometrica, stringere i dadi con una coppia non

maggiore di 1.92 Nm (17 poll.-lb) al fine di mantenere il grado di protezione

NEMA Tipo 4X.

Non stringere troppo.

Publication 2711P-IN010C-MU-P - March 2007

Page 31

Kit adattatore per finestrature dei terminali PanelView standard e PanelView “e” 31

Solo 1000 con tastierino numerico

I perni presenti sulla cornice adattatrice entrano all'interno della finestratura del

terminale.

1. Inserire la cornice adattatrice nella finestratura del pannello fino a quando la

guarnizione di tenuta non tocca con il frontale del pannello.

Cornice adattatrice

Frontale del pannello o della custodia

Dado e

rondella

Barre adattatrici

con 4 fori

Interno del pannello o della custodia

2. Da dietro il pannello (con il lato liscio della barra rivolto verso l'interno della

custodia), montare la barra adattatrice sui perni della cornice anteriore.

Stringere la barra adattatrice posteriore sui perni, utilizzando i dadi e le

rondelle (8).

3. Utilizzando la chiave dinamometrica, stringere i dadi con una coppia

maggiore di 1.13 Nm (10 poll.-lb) al fine di mantenere il grado di protezione

NEMA Tipo 4X.

Non stringere troppo.

Publication 2711P-IN010C-MU-P - March 2007

Page 32

32 Kit adattatore per finestrature dei terminali PanelView standard e PanelView “e”

Fissare il terminale alla cornice adattatrice

1. Inserire il nuovo terminale nel frontale della custodia fino a quando la

guarnizione del terminale risulta allineata con la cornice adattatrice.

2. Installare le clip di montaggio. Il numero delle clip varia a seconda del tipo

di terminale. Le estremità delle clip di montaggio si inseriscono nei fori del

terminale.

La seguente figura si riferisce alla vista dall'interno della custodia. Le clip

superiori o inferiori si inseriscono direttamente sulla cornice adattatrice.

Foro per clip di montaggio

Barra adattatrice

Clip di montaggio

Dado e

rondella

Pannello o custodia

Vista posteriore del terminale

Cornice adattatrice

3. Stringere a mano le viti delle clip di montaggio fino a quando la guarnizione

aderisce uniformemente alla superficie di montaggio.

4. Utilizzando la chiave dinamometrica, stringere le viti delle clip di montaggio

in base ai valori di coppia forniti nelle istruzioni per l'installazione del nuovo

terminale.

Ciò è necessario per mantenere il grado di protezione NEMA Tipo 4X. Non

stringere troppo.

AVVERTENZA

Avvitare le clip di montaggio con una coppia di serraggio adeguata per fornire

una corretta tenuta e per evitare potenziali danni al terminale. Allen-Bradley

non si assume alcuna responsabilità per danni al terminale o ad altre

apparecchiatura poste all'interno della custodia provocati da acqua o agenti

chimici e riconducibili ad una errata installazione.

Publication 2711P-IN010C-MU-P - March 2007

Page 33

Instruções de Instalação

Kit de Adaptador para Cortes dos Terminais

PanelView Standard e PanelView “e”

Código de Catálogo 2711P-RAK7, 2711P-RAT7, 2711P-RAK10,

2711P-RAT10, 2711P-RAK12S, 2711P-RAT12S

Português

Para Consulte a página

Descrição 33

Conteúdo do Pacote 34

Ferramentas Necessárias 34

Desconexão do Terminal 34

Remoção do Terminal Existente 35

Ligação das Placas do Adaptador ao Painel 35

Fixação do Terminal à Placa do Adaptador 37

Publication 2711P-IN010C-MU-P - March 2007

Page 34

34 Kit de Adaptador para Cortes dos Terminais PanelView Standard e PanelView “e”

Descrição

Este documento fornece instruções sobre como montar os seguintes dispositivos

em cortes dos terminais PanelView Standard e PanelView “e” existentes.

• PanelView Plus 700-1250

• PanelView Plus CE 700-1250

Cód. Cat. Este Novo Terminal: Encaixa no Corte Existente:

2711P-RAK7 PanelView Plus 700 com Teclado

2711P-RAT7 PanelView Plus 700 com Tela Touch

2711P-RAK10 PanelView Plus 1000 com Teclado

2711P-RAT10 PanelView Plus 1000 com Tela Touch

2711P-RAK12S PanelView Plus 1250 com Teclado

2711P-RAT12S PanelView Plus 1250 com Tela Touch

PanelView Plus CE 700 com Teclado

PanelView Plus CE 700 com Tela Touch

PanelView Plus CE 1000 com Teclado

PanelView Plus CE 1000 com Tela Touch

PanelView Plus CE 1250 com Teclado

PanelView Plus CE 1250 com Tela Touch

PanelView Standard 900 com Teclado

(2711-K9xxx)

PanelView Standard 900 com Tela Touch

(2711-T9xxx)

PanelView Standard 1000 com Teclado

(2711-K9xxx)

PanelView 1000e com Teclado (2711E-K14xxx)

PanelView Standard 1000 com Tela Touch

(2711-T9xxx)

PanelView 1000e com Tela Touch (2711E-K14xxx)

PanelView Standard 1400 com Teclado

(2711-K9xxx)

PanelView Standard 1400 com Tela Touch

(2711-T9xxx)

Conteúdo do Pacote

O Kit de Adaptador de Corte inclui:

• placas do adaptador de corte com junta e espaçador de rolamento de esferas

• barras do adaptador para placas com 3 ou 4 furos

• porcas de 8, 10 ou 12 #10-32 com arruelas chatas (dependendo do número

de pinos na placa do adaptador)

Ferramentas Necessárias

As seguintes ferramentas são necessárias para a instalação:

• chave para soquete de 3/8 pol.

