Page 1

Allen-Bradley

PanelBuilder1400e

Configuration

Modbus

Software for

Windows

(Cat. No. 2711E–UMOD)

User

Manual

1

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PanelBuilder, PanelView, Data Highway Plus, ControlNet, DH+, and SLC are trademarks, and

PLC, PLC-2, and PLC-3 are registered trademarks of Allen-Bradley Company, Inc.

RSView is a trademark of Rockwell Software, Inc.

IBM, PC, PS/2, VGA, and PC-DOS are registered trademarks of International Business Machines

Corporation.

Epson is a registered trademark of Seiko Epson Corporation.

Microsoft, Windows, MS, and MS-DOS are registered trademarks of Microsoft Corporation.

Mouse Systems is a trademark of MSC Technologies, Inc.

AutoCAD is a registered trademark of Autodesk, Inc.

Taylor, and ProWORXPLUS are registered trademarks of Taylor Industrial Software, Inc.

MODICON, MODSOFT, Quantum, and Modbus are registered trademarks of

AEG Schneider Automation, Inc.

All other brand and product names are trademarks of their respective companies

and are hereby acknowledged.

Page 3

Preface

About this Manual P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Registering Your Copy of PanelBuilder 1400e P–1. . . . . . . . . . . . . . . .

Other Documentation P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What’s in This Manual? P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Who Should Read This Manual P–3. . . . . . . . . . . . . . . . . . . . . . . . .

Terminology P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions Used P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mouse Conventions P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection Conventions P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selection Conventions in Dialog Boxes P–5. . . . . . . . . . . . . . . . .

Key Conventions P–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Command Conventions P–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin P–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supported Devices P–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support Services P–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of PanelBuilder 1400e with Modbus Connectivity

Planning an Application for Modbus

Basic Application Operations

Chapter 1

About PanelBuilder 1400e 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder , PanelView Terminals, and the Controller or Other Modbus

Slave Device 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder 1400e 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Operator Terminals 1–2. . . . . . . . . . . . . . . . . . . . . . . . .

The Controller or Other Modbus Slave Device 1–5. . . . . . . . . . . . . .

Understanding the Modbus Network 1–5. . . . . . . . . . . . . . . . . . . . .

Chapter 2

Defining Nodes and Scan Classes 2–1. . . . . . . . . . . . . . . . . . . . . . . .

Defining the Nodes 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recording Node Information 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

About Scanning 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recording Tag Information 2–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Creating a New Application 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Reports 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Additional Report on Options 3–2. . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-6.12 – November 1997

Page 4

Table of Contentstoc–ii

Defining Communications

Changing the Network Type

Defining Tags

Chapter 4

Configuring Communications 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up Terminal Communications 4–2. . . . . . . . . . . . . . . . . . . . .

Setting the Driver Parameters 4–2. . . . . . . . . . . . . . . . . . . . . . . .

Configuring Nodes 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Scan Classes 4–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Converting from DH+ to Modbus 5–1. . . . . . . . . . . . . . . . . . . . . . . . . .

Converting from Remote I/O to Modbus 5–2. . . . . . . . . . . . . . . . . . . . .

Converting from ControlNet to Modbus 5–4. . . . . . . . . . . . . . . . . . . . .

Converting from Modbus to DH+ 5–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Converting from Modbus to Remote I/O 5–6. . . . . . . . . . . . . . . . . . . . .

Converting from Modbus to ControlNet 5–7. . . . . . . . . . . . . . . . . . . . .

Chapter 6

Tag Types 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Read and Write Tags 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Sources 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Tag Type 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring an Analog Tag 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Address Space 6–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Syntax 6–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Digital Tag 6–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Syntax 6–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a String Tag 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Syntax 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring a Block Tag 6–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Addressing Syntax 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying a Data Source 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Data Source 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Validation 6–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifying Device as the Data Source 6–16. . . . . . . . . . . . . . . . . . . .

Tag Database Import and Export 6–17. . . . . . . . . . . . . . . . . . . . . . . . . .

Database Formats Supported 6–17. . . . . . . . . . . . . . . . . . . . . . . . . .

CSV File Column Ordering 6–23. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a New Tag Database 6–24. . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711E-6.12 – November 1997

Page 5

Table of Contents toc–iii

Configuring the PanelView Terminal for Modbus Communications

Transferring Applications

Troubleshooting for Modbus Applications

Sample Worksheets

Chapter 7

Configuring the Modbus Communication Interface Card 7–1. . . . . . . . .

Installing Modbus Firmware in the PanelView Terminal 7–3. . . . . . . . . .

Configuring the Terminal Network Setup Screen 7–5. . . . . . . . . . . . . . .

Chapter 8

V alidating Applications 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Application File Transfers and Modbus 8–1. . . . . . . . . . . . . . . . .

Chapter 9

Modbus Communication Errors 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Index

Publication 2711E-6.12 – November 1997

Page 6

About this Manual

Registering Your Copy of PanelBuilder 1400e

Other Documentation

"

This manual is designed to supplement the regular set of

PanelBuilder and PanelView manuals, listed under “Other

Documentation,” below. This manual contains information specific

to creating PanelBuilder applications for Modbus, and running them

on PanelView 1000e and 1400e terminals equipped with

Modbus-capable hardware and software.

Note: PanelView 1200 and 1200e terminals do not support Modbus

communications.

To register your software, mail the registration card to this address:

Rockwell Software

Software Services

6680 Beta Drive

Mayfield Village, Ohio 44143

or fax the card to (216) 646-7701.

Your PanelBuilder 1400e software comes with the following

manuals, which you may need to refer to periodically while reading

this manual:

• Getting Started with PanelBuilder 1400e Configuration Software

for Windows (Publication Number 2711E-818) guides you

through setting up PanelBuilder 1400e and introduces you to

PanelBuilder 1400e basics. It includes a tutorial to give you

hands-on experience in creating and running a sample

application.

• The PanelBuilder 1400e Configuration Software for Windows

User Manual (Publication Number 2711E-819) explains

PanelBuilder 1400e in more detail, and provides step-by-step

instructions for planning, creating, and working with applications.

• The PanelBuilder 1400e Screen Objects Reference Manual

(Publication Number 2711E-820) provides detailed reference

information for application screen objects.

• The PanelBuilder 1200/1400e Transfer Utility User Manual

(Publication Number 2711E-6.8) provides detailed instructions

for transferring application files using the Transfer Utility that

comes with PanelBuilder 1400e, Version 3.

Publication 2711E-6.12 – November 1997

Page 7

PrefaceP–2

• Context-sensitive Help provides a quick reference for any

procedures or commands you need explained, or problems you

may encounter. To get help, press F1 or choose the Help button if

you’re in a dialog box.

• The PanelBuilder 1400e Readme file is a Microsoft Windows

Notepad file that is copied to your hard disk when you install

PanelBuilder 1400e. The Readme file informs you of any

software changes after the manuals were printed.

• The PanelView 1000e, 1200e, and 1400e Operator Terminals

User Manual (Publication Number 2711E-821) describes how to

install, configure, maintain, and troubleshoot the PanelView

terminal.

A complete list of publications relating to PanelBuilder 1400e,

PanelView terminals, and programmable logic controllers is

available in the preface of the PanelBuilder 1400e User Manual.

What’s in This Manual?

This manual provides information which is specific to creating

Modbus applications with PanelBuilder, and running them at the

PanelView terminal.

Chapter 1, Overview of PanelBuilder 1400e with Modbus

Connectivity, provides an introduction to what PanelBuilder 1400e

is, what it does, and how it works with PanelView terminals and the

programmable logic controller.

Chapter 2, Planning an Application for Modbus, provides

information about planning a Modbus application, including defining

nodes. It is a supplement to Chapter 2, “Planning Applications,” in

the PanelBuilder 1400e Configuration Software for Windows User

Manual, publication 2711E-819, which provides details about

assigning scan classes and assigning tags.

Chapter 3, Basic Application Operations, describes basic application

operations for the Modbus network, and supplements the information

in the PanelBuilder 1400e Configuration Software for Windows User

Manual, publication 2711E-819.

Chapter 4, Defining Communications, provides instructions for

defining PLC communications for Modbus applications, including

selecting the controller, and defining nodes and scan classes. This

chapter supplements information in the PanelBuilder 1400e

Configuration Software for Windows User Manual, publication

2711E-819.

Publication 2711E-6.12 – November 1997

Chapter 5, Changing the Network Type, describes how to convert an

application from one network type to another.

Page 8

Preface P–3

Chapter 6, Defining Tags, provides information about using the Tag

Database editor to define tags. This chapter supplements information

in the PanelBuilder 1400e Configuration Software for Windows User

Manual, publication 2711E-819.

Chapter 7, Configuring the PanelView Terminal for Modbus

Communications, provides instructions for configuring the firmware

in PanelView terminals for use with the Modbus network. This

chapter supplements information in the PanelView 1000e, 1200e,

and 1400e Operator Terminals User Manual, publication

2711E-821.

