Page 1

Installation Instructions

FLEX Ex Power Supply

Catalog Number 1797-PS2E2

Top ic Page

Important User Information 2

About the Power Supply 3

Understand System Planning 4

Installation in Zone 1, 22 6

Electrostatic Charge 8

Outputs 8

Mount the 1797-PS2E2 Power Supply 8

Customer Connections 10

Typical Wiring Configurations 10

Mounting Dimensions and Terminal Base Assignments for the

1797-PS2E2 Power Supply

Repair 11

FLEX Ex Power Supply, cat. no. 1797-PS2E2 12

Ferrite Beads 15

11

Publication 1797-5.8 - June 2010

Page 2

2 FLEX Ex Power Supply

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical

equipment. Safety Guidelines for the Application, Installation and Maintenance of Solid State Controls

(Publication SGI-1.1 available from your local Rockwell Automation sales office or online at

http://literature.rockwellautomation.com) describes some important differences between solid state

equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must

satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages

resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the

many variables and requirements associated with any particular installation, Rockwell Automation, Inc.

cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits,

equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell

Automation, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety considerations.

Identifies information about practices or circumstances that can cause an explosion in a

hazardous environment, which may lead to personal injury or death, property damage, or

economic loss.

Identifies information that is critical for successful application and understanding of the

product.

Identifies information about practices or circumstances that can lead to personal injury or

death, property damage, or economic loss. Attentions help you identify a hazard, avoid a

hazard, and recognize the consequence

Labels may be on or inside the equipment to alert people that dangerous voltage may be

present.

Publication

Labels may be on or inside the equipment to alert people that surfaces may be dangerous

temperatures.

1797-5.8 - June 2010

Page 3

ATTENTION

This equipment is considered Group 1, Class A industrial equipment

1797-PS2E2

30686

according to IEC/CISPR Publication 11. Without appropriate

precautions, there may be potential difficulties ensuring

electromagnetic compatibility in other environments due to

conducted as well as radiated disturbance.

This equipment is supplied as enclosed equipment. It should not

require additional system enclosure when used in locations

consistent with the enclosure type ratings stated in the

Specifications section of this publication. Subsequent sections of

this publication may contain additional information regarding

specific enclosure type ratings, beyond what this product provides,

that are required to comply with certain product safety certifications.

About the Power Supply

FLEX Ex Power Supply 3

The power supply is an essential component in the operation of an

intrinsically safe system. It must isolate the unsafe incoming power from the

control system and limit the available energy to IS-safe levels.

No other power sources are needed to operate any components attached to

the FLEX Ex system in the hazardous area. Power for valves, actuators, or

transmitters come from the FLEX Ex modules.

Publication

1797-5.8 - June 2010

Page 4

4 FLEX Ex Power Supply

The 1797-PS2E2 is a 24V dc in/quad-Ex dc out power supply in an

flame-proof enclosure with increased safety input and output terminations.

The 24V dc gland is an M20 x 1,5 and can accept a cable from 6…12

mm

(0.267…0.472 in.) in diameter. The Ex outputs are M16 x 1,5 and can accept a

cable from 4…8 mm (0.157…0.315 in.) in diameter.

Features include the following:

24V dc supply source

Four channels, 8.5 W output each channel

Dual power feeds for source input redundancy

Outputs are IS galvanically isolated from the source

All channels are independently IS limited

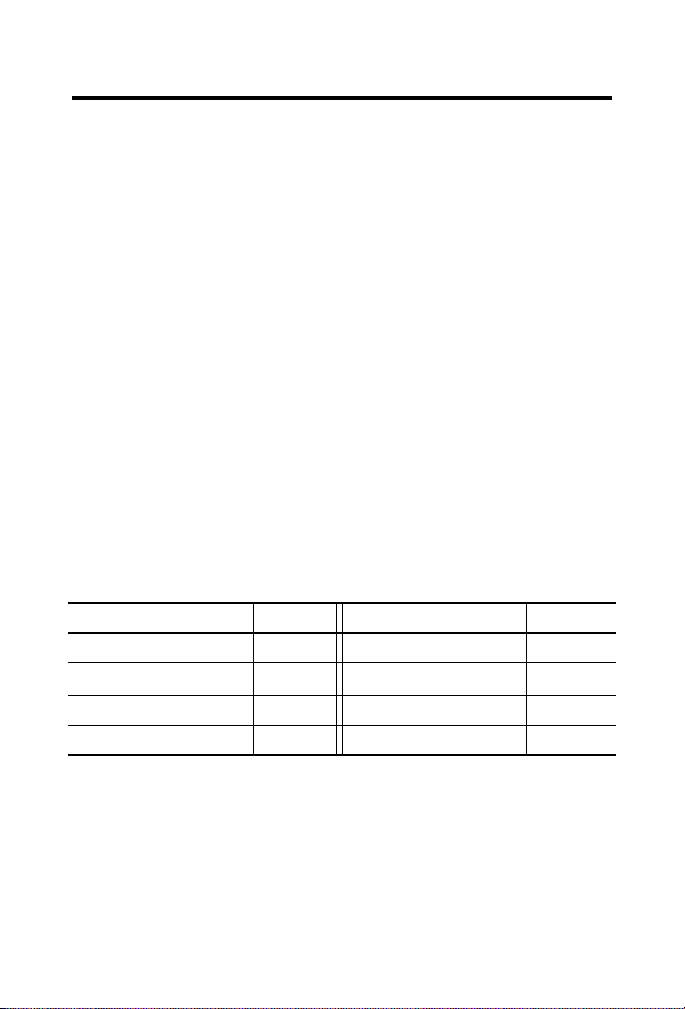

Understand System Planning

Part of system planning is determining what modules are needed for the

application, how many power supplies are needed, how to best partition the

system, and where to locate the system cabinets.

A key task in the development cycle is determining the number of power

supply outputs (thus power supplies) you will need. In the following example,

you will need 11 power outputs if you are using the fiber hub, which requires

8.5 W.

Modules Requires Modules Requires

Fiber hub 8.5 W Two thermocouple inputs 1.6 W each

Two ControlNet adapters

Two analog inputs 7.5 W each Three NAMUR digital inputs 2.8 W each

Two analog outputs 6.3 W each Two counter inputs 4.25 W each

8.5 W each Two digital outputs 7.5 W each

Each power supply has four independent IS-power outputs capable of 8.5 W

each. In the above example, we required 11 IS-power outputs so 3 power

supplies were sufficient.

Publication

1797-5.8 - June 2010

Page 5

IMPORTANT

IS Pwr

Safe Area

Hazardous Area

1797 power supply

1797 power supply

1797 power supply

ACNR

Spare

IE8 OE8 IRT8 Spare Spare IJ2 IJ2

ACNR OB4 OB4D IBN16 IBN16 IBN16 IE8 IRT8 OE8

RPA RPFM RPFM

IS 1797 I/O

IS 1797 I/O

IS 1797 Fiber Hub

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

IS Pwr

Ex d/e

Ex ib

Ex d/e

Ex ib

Ex d/e

Ex ib

41306

Unsafe

Power

Entrance

Spare

Unsafe

Power

Entrance

Unsafe

Power

Entrance

FLEX Ex Power Supply 5

The total number of power supplies needed depends on the modules used

and the total system configuration. The following illustration shows how this

example may be configured.

Even though modules may be supplied with power from the same

power-supply output channel, galvanic isolation in the module

provides module-to-module galvanic isolation. Depending upon

the module-type, galvanic isolation (channel-to-channel within the

module) may or may not be provided. See the module’s

specifications for more information.

Publication

1797-5.8 - June 2010

Page 6

6 FLEX Ex Power Supply

WARNING

41307

Make certain that you only connect intrinsically-safe power supplies to other

intrinsically-safe system modules or adapters to maintain the integrity of the

intrinsically-safe backplane.

Installation in Zone 1, 22

The 1797-PS2E2 power supply has a protection factor of IP65. Refer to the

specifications table for the IS module type.

The power supply cannot be used in an intrinsically safe environment

after its outputs have been exposed to nonintrinsically safe signals.

Application

When installing, commissioning, operating, and maintaining devices or device

components of the FLEX Ex system as intrinsically-safe electrical apparatus

in potentially explosive atmospheres according to EN 60079-11, you must

heed the EC- type examination certificate and the applicable national and

local construction, installation, and operating regulations.

Zone 1

The power supply can be located in Zone 1. The permissible ambient

temperature of -20…70 °C must not be exceeded.

Zone 22

The housing type of the power supply is applicable for use in Zone 22. It

corresponds with the category 3D acc. to directive 94/9 EC and is marked

with a type label accordingly.

Publication

1797-5.8 - June 2010

Page 7

FLEX Ex Power Supply 7

Installation and Commissioning

The power supply unit can be located in Zones 1, 2, and 22 as stated on its

label. The output circuits are according to the ignition protection class Ex ib

and can be installed in Zones 1, 2, and 22. When installing, you must heed the

EC- type examination certificate (especially the special conditions) and the

applicable national and local construction, installation, and operating

regulations.

