Modbus Applications

For PanelView Plus and

PanelView Plus CE Terminals

2711P

User Manual

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

differences between solid state equipment and hard-wired electromechanical

devices. Because of this difference, and also because of the wide variety of

uses for solid state equipment, all persons responsible for applying this

equipment must satisfy themselves that each intended application of this

equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware

of safety considerations.

) describes some important

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that dangerous voltage may be present.

Labels may be on or inside the equipment, for example, a drive or

motor, to alert people that surfaces may reach dangerous

temperatures.

Table of Contents

Preface

Installing Software

Modbus KEPServer Drivers

Topics Covered. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Software Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Chapter 1

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install RSView Studio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Install KEPServer Enterprise. . . . . . . . . . . . . . . . . . . . . . . . . 10

Firmware Upgrade Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modbus Master/Slave . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modbus (RTU) Serial . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Modbus Unsolicited Serial . . . . . . . . . . . . . . . . . . . . . . . 11

Modbus ASCII. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Modbus/TCP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Modbus Device Model . . . . . . . . . . . . . . . . . . . . . . . . . . 13

MailBox. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Guidelines for Developing Modbus Applications . . . . . . . . . 14

Create a Modbus Application . . . . . . . . . . . . . . . . . . . . . 14

Compile, Download and Run a Modbus application . . . . 14

Configuring KEPServer Drivers for

Modbus

Testing KEPServer

Communications

Making KEPServer Drivers and

Tags Available in RSView Studio

Chapter 3

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Create a Project File . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Select the Default Project File (.pfe) . . . . . . . . . . . . . . . . . . . 16

Configure Drivers for Modbus Protocols. . . . . . . . . . . . . . . . 17

Add a Channel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Add A Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Create Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Chapter 4

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Use the OPC Quick Client . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Chapter 5

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Create an OPC Data Server . . . . . . . . . . . . . . . . . . . . . . . . . 37

Browse KEPServer Tags. . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3 Publication 2711P-UM002B-EN-P - March 2007

4 Table of Contents

Installing KEPServer Drivers on

Terminal

Compiling, Downloading, and

Running Application

Troubleshooting

Chapter 6

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Firmware Upgrade Wizard. . . . . . . . . . . . . . . . . . . . . . . . . . 41

Preparing Terminal for Firmware Upgrade . . . . . . . . . . . 41

Copy FUP Files to Development Computer . . . . . . . . . . . . . 42

Upgrade Firmware using a Compact Flash Card . . . . . . . . . . 42

Upgrade Firmware using a Network (Ethernet) Connection. . 46

Chapter 7

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Compile a Runtime Application File. . . . . . . . . . . . . . . . . . . 53

Download Application to Terminal . . . . . . . . . . . . . . . . . . . 54

Connect Terminal to Modbus Network. . . . . . . . . . . . . . . . . 56

Modbus Serial Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Modbus Ethernet Cables. . . . . . . . . . . . . . . . . . . . . . . . . 57

Run Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 8

Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Common Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Runtime Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Data Types

Modbus/TCP Address Definitions

Modbus ASCII Address Definitions

Modbus Unsolicited Serial

Address Definitions

Appendix A

Appendix B

Output Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Input Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Internal Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Holding Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Mailbox Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Instromet Addressing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Appendix C

Output Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Input Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Internal Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Holding Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Appendix D

Output Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Input Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Internal Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Holding Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Publication 2711P-UM002B-EN-P - March 2007

Modbus (RTU) Serial Address

Definitions

Table of Contents 5

Appendix E

Output Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Input Coils . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Internal Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Holding Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Magnetek Address Descriptions . . . . . . . . . . . . . . . . . . . . . . 81

Elliott Flow Computer Address Descriptions. . . . . . . . . . . . . 82

Omni Address Descriptions . . . . . . . . . . . . . . . . . . . . . . . . . 83

Daniel S500 Address Descriptions . . . . . . . . . . . . . . . . . . . . 88

Index

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . 93

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . 93

New Product Satisfaction Return. . . . . . . . . . . . . . . . . . . 93

Publication 2711P-UM002B-EN-P - March 2007

6 Table of Contents

Publication 2711P-UM002B-EN-P - March 2007

Preface

For communication with controllers, RSView Machine Edition

products are configured with:

• RSLinx Enterprise for most Rockwell Automation networks or

• KEPServer Enterprise for RSView OPC servers.

