Page 1

ControlNet Ex

Media

1797-series

Planning and Installation

Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

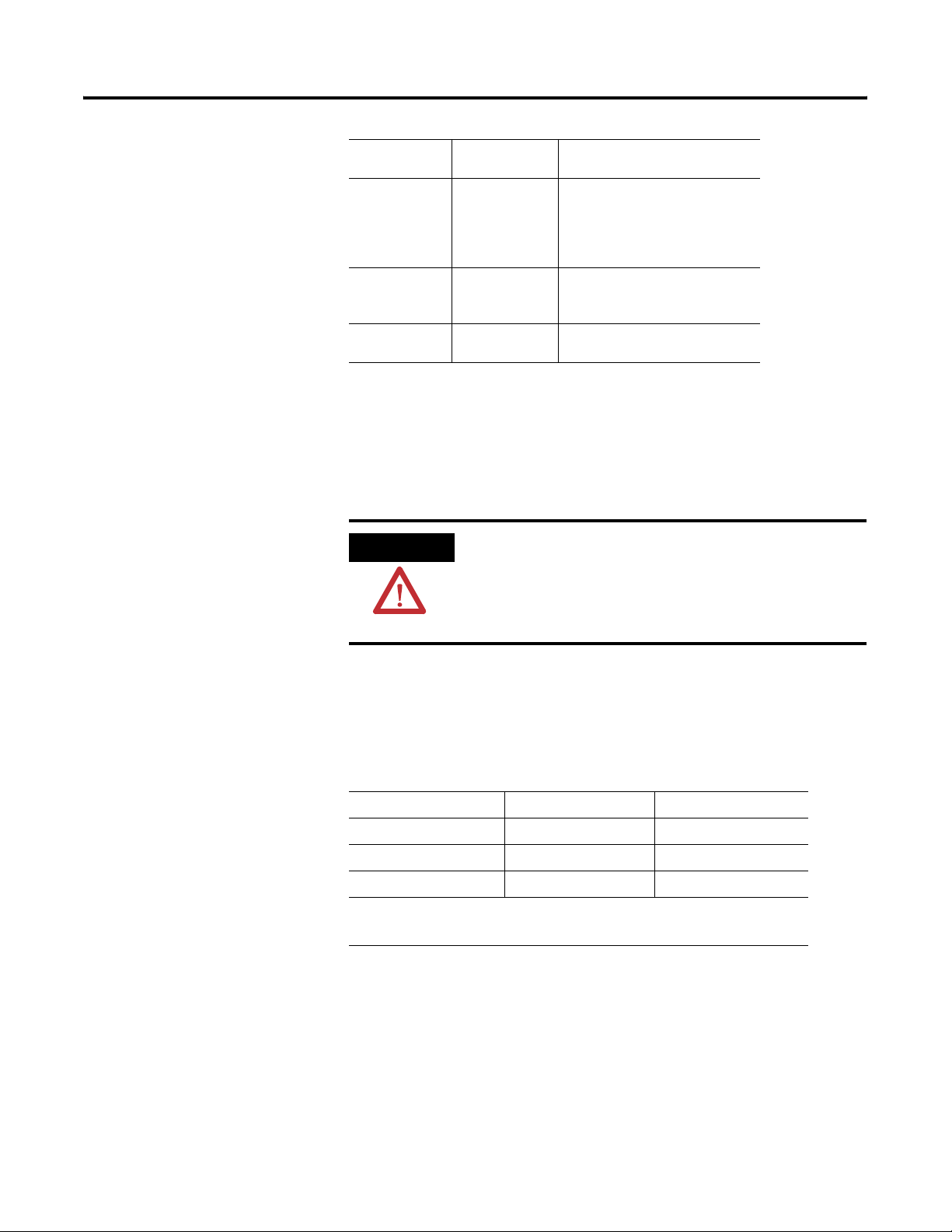

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

Table of Contents

Preface

Overview of the ControlNet Ex

Media System

What’s in This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Abbreviations and Symbols . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Common Techniques . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