The housing (Ex d) must not be opened (screw cover). Connections are made

in the (Ex e) terminal box.

Install the power feed lines only in the deenergized state. Also follow the

information on the type label, respectively the covers of the terminals.

You can connect and disconnect the intrinsically-safe output terminals during

operation.

All unused cable glands must be covered by appropriate prototype tested Ex e

lead seals to keep the requirement of IP54.

The cover installed on the nonintrinsically-safe screw terminals

(IP30) may be removed only in the deenergized state and must be remounted

after working on these terminals.

Before closing the cover of the (Ex e) wiring box, inspect the seal for any

signs of damage. In case of damage, the seal must be replaced by a new seal

that is identical to the damaged seal.

The power supply housing contains two flanges, which can be connected to a

wall or other structural part by means of fixing screws. Select fixing screws

that ensure secure fixing of the power supply. Consider the condition of

vibration of the power supply when making this selection.

On the (Ex d) housing there is an earthing screw. This screw must be

connected to Earth with a conductor having a minimum of 4 mm² (0.006 in.

area. The connection has to be protected against self-opening and corrosion.

Corrosion protection can be achieved by using tinned terminal ends.

Before opening the (Ex e) terminal box (for example, for maintenance

purposes), it must be cleaned of all dust particles to ensure that no dust can

enter the box.

2

)

Publication

1797-5.8 - June 2010

Page 8

8 FLEX Ex Power Supply

IMPORTANT

ATTENTION

Electrostatic Charge

Protect the system against electrostatic charge. Post a sign near this module.

WARNING Avoid electrostatic charging.

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO DE CARGA

ELETROSTÁTICA.

For your convenience, a sign that can be cut out and posted is included on the

last page of these installation instructions.

Outputs

When using an intrinsically-safe electrical apparatus according to EN

60079-11, the European directives and regulations must be followed.

The channels in the power supply are electrically connected to each other and

have a common +V line.

You cannot interconnect lines because of the intrinsic safety

requirements.

Mount the 1797-PS2E2 Power Supply

Follow these directions to properly install the 1797-PS2E2 power supply.

Refer to the Installation and Commissioning section, page

precautions and considerations.

7, for important

Use star washers and nuts to make sure you have a good electrical

connection. Scrape the paint off the back panel in those areas where

grounding bolts will be located.

1. Remove the screws on the cover of the power supply Ex e terminal

box to access the input and output terminals.

2. Thread the blue IS-safe output power wiring through the blue IS

compression seals.

Publication

1797-5.8 - June 2010

Page 9

FLEX Ex Power Supply 9

ATTENTION

3. Connect the blue IS-safe output power wiring to the output terminals

making sure all connections are tight.

These power supply outputs provide the input power to the FLEX Ex

modules.

4. Thread the hazardous incoming-power wiring through the black

compression seals.

5. Connect the hazardous incoming-power wiring to the input terminals

making sure all connections are tight.

You can daisy-chain the hazardous incoming-power wiring to further

supplies to simplify system wiring.

Keep hazardous and IS-safe wiring separated in a suitable

fashion. Do not leave long, excess wiring that could bridge

between the hazardous and safe areas.

