Page 1

Installation Instructions

Mounting Clips

Catalog Number 2711P-RTMC

Language Page

English 3

Français 5

Deutsch 7

Español 9

Italiano 11

Português 13

Publication 2711P-IN006B-MU-P - March 2007

Page 2

2 Mounting Clips

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication

SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you to identify a hazard,

avoid a hazard, and recognize the consequences.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert

people that surfaces may reach dangerous temperatures.

Publication 2711P-IN006B-MU-P - March 2007

Page 3

Installation Instructions

Mounting Clips

Catalog Number 2711P-RTMC

English

About This Publication

This document provides instructions on how to install the following devices in a

panel or enclosure using the 2711P-RTMC mounting clips. Eight mounting clips are

provided with kit.

• 2711P PanelView Plus terminal

• 2711P PanelView Plus CE terminal

• RAC6182 industrial computer

The mounting clips hold the device tightly against the mounting enclosure. The

number clips used for installation varies by device.

Number

of Clips

Device Clip Location on Device

RAC6182 (all sizes)

4

PanelView Plus and PanelView Plus CE 700 (all versions)

PanelView Plus and PanelView Plus CE 1000 Touch Only

PanelView Plus and PanelView Plus CE 1000 Keypad or

6

Keypad & Touch

PanelView Plus and PanelView Plus CE 1250 (all versions)