The KEPServer OPC server expands PLC and device connectivity

options by incorporating 26 communication drivers for the PanelView

Plus and PanelView Plus CE platforms, and over 31 communication

drivers for RSView Machine Edition running on a desktop.

This guide will show you how to configure KEPServer drivers,

specifically Modbus drivers, for RSView ME applications that run on:

• PanelView Plus CE terminals,

• PanelView Plus terminals,

• or the Windows 2000/XP environment.

Using configured KEPServer drivers in your RSView ME application,

the terminals will be able to communicate with devices on a Modbus

network.

Topics Covered

•

Chapter 1 Installing Software - Covers software installation for

RSView Studio, RSView Enterprise, KEPServer Enterprise and the

Firmware Upgrade Wizard.

• Chapter 2 Overview of Modbus Protocols - Gives an overview of

Modbus Master/Slave Protocol and each of the KEPServer

drivers for Modbus communication protocols.

• Chapter 3 Configuring KEPServer Drivers for Modbus - Shows

how to use KEPServer Enterprise software to configure

KEPServer drivers for Modbus protocols. For each driver, you

will create a channel, add a device, and create tags. The driver is

saved to a .pfe project file that you will set as the default project.

•

Chapter 4 Testing KEPServer Communications - Shows how to

use the OPC Quick Client to test KEPServer communications for

the driver and tags created in Chapter 3.

•

Chapter 5 Making KEPServer Driver and Tags Available in

RSView Studio - Shows how to create an OPC data server in

RSView Enterprise or RSView Studio. This server will allow you

to access the KEPServer driver and tags from your RSView ME

application.

• Chapter 6 Installing KEPServer Drivers on Terminal - Shows how

to use the Firmware Upgrade Wizard to install KEPServer drivers

on PanelView Plus/PanelView Plus CE terminals.

7 Publication 2711P-UM002B-EN-P - March 2007

8

•

Chapter 7 Compiling, Downloading, and Running Application -

Shows how to compile a runtime .mer file, connect your

PanelView Plus/PanelView Plus CE terminal to a Modbus

network, download the .mer file to the terminal, and run the

application.

• Chapter 8 Troubleshooting - Covers common error types that

occur during runtime and how you can correct these errors.

Software Requirements

Additional Resources

The following software must be installed on the development

desktop:

• RSView Studio 3.0, or later

• KEPServer Enterprise software

• Firmware Upgrade Wizard

You might want to consult the following sources for additional

information:

• KEPServer Enterprise Software online help

• RSView Enterprise or RSView Studio online help

• PanelView Plus User Manual, publication no. 2711P-UM001

An electronic version of the PanelView Plus user manual is

available at:

http://literature.rockwellautomation.com

Publication 2711P-UM002B-EN-P - March 2007

Installing Software

Chapter

1

Objectives

Install RSView Studio

To develop RSView ME applications, configure KEPServer drivers, and

use these drivers with applications that run on PanelView

Plus/PanelView Plus CE terminals, the following software must be

loaded on your development computer:

• RSView Studio for ME or RSView Enterprise

• KEPServer Enterprise

• Firmware Upgrade Wizard

Refer to the installation information provided with RSView Studio and

KEPServer Enterprise for the latest details on installation requirements.

RSView Studio Enterprise or RSView Studio for Machine Edition

software is installed from:

• a CD or

• downloaded from the Rockwell Software website at

www.software.rockwell.com.

IMPORTANT

A current registered serial number is required to download

software from the Rockwell Software website.

The installation menu with instructions will appear when inserting the

CD into a computer or you can run setup.exe from the root directory.

