Page 1

Installation Instructions

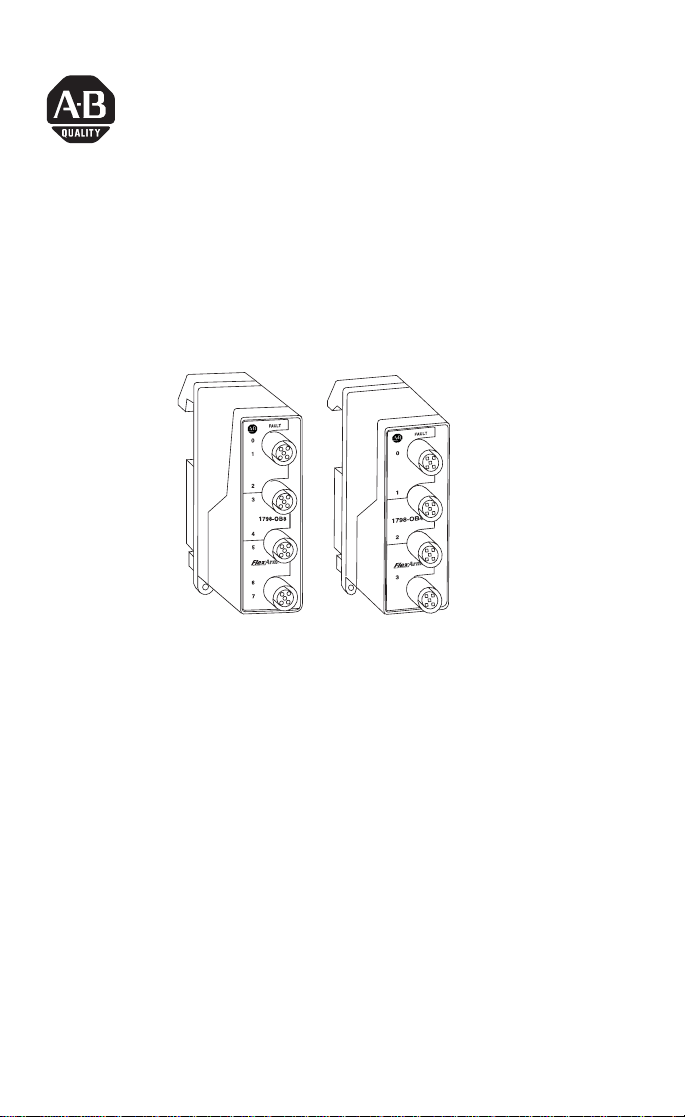

FlexArmor 24V dc Sourcing

Output Modules

Catalog Number 1798-OB4E & 1798-OB8E

42639

The FlexArmor I/O modules (Cat. No. 1798-OB4E & 1798-OB8E)

mount in a FlexArmor Baseplate. Use compatible sealed cordsets to

connect all field side wiring.

The 1798-OB4E module provides connections for up to 4 outputs.

The 1798-OB8E module provides connections for up to 8 outputs.

Both of these modules have four 12 mm connectors. Outputs are 24V

dc configured for sinking devices. A diagnostic feature for both

modules includes output short-circuit detection.

Package Contents

Your package contains:

• 1 FlexArmor -OB4E or -OB8E module

• installation instructions

(Note: Baseplates and other components are ordered and shipped

separately.)

Publication 1798-IN002A-EN-P - January 2001

Page 2

2 FlexArmor 24V dc Sourcing Output Modules

European Union Directive Compliance

If this product has the CE mark it is approved for installation within

the European Union and EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2 EMC - Generic Emission Standard, Part 2 -

Industrial Environment

• EN 50082-2 EMC - Generic Immunity Standard, Part 2 -

Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low

Voltage, by applying the safety requirements of EN 61131-2

Programmable Controllers, Part 2 - Equipment Requirements and

Tests.

For specific information required by EN 61131-2, see the appropriate

sections in this publication, as well as the following Allen-Bradley

publications:

• Industrial Automation Wiring and Grounding Guidelines For

Noise Immunity, publication 1770-4.1

• Automation Systems Catalog, publication B113

Related Publications

For software configuration information, refer to the 1798-ADN User

Manual, publication 1798-UM001A-US-P and the 1798-APB User

Manual, publication 1798-UM002A-EN-P.

