Page 1

FlexArmor

1798-ADN (Contains information

on 1798-IB4, -IB8, -OB4E, -OB8E,

-IB4D, -IE4, -OE2)

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of these

products must satisfy themselves that all necessary steps have been

taken to assure that each application and use meets all performance

and safety requirements, including any applicable laws, regulations,

codes and standards. In no event will Rockwell Automation be

responsible or liable for indirect or consequential damage resulting

from the use or application of these products.

Any illustrations, charts, sample programs, and layout examples

shown in this publication are intended solely for purposes of

example. Since there are many variables and requirements associated

with any particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation and Maintenance of Solid-State Control

(available from your local Rockwell Automation office), describes

some important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole

or part, without written permission of Rockwell Automation, is

prohibited.

Throughout this publication, notes may be used to make you aware of

safety considerations. The following annotations and their

accompanying statements help you to identify a potential hazard,

avoid a potential hazard, and recognize the consequences of a

potential hazard:

WARNING

Identifies information about practices or

circumstances that can cause an explosion in a

hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

!

ATTENTION

Identifies information about practices or

circumstances that can lead to personal injury or

death, property damage, or economic loss.

!

IMPORTANT

Identifies information that is critical for successful

application and understanding of the product.

FlexArmor and RSNetWorx for DeviceNet are trademarks of Rockwell Automation.

MicroSoft Windows is a registered trademark of Microsoft Corporation.

Page 3

Summary of Changes

New Modules Information

In this version of the FlexArmor™ User Manual information was

added about the following three FlexArmor modules:

1798-IB4D,

•

1798-IE4, and

•

1798-OE2.

•

Communication and mapping information about these modules are

contained in chapter 2. Configuration information is found in chapter

3.

1 Publication 1798-UM001B-EN-P - November 2002

Page 4

Summary of Changes 2

Notes:

Publication 1798-UM001B-EN-P - November 2002

Page 5

Preface

Introduction

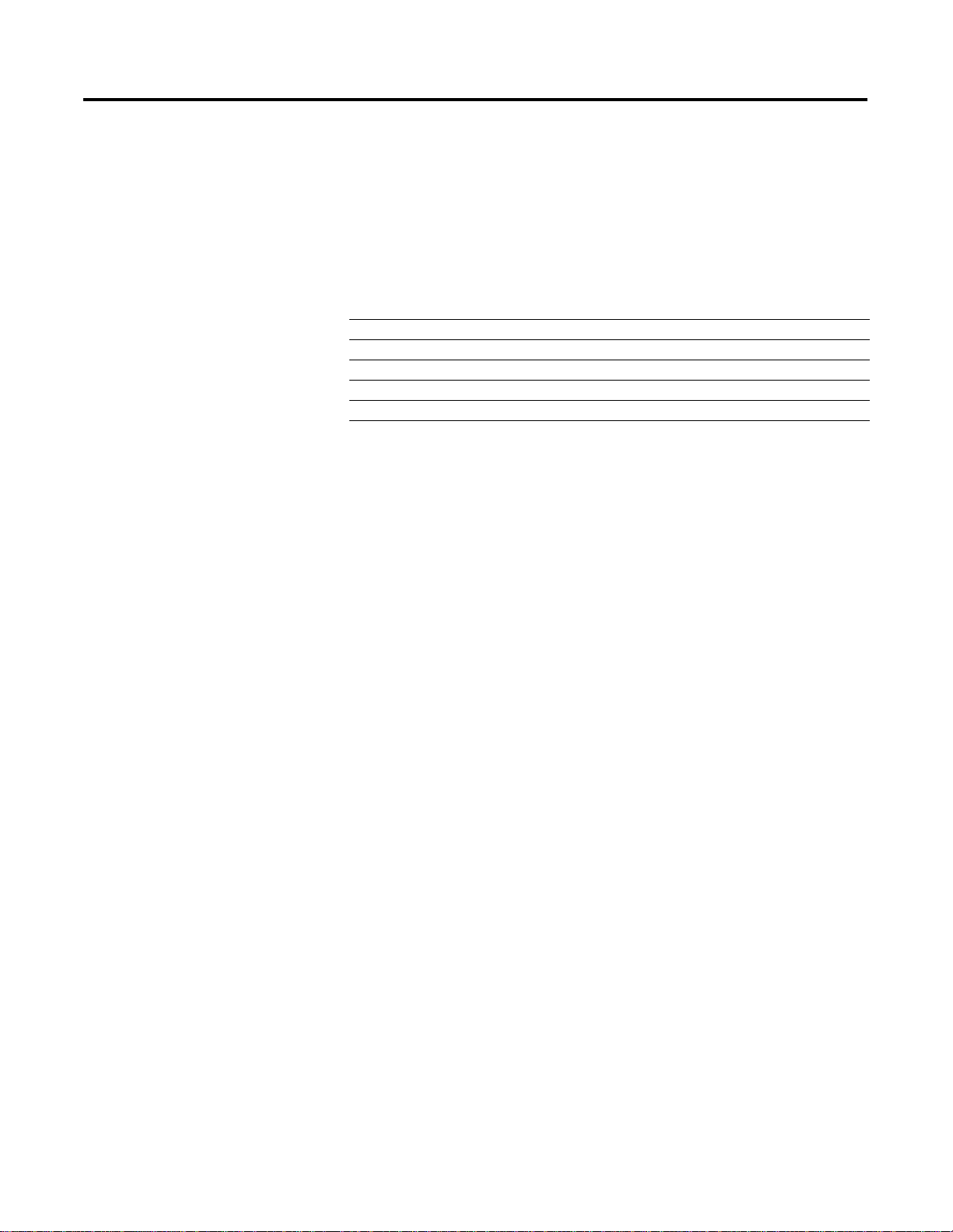

Contents

Audience

What We assume

Use this manual to install, communicate with, map, configure, and

troubleshoot the FlexArmor system.

You will find the following information in this manual:

For information about See

installing your DeviceNet adapter module Chapter 1

how communication takes place and I/O image mapping Chapter 2

how to configure your DeviceNet adapter Chapter 3

troubleshooting Chapter 4

module specifications Appendix A

This manual is intended for engineers and technicians who are

installing, programming, and maintaining a FlexArmor system.

We assume you:

Common Techniques Used in This Manual

know each of your device’s I/O parameters and requirements

•

are familiar with RSNetWorx for DeviceNet™

•

®

are familiar with the Microsoft

•

The following conventions are used throughout this manual:

Bulleted lists provide information, not procedural steps.

•

Numbered lists provide sequential steps.

•

• Pictures of keys and/or screens represent the actual keys you

press or the screens you use.

• Actions you must perform appear in bold text. For example:

Click View to display the EDS file.

Windows® environment

1 Publication 1798-UM001B-EN-P - November 2002

Page 6

Preface 2

Rockwell Automation Support

Before you contact Rockwell Automation for technical assistance, we

suggest you please review the troubleshooting information contained

in chapter 4 of this publication first.

If the problem persists, call your local distributor or contact Rockwell

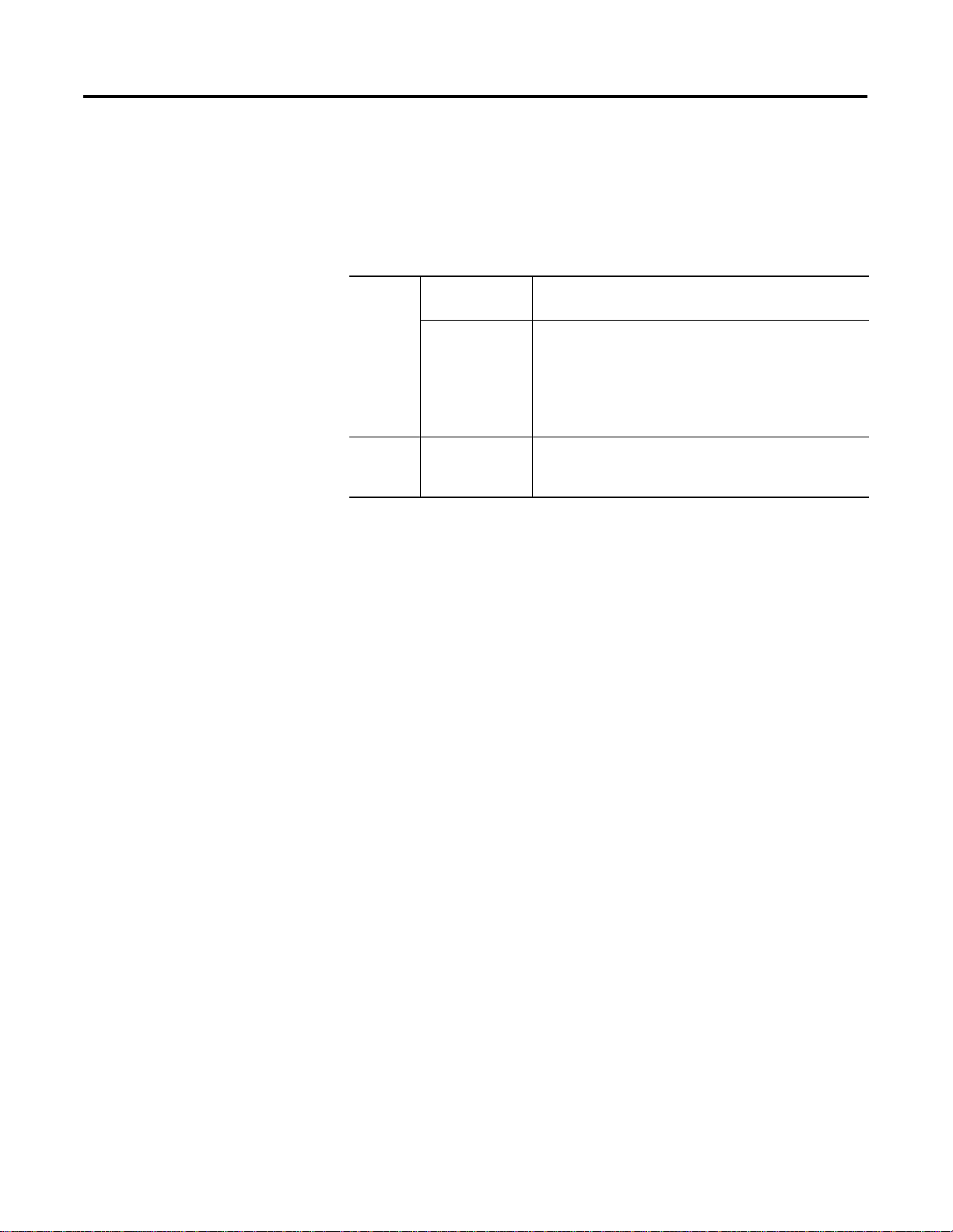

Automation in one of the following ways:

Phone United

States/Canada

Outside United

States/Canada

Internet

⇒

1.440.646.5800

You can access the phone number for your country via the

Internet:

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

3. Under

1. Go to http://www.ab.com

2. Click on

(http://support.automation.rockwell.com)

Product Support

Support Centers

Product Support

, click on

Contact Information

Your Questions or Comments on this Manual

If you find a problem with this manual, please notify us of it on the

enclosed How Are We Doing form found in the back of the manual.

Publication 1798-UM001B-EN-P - November 2002

Page 7

Install Your DeviceNet Adapter

Module

How Communication Takes Place

and I/O Image Table Mapping

Table of ContentsTable of Contents

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

About the FlexArmor System . . . . . . . . . . . . . . . . . . . . . . . 1-1

DeviceNet Adapter Components . . . . . . . . . . . . . . . . . . . . 1-2

Diagnostic Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Mount the FlexArmor Platform. . . . . . . . . . . . . . . . . . . . . . 1-3

Mounting Instructions . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Set the Network Address Switch on the DeviceNet Adapter. 1-4

Install Your FlexArmor DeviceNet Adapter Module. . . . . . . 1-4

Connect External Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Communication Over the FlexArmor Backplane . . . . . . . . . 2-1

About I/O Structure. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Description of Adapter Input Status Word. . . . . . . . . . . 2-3

Communication Choices . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Mapping Data into the Image Table. . . . . . . . . . . . . . . . . . 2-5

Description of 1798-IB4 Image Table Mapping . . . . . . . 2-5

Description of 1798-IB4D Image Table Mapping . . . . . . 2-6

Description of 1798-IB8 Image Table Mapping . . . . . . . 2-7

Description of 1798-OB4E Image Table Mapping . . . . . 2-8

Description of 1798-OB8E Image Table Mapping . . . . . 2-9

Description of 1798-IE4 Image Table Mapping . . . . . . . 2-9

Description of 1798-OE2 Image Table Mapping. . . . . . . 2-12

Chapter 3

Configure Your DeviceNet Adapter

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configure Your Adapter’s FlexArmor System. . . . . . . . . 3-1

About RSNetWorx for DeviceNet . . . . . . . . . . . . . . . . . . . . 3-2

Configure Your FlexArmor Adapter and System Online . . . 3-3

Configure the Adapter . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Configure the Module . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

View Adapter Parameters . . . . . . . . . . . . . . . . . . . . . . . 3-7

Special Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

View I/O Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-15

Map the Scanner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Chapter 4

Troubleshooting

i Publication 1798-UM001B-EN-P - November 2002

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Troubleshoot With the Indicators. . . . . . . . . . . . . . . . . . . . 4-1

Page 8

Table of ContentsTable of Contents ii

Specifications

Appendix A

Input Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . A-1

Specifications for the 1798-IB4 Module . . . . . . . . . . . . . A-1

Specifications for the 1798-IB8 Module . . . . . . . . . . . . . A-2

Specifications for the 1798-IB4D Module. . . . . . . . . . . . A-3

Specifications for the 1798-IE4 Module . . . . . . . . . . . . . A-5

Output Module Specifications . . . . . . . . . . . . . . . . . . . . . . A-7

Specifications for the 1798-OB4E Module . . . . . . . . . . . A-7

Specifications for the 1798-OB8E Module . . . . . . . . . . . A-8

Specifications for the 1798-OE2 Module . . . . . . . . . . . . A-9

Communication Adapter Specifications. . . . . . . . . . . . . . . A-12

Field Termination Plug Specifications. . . . . . . . . . . . . . . . A-13

Baseplate Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . A-14

Publication 1798-UM001B-EN-P - November 2002

Page 9

Chapter

Install Your DeviceNet Adapter Module

1

Chapter Objectives

About the FlexArmor System

This chapter describes the FlexArmor system, the DeviceNet Adapter

and the procedures for installing your DeviceNet adapter module. The

sections in this chapter include:

the FlexArmor system

•

adapter components

•

power requirements

•

mount the adapter

•

set the adapter address switches

•

install the adapter module

•

connect the external wiring

•

FlexArmor is a small, modular block I/O system for distributed

applications that performs all of the functions of rack-based I/O. The

FlexArmor system contains the following components:

