Page 1

Installation Instructions

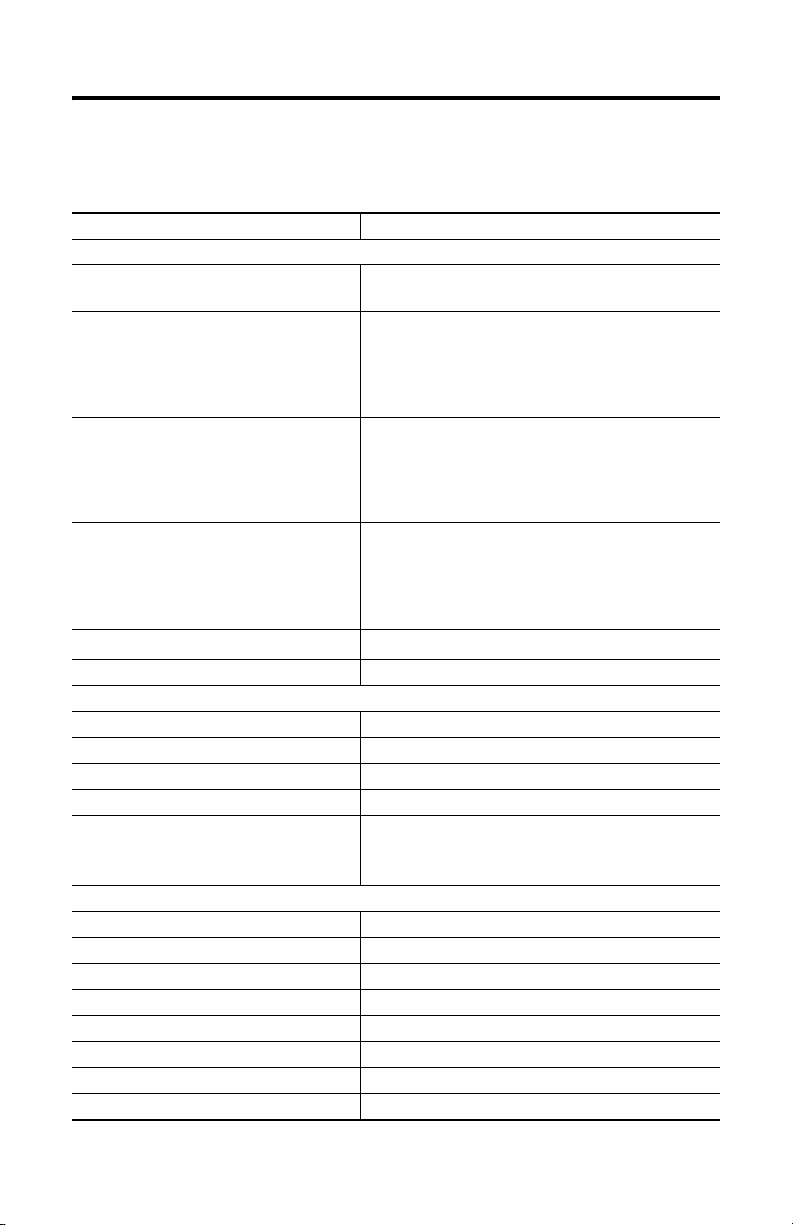

PanelView Plus 700 to 1500 and PanelView Plus

Compact 1000 Terminals and Display Modules

Catalog Numbers 2711P-Kxxxx, 2711P-Txxxx, 2711P-Bxxxx, 2711P-RDxxxx,

2711PC-T10C4D1

Top ic Page

Important User Information 2

Environment and Enclosure 3

Hazardous Locations 4

Wiring and Safety Guidelines 8

About the PanelView Plus 700 to 1500 Terminals 8

Parts List 10

Required Tools 10

Install the Terminal 10

DC Power Connections 16

AC Power Connections 20

Battery Precautions 22

Troubleshooting 24

Specifications 28

Additional Resources 30

About This Publication

This document provides instructions on how to install these devices in a panel.

• Factory-assembled PanelView Plus or PanelView Plus CE 700 to 1500 terminals

• PanelView Plus or PanelView Plus CE 700 to 1500 display modules

• Factory-assembled PanelView Plus Compact 1000 terminal

For complete information on installing, wiring, and troubleshooting the terminals, refer to the

publications listed under Additional Resources.

Page 2

2 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment.

Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls (Publication

SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many

variables and requirements associated with any particular installation, Rockwell Automation, Inc. cannot

assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

) describes some important differences between solid state

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause an explosion in

a hazardous environment, which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful application and understanding of

the product.

Identifies information about practices or circumstances that can lead to personal injury

or death, property damage, or economic loss. Attentions help you identify a hazard,

avoid a hazard and recognize the consequences.

Labels may be on or inside the equipment (for example, a drive or motor) to alert

people that dangerous voltage may be present.

Labels may be on or inside the equipment (for example, a drive or motor) to alert

people that surfaces may reach dangerous temperatures.

Publication 2711P-IN001I-EN-P - November 2009

Page 3

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 3

Environment and Enclosure

ATTENTION

This equipment is intended for use in a Pollution Degree 2 industrial environment, in

overvoltage Category II applications (as defined in IEC publication 60664-1), at altitudes

up to 2000 m (6561 ft) without derating.

The terminals are intended for use with programmable logic controllers. Terminals that

are AC powered must also be connected to the secondary of an isolating transformer.

This equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR Publication 11. Without appropriate precautions, there may be potential

difficulties ensuring electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

Korean Radio Wave Suitability Registration - This equipment is registered for

Electromagnetic Conformity Registration as business equipment (A), not home

equipment. Sellers or users are required to take caution in this regard.

This equipment is supplied as open-type equipment. It must be mounted within an

enclosure that is suitably designed for those specific environmental conditions that will

be present and appropriately designed to prevent personal injury resulting from

accessibility to live parts. The interior of the enclosure must be accessible only by the use

of a tool. The terminals meet specified NEMA Type and IEC ratings only when mounted in

a panel or enclosure with the equivalent rating. Subsequent sections of this publication

may contain additional information regarding specific enclosure type ratings that are

required to comply with certain product safety certifications.

In addition to this publication, see:

• Industrial Automation Wiring and Grounding Guidelines, for additional installation

requirements, publication 1770-4.1

• NEMA Standards publication 250 and IEC publication 60529, as applicable, for

explanations of the degrees of protection provided by different types of enclosure.

.

ControlNet Communication Port

ATTENTION

PanelView Plus terminals with ControlNet communications ports include a Network

Applications Port (NAP). This port is for temporarily connecting programming terminals

to devices on a ControlNet network, and are not intended for continuous operation.

Publication 2711P-IN001I-EN-P - November 2009

Page 4

4 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Hazardous Locations

This equipment is suitable for these locations:

• Class I, Division 2 Groups A, B, C, D

• Class II, Division 2 Groups F, G

• Class III

• Ordinary, nonhazardous locations only

The following statement applies to use in hazardous locations.

WARNING

Explosion Hazard

• Substitution of components may impair suitability for hazardous locations.

• Do not disconnect equipment unless power has been switched off and area is

known to be nonhazardous.

• Do not connect or disconnect components unless power has been switched off.

• All wiring must comply with N.E.C. articles 501, 502, 503, and/or C.E.C. section

18-1J2 as appropriate.

• Peripheral equipment must be suitable for the location in which it is used.

The terminals have a temperature code of T4 when operating in a 55 °C (131 °F) maximum

ambient temperature. Do not install the terminals in environments where atmospheric gases

have ignition temperatures less than 135 °C (275 °F).