• chave de fenda ou Phillips

• chave de torque com capacidade de 17 pol/lbs

Publication 2711P-IN010C-MU-P - March 2007

Page 35

Kit de Adaptador para Cortes dos Terminais PanelView Standard e PanelView “e” 35

Desconexão do Terminal

1. Desconecte a alimentação na fonte e remova o fio de alimentação do

terminal PanelView.

2. Desconecte todos os cabos de comunicação do terminal.

ADVERTÊNCIA

Certifique-se de que o fio de alimentação do terminal PanelView esteja

desconectado e que todos os cabos tenham sido desconectados do terminal.

Remoção do Terminal Existente

1. Remova os clips de montagem que prendem o terminal no painel.

TIP

2. Deslize o terminal existente para fora do painel.

Os clips de montagem do PanelView Standard/PanelView “e” são diferentes

dos clips do PanelView Plus. Armazene os clips de montagem separadamente

para evitar confusões futuras.

Publication 2711P-IN010C-MU-P - March 2007

Page 36

36 Kit de Adaptador para Cortes dos Terminais PanelView Standard e PanelView “e”

Ligação das Placas do Adaptador ao Painel

Os pinos na placa frontal do adaptador se encaixam dentro do corte do terminal.

1. Posicione a placa frontal do adaptador no painel de corte, até que o material

da junta de vedação esteja firmemente encaixada na parte frontal do painel.

Placa Frontal do

Parte Interna do Painel ou

Gabinete

Porca e

Arruela

Placa Traseira do Adaptador

com 12 furos

Adaptador

Parte Frontal do Painel ou

Gabinete

2. Encaixe a placa traseira do adaptador aos pinos da placa frontal do

adaptador a partir da parte posterior do painel (lado chato da placa traseira

do adaptador em direção à parte traseira do gabinete).

3. Ao utilizar as porcas (8, 10 ou 12) e arruelas chatas, fixe a placa traseira do

adaptador aos pinos.

4. Ao utilizar a chave de torque, aperte as porcas não mais que 1,92 Nm

(17 pol-lbs) para manter uma classificação NEMA Tipo 4X.

Não aperte demais.

Publication 2711P-IN010C-MU-P - March 2007

Page 37

Kit de Adaptador para Cortes dos Terminais PanelView Standard e PanelView “e” 37

Somente Teclado 1000

Os pinos na placa de adaptador se encaixam dentro do corte do terminal.

1. Posicione a placa do adaptador no corte do painel, até que o material de

junta de vedação esteja firmemente encaixada na parte frontal do painel.

Placa do Adaptador

Parte Frontal do Painel ou Gabinete

Porca e

Arruela

Barras do Adaptador

com 4 Furos

Parte Interna do Painel ou Gabinete

2. Encaixe a barra do adaptador aos pinos da placa do adaptador, a partir da

parte posterior do painel (lado chato da barra em direção à parte traseira do

gabinete).

Ao utilizar as porcas (8) e arruelas chatas, fixe a barra do adaptador nos

pinos.

3. Ao utilizar a chave de torque, aperte as porcas não mais que 1,13 Nm

(10 pol-lbs) para manter uma classificação NEMA Tipo 4X.

Não aperte demais.

Fixação do Terminal à Placa do Adaptador

1. Insira o novo terminal na parte frontal do gabinete até que a junta do

terminal esteja alinhada com a placa do adaptador.

2. Instale os clips de montagem.

Publication 2711P-IN010C-MU-P - March 2007

Page 38

38 Kit de Adaptador para Cortes dos Terminais PanelView Standard e PanelView “e”

O número de clips varia de acordo com o tipo de terminal. As extremidades

dos clips deslizam para dentro das ranhuras no terminal.

A seguinte ilustração é uma visualização da parte interna do gabinete. Os

clips superiores e inferiores são fixados diretamente à placa do adaptador.

Ranhura do Clip de Montagem

Barra do Adaptador

Clip de Montagem

Porca e

Arruela

Painel ou Gabinete

Parte Traseira do Terminal

Placa do Adaptador

3. Aperte manualmente os parafusos nos clips de montagem, até que a junta de

vedação entre uniformemente em contato com a superfície de montagem.

4. Ao utilizar a chave de torque, aperte os parafusos nos clips de montagem,

de acordo com a classificação adequada de torque, fornecida nas instruções

de instalação para o novo terminal.

Este procedimento é necessário para manter uma classificação NEMA Tipo

4X. Não aperte demais.

ADVERTÊNCIA

Aperte os clips de montagem de acordo com a classificação de torque correta

para criar uma vedação adequada e evitar possíveis danos ao terminal. A

Allen-Bradley não se responsabiliza por danos causados por agentes químicos

ou água ao terminal ou outros equipamentos dentro do gabinete devido a uma

instalação inadequada.

Publication 2711P-IN010C-MU-P - March 2007

Page 39

Page 40

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration,

and troubleshooting, we offer TechConnect Support programs. For more

information, contact your local distributor or Rockwell Automation representative,

or visit http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running.

, you can find

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning, it may need to be returned.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Allen-Bradley, PanelView, TechConnect, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Inc. are property of their respective companies.

Publication 2711P-IN010C-MU-P - March 2007 PN 41061-305-01(3)

Supersedes Publica tion 2711P-IN010B-MU-P - April 2003 Copyright © 2007 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Loading...

Loading...