Publication 1798-IN002A-EN-P - January 2001

Page 3

FlexArmor 24V dc Sourcing Output Modules 3

Install Your FlexArmor I/O Module

To install the module:

• Install the modules into the Baseplate

• Connect the cordsets

• Communicate with the module

These steps are explained in more detail in the following

procedures.

For instructions on how to mount the FlexArmor Baseplate,

refer to publication no. 1798-IN003A-EN-P.

Install the Modules into the Baseplate

To install the modules into the Baseplate:

1. Hold the module at an angle and engage the top of the

module in the indention on the rear of the Baseplate.

2. Press the module down flush with the panel until the locking

lever locks.

3. Repeat these steps for each I/O module and each remaining

Baseplate I/O slot.

IMPORTANT

Screw down the module retaining screws to ensure IP67 compliance.

IMPORTANT

I/O modules can be installed in any slot location

to the right of the adapter module. The adapter is

capable of addressing up to eight I/O modules.

• Torque the screws to 0.5-0.7 Nm. (4.43 - 6.2

inch pounds).

• Dust caps must have 4 inch pounds of torque

to maintain IP67 compliance.

Publication 1798-IN002A-EN-P - January 2001

Page 4

4 FlexArmor 24V dc Sourcing Output Modules

Connect the Cordset to the FlexArmor Module

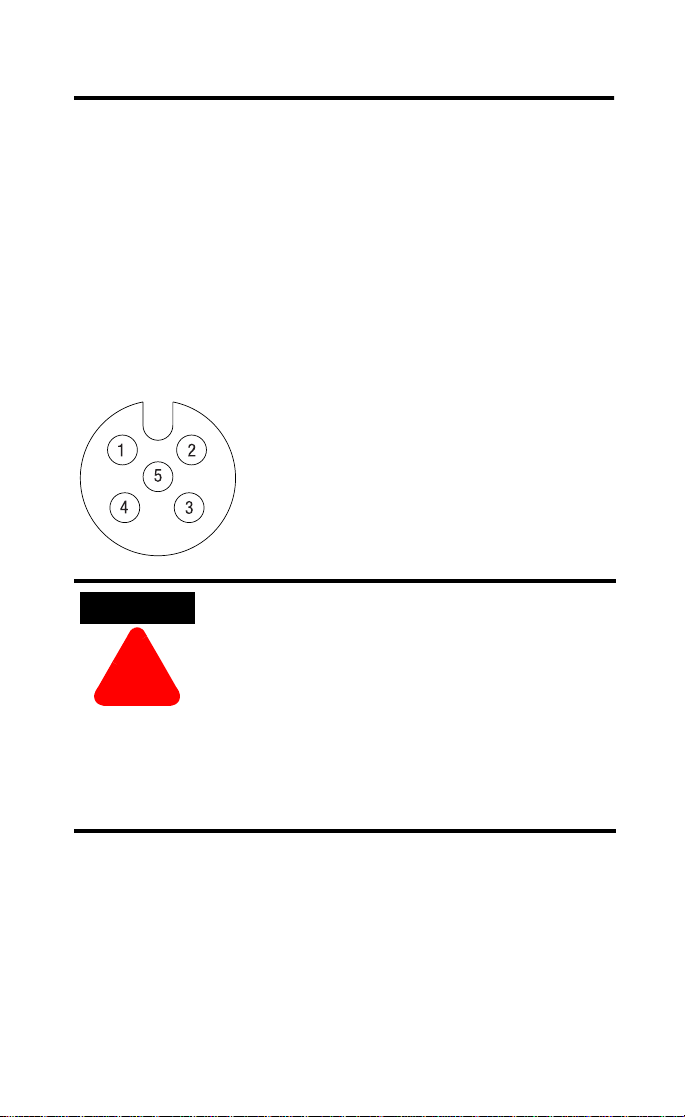

These modules use 5 pin micro (12mm) style PCB mounted

connectors.

Four micro caps cover the I/O connectors on both your modules.

Remove the caps and connect your cables to the appropriate ports.

Keep the caps in place on any unused connector to maintain the IP67

rating.

Refer to publication no. 889-CP0021A-EN-P for compatible Rockwell

Automation cables and cordsets.

A pinout diagram for the connectors is shown below.