Publication 2711P-IN001I-EN-P - November 2009

Page 5

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 5

Environnements dangereux

Cet équipement ne peut être utilisé que dans les environnements suivants :

• Classe I, Division 2, Groupes A, B, C, D

• Classe II, Division 2, Groupes F, G

• Classe III

• ou environnements non-dangereux

La mise en garde suivante s’applique à une utilisation en environnement dangereux.

AVERTISSEMENT

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement impropre à une

utilisation en environnement dangereux.

• Ne pas déconnecter l’équipement sans s’être assuré que l’alimentation est

coupée ou que l’environnement est classé non dangereux.

• Ne pas connecter ou déconnecter des composants sans s’être assuré que

l’alimentation est coupée.

• L’ensemble du câblage doit être conforme, selon le cas, aux articles 501-4(b),

502-4(b) et 503-3(b) du Code national de l’électricité des Etats-Unis.

• L’équipement périphérique doit être adapté à l’environnement dans lequel il

est utilisé.

Le code de température de fonctionnement des terminaux PanelView Plus et PanelView

Plus CE est T4 pour une température ambiante maximale de 55 °C. N’installez pas les

terminaux dans des environnements contenant des gaz atmosphériques inflammables à

moins de 135 °C.

Publication 2711P-IN001I-EN-P - November 2009

Page 6

6 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

USB Ports

All PanelView Plus and PanelView Plus Compact terminals contain universal serial bus (USB)

ports that comply with hazardous location environments. This section details the field-wiring

compliance requirements and is provided in accordance with the National Electrical Code,

article 500.

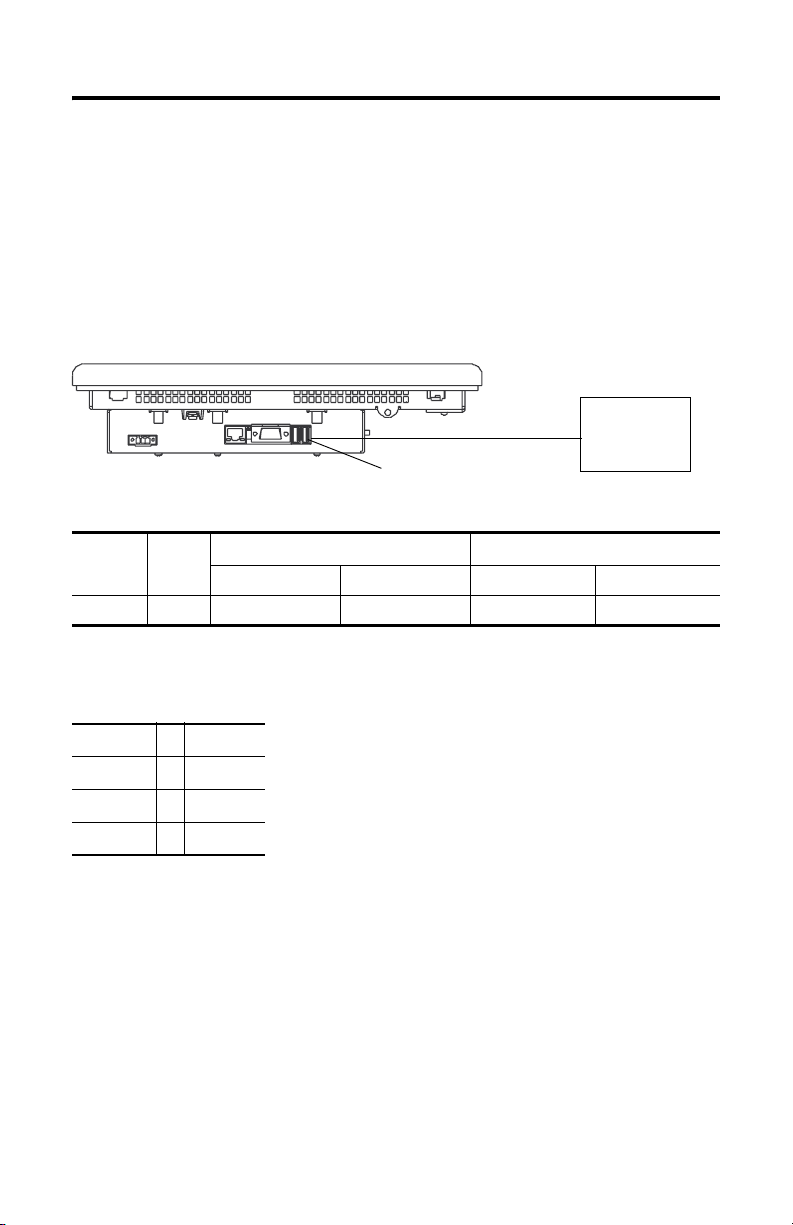

Terminals Control Drawing

Associated Nonincendive Field Wiring Apparatus

PanelView Plus Host Product

Nonincendive Field

Wiring Apparatus

Nonincendive Field Wiring

USB Port

USB

Peripheral

Device

Table 1 - PanelView Plus USB Port Circuit Parameters

C

V

oc

I

sc

Groups A and B Groups C and D Groups A and B Groups C and D

a

5.25V DC 1.68 A 10 µF 10 µF 15 µH 15 µH

Selected nonincendive field wiring apparatus must have nonincendive circuit parameters

conforming with Table 2.

L

a

Table 2 - Required Circuit Parameters for the USB Peripheral Device

V

max

I

max

Ci + C

+ L

L

i

cable

cable

≥ V

≥ I

≤ Ca

≤ L

oc

sc

a

Publication 2711P-IN001I-EN-P - November 2009

Page 7

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 7

Application Information

Per the National Electrical Code the circuit parameters of nonincendive field wiring apparatus

for use in hazardous locations shall be coordinated with the associated nonincendive field

wiring apparatus such that their combination remains nonincendive. The PanelView Plus

terminals and the USB peripheral device shall be treated in this manner.

The circuit parameters of the PanelView Plus USB port are given in Table 1. The USB

peripheral device and its associated cabling shall have circuit parameters with the limits given

in Table 2 for them to remain nonincendive when used with the PanelView Plus USB port. If

cable capacitance and inductance are not known the following values from ANSI/ISA-RP

12.06.01-2003 may be used:

= 197 µF/m (60 µF/ft)

C

cable

= 0.7 µF/m (0.20 µH/ft)

L

cable

Nonincendive field wiring must be wired and separated in accordance with 501.10(B)(3) of

the National Electrical Code (NEC) ANSI/NFPA 70 or other local codes as applicable.

This associated nonincendive field wiring apparatus has not been evaluated for use in

combination with another associated nonincendive field wiring apparatus.

Symbol Definitions

V

oc

I

sc

V

max

I

max

C

i

C

a

L

i

L

a

Open circuit voltage of the host USB port.

Maximum output current of the host USB port.

Maximum applied voltage rating of the USB peripheral device.

V

shall be greater than or equal to Voc in Table 1 (V

max

max

≥ V

oc ).

Maximum current to which the USB peripheral device can be subjected.

I

shall be greater than or equal to Isc in Table 1 (I

max

max

≥ Isc).

Maximum internal capacitance of the USB peripheral device.

Maximum allowed capacitance of the USB peripheral device and its associated cable. The

sum of C

of the USB peripheral device and C

i

≤ Ca).

a

than or equal to C

+ C

(C

i

cable

of the associated cable shall be less

cable

Maximum internal inductance of the USB peripheral device.

