Page 1

Installation Instructions

IMPORTANT

Single Motor Cables with Circular DIN Connector Type 740

Catalog Numbers 2090-CSBM1DF-10AFxx

About Single Motor Cables

Single motor cables have an M40 SpeedTec connector at the motor end and flying leads at the

drive end. These cables can be bent or reformed during installation and maintenance. Use the

2090-CSBM1DF-10AFxx cables in continuous-flex operations (available only with brake

conductors).

Installing Single Motor Cables

Follow these safety notices when installing this cable between your servo drive and the motor.

Additional precautions are noted in the Kinetix Motion Accessories Specifications Technical

Data, publication GMC-TD004

.

ATTENTION: Always remove power to the ser vo drive before connec ting or disconnecting

cables at the drive or at the motor.

Arcing or unexpected motion can occur if the cable is connected or disconnec ted while power is

applied to the drive.

ATTENTION: Always ground the overall shield of the cable. Doing so improves system EMC/EMI

performance and helps to provide uninterrupted operation. Electrical noise can cause

communication signals to fail.

ATTENTION: Do not tightly gather or coil a cable that transfers power. Heat is generated within

a cable whenever power is applied and only an uncoiled cable can freely dissipate that heat.

The feedback wire pair (Data+/Data-) requires a metallic feedback connector kit for proper

signal termination. Refer to Additional Resources

the feedback connector kit and other related publications.

The feedback connector kit is included with the servo drive.

on page 4 for the installation instructions for

Page 2

2 Single Motor Cables with Circular DIN Connector Type 740

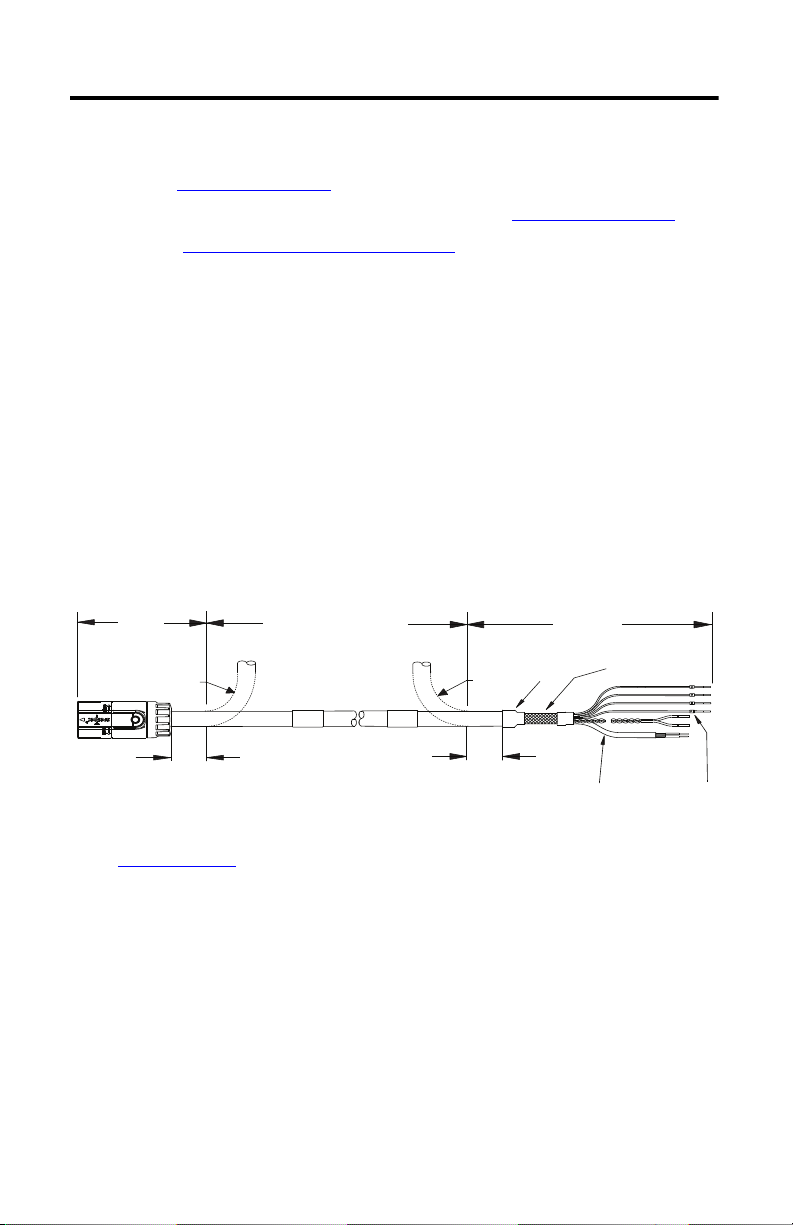

Continuous-flex Zone

Installation

Area

Installation

Area

Signal

Labels

Exposed Shield

Shrink

Wrap

Refer to Specifications

on page 3 for recommended

continuous-flex zone radius values.

