Page 1

Installation Instructions

IMPORTANT

Battery Replacement

Catalog Number

Topi c Pag e

Important User Information 2

Precautions 3

Replace Battery in PanelView Plus Terminals 3

Replace Battery in PanelView Component Terminals 5

Replace Battery in PanelView Plus 6 and PanelView Plus 6

Compact Terminals

400 and 600 Terminals 5

Replace Battery in PanelView Plus 6 Compact Terminals 7

1000 Terminals 7

Replace Battery in PanelView Plus 7 Standard Terminals 8

Additional Resources 9

2711P-RY2032

5

About This Publication

This document provides information on how to replace the lithium battery, catalog number

2711P-RY2032, in these devices:

• 2711P PanelView Plus, 700 to 1500 terminals, running FactoryTalk View Machine

Edition firmware revision 5.1 or earlier

• 2711C PanelView Component, C400, C600, and C1000 terminals

• 2711P PanelView™ Plus 6, 400 and 600 terminals

• 2711PC PanelView Plus 6, Compact 400, 600, and 1000 terminals

• 2711P PanelView Plus 7, Standard 400 to 1000 terminals

Use only replacement battery catalog number 2711P-RY2032, or an equivalent CR2032 lithium coin cell

battery, in these products.

Page 2

2 Battery Replacement

IMPORTANT

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of

this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize themselves with

installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be

carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or

application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requi rements associ ated wit h any pa rticu lar ins tallat ion, Roc kwell Au tomati on, Inc. cannot assume respon sibili ty or li abilit y for actual

use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNIN G: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for exampl e, a motor control center, to alert

people to potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective

Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for Personal Protective

Equipment (PPE).

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 3

Battery Replacement 3

Precautions

These products contain a sealed lithium battery which may need to be replaced during the life of the product.

At the end of its life, the battery contained in this product should be collected separately from any unsorted

municipal waste.

The collection and recycling of batteries helps protect the environment and contributes to the conservation of

natural resources as valuable materials are recovered.

WARNIN G: There is a danger of explosion if the lithium battery or real-time clock module in this product is

incorrectly placed. Replace the battery only with the indicated type. Do not replace the battery or real-time clock

module unless power has been removed or the area is known to be nonhazardous.

Do not dispose of the lithium battery or real-time clock module in a fire or incinerator. Dispose of the battery in

accordance with the local regulations. For safety information on the handling of lithium batteries. including

handling and disposing of leaking batteries, see Guidelines for Handling Lithium Batteries, publication AG-5.4

WARNIN G: The battery or real-time clock module in these products must only be changed in an area known to be

nonhazardous.

ATTENTION: Work in a static-free environment and wear a properly grounded electrostatic discharge (ESD)

wristband.

Be careful when touching any of the exposed electronic components to prevent damage from ESD.

Perchlorate material – special handling may apply. See

www.dtsc.ca.gov/hazardouswaste/perchlorate.

This perchlorate warning only applies to primary Lithium Manganese Dioxide (LiMnO

or batteries, and products containing these cells or batteries, sold or distributed in California,

USA.

2

) cells

.