For More Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Chapter 1

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 1-1

Understand the ControlNet Ex Media System . . . . . . . . . . . 1-2

Understand ControlNet Ex Components . . . . . . . . . . . . . . . 1-4

Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Trunk Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Cable Connectors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Trunk Terminator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Tap Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Segments. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Fiber Repeater Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Insulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

ControlNet Ex System Installation Requirements . . . . . . . . . 1-9

Certified Equivalent ControlNet Ex System Components 1-10

UL, cUL I/O Entity Parameters and Requirements . . . . . 1-11

European Community Directive Compliance . . . . . . . . . 1-12

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Ex Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

What Is Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-13

Plan a ControlNet Ex Media

System

Chapter 2

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 2-1

Determine How Many Taps You Need. . . . . . . . . . . . . . . . 2-2

Connect Programming Devices in Safe Areas . . . . . . . . . . . 2-3

Coax Cable Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Fiber Media Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Determine Trunk Cable Section Lengths. . . . . . . . . . . . . . . 2-4

Determine Trunk Cable Section Length When

You Use a FLEX Ex Redundant ControlNet

Barrier Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Estimate Fiber Media Lengths . . . . . . . . . . . . . . . . . . . . . . 2-7

Determine How Many Trunk Terminators You Need . . . . . 2-7

Determine What Type of Connectors You Need . . . . . . . . . 2-8

Use Redundant Media in a Hazardous Area . . . . . . . . . . . . 2-10

Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Understand Conductor Categories. . . . . . . . . . . . . . . . . 2-13

General Wiring Guidelines . . . . . . . . . . . . . . . . . . . . . . 2-14

Ferrite Beads. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Required Ferrite Beads. . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Add Ferrite Beads . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-16

i Publication CNET-IN003A-EN-P - January 2006

Page 4

Table of Contents ii

Install a ControlNet Ex Media

System

Order Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

General Planning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Plan a Segment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-17

Plan Your Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

Order Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-18

What Is Next? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-20

Chapter 3

What This Chapter Contains . . . . . . . . . . . . . . . . . . . . . . . 3-1

Install the Trunk Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Wire External to Enclosures . . . . . . . . . . . . . . . . . . . . . 3-1

Wire Inside Enclosures. . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Mount the Taps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Select Where to Mount the Taps. . . . . . . . . . . . . . . . . . 3-2

Mount the Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Install Fiber Hubs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Installation in Zone 1 . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Electrostatic Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Select a Fiber Repeater Hub Mounting Location . . . . . . 3-8

Mount the Fiber Repeater Hub . . . . . . . . . . . . . . . . . . . 3-9

Connect the Fiber Repeater Hub to a ControlNet

Ex Network . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Install Cable Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Collect Your Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Strip the Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Test for Electrical Shorts and Continuity Between the

Center Conductor and the Shield . . . . . . . . . . . . . . . . . 3-19

Attach the Connectors to the Cable. . . . . . . . . . . . . . . . 3-20

Test for Electrical Shorts and Continuity Between the

Connector Body and Pin . . . . . . . . . . . . . . . . . . . . . . . 3-24

Connect Cable Sections . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Terminate Segments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-25

Connect Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-27

Install the 1797-BCNR Module . . . . . . . . . . . . . . . . . . . . . . 3-28

Mounting Dimensions

Publication CNET-IN003A-EN-P - January 2006

Appendix A

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . A-1

Tap Placement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Universal Mounting Bracket. . . . . . . . . . . . . . . . . . . . . . . . A-2

Page 5

Adjust the Cable Strip Tool

Protect Your System Against

Electrostatic Discharge

Index

Table of Contents iii

Appendix B

What This Appendix Contains . . . . . . . . . . . . . . . . . . . . . . B-1

Calibrate the Cutting Blades. . . . . . . . . . . . . . . . . . . . . . . . B-1

Reverse and Replace the Cutting Blades. . . . . . . . . . . . . . . B-3

Change the Memory Blade Holder . . . . . . . . . . . . . . . . . . . B-5

Appendix C

Publication CNET-IN003A-EN-P - January 2006

Page 6

Table of Contents iv

Publication CNET-IN003A-EN-P - January 2006

Page 7

Preface

What’s in This Chapter

Use this manual to plan and install a ControlNet Ex media system.