Insulated and

Shielded

Twi ste d Pai r

2090-CSBM1DF-10AFxx cable shown.

76.2 mm

(3.0 in.)

76.2 mm

(3.0 in.)

Bend

Radius

Bend Radius

Follow these guidelines when installing a single motor cable:

• Do not bend the cable within 76.2 mm (3.0 in.) of the connector or the flying-lead end.

See the Installation Guidelines

illustration.

• Do not exceed the bend radius limitation specified in the Specifications on page 3.

• Refer to Cable Pinouts and Schematics on page 3 to identify each wire and its respective

drive connection.

• Remove and discard the protective sleeve from the data signal wires shortly before you

install these wires on the feedback connector kit.

• Connect unused brake conductors to the drive to prevent accidental contact.

For continuous-flex cables, follow these additional installation requirements:

• The continuous-flex zone is the area where the cable can repeatedly flex up to its

specified bend radius.

• Installation areas require rigid mounting to prevent the cable from flexing where it

connects to other components.

Installation Guidelines

Rockwell Automation Publication 2090-IN049A-EN-P - October 2013

Page 3

Single Motor Cables with Circular DIN Connector Type 740 3

U

V

W

GND

BRK+

BRK-

+

U

V

W

1

2

L

H

U

V

2

+

H

L

1

N

W

The braided shields

are grounded to the

motor connector.

Shield Connection

To

Drive

Twi ste d Wi re Pa ir

Braided Shield

To

Motor

Brown

Black

Blue

Green/Yellow

Black

White

Blue

White/Blue

Braided Shield

Cable Pinouts and Schematics

This diagrams provides wire colors and pinouts for single motor cables with brake conductors.

2090-CSBM1DF

-10AFxx Cable (with brake)

Specifications

Additional specifications for each cable are available in the Kinetix Motion Accessories

.

Specifications Technical Data, publication GMC-TD004

Attribute 2090-CSBM1DF-10AFxx

Conducto r size (gauge):

DC bus

Digital servo link (data)

(1)

Brake

Diameter 19 mm (0.75 in.)

Continuous-flex zone radius, max 190 mm (7.5 in.)

(1) Controlled impedance data pair.

5.4 mm2 (10 AWG)

0.4 mm

0.4 mm

2

(22 AWG)

2

(22 AWG)

Rockwell Automation Publication 2090-IN049A-EN-P - October 2013

Page 4

Additional Resources

These documents contain information concerning related products from Rockwell Automation.

Resource Description

Kinetix 5500 Servo Drives User Manual, publication

2198-UM001

Kinetix 5500 Feedback Connector Kit Installation

Instructions, publication 2198-IN002

Kinetix VP Low-inertia Servo Motor with 063…165 mm

Frame Size Installation Instructions, publication VPL-IN001

Information on installing, configuring, starting, and

troubleshooting a Kinetix® 5500 servo drive system with a servo

motor.

Information on installing the Kinetix 5500 feedback connector kit.

Information on the installation of your Kinetix VP servo motor with

063…165 mm frame size.

You can view or download publications at http://www.rockwellautomation.com/literature

To order paper copies of technical documentation, contact your Allen-Bradley distributor or

Rockwell Automation sales representative.

Allen-Bradley, Kinetix, Rockwell Software, and Rockwell Automation are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Ro ckwell Automation are property of their respective companies.

.

Rockwell Otomasyon Ticaret A.Ş., Kar Plaza İş Merkezi E Blok Kat:6 34752 İçerenköy, İstanbul, Tel: +90 (216) 5698400

Publication 2090-IN049A-EN-P - October 2013 PN-226153

Copyright © 2013 Rockwell Automation, Inc. All rights reserved. Printed in the U.S.A.

Loading...

Loading...