Maximum allowed inductance of the USB peripheral device and its associated cable. The

sum of L

of the USB peripheral device and L

i

cable

a

≤ La).

or equal to L

(L

+ L

i

of the associated cable shall be less than

cable

Publication 2711P-IN001I-EN-P - November 2009

Page 8

8 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Wiring and Safety Guidelines

Use publication NFPA 70E, Electrical Safety Requirements for Employee Workplaces, IEC

60364 Electrical Installations in Buildings, or other applicable wiring safety requirements for

the country of installation when wiring the devices. In addition to the NFPA guidelines:

• connect the device and other similar electronic equipment to its own branch circuit.

• protect the input power by a fuse or circuit breaker rated at no more than 15 A.

• route incoming power to the device by a separate path from the communication lines.

• cross power and communication lines at right angles if they must cross.

Communication lines can be installed in the same conduit as low-level

DC I/O lines (less than 10V).

• shield and ground cables appropriately to avoid electromagnetic interference (EMI).

Grounding minimizes noise from EMI and is a safety measure in electrical

installations.

For more information on grounding recommendations, refer to the National Electrical Code

published by the National Fire Protection Association.

For more information, refer to Wiring and Grounding Guidelines for PanelView

Plus/PanelView Plus CE Devices Technical Data, publication 2711P-TD001

this publication in the Literature Library website, http://literature.rockwellautomation.com

. You can find

.

About the PanelView Plus 700 to 1500 Terminals

The PanelView Plus terminals have these modular components:

• Display module (700, 1000, 1250, and 1500)

• Logic module with AC or DC power, CompactFlash card slot, Ethernet port, serial

port, and USB ports

• Internal CompactFlash card with firmware or operating system, RAM memory

(SO-DIMM)

• Communication module for specific communication protocols

These items can be ordered as separate components for field installation or factory assembled

per your configuration. The base-configured unit includes the display module and the logic

module with internal CompactFlash and RAM.

Publication 2711P-IN001I-EN-P - November 2009

Page 9

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 9

Modular Components

Communication Module

Power Input, AC or DC

Ethernet Port

Serial Port

Display Module

Logic Module

CompactFlash Card Slot

USB Ports

If the modules are ordered separately, attach the logic and communication module to the

display module before panel installation. See the instructions shipped with each module.

The logic module for the terminals is available with or without RAM and CompactFlash

preinstalled. If memory is ordered separately, you must install the memory before attaching

the logic module to the display module. See the instructions shipped with the logic module.

About the PanelView Plus Compact 1000 Terminal

The PanelView Plus Compact 1000 terminal has a fixed configuration. It does not support

communication modules, or the replacement of the logic module. The 1000 terminal contains

a non-isolated DC power supply.

Compact Flash

USB Ports

RS-232 Serial Port

The PanelView Plus Compact 1000 terminal has these features:

• 1000 touch screen display module

• USB ports (2)

• RS-232 serial port

• 10/100Base T Ethernet port

• Power input, 24V DC non-isolated

• CompactFlash Type 1 card slot

Publication 2711P-IN001I-EN-P - November 2009

Power Input, 24V DC

Ethernet Port

Page 10

10 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Parts List

These items are shipped with the terminals:

• Power terminal block

• Mounting clips

• FactoryTalk View software preloaded

• Installation instructions and panel cutout template

Required Tools

These tools are required for panel installation:

• Panel cutout tools

• Small, slotted screwdriver

• Torque wrench (lb•in)

Install the Terminal

Before installing the terminal in a panel, review the following topics:

• Mounting clearances

• Panel cutout dimensions

• Product dimensions

Mounting Clearances

Allow adequate clearance around the terminal, inside the enclosure, for adequate ventilation.

Consider heat produced by other devices in the enclosure. The ambient temperature around

the terminals must be between 0…55 °C (32…131 °F).

These minimum clearances are required for ventilation.

• Top clearance: 51 mm (2 in.)

• Bottom clearance: 102 mm (4 in.)

• Side clearances: 25 mm (1 in.)

• Back clearance: 25 mm (1 in.)

Minimum side clearance for insertion of memory card is 102 mm (4 in.).

Publication 2711P-IN001I-EN-P - November 2009

Page 11

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 11

Panel Cutout Dimensions

Use the full size template shipped with your terminal to mark the cutout dimensions.

Terminal Type Height, mm (in.) Width, mm (in.)

700 Keypad or Keypad and Touch 167 (6.57) 264 (10.39)

700 Touch 154 (6.08) 220 (8.67)

1000 Keypad or Keypad and Touch 224 (8.8) 375 (14.75)

1000 Touch 224 (8.8) 305 (12.00)

1250 Keypad or Keypad and Touch 257 (10.11) 390 (15.35)

1250 Touch 257 (10.11) 338 (13.29)

1500 Keypad or Keypad and Touch 305 (12.00) 419 (16.50)

1500 Touch 305 (12.00) 391 (15.40)

Mount the Terminal in a Panel

Mounting clips secure the terminal to the panel. The number of clips you use

(4, 6, or 8) varies by terminal type.

ATTENTION

Disconnect all electrical power from the panel before making the panel cutout.

Make sure the area around the panel cutout is clear.

Take precautions so metal cuttings do not enter any components already installed in

the panel.

Failure to follow these instructions may result in personal injury or damage to panel

components.

Follow these steps to mount the terminal in a panel.

1. Cut an opening in the panel by using the panel cutout shipped with the terminal.

2. Make sure the terminal sealing gasket is properly positioned on the terminal.

Publication 2711P-IN001I-EN-P - November 2009

Page 12

12 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

This gasket forms a compression type seal. Do not use sealing compounds.

Sealing Gasket

3. Install the legend strips before installing the terminal if you are using keypad legend

strips on keypad terminals.

Be careful not to pinch the legend strip during installation.

4. Place the terminal in the panel cutout.

5. Slide the ends of the mounting clips into the slots on the terminal.

Mounting Clip Slot

Mounting Clip

6. Tighten the mounting clip screws by hand until the gasket seal contacts the mounting

surface uniformly.

Publication 2711P-IN001I-EN-P - November 2009

Page 13

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 13

7. Tighten the mounting clip screws to a torque of 0.90…1.1 N•m

(8…10 lb•in) by using the specified torque sequence, making sure not to overtighten.

14

4 Clips

32

ATTENTION

Tighten the mounting clips to the specified torque to provide a proper seal and prevent

damage to the product. Rockwell Automation assumes no responsibility for water or

chemical damage to the product or other equipment within the enclosure because of

improper installation.

