Page 1

Installation Instructions

ControlNet Ex Tap Terminator Installation Instructions

(Cat. No. 1797-TCAP)

Use this document as a guide when you install a ControlNetTM Ex tap

terminator. This document will be packaged with 5 tap terminators.

About the Tap Terminator

The tap terminator allows you to install extra taps on your trunk line

without installing ControlNet Ex nodes. The tap terminator facilitates the

maintenance of your network by providing termination of a tap not in use;

holding a space for a node to be added in the future.

The tap terminator can be used on any number of taps in your ControlNet

Ex system. Refer to the ControlNet Ex Coax Media Planning and

Installation Manual, publication CNET-IN002A-EN, to determine how

many taps you can install in your system.

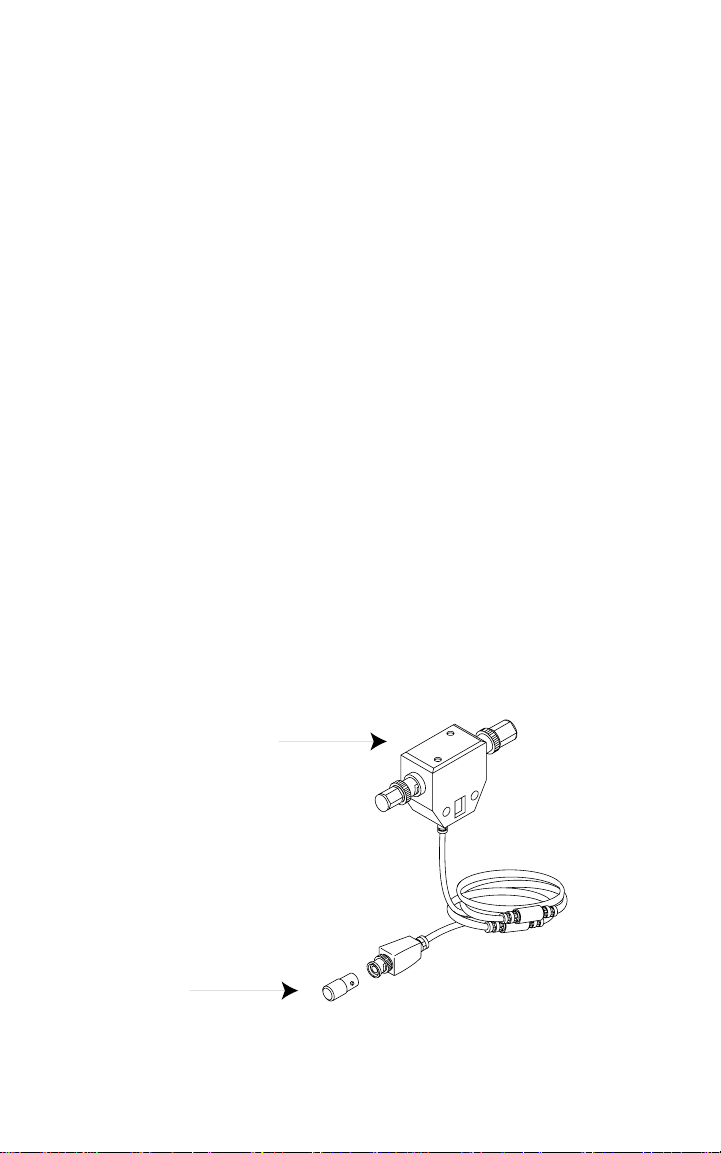

Installing the Tap Terminator

1. Remove the dust cap from the exis ting tap.

2. Install the tap terminator over the exposed end of dummy as shown

below.

ControlNet Ex Tap

1797-TCAP Tap

Terminator

FLEX Ex is a trademark of Rockwell Automation. 1797-5.30 - September 1999

30131-M

Page 2

2 ControlNet Ex Tap Terminator Installation Instructions

ControlNet Ex System Diagram

C.

o

Zone 1 or 2, IIC

Flexbus Uo= 5.4V,

3

,

µmA, Po=2.16W,

µF, L o= 1 0µH

Co=65

Io=400

any IS device with entity

concept parameters V

.

Node 4 ... 48

1797-ACNR15

,

max

1

max

) appropriate for

i

, L

i

C

max

I

connection to associated

apparatus with entity

concept parameters

listed in ta ble 1

.