Baseplate, 1798-BP2, -BP4, -BP6, or -BP8

•

DeviceNet adapter/power supply, 1798-ADN - powers the

•

internal logic for as many as eight I/O modules

I/O modules contain the bus interface and circuitry needed to

•

perform specific functions related to your application. These I/O

modules include:

– Input modules, 1798-IB4 or -IB8, -IB4D, and -IE4

– Output modules, 1798-OB4E or -OB8E, and OE2

• Field Termination Plug (FTP), 1798-DFTP1 or -DFTP2

• Filler module, 1798-N2

1 Publication 1798-UM001B-EN-P - November 2002

Page 10

1-2 Install Your DeviceNet Adapter Module

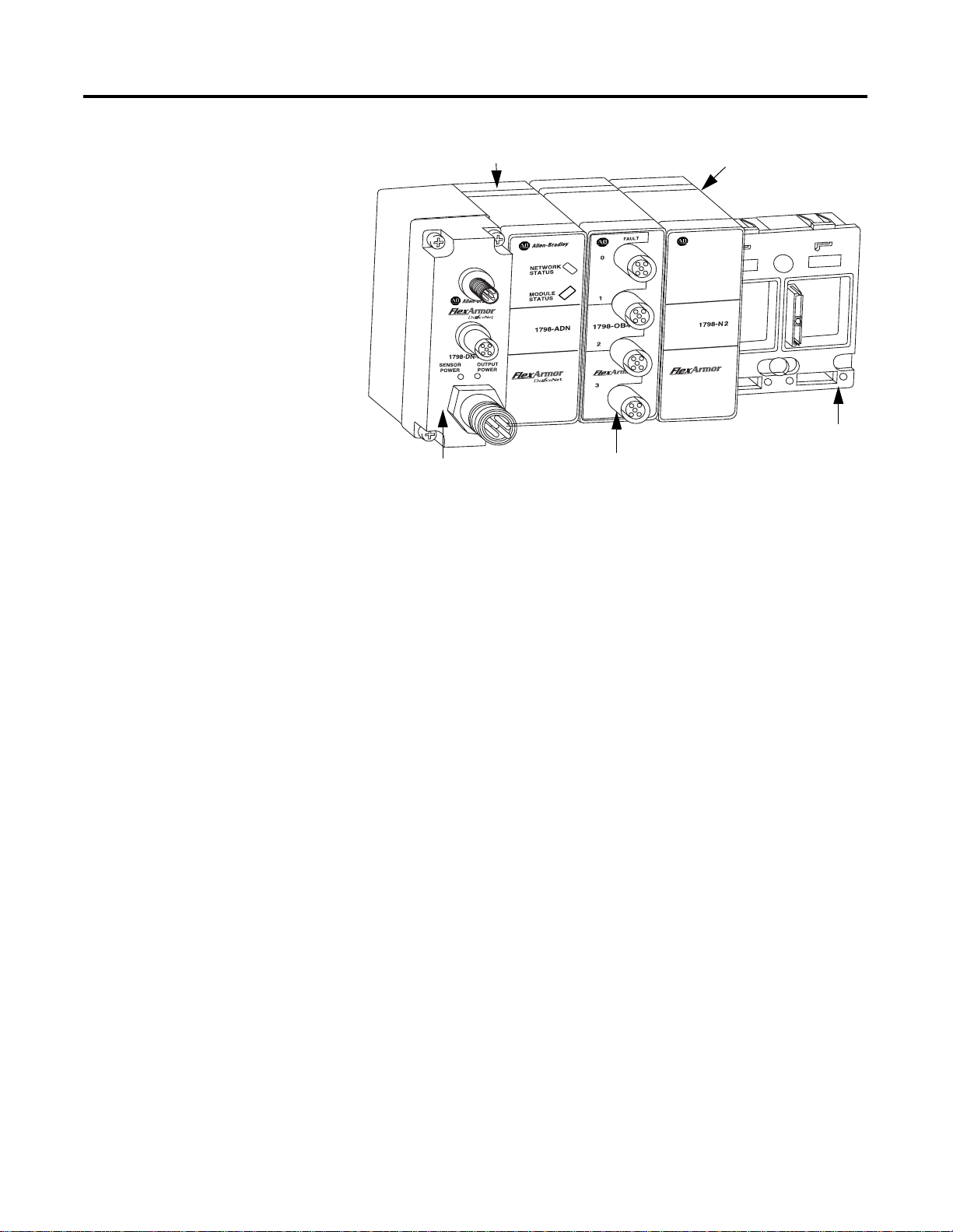

1798-ADN

FTP (Field Termination Plug)

1798-0B4E

1798-N2

42537

1798-BP4

4-position

Baseplate

For information on how communications occurs on the FlexArmor

system backplane, refer to Chapter 2.

DeviceNet Adapter Components

Power Requirements

The adapter module consists of the following major components:

diagnostic indicators

•

node address switch

•

Diagnostic Indicators

Diagnostic indicators are located on the front panel of the adapter

module. They show both normal operation and error conditions in

your remote I/O system. The indicators are:

• Mod/Net status

• I/O status

A complete description of the diagnostic indicators and how to use

them for troubleshooting is explained in Chapter 4.

The FlexArmor system requires a current of 400 mA at 24V dc from

the 1798-FTP sensor power connector for FLEX bus operation. This is

sufficient to support up to 8 modules. Remember to add this amount

to current requirements for other modules using the same 24V supply.

The FlexArmor system consumed 90 mA of DeviceNet power.

Publication 1798-UM001B-EN-P - November 2002

Page 11

Install Your DeviceNet Adapter Module 1-3

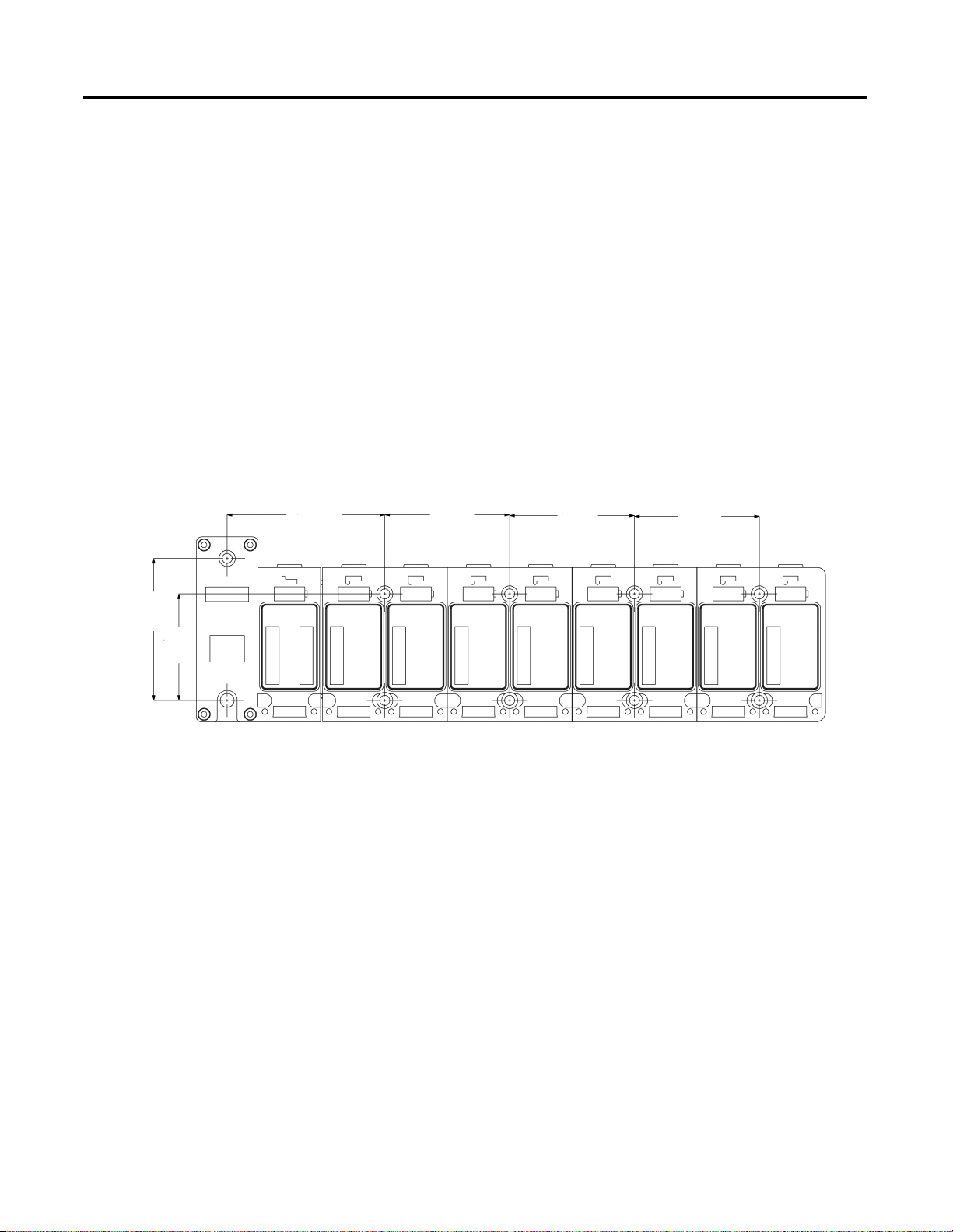

Mount the FlexArmor Platform

102.5 mm

4.0 in.

The DeviceNet adapter module can be mounted directly on a

machine. Refer to the specific method of mounting below.

Mounting Instructions

To mount the platform on a wall or panel, use the screw holes

provided in the FlexArmor Baseplate.

Install the mounting Baseplate as follows:

1. Lay out the required points as shown in the drilling dimension

drawing.

25 mm (0.98 in.) clearanc e all around

102.5 mm

4.0 in.

102.5 mm

4.0 in.

102.5 mm

4.0 in.

92 mm

3.6 in.

69 mm

2.7 in.

42665

2. Drill the necessary holes for #10 (M6) machine or self-tapping

screws.

3. Mount the Baseplate using #10 (M6) screws.

4. Connect functional ground to ground using the functional

ground lug connector.

To view a drill template for the FlexArmor Baseplate, refer to the

website http://www.ab.com/abecad/.

You are now ready to set the node address on the FlexArmor adapter

module and to install your selected FlexArmor components. Please

refer to the individual component installation instructions for

guidelines.

Publication 1798-UM001B-EN-P - November 2002

Page 12

1-4 Install Your DeviceNet Adapter Module

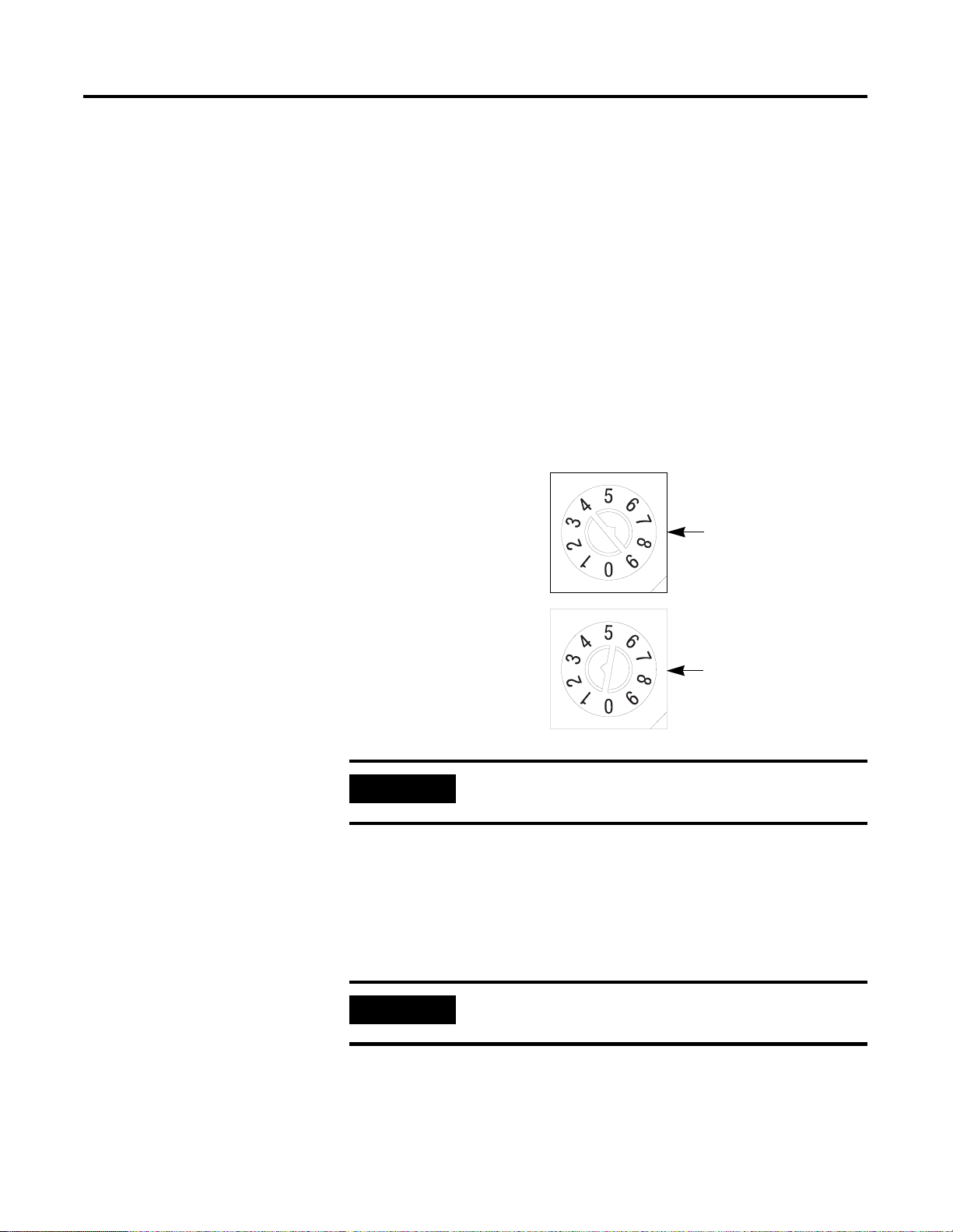

Set the Network Address Switch on the DeviceNet Adapter

Valid node addresses are 00 to 63.