8 PanelView Plus and PanelView Plus CE 1500 (all versions)

Publication 2711P-IN006B-MU-P - March 2007

Top: left and right slots

Bottom: left and right slots

Top: left and right slots

Bottom: left and right slots

Sides: left and right slots

Top: left and right slots

Bottom: left and right slots

Sides: top and bottom

Page 4

4 Mounting Clips

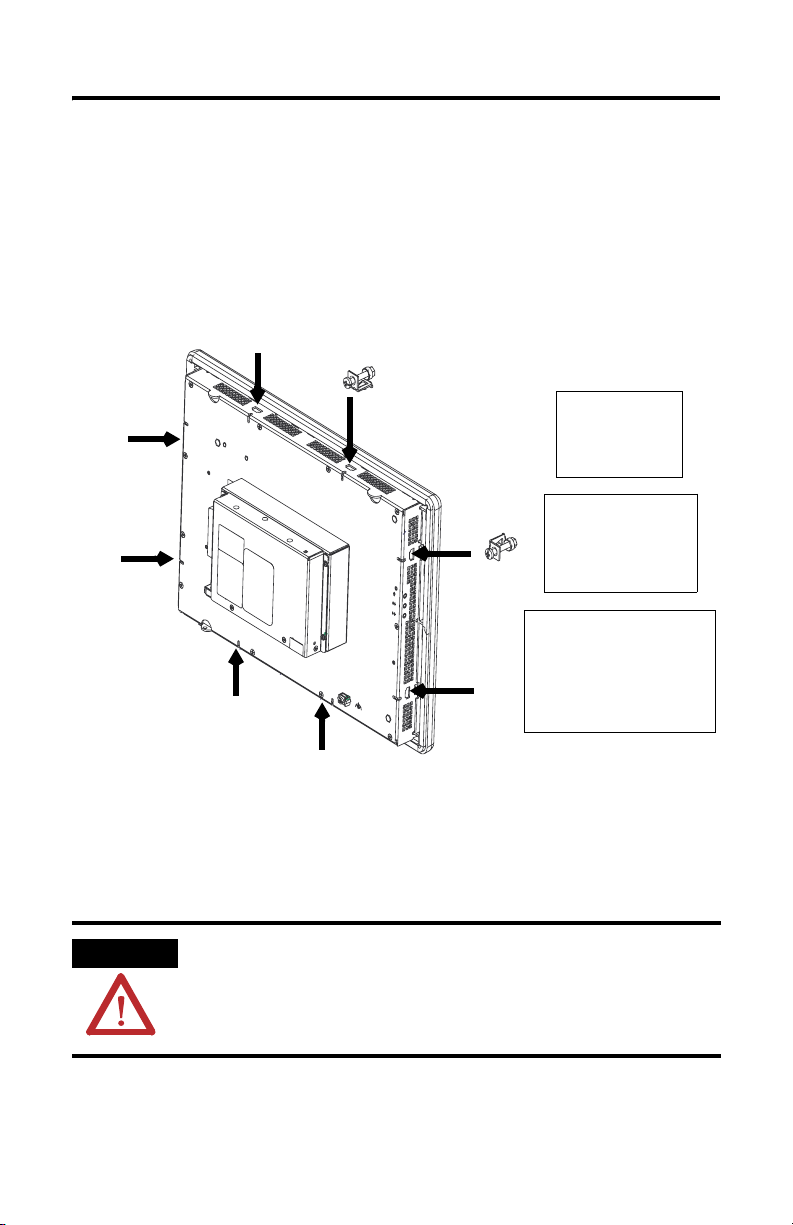

Install the Mounting Clips

Follow these steps to install the mounting clips.

1. Install the mounting clips on the terminal.

The ends of the clips slide into the slots on the terminal. Tighten the

mounting clip screws by hand until the gasket seal contacts the mounting

surface uniformly.

The recommended torque sequences

are shown below.

14

3

4 Clips

2

513

6 Clips

246

1

3

7

5

8 Clips

6

8

4

2

2. Alternately tighten the mounting clip screws to a torque of:

• 1.13 Nm (10 lb-in) for the RAC6182 device.

• 0.90…1.1 Nm (8…10 lb-in) for the 2711P PanelView Plus or PanelView

Plus CE device.

Do not overtighten.

ATTENTION Tighten the mounting clips to the recommended torque to provide a proper seal

and to prevent damage to the device. Allen-Bradley assumes no responsibility

for water or chemical damage to the product or other equipment within the

enclosure because of improper installation.

Publication 2711P-IN006B-MU-P - March 2007

Page 5

Notice d’installation

Colliers de fixation

Référence 2711P-RTMC

Français

Présentation

Le présent document indique comment installer les équipements suivants sur un

panneau ou dans une armoire à l’aide de colliers de fixation 2711P-RTMC. Un kit

contient huit colliers de fixation.

• PanelView Plus 2711P ;

• PanelView Plus CE 2711P ;

• station industrielle RAC6182.

Les colliers de fixation permettent de maintenir le terminal contre le support de

montage. Le nombre de colliers à utiliser varie selon l’équipement.

Nombre

de

colliers

Equipement

RAC6182 (toutes tailles)

PanelView Plus/PanelView Plus CE 700 (toutes versions)

4

PanelView Plus/PanelView Plus CE 1000 à écran tactile

uniquement

PanelView Plus/PanelView Plus CE 1000 à clavier ou

6

à clavier et écran tactile

PanelView Plus/PanelView Plus CE 1250 (toutes versions)

8 PanelView Plus/PanelView Plus CE 1500 (toutes versions)

Emplacement des colliers sur

l’équipement

Haut : encoches gauche et droite

Bas : encoches gauche et droite

Haut : encoches gauche et droite

Bas : encoches gauche et droite

Côtés : encoches gauche et droite

Haut : encoches gauche et droite

Bas : encoches gauche et droite

Côtés : encoches supérieure et

inférieure

Publication 2711P-IN006B-MU-P - March 2007

Page 6

6 Colliers de fixation

Mise en place des colliers de fixation :

1. Mettez les colliers de fixation en place sur le terminal.

Les extrémités des colliers s’insèrent dans les encoches situées sur le

terminal. Serrez les vis des colliers de fixation à la main jusqu’à ce que le

joint soit comprimé uniformément contre la surface de montage.

Les séquences de serrage recommandées

sont indiquées ci-dessous.

14

3

4 colliers

2

513

6 colliers

246

1

6

3

8 colliers

7

5

2

2. Serrez les vis des colliers de fixation l’une après l’autre, avec un couple de :

• 1,13 Nm pour la station RAC6182 ;

• 0,90 à 1,1 Nm pour les PanelView Plus 2711P et les PanelView

Plus CE 2711P.

Veillez à ne pas trop les serrer.

ATTENTION

Serrez les vis au couple recommandé pour assurer une bonne étanchéité et

éviter d’endommager l’équipement. Allen-Bradley ne saurait être tenu pour

responsable des dégâts causés par une infiltration d’eau ou de produit

chimique dans l’équipement ou dans tout autre équipement présent dans

l’armoire, suite à une installation incorrecte.