Chapter 8, Transferring Applications, provides information to get

you started on validating and transferring applications.

Chapter 9, Troubleshooting for Modbus Applications, lists the

Modbus error messages that could occur and their causes, and

provides possible solutions to the problems.

Who Should Read This Manual

This manual is designed for the novice or experienced user of

PanelBuilder. It does require that you have knowledge of the

Modbus Communications Protocol.

If this describes you: Read this:

Want information about installing PanelBuilder

Unfamiliar with both PanelBuilder 1400e and Windows Getting Started, Chapters

Familiar with PanelBuilder 1400e and want to know about

writing applications for Modbus using PanelBuilder

Want information about the PanelBuilder Drawing Objects Reference Manual

Want information about validating PanelBuilder

applications, including those for Modbus

Want information about transferring applications to and

from PanelView terminals

Getting Started, Chapter 2

1–3

Windows User

Documentation

This manual

User Manual, Appendix D

Transfer Utility User Manual

and Operator Terminals

User Manual

Publication 2711E-6.12 – November 1997

Page 9

PrefaceP–4

Terminology

Conventions Used

"

The term PanelBuilder refers to PanelBuilder 1400e Configuration

Software for Windows. Where confusion may arise between the

current and previous versions of the software, the current release of

the software is “PanelBuilder 1400e, Version 3.”

Similarly, the terms terminal and PanelView terminal refer to a

PanelView 1000e or 1400e terminal. Where confusion may arise

between the 1000e and 1400e terminals and previous revisions,

specific series and revision names will be used.

Note: PanelView 1200 and 1200e terminals do not support Modbus

communications.

The terms programmable controller and controller refer to the

Modicon line of Programmable Logic Controllers or any other

controlling device.

Information is provided in a consistent way throughout the entire

PanelBuilder user documentation set. There are mouse selection,

shortcut key, and command conventions.

Mouse Conventions

You can use a mouse with one or two buttons. This manual assumes

that if you have a multiple-button mouse, the left mouse button is

configured as the primary mouse button. Procedures that require you

to click a secondary button refer to it as the right mouse button.

Selection Conventions

This word or phrase Means

Choose

Choose OK Either click on the OK button with the mouse or press Enter

Select Either highlight the piece of text you want your next action to

Click Position the mouse pointer on the object, area, or field, and

Double-click Position the mouse pointer on the object, area, or field, and

Carry out a menu command or a command button in a dialog

box or Help window. Choose also means to double-click an

icon.

on the keyboard to carry out the action.

affect, or select a specific dialog box option.

click the left button once.

click twice quickly.

Publication 2711E-6.12 – November 1997

Page 10

Preface P–5

Selection Conventions in Dialog Boxes

Dialog boxes contain standard Windows fields that require different

selection conventions. Refer to your Windows user documentation

for information on the selection conventions.

The following shortcut keys allow you to complete dialog boxes

faster:

This key or key

combination

Tab

Shift+Tab Moves the cursor to the previous field, option, or command

Alt+underlined letter Selects an option, or displays a drop-down list.

Alt+ Displays a drop-down list.

Spacebar Turns check boxes on or off.

Does this

Moves the cursor to the next field, option, or command

button.

button.

Key Conventions

This key combination Means

Key1+Key2

Shift+click Press and hold the Shift key while you click an object with

Press and hold the first key while you press the second

key. For example, press “Ctrl+A” means to press the Ctrl

key, and while pressing it, press the A key. Then release

both keys.

the pointer.

Command Conventions

Following are three methods for carrying out commands.

Instructions in this manual don’t always outline each method.

• choosing a menu command

• choosing an icon on the toolbar

• using a key combination

For example:

Use any of these commands to open an application:

Choose “Open Application” in the File menu.

Choose from the toolbar.

Press Ctrl+O.

Publication 2711E-6.12 – November 1997

Page 11

PrefaceP–6

Before You Begin

Supported Devices

Before you begin, you should already have installed and know how

to operate this equipment and software:

• a personal computer with at least a 486, 25-MHz microprocessor

and at least 8 MB Random Access Memory (RAM) (16 MB

recommended), and SVGA monitor with 256 colors

(recommended). For users working with imported .dxf files, at

least 16 MB RAM is required.

If you want to resize graphic images in PanelBuilder, set your

display adapter to 65,536 colors.

• Microsoft Windows 3.1 operating system and above, or

Windows 95

• the family of programmable logic controllers you’ll be

monitoring and controlling

PanelView terminals have been tested and verified to work with the

following Modbus-capable devices:

• Quantum 140 CPU 113 02

• Quantum 140 CPU 113 03

• Compact PC-A984-145

• Modicon 984X

• BM85 Bridge Multiplexer

• LD485A-MP line driver

Technical Support Services

The PanelView terminal is always a master device on the Modbus

network, never a slave.

If you have questions about PanelBuilder, please consult the manuals

or Help first. If you can’t find the answer, take advantage of our

Technical Support Fax Back system, available 24 hours a day, 7 days

a week at 1-216-646-5436, or browse through our technical support

document library at http://www.ab.com/mem/prodserv/services/

technotes/techmain.html on the World Wide Web.

Alternatively, contact:

Allen-Bradley

Technical Support

1 Allen Bradley Drive

Mayfield Heights, Ohio 44124-6118

or call 1-216-646-6800 or fax 1-216-646-6890 for technical support

between the hours of 8

AM and 5 PM (EST), Monday to Friday.

Publication 2711E-6.12 – November 1997

Page 12

Preface P–7

Please have the serial number for your software ready when you call,

or include it on your fax. You can find this number in three places:

• on the Software Registration card that was shipped with your

software

• on the screen that appears when you start up PanelBuilder

• in the main Help menu, when you choose “About”

If you have questions about your Modbus controller or device,

contact the manufacturer directly.

Publication 2711E-6.12 – November 1997

Page 13

Overview of

PanelBuilder 1400e with

Modbus Connectivity

This chapter provides an overview of PanelBuilder 1400e. It

describes these topics:

• what PanelBuilder is

• how PanelBuilder interacts with the PanelView terminal and the

controller or other Modbus slave device

• important new PanelBuilder features

About PanelBuilder 1400e

PanelBuilder, PanelView Terminals, and the Controller or Other Modbus Slave Device

PanelBuilder 1400e is a software package that runs under Microsoft

Windows 3.1 and Windows 95. With it you create and design control

panel applications for PanelView operator terminals.

As human-machine interfaces, these control panel applications

enable an operator to monitor and control automated plant processes.

Important: To create applications for Modbus networks, you need

PanelBuilder Version 3 or later.

The relationship between PanelBuilder, the PanelView terminal, and

the controller or other Modbus slave device is as follows:

• PanelBuilder—The Modbus application is created in

PanelBuilder on the personal computer, and downloaded to the

PanelView terminal.

• Controller or other Modbus slave device—When

communicating over a Modbus network, the controller or other

Modbus slave device can respond to queries from the PanelView

terminal and other input or output devices.

• PanelView terminal—The PanelView terminal displays the

process status information sent from the controller. This enables

the operator to make decisions about the process. The operator

provides input back to the controller. The PanelView terminal is a

master on the Modbus network, never a slave. In addition:

• the PanelView 1200/1400e Transfer Utility is used to transfer

Modbus applications from the development computer to the

terminal.

• the PanelView Serial Firmware Upgrade Utility is used to

install or upgrade firmware in the PanelView terminal. You

need to install Modbus-capable firmware in all PanelView

terminals you intend to connect to the Modbus network.

Publication 2711E-6.12 – November 1997

Page 14

1–2 Overview of PanelBuilder 1400e with Modbus Connectivity

"

Note: The development computer doesn’t need to be connected to

the controller or the PanelView terminal to run the process. It must

be connected only when you’re installing or upgrading firmware in

the PanelView terminal, using the PanelView Serial Firmware

Upgrade Utility, or when downloading or uploading the application

serially. To upload or download the application you can also install

the PanelView 1200/1400e Transfer Utility on a portable computer,

transfer the application to the portable computer, and then upload or

download it from the portable computer. See the PanelView

1200/1400e Transfer Utility User Manual for details. For

information about installing or upgrading the terminal’s firmware,

see Chapter 7, “Configuring the PanelView Terminal for Modbus

Communications,” in this manual, or see the Readme file on the

PanelView Serial Firmware Upgrade Utility diskette.

PanelBuilder 1400e

PanelBuilder is the development software package you use to create

and configure control panel application screens. Applications

developed with PanelBuilder software on a personal computer are

downloaded to PanelView terminals, where they are run.