Output Micro-Connector

(View into Socket)

Pin 1 Not Used

Pin 2 Output B (OB8E modules only)

Pin 3 Output Common

Pin 4 Output A

Pin 5 Not Used

42652

ATTENTION

!

Publication 1798-IN002A-EN-P - January 2001

• Make sure all connectors and caps are

securely tightened to properly seal the

connections against leaks and maintain IP67

requirements.

• For maximum noise immunity, input and

output cable return wires must be properly

terminated. When inputs and outputs are

connected in loopback, return wires should

be connected together.

• I/O cable length should be less than 30

meters.

Page 5

FlexArmor 24V dc Sourcing Output Modules 5

Communicate with Your FlexArmor System

The FlexArmor DeviceNet adapter module supports multiple

communication choices. The network master makes the actual

communication choice. The choices are:

Polled - data is sent by the adapter in response to received data.

Strobe - data is sent by the adapter in response to the strobe

command. The single bit allocated to the adapter in the strobe

message is not used. If the configured size of the input data (sent

from the adapter) is greater than 8 bytes, the strobe connection

establishment will fail. In this case, the input size must be

re-configured to 8 bytes or less.

Change of State - data is sent by the adapter based on detection of

any changed value within the input data. Data is independently

received based on change of state from the sender. Data in both

directions can be acknowledged or unacknowledged depending on

the run time configuration of the system.

Cyclic - data is sent cyclically by the adapter based on a configured

time value. Data is independently received cyclically from the sender.

Data in both directions can be acknowledged or unacknowledged

depending on the run time configuration of the system.

Troubleshooting with the Indicators

The following table describes status indicators on digital output

modules.

I/O Status Indicators

Function Indicator Status

Outputs

Outputs

Fault LED

Yellow

Off

Red

Off

Output ON

Output OFF

One or more outputs shorted

Normal

Publication 1798-IN002A-EN-P - January 2001

Page 6

6 FlexArmor 24V dc Sourcing Output Modules

Specifications

Output Module Specifications

Specifications 1798-0B4E 1798-0B8E

Module Type Digital Output, Sourcing Digital Output, Sourcing

Number of Channels 1 group of 4 1 group of 8

On-state Voltage 10-28.8V dc; 24V dc nominal 10-28.8V dc; 24V dc nominal

On-state Current

(per channel)

On-state Current (per module) 4.0A per module 5.0A per module

Off-state Voltage 28.8V dc maximum 28.8V dc maximum

Off-State Current 0.5 mA maximum leakage 0.5 mA maximum leakage

On-State Voltage Drop 0.5V dc maximum drop 0.5V dc maximum drop

Surge Current 2.0A for 50 ms

Isolation Voltage 850V dc for 1 second 850V dc for 1 second

Delay Times: Off to On

FlexBus Current 60 mA maximum 60 mA maximum

Power Dissipation 2.4 W @ 28.8 V dc 2.9 W @ 28.8 V dc

Thermal Dissipation 8.2 BTU/hr. @ 28.8V dc 9.9 BTU/hr. @ 28.8V dc

Indicators 4 channel status - yellow

External DC Power

Dimensions

(H x D x W)

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Conductors See publication DN-6.7.2

Cordsets 5 pin micro (12mm) style connectors

Enclosure Meets IP67

Agency Certification

(When product is marked)

On to Off

Voltage (24V dc nom.)

Current

1.0A per channel 1.0A per channel

(Repeatable every 2 seconds)

0.5 ms maximum

1.0 ms maximum

4 fault LED indicators- red

10-28.8V dc; 5% AC ripple

4.0A maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1ms pulse width

50G peak, 11±1ms pulse width

5G @ 10-500Hz per IEC 68-2-6

(see graph on next page)

CUL listed

UL Hazardous Class 1, Division 2, Groups A, B, C, D certified

CE marked for all applicable directives

2.0A for 50 ms

(Repeatable every 2 seconds)

0.5 ms maximum

1.0 ms maximum

8 channel status - yellow

8 fault LED indicators - red

10-28.8V dc; 5% AC ripple

5.0A maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1ms pulse width

50G peak, 11±1ms pulse width

5G @ 10-500Hz per IEC 68-2-6

(see graph on next page)

marked for all applicable acts

N223

Publication 1798-IN002A-EN-P - January 2001

Page 7

FlexArmor 24V dc Sourcing Output Modules 7

Derating Curve

1A

0.5A

Output Current (per channel)