Set the network address using the rotary switches. The setting of the

network address cannot be changed using the DeviceNet

configuration software.

Each module is shipped set for node address 63. The switches are

located on the underside of the module. The two switches are:

MSD (most significant digit)

•

LSD (least significant digit)

•

To reset the node address, use a small blade screwdriver to rotate the

switches. Line up the small black dot on the switch with the number

setting you wish to use.

MSD

Install Your FlexArmor DeviceNet Adapter Module

Switches are

shown in the

63 position.

IMPORTANT

To install the FlexArmor DeviceNet Adapter Module:

1. Hold the adapter at an angle and engage the top of the adapter

in the indention on the rear of the Baseplate.

IMPORTANT

2. Press the module down flush with the panel until the locking

lever locks.

The baud rate for the adapter is set by way of “baud

detection” (Autobaud) at power up.

The adapter module must be installed only in the

adapter slot, next to the FTP.

LSD

43387

Publication 1798-UM001B-EN-P - November 2002

Page 13

Install Your DeviceNet Adapter Module 1-5

3. Repeat steps 1 and 2 for each I/O module for the remaining

Baseplate I/O slots.

Connect External Wiring

IMPORTANT

I/O modules can be installed in any slot location to

the right of the adapter module. The adapter is

capable of addressing eight modules.

4. Screw down the module retaining screws to ensure IP67

compliance.

Torque the screws to 0.5-0.7 Nm. (4.43-6.2 inch

IMPORTANT

•

pounds).

Dust caps on the I/O modules must have 4 inch

•

pounds of torque to maintain IP67 compliance.

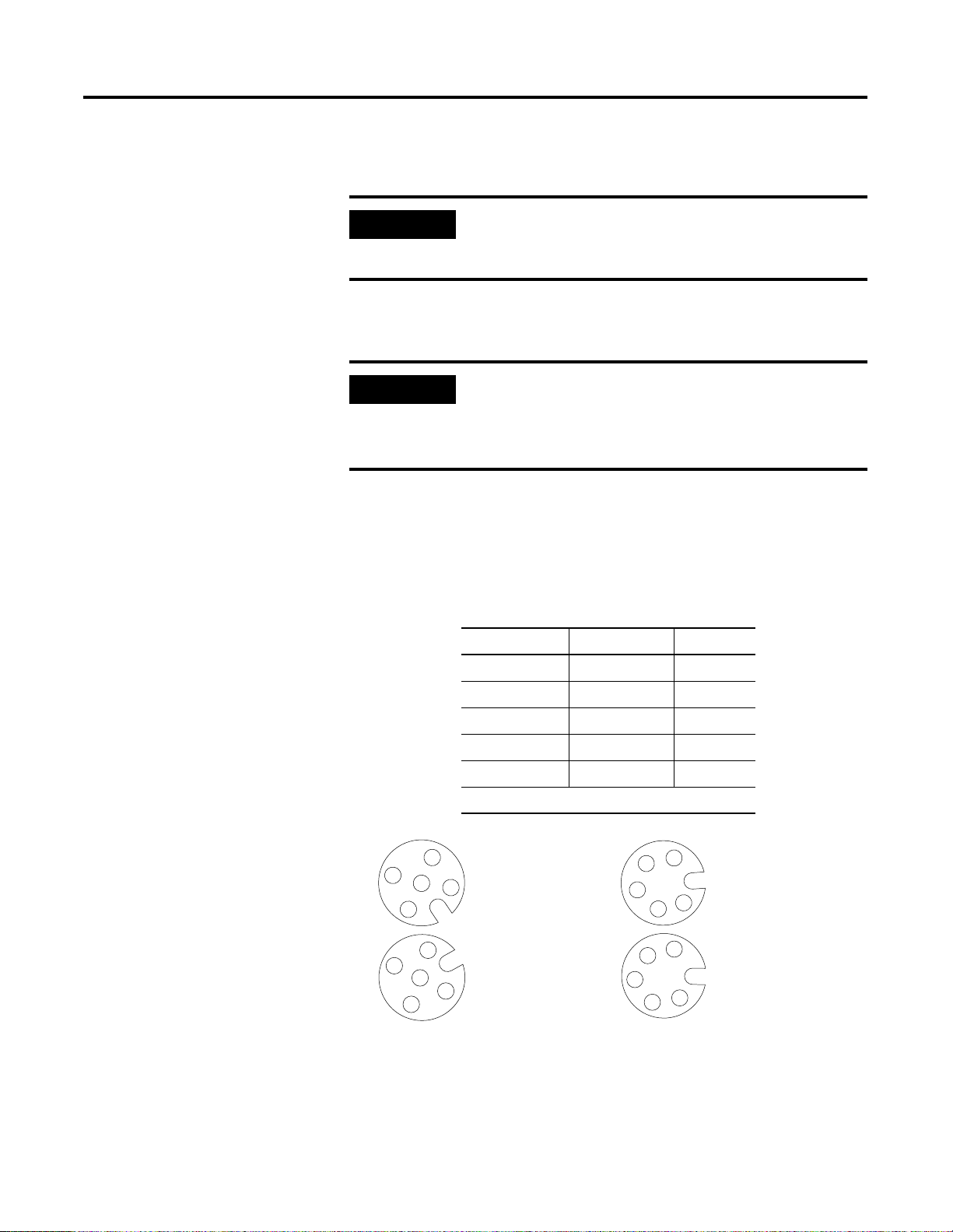

Connect external wiring to the DeviceNet Field Termination Plug

(DFTP) as shown below.

1. Connect the DeviceNet cable to the DFTP as shown.

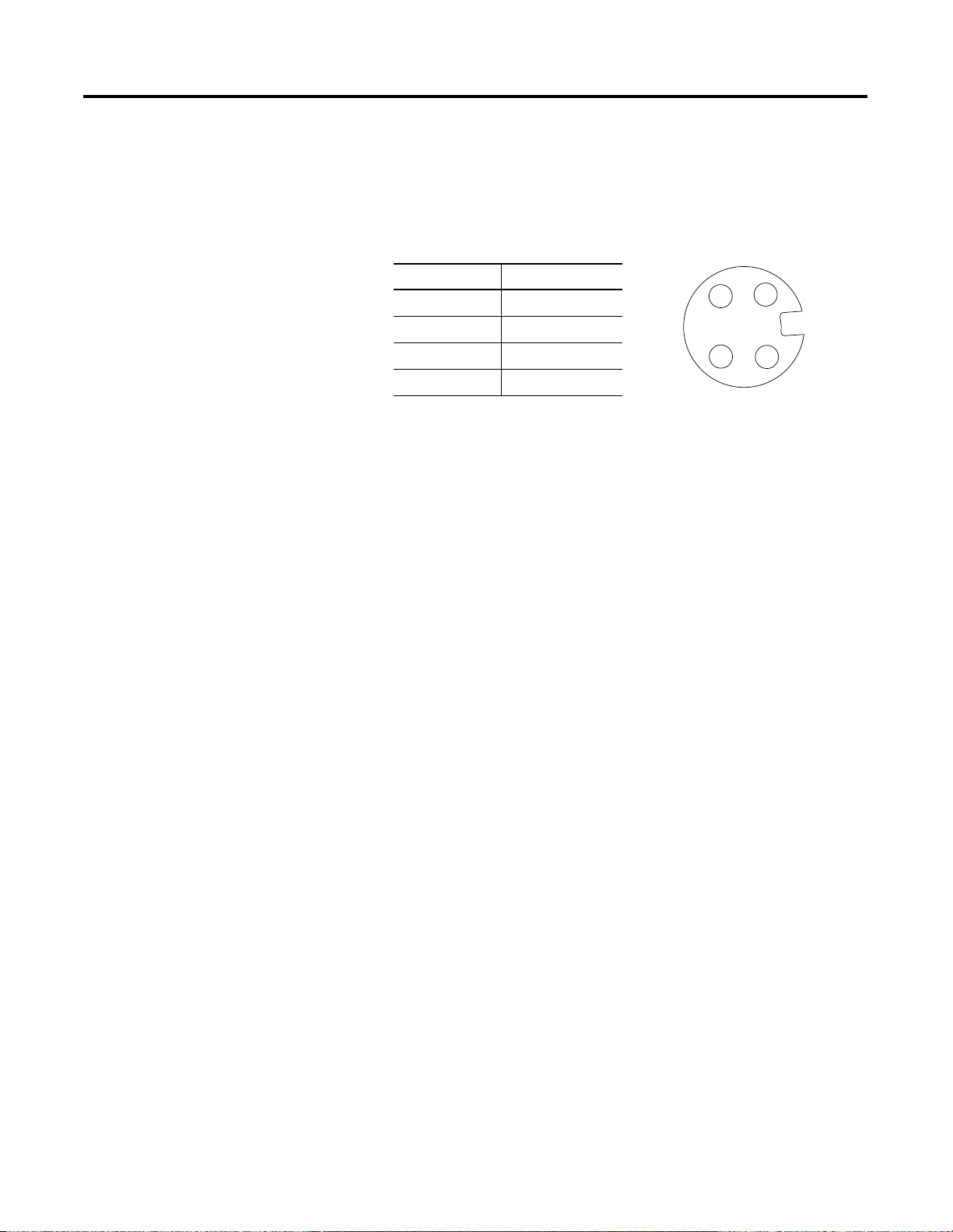

Connect Connector Pin To

BLK Wire 3 -V

BLU Wire 5 CAN* Low

Base Wire 1 Drain

WHT Wire 4 CAN High

RED Wire 2 +V

*CAN=Controller Area Network

Micro Male connector (In)

3

4

5

2

1

1

4

5

3

DFTP1 DFTP2

Micro Female connector

(Daisy Chain Out)

2

42538

3

3

2

4

4

2

Mini Male connector (In)

1

5

5

Mini Female connector

(Daisy Chain Out)

1

42653

2. Insert the connector into the mating connector on the

3. DeviceNet FTP module.

Publication 1798-UM001B-EN-P - November 2002

Page 14

1-6 Install Your DeviceNet Adapter Module

4. Connect 24V dc power to sensor voltage for adapter and input

module power.

5. Connect 24V dc power to output voltage for output module

power.

Pin Function

1 Output Power +

2 Sensor Power +

3 Sensor Power 4 Output Power -

34

1

2

Male Connector

42539

Publication 1798-UM001B-EN-P - November 2002

Page 15

Chapter

How Communication Takes Place and I/O

Image Table Mapping

2

Chapter Objectives

Communication Over the FlexArmor Backplane

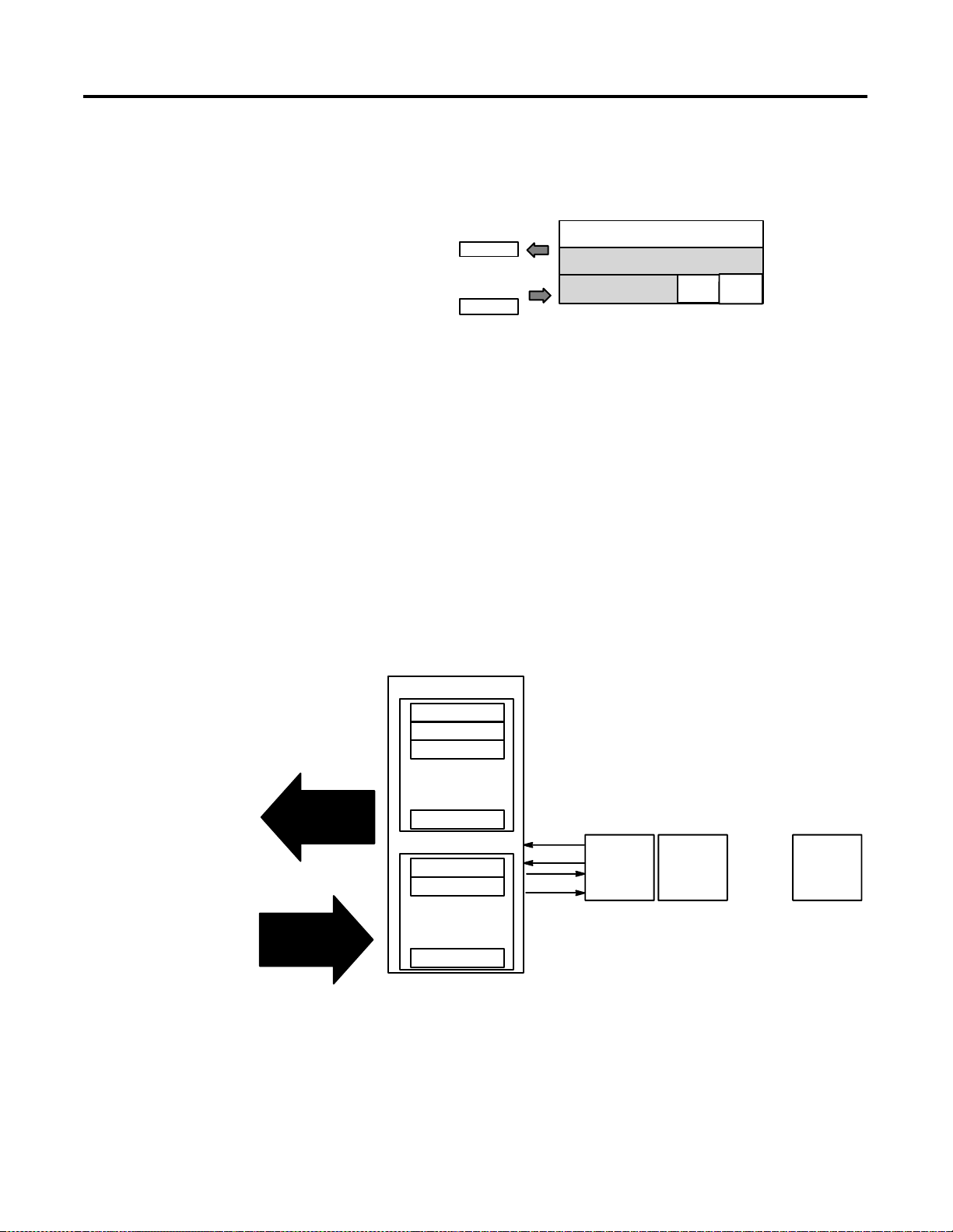

Read

Network

DeviceNet

Adapter

Write

In this chapter, you will learn about:

communication over the FlexArmor backplane (between the

•

DeviceNet adapter and the I/O modules)

how data is mapped into the I/O image table

•

One 1798-ADN DeviceNet adapter can interface with up to eight

FlexArmor I/O modules placed in a FlexArmor baseplate. The adapter

communicates to other network system components (typically one or

more controllers or scanners, and/or programming terminals) over the

DeviceNet network. The adapter communicates with its I/O modules

over the backplane.