9 Publication 2711P-UM002B-EN-P - March 2007

10 Installing Software

Install KEPServer Enterprise

KEPServer Enterprise is used to:

• configure the KEPServer driver

• create tags

• test communications on the desktop.

KEPServer Enterprise is included with RSView Studio and can be

installed from:

• a CD or

• downloaded from the Rockwell Software web site at

www.software.rockwell.com.

KEPServer runs as a service and an icon will display in the toolbar.

IMPORTANT

The software can be installed by running the setup.exe file from the

CD or downloaded version.

IMPORTANT

A current registered serial number is required to download

software from the Rockwell Software website.

When installing KEPServer Enterprise, be sure to select the

Modbus drivers if you are not doing a full install.

Firmware Upgrade Wizard

The Firmware Upgrade Wizard is used to install KEPServer drivers and

upgrade firmware in the following devices:

• PanelView Plus

• PanelView Plus CE

The Firmware Upgrade Wizard is installed automatically with RSView

Studio.

The Firmware Upgrade (FUP) files with the KEPServer drivers is

available at http://support.rockwellautomation.com under

Downloads.

Publication 2711P-UM002B-EN-P - March 2007

Modbus KEPServer Drivers

Chapter

2

Objectives

Modbus Master/Slave

This chapter provides an overview of MODBUS KEPServer drivers

available in the RSView Enterprise software.

• Modbus Master/Slave

– Modbus (RTU) Serial

– Modbus Unsolicited Serial

• Modbus ASCII

• Modbus/TCP

A Modbus master/slave network provides a protocol for data transfer

and programming with a single RTU master and up to 247 slave

devices. A Modbus network links distributed devices with a central

computer terminal or controller for supervisory control and data

acquisition. Up to 247 nodes can be connected at data rates of up to

19,200 baud using media such as twisted pair cable, common carrier

phone lines, or microwave transmission. This network is commonly

used in SCADA application over large areas such as the water/waste

water and oil & gas industries.

Modbus (RTU) Serial

Modbus (RTU) Serial is the protocol for a master and includes RTS

support for radio modems. Supported devices include:

• Modbus compatible devices

• Elliott Flow Computer

• Magnetek GPD 515 Drive

• Omni Flow Computer

• Daniel S500 Flow Computer

• Dynamic Fluid Meter (DFM) SFC3

• Instromet

Modbus Unsolicited Serial

Modbus Unsolicited Serial simulates up to 247 Modbus slave devices.

Supported devices include Modbus compatible devices.