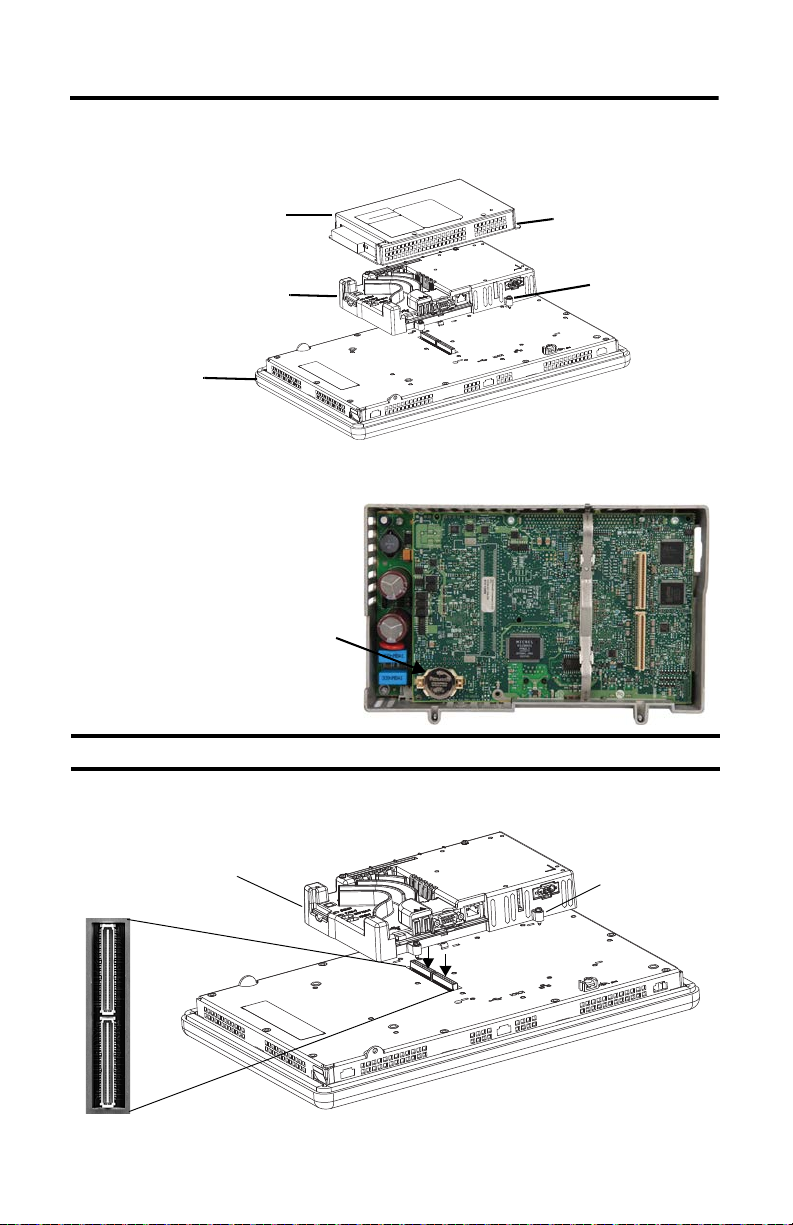

Replace Battery in PanelView Plus Terminals

Follow these steps to replace the battery in the logic module of any PanelView Plus terminal with

a 700 to 1500 display.

1. Disconnect power from the terminal.

2. Disconnect all power and communication cables.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 4

4 Battery Replacement

IMPORTANT

Logic Module

Communication Module

Screw

Captive Screw

Display Module

Captive Screw

Logic Module

3. Detach the communication module, if attached, from the logic module by removing the

four screws.

4. Loosen the captive screws that secure the logic module to the display module and

carefully lift the logic module away from the back of the display.

5. Locate the battery on the

circuit board.

6. Remove the batter y by lifting

up the side of the battery.

7. Insert the new battery with

the positive polarity (+)

facing up.

The battery may be removed for up to 15 seconds without losing the clock and calendar data.

8. Reattach the logic module by aligning the logic module connector with the connector

on the display module.

9. Push down on the logic module until it is firmly seated.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 5

Battery Replacement 5

Battery

Cover

Battery

C600 /C1000

C400

10. Tighten the captive screws that secure the logic module to the display module and torque

to 0.58…0.79 N•m (5…7 lb•in).

11. Reattach the communication module, if necessary, and tighten the screws to a torque of

0.58…0.79 N•m (5…7 lb•in).

Replace Battery in PanelView Component Terminals

The PanelView Component C400, C600, and C1000 terminals, catalog numbers 2711C-T4T,

2711C-T6x, and 2711C-T10C, contain a lithium battery on the back of the terminal. No

special tools are required to remove the battery cover and replace the battery.

Follow these steps to replace the battery in the PanelView Component terminals.

1. Disconnect power from the terminal.

2. Remove or unlatch the battery cover on the back of the terminal.

3. Remove the battery.

4. Insert the new battery with the positive polarity (+) facing up.

Replace Battery in PanelView Plus 6 and PanelView Plus 6 Compact Terminals

400 and 600 Terminals

You can replace the battery with the terminal mounted in the panel. No special tools are required

to remove the battery.

Follow these steps to replace the battery in a 400 or 600 terminal.

1. Disconnect power from the terminal.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 6

6 Battery Replacement

CR2032

2. Unlatch the battery cover by pulling it straight out.

3. Lift up on the cover.

4. Remove the battery.

5. Insert the new battery with the positive (+) polarity facing up and press gently until the

battery snaps into place.

6. Close the battery cover and push the end in until you hear a click.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 7

Battery Replacement 7

Communication Module

Display Module

Captive S crew

Screw

Logic Module

Replace Battery in PanelView Plus 6 Compact Terminals

1000 Terminals

Follow these steps to replace the battery in a 1000 terminal.

1. Disconnect power from the terminal.

2. Place the terminal, display side down, on a flat stable surface.

3. Detach the communication module, if attached, from the logic module by removing the

four screws.

4. Loosen the four captive screws that attach the logic module to the display.

5. Carefully lift the logic module away from the terminal and turn over to expose the circuit

board.

6. Locate the battery on the circuit board.

7. Remove the battery by lifting up the side of the battery.

8. The battery can be removed up to 15 seconds without losing clock and calendar data.

9. Insert the new battery.

10. Reattach the logic module by aligning the two connectors on the bottom of the logic

module with the connectors on the back of the display module.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 8

8 Battery Replacement

11. Push down on the logic module until it is firmly seated.

12. Tighten the four captive screws that secure the logic module to a torque of 0.58 N•m

(5…7 lb•in).