I/O Module I/O Module I/O Module

Inputs Inputs Inputs

Read

Status Status Status

Outputs Outputs Outputs

Configuration Configuration Configuration

Words

Write

Words

Slot 0

The I/O map for a module is divided into read words and write

words. Read words consist of input and status words and write words

consist of output and configuration words. The number of read words

or write words can be zero or more. The length of each I/O module’s

read words and write words varies in size depending on module

complexity. Each I/O module will support at least 1 input word or 1

output word. Status and configuration are optional, depending on the

module.

1 Publication 1798-UM001B-EN-P - November 2002

Slot 1 Slot 7

Page 16

2-2 How Communication Takes Place and I/O Image Table Mapping

For example, a 4 point discrete input module will have up to 2 read

words and 1 write word.

About I/O Structure

4-point Discrete Input Module

Check the I/O map for each module for the exact mapping.

Output data is received by the adapter in the order of the installed I/O

modules. The Output data for slot 0 is received first, followed by the

Output data for slot 1, and so on up to slot 7.

The first word of input data sent by the adapter is the Adapter Status

Word. This is followed by the input data from each slot, in the order

of the installed I/O modules. The Input data from slot 0 is first after

the status word, following by Input data from slot 2, and so on up to

slot 7.

I/O Image

Input Size

1 or 2 Words

Output Size

0 or 1 Words

Not used

Module Image

Inputs

Not used

Delay

Time

Delay

Tim e

Network READ

Network WRITE

DeviceNet Adapter

Read Data

Adapter Status

Slot 0 Input Data

Slot 1 Input Data

...

Slot 7 Input Data

Slot 0 Output Data

Slot 1 Output Data

...

Slot 7 Output Data

...

...

Read

Write

I/O Module

Slot 0

I/O Module

Slot 1

...

I/O Module

Slot 7

Publication 1798-UM001B-EN-P - November 2002

Page 17

How Communication Takes Place and I/O Image Table Mapping 2-3

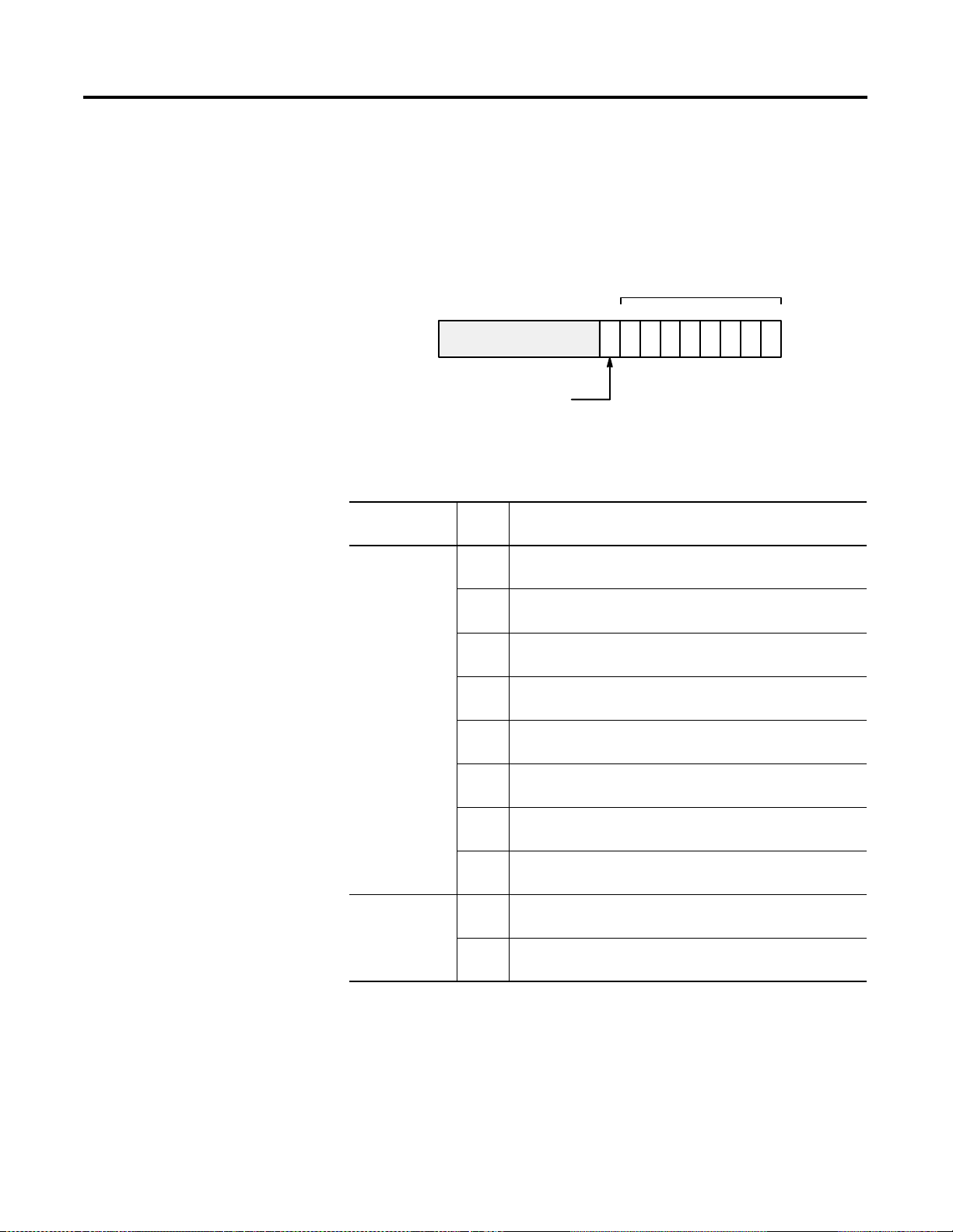

Description of Adapter Input Status Word

The input status word consists of:

I/O module fault bits - 1 status bit for each slot

•

node address changed - 1 bit

•

I/O Module Fault Bits

Bit: 15 9 through 15 8 7 6 5 4 3 2 1 0

Not Used

Node Address Changed Bit

Slot 7

Slot 6

Slot 5

Slot 4

Slot 3

Slot 2

Slot 1

Slot 0

42843

The adapter input status word bit descriptions are shown in the

following table.

Bit

Description

I/O Module

Fault

Bit Explanation

0 This bit is set (1) when an error is detected in slot

position 0.

1 This bit is set (1) when an error is detected in slot

position 1.

2 This bit is set (1) when an error is detected in slot

position 2.

3 This bit is set (1) when an error is detected in slot

position 3.

4 This bit is set (1) when an error is detected in slot

position 4.

5 This bit is set (1) when an error is detected in slot

position 5.

Node Address

Changed

6 This bit is set (1) when an error is detected in slot

position 6.

7 This bit is set (1) when an error is detected in slot

position 7.

8 This bit is set (1) when the node address switch setting

has been changed since power up.

9 thru 15Not used - sent as zeroes.

Publication 1798-UM001B-EN-P - November 2002

Page 18

2-4 How Communication Takes Place and I/O Image Table Mapping

Possible causes for an I/O Module Fault are:

transmission errors on the FlexArmor backplane

•

a failed module

•

a module removed from the FlexArmor Baseplate

•

incorrect module inserted in a slot position

•

the slot is empty, but the platform is configured for a module in

•

the slot location

Communication Choices

The FlexArmor DeviceNet adapter module supports multiple

communication choices. These choices all use the default I/O

structure previously described. The adapter master makes the actual

communication choice. The choices are:

Polled - data is sent by the adapter in response to received data

Strobe - data is sent by the adapter in response to the strobe

command. The single bit allocated to the adapter in the strobe

message is not used. If the configured size of the input data (sent from

the adapter) is greater than 8 bytes, the strobe connection

establishment will fail. In this case, the input size must be

re-configured to 8 bytes or less.

Change of State - data is sent by the adapter based on detection of

any changed value within the input data. Data is independently

received based on change of state from the sender. Data in both

directions can be acknowledged or unacknowledged depending on

the run time configuration of the system.

Cyclic - data is sent cyclically by the adapter based on a configured

time value. Data is independently received cyclically from the sender.

Data in both directions can be acknowledged or unacknowledged

depending on the run time configuration of the system.

Publication 1798-UM001B-EN-P - November 2002

Page 19

How Communication Takes Place and I/O Image Table Mapping 2-5

Mapping Data into the Image Table

All FlexArmor modules are supported by the DeviceNet adapter. At

present, these consist of:

Module Description Catalog Number For image table

mapping refer to:

4 Sinking Input Module 1798-IB4 2-5

4 Sinking Input

1798-IB4D 2-6

Diagnostic Module

8 Sinking Input Module 1798-IB8 2-7

4 Electronically Fused

1798-OB4E 2-8

Sourcing Output Module

8 Electronically Fused

1798-OB8E 2-9

Sourcing Output Module

4 Analog Input Module 1798-IE4 2-9

2 Analog Output Module 1798-OE2 2-12

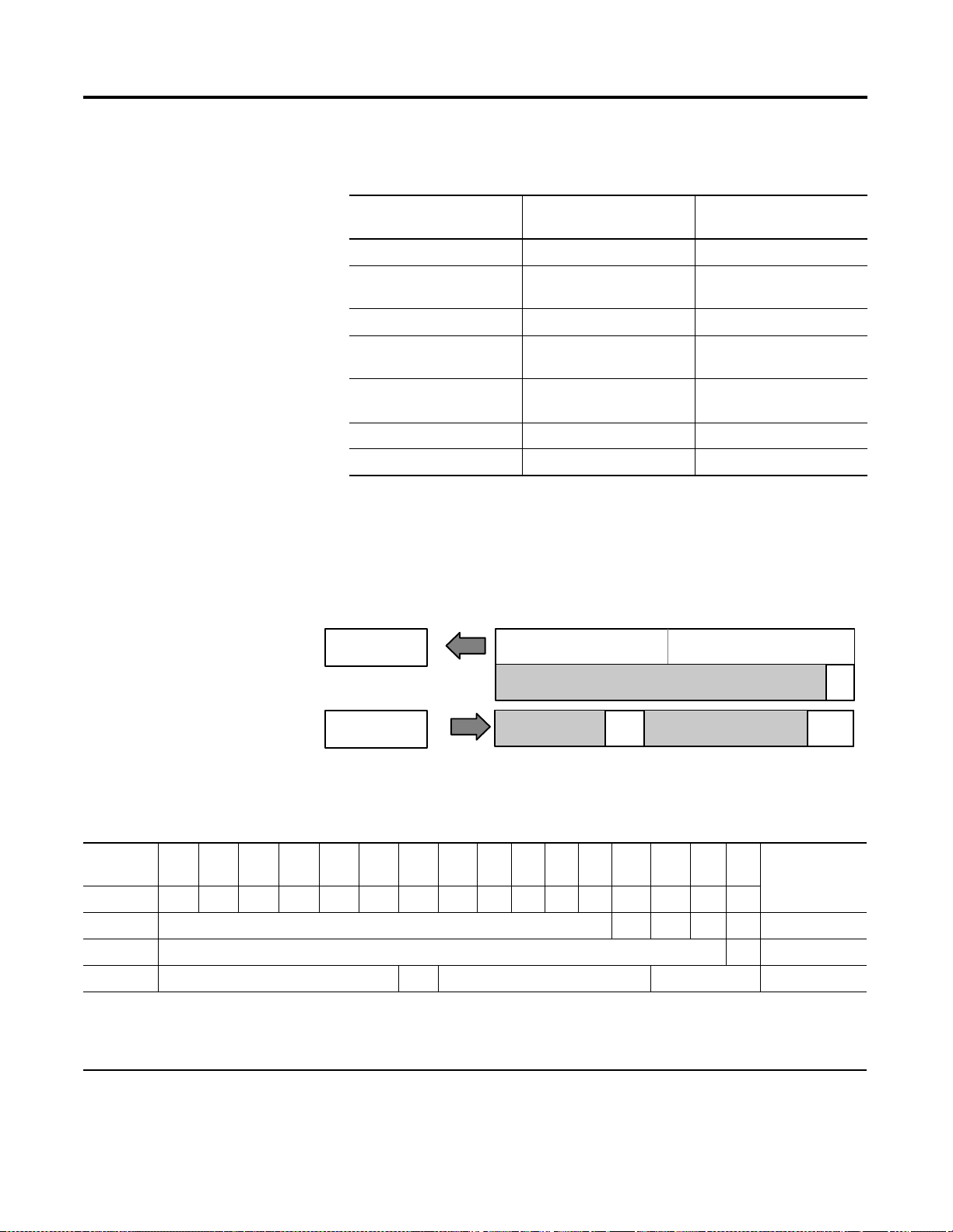

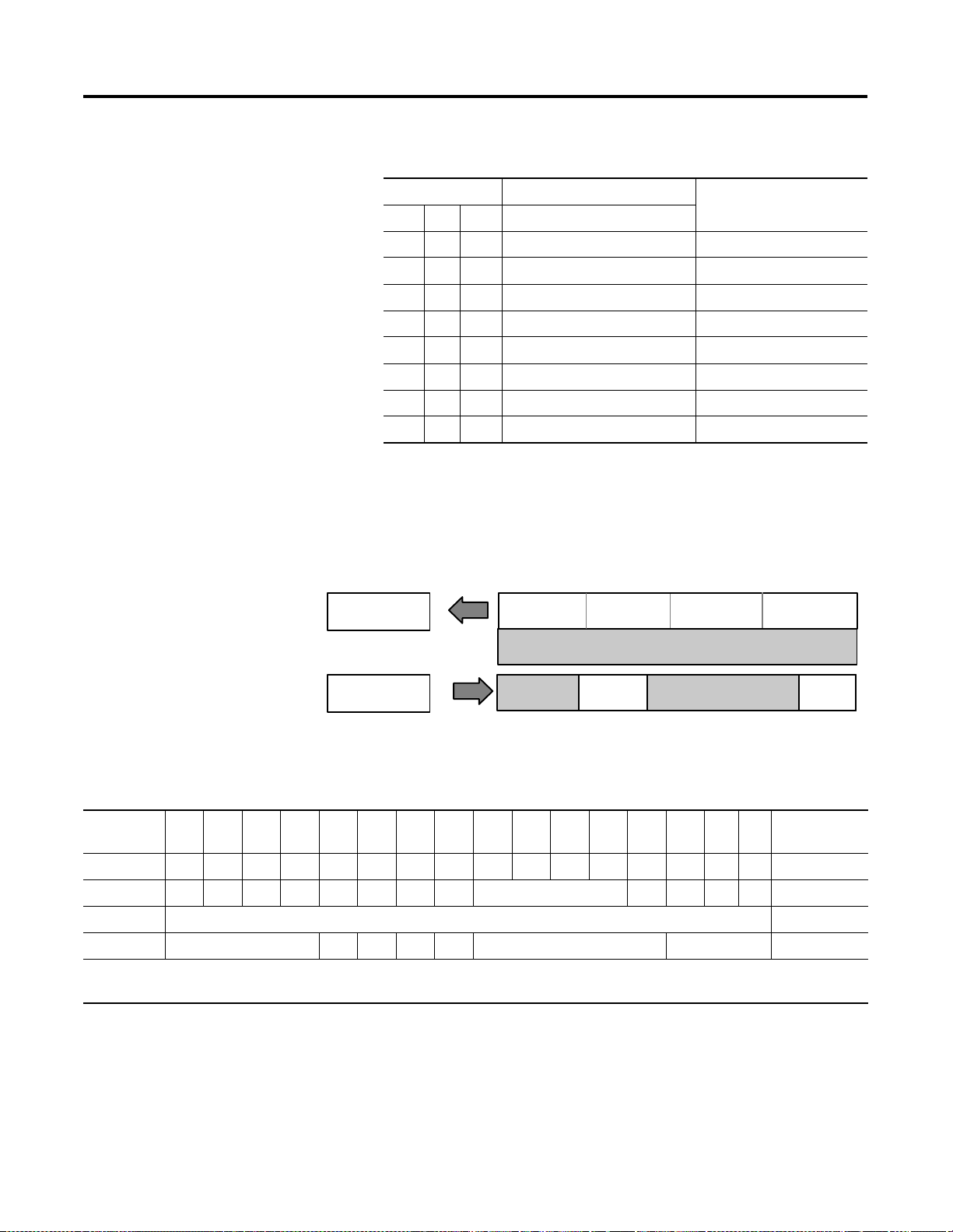

Description of 1798-IB4 Image Table Mapping

Read

Write

I/O Image

Input Size

1 or 2 Words

Output Size

0 or 1 Word

Reserved

Reserved

Fault

Enabled

Not used

Module Image

Reserved

Inputs

Fault

Input

Delay

Time

42840

Memory Map of 4 Point Discrete Input Module Image Table - 1798-IB4

Decimal

Bit

Octal Bit17161514131211100706050403020100

Where D = Input Data (D0 correspon ds to input 0, D1 corresponds to input 1, etc.), DT = Input Delay Time (DT 00-3

corresponds to inputs 0 through 3), FO = Fault Bit - Indicates status of module sensor power (0=Normal, 1=Sensor Power

Shorted), FE = Fault Enabled Bit, must be set to return fault bit (FO) from module. The “Fault Enabled” bit will be set

automatically if the input filter times are configured through RSNetWorx for DeviceNet.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Size

Not used D3 D2 D1 D0 Read Word 1

Not used FO Read Word 2

Reserved FE Reserved DT 00-3 Write Word 1

Publication 1798-UM001B-EN-P - November 2002

Page 20

2-6 How Communication Takes Place and I/O Image Table Mapping

Input Delay Times for the 1798-IB4 Input Module

Bits Description Selected Delay Time

02 01 00 Delay Time for Inputs 00-03

0 0 0 Delay Time 0 (default) 256µs

0 0 1 Delay Time 1 512µs

0 1 0 Delay Time 2 1ms

0 1 1 Delay Time 3 2ms

1 0 0 Delay Time 4 4ms

1 0 1 Delay Time 5 8ms

1 1 0 Delay Time 6 16ms

1 1 1 Delay Time 7 32ms

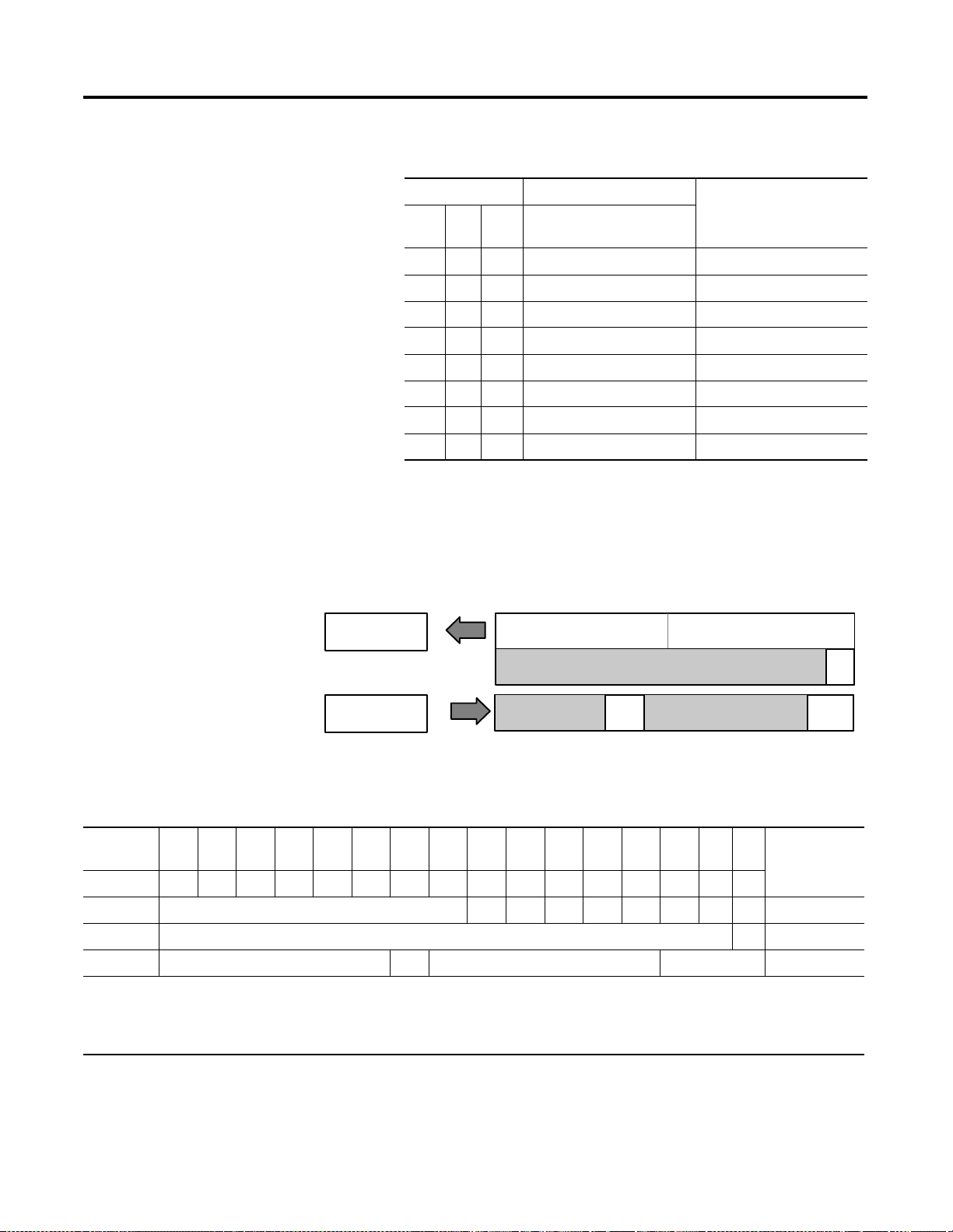

Description of 1798-IB4D Image Table Mapping

Read

Write

I/O Image

Input Size

1 or 2 Words

Output Size

0 or 1 Word

Short Circuit

Detect

Reserved

Open Wire

Detect

Open Wire

Disables

Module Image

Not Used

Not used

Reserved

Inputs

Delay

Tim e

Memory Map of 4 Point Discrete Input Module Image Table - 1798-IB4D

Decimal

Bit

Octal Bit17161514131211 100706050403020100Dec

Where I = Input Data (I0 corresponds to input 0, I1 corresponds to input 1, etc.); DT = Input Delay Time (DT 00-3

corresponds to inputs 0 through 3) W = Open Wire Detect; S = Short Circuit Detect; D = Open Wire Disable

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Size

S3 S2 S1 S0 W3 W2 W1 W0 Not Used I3 I2 I1 I0 Read W ord 1

Not Used Read W ord 2

Reserved D3 D2 D1 D0 Reserved DT 00-3 Write Word 1

43388

Publication 1798-UM001B-EN-P - November 2002

Page 21

How Communication Takes Place and I/O Image Table Mapping 2-7

Input Delay Times for the 1798-IB4D Input Module

Bits Description Selected Delay Time

02 01 00 Delay Time for Inputs

00-03

0 0 0 Delay Time 0 (default) 256µs

0 0 1 Delay Time 1 512µs

0 1 0 Delay Time 2 1ms

0 1 1 Delay Time 3 2ms

1 0 0 Delay Time 4 4ms

1 0 1 Delay Time 5 8ms

1 1 0 Delay Time 6 16ms

1 1 1 Delay Time 7 32ms

Description of 1798-IB8 Image Table Mapping

Read

Write

I/O Image

Input Size

1 or 2 Words

Output Size

0 or 1 Word

Reserved

Reserved

Fault

Enabled

Not used

Module Image

Reserved

Inputs

Fault

Input

Delay

Time

42840

Memory Map of 8 Point Discrete Input Module Image Table - 1798-IB8

Decimal

Bit

Octal Bit17161514131211100706050403020100

Where D = Input Data (D0 correspon ds to input 0, D1 corresponds to input 1, etc.), DT = Input Delay Time (DT 00-07

corresponds to inputs 0 through 7) FO = Fault Bit - Indicates status of module sensor power (0=Normal, 1=Sensor Power

Shorted), FE = Fault Enabled Bit, must be set to return fault bit (FO) from module. The “Fault Enabled” bit will be set

automatically if the input filter times are configured through RSNetWorx for DeviceNet.