PanelBuilder

1400e Software

Development

Computer

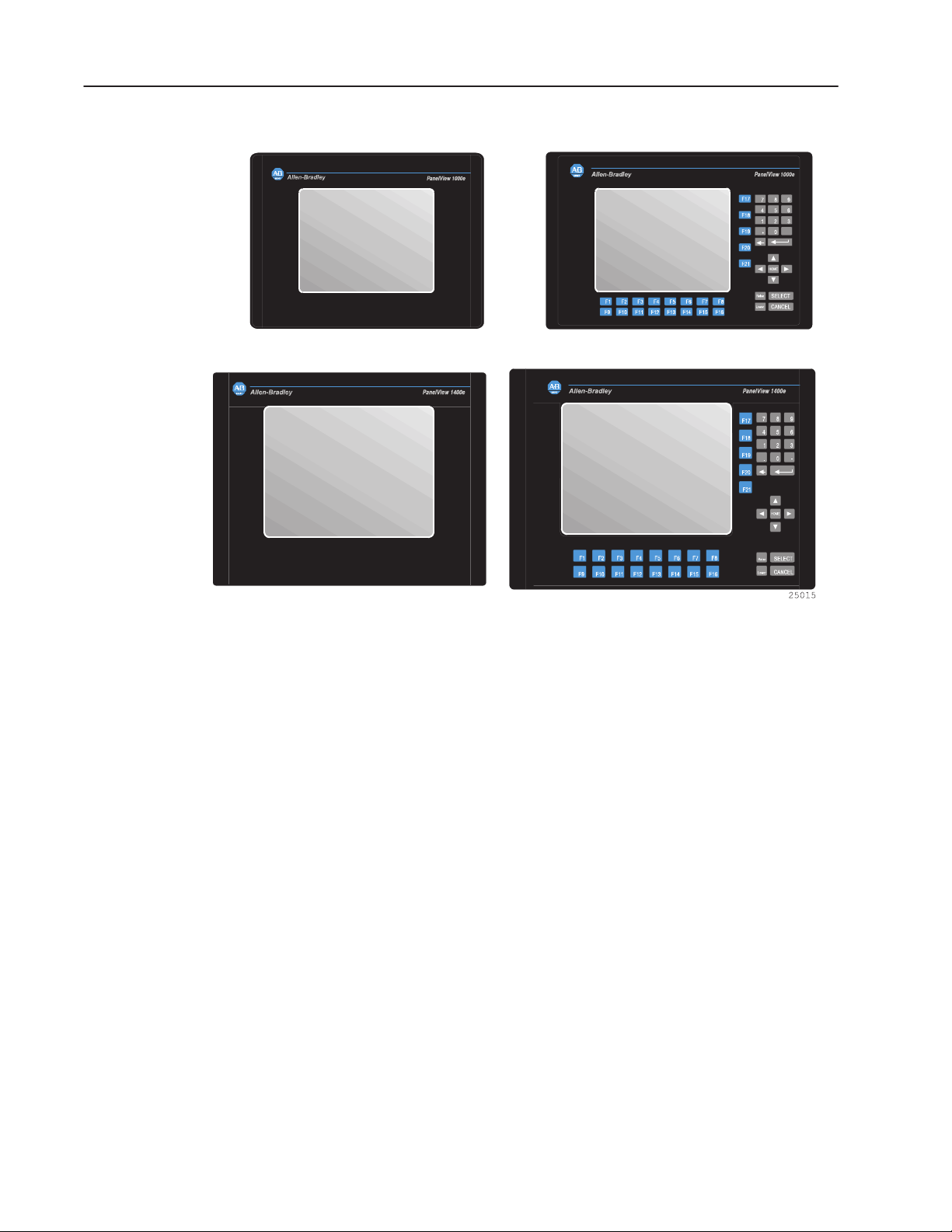

PanelView Operator Terminals

The following terminals will run PanelBuilder 1400e applications on

the Modbus network:

• PanelView 1000e terminals, Series A and above, running

Version 3 and later firmware

• PanelView 1400e terminals, Series A and above, running Version 3

and later firmware

Publication 2711E-6.12 – November 1997

Page 15

1–3Overview of PanelBuilder 1400e with Modbus Connectivity

"

Note: To communicate over a Modbus network, you must use a

PanelView 1000e or 1400e terminal that has been upgraded to

include a supported Modbus ISA communications card and Version 3

firmware with the Modbus communications driver. The PanelView

Serial Firmware Upgrade Utility must be used to install

Modbus-capable firmware in the terminal. For details about

installing and configuring a Modbus communications device (serial

card), and installing Modbus-capable firmware, see Chapter 7,

“Configuring the PanelView Terminal for Modbus

Communications.”

See the PanelView Enhanced Modbus Communications Option Kit

Release Note, Publication Number 2711E-6.12.1, for a list of

currently-supported Modbus communications cards.

The application screens created in PanelBuilder appear on the

PanelView terminal, replacing traditional hard-wired control panels.

They provide the physical interface between the controller and the

human operator.

Application screens contain objects that function like control panel

components. By using these objects to enter data or carry out

commands, the operator can monitor and control the process.

For information about installing and running PanelBuilder, see

Getting Started with PanelBuilder 1400e Configuration Software for

Windows, Publication Number 2711E-818. This manual also contains

a tutorial that guides you through enhancing an existing application

and running it on the PanelView terminal. A Modbus version of this

tutorial is also provided. The following .pvc files in the Tutorial

directory are the Modbus versions, which need to be enhanced:

• Mkctutor.pvc

• Mtctutor.pvc

The following .pvc files in the Tutorial directory are the Modbus

versions which have been enhanced:

• Mtutork.pvc

• Mtutort.pvc

The program for Modicon controllers is called “Tutorial,” and it is

located in the Tutorial directory.

Publication 2711E-6.12 – November 1997

Page 16

1–4 Overview of PanelBuilder 1400e with Modbus Connectivity

PanelView 1000e

Terminals

PanelView 1400e

Terminals

Touch Screen Terminals

Keypad Terminals

Publication 2711E-6.12 – November 1997

Page 17

The Controller or Other Modbus Slave Device

When communicating over a Modbus network, the controller can

respond to queries from the PanelView terminal and other input or

output devices.

Modicon Controller

24762

1–5Overview of PanelBuilder 1400e with Modbus Connectivity

The PanelView terminal can be connected to a controller, or other

slave device on the Modbus network. The terminal can control and

monitor coils, inputs, and registers in these devices on the network.

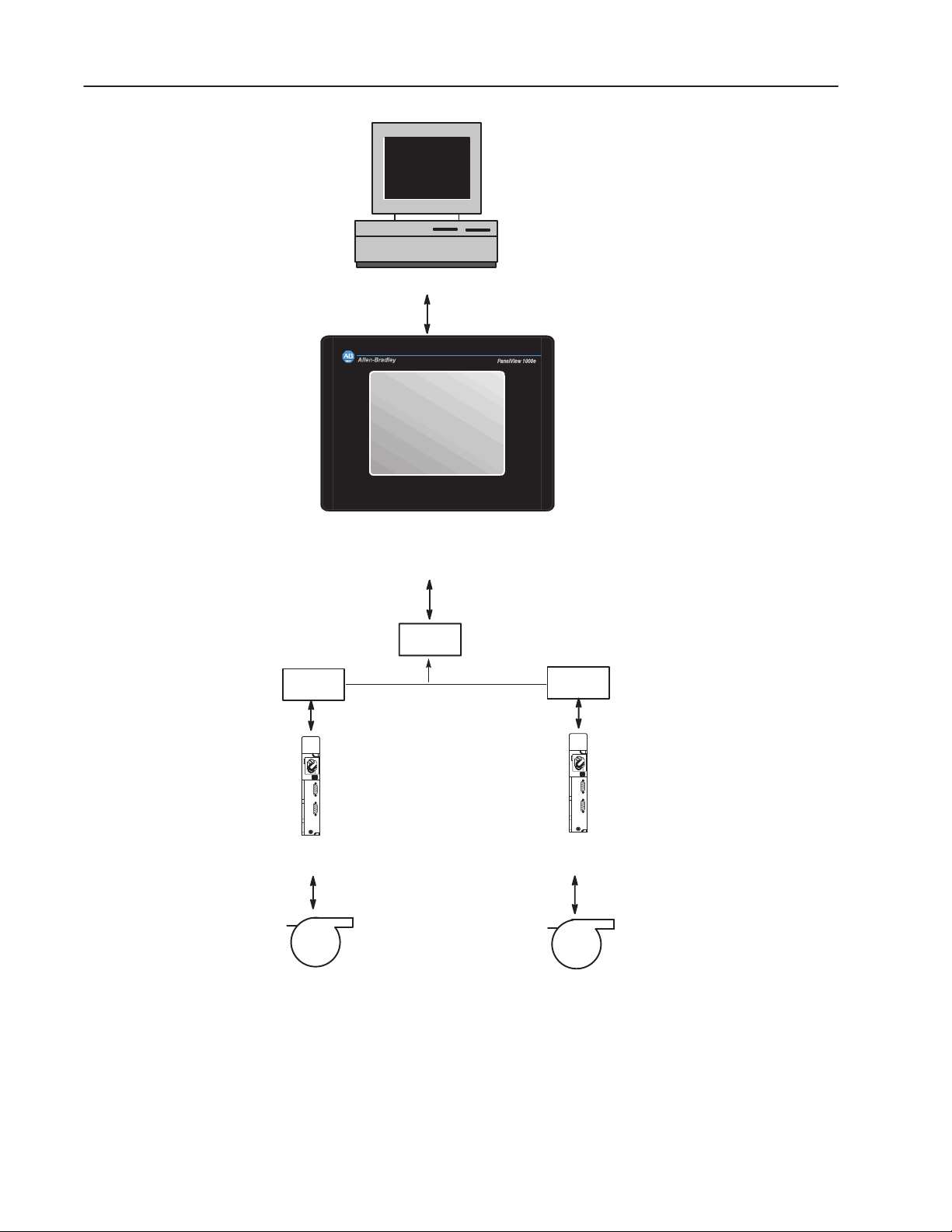

Understanding the Modbus Network

The following illustration shows the relationship between

PanelBuilder, the PanelView terminal, and the controller. In the

following illustration, the PanelView terminal is connected over

Modbus:

Publication 2711E-6.12 – November 1997

Page 18

1–6 Overview of PanelBuilder 1400e with Modbus Connectivity

The application is created in PanelBuilder on the

personal computer, and downloaded to the

PanelView operator terminal.