8

4

Publication 2711P-IN006B-MU-P - March 2007

Page 7

Installationsanleitung

Montageklammern

Bestellnummer 2711P-RTMC

Deutsch

Überblick

Dieses Dokument enthält Anleitungen zur Montage der folgenden Geräte in einem

Schaltschrank oder Gehäuse mit Hilfe der Montageklammern 2711P-RTMC. Ein

Bausatz enthält acht Montageklammern.

• 2711P PanelView Plus

• 2711P PanelView Plus CE

• RAC6182-Industriecomputer

Die Montageklammern befestigen das Terminal fest am Montagegehäuse. Die

Anzahl der für die Montage zu verwendenden Klammern hängt vom jeweiligen

Gerät ab.

Anzahl

der

Klam-

mern

Gerät

RAC6182 (alle Größen)

4

PanelView Plus/PanelView Plus CE 700 (alle Versionen)

PanelView Plus/PanelView Plus CE 1000 (nur Touchscreen)

PanelView Plus/PanelView Plus CE 1000 (Keypad oder

6

Keypad & Touchscreen)

PanelView Plus/PanelView Plus CE 1250 (alle Versionen)

8 PanelView Plus/PanelView Plus CE 1500 (alle Versionen)

Publication 2711P-IN006B-MU-P - March 2007

Position der Klammern am

Gerät

Oben: Schlitze links uns rechts

Unten: Schlitze links uns rechts

Oben: Schlitze links uns rechts

Unten: Schlitze links uns rechts

Seitlich: Schlitze links uns rechts

Oben: Schlitze links uns rechts

Unten: Schlitze links uns rechts

Seitlich: Oben und unten

Page 8

8 Montageklammern

Zum Installieren der Montageklammern wie folgt vorgehen:

1. Die Montageklammern am Terminal befestigen. Die Anzahl der Klammern

hängt vom jeweiligen Gerät ab.

Die empfohlene Anzugsreihenfolge

ist im Folgenden abgebildet.

14

4

Klammern

3

513

6

Klammern

246

2

1

3

Klammern

7

5

2. Ziehen Sie die Schrauben der Montageklammern abwechselnd mit

folgendem Anzugsdrehmoment fest:

• 1,13 Nm für RAC6182

• 0,90…1,1 Nm für PanelView Plus 2711P und PanelView Plus CE 2711P

Ziehen Sie die Schrauben nicht zu fest an.

ACHTUNG

Ziehen Sie die Montageklammern mit dem empfohlenen Anzugsdrehmoment

fest, um eine ausreichende Dichtigkeit zu gewährleisten und mögliche Schäden

am Gerät zu vermeiden. Rockwell Automation übernimmt keine Haftung für

Schäden, die durch Wasser oder Chemikalien am Gerät oder an anderen

Geräten innerhalb des Gehäuses entstehen und auf eine falsche Installation

zurückzuführen sind.

6

8

8

4

2

Publication 2711P-IN006B-MU-P - March 2007

Page 9

Instrucciones de Instalación

Sujetadores de montaje

Número de catálogo 2711P-RTMC

Español

Descripción general

Este documento proporciona instrucciones sobre cómo instalar los siguientes

dispositivos en un panel o envolvente, usando los sujetadores de montaje

2711P-RTMC. Cada juego incluye ocho sujetadores de montaje.

• 2711P PanelView Plus

• 2711P PanelView Plus CE

• Computadora industrial RAC6182

Los sujetadores de montaje acoplan firmemente el terminal al envolvente de

montaje. El número de sujetadores que se usa para la instalación varía

dependiendo del dispositivo.