This manual describes the required components of an intrinsically-safe

cable system and how to plan for and install these required

components.

This manual targets the configurion of a ControlNet Ex system.

However, since a ControlNet Ex system and a ControlNet system can

be linked, it may be necessary to introduce and refer to concepts on

the ControlNet side of the network.

Some configurations on a standard ControlNet system may not be

possible within a ControlNet Ex configuration. Many of the installation

methods and equipment for the ControlNet Ex system is the same as

those available for the ControlNet system. However, some differences

do exist. As you use this manual, note these differences.

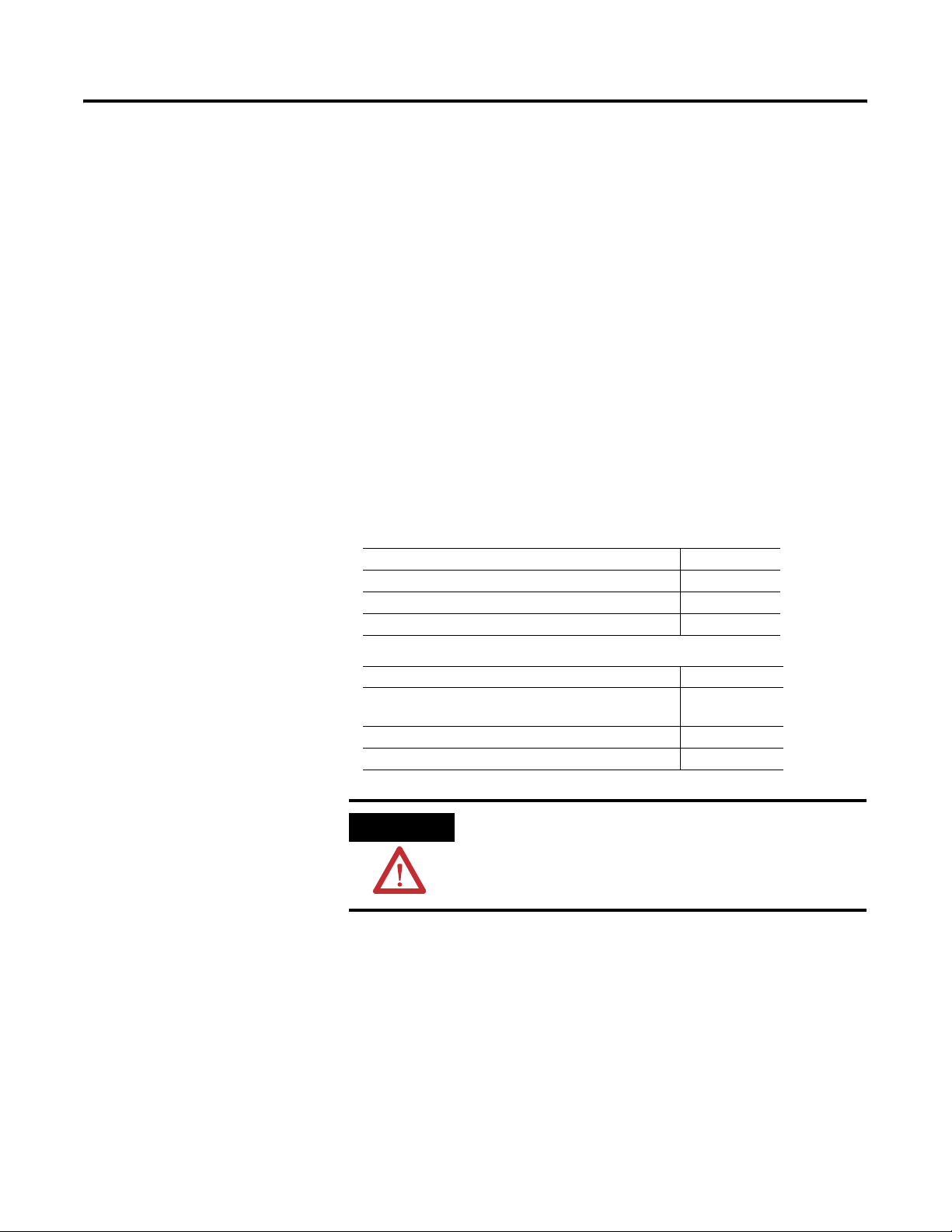

The following tables describe where specific information is found in

this manual.