Development Computer

Serial Connection

PanelView

The PanelView terminal queries the

controller for process or machine

status information.

Operator input to the terminal is sent to

the controller. The controller uses this

information to control the machine or

process.

PanelView 1000e/1400e

Terminal

(Touch Screen)

Modem

Modem

Modbus

Programmable

Controller

Machine or

Process

Modem

Modbus

Programmable

Controller

Machine or

Process

24717

Publication 2711E-6.12 – November 1997

Page 19

Planning an Application for

Modbus

This chapter provides information about planning a Modbus

application, including defining nodes. For details about assigning

scan classes and assigning tags, refer to Chapter 2, “Planning

Applications,” in the PanelBuilder 1400e Configuration Software for

Windows User Manual, publication 2711E-819.

To plan a Modbus application, use the Modbus Communications

Worksheet and the Device Tags Worksheet (included in

Appendix A). They help you identify the devices with which your

application will be communicating and the device addresses relevant

to your application.

Use the information you record in these worksheets when assigning

tags to objects in the Tag Database editor and defining

communications using the Nodes editor and Scan Classes editor.

Defining Nodes and Scan Classes

Record node and scan class information on the Modbus

Communications worksheet to help keep track of terminal

communication information. Use these worksheets as a reference

when configuring nodes in the Nodes editor, and when assigning

scan classes to tags in the Tag Database editor. See Chapter 4,

“Defining Communications,” for details about working with these

editors.

Publication 2711E-6.12 – August 1997

Page 20

2–2 Planning an Application for Modbus

Defining the Nodes

A node is a Modbus slave device with which your application will be

communicating on a network. For each node, you must identify the

type of addressing the device uses (5- or 6-digit addressing), its

station address, and the timeout value. Each node must be given a

name to be used when defining tags.

Recording Node Information

"

"

For each node, fill in:

• Node Name: A user-defined node name. The name can be up to

40 characters long, and can include letters, numbers, dash ( – ),

and the underscore character ( _ ). You cannot use spaces.

Tip: Use a name that will help you to identify your Modbus

device when you are assigning tags later in your application. For

example, you could name your Modbus devices according to their

locations or the machine or part of the process they will be

controlling or monitoring.

Note: The node name “Unsolicited_Msgs is reserved for system

use in DH+ applications and cannot be assigned to a node defined

by the user. It allows the terminal to support unsolicited messages

to and from the controller. You cannot use a node with this name

in Modbus applications.

• Device: The type of controller or Modbus device. Specify a 5- or

6-digit addressable device.

• Channel: The Channel number is 1 by default. The application

network type determines this channel. You cannot change this

value.

• Station: The address that identifies the Modbus device’s location

on the network. Valid station addresses are between 1 and

247 (decimal).

Publication 2711E-6.12 – August 1997

Page 21

2–3Planning an Application for Modbus

About Scanning

"

Note: The PanelView terminal communicates with local Modbus

stations or with remote, bridged devices if a BM85 module is

connected and configured for the network.

• Enabled: If a node is enabled, the terminal will communicate

with the device at the node. If the node is not enabled, the

terminal will not communicate with the device. Instead, the

PanelView terminal stores values to be written to the device. This

allows system designers to test their applications without setting

up communications, and to avoid communication errors at the

terminal during testing.

• Timeout: The number of seconds the PanelView terminal should

wait before reporting a communication error. Three seconds is the

default when a new node is created.

Scanning works the same way for Modbus as it does for Data

Highway Plus. For information about scanning, refer to Chapter 2,

“Planning Applications,” in the PanelBuilder 1400e Configuration

Software for Windows User Manual, publication 2711E-819.

Recording Tag Information

"

"

Assigning tags to objects for the Modbus release of PanelBuilder is

similar to assigning tags to objects for DH+. You assign tags with the

Data Source type Device for Modbus applications. Analog, digital,

string, and block tags can all be used in Modbus applications. Where

differences exist between DH+ and Modbus applications, with

respect to assigning tags, they are highlighted in Chapter 6,

“Defining Tags.”

For generic information about assigning tags, see Chapter 2,

“Planning Applications,” in the PanelBuilder 1400e Configuration

Software for Windows User Manual, publication 2711E-819.

Note: You can use the Device Tags Worksheet to record tag

information for each dynamic object in a PanelBuilder application

for Modbus.

Note: For Modbus Device tags, the Tag Database editor supports the

full addressing syntax and range supported by the 5- and 6-digit

addressable devices.

Publication 2711E-6.12 – August 1997

Page 22

Basic Application Operations

This chapter supplements the information in the PanelBuilder 1400e

Configuration Software for Windows User Manual, publication

2711E-819. It describes only changes to basic application operations

for the Modbus network. For detailed information about other basic

application operations, consult Chapter 3, “Working with

Applications,” in the PanelBuilder 1400e Configuration Software for

Windows User Manual, publication 2711E-819.

This chapter describes how to create a new application, and some

changes to report options.

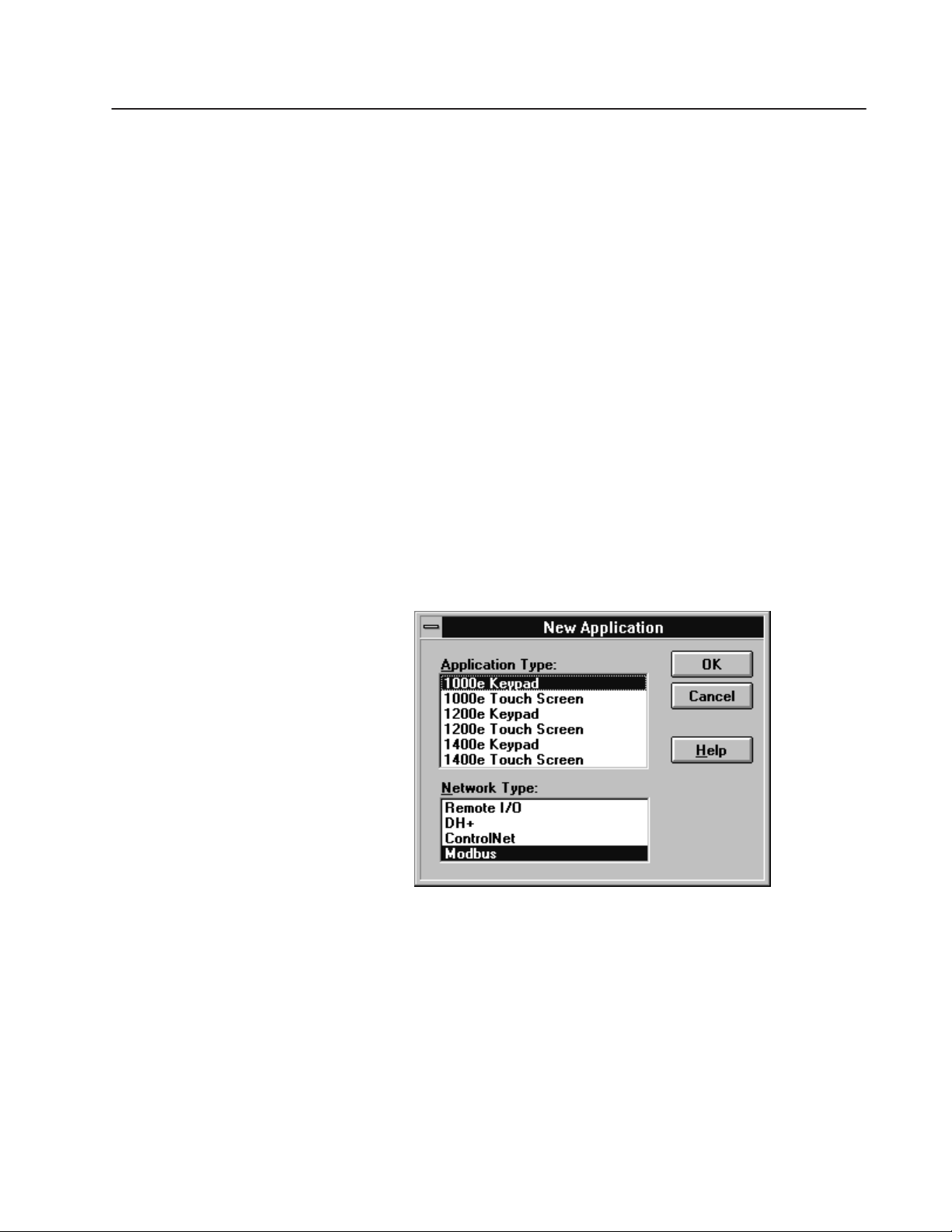

Creating a New Application

"

Note: PanelView 1200 and 1200e terminals do not support Modbus

communications.