11 Publication 2711P-UM002B-EN-P - March 2007

12 Modbus KEPServer Drivers

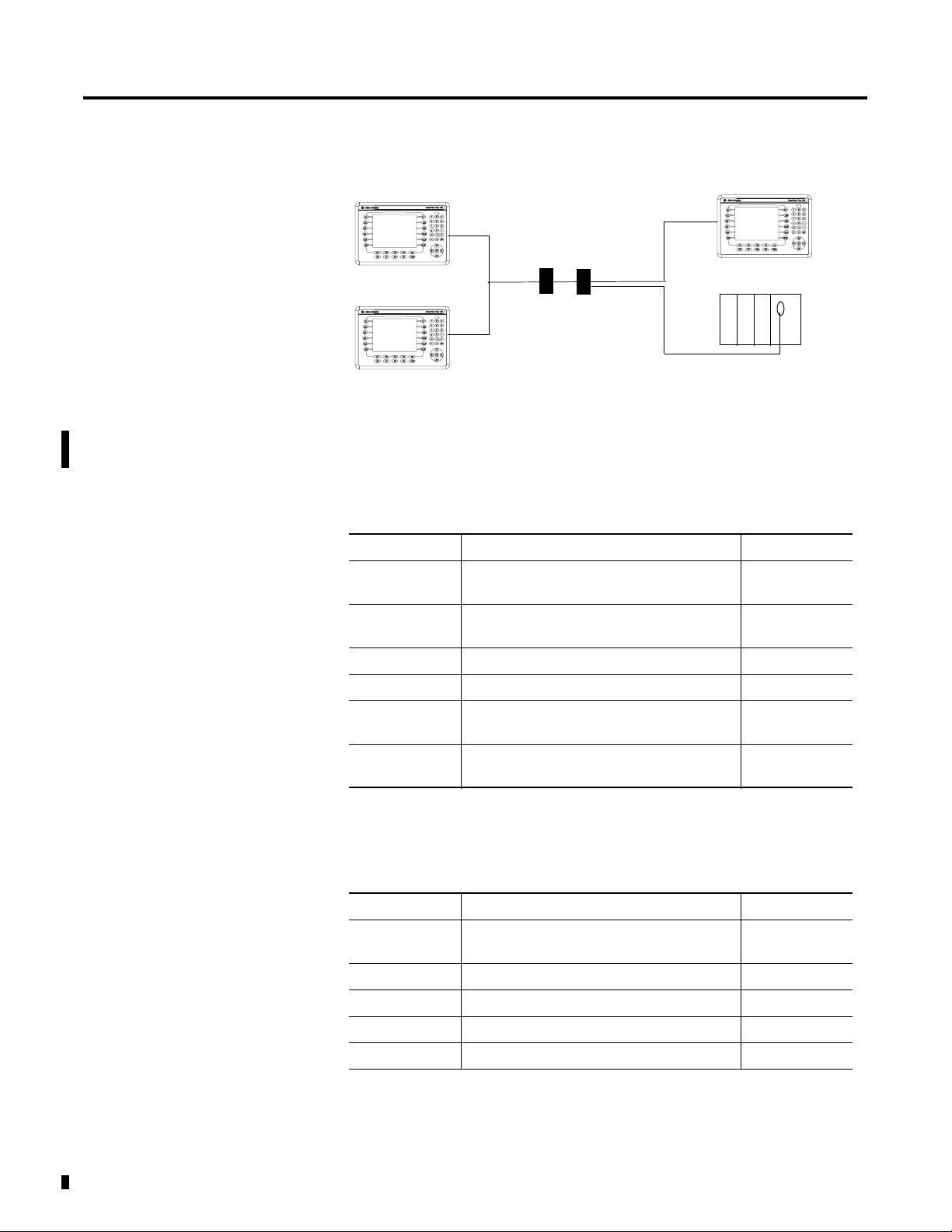

Modbus Master/Slave Networks

See Chapter 7 for cable information.

Direct Connection

PanelView Plus

(Modbus Serial or

Unsolicited Serial Driver)

RS-232/RS-485 Converter

(1)

1761-NET-AIC or Comparable Device

Master/Slave Network (Multiple Slave Terminals Connect to one Master Controller)

(3) PanelView Plus Slave Devices

Each uses Modbus Unsolicited Serial Driver

Controller (Master or Slave)

(1)

PanelView Plus

RS-232/RS-485

Converters

PanelView Plus

RS-232/RS-485

Converters

Modem Connection

PanelView Plus

PanelView Plus

RS-232/RS-485

Converters

(1) PanelView Plus Master Device

Uses the Modbus Serial Driver

Modbus Device

RS-232/RS-485

Converters

(2) PanelView Plus Slave Devices Modbus

Each uses the Modbus Unsolicited Serial Driver

PanelView Plus

Modbus Device

RS-232/RS-485

Converters

Master Controller

Master Controller

Modbus Device

Publication 2711P-UM002B-EN-P - March 2007

PanelView Plus

Modems

Modbus KEPServer Drivers 13

Modbus ASCII

Modbus/TCP

Modbus ASCII protocol is typically used to connect to other ASCII

devices that support the Modbus ASCII protocol. KEPServer support

includes:

• Modbus ASCII compatible devices

• Flow Computers using Daniels/Omni/Elliott register addressing

Modbus/TCP is a Modbus messaging protocol over Ethernet TCP/IP

and is intended for supervision and control of automation equipment.

The most common use of this protocol is for Ethernet attachment of

PLCs, I/O modules, and gateways to other simple field buses or I/O

networks.