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Size

Not used D7 D6 D5 D4 D3 D2 D1 D0 Read Word 1

Not used FO Read Word 2

Reserved FE Reserved DT 00-07 Write Word 1

Publication 1798-UM001B-EN-P - November 2002

Page 22

2-8 How Communication Takes Place and I/O Image Table Mapping

Input Delay Times for the 1798-IB8 Input Module

Bits Description Selected Delay Time

02 01 00 Delay Time for Inputs 00-07

0 0 0 Delay Time 0 (default) 256µs

0 0 1 Delay Time 1 512µs

0 1 0 Delay Time 2 1ms

0 1 1 Delay Time 3 2ms

1 0 0 Delay Time 4 4ms

1 0 1 Delay Time 5 8ms

1 1 0 Delay Time 6 16ms

1 1 1 Delay Time 7 32ms

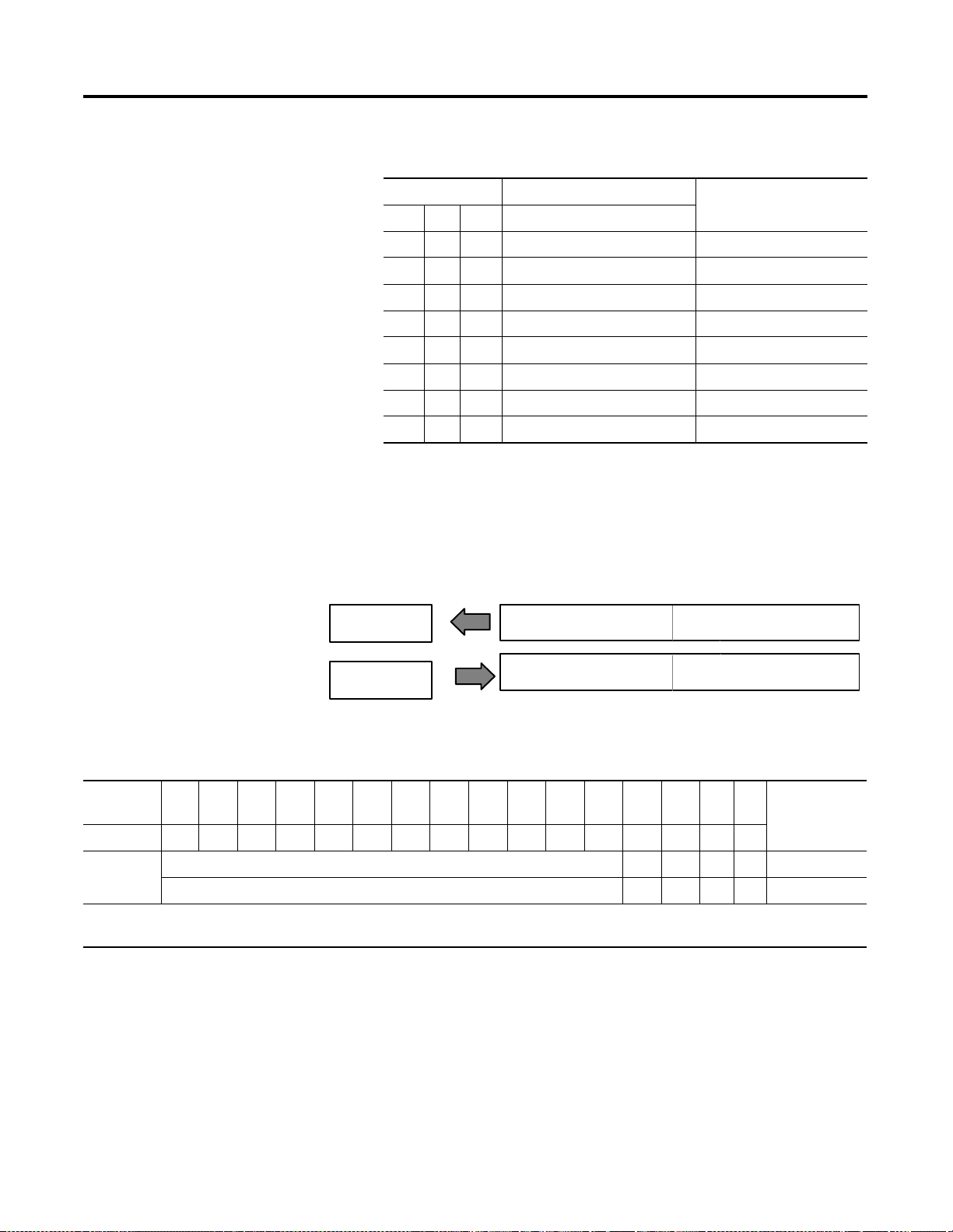

Description of 1798-OB4E Image Table Mapping

I/O Image

Read

Write

Input Size

0 or 1 Word

Output

1 Word

Not Used

Reserved

Module Image

Fault Bits

Outputs

Memory Map of 4 Point Discrete Output Module Image Table - 1798-OB4E

Decimal

Bit

Octal Bit17161514131211100706050403020100

Where O = Output Value (O0 corresponds to output 0, O1 corresponds to output 1, etc.)

F0-F3 = Indicate the status of each output point (0=Output normal, 1=Output faulted)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Not used F3 F2 F1 F0 Read Word 1

Reserved O3 O2 O1 O0 Write Word 1

42824

Size

Publication 1798-UM001B-EN-P - November 2002

Page 23

How Communication Takes Place and I/O Image Table Mapping 2-9

Description of 1798-OB8E Image Table Mapping

I/O Image

Input Size

Module Image

Read

Write

0 or 1 Word

Output

1 Word

Not Used

Reserved

Fault Bits

Outputs

Memory Map of 8 Point Discrete Output Module Image Table - 1798-OB8E

Decimal

Bit

Octal Bit17161514131211100706050403020100

Where O = Output Value (O0 corresponds to output 0, O1 corresponds to output 1, etc.)

F0-F7 = Indicate the status of each output point (0=Output normal, 1=Output faulted)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Not used F7 F6 F5 F4 F3 F2 F1 F0 Read Word 1

Reserved O7 O6 O5 O4 O3 O2 O1 O0 Write Word 1

Description of 1798-IE4 Image Table Mapping

I/O Image Module Image

Input Size Input Data Channel 0

42824

Size

1 to 9 Words Input Data Channel 1

Input Data Channel 2

Input Data Channel 3

Not Used

Not Used

Not Used

Not Used

PU Underrange

Configure Select

Output Size Not Used

0 to 1 Word Not Used

Not Used

Not Used

Not Used

Publication 1798-UM001B-EN-P - November 2002

Page 24

2-10 How Communication Takes Place and I/O Image Table Mapping

Memory Map of Analog Input Module Image Table - 1798-IE4

Decimal

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Bit

Octal Bit17161514131211100706050403020100

S Analog Value Channel 0 Read Word 1

S Analog Value Channel 1 Read Word 2

S Analog Value Channel 2 Read Word 3

S Analog Value Channel 3 Read Word 4

S Not Used Read Word 5

S Not Used Read Word 6

S Not Used Read Word 7

S Not Used Read Word 8

PU Not Used - Set to Zero U3 U2 U1 U0 Read Word 9

Not Used - Set to 0C3C2C1C0Not Used - Set to 0 F3F2F1F0Write Word 1

Not Used - Set to 0 Write Word 2 thru 6

Where PU = Power up bit; U = Underrange bits for 4-20mA inputs; C = Co nfigure select bit; F = Full range bit;

S = Sign bit (in 2’s complement)

Range Selection Bits for the 1798-IE4

Size

Channel No. Channel 0 Channel 1 Channel 2 Channel 3

F0 C0 F1 C1 F2 C2 F3 C3

Decimal Bit 000801090210 0311

0-10V dc/0-20mA 1 0 1 0 1 0 1 0

4-20mA 0 1 0 1 0 1 0 1

10 to +10V dc 1 1 1 1 1 1 1 1

Off

1

000000 00

C = Configure select bit; F = Full range bit

1. When configured to off, individual channels will return 0000H.

Publication 1798-UM001B-EN-P - November 2002

Page 25

How Communication Takes Place and I/O Image Table Mapping 2-11

Word/Bit Descriptions for the 1798-IE4 Analog Input Module Write

Word Decimal Bit Definition

Bits 00-14 Channel 0 analog data - 12-bit left justified two’s

Read Word 1

Bit15 Channel 0 analog data sign bit

Bits 00-14 Channel 1 analog data - 12-bit left justified two’s

Read Word 2

Bit15 Channel 1 analog data sign bit

Bits 00-14 Channel 2 analog data - 12-bit left justified two’s

Read Word 3

Bit15 Channel 2 analog data sign bit

Bits 00-14 Channel 3 analog data - 12-bit left justified two’s

Read Word 4

complement number; unused lower bits are zero;

4-20mA uses all 16 bits

complement number; unused lower bits are zero;

4-20mA uses all 16 bits

complement number; unused lower bits are zero;

4-20mA uses all 16 bits

complement number; unused lower bits are zero;

4-20mA uses all 16 bits

Bit15 Channel 3 analog data sign bit

Read Word 5-8 Not Used

Bits 00-03 Underrange bits (U) for individual channels (4-20mA

current input only) - Bit 00 corresponds to input

channel 0, bit 01 corresponds to input channel 1, and

so on. When set (1), indicates either a broken or open

input wire, or input current below 4-20mA.

Read Word 9

Write Word 1

Write Word 2-6 Bits 00-15 Not used - set to 0

Bits 04-14 Not used - set to 0

Bit 15 Power Up bit - This bit is set to 1 when all bits in the

configuration register are 0 (unconfigured state). The

configuration register can be cleared by either of the

reset inputs, or by the user writing all zeroes to it.

Bits 00-03 Full range bits (F) for individual channels - Bit 00

corresponds to input channel 0, bit 01 corresponds to

input channel 1, and so on. Refer to range selection

above.

Bits 08-11 Configure select bits (C) for individual channels - Bits

08 corresponds to input channel 0, bit 09 corresponds

to input 1, and so on. Refer to range selection above.

Publication 1798-UM001B-EN-P - November 2002

Page 26

2-12 How Communication Takes Place and I/O Image Table Mapping

Description of 1798-OE2 Image Table Mapping

I/O Image

Input Size

0 to 1 Words PU Not Used Diagnostics

Output Size Analog Output Data 1

1 to 6 Words Not Used

Analog Output Data 0

Not Used

Not Used OE

Not Used Config. Select Not Used Full Range

Not Used

Not Used

Not Used

Not Used

Not Used

Memory Map of Analog Output Module Image Table - 1798-OE2

Decimal

Bit

Octal Bit171615141312111007060504030201 00

Where PU = Power up bit; W = Diagno stic bits for current output broken or load resistance high (Not used on voltage

outputs.); OE = Output enable b its (bit 00 cor responds to output 0, bi t 01 correspond s to output 1. ATTENTION: These bits

must be set to 1. C = Configure select bit; F = Full range bit; S = Sign bit (in 2’s complement)

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Size

PU Not Used - Set to Zero W1 W0 Read Word 1

S Analog Value Channel 0 Write Word 1

S Analog Value Channel 1 Write Word 2

S Not Used Write Word 3

S Not Used Write Word 4

S Not Used - Set to 0 OE1 OE0 Write Word 5

S Not Used - Set to 0 C1 C0 Not Used - Set to 0 F1 F0 Write Word 6

S Not Used - Set to 0 Write Word 7 thru 14

Publication 1798-UM001B-EN-P - November 2002

Page 27

How Communication Takes Place and I/O Image Table Mapping 2-13

Range Selection Bits for the 1798-OE2

Channel No. Channel 0 Channel 1

F0 C0 F1 C1

Decimal Bit 00 08 01 09

0-10V dc/0-20mA 1 0 1 0

4-20mA 0 1 0 1

10 to +10V dc 1 1 1 1

Off

1

0000

C = Configure select bit; F = Full range bit

1. When configured to off, individual channels will return 0V.

Word/Bit Descriptions for the 1798-OE2 Analog Output Module

(Write Word 6)

Word Decimal Bit Definition

Bits 00-01 Current outputs only - When set (1), the wire on the

output is broken or the load resistance is too high. Bit

00 corresponds to channel 0, bit 01 corresponds to

channel 1.

Read Word 1

Bit 02-14 Not Used - Set to 0.

Bit 15 Power Up bit - This bit is set to 1 when all bits in the

configuration register are 0 (unconfigureed state).

The configuration register can be cleared by either of

the reset inputs, or by the user writing all zeroes to it.

Bits 00-14 Channel 0 analog data - 12-bit left justified two’s

complement number; unused lower bits are zero;

Write Word 1

4-20mA uses all 16 bits.

Bit15 Channel 0 analog data sign bit.

Bits 00-14 Channel 1 analog data - 12-bit left justified two’s

complement number; unused lower bits are zero;

Write Word 2

4-20mA uses all 16 bits.

Bit15 Channel 1 analog data sign bit.

Read Word 3-4 Not Used

Bit 00-01 Output Enable Bits. Bit 00 corresponds to output 0,

01 corresponds to output 1. These bits must be set

Write Word 5

to 1.

Bits 02-15 Not Used - Set to 0.

Bits 00-02 Full range bits (F) for individual channels - Bit 00

corresponds to input channel 0, bit 01 corresponds to

input channel 1. Refer to the range selection above.

Write Word 6

Bits 08-09 Configure select bits (C) for individual channels - Bit

08 corresponds to input channel 0, bit 09 corresponds

to input channel 1. Refer to range selection above.

Write Word 7-14 Not Used - Set to 0.

Publication 1798-UM001B-EN-P - November 2002

Page 28

2-14 How Communication Takes Place and I/O Image Table Mapping

Notes:

Publication 1798-UM001B-EN-P - November 2002

Page 29

Configure Your DeviceNet Adapter

Chapter

3

Chapter Objectives

In this chapter, you will learn how to use RSNetWorx for DeviceNet

software to configure the adapter. You will:

learn briefly about RSNetWorx for DeviceNet

•

configure your FlexArmor adapter and system online

•

map the scanner

•

Configure Your Adapter’s FlexArmor System

Configure your FlexArmor system by specifying the FlexArmor

module that will reside in each slot. Remember, slot 0 is the closet slot

to the adapter and slot 7 is the farthest or last slot.

1 Publication 1798-UM001B-EN-P - November 2002

Page 30

3-2 Configure Your DeviceNet Adapter

About RSNetWorx for DeviceNet

RSNetWorx for DeviceNet is the software tool used to configure your

FlexArmor DeviceNet adapter and its related modules. This software

tool can be connected to the adapter via the DeviceNet network.

In this chapter, we assume that you have established a network, and

are adding a FlexArmor Adapter to your network.

If you are working off line, drag and drop the devices from the

hardware list onto the graph.

IMPORTANT

You will be able to perform most of the functions

discussed in this section while working off line but

you must be on line to perform all of the functions

discussed in this chapter.

graph

hardware

list

Publication 1798-UM001B-EN-P - November 2002

Page 31

Configure Your DeviceNet Adapter 3-3

Configure Your FlexArmor Adapter and System Online

To configure your adapter:

1. Open RSNetWorx for DeviceNet.

2. Click the Online icon . (If you are working off line, skip to

the next section to learn how to configure the adapter.)

You see the Browse for Network window.

3. Locate the network you wish to access.

4. Click OK.

You are now in Online mode.

5. Click the Browse for Network icon .

Publication 1798-UM001B-EN-P - November 2002

Page 32

3-4 Configure Your DeviceNet Adapter

The network displays on the screen.

FlexArmor adapter icon DeviceNet scanner module icon

Publication 1798-UM001B-EN-P - November 2002

Configure the Adapter

You can determine the adapter configuration and system configuration

for an adapter at a specific node address. The node address is

assigned at the adapter (using the rotary switch) and in the adapter

configuration screen.

IMPORTANT

If addressing the adapter in the adapter configuration

screen, the address must agree with the physical

address of the rotary switches on the adapter.

Page 33

To access the adapter configuration screen, double-click the

FlexArmor adapter icon.

You see the adapter configuration screen.

If configuring the adapter off line,

set this address to match the Node

Address switches on the 1798-ADN.

Configure Your DeviceNet Adapter 3-5

Publication 1798-UM001B-EN-P - November 2002

Page 34

3-6 Configure Your DeviceNet Adapter

IMPORTANT

IMPORTANT

Configure the Module

1. Click the Module Configuration tab.

2. Click Upload.

Use these icons to move the

selected module to the next

empty slot in the chassis.