To create a new application for Modbus:

1. Select the Application Type and highlight the Modbus option in

the Network Type list box.

Creating Reports

2. Choose OK.

Creating reports for a Modbus application is the same as for DH+

and Remote I/O applications. The only difference is the PLC

Communications report.

For detailed information about creating reports, see “Creating

Application Reports” in Chapter 3, “Working with Applications,” in

the PanelBuilder 1400e Configuration Software for Windows User

Manual, publication 2711E-819.

Publication 2711E-6.12 – November 1997

Page 23

3–2 Basic Application Operations

Additional Report on Options

You can generate a PLC Communications report for a Modbus

application that will display the following information:

• communications setup information

• node and scan class definitions

Publication 2711E-6.12 – November 1997

Page 24

Defining Communications

To define communications for a Modbus application, use these three

editors:

• Communication Setup editor—to specify the driver

information for connecting a PanelView terminal to a Modbus

device.

• Nodes editor—to identify the types and addresses of the

controllers the application will communicate with.

• Scan Classes editor—to define the speed at which tags used in

an application will be scanned for new values.

The other two editors in the PLC Communications folder, the RIO

Racks and RIO Block Transfer Files editors, are used exclusively for

defining Remote I/O communications.

Configuring Communications

The Configure Communication Setup dialog box has two tabs:

Terminal Communications and Network File Transfer.

In the Terminal Communications tab, you specify the driver

parameters for communicating with the Modbus network.

You cannot access the Network File Transfer tab from the

Communication Setup dialog box, because Network File Transfers

are not supported on Modbus networks.

T o open the Configure Communication Setup dialog box:

" Open the PLC Communications folder and choose

Communication Setup, or choose

from the toolbar.

Publication 2711E-6.12 – November 1997

Page 25

4–2 Defining Communications

Setting up Terminal Communications

In the Terminal Communications tab you can set the driver

parameters.

Setting the Driver Parameters

You must configure the driver parameters to correspond with the

communication settings of the device to which the PanelView

terminal is most immediately connected (whether a controller,

modem, BM85 module, or other Modbus device).

" Fill in the fields in the Driver section of the Configure

Communication Setup dialog box as follows:

Baud Rate

Specify the data-transfer rate between the PanelView terminal and

the device to which it is connected. The default setting is 9600.

Parity

Specify None, Even, or Odd for the type of error-checking to be

used. The default setting is Even.

Configuring Nodes

"

"

Flow Control

Specify Hardware or None to determine whether handshaking is

used for data transfer between the PanelView terminal and the

device to which it is connected. The default setting is None.

Note: Hardware flow control must be used with line drivers or

modems.

Stop Bits

Specify the number of stop bits used to signal the end of a data

packet transferred between the PanelView terminal and the device

to which it is connected. The default setting is 1.

Note: The number of data bits is fixed at 8.

A node is a device connected to the Modbus network. When you

configure nodes, you specify a name, device type, and station

address for each device the application will communicate with. A

device at a Modbus station is referred to throughout a PanelView

application by its node name.

You should already have determined the station address for each

node when you completed the Modbus Communications Worksheet.

If not, see Chapter 2, “Planning an Application for Modbus,” for

details about determining station addresses.

Publication 2711E-6.12 – November 1997

Page 26

4–3Defining Communications

Data Entry Form

Spreadsheet

Viewer

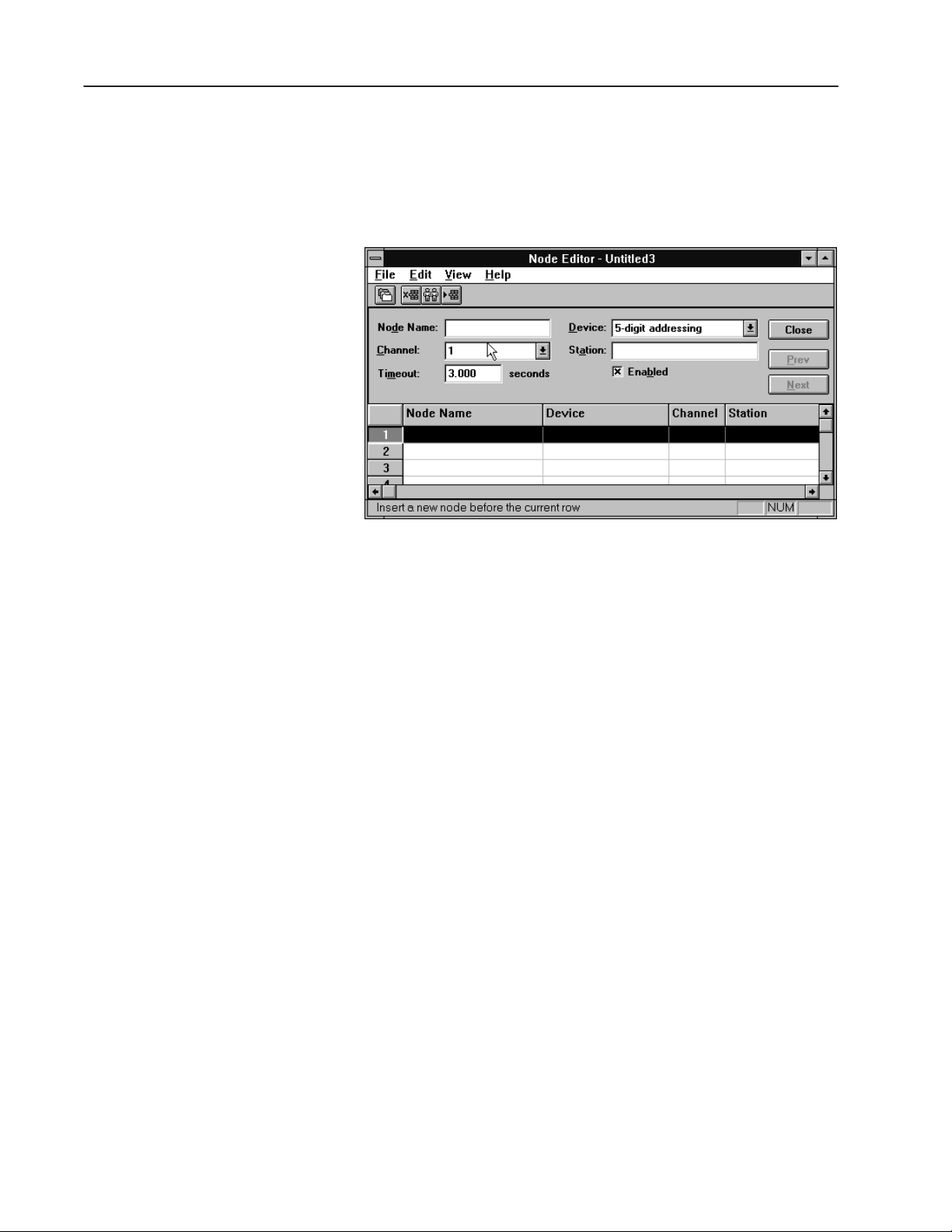

"

Note: A node configuration can be changed at any time during

application development. At application or screen validation, or

download, the nodes used by the tags in the application must be

defined. If you change the node’s device type, the tags that use this

node may have invalid addresses. If you change the node name, you

can automatically update your tags at the same time.

T o open the Node Editor:

" Open the PLC Communications folder and choose Nodes, or

choose

from the toolbar. The Node Editor opens.

"

The Node Editor has two parts: the data entry form on top where

you define the node, and the spreadsheet viewer on the bottom where

you see all the nodes and select one for editing.

T o configure the nodes:

1. Fill in the following information for each node. Use the

information you recorded in the Communications worksheet.

Node Name

Type a name of your choice up to 40 characters long. This name

represents a device on the network. The only valid characters for

a node name are a-z, A-Z, 0-9, – (dash), and _ (underscore). You

cannot use spaces. The name is not case-sensitive; your characters

will be displayed as you typed them.

Note: The node name “Unsolicited_Msgs is reserved for system

use in DH+ applications and cannot be assigned to a node defined

by the user. It allows the terminal to support unsolicited messages

to and from the controller. You cannot use a node with this name

in Modbus applications.