The Modbus/TCP KEPServer driver supports Modbus and Mailbox

device models.

Modbus Device Model

The most common Modbus device model is where the driver connects

to physical devices (e.g. Modicon TSX Quantum, other Modbus Open

Ethernet compatible devices) and acts as a device on the network

with a device ID equivalent to the machine's IP address. The driver

accepts any unsolicited commands it receives and attempts to process

them as if it were another PLC.

MailBox

The Mailbox model determines the manner unsolicited requests are

handled. By defining a mailbox device, the driver does not act like a

PLC on the network (as described above). Instead, it acts as a storage

area for each and every mailbox device defined. When the driver

receives an unsolicited command, the driver detects the IP address the

message came from and places the data in the storage area allocated

for the device. If the message comes from a device with an IP address

that has not been defined as a mailbox device, the message is not

processed. Any client application that reads/writes to this type of

device, reads/writes to the storage area contained in the driver, not

the physical device.

Publication 2711P-UM002B-EN-P - March 2007

14 Modbus KEPServer Drivers

Refer to the MSTR instruction in your Modicon documentation for

details on sending unsolicited requests to the Modbus Ethernet driver.

PanelView Plus

PanelView Plus

Ethernet

Switch

Ethernet

Switch

PanelView Plus

Master Controller

Guidelines for Developing Modbus Applications

The section provides general guidelines for creating and running

Modbus applications on PanelView Plus/PanelView Plus CE terminals.

Create a Modbus Application

General Steps Description Reference

Step 1 Create a .pfe project file in KEPServer

Enterprise.

Step 2 Configure a KEPServer Modbus Driver. Add a

channel and device to the project file.

Step 3 Enter application tags. Chapter 3

Step 4 Set your .pfe file as the default project file. Chapter 3

Step 5 Test KEPServer communications to verify your

project file and tags.

Step 6 Create an OPC Data Server to make your tags

available in RSView Studio.

Chapter 3

Chapter 3

Chapter 4

Chapter 5

Compile, Download and Run a Modbus application

Publication 2711P-UM002B-EN-P - March 2007

General Steps Description Reference

Step 1 Create a firmware upgrade card that contains

the KEPWare driver and upgrade the terminal.

Step 2 Compile the RSView .mer application. Chapter 7

Step 3 Download the .mer runtime file to terminal. Chapter 7

Step 4 Connect the terminal to the Modbus network. Chapter 7

Step 5 Run the application. Chapter 7

Chapter 6

Chapter

Configuring KEPServer Drivers for Modbus

3

Objectives

Create a Project File

This chapter shows how to use KEPServer Enterprise software to

configure KEPServer drivers for Modbus protocols including Ethernet

TCP/IP, RTU Serial, Unsolicited Serial, and ASCII Serial. You will:

• create a project (.pfe) for the drivers

• set the project file as the default project

For each Modbus driver in your project file, you will:

• add a channel

• add a device (or controller)

• create tags

The first thing you need to do is create a project file.

1. Double-click the KEPServer Enterprise icon in the Systray to

open the default project window below.

15 Publication 2711P-UM002B-EN-P - March 2007

16 Configuring KEPServer Drivers for Modbus

2. Create a new KEPServer project (.pfe) file. From the menu,

select File>Save As and save the project as a .pfe file.

Select the Default Project File (.pfe)

The steps in this section ensure that the correct project file is used in

your RSView Studio application.

When RSView Studio creates a runtime application and the application

contains the KEPware OPC server, RSView Studio will merge the

KEPware project file (.pfe) into the runtime file (.mer). The project file

that RSView Studio uses is defined by the Default project field in the

General tab of the Tools>Options menu in KEPware Server

Enterprise.

TIP

1. From the Menu bar, select Tools>Options…

This may not be the current configuration running in

KEPware Server Enterprise. If you are testing the

application on a PC, make sure the project name in

the title bar of KEPware Server Enterprise matches

the Project default field.