2

.

.

1

hazardous (classified) location

) appropria te for

µmA, Po=2.16W,

i

µF, L o=1 0µH

Node 2

Class I, Zones 1 and 2, Groups IIC, IIB, IIA

1797-RPFM 1797-RPFM

1797-RPA

The ambient temperature rang e of the ControlNet Ex system is -20 to + 70

Class I Division 1 and 2, Groups A, B, C, D

.

.

.

.

Flexbus Uo=5.4V,

.

.

.

Io=400

Co=65

Node 3

1797-ACNR15

power supply Vmax or

ControlNet Ex

BNC Uo=5.4V,

, L

i

ControlNet Ex

C

max

I

any IS device with entity

concept parameters V

.

.

Ch2

Ch1

120nF, Li=0

Ui=9.5V, Imax or Ii=1A,

Ci<

to any approved device

500kHz

Io=201mA,

F>

BNC Uo=5.4V,

connection to associated

apparatus with entity

concept parameters

listed in table 1

.

1

.

54

ControlNet Ex

BNC Uo=5.4V,

fiber optic cable

Ch2

2

Ch1

1

<9.5V

o

<1A

o

or associated apparatus

with Entity Concept

parameters of V

and I

1

<1A

sc

120nF, Li=0

<9.5V and I

oc

CNet Ex

power supply Vmax or Ui=9.5V,

Imax or Ii=1A, Ci<

to any approved device or associated

apparatus with Entity Concept

parameters of V

ChBChA

500kHz

1

Io=160mA,

F>

<1A

o

120nF, Li=0

<9.5V and I

o

ChB

to any approved device or associated

apparatus with Entity Concept

parameters of V

power supply Vmax or Ui=9 .5V,

Imax or Ii=1A, Ci<

ChA

500kHz

Io=160mA,

F>

2

trk trm

tap

ControlNet Ex

2

cable

coax trunk

tap

ControlNet Ex

Zone 1 or 2, IIC

hazardous (classified) location

2

tap

ControlNet Ex

CNet Ex

tap trm

tap

ControlNet Ex

Node 1

CNet Ex

trk trm

30670

Class III, Division 1 and 2

Class II, Division 1 and 2, Groups E, F, G

Class I, Zones 1 and 2, Groups IIC, IIB, IIA

Class I Division 1 and 2, Groups A, B, C, D

cable

coax trunk

2

is <5mW/mm

(e.g. Hewlett Packard

1786-RPFM or any associated

emitting diode output

apparatus where the light

HFBR-1312 or HFBR-1414).

nonhazardous location

1797-5.30 - September 1999

Zone 0, 1 or 2, IIC

Groups A, B, C, D

Groups IIC, IIB, IIA

Class I Division 1 and 2,

Class I, Zones 0, 1 and 2,

hazardous (classified) location

Groups E, F, G

Class II, Division 1 and 2,

Class III, Division 1 and 2

Page 3

ControlNet Ex Tap Terminator Installation Instructions 3

Describing the ControlNet Ex System Diagram

A maximum of 48 ControlNet ExTM nodes may be connected together by

820ft (250m) of coax cable and 48 taps. The distance to increases to 3280ft

(1000m) when you use only 2 taps. See the table below for more

information.

The fiber media of the 1797-RPFM can be installed in a hazardous location

(Zone 0, 1 or 2; Class I, Zones 0, 1, and 2; Class I, Divisio n 1 and 2; Class

II, Division 1 and 2; Class III, Division 1 and 2) to connect two

1797-RPFM modules or they can be installed through different locations

into the non-hazardous location to connect the 1797-RPFM with any

approved as sociated appar atus.

All cables and fibe r media that are not light blue must be marked as I S

using the 1797-EXMK marking kit or other locally approved IS

identification and/or segregation method.

During the installation of the Co ntrolNet Ex system, all m etallic parts must

be isolated to prevent an earth connection (high voltage withstanding of

isolating material must be > 500V ac).