13

46

5

6 Clips

2

1

3

8 Clips

7

52

6

8

4

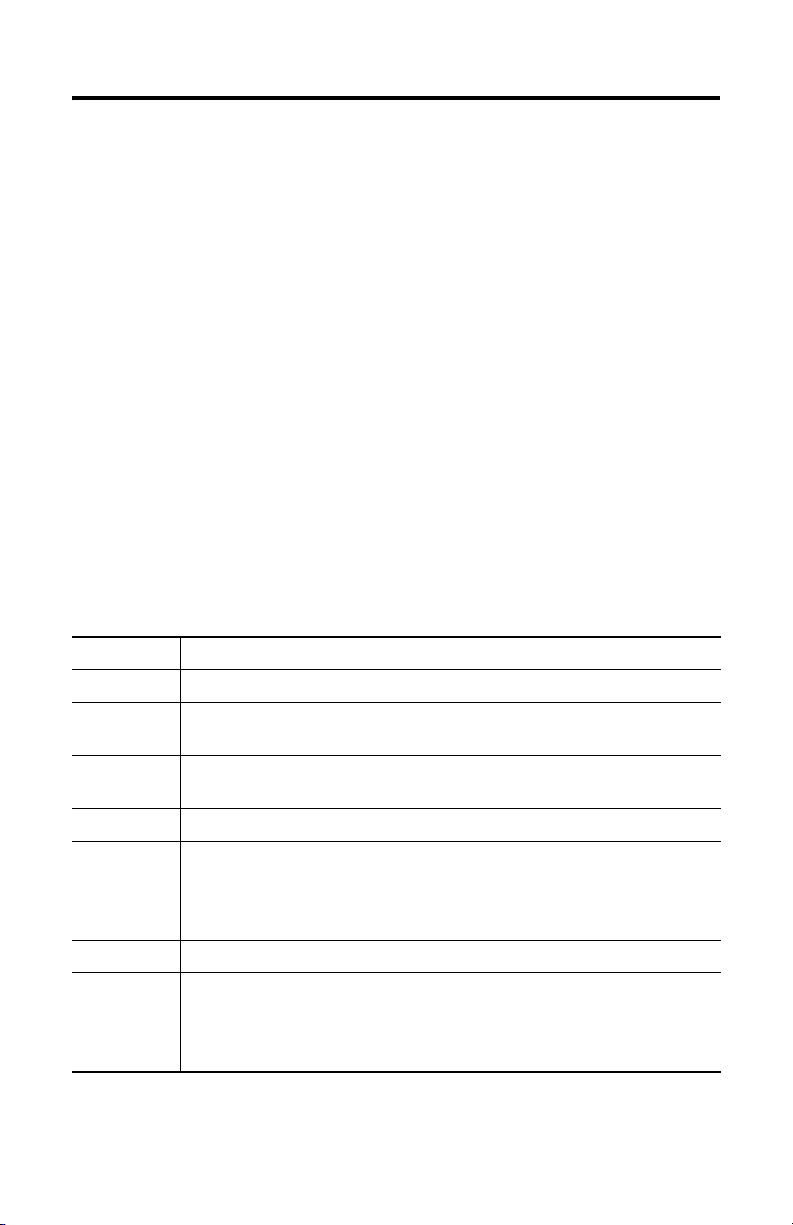

Product Dimensions

The table provides product dimensions for the terminals including depth dimensions for the:

• base configured unit (display module and logic module).

• base configured unit with communication module.

Height,

Terminal Type

700 Keypad or Keypad and Touch 193 (7.58) 290 (11.40) 55 (2.18)

700 Touch Screen 179 (7.04) 246 (9.68)

1000 Keypad or Keypad and Touch 248 (9.77) 399 (15.72)

1000 Touch Screen 248 (9.77) 329 (12.97)

1250 Keypad or Keypad and Touch 282 (11.12) 416 (16.36)

1250 Touch Screen 282 (11.12) 363 (14.30)

1500 Keypad or Keypad and Touch 330 (12.97) 469 (18.46) 65 (2.55)

1500 Touch Screen 330 (12.97) 416 (16.36)

Approx.,

mm (in.)

Width,

Approx.,

mm (in.)

Depth, Approx., mm (in.)

display to logic module

83 (3.27)

display to comm module

display to logic module

93 (3.65)

display to comm module

Publication 2711P-IN001I-EN-P - November 2009

Page 14

14 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

The illustration shows product dimensions for the PanelView Plus and PanelView Plus

Compact 1000 touch only terminals. The other size terminals look similar. Measurements are

in mm (in.).

1000 Terminal Dimensions

Keypad or Keypad & Touch

399 (15.72)

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Comm Module

a

b

Touch Screen

329 (12.97)

248 (9.77)

248 (9.77)

a 55 (2.18) Display to Logic Module

b 83 (3.27) Display to Comm Module

a

b

Publication 2711P-IN001I-EN-P - November 2009

Page 15

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 15

Ethernet Wiring

Use Belden 7921A shielded Ethernet Category 5e cable according to TIA 568-B.1 and RJ45

connector according to IEC 60603-7 for compliance with Marine emissions limits and

European Union 89/336/EEC EMC Directive.

The maximum cable length between the terminal’s Ethernet port and a 10/100 Base-T port

on an Ethernet hub (without repeaters or fiber) is 100 m (328 ft).

Remove and Install the Power Terminal Block

The terminals are shipped with a power terminal block installed. You can remove the terminal

block for ease of installation, wiring, and maintenance.

WARNING

ATTENTION

Explosion Hazard

Substitution of components may impair suitability for hazardous locations.

Do not disconnect equipment unless power has been switched off and area is known to

be nonhazardous.

Do not connect or disconnect components unless power has been switched off.

All wiring must comply with N.E.C. articles 501, 502, 503, and/or C.E.C. section 18-1J2 as

appropriate.

Peripheral equipment must be suitable for the location in which it is used.

Disconnect all power before installing or replacing components. Failure to disconnect

power may result in electrical shock or damage to the terminal.

• Series A to D, DC logic modules use a 3-position terminal block.

• Series E or later, DC logic modules use a 2-position terminal block.

• All logic modules with an AC power input use a 3-position terminal block.

Publication 2711P-IN001I-EN-P - November 2009

Page 16

16 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Follow these steps to remove the terminal block.

1. Loosen the two screws that secure the terminal block.

2. Gently pull the terminal block away from the connector.

2-position DC Terminal Block

(series E or later)

3-position AC or DC

Terminal Block

Follow these steps to install the terminal block.

1. Reattach the terminal block to the connector until seated.

2. Tighten the two screws that secure the terminal block to the connector.

DC Power Connections

DC-powered PanelView Plus devices have an integrated 24V DC power supply. Both isolated

and non-isolated power supplies have these ratings:

• 24V DC nominal (18…32V DC)

• 70 W maximum (2.9 A at 24V DC)

The power supply is internally protected against reverse polarity of the DC+ and DCconnections. Connecting DC+ or DC- to the earth/ground terminal may damage the device.

The input power terminal block supports these wire sizes.

Wire Specifications for DC Input Power Terminal Block

Logic Module Wire Type

Series A to D

Series E and later 0.56 N•m (5 lb•in)

(1)

Two-wire max per terminal.

Stranded

or solid

Cu 90 °C

(194 °F)

Dual-wire

Gauge

22…16 AWG 22…14 AWG

(1)

Single-wire

Gauge

Ter minal Scre w

Tor qu e

0.23…0.34 N•m

(2…3 lb•in)

Publication 2711P-IN001I-EN-P - November 2009

Page 17

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 17

External Power Supply For Non-isolated DC Terminals

TIP

To identify non-isolated DC logic modules refer to the PanelView Plus Terminals user

manual, publication 2711P-UM001

.

Use a single, 24V DC power supply to power each PanelView Plus device, such as catalog

number 2711P-RSACDIN. Using a separate, isolated and ungrounded source to power each

terminal prevents ground loop currents from damaging the terminals.

The output on the power supply must be isolated from the input and not connected to

earth/ground.

ATTENTION

Use a Class 2 or SELV supply as required by local wiring codes for your installation. The

Class 2 and SELV power sources provide protection so that under normal and single-fault

conditions, the voltage between the conductors, and between the conductors and

functional earth or protective earth does not exceed a safe value.