6. Replace the lid of the Ex e terminal box.

7. Screw the lid back into place making sure all of the screws are tight.

Publication

1797-5.8 - June 2010

Page 10

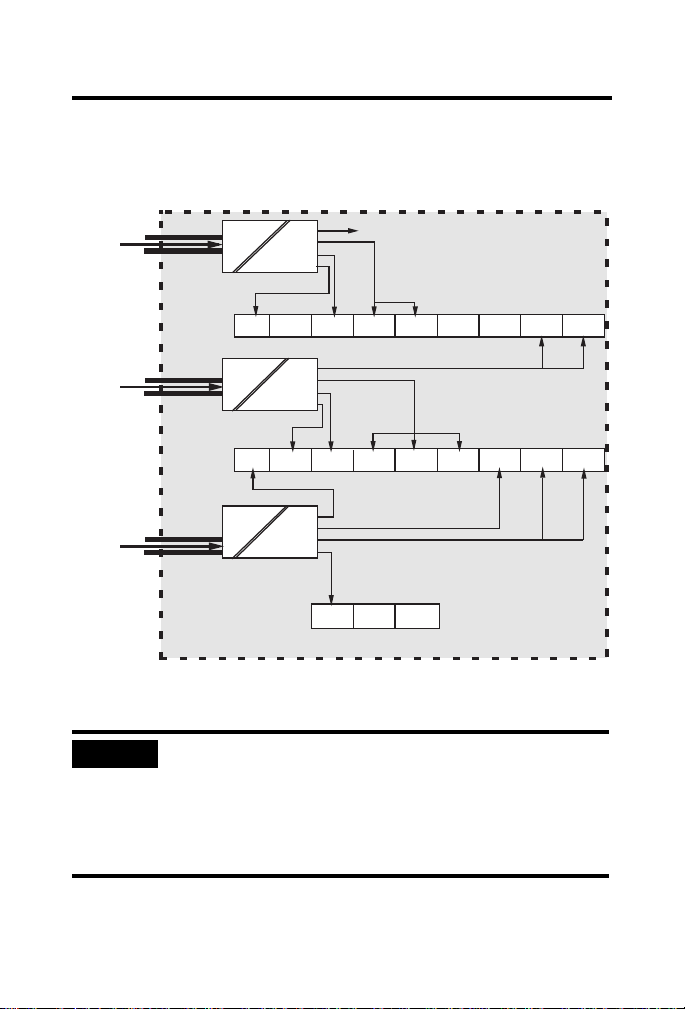

10 FLEX Ex Power Supply

Vin1

Vin2

Chassis GND

IS Isolation

Hazardous to IS

-V

+V

Out 1

-V

+V

Out 2

-V

+V

Out 3

41315

Dual Input

Diodes

IS Limiters

Voltage and Current

-V

+V

Out 4

+

+

-

dc

Type of Power Input

IS Power Output

Daisy-chaining

+V, -V

You can use the daisy chain configuration if the

total module power draw is < 8.5 W. Otherwise,

power is connected to individual modules.

Combination

Wiring when total module current

power is greater than 8.5 W.

<8.5 W

+V, -V

Other variations are possible depending

upon individual module power.

<8.5 W+V, -V

1797-PS2E2

Hazardous

Incoming

Power

IS-safe

Output Power

Keep Wires Separate

41316

Customer Connections

Typical Wiring Configurations

Publication

1797-5.8 - June 2010

Page 11

FLEX Ex Power Supply 11

41298A

mm (in.)

218 (8.58)

174 (6.85)

174

(6.85)

280

(11)

Mounting Dimensions

149

(5.87)

10 (0.39) 2 Holes

Chassis Ground

194 (7.64)

Height

140 (5.51)

42489

10 11 12 13 14 15 16 17

1245

Chassis GND

-+

Vin1-+Vin2

+V -V +V -V +V -V +V -V

Out 1 Out 2 Out 3 Out 4

Terminal Base Assignments

European DC Power Input IS Power Output

Mounting Dimensions and Terminal Base Assignments for the 1797-PS2E2 Power Supply

Repair

The power supply is not field-repairable. Any attempt to open this module

will void the warranty and IS certification. If repair is necessary, return this

module to the factory.

Publication

1797-5.8 - June 2010

Page 12

12 FLEX Ex Power Supply

Specifications

Table 1 FLEX Ex Power Supply, cat. no. 1797-PS2E2

Attribute Value

Zone 1 II 2G Ex de [ib] IIC T4 (DMT 02 ATEX E253 X)

Zone 22 II 3D IP54 T90C

Input connectors 24V dc

Voltage range 18…32V

Input frequency N/A

Current consumption 3.1…1.6 A

Ripple 5% ac

Input power entrance Increased safety

Output connectors Terminals 10…17

Output power 4 x 8.5 W

Inset voltage range 18…32V dc

Voltage U

O

Current I

O

Co (IIC) <500 nF

Lo (IIC) <8 H

Max output cable resistance

(both directions)

Isolation path

Input power to output power

Output to output

Input power 55 W

Power dissipation 21 W

Thermal dissipation 71.67 BTU/hr

Conductors wire size

Dimensions (HxWxD) approx. 140 mm x 174 mm x 280 mm

Protections class IP 65/NEMA 7B

Weight (approx.) 7.7 kg (17 lb)

Terminals 1, 2, 4, 5

<9.5V

<1 A

<0.1

Galvanic to DIN EN 60079-11

None

4 mm2 (12 gauge) max wire rated at 100 °C (212 °F) or higher

1.2 mm (3/64 in.) insulation max

(5.51 in. x 6.9 in. x 11.0 in.)