List of available

hardware. Add to

the current network

by selecting the

hardware and

clicking the arrow to

the right.

IMPORTANT

You must be online to perform an upload.

Use the following functions, as needed, to configure the

module.

Delete the module at the selected slot.

Upload data for the

entire chassis. You must

be on line to perform

this function.

Download data for

the entire chassis.

You must be on line

to perform this

function.

Change to Display

Hardware By

Product Name or

by Catalog

Number

Configure the

module at the

selected slot.

(Note: You can

also configure the

module by double

clicking on it.)

Modules identified

by slot number.

Publication 1798-UM001B-EN-P - November 2002

Downloading to the adapter is an option only when

the 1798-ADN is not in the master’s scanlist.

If you attempt to download when the adapter is in a

scanlist, you will receive an object state conflict error

message.

Page 35

Configure Your DeviceNet Adapter 3-7

View Adapter Parameters

1. To display the adapter parameter window, from the Module

Configuration window, double-click the adapter icon (1798-ADN)

under Module Type. You see the following window.

Click these tabs to view configuration information.

The General window is shown here.

The General window lists

information about the

module currently

selected.

Publication 1798-UM001B-EN-P - November 2002

Page 36

3-8 Configure Your DeviceNet Adapter

The adapter Configuration Settings window lists the status of

each module in the FlexArmor system.

Module Bad Flag

Possible causes for a

Module Bad Flag:

• Transmission errors

on the FlexArmor

backplane

• A failed module

• A module removed

from the baseplate

• Incorrect module

inserted in a slot

position

• An empty slot

Idle-to-Fault

Determines the state of

the Outputs immediately

following an Idle to Fault

transition. The options are:

• Output Remains in

Idle State

• Output Goes to

Fault State

The EDS File window lists information about the EDS file

currently being used.

Click View to display

the EDS file.

Publication 1798-UM001B-EN-P - November 2002

Page 37

Configure Your DeviceNet Adapter 3-9

Module Parameters

To view individual module parameters, from the Module Configuration

tab, double click on the module whose parameters you wish to view.

Double click on the

module whose

parameters you wish to

view. For this example,

the 1798-OB8E was

chosen.

Publication 1798-UM001B-EN-P - November 2002

Page 38

3-10 Configure Your DeviceNet Adapter

The General window lists information about the module currently

selected.

The Advanced Parameters window lists status information about the

module currently selected.

Use this icon to

restore the

parameters

selections to the

module default

(obtained from the

EDS file.)

Displays help

information on the

selected

parameters.

Publication 1798-UM001B-EN-P - November 2002

Page 39

Configure Your DeviceNet Adapter 3-11

The following table describes the parameters in the Advanced

Parameters window.

Parameter # Parameter Name Description

3 Input Size Number of Read words. These are determined by

other Parameter selections and cannot be set by

the user.

5 Output Size Number of Write words. These are determined by

other Parameter selections and cannot be set by

the user.

6 Config. Size Number of Configuration words. These are

determined by other Parameter selections and

cannot be set by the user

10 Program Mode

Behavior

11 Communication

Fault Behavior

13 Module Fault Determines the state of the Inputs in the event of a

Determines the state of the Outputs when the

Controller enters Program mode. The options are:

Reset to Zero

•

Hold Outputs in Last State

•

Use Safe State Output Values (Set under

•

Flex Config. tab.)

Determines the state of the Outputs when the

Controller enters Program mode. The options are:

Reset to Zero

•

Hold Outputs in Last State

•

Use Safe State Output Values (Set under

•

FLEX Config. tab.)

Module Fault. The options are:

Zero Inputs

•

Hold Last Input Values

•

Publication 1798-UM001B-EN-P - November 2002

Page 40

3-12 Configure Your DeviceNet Adapter

Safe State Data found under the Flex Configuration Settings tab is

shown below.

Set the value of the safe

state data by selecting the

value and then choosing

either ON or OFF from the

drop down list.

Publication 1798-UM001B-EN-P - November 2002

Page 41

Configure Your DeviceNet Adapter 3-13

Special Parameters

Special parameters for individual modules can also be found under

the Flex Configuration Settings tab. The following section identifies

special parameter windows for the 1798-IB4D, -IE4, and -OE2

modules.

1798-IB4D Filter Time and Open Wire Disable

Enter filter time and open wire

parameters for the 1798-IB4D.

Publication 1798-UM001B-EN-P - November 2002

Page 42

3-14 Configure Your DeviceNet Adapter

1798-IE4 Input Channel Range Selection

Select the proper current or

voltage range for your

application.

1798-OE2 Output Channel Enable and Range Selection

Enable output channels and

select the output channel

range appropriate for your

application.

Set safe state values

Publication 1798-UM001B-EN-P - November 2002

Page 43

Configure Your DeviceNet Adapter 3-15

The EDS File window is the last tab in the module parameters

window. The EDS File window lists information about the EDS file

currently being used.

Click View to display

the EDS file.

View I/O Summary

1. To view I/O summary information, click the I/O Summary tab

from the adapter window.

Select Communication

choice. Refer to Chapter 2,

page 2-4.

Module I/O summary

information

Identifies the total amount

of data to be mapped to the

scanner.

Publication 1798-UM001B-EN-P - November 2002

Page 44

3-16 Configure Your DeviceNet Adapter

2. Click the + sign to the left of the input or output module to view

the amount of data mapped to each module in the system.

3. Click the + sign to the left of a module to display detailed

module information.

Publication 1798-UM001B-EN-P - November 2002

Page 45

Toggle

between

input and

output data

mapped to

the module.

Clicking the

Monitor

button will

display the

current

value of the

listed

parameters.

Configure Your DeviceNet Adapter 3-17

Highlight a module

and then click the

Monitor button to

display detailed

module information

as shown in the

example on the next

page. NOTE: You

must be in online

mode to perform

this function.

Publication 1798-UM001B-EN-P - November 2002

Page 46

3-18 Configure Your DeviceNet Adapter

Map the Scanner

To map the scanner:

1. From the RSNetWorx for DeviceNet configuration screen,

double-click the scanner.

FlexArmor adapter icon DeviceNet scanner module icon

Publication 1798-UM001B-EN-P - November 2002

Page 47

Configure Your DeviceNet Adapter 3-19

You see the scanner configuration window.

2. Click the Scanlist tab.

Publication 1798-UM001B-EN-P - November 2002

Page 48

3-20 Configure Your DeviceNet Adapter

3. Highlight the device in the Available Devices list and click the

right arrow to move the device to the Scanlist.

Select Automap on Add to

automatically map the

correct amount of input and

output data at the time the

FlexArmor system is added

to the scanlist.

4. Click OK.

The devices in the scanlist will be mapped automatically.

To map devices manually, click the Edit I/O Parameters button.

5. Click Yes to download the changes. (You must be on line to

perform this function.)

Publication 1798-UM001B-EN-P - November 2002

Page 49

Configure Your DeviceNet Adapter 3-21

6. Click the Input tab to view input data mapped to the scanner.

7. Click the Output tab to view output data mapped to the scanner.

Publication 1798-UM001B-EN-P - November 2002

Page 50

3-22 Configure Your DeviceNet Adapter

8. Click the ADR tab to view ADR (Auto Device Replace) options.

For information about

enabling ADR, see the

documentation that comes

with the scanner.

The Summary tab contains a list of the devices to which the

scanner is currently talking.

Publication 1798-UM001B-EN-P - November 2002

Page 51

Troubleshooting

Chapter

4

Chapter Objectives

Troubleshoot With the Indicators

This chapter describes how to use the indicators on the module for

troubleshooting.

Diagnostic indicators are located on the front of the adapter module.

They show both normal operation and error conditions in your

remote I/O system. The indicators are:

Mod/Net status

•

I/O status

•

The table below provides the indicator conditions and status.

Mod/Net Status Indicator

Indication Status

Off No power, or no network access

Flashing Green/OFF On line, but not connected to master

Solid Green On line, link OK, connected

Flashing Red Recoverable fault

Solid Red Critical adapter failure

I/O Status Indicator

Indication Status

Off No power or outputs off

Flashing Red/Off Recoverable fault - outputs in fault

Flashing Green/Off Idle/program mode - outputs in Idle

Solid Green Device operational - outputs live - run

Solid Red Critical adapter fault - unrecoverable

1 Publication 1798-UM001B-EN-P - November 2002

Page 52

4-2 Troubleshooting

Notes:

Publication 1798-UM001B-EN-P - November 2002

Page 53

Specifications

Appendix

A

Input Module Specifications

Specifications for the 1798-IB4 Module

Specifications 1798-IB4

Module Type Digital Input, Sinking

Number of Channels 1 group of 4

Sensor Source Current 400 mA maximum

On-state Voltage 10-28.8V dc; 24V dc nominal

On-state Current 2-12 mA; 8 mA @ 24V dc

Off-state Voltage 5V dc maximum

Off-State Current 1.5 mA minimum

Channel Impedance 4.6KΩ maximum

Isolation Voltage 850V dc channel-to-system for 1s

Delay Times:Off to On

On to Off

FlexBus Current 20 mA maximum

Power Dissipation 2.0W @ 28.8V dc

Thermal Dissipation 6.8 BTU/hr. @ 28.8V dc

Indicators 4 channel status - yellow

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Conductors See publication DN-6.7.2

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

256 us, 512 us, 1 ms, 2ms

4 ms, 8 ms, 16 ms, 32 ms

(Selectable; 256 us default)

1 fault LED indicator- red

10-28.8V dc; 5% AC ripple

450 mA maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1 ms pulse width

50G peak, 11±1 ms pulse width

5G @ 10-500 Hz per IEC 68-2-6

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

C-Tick

compliant with: AS/NZS 2064; Industrial

Emissions

European Union 89/336/EEC EMC

Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

Australian Radiocommunications Act,

1 Publication 1798-UM001B-EN-P - November 2002

Page 54

A-2 Specifications

Specifications for the 1798-IB8 Module

Specifications 1798-IB8

Module Type Digital Input, Sinking

Number of Channels 1 group of 8

Sensor Source Current 400 mA maximum

On-state Voltage 10-28.8V dc; 24V dc nominal

On-state Current 2-12 mA; 8 mA @ 24V dc

Off-state Voltage 5V dc maximum

Off-State Current 1.5 mA minimum

Channel Impedance 4.6KΩ maximum

Isolation Voltage 850V dc channel-to-system for 1s

Delay Times:Off to On

On to Off

FlexBus Current 20 mA maximum

Power Dissipation 3.0W @ 28.8V dc

Thermal Dissipation 10.2 BTU/hr. @ 28.8V dc

Indicators 8 channel status - yellow

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Conductors See publication DN-6.7.2

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

256 us, 512 us, 1 ms, 2ms

4 ms, 8 ms, 16 ms, 32 ms

(Selectable; 256 us default)

1 fault LED indicator - red

10-28.8V dc; 5% AC ripple

500 mA maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1 ms pulse width

50G peak, 11±1 ms pulse width

5G @ 10-500 Hz per IEC 68-2-6

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

European Union 89/336/EEC EMC

Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

C-Tick

Australian Radiocommunications Act,

compliant with: AS/NZS 2064; Industrial

Emissions

Publication 1798-UM001B-EN-P - November 2002

Page 55

Specifications A-3

Specifications for the 1798-IB4D Module

Specifications - 1798-IB4D

Module Type Digital Input, Sinking

Number of Channels 1 group of 4

Sensor Source Current 50 mA per connector

On-state Voltage 10-28.8V dc; 24V dc nominal

On-state Current 2-12 mA; 8 mA @ 24V dc

Off-state Voltage 5V dc maximum

Off-State Current 1.5 mA minimum

Channel Impedance 4.6KΩ maximum

Isolation Voltage 850V dc channel-to-system for 1s

Delay Times:Off to On

On to Off

FlexBus Current 80 mA maximum

Power Dissipation 2.0W @ 28.8V dc

Thermal Dissipation 6.8 BTU/hr. @ 28.8V dc

Indicators 4 channel status - yellow

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Operational Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

Shock IEC60068-2-27 (Test Ea, Unpackaged shock):

Emissions CISPR 11:

ESD Immunity IEC 61000-4-2:

Radiated RF Immunity IEC 61000-4-3:

EFT/B Immunity IEC 61000-4-4:

Surge Transient Immunity IEC 61000-4-5:

Conducted RF Immunity IEC 61000-4-6:

256 us, 512 us, 1 ms, 2ms

4 ms, 8 ms, 16 ms, 32 ms

(Selectable; 256 us default)

4 diagnostic indicators- red

10-28.8V dc; 5% AC ripple

300 mA maximum

118 mm x 57 mm x 40 mm

4.63 in. x 2.25 in. x 1.58 in.