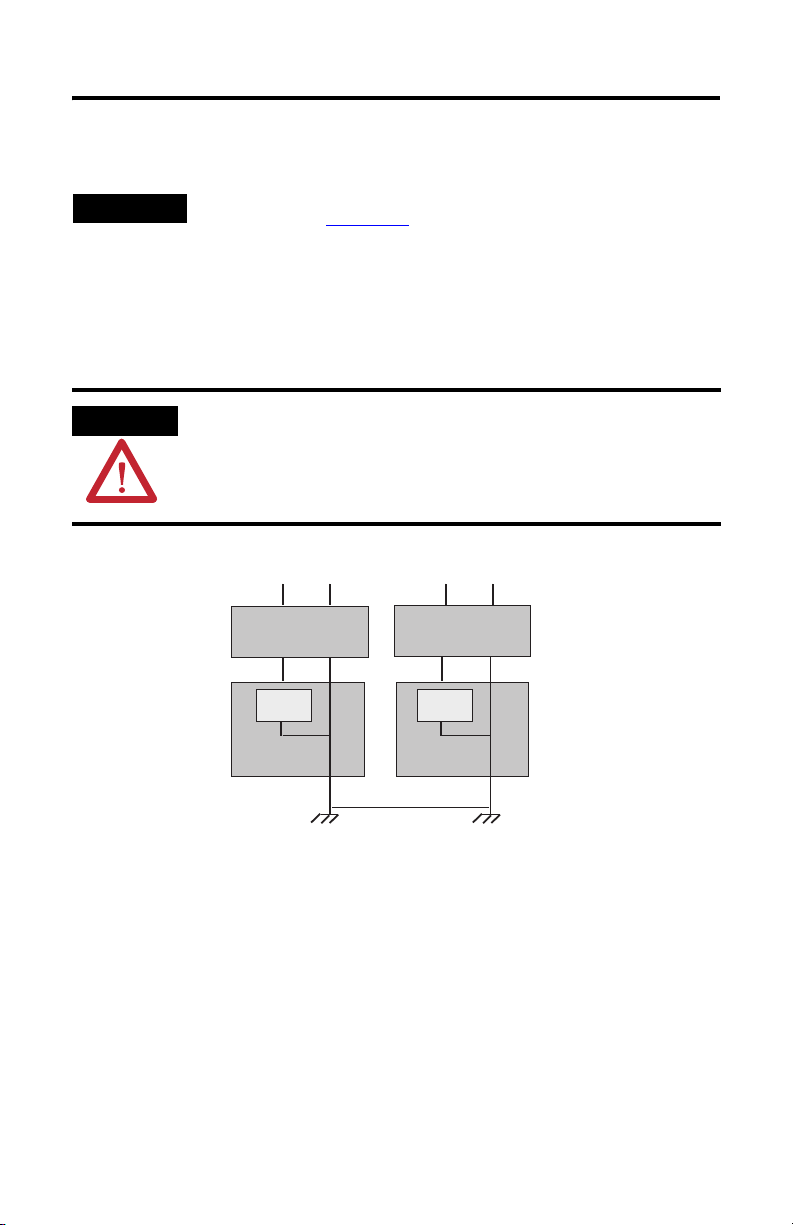

Multiple AC Power Supplies to Power Multiple DC Terminals

L1L2

AC/DC Power Supply

(2711P-RSACDIN)

dc+

dc- dc+ dc-

Circuitry Circuitry

AC/DC Power Supply

L1L2

(2711P-RSACDIN)

PanelView Plus

PanelView Plus

Publication 2711P-IN001I-EN-P - November 2009

Page 18

18 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

External Power for Isolated DC Terminals

TIP

Isolated DC logic modules are identified by catalog number 2711P-RPxDx.

Use an SELV or PELV 24V DC power supply, such as catalog number 2711P-RSACDIN, to

power the isolated DC PanelView Plus terminal.

The isolated DC terminals may be powered by the same power source as other equipment.

ATTENTION

Use an SELV or PELV supply as required by local wiring codes for your installation. The

SELV and PELV power sources provide protection so that under normal and single fault

conditions, the voltage between conductors and earth ground does not exceed a safe

value.

Earth/Ground Connection

PanelView Plus devices with a DC power input have a earth/ground terminal that you must

connect to a low-impedance earth/ground. The earth/ground connection is on the rear of

the display module.

IMPORTANT

The earth/ground terminal requires a minimum wire gauge.

Earth/Ground Wire Specifications for DC Power

The earth/ground connection to ground is mandatory. This connection is required for

noise immunity, reliability, and Electromagnetic Compliance (EMC) with the European

Union (EU) EMC directive for CE-mark conformance. This connection is required for safety

by Underwriters Laboratory.

Symbol Wire Type Wire Gauge Terminal Screw Torque

GND

Stranded or solid Cu 90 °C (194 °F) 14…10 AWG 1.13…1.36 N•m (10…12 lb•in)

On most PanelView Plus devices, the earth/ground terminal is internally connected to the

DC- terminal within the product.

ATTENTION

Damage or malfunction can occur when a voltage potential exists between two

separate ground points. Make sure the terminal does not serve as a conductive

path between ground points at different potentials.

The PanelView Plus devices have isolated and non-isolated communication ports.

For more information refer to the PanelView Plus Terminals User Manual, publication

2711P-UM001

.

Publication 2711P-IN001I-EN-P - November 2009

Page 19

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 19

Connect DC Power

WARNING

Explosion Hazard - Do not disconnect equipment unless power has been switched off and

area is known to be nonhazardous.

Disconnect all power before installing or replacing components. Failure to disconnect

power may result in electrical shock or damage to the terminal.

Follow these steps to connect the terminal DC power.

1. Verify that the terminal is not connected to a power source.

2. Secure the DC power wires to the terminal block.

Follow the markings on the terminal blocks and the terminal for proper connections.

3. Secure the earth/ground wire to the earth/ground terminal screw at the bottom of

the display.

DC Power Supply Connections

3-position Terminal Block

(series A to D logic modules)

–

+

DC+

DC-

2-position Terminal Block

(series E or later logic modules)

GND

–

+

Earth/Ground to Ground Bus

Publication 2711P-IN001I-EN-P - November 2009

GND

DC -

DC+

Page 20

20 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

AC Power Connections

PanelView Plus devices with an integrated AC power supply have these power ratings:

• 85…264V AC (47…63 Hz)

• 160V A max

The input power terminal block supports these wire sizes.

Wire Specifications for AC Input Power Terminal Block

Wire Type

Stranded or solid Cu 90 °C (194 °F) 22…16 AWG 22…14 AWG 0.56 N•m (5 lb•in)

(1)

Two-wire max. per terminal.

Dual-wire

(1)

Gauge

Single-wire

Gauge

Terminal Screw Torque

Protective Earth and Functional Earth Connection

PanelView Plus devices with an AC power input have both a protective earth and functional

earth terminal that you must connect to a low-impedance earth ground.

• Protective earth terminal is on the power input terminal block.

• Functional earth connection is on the back of the display.

ATTENTION

IMPORTANT

The protective earth and functional earth terminals require a minimum wire gauge.

The functional earth and protective earth connections to ground are mandatory. The

functional earth ground connection is required for electromagnetic compliance (EMC)

with the EU (European Union) EMC directive for CE-mark conformance. The protective

earth ground connection is required for safety and regulatory compliance.

On PanelView Plus devices with an AC power input, you must connect both protective

earth and functional earth to ground.

Functional Earth and Protective Earth Wire Specifications for AC Power

Connection Wire Type Wire Gauge Terminal Screw

Protective earth Stranded or solid Cu 90 °C (194 °F) 14…12 AWG 0.56 N•m (5 lb•in)

Functional earth

Stranded or solid Cu 90 °C (194 °F) 14…10 AWG 1.13… 1.36 N•m

GND

Publication 2711P-IN001I-EN-P - November 2009

Tor qu e

(10…12 lb•in)

Page 21

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 21

Connect AC Power

WARNING

ATTENTION

Explosion Hazard - Do not connect or disconnect equipment while circuit is live unless

area is known to be nonhazardous.