Número

de

sujeta-

dores

4

6

8

Dispositivo

RAC6182 (todos los tamaños)

PanelView Plus/PanelView Plus CE 700 (todas las

versiones)

PanelView Plus/PanelView Plus CE 1000 de pantalla táctil

solamente

PanelView Plus/PanelView Plus CE 1000 de techado o

teclado y pantalla táctil

PanelView Plus/PanelView Plus CE 1250 (todas las

versiones)

PanelView Plus/PanelView Plus CE 1500 (todas las

versiones)

Publication 2711P-IN006B-MU-P - March 2007

Ubicación del sujetador en el

dispositivo

Parte superior: Ranuras izquierda

y derecha

Parte inferior: Ranuras izquierda y

derecha

Parte superior: Ranuras izquierda

y derecha

Parte inferior: Ranuras izquierda y

derecha

Lados: Ranuras izquierda y

derecha

Parte superior: Ranuras izquierda

y derecha

Parte inferior: Ranuras izquierda y

derecha

Lados: Parte superior y parte

inferior

Page 10

10 Sujetadores de montaje

Cómo instalar los sujetadores de montaje:

1. Instale los sujetadores de montaje en el terminal. El número de sujetadores

varía para cada dispositivo.

Los extremos de los sujetadores se deslizan dentro de las ranuras en el

terminal. Apriete manualmente los tornillos de los sujetadores de montaje

hasta que el sello de la empaquetadura haga contacto con la superficie de

montaje de manera uniforme.

Las secuencias de par de apriete

se muestran a continuación.

14

4 sujetadores de

montaje

3

513

6 sujetadores de

montaje

246

2

1

3

8 sujetadores de montaje

7

5

2. Como alternativa, apriete los tornillos de los sujetadores de montaje a un

par de:

• 1.13 Nm (10 lbs-pulg.) para RAC6182

• 0.90…1.1 Nm (8…10 lbs-pulg.) para PanelView Plus 2711P y PanelView

Plus CE 2711P

3. No sobreapriete.

ATENCIÓN

Apriete los sujetadores de montaje al par recomendado para proporcionar un

sello adecuado y para evitar dañar el dispositivo. Allen-Bradley no asumirá

ninguna responsabilidad por los daños causados por agua u otros productos

químicos que puedan sufrir el dispositivo u otros equipos dentro del envolvente

debido a una instalación incorrecta.

Publication 2711P-IN006B-MU-P - March 2007

6

8

4

2

Page 11

Istruzioni per I’installazione

Clip di montaggio

Numero di catalogo 2711P-RTMC

Italiano

Panoramica

Questo documento descrive come installare i seguenti dispositivi su un pannello o

in una custodia utilizzando le clip di montaggio 2711P-RTMC. Il kit contiene otto

clip di montaggio.

• PanelView Plus 2711P

• PanelView Plus CE 2711P

• Computer industriale RAC6182

Le clip di montaggio servono a bloccare il terminale sulla custodia di montaggio. Il

numero di clip utilizzate varia in base al tipo di dispositivo

Numero

di clip

Dispositivo

RAC6182 (tutte le dimensioni)

4

PanelView Plus/PanelView Plus CE 700 (tutte le versioni)

PanelView Plus/PanelView Plus CE 1000 solo Touch Screen

PanelView Plus/PanelView Plus CE 1000 solo tastierino

6

numerico o tastierino e touchscreen

PanelView Plus/PanelView Plus CE 1250 (tutte le versioni)

8 PanelView Plus/PanelView Plus CE 1500 (tutte le versioni)

Publication 2711P-IN006B-MU-P - March 2007

Posizione della clip sul

dispositivo

In alto: fori di sinistra e di destra

In basso: fori di sinistra e di destra

In alto: fori di sinistra e di destra

In basso: fori di sinistra e di destra

Ai lati: fori di sinistra e di destra

In alto: fori di sinistra e di destra

In basso: fori di sinistra e di destra

Ai lati: In alto e in basso

Page 12

12 Clip di montaggio

A

Per installare le clip di montaggio:

1. Installare le clip di montaggio sul terminale. Il numero di clip varia per

ciascun dispositivo.

Le estremità delle clip vanno inserite nei fori presenti sul terminale. Avvitare

a mano le viti delle clip di montaggio fino a quando la guarnizione risulta

completamente aderente alla superficie di montaggio.

Sequenze di avvitamento

consigliate.

14

4 clip

3

6 clip

2

513

246

1

3

7

5

8 clip

6

8

4

2

2. Stringere alterntivamente le viti delle clip di montaggio con una coppia di:

• 1,13 Nm (10 pollici-libbra) per il RAC6182

• 0,90…1,1 Nm (8…10 pollici-libbra) per PanelView Plus 2711P e

PanelView Plus CE 2711P

Non stringere troppo.