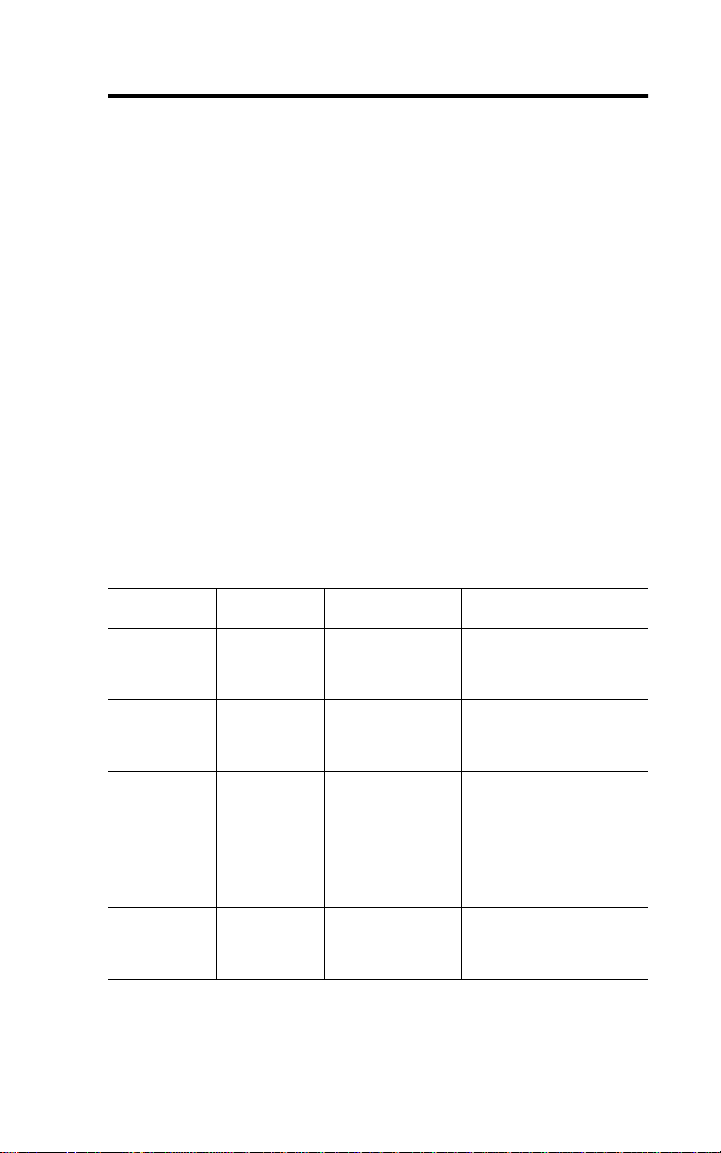

System

Diagram Name

1797-RPA 1797-RPA ControlNet Ex

1797-RPFM 1797-RPFM ControlNet Ex Fiber

1797-ACNR15 1797-ACNR15 Redundant Media

CNet Ex Tap Trm 1797-TCAP ControlNet Ex Tap

Catalog

Number

Catalog Name Description

Modular Repeater

Adapter

Repeater Module,

Medium Distance

ControlNet Ex

Adapter

(Dummy) Terminator

Represents one ControlNet Ex

node and must be connected

to a coax trunk cable by

1797-TPx

Allows connection of a

maximum of two devices per

1797-RPA and is powered

directly by 1797-RPA

Represents one ControlNet Ex

node and must be connected

to a coax trunk cable by

1797-TPx -each one with two

redundant output channels

that are connected to different

ControlNet Ex networks (coax

cables and 1797-TPx)

Represents one ControlNet Ex

node and is a simple

capacitor (56pF) with a coax

connector

1797-5.30 - September 1999

Page 4

4 ControlNet Ex Tap Terminator Installation Instructions

System

Diagram Name

ControlNet Ex

Tap

Catalog

Number

Catalog Name Description

1797-TPx ControlNet Ex Coax

Tap

Four types of connections

available: S (straight t-tap), R

(right angle t-tap), YS (straight

y-tap), and YR (right angle

y-tap) - a maximum of 48

taps can be connected

together by coax trunk cable

CNet Ex Trk Trm 1797-XT ControlNet Ex Trunk

Terminator

Coax Trunk

Cable

1797-RG6 Quad-Shield, RG-6

75Ω Coax Trunk

Cable

Simple resistor (75Ω) with

coax connector that must be

on each end of the ControlNet

Ex coax trunk for termination

Maximum (functional) length

between 2 1797-TPx is

3280ft (1000m) - each

1797-TPx reduces the

(functional) coax cable length

by 53.4ft (16.3m)

None None Standard Coax Trunk

Cable BNC Couplers

Different standard cable

couplers, 90

o

, 180o, etc.