13. Reattach the communication module, if necessary, and tighten the four screws to a

torque of 0.58 N•m (5…7 lb•in).

Replace Battery in PanelView Plus 7 Standard Terminals

Follow these steps to replace the battery in PanelView Plus 7 Standard 400 to 1000 terminals.

1. Disconnect power from the terminal.

2. Remove the battery cover by rotating it from the C(lose) to O(pen) position.

3. To disengage the battery, on the metal latch, press the vertical center tab away from the

battery.

The battery is released.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 9

Battery Replacement 9

IMPORTANT

4. Insert the new battery at an angle under the metal latch, with the positive polarity (+)

facing up.

5. Gently press down on the opposite side of the battery until it locks into place.

Make sure that the battery is fully inserted under the plastic tabs. If this is not done, damage can occur, and this

voids the warranty.

6. Replace the battery cover by aligning its tabs with the battery opening and rotate the

cover from the O(pen) to C(lose) position.

Additional Resources

These documents contain additional information concerning related products from Rockwell

Automation.

Resource Description

PanelView Plus 7 Standard Terminals User Manual,

publication 2711P-UM007

PanelView Plus 6 Terminals User Manual,

publication 2711P-UM006

PanelView Plus Terminals User Manual, publication

2711P-UM001

PanelView Plus Compact Terminals User Manual,

publication 2711PC-UM001

PanelView Component Terminals User Manual,

publication 2711C-UM001

Guidelines for Handling Lithium Batteries,

publication AG-5.4

Provides information on how to install, operate, configure, and

troubleshoot PanelView Plus 7 Standard terminals.

Provides information on how to install, operate, configure, and

troubleshoot PanelView Plus 6 terminals (700, 1000, 1250, 1500) running

FactoryTalk View Machine Edition firmware revision 6.0 or later.

Provides information on how to install, operate, configure, and

troubleshoot PanelView Plus 700, 1000, 1250, and 1500 terminals running

FactoryTalk View Machine Edition firmware revision 5.1 or earlier.

Provides information on how to install, operate, configure, and

troubleshoot PanelView Plus Compact terminals.

Provides information on how to install, operate, configure, and

troubleshoot PanelView Component terminals.

Provides safety information on the handling of lithium batteries, including

handling and disposing of leaking batteries

You can view or download publications at http://www.rockwellautomation.com/literature/

order paper copies of technical documentation, contact your local Allen-Bradley® distributor or

Rockwell Automation sales representative.

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

. To

Page 10

10 Battery Replacement

Notes:

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 11

Notes:

Battery Replacement 11

Rockwell Automation Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014

Page 12

Rockwell Automation Support

Rockwell Automation provides tec hnical information on the Web to assist you in using its products.

At http://www.rockwellautomation.com/support

service packs. You can also visit our Support Center at https://rockwellautomation.custhelp.com/

and forums, technical information, FAQs, and to sign up for product notification updates.

In addition, we offer multiple support programs for installation, configuration, and troubleshooting. For more information, contact

your local distributor or Rockwell Automation representative, or visit http://www.rockwellautomation.com/services/online-phone

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the information that's contained in this manual.

You can also contact a special Customer Support number for initial help in getting your product up and running.

United States or Canada 1.440.646.3434

Outside United States or

Canada

Use the Wor ldwi de Loc ator

http://www.rockwellautomation.com/rockwellautomation/support/overview.page

local Rockwell Automation representative.

New Product Satisfaction Return

Rockwell Automation tests all of its products to help ensure that they are fully operational when shipped from the manufacturing

facility. However, if your product is not functioning and needs to be returned, follow these procedures.

you can find technical and application notes, sample code, and links to software

for software updates, support chats

at

, or contact your

.

United States

Outside United States Please contact your local Rockwell Automation representative for the return procedure.

Contact your distributor. You must provide a Customer Support case number (call the phone number

above to obtain one) to your distributor to complete the return process.

Documentation Feedback

Your comments will help us serve your documentation needs better. If you have any suggestions on how to improve this document,

complete this form, publication RA-DU002

Rockwell Automation maintains current product environmental information on its website at

http://www.rockwellautomation.com/rockwellautomation/about-us/sustainability-ethics/product-environmental-compliance.page

Allen-Bradley, PanelView, InView, FactoryTalk, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of thei r respective companies.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Rockwell Automation Publication 2711P-IN009F-EN-P - July 2014 PN-149900

Supersedes Publication 2711P-IN009E-EN-P - January 2011 Copyright © 2014 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

, available at http://www.rockwellautomation.com/literature/.

.

Loading...

Loading...