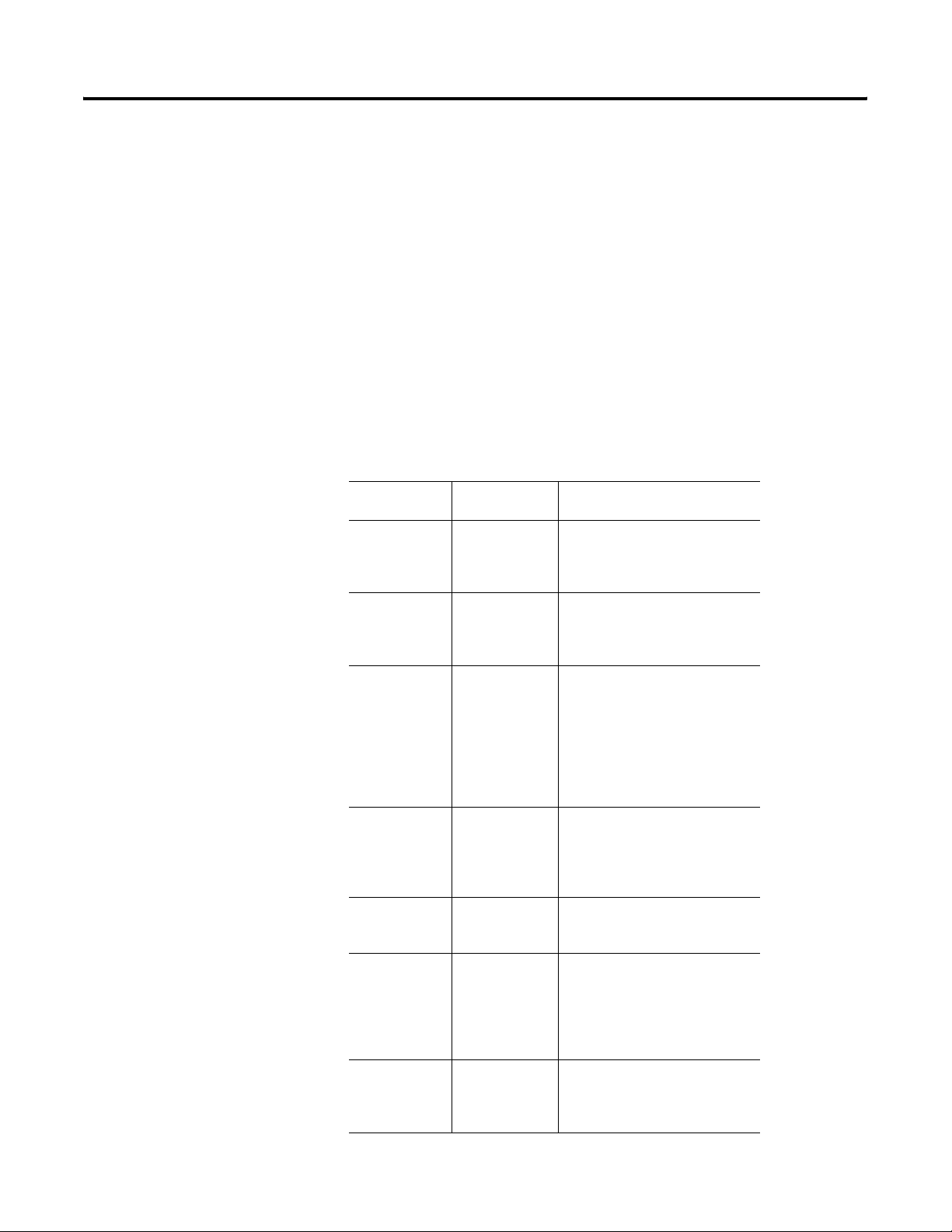

For See Chapter

Help understanding the ControlNet Ex Media System 1

Help planning a ControlNet Ex Media System 2

Installation of a ControlNet Ex Media System 3

For See Appendix

Mounting dimensions (taps, universal mounting

bracket, and repeater)

Adjusting the cable strip tool B

Protecting your system against electrostatic discharge C

ATTENTION

You must have fundamental knowledge about

A

electronics and electrical codes to interpret and

apply the concepts in this manual.