Disconnect all power before installing or replacing components. Failure to disconnect

power may result in electrical shock and/or damage to the terminal.

Improper wiring of power terminals may result in voltage at the communication

connector shells. Refer to the following figure when wiring.

Do not apply power to the terminal until all wiring connections have been made. Failure

to do so may result in electrical shock.

Follow these steps to connect the terminal to AC power.

1. Verify that the terminal is not connected to a power source.

2. Secure the AC power wires to the terminal block.

Follow the markings on terminal blocks and terminal for proper connections.

3. Secure the protective earth ground wire to the marked position of the power input

terminal block.

4. Secure the functional earth ground wire to the functional earth ground screw on the

back of the display to ground bus.

Functional Earth Ground to Ground Bus

5. Apply AC power to the terminal.

L1

L2/Neutral

GND

Protective Earth

to Ground Bus

Publication 2711P-IN001I-EN-P - November 2009

Page 22

22 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Battery Precautions

WARNING

When you connect or disconnect the battery an electrical arc can occur. This could cause

an explosion in hazardous location installations. Be sure that power is removed and the

area is nonhazardous before proceeding.

For safety information on the handling of lithium batteries, including handling and

disposal of leaking batteries, see Guidelines for Handling Lithium Batteries, publication

AG 5-4

. Replace the battery only with the indicated catalog number.

Do not dispose of battery in a fire or incinerator. Dispose of used batteries in accordance

with local regulations.

Store batteries in a cool, dry environment. We recommend 25 °C (77 °F) with 40…60%

relative humidity. You may store batteries for up to 30 days between -45…85 °C

(-49…185 °F), such as during transportation. To avoid possible leakage, do not store

batteries above 60 °C (140 °F) for more than 30 days.

Replace the Battery

Follow these steps to replace the lithium battery in the logic module of PanelView Plus or

PanelView Plus Compact terminals.

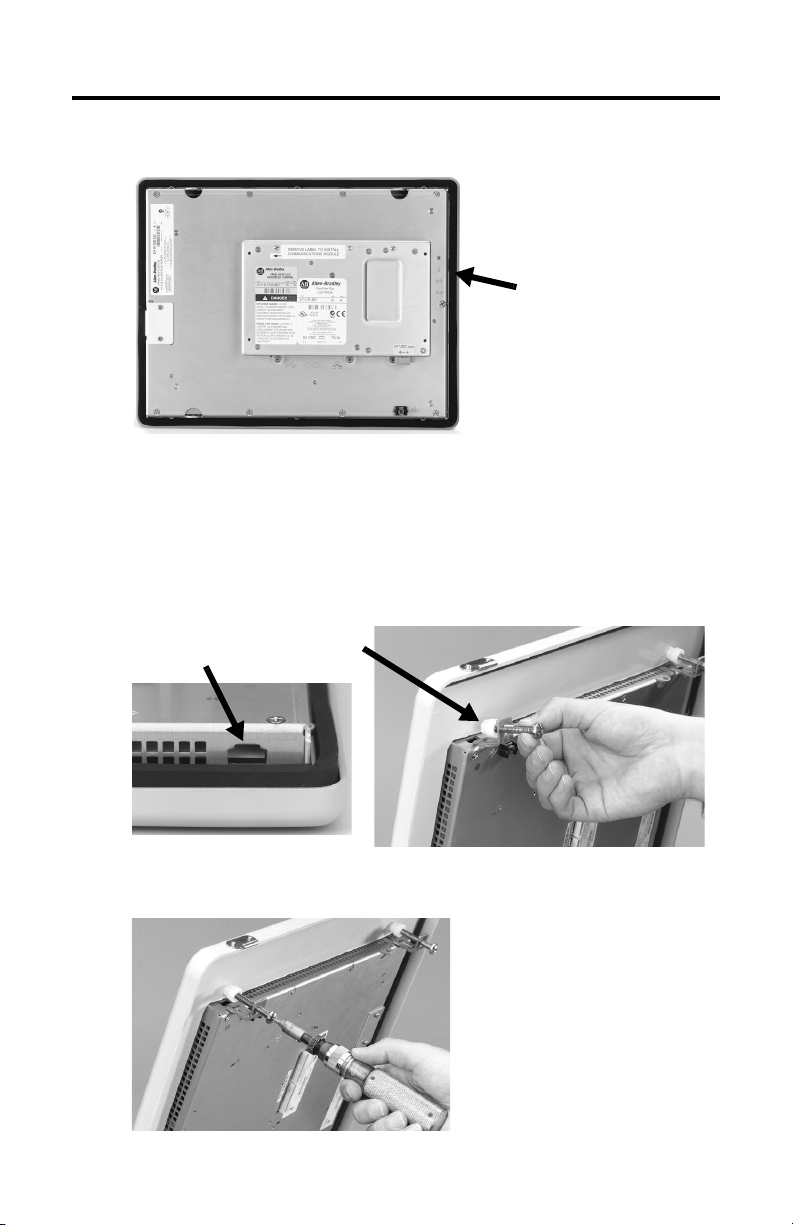

1. Disconnect power from the terminal.

2. Place the terminal, display side down, on a flat stable surface.

3. Detach the communication module, if attached, from the logic module by removing

the four screws.

4. Loosen the six captive screws that attach the logic module to the display module.

Communication Module

Screw

Logic Module

Display Module

5. Carefully lift the logic module away from the terminal and turn over to expose the

circuit board.

Publication 2711P-IN001I-EN-P - November 2009

Captive

Screw

Page 23

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 23

6. Locate the battery on the circuit board.

Lift up the edge of the

battery indicated by

the arrow.

7. Remove the battery by lifting up the side of the battery.

8. Insert the new battery.

IMPORTANT

Use only replacement battery catalog number 2711P-RY2032.

9. Reattach the logic module by aligning the two connectors on the bottom of the

module with the connectors on the terminal.

10. Push down on the logic module until it is firmly seated.

11. Tighten the six captive screws that secure the logic module to a torque of 0.58 N•m

(5…7 lb•in).

Publication 2711P-IN001I-EN-P - November 2009

Page 24

24 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

12. Reattach the communication module, if necessary, and tighten the four screws to a

torque of 0.58 N•m (5…7 lb•in).

This product contains a hermetically sealed lithium battery which may need to be

replaced during the life of the product.

At the end of its life, the battery contained in this product should be collected separately

from any unsorted municipal waste.

The collectioin and recyling of batteries helps protect the environment and contributes to

the conservation of natural resources as valuable materials are recovered.

Troubleshooting

If the terminal is not operating correctly, check the power, display settings, status indicators,

and review the system startup and error messages.

Check for Adequate Power

A terminal that does not receive adequate power could cause unpredictable behavior. Verify

the power requirements in the Specifications table.

Check Status Indicators

The terminal has two status indicators to isolate operating problems.

• COMM indicator (green) for communication

• FAULT indicator (red) for hardware faults

COMM and FAULT Indicators

When the terminal starts, the fault indicator should be off, except for a few brief flashes, and

the comm indicator on. If the indicators remain off, the power supply or logic module has

failed. Check the power cable. If the power is not within range, replace the power supply. If

the power is within range, replace the logic module. After a successful startup, both indicators

are off and controlled by the application running on the terminal.