Publication

1797-5.8 - June 2010

Page 13

FLEX Ex Power Supply 13

Table 2 Environmental Specifications

Attribute Value

Operating temperature IEC 60068-2-1 (Test Ad, Operating Cold),

Storage temperature IEC 60068-2-1 (Test Ab, Unpackaged Nonoperating Cold),

Relative humidity IEC 60068-2-30 (Test Db, Unpackaged Nonoperating Damp

Shock

Vibration IEC60068-2-6 (Test Fc, Operating):

Emissions CISPR 11

Operating

Nonoperating

IEC 60068-2-2 (Test Bd, Operating Dry Heat),

IEC 60068-2-14 (Test Nb, Operating Thermal Shock):

-20…70 °C (-4…158 °F)

IEC 60068-2-2 (Test Bb, Unpackaged Nonoperating Dry Heat),

-40…85 °C (-40…185 °F)

Heat):

5…95% noncondensing

IEC60068-2-27 (Test Ea, Unpackaged shock):

15 g

15 g

2 g @ 10…500 Hz

Radiated, Class A

Conducted, Class B

Publication

1797-5.8 - June 2010

Page 14

14 FLEX Ex Power Supply

Table 3 Certifications

Certifications

(when

product is marked)

CE

EE

C-Tick

INMETRO

IECEx

(1)

See the Product Certification link at www.ab.com for Declarations of Conformity, Certificates, and other

certification details.

Valu e

(1)

European Union EMC Directive (2004/108/EC) , compliant

with:

EN 61000-6-4:2007; Electromagnetic Compatibility (EMC) -

Part 6-4: Generic Standard for Industrial Environments

(Class A)

EN 61000-6-2:2005; Electromagnetic Compatibility (EMC) -

Part 6-2: Generic Standard - Immunity for Industrial

Environments

EN 61326-1-4:2006 (Industrial), Electrical Equipment For

Measurement, Control, and Laboratory Use - Industrial EMC

Requirements

European Union 94/9/EC ATEX Directive, compliant with:

EN 60079-0:2006; Potentially Explosive Atmospheres,

General Requirements

EN 60079-1:2007; Potentially Explosive Atmospheres,

Protection “d”

EN 60079-7:2007; Potentially Explosive Atmospheres,

Protection “e”

EN 60079-11:2007; Potentially Explosive Atmospheres,

Protection “i”

EN 61241-1: 2004; Electrical apparatus protected by

enclosure

Australian Radiocommunications Act, compliant with:

AS/NZS CISPR11; Industrial Emissions

BR-Ex de [ib] IIC T4

Certificate number 05/UL-BRAE-0018X

Ex de[ib] IIC T4

Cert no. IECEx BVS 09.0019X

Publication

1797-5.8 - June 2010

Page 15

Ferrite Beads

Pass all IS power-supply output

wires through the ferrite bead

before connecting the cable to

the power supply.

30889

WARNING Avoid electrostatic charging.

ADVERTÊNCIA! PREVENIR CONTRA O ACÚMULO

DE CARGA ELETROSTÁTICA.

FLEX Ex Power Supply 15

Publication

1797-5.8 - June 2010

Page 16

Rockwell Automation Support

Rockwell Automation provides technical information on the Web to assist you in using

its products. At http://support.rockwellautomation.com

manuals, a knowledge base of FAQs, technical and application notes, sample code and

links to software service packs, and a MySupport feature that you can customize to

make the best use of these tools.

For an additional level of technical phone support for installation, configuration, and

troubleshooting, we offer TechConnect Support programs. For more information,

contact your local distributor or Rockwell Automation representative, or visit

http://support.rockwellautomation.com

.

Installation Assistance

If you experience a problem with a hardware module within the first 24 hours of

installation, please review the information that's contained in this manual. You can also

contact a special Customer Support number for initial help in getting your module up

and running.

United States 1.440.646.3434 Monday – Friday, 8am – 5pm EST

Outside United States Please contact your local Rockwell Automation representative for

any technical support issues.

New Product Satisfaction Return

Rockwell tests all of its products to ensure that they are fully operational when shipped

from the manufacturing facility. However, if your product is not functioning, it may

need to be returned.

United States Contact your distributor. You must provide a Customer Support case

number (see phone number above to obtain one) to your distributor

in order to complete the return process.

Outside United States Please contact your local Rockwell Automation representative for

return procedure.

Allen-Bradley, Rockwell Automation, ControlLogix, RSLinx, TechConnect, and FLEX I/O are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

, you can find technical

Publication 1797-5.8 - June 2010 PN -79489

Supersedes Publication 1797-5.8 - April 2006 Copyright © 2010 Rockwell Automation, Inc. All rights reserved. Pri nted in the U.S.A.

Loading...

Loading...