Publication 2711E-6.12 – November 1997

Page 27

4–4 Defining Communications

"

Tip: Use a name that will help you to identify your controllers

when you are assigning tags later in your application. For

example, you could name your controllers according to their

locations or according to the machine or part of the process they

will be controlling or monitoring.

Device

Select the type of device you are using from the drop-down list.

The type of device determines the addressing syntax and range

for all the tags with addresses on this node.

For Modbus applications, select 5-digit addressing or 6-digit

addressing, depending on the device you are using. See the user

manual for the device you are using, to determine whether to use

5- or 6-digit addressing.

Channel

The Channel number is 1 by default. The application network

type that you specified when you created your application refers

to this channel. You cannot change this value. This field

maintains compatibility with RSView and provides future

communication option expansion.

Station

Type the address of the device.

For Modbus applications, values are between 1 and

247 (decimal), whether the station is local or bridged.

Timeout

Type the number of seconds (0.100 to 6553.500) you want the

terminal to wait before reporting a communication error. The

default timeout period is 3 seconds.

Enabled

Normally nodes are enabled, allowing data collection. However,

while you are debugging your application or troubleshooting your

network, you can disable a node to prevent communication faults

or invalid data. Once the application file is downloaded and

running, any values normally sent to a disabled node will be

recorded in the terminal, but the actual device value will remain

unchanged.

To disable nodes, clear the Enabled check box.

Important: Make sure the nodes are enabled before you run

an application in an online environment.

2. When you’ve finished configuring nodes, choose Close.

Publication 2711E-6.12 – November 1997

Page 28

4–5Defining Communications

Configuring Scan Classes

Any tag that has Device as its data source must be assigned to a scan

class. At runtime, the PanelView terminal periodically updates its tag

information by scanning the device addresses. You determine how

often a tag value is updated by assigning the tag to a scan class that

you have configured in the Scan Classes editor. Make sure that tags

with rapidly changing device values are assigned to a fast scan rate,

while those that don’t change often are scanned less frequently. This

helps optimize traffic flow on the Modbus network. Proper use of

scan classes can reduce traffic on the Modbus network.

You should already have determined the rates for the scan classes

when you completed the Communications worksheet. If not, see

Chapter 2, “Planning Applications,” in the PanelBuilder 1400e

Configuration Software for Windows User Manual, for tips on

assigning foreground and background scan rates.

T o open the Scan Class Editor dialog box:

" Open the PLC Communications folder and choose Scan Classes,

or choose

from the toolbar.

The Scan Class Editor opens.

T o configure scan classes:

1. Fill in the following information for each scan class. Use the

information you recorded in the Communications worksheet.

Name—A Through K

You can keep the letter for the name of the scan class or you can

type a name up to 20 characters long. The name can have upper

and lower case letters, numbers, dashes, and underscores. You

cannot use spaces.

If you type a meaningful name, it will be easier to keep track of

what the scan classes represent. For example, you might name

one scan class TimeCritical, another SlowChanging, and so on.

Publication 2711E-6.12 – November 1997

Page 29

4–6 Defining Communications

Foreground and Background Period

The period specifies, in seconds, how often the device address

will be scanned. A foreground period applies to tags used on the

current screen, to the alarm and information window tags, and to

the tags under the PLC Controlled tab in the PLC I/O Control

dialog. The background scan period applies to tags used in all

other screens in the system. The valid range of values is 0 to

86,400 seconds (24 hours), with a 0.1 second resolution.

To specify a period, type a number. You can use fractions of a

second. For example, 0.6 means scan every six-tenths of a

second. Keep the background rate slow so as not to slow down

network traffic.

"

"

"

Tip: For more information about optimizing Modbus network

traffic, refer to your network user documentation. Also see

“Guidelines for Configuring Scan Classes” in Chapter 2,

“Planning Applications,” in the PanelBuilder 1400e

Configuration Software for Windows User Manual.

Note: If a tag is being used by both a foreground and background

component, the tag will be scanned at the foreground rate.

2. To save the information you’ve configured, choose OK.

Note: If you change the name of a scan class used by tags, you

have the option of automatically updating the tags with the new

name.

Publication 2711E-6.12 – November 1997

Page 30

Changing the Network Type

When you create an application, you specify the type of network it is

to run on, and set up the communication parameters accordingly. You

can change the network type of an existing application to run it on

another network. You do this using the Change Network Type dialog

box.

Converting from DH+ to Modbus

"

"

Note: When you change the network type to Remote I/O, all

communication specifications, including node definitions and scan

classes, will be lost. You will have to re-configure communications

for your application.

This chapter describes the following network switches:

• converting from DH+ to Modbus

• converting from Remote I/O to Modbus

• converting from ControlNet to Modbus

• converting from Modbus to DH+

• converting from Modbus to Remote I/O

• converting from Modbus to ControlNet

Note: You can either convert only the application, or the application

and its tags. In either case, you must edit tag addresses and node

definitions to make them valid for the new network type.

To change the network type from DH+ to Modbus:

Important: When you change an application from DH+ to Modbus,

you will have to add valid Modbus device tag

addresses.

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose Modbus.

3. Choose OK.

The following message will appear:

Publication 2711E-6.12 – August 1997

Page 31

5–2 Changing the Network Type

4. Choose Yes to change your DH+ application to Modbus. Choose

No if you do not wish to continue with the conversion.

"

Note: When converting to a Modbus application, the device type

defined for each node will be incompatible with the Modbus

network type. The following message will appear, prompting you

to convert the incompatible nodes.

5. Select Yes or No.

If you select Yes:

• the device type of any node will be changed to 5-digit

addressing

• the Unsolicited_Msgs node will be deleted

• any node with an invalid station number for the Modbus

network will be changed to have a station number of 1

• tag addresses will remain as DH+ addresses. You must change

these tag addresses to Modbus tag addresses.

Converting from Remote I/O to Modbus

If you select No, the network conversion will be cancelled.

To change the network type from Remote I/O to Modbus:

Important: When you change an application from Remote I/O to

Modbus, you will have to define the necessary Modbus

nodes and scan classes and add valid Modbus device tag

addresses.

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose Modbus.

3. To convert the tags in the application, select the Convert Tags

check box. If you don’t want to convert tags in the application,

clear the check from the Convert Tags check box.

• If you don’t convert the tags to Modbus format, the tags’ data

source remains Remote I/O. For any tags to be used in the

Modbus application, you will have to change the data source

to Device and give them valid Modbus addresses.

• If you do convert the tags to Modbus format, all the tags in the

database that are used by your application will be converted to

Device tags. Analog tags using the binary data type will be

switched to unsigned integer because binary is not supported

for Modbus applications.

Publication 2711E-6.12 – August 1997

Page 32

5–3Changing the Network Type

"

"

Note: If you convert shared tags, this may make them invalid for

the other applications that are using them. Unused tags are not

converted and remain as Remote I/O tags.

Note: If you convert an application from Remote I/O to Modbus,

or vice-versa, the tag addresses will be invalid for the network to

which you are converting. Change the tag addresses to match the

network type.

4. Specify a node name and scan class if required.

You can specify a node name and scan class when you do the

conversion, or you can leave them blank. If you enter a node

name and scan class, they will be used in all the tags that are

converted. In addition, the node and scan class will be created for

you with the default settings. You can change the settings to suit

your application later.

If you leave the Node Name and Scan Class fields blank, you will

have to create the nodes and scan classes that your tags will use,

then update each tag with the node and scan class names that you

have created. The converted tags will have a blank node and scan

class name.

Publication 2711E-6.12 – August 1997

Page 33

5–4 Changing the Network Type

5. Choose OK.

The following message will appear:

6. Choose Yes to confirm that you want to continue.

Converting from ControlNet to Modbus

To change the network type from ControlNet to Modbus:

Important: When you change an application from ControlNet to

Modbus, you will have to add valid Modbus device tag

addresses.

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose Modbus.

3. Choose OK.

The following message will appear:

Publication 2711E-6.12 – August 1997

Page 34

4. Choose Yes to change your ControlNet application to Modbus.

Choose No if you do not wish to continue with the conversion.

5–5Changing the Network Type

"

Note: When converting to a Modbus application, the device type

defined for each node will be incompatible with the Modbus

network type. The following message will appear, prompting you

to convert the incompatible nodes.

5. Select Yes or No.

If you select Yes:

• the device type of any node will be changed to 5-digit

addressing

• any node with an invalid station number for the Modbus

network will be changed to have a station number of 1

If you select No, the network conversion will be cancelled.

Converting from Modbus to DH+

To change the network type from Modbus to DH+:

Important: When you change an application from Modbus to DH+,

you will have to add valid DH+ device tag addresses.

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose DH+.

3. Choose OK.

The following message will appear:

Publication 2711E-6.12 – August 1997

Page 35

5–6 Changing the Network Type

4. Choose Yes to change your Modbus application to DH+. Choose

No if you do not wish to continue with the conversion.