Publication 2711P-IN001I-EN-P - November 2009

Page 25

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 25

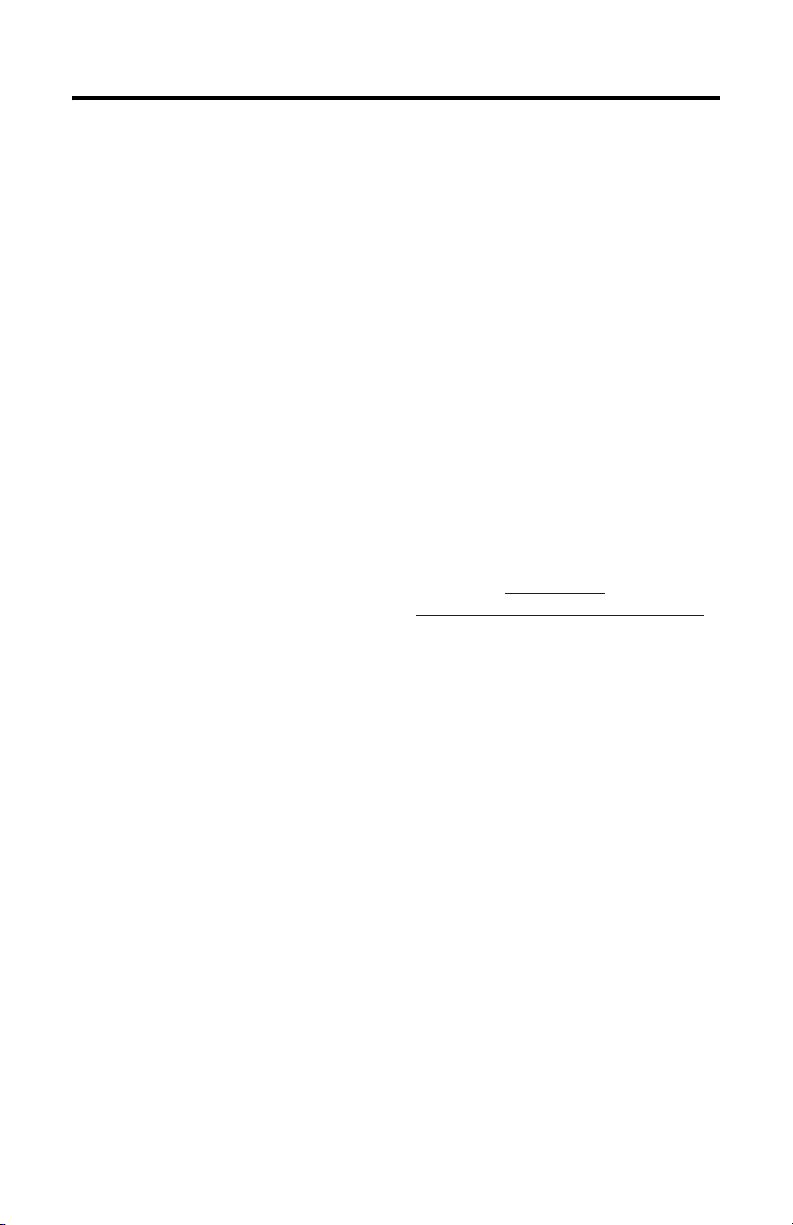

The table shows indicator states if the terminal powers on and stops during startup.

Indicator States If the Terminal Stops During Startup

Fault (Red)

Indicator

(1)

Blinking

(2)

On

(1)

Blinking red indicates a recoverable error.

(2)

Solid red indicates a nonrecoverable or fatal error.

Comm (Green)

Indicator

Off Last firmware download failed.

Blinking EBC boot loader firmware failed or is missing.

On Windows CE OS firmware failed or is missing.

Off Fatal hardware error occurred.

Blinking Fatal hardware error in display.

Description

Reload firmware using Firmware Upgrade Wizard (FUW) utility.

Reload firmware using Firmware Upgrade Wizard (FUW) utility.

Reload firmware using Firmware Upgrade Wizard (FUW) utility.

Replace the logic module.

Replace the display module.

Check the Display

If the terminal display is dim or unreadable:

• check the brightness setting of the display. From Configuration mode on the terminal,

access Terminal Settings>Display Intensity.

• check the Screen Saver settings. The backlight may be turning off or dimming the

display unexpectedly. From Configuration mode on the terminal, access Terminal

Settings>Display>Screen Saver.

Publication 2711P-IN001I-EN-P - November 2009

Page 26

26 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Startup Information Messages

Startup information messages display in a specific sequence on the terminal during startup

and typically display for a few seconds. These messages do not require that you perform any

action.

Message # Message Description

37 Video Initialized Configures and initializes the graphics video system.

30 Watchdog Test Tests the watchdog circuitry to verify system integrity.

1 RAM Test Tests the RAM memory.

31 Stuck Key Checks the integrity of the function key hardware.

31.5 Stuck Touch Checks the integrity of the touch screen hardware.

32 Battery Test Checks the integrity of the battery hardware.

2.5 Registry Search Locates and loads the most recent, valid registry. Multiple copies of

2 Image Search Checks for a new OS firmware upgrade on the external CompactFlash

50 External CF Transfers a new OS firmware upgrade from the external

23 Internal CF Programs the OS firmware just downloaded into the internal flash

24 CRC Check Checks the integrity of the OS firmware.

28 Starting System Launches the operating system (OS).

29 System Check ### Internal file system integrity check (### is percent progress indicator).

29.1 System Check Internal file system integrity check disabled. Contact technical

the registry are maintained. If power is lost during a registry update, a

valid registry is available the next time power is applied to the

terminal.

card and the serial port.

CompactFlash card to the terminal. Message may display for several

minutes.

memory. Message may display for several minutes.

support.

Publication 2711P-IN001I-EN-P - November 2009

Page 27

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 27

Startup Error Messages

When an error occurs, the terminal displays an error number with a text message. The word

ERROR! appears under the message in different languages.

# Displayed Message

ERROR! FEHLER! ERREUR! ERRORE!

Error # Message Description Recommended Corrective Action

1 RAM Test RAM test failure. Reset the terminal. If error persists, reseat the

SO-DIMM RAM module. If error still persists, replace

the logic module.

23 Internal CF Error programming

the new OS firmware

to internal

CompactFlash card.

24 CRC Check Checksum of the OS

firmware failed.

30 Watchdog Test Watchdog test

failure.

31 Stuck Key Function key failure. Check that nothing is pressed against a key. Reset

31.5 Stuck Touch Touch screen failure. Check that nothing is pressed against the touch

32 Battery Test Battery failure. Replace the battery. If error persists, replace the logic

33.5 NVRAM Access Nonvolatile memory

failure.

40 EXE Check System OS firmware

is missing or corrupt.

50 External CF Error loading the OS

firmware from the

external

CompactFlash card.

Reload the firmware. If error persists, replace the

internal CompactFlash card. If error still persists,

replace the logic module.

Reload the firmware. If error persists, replace the

internal CompactFlash card. If error still persists,

replace the logic module.

Reload the firmware. If error persists, replace the

logic module.

the terminal without key presses. If error persists,

replace the display module.

screen. Reset the terminal without pressing the touch

screen. If error persists, replace the display module.

module.

Upgrade the system firmware to revision 3.10.03 or

later.

Reload the firmware. If error persists, replace the

internal CompactFlash card. If error still persists,

replace the logic module.

Reload the firmware. If error persists, replace the

external CompactFlash card and attempt the

firmware upgrade again.