42700

-20° 40° 60°

Ambient Temperature (Celsius)

Hazardous Location Approval

The following information applies only to products marked

with Hazardous Location Approval, when operating in

hazardous locations:

Products marked “CL I, DIV 2, GP A, B, C, D” are suitable for use in

Class I Division 2 Groups A, B, C, D, Hazardous Locations and

nonhazardous locations only. Each product is supplied with markings

on the rating nameplate indicating the hazardous location

temperature code. When combining products within a system, the

most adverse temperature code (lowest “T” number) may be used to

help determine the overall temperature code of the system.

Combinations of equipment in your system are subject to

investigation by the local Authority Having Jurisdiction at the time of

installation.

Publication 1798-IN002A-EN-P - January 2001

Page 8

8 FlexArmor 24V dc Sourcing Output Modules

WARNING

!

WARNING

!

WARNING

!

EXPLOSION HAZARD -

• Do not disconnect equipment unless power

has been removed or the area is known to be

nonhazardous.

• Do not disconnect connections to this

equipment unless power has been removed

or the area is known to be nonhazardous.

Secure any external connections that mate to

this equipment by using screws, sliding

latches, threaded connectors, or other means

provided with this product.

• Substitution of components may impair

suitability for Class I, Division 2.

• If this product contains batteries, they must

only be changed in an area known to be

nonhazardous.

Use supply wires suitable for 30°C above

surrounding ambient.

When used in a Class I, Division 2, hazardous

location, this equipment must be mounted in a

suitable enclosure with proper wiring method that

complies with the governing electrical codes.

Publication 1798-IN002A-EN-P - January 2001

Page 9

FlexArmor 24V dc Sourcing Output Modules 9

Les informations suivantes ne concernent que les produits

marqués pour une utilisation en environnements dangereux :

Les produits marqués « CL I, DIV 2, GP A, B, C, D » ne conviennent

qu’à une utilisation en environnements de Classe I Division 2

Groupes A, B, C, D dangereux et non dangereux. Chaque produit est

livré avec des marquages sur sa plaque d’identification qui indiquent

le code de température pour les environnements dangereux. Lorsque

plusieurs produits sont combinés dans un système, le code de

température le plus défavorable (code de température le plus faible)

peut être utilisé pour déterminer le code de température global du

système. Les combinaisons d’équipements dans le système sont

sujettes à inspection par les autorités locales qualifiées au moment de

l’installation.

AVERTISSEMENT

!

AVERTISSEMENT

!

RISQUE D’EXPLOSION -

• Couper le courant ou s’assurer que

l’environnement est classé non dangereux

avant de débrancher l’équipement.

• Couper le courant ou s’assurer que

l’environnement est classé non dangereux

avant de débrancher les connecteurs. Fixer

tous les connecteurs externes reliés à cet

équipement à l’aide de vis, loquets

coulissants, connecteurs filetés ou autres

moyens fournis avec ce produit.

• La substitution de composants peut rendre cet

équipement inadapté à une utilisation en

environnement de Classe I, Division 2.

• S’assurer que l’environnement est classé non

dangereux avant de changer les piles.

Utiliser des fils d’alimentation qui conviennent à

une température de 30°C au-dessus de la

température ambiante.

Publication 1798-IN002A-EN-P - January 2001

Page 10

10 FlexArmor 24V dc Sourcing Output Modules

AVERTISSEMENT

!

Pour une utilisation en environnement de classe i,

division 2 dangereux, cet equipement doit etre

monte dans un boitier avec un cablage approprie

conforme aux normes electriques en vigueur.

Publication 1798-IN002A-EN-P - January 2001

Page 11

Notes:

FlexArmor 24V dc Sourcing Output Modules 11

Publication 1798-IN002A-EN-P - January 2001

Page 12

Allen-Bradley is a registered trademark of Rockwell Automation.

DeviceNet is a trademark of Open DeviceNet Vendor Association (ODVA).

RSNetWorx for DeviceNet is a trademark of Rockwell Software, Inc.

Publication 1798-IN002A-EN-P - January 2001 PN 957259-72

© 2001 Rockwell Internati onal Corporation. Printed in USA

Loading...

Loading...