"

Note: PanelBuilder checks that the station numbers and device types

of all Modbus nodes are valid when the network type is converted to

DH+. For example, station number 8 is an invalid octal number. The

following message will appear, prompting you to convert

incompatible nodes:

5. Select Yes or No.

If you select Yes:

• the device type of any node will be changed to PLC-5

(Enhanced)

• an Unsolicited_Msgs node will be added

If you select No, the network conversion will be cancelled.

Converting from Modbus to Remote I/O

"

If you change an application from Modbus to Remote I/O, you will

have to define the necessary Racks, specify the Block Transfer File

and Pass-Through control bytes, if needed, and add new tag

addresses, which are valid for Remote I/O.

T o change the network type from Modbus to Remote I/O:

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose Remote I/O.

3. To convert the tags in the application, select the Convert Tags

check box. If you don’t want to convert tags in the application,

clear the check from the Convert Tags check box.

• If you don’t convert the tags to Remote I/O format, the tags’

data source remains Device and the address is unchanged. You

will have to change the data source to Remote I/O manually

for any of these tags that you want to use, and give them each

a Remote I/O address.

• If you convert the tags to Remote I/O, the data source for all

the tags is changed to Remote I/O, but you will still have to

give them valid Remote I/O addresses manually.

Note: Converting tags that are shared may make them invalid for

the other applications that are using them. Unused tags that are

not converted will stay as Modbus tags.

Publication 2711E-6.12 – August 1997

Page 36

5–7Changing the Network Type

"

Note: If you convert an application from Modbus to Remote I/O,

or vice-versa, the tag addresses will be invalid for the network to

which you are converting. Change the tag addresses to match the

network type.

4. Choose OK.

The following message appears:

5. Choose Yes to confirm that you want to continue.

6. Once you have changed the network type you will have to

configure the controller type, rack assignments, block transfer

files, and Pass-Through control byte, if needed, in the Rack and

Block Transfer File editors.

Converting from Modbus to ControlNet

To change the network type from Modbus to ControlNet:

Important: When you change an application from Modbus to

ControlNet, you will have to add valid ControlNet

device tag addresses.

1. Choose Change Network Type from the Tools menu.

2. In the Target Network field, choose ControlNet.

3. Choose OK.

The following message will appear:

Publication 2711E-6.12 – August 1997

Page 37

5–8 Changing the Network Type

4. Choose Yes to change your Modbus application to ControlNet.

Choose No if you do not wish to continue with the conversion.

"

Note: If a Modbus node is defined as station 1, or station 64

through 247 (inclusive), it will be invalid for a ControlNet

application. The following message will appear, prompting you to

convert the station number. The device types defined for all nodes

will also have to be changed when the application is converted to

ControlNet.

5. Select Yes or No.

If you select Yes:

• the device type of any node will be changed to

PLC5-Enhanced

• any node with an invalid station number for the ControlNet

network will be changed to have a station number of 2

If you select No, the network conversion will be cancelled.

Publication 2711E-6.12 – August 1997

Page 38

Defining Tags

Use tags to name controller addresses for easy reference. For more

information about tags and their role, the tag database editor, and

how to create tags, see Chapter 6, “Defining Tags,” in the

PanelBuilder 1400e Configuration Software for Windows User

Manual.

Tag Types

PanelBuilder uses the following types of tags:

This tag

type:

Analog

Digital 0 or 1

String ASCII string, series of characters or whole words (maximum of 82

Block A contiguous bit stream of up to 1024 bits. A block tag is used strictly for

Stores this type of data:

Range of values (depends on the data type (integer or floating point)

selected)

These tags can represent complex states such as temperature or the

position of rotary controls.

These tags can represent devices that can only be on (1) or off (0), such

as push buttons.

characters)

These tags are used only when defining ASCII Input and ASCII Display

objects, and for sending alarm messages to the controller.

defining the Alarm Triggers tag and Acknowledge to PLC tag when

multiple simultaneous alarms need to be monitored. Use Block Tags when

using bit-triggered alarms. PanelBuilder Version 3 supports Device block

tags as well as Remote I/O block tags.

Read and Write Tags

"

At runtime, PanelBuilder objects and control functions can read from

or write to controller addresses assigned to any of the tag types. The

terms read tag and write tag will sometimes be used. A read tag is a

tag with a controller address that only needs to be read by

PanelBuilder objects and functions. A write tag is a tag with a

controller address that can be written to by PanelBuilder objects and

functions.

Note: When connected to a Modbus network, the PanelView

terminal is the only device initiating reads and writes (master

device). All other devices are slaves.

Publication 2711E-6.12 – August 1997

Page 39

6–2 Defining Tags

Data Sources

"

Note: You can use Expressions to perform calculations, logical, and

conditional operations to manipulate the values of tags. See

Chapter 7, “Creating Expressions” in the PanelBuilder 1400e

Configuration Software for Windows User Manual.

The other two data sources you can see in the Tag Database editor,

Memory and DDE, are used only by RSView.

Device

When you create tags for a Modbus application, select Device as the

data source. This means that the data comes from a specific memory

location in a controller that is connected to the Modbus network.

For each tag you must specify a node name, a scan class, and the

physical address within the controller that the tag references. The

node name refers to the controller’s location on the Modbus network;

the scan class determines how often the terminal checks the value at

this address. See Chapter 2, “Planning Applications,” in the

PanelBuilder 1400e Configuration Software for Windows User

Manual, for details on configuring nodes and scan classes. Appendix

A of this manual contains a worksheet to help you plan scan classes.

Configuring Tag Type

"

"

This section describes how to fill in the fields for analog, digital,

string, and block tag types. Use the information you entered on the

Device Tags worksheet described in Chapter 2, “Planning

Applications,” in the PanelBuilder 1400e Configuration Software for

Windows User Manual. The Device Tags worksheet is included in

Appendix A of this manual.

Note: The Log Data and Alarm check boxes in the Tag Database

editor are present to maintain compatibility with RSView databases.

You cannot use them in PanelBuilder.

Tip: For information about assigning tag addresses that optimize

network traffic, see “Guidelines For Organizing Tags to Optimize

Network Performance” in Chapter 2, “Planning Applications,” in the

PanelBuilder Configuration Software for Windows User Manual.

Publication 2711E-6.12 – August 1997

Page 40

6–3Defining Tags

Configuring an Analog Tag

1. If the tag is part of a folder, select that folder in the folder

hierarchy. The folder name appears in the Name field and is the

first part of the tag name.

2. Type a tag name. If the tag is part of a folder, type the name after

the backslash (\).

3. For Type, select Analog.

4. Fill in the fields as outlined below:

Security

This field is reserved for RSView databases. You cannot enter

anything in the Security field.

Description

Type a description of this tag up to 128 characters long.

Minimum and Maximum

These fields are reserved for RSView databases. You cannot enter

anything in the Minimum and Maximum fields.

Publication 2711E-6.12 – August 1997

Page 41

6–4 Defining Tags

Scale and Offset

Type a number. For the scale, do not use 0.

Scale and offset together transform raw controller data into

meaningful units for the operator. At runtime, all data read from

the controller into an analog tag will be scaled using the formula:

y = (mx) + b

where m = scale

x = raw PLC data

b = offset

y = scaled value

The terminal displays the scaled value. When data is written to

the controller using an analog tag, the value will be inversely

scaled using the formula:

ǒ

Ǔ

*

+

This converts the value back to raw controller data before it is

written to the PLC. With Scale = 1 and Offset = 0 (the default

values for a new analog tag), the controller data is not changed.

Important: A fractional scale or offset value will result in a

floating point scaled value. This will be true

regardless of the tag’s data type. Extensive use

of floating point values can slow a terminal’s

performance.

"

Important: If the descaled value to be written to the tag

address is a fraction, but the tag is not

configured to deal with floating point data (i.e.,

Float data type or Default data type with a tag

address in the Float section of the controller),

the value will be truncated to the nearest whole

number before it is written to the tag address.

Note: You can also use expressions to perform calculations on

the values of analog and digital tags that read information from

the controller. See Chapter 7, “Creating Expressions,” in the

PanelBuilder 1400e Configuration Software for Windows User

Manual.

Units

This field is reserved for RSView databases. You cannot enter

anything in the Units field.

Publication 2711E-6.12 – August 1997

Page 42

6–5Defining Tags

Data Type

Select the data type that matches the format of the data stored in

the controller. The default entry in the data type field is Default.

In Modbus applications, the Default data type is Unsigned Integer

with an address length of 16 bits. Unless special data is expected,

Default should be acceptable.

The following data types are supported for Analog tags in a

Modbus application:

Data Type Description

Default

Byte Unsigned 8-bit value. Uses the lower 8 bits of the 16-bit

Unsigned Integer Unsigned 16-bit value.

Integer Signed 16-bit value.

Long Integer Signed 32-bit value.

Bit Position Value range from 0 to 16. Address length fixed at 16 bits.