Publication 2711P-IN001I-EN-P - November 2009

Page 28

28 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Specifications

PanelView Plus Terminals - 2711P-Kxxxx, 2711P-Txxxx, 2711P-Bxxxx, 2711P-RDxxxx, 2711PC-Txxxx

Attribute Value

Display

Display type Color active matrix, thin film transistor (TFT), liquid crystal

display (LCD)

Display size

700

1000

1250

1500

Display area (WxH)

700

1000

1250

1500

Display resolution

700

1000

1250

1500

Luminance

Touch screen Analog resistive

Electrical

Input voltage, DC 24V DC nom (18… 32V DC)

Power consumption, DC 70 W max (2.9 A @ 24V DC) 39 W typical (1.6 A @ 24V DC)

Input voltage, AC 85… 264V AC (47…63 Hz)

Power consumption, AC 160 VA max (65 VA typical)

(1)

PCI slot max. available power

Supply, DC

Supply, AC

Dimensions, Approx., (HxWxD) for based configured unit without communication module

700 keypad, or keypad and touch 193 x 290 x 55 mm (7.58 x 11.40 x 2.18 in.)

700 touch 179 x 246 x 55 mm (7.04 x 9.68 x 2.18 in.)

1000 keypad, or keypad and touch 248 x 399 x 55 mm (9.77 x 15.72 x 2.18 in.)

1000 touch 248 x 329 x 55 mm (9.77 x 12.97 x 2.18 in.)

1250 keypad, or keypad and touch 282 x 416 x 55 mm (11.12 x 16.36 x 2.18 in.)

1250 touch 282 x 363 x 55 mm (11.12 x 14.30 x 2.18 in.)

1500 keypad, or keypad and touch 330 x 469 x 65 mm (12.97 x 18.46 x 2.55 in.)

1500 touch 330 x 416 x 65 mm ((12.97 x 16.37 x 2.55 in.)

(1)

The PCI slot does not apply to the PanelView Plus Compact 1000 terminal.

6.5 in.

10.4 in.

12.1 in.

15 in.

132 x 99 mm (5.2 x 3.9 in.)

211 x 158 mm (8.3 x 6.2 in.)

246 x 184 mm (9.7 in x 7.2 in.)

304 x 228 mm (12.0 x 9.0 in.)

640 x 480

640 x 480

800 x 600

1024 x 768

2

300 cd/m

Nits

11 W

5 W

Publication 2711P-IN001I-EN-P - November 2009

Page 29

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 29

PanelView Plus Terminals - 2711P-Kxxxx, 2711P-Txxxx, 2711P-Bxxxx, 2711P-RDxxxx, 2711PC-Txxxx

Weight, Approx. for base configured unit without communication module

700 keypad, or keypad and touch 1.9 kg (4.2 lb)

700 touch 1.7 kg (3.8 lb)

1000 keypad, or keypad and touch 2.9 kg (6.3 lb)

1000 touch 2.6 kg (5.7 lb)

1250 keypad, or keypad and touch 3.4 kg (7.6 lb)

1250 touch 3.2 kg (7.1 lb)

1500 keypad, or keypad and touch 4.6 kg (10.0 lb)

1500 touch 4.2 kg (9.3 lb)

General

Battery life 4 years min. at 25 °C (77 °F)

Clock Battery-backed, + /- 2 minutes per month

Status indicators COMM (green), Fault (red)

Application flash memory

700 to 1500 series D or earlier logic modules

2711P-RW1

2711P-RW2

2711P-RW3

700 to 1500 series E or later logic modules

2711P-RW6

2711P-RW7

2711P-RW8

External CompactFlash storage 512 MB max

26 MB

72 MB

95 MB

80 MB

203 MB

446 MB

Environmental Specifications

Specification Value

Temperature, operating 0…55 °C (32…131 °F)

Temperature, nonoperating -20…70 °C (-13…158 °F)

Vibration 10… 57 Hz, 0.012 pk-pk displacement

57…500 Hz 2.0 g pk acceleration

Shock, operating 15 g at 11 ms

Shock, nonoperating 30 g at 11 ms

Relative humidity 5…95% without condensation

Enclosure ratings NEMA Type 12, 13, 4X (indoor use only), IP54, IP65

Airborne Contaminants ANSI/ISA S71.04-1985 Severity Level G3

EN60654-4:1998 Class 3

Publication 2711P-IN001I-EN-P - November 2009

Page 30

30 PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules

Certifications

Certification

c-UL-us UL Listed Industrial Control Equipment, certified for use in US and

CE (EMC) European Union 89/336/EEC EMC Directive, compliant with:

CE (LVD) EN 61131-2; Programmable Controllers

C-Tick Australian Radiocommunications Act, compliant with:

Marine Products identified with the suffix M in the catalog number, are certified

(1)

See the Product Certification link on http://www.ab.com for declarations of conformity, certificates, and other certification

details.

(1)

Canada. See File E10314.

UL Listed Industrial Control Equipment for use in:

• Class I, Div 2, Group A, B, C, D

• Class II, Div 2 Groups F, G

• Class III Hazardous Locations

EN 61000-6-2; Industrial Immunity

EN 61000-6-4; Industrial Emissions

AS/NZS CISPR 11; Industrial Emissions

to the requirements of one or more marine societies.

Additional Resources

For additional information on the terminals, refer to these publications.

Resource Description

PanelView Plus User Manual,

publication 2711P-UM001

Wiring and Grounding Applications for

PanelView Plus devices Technical Data,

publication 2711P-TD001

PanelView Plus Compact Terminals User

Manual, publication 2711PC-UM001

Provides an overview of the PanelView Plus and PanelView

Plus CE terminals and gives information on how to install,

operate, configure, and troubleshoot these devices.

Provides additional information on wiring and grounding the

PanelView Plus and PanelView Plus CE terminals.

Provides an overview of the PanelView Plus Compact

terminals and gives information on how to install, operate,

configure, and troubleshoot these devices.

You can view or download publications and translated versions of the installation instructions

at http://literature.rockwellautomation.com

.

To order paper copies of technical documentation, contact your local Rockwell Automation

distributor or sales representative.

Publication 2711P-IN001I-EN-P - November 2009

Page 31

PanelView Plus 700 to 1500 and PanelView Plus Compact 1000 Terminals and Display Modules 31

Publication 2711P-IN001I-EN-P - November 2009

Page 32

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using its

products. At http://support.rockwellautomation.com

knowledge base of FAQs, technical and application notes, sample code and links to software

service packs, and a MySupport feature that you can customize to make the best use of these

tools.

For an additional level of technical phone support for installation, configuration and

troubleshooting, we offer TechConnect support programs. For more information, contact

your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem within the first 24 hours of installation, please review the

information that's contained in this manual. You can also contact a special Customer Support

number for initial help in getting your product up and running.

, you can find technical manuals, a

United States 1.440.646.3434

Monday – Friday, 8 a.m. – 5 p.m. EST

Outside United

States

Please contact your local Rockwell Automation representative for any

technical support issues.

New Product Satisfaction Return

Rockwell Automation tests all of its products to ensure that they are fully operational when

shipped from the manufacturing facility. However, if your product is not functioning and

needs to be returned, follow these procedures.

United States Contact your distributor. You must provide a Customer Support case number

Outside United

States

Allen-Bradley, Rockwell Automation, FactoryTalk View, PanelView, PanelView Plus, and TechConnect are trademarks of Rockwell

Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

(see phone number above to obtain one) to your distributor to complete the

return process.

Please contact your local Rockwell Automation representative for the return

procedure.

Publication 2711P-IN001I-EN-P - November 2009

Supersedes Publication 2711P-IN001H-EN-P - March 2009 Copyright © 2009 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...