1 Publication CNET-IN003A-EN-P - January 2006

Page 8

Preface 2

Abbreviations and Symbols

Common Techniques

The following table explains abbreviations and symbols we use in this

manual.

This Means

PVC cable polyvinyl chloride cable

FEP cable fluorinated ethylene propylene cable

PLC processor Allen-Bradley programmable logic controller

network continues (other nodes not shown)

We use the following conventions throughout this manual:

• bulleted lists indicate information, not procedural steps

• numbered lists indicate sequential step

TIP

This symbol identifies helpful tips.

For More Information

For more information, refer to the following:

• Electronic Data Sheets:

http://www.ab.com/networks/eds/index.html

• RSNetWorx and RSLinx Software Demos and Tutorials

Publication CNET-IN003A-EN-P - January 2006

Page 9

Chapter

1

Overview of the ControlNet Ex Media System

What This Chapter Contains

Use this chapter to familiarize yourself with the ControlNet Ex media

system. The following table describes what this chapter contains and

where to find specific information.

For Information On See Page

Understand the ControlNet Ex Media System 1-2

Understand ControlNet Ex Components 1-4

ControlNet Ex System Installation Requirements 1-9

This system is an intrinsically-safe system specifically designed for use

in hazardous areas.

TIP

TIP

For information on installation requirements for

hazardous areas, refer to NFPA 70 (National Electrical

Code NEC), Article 500.

This publication describes how to plan and install a

ControlNet Ex media system in a hazardous area.

Refer to the following publications for information

on how to plan and install a coax and fiber media

system in a non-hazardous environment:

• CNET-IN002, ControlNet Coax Media Planning

and Installation Manual

• CNET-IN001, ControlNet Fiber Media Planning

and Installation Manual

ATTENTION

1 Publication CNET-IN003A-EN-P - January 2006

The ControlNet Ex media system cannot be used in a

safe environment after it has been exposed to signals

from a hazardous area.

Page 10

1-2 Overview of the ControlNet Ex Media System

Understand the ControlNet Ex Media System

Safe Area

Coax Segment

TT

Network

N

Trunk Cable

N

Coax (1786) Fiber Hubs

The ControlNet Ex media system gives you the flexibility to design a

communication network for your particular application. To take full

advantage of this flexibility, spend sufficient time when you plan how

to install your network before you assemble any of the hardware.

For information on installing ControlNet media in a hazardous area,

refer to the ControlNet Coax Media Planning and Installation Manual,

publication CNET-IN002.