Certified Equivalent ControlNet Ex System Diagram Items

You may use these items as equivalents for the items shown on the system

diagram.

System Diagram Name Catalog Number Source

Coax Trunk Cable 1797-RG6 Allen-Bradley

1

3092A

3092A with blue jacket Belden Wire & Cable Co.

1 Belden Wire & Cable 1189A may be used, but with functional loss of communication

distance and/or nodes.

Belden Wire & Cable Co.

1797-5.30 - September 1999

Page 5

ControlNet Ex Tap Terminator Installation Instructions 5

UL, cUL I/O Entity Parameters and Requirements

Tab l e 1

Ter m i nals Vt (V) It (mA) Groups C

Male Bus

Connector

The entity concept allows interconnection of intrinsically safe

5.8 400 A-G 3.0 3.0

apparatus with associated apparatus not specifically examin ed in

combination as a system when t he approved values of Voc and Isc or Vt and

I

of the associated apparatus are less th an or equal to V

t

intrinsically safe apparatus and the approved values of C

associated apparatus are greater than C

+ C

i

cable

for the intrinsically safe apparatus.

ó

Wiring methods must be in accordance with the National Electric

Code, ANSI/NFPA 70, Article 504 and 505 or the Canadian Electric Code

CSA C22.1, Part 1, Appendix F. For additional information refer to ANSI/

ISA RP12.6.

ì

WARNING: Substitution of components may impair intrinsic safety.

AVERTISSEMENT: La substitution de composant peut compromettre la

securite intrinseque.

ö

If fiber optic cable is provided with a meta l shield, it must be connected

to a dedicated intrinsic safety ground in the non-hazardous location and

tied back in the haza rdous location or be c onnected to a ground in the

hazardous location and tied back in the non-hazardous location.

(µF) La (µH)

a

max

and Li + L

and I

and La of the

a

cable

of the

max

respectively

ú

The glass fiber mus t ha ve a minimum diameter of 6µm.

1797-5.30 - September 1999

Page 6

6 ControlNet Ex Tap Terminator Installation Instructions

Installation in Zone 1

ATTENTION: This tap terminator cannot be used in an

intrinsically safe environment after it has been exposed to

non-intrinsically safe signals.

!

Make certain th at you only connect ControlNet Ex products to other

intrinsically safe system products to maintain the integrity of the

intrinsically-safe system.

41307

Electrostatic Charge

Protect the system against electrostatic charge. Post a sign near the adapter:

Attention! Avoid electrostatic charge. For your conve nie n ce , a sign

which can be cut out is included in this installation instruction.

European Community Directive Compliance

If this product has the CE mark it is approved for installation within the

European Community or EEA regions. It has been designed and tested to

meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction file:

• EN50081-2

EMC - Generic Emission Standard, Part 2 - Industrial Environment

• EN50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial Environment

1797-5.30 - September 1999

Page 7

ControlNet Ex Tap Terminator Installation Instructions 7

This product is intended for use in an industrial environment.

Ex Directive

This product is tested to meet the Council Dir ectiv e 94 /9 EC (ATEX 100a)

Equipment and Protective Systems Intended for Use in Potentially

Explosive Atmospheres by applying the following standards:

• EN50014:1992, Electrical Apparatus for Potentially Explosive

Atmospheres

• EN50020:1994, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsic Safety “i”

• EN50039:1980, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsically Safe Electrical Systems “i”

• pr EN50284:1997, Special requirements for construction, test, and

marking of electrical apparatus of equipment group II, category 1 G

Important: For detailed certification information, refer to the FLEX Ex

System Certification Reference Manual, public ation

1797-6.5.6.

Attention: Avoid electrostatic charge.

1797-5.30 - September 1999

Page 8

ControlNet is a trademark of ControlNet International.

ControlNet Ex is a trademark of Rockwell Automation.

Publication 1797-5.30 - September 1999 PN 957236-26

© (1999) Rockwell International Corporation.Printed in USA

Loading...

Loading...