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20 to 60°C (-4 to 140°F)

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating Thermal

Shock):

–40 to 85°C (–40 to 185°F)

Operating 30g

Non-operating 50g

Group 1, Class A

6kV contact discharges

8kV air discharges

10V/m with 1kHz sine-wave 80%AM from 30MHz to 2000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900MHz

±2kV at 5kHz on power ports

±2kV at 5kHz on signal ports

±1kV line-line(DM) and ±2kV line-earth(CM) on power ports

±1kV line-line(DM) and ±2kV line-earth(CM) on signal ports

10Vrms with 1kHz sine-wave 80%AM from 150kHz to 80MHz

Publication 1798-UM001B-EN-P - November 2002

Page 56

A-4 Specifications

Specifications - 1798-IB4D (continued)

Vibration IEC60068-2-6 (Test Fc, Operating):

5g @ 10-500Hz

Conductors See publication DN-6.7.2

Enclosure Meets IP67

Certifications

(When product is marked)

c-UL-usUL Listed Industrial Control Equipment, certified for US

and Canada

UL UL Listed Industrial Control Equipment

1

European Union 89/336/EEC EMC Directive, compliant

CE

with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

Australian Radiocommunications Act, compliant with:

C-Tick

AS/NZS 2064; Industrial Emissions

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

Publication 1798-UM001B-EN-P - November 2002

Page 57

Specifications A-5

Specifications for the 1798-IE4 Module

Specifications - 1798-IE4 Analog Input Module

Module Type Analog Input

Number of Channels 4 single-ended, non-isolated

ResolutionBits

Voltage/Cnt

Current/Cnt

Data Format 16 bit; 2’s complement; left-justified

Conversion Type Successive approximation

Conversion Rate 256 us - All channels

Current Terminal 4-20 mA; 0-20 mA (user configurable)

Voltage Terminal ±10V; 0-10V (user configurable)

Normal Mode Rejection

Voltage Terminal

Current Terminal

Step Response to 63%

Voltage Terminal

Current Terminal

Impedance:Voltage Terminal

Current Terminal

Absolute Accuracy

Voltage Terminal

Current Terminal

Accuracy Drift:Voltage Terminal

Current Terminal

Calibration None Required

Maximum Overload

Voltage Terminal

Current Terminal

Isolation Voltage 850V dc channel-to-system for 1s

FlexBus Current 10 mA maximum

Sensor Source Current

(per connector) 50 mA

Power dissipation 2.5W @ 28.8V dc

Thermal Dissipation 8.5 BTU/hr @ 28.8V dc

Indicator 1 fault LED Indicator - red

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Operational Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

12 - Unipolar, 11+ sign - Bipolar

2.56 mV - Unipolar; 5.13 mV - Bipolar

5.13 uA

-3 db @ 17 Hz; -20 db/decade;

-10 db @ 50 Hz; 11.4 db @ 60 Hz

-3 db @ 9 Hz; -20 db/decade;

-15.3 db @ 50 Hz; -16.8 db @ 60 Hz

9.4 ms

18.2 ms

100 kΩ; 200 kΩ @ DC

238

Ω

0.20% FS @ 25°C

0.20% FS @ 25°C

0.00428% FS per°C

0.00407% FS per°C

Single channel; continuous

30V

32 mA

10-28.8V dc; 5% AC ripple

50 mA @ 24V dc

118 mm x 57 mm x 40 mm

4.63 in. x 2.25 in. x 1.58 in.

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20 to 60°C (-4 to 140°F)

Publication 1798-UM001B-EN-P - November 2002

Page 58

A-6 Specifications

Specifications - 1798-IE4 Analog Input Module (Continued)

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating

Cold),

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating

Dry Heat),

IEC 60068-2-14 (Test Na, Un-packaged

Non-operating Thermal Shock):

–40 to 85°C (–40 to 185°F)

Shock IEC60068-2-27 (Test Ea, Unpackaged shock):

Operating 30g

Non-operating 50g

Emissions CISPR 11:

Group 1, Class A

ESD Immunity IEC 61000-4-2:

6kV contact discharges

8kV air discharges

Radiated RF Immunity IEC 61000-4-3:

10V/m with 1kHz sine-wave 80%AM from 30MHz to

2000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900MHz

EFT/B Immunity IEC 61000-4-4:

±2kV at 5kHz on power ports

±2kV at 5kHz on signal ports

Surge Transient Immunity IEC 61000-4-5:

±1kV line-line(DM) and ±2kV line-earth(CM) on

power ports

±1kV line-line(DM) and ±2kV line-earth(CM) on signal

ports

Conducted RF Immunity IEC 61000-4-6:

10Vrms with 1kHz sine-wave 80%AM from 150kHz

to 80MHz

Vibration IEC60068-2-6 (Test Fc, Operating):

5g @ 10-500Hz

Enclosure Meets IP67

Certifications

(When product is marked)

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

European Union 89/336/EEC EMC Directive,

compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

1

C-Tick

Australian Radiocommunications Act,

compliant with: AS/NZS 2064; Industrial

Emissions

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

Publication 1798-UM001B-EN-P - November 2002

Page 59

Specifications A-7

Output Module Specifications

Specifications for the 1798-OB4E Module

Specifications 1798-OB4E

Module Type Digital Output, Sourcing

Number of Channels 1 group of 4

On-state Voltage 10-28.8V dc; 24V dc nominal

On-state Current (per channel) 1.0A per channel

On-state Current (per module) 4.0A per module

Off-state Voltage 28.8V dc maximum

Off-State Current 0.5 mA maximum leakage

On-State Voltage Drop 0.5V dc maximum drop

Surge Current 2.0A for 50 ms (Repeatable every 2 seconds)

Isolation Voltage 850V dc for 1 second

Delay Times:Off to On

On to Off

FlexBus Current 60 mA maximum

Power Dissipation 2.4 W @ 28.8 V dc

Thermal Dissipation 8.2 BTU/hr. @ 28.8V dc

Indicators 4 channel status - yellow

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Conductors See publication DN-6.7.2

Cordsets 5 pin micro (12mm) style connectors

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

0.5 ms maximum

1.0 ms maximum

1 fault LED indicator- red

10-28.8V dc; 5% AC ripple

4.0A maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1ms pulse width

50G peak, 11±1ms pulse width

5G @ 10-500Hz per IEC 68-2-6

(see graph on next page)

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

C-Tick

compliant with: AS/NZS 2064;

European Union 89/336/EEC EMC

Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

Australian Radiocommunications Act,

Industrial Emissions

Publication 1798-UM001B-EN-P - November 2002

Page 60

A-8 Specifications

Specifications for the 1798-OB8E Module

Specifications 1798-OB8E

Module Type Digital Output, Sourcing

Number of Channels 1 group of 8

On-state Voltage 10-28.8V dc; 24V dc nominal

On-state Current

(per channel)

On-state Current (per module) 5.0A per module

Off-state Voltage 28.8V dc maximum

Off-State Current 0.5 mA maximum leakage

On-State Voltage Drop 0.5V dc maximum drop

Surge Current 2.0A for 50 ms

Isolation Voltage 850V dc for 1 second

Delay Times:Off to On

On to Off

FlexBus Current 60 mA maximum

Power Dissipation 2.9 W @ 28.8 V dc

Thermal Dissipation 9.9 BTU/hr. @ 28.8V dc

Indicators 8 channel status - yellow

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Conductors See publication DN-6.7.2

Cordsets 5 pin micro (12mm) style connectors

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

1.0A per channel

(Repeatable every 2 seconds)

0.5 ms maximum

1.0 ms maximum

1 fault LED indicator - red

10-28.8V dc; 5% AC ripple

5.0A maximum

118 mm X 57 mm X 40 mm

4.63 in. X 2.25 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1ms pulse width

50G peak, 11±1ms pulse width

5G @ 10-500Hz per IEC 68-2-6

(see graph on next page)

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

European Union 89/336/EEC EMC

Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

C-Tick

Australian Radiocommunications Act,

compliant with: AS/NZS 2064;

Industrial Emissions

Publication 1798-UM001B-EN-P - November 2002

Page 61

Derating Curve

1A

0.5A

Output Current (per channel)

-20° 40° 60°

Ambient Temperature (Celsius)

Operating Temperature CD Rating Curve

Specifications A-9

42700

Specifications for the 1798-OE2 Module

Specifications - 1798-OE2 Analog Output Module

Module Type Analog Output

Number of Channels 2 single-ended, non-isolated

ResolutionBits

Voltage/Cnt

Current/Cnt

Data Format 16 bit; 2’s complement; left-justified

Conversion Type Pulse width modulation

Conversion Rate 1.024 ms - All channels

Current Terminal 4-20 mA; 0-20 mA (0 mA output until the module is

Voltage Terminal ±10V; 0-10V - 3 mA maximum (0V output until the module is

Step Response to 63% of FS 24 mS

Output Load on Voltage 3 mA maximum

Resistive Load on mA

Output

Absolute Accuracy

Voltage Terminal

Current Terminal

Accuracy Drift

Voltage Terminal

Current Terminal

Calibration None Required

FlexBus Current 10 mA maximum

Power dissipation 2.5W @ 28.8V dc

Sensor Source Current

(per connector)

12 + sign

2.56 mV

5.13 uA

configured)

configured)

15-750 ohms

0.133% FS @ 25°C

0.425% FS @ 25°C

0.0045% FS per°C

0.0069% FS per°C

50 mA

Publication 1798-UM001B-EN-P - November 2002

Page 62

A-10 Specifications

Specifications - 1798-OE2 Analog Output Module

Thermal Dissipation 8.5 BTU/hr @ 28.8V dc

Indicator 1 fault LED Indicator - red

External DC Power

Voltage (24V dc nom.)

Current

Dimensions

(H x D x W)

10-28.8V dc; 5% AC ripple

85 mA @ 24V dc

118 mm x 57 mm x 40 mm

4.63 in. x 2.25 in. x 1.58 in.

Operational Temperature IEC 60068-2-1 (Test Ad, Operating Cold),

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20 to 60°C (-4 to 140°F)

Storage Temperature IEC 60068-2-1 (Test Ab, Un-packaged Non-operating Cold),

IEC 60068-2-2 (Test Bb, Un-packaged Non-operating Dry

Heat),

IEC 60068-2-14 (Test Na, Un-packaged Non-operating

Thermal Shock):

–40 to 85°C (–40 to 185°F)

Shock IEC60068-2-27 (Test Ea, Unpackaged shock):

Operating 30g

Non-operating 50g

Emissions CISPR 11:

Group 1, Class A

ESD Immunity IEC 61000-4-2:

6kV contact discharges

8kV air discharges

Radiated RF Immunity IEC 61000-4-3:

10V/m with 1kHz sine-wave 80%AM from 30MHz to

2000MHz

10V/m with 200Hz 50% Pulse 100%AM at 900MHz

EFT/B Immunity IEC 61000-4-4:

±2kV at 5kHz on power ports

±2kV at 5kHz on signal ports

Surge Transient Immunity IEC 61000-4-5:

±1kV line-line(DM) and ±2kV line-earth(CM) on power ports

±1kV line-line(DM) and ±2kV line-earth(CM) on signal ports

Conducted RF Immunity IEC 61000-4-6:

10Vrms with 1kHz sine-wave 80%AM from 150kHz to

80MHz

Conductors See publication DN-6.7.2

Vibration IEC60068-2-6 (Test Fc, Operating):

5g @ 10-500Hz

Enclosure Meets IP67

Publication 1798-UM001B-EN-P - November 2002

Page 63

Specifications A-11

Certifications

(When product is marked)

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

European Union 89/336/EEC EMC Directive,

compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

1

C-Tick

Australian Radiocommunications Act,

compliant with: AS/NZS 2064; Industrial

Emissions

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

Publication 1798-UM001B-EN-P - November 2002

Page 64

A-12 Specifications

Communication Adapter Specifications

Specifications for the 1798-ADN modules are listed below.

Specifications 1798-ADN

External DC Power (Input Power):

Voltage (24V dc nom.)

Current

FlexBus (Output Power):

Voltage (5V dc nom.)

Current

Isolation Voltage

(Communication Lines/System):

24V dc External Power to 5V dc

FlexBus Output

Dimensions (H x D x W) 118 mm X 50 mm X 40 mm

Environmental Conditions:

Operating Temperature

Storage Temperature

Shock: Operating

Non-Operating

Vibration

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

10-28.8V dc; 5% AC ripple

400 mA @ 24V dc

4.75 - 5.2V dc; 5% AC ripple

640 mA @ 5.2V dc

850V dc for 1 second

4.63 in. X 1.95 in. X 1.58 in.

-20 to 60°C (-4 to 140°F)

-40 to 85°C (-40 to 185°F)

30G peak, 11±1 ms pulse width

50G peak, 11±1 ms pulse width

5G @ 10-500 Hz per IEC 68-2-6

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

C-Tick

compliant with: AS/NZS 2064;

ODVA ODVA conformance tested to ODVA

European Union 89/336/EEC

EMC Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab.,

Industrial Requirements

EN 61000-6-2; Industrial Immunity

1

Australian Radiocommunications Act,

Industrial Emissions

DeviceNet specifications

Publication 1798-UM001B-EN-P - November 2002

Page 65

Specifications A-13

Field Termination Plug Specifications

Specifications for the Field Termination Plug are listed below.

Voltage Rating 28.8V dc maximum

Sensor and Adapter Current 2.5A maximum

Output Current 10A maximum

Sensor/Output Voltage 10-28.8V dc

Sensor/Output Power Connector 0.875 in male

Dimensions (H x D x W) 121 mm X 36.3 mm X 42 mm

4.75 in. X 1.43 in. X 1.65 in.

Environmental Conditions

Operational Temperature

Storage Temperature

Shock Operating

Non-operating

Vibration

Conductors See publication DN-6.7.2

Enclosure Meets IP67

Agency Certification

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

-20 to 60°C (-4 to 140°F)

°

-40 to 85

C (-40 to 185°F)

30g peak acceleration, 11(±1) ms pulse width

50g peak acceleration, 11(±1) ms pulse width

Tested 5g @ 10-500 Hz per IEC 68-2-6

c-UL-us UL Listed Industrial Control Equipment,

certified for US and Canada

UL UL Listed Industrial Control Equipment

1

CE

European Union 89/336/EEC

EMC Directive, compliant with:

EN 50081-2; Industrial Emissions

EN 50082-2; Industrial Immunity

EN 61326; Meas./Control/Lab., Industrial

Requirements

EN 61000-6-2; Industrial Immunity

1

C-Tick

Australian Radiocommunications Act,

compliant with:

AS/NZS 2064; Industrial Emissions

Publication 1798-UM001B-EN-P - November 2002

Page 66

A-14 Specifications

Baseplate Specifications

Specifications for the Baseplate are listed below.

FlexArmor Baseplates - Cat. No. 1798-BP2, -BP4, -BP6, -BP8

General Specifications

External Power 28.8V dc maximum

Sensor Power Bus

Output Power Bus

Environmental Conditions

Operational Temperature

Storage Temperature

Shock Operating

Non-operating

Vibration

Enclosure Meets IP67

Certifications

(When product is marked)

1. See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

2.5A maximum

10A maximum

-20 to 60°C (-4 to 140°F)

°

-40 to 85

C (-40 to 185°F)

30g peak acceleration, 11(±1) ms pulse width

50g peak acceleration, 11(±1) ms pulse width

Tested 5g @ 10-500 Hz per IEC 68-2-6