Publication 2711P-UM002B-EN-P - March 2007

2. On the General tab, click the button next to the Default

project textbox.

3. Select the desired .pfe file and click the button.

Configuring KEPServer Drivers for Modbus 17

You should now see the following:

4. Click the button and OK to accept the new project as

the default.

Configure Drivers for Modbus Protocols

TIP

This section shows how to configure KEPServer drivers that will allow

a PanelView Plus/PanelView Plus CE terminal to communicate on a

Modbus network.

The KEPServer configuration is not archived with the

RSView Studio application backup (.apa) file. If you

need to reuse the project configuration file on

another computer, copy the .pfe file.

Add a Channel

The first step in communicating to any device using the KEPServer

software is to create a channel. A channel describes the protocol and

driver properties used for communication. While a single channel can

be used to communicate to multiple devices, separate channels must

be defined for each unique driver to be used. Only one project

configuration file can run at a time, but it may contain multiple

channels and devices.

Step 1 - Add a New Channel

Click on the New Channel icon or right-click anywhere in the left

pane. This will bring up the new channel wizard.

Step 2 - Enter a Channel Name

Enter a unique name for the channel.

Publication 2711P-UM002B-EN-P - March 2007

18 Configuring KEPServer Drivers for Modbus

Step 3 -Select a Device Driver

Select a driver from the drop down list. The table below lists the

correct driver for each Modbus protocol.

For this Protocol: Select this Driver:

Modbus/TCP Modbus Ethernet

Modbus RTU Serial (Master) Modbus Serial

Modbus Unsolicited Serial (Slave) Modbus Unsolicited Serial

Modbus ASCII Modbus ASCII Serial

Step 4 - Select a Network Adapter (for Modbus/TCP only)

The Network Adapter selection left allows you to select a specific NIC

card based on either the NIC name or its currently assigned IP

address. The list of available NICs will include either unique NIC cards

or NICs that have multiple IP addresses assigned to them.

Additionally, the selection will display any WAN connections you may

have active such as a dialup connection.

For PanelView Plus/PanelView Plus CE, select Default and click Next.

Step 5 - Enter Communication Settings (doesn’t apply to Modbus/TCP)

In the New Channel - Communications dialog, make sure the Modicon

controller configuration settings match those in slave controllers or

devices.

Parameter Selections Recommended

Data Bits 5, 6, 7, 8 8

Stop Bits 1, 2 1

Parity None, Even, Odd Even

Baud 300 to 256000 9600 or 19200

Publication 2711P-UM002B-EN-P - March 2007

Modbus RTU Serial

Modbus Unsolicited Serial

Configuring KEPServer Drivers for Modbus 19

Publication 2711P-UM002B-EN-P - March 2007

20 Configuring KEPServer Drivers for Modbus

Modbus ASCII

Step 6 - Set the Optimization Method for Data Requests

The New Channel - Write Optimization dialog sets the optimization

method for data requests. Select the best optimization for your

application and click Next.

For more information on KEPServer read and write optimization

options refer to the online Driver help.

Applies to all Modbus protocols

Publication 2711P-UM002B-EN-P - March 2007

Configuring KEPServer Drivers for Modbus 21

Step 7 -Select Socket Usage (Applies to Modbus/TCP only)

The New Channel - Socket Usage dialog controls how the Modbus

Ethernet driver will utilize Windows sockets when establishing a

connection to the target device. For a normal Modbus Ethernet

enabled device, the default Use Multiple Sockets for device

connection (checked) mode of operation is designed to give the best

performance from the driver.

Normally, the Modbus Ethernet driver will use a Windows socket for

each device on the network. When using a new socket connection for

each device, the Modbus Ethernet driver maintains that socket as an

active connection. Normally this provides a very high level of

performance since the driver does not need to reestablish a

connection each time it needs to read or write data to a given device.

For more information on using Sockets in a Modbus RTU bridge

application, refer to the online help.

Click Next.