TTENZIONE

Avvitare le clip di montaggio secondo la coppia consigliata per fornire una

tenuta corretta ed evitare danni al dispositivo. Allen-Bradley non è

responsabile per eventuali danni causati da acqua o agenti chimici al

dispositivo o ad altre apparecchiature all'interno della custodia dovuti ad

un'installazione errata.

Publication 2711P-IN006B-MU-P - March 2007

Page 13

Instruções de Instalação

Clipes de Montagem

Código de Catálogo 2711P-RTMC

Português

Características Gerais

Este documento fornece instruções sobre como instalar os dispositivos a seguir em

um painel ou gabinete utilizando clipes de montagem 2711P-RTMC. São fornecidos

oito clipes de montagem com o conjunto.

• 2711P PanelView Plus

• 2711P PanelView Plus CE

• Computador Industrial RAC6182

Os clipes de montagem fixam o terminal ao gabinete de montagem. O número de

clipes utilizados para instalação varia de acordo com o dispositivo

Número

de

Clipes

Dispositivo Local do Clip no Dispositivo

RAC6182 (todos os tamanhos)

4

PanelView Plus/PanelView Plus CE 700 (todas as versões)

PanelView Plus/PanelView Plus CE 1000 Touch Only

PanelView Plus/Teclado PanelView Plus CE 1000 ou

6

Teclado e Touchscreen

PanelView Plus/PanelView Plus CE 1250 (todas as versões)

8 PanelView Plus/PanelView Plus CE 1500 (todas as versões)

Publication 2711P-IN006B-MU-P - March 2007

Superior: Slots Esquerdo e Direito

Inferior: Slots Esquerdo e Direito

Superior: Slots Esquerdo e Direito

Inferior: Slots Esquerdo e Direito

Laterais: Slots Esquerdo e Direito

Superior: Slots Esquerdo e Direito

Inferior: Slots Esquerdo e Direito

Laterais: Superior e Inferior

Page 14

14 Clipes de Montagem

Instalação dos Clipes de Montagem:

1. Instale os clipes de montagem no terminal. O número de clipes varia em

cada dispositivo.

As extremidades dos clipes deslizam para dentro dos slots no terminal.

Aperte os parafusos dos clipes de montagem manualmente até que as juntas

de vedação fiquem em contato com a superfície de montagem de modo

uniforme.

As sequências de torque recomendadas

são exibidas abaixo.

14

4 Clipes

3

513

6 Clipes

246

2

1

6

3

8 Clipes

7

5

2. Aperte os parafusos dos clipes de montagem alternadamente utilizando um

torque de:

• 1,13 Nm (10 pol-libras) para o RAC6182

• .90…1.1 Nm (8…10 pol-libras) para o PanelView Plus 2711P e o

PanelView Plus CE 2711P

3. Não aperte demais.

ATENÇÃO

Aperte os clipes de montagem até o torque recomendado para fornecer a

vedação adequada e para prevenir danos ao dispositivo. A Allen-Bradley não

se responsabiliza por danos causados por água ou produtos químicos ao

dispositivo ou outro equipamento dentro do gabinete devido à instalação

incorreta.

Publication 2711P-IN006B-MU-P - March 2007

8

4

2

Page 15

Page 16

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in

using its products. At http://support.rockwellautomation.com

technical manuals, a knowledge base of FAQs, technical and application notes,

sample code and links to software service packs, and a MySupport feature that you

can customize to make the best use of these tools.

For an additional level of technical phone support for installation, configuration,

and troubleshooting, we offer TechConnect Support programs. For more

information, contact your local distributor or Rockwell Automation representative,

or visit http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can

also contact a special Customer Support number for initial help in getting your

module up and running.

, you can find

United States 1.440.646.3223

Outside United

States

Monday – Friday, 8am – 5pm EST

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not

functioning, it may need to be returned.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Publication 2711P-IN006B-MU-P - March 2007 PN 41061-302-01(2)

Supersedes Pub lication 2711P-IN006A-M U-P - November 2002 Copyright © 20 07 Rockwell Automatio n, Inc. All rights reser ved. Printed in the U.S.A.

(see phone number above to obtain one) to your distributor in order to

complete the return process.

Please contact your local Rockwell Automation representative for return

procedure.

Loading...

Loading...