1 BCD Value range 0 to 9. Uses lower 4 bits of 16-bit address.

2 BCD Value range 0 to 99. Uses lower 8 bits of 16-bit address.

3 BCD Value range 0 to 999. Uses lower 12 bits of 16-bit address.

4 BCD Value range 0 to 9999.

Floating Point Single-precision (32-bit) floating point value. The range of data

BIN 3 Value range 0 to 999. Uses a 16-bit address.

BIN 4 Value range 0 to 9999. Uses a 16-bit address.

BIN 6 Value range 0 to 999999. Uses a 32-bit address.

BIN 8 Value range 0 to 99999999. Uses a 32-bit address.

Unsigned 16-bit value.

address.

values is –3.402823E +38 to –1.175494E –37, 0, and

+1.175494E –37 to +3.402823E +38.

"

Initial Value

This is the default value of the tag at the terminal. When a tag is

used with a PanelBuilder input object or function, this initial

value, after descaling, is written to the controller when the

application first executes.

For a PanelBuilder object with an initial state and a main control

tag, the object’s initial state value supersedes the tag’s initial

value, so that the initial state value is written to the controller

instead of the tag’s initial value. On application upload, the

object’s initial state value is used as the tag’s initial value.

Note: For the PanelView terminal to write default values to the

controller, you must choose No for “Use Default Operation,” on

the terminal’s Application Startup screen, and you must cycle

power to the terminal. Default values are written to the controller

whenever you subsequently cycle power to the terminal.

Publication 2711E-6.12 – August 1997

Page 43

6–6 Defining Tags

5. To fill in the fields for data source, see Specifying a Data

Source” later in this chapter.

Modbus Address Space

Modbus devices can contain four distinct address spaces. Two spaces

are reserved for Coil data and two are reserved for Register data. The

PanelView terminal can only write to one of the two Coil address

spaces but can read from both spaces. The same is true for the two

Register address spaces.

Modicon controllers store read and write address spaces in the

following data table locations:

Reference Address Type Data Access Description

0

1 Discrete Input bit read-only Use to drive contacts in the logic

3 Input Register word

Discrete

Output or Coil

(internal)

bit read or

write

read-only

Use to drive a real output through an

output module or to set one or more

internal coils. A coil can be used to

drive multiple contacts.

program. The input state is controlled

by an input module.

Holds numeric inputs from an external

source (for example, a thumb wheel

entry, an analog signal or data from a

high speed counter). A 3x register can

also store 16 contiguous discrete

signals that are entered into the

register in either binary or binary coded

decimal (BCD) formats.

Publication 2711E-6.12 – August 1997

Page 44

Reference DescriptionData AccessAddress Type

4

6 Extended

Output Holding

Register

Memory

Register

word read and

write

access

through Logic

Program only

Use to store numerical (decimal or

binary) information or to send the

information to an output module.

Use to store information in an extended

memory area. Only available in

controllers with 24 bit CPUs that

support extended memory such as the

984B, E984-785, and Quantum series

of controllers.

Addressing Syntax

For analog tags, the addressing syntax is as follows:

Addressing Syntax for Devices Using 5-digit Addressing:

Reference Operations Addressing Syntax

0

1 bit

3 word

4 word

bit

read and write

read only

read only

read and write

0bbbb where

bbbb = bit 0001 to 9999 (decimal)

and bbbb must align on word boundaries

(e.g. 00001, 00017, 00033)

1bbbb where

bbbb = bit 0001 to 9999 (decimal)

and bbbb must align on word boundaries

e.g. 00001, 00017, 00033)

3wwww where

wwww = word offset 0001 to 9999 (decimal).

Bit offsets are not supported.

4wwww where

wwww = word offset 0001 to 9999 (decimal).

Bit offsets are not supported.

6–7Defining Tags

Addressing Syntax for Devices Using 6-digit Addressing:

Reference Operations Addressing Syntax

3

4 word

word

read only

read and write

3wwwww where

wwwww = word offset 00001 to 65535 (decimal).

Bit offsets are not supported.

4wwwww where

wwwww = word offset 00001 to 65535 (decimal).

Bit offsets are not supported.

Publication 2711E-6.12 – August 1997

Page 45

6–8 Defining Tags

Important: Because analog tags with References 1 or 3 are read

only, they can only be assigned to display objects (e.g.

Numeric Data Display). An error will be generated

when you validate the application, if a tag with

Reference 1 or 3 has been assigned to an input object.

For more information about types of objects, see

Chapter 9, “Creating Objects,” in the PanelBuilder

1400e Configuration Software for Windows User

Manual, Publication Number 2711E-819.

Configuring a Digital Tag

A digital tag has two possible values at runtime: 0 or 1. Use a digital

tag wherever a toggle or Boolean function is needed.

1. If the tag is part of a folder, select the folder in the folder

hierarchy. The folder name appears in the Name field and is the

first part of the tag name.

2. Type a tag name. If the tag is part of a folder, type the name after

the backslash (\).

3. For Type, select Digital.

Publication 2711E-6.12 – August 1997

Page 46

4. Fill in the fields as outlined below:

Security

This field is reserved for RSView databases. You cannot enter

anything in the Security field.

Description

Type a description of this tag up to 128 characters long.

Off Label and On Label

These fields are reserved for RSView databases. You cannot enter

anything in them.

Initial Value

Enter an initial value of 0 or 1 for the digital tag. When a tag is

used with a PanelBuilder input object or function, this initial

value is written to the controller when the application first

executes.

For a PanelBuilder object with an initial state and a main control

tag, the object’s initial state value supersedes the tag’s initial

value, so that the initial state value is written to the controller

instead of the tag’s initial value. On application upload, the

object’s initial state value is used as the tag’s initial value.

6–9Defining Tags

"

Note: For the PanelView terminal to write default values to the

controller, you must choose No for “Use Default Operation,” on

the terminal’s Application Startup screen, and you must cycle

power to the terminal. Default values are written to the controller

whenever you subsequently cycle power to the terminal.

5. To fill in the fields for data source, see Specifying a Data

Source” later in this chapter.

Addressing Syntax

For digital tags, the addressing syntax is as follows:

Addressing Syntax for Devices Using 5-digit Addressing:

Reference Operations Addressing Syntax

0

1 bit

3 word

4 word

bit

read and write

read only

read only

read only

0bbbb where

bbbb = bit 0001 to 9999 (decimal)

1bbbb where

bbbb = bit 0001 to 9999 (decimal)

3wwww/bb where

wwww = word offset 0001 to 9999 (decimal)

/bb = bit offset in word 01 to 16 (decimal)

4wwww/bb where

wwww = word offset 0001 to 9999 (decimal)

/bb = bit offset in word 01 to 16 (decimal)

Publication 2711E-6.12 – August 1997

Page 47

6–10 Defining Tags

Addressing Syntax for Devices Using 6-digit Addressing:

Reference Operations Addressing Syntax

3

4 word

word

read only

read only

3wwwww/bb where

wwwww = word offset 00001 to 65535 (decimal)

/bb = bit offset in word 01 to 16 (decimal)

4wwwww/bb where

wwwww = word offset 00001 to 65535 (decimal)

/bb = bit offset in word 01 to 16 (decimal)

"

Note: Digital tags support only bit addresses.

Important: Because digital tags with References 1, 3, or 4 are

read-only, they can only be assigned to display objects

(e.g. Numeric Data Display). An error will be generated

when you validate the application if a tag with

Reference 1, 3, or 4 has been assigned to an input

object. For more information about types of objects, see

Chapter 9, “Creating Objects,” in the PanelBuilder

1400e Configuration Software for Windows User

Manual, Publication Number 2711E-819.

Configuring a String Tag

1. If the tag is part of a folder, select the folder in the folder

hierarchy. The folder name appears in the Name field and is the

first part of the tag name.

Publication 2711E-6.12 – August 1997

Page 48

"

6–11Defining Tags

2. Type a tag name. If the tag is part of a folder, type the name after

the backslash (\).

3. For Type, select String.

4. Fill in the fields as outlined below:

Security

This field is reserved for RSView databases. You cannot enter

anything in the Security field.

Description

Type a description of this tag up to 128 characters long.

Length

Type a number between 1 and 82 to specify the length of the

string tag in bytes. The length must be a multiple of 2. Tags using

References 0 and 1 must align on word boundaries.

Initial Value

Enter an initial value for the tag. When a tag is used with a

PanelBuilder input object or function, this initial value is written

to the controller when the application first executes.

Note: For the PanelView terminal to write default values to the

controller, you must choose No for “Use Default Operation,” on

the terminal’s Application Startup screen, and you must cycle

power to the terminal. Default values are written to the controller

whenever you subsequently cycle power to the terminal.

"

Note: There can be no more than 720 string tags in an

application.

5. To fill in the fields for data source, see Specifying a Data

Source” later in this chapter.

Publication 2711E-6.12 – August 1997

Page 49

6–12 Defining Tags

Addressing Syntax

For string tags, the addressing syntax is as follows:

Addressing Syntax for Devices Using 5-digit Addressing:

Reference Operations Addressing Syntax

0

1 bit

3 word

4 word

bit

read and write

read only

read only

read and write