Publication 2711P-UM002B-EN-P - March 2007

22 Configuring KEPServer Drivers for Modbus

Step 8 - View and Verify Channel Summary

The New Channel - Summary dialog provides a summary of the new

channel settings. Verify the settings below and click Finish.

Modbus/TCP

Modbus RTU Serial

Publication 2711P-UM002B-EN-P - March 2007

Modbus Unsolicited Serial

Modbus ASCII Serial

Configuring KEPServer Drivers for Modbus 23

TIP

The red X next to the channel name will disappear

when a destination device is added under this driver.

Step 9 - Save Project File

From the Menu bar, select File>Save or click the Save button.

Publication 2711P-UM002B-EN-P - March 2007

24 Configuring KEPServer Drivers for Modbus

Add A Device

Now that a new channel is defined, you need to add a new device to

the channel. In most cases, selecting the default settings will allow

you to quickly configure and connect to a device.

Step 1 - Add a Device

Add a device by clicking on the Click to add a device hypertext or the

New Device icon. This will bring up the new device wizard. Here

you’ll add the information pertinent to the controller that you are

going to communicate with.

Step 2 - Enter a Device Name

In the New Device - Name dialog, enter a device name that will help

you identify the device later and click Next. In most cases, the device

will be a logic controller.

Step 3 - Select a Device Model

If the device you are defining supports more than one model, select a

model that best describes the device.

For this Protocol: Most Common Model:

MODBIS/TCP Modbus

Modbus RTU Serial Modbus

Modbus Unsolicited Serial N/A

Modbus ASCII Modbus ASCII

Publication 2711P-UM002B-EN-P - March 2007

Configuring KEPServer Drivers for Modbus 25

Step 4 - Select a Device ID

The device you are defining may be multidropped as part of a

network of devices. To communicate with the device, it must be

assigned a unique ID.

In the New Device - ID dialog, enter a unique Device ID (decimal

address) to identify the controller on the network. Enter the Device ID

and click Next.

For this Protocol: Device ID Range Data Format

Modbus/TCP

ModbusModbus RTU Serial 0 - 255 Decimal

Modbus Unsolicited Serial 1 - 247 Decimal

Modbus ASCII 1 - 247 Decimal

(1)

For master/slave communications, add a fifth octet to the IP address. Refer to your KEPWare

documentation for more details on Modbus/TCP master/slave communications.

(1)

xxx.xxx.xxx.xxx IP Address

Step 5 - Enter Device Communication Parameters

(Doesn’t apply to Modbus Unsolicited Serial Protocol)

In the New Device - Communication Parameters dialog, accept the

default communication parameters by clicking Next.

Publication 2711P-UM002B-EN-P - March 2007

26 Configuring KEPServer Drivers for Modbus

Step 6 - Configure Tag Database Options

(Doesn’t apply to Unsolicited Serial or ASCII Protocols)

In the New Device - Database Creation dialog, click Next to accept

the default tag database configuration options.

The automatic OPC tag database generation features of the server

have been designed to make the setup of your OPC application a Plug

and Play operation. For communication drivers that support this

feature, you can configure them to automatically build a list of OPC

tags within the server that correspond to device specific data. The

automatically generated OPC tags can then be browsed from your

OPC client.

Publication 2711P-UM002B-EN-P - March 2007

Configuring KEPServer Drivers for Modbus 27

Step 7 - Enter Device Settings

In the New Device - Settings dialog, accept the default settings by

clicking Next

Modbus/TCP

Modbus RTU Serial

Publication 2711P-UM002B-EN-P - March 2007

28 Configuring KEPServer Drivers for Modbus

Modbus Unsolicited Serial and Modbus ASCII

Step 8 - Set the Block Size for Reading Data from Device

(Doesn’t apply to Unsolicited Serial Protocol)

The New Device - Block Sizes dialog sets the largest block size for

reading I/O (coils) and data tables (Registers). Click Next.

Modbus/TCP, Modbus RTU Serial, Modbus ASCII

Publication 2711P-UM002B-EN-P - March 2007

Loading...

Loading...