Use the following figures and term definitions to understand the

ControlNet Ex media system

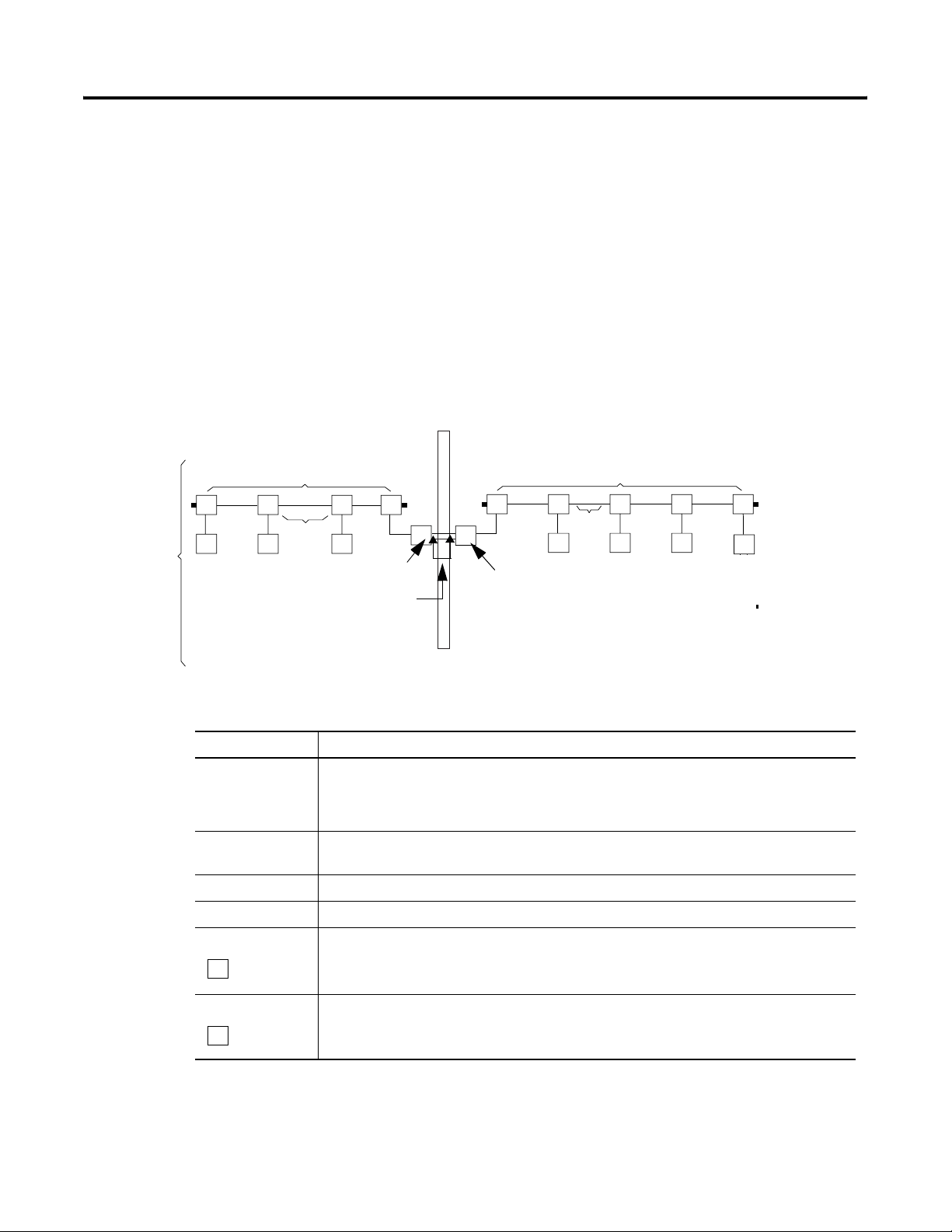

Figure 1.1 ControlNet Coax to Fiber system for FLEX Ex

Hazardous Area

Coax Segment

T

N

Fiber Segment

T

H

T

H

Ex (1797) Fiber Hubs

T

Trunk Cable

NN

T

N

T

T

N

Term Means

Network • A collection of connected nodes

• A collection of nodes with unique addresses in the range of 1-99

• The connection paths between any pair of devices may include repeaters and bridges.

Segment • Trunk cable sections connected via taps with terminators at each end and with no

repeaters.

Trunk Cable • The bus or central part of a media system

Trunk Cable Section • A length of a cable between any two taps

Fiber Repeater Hub • Consists of a fiber repeater and fiber adapter

H

• The components reconstruct and retransmit all traffic on one fiber or coax segment

side to another coax or fiber segment side.

Tap • The connection between any device and the ControlNet Ex or ControlNet media

system

T

41326

Publication CNET-IN003A-EN-P - January 2006

Page 11

Overview of the ControlNet Ex Media System 1-3

Te rm M ean s

Node • Any physical device connecting to the ControlNet Ex or ControlNet media system that

requires a network address to function on the network

N

• A network may contain a maximum of 99 nodes

• This address must be in the range of 1...99 and be unique to that network.

Trunk Terminator • A 75 Ω resistor mounted in a BNC plug

Tap Terminator • Terminates a tap drop-cable that has yet to be connected to a node with a “dummy”

node

D

Barrier • Barrier for coax cable provides isolation between safe and hazardous areas

B

Repeater • A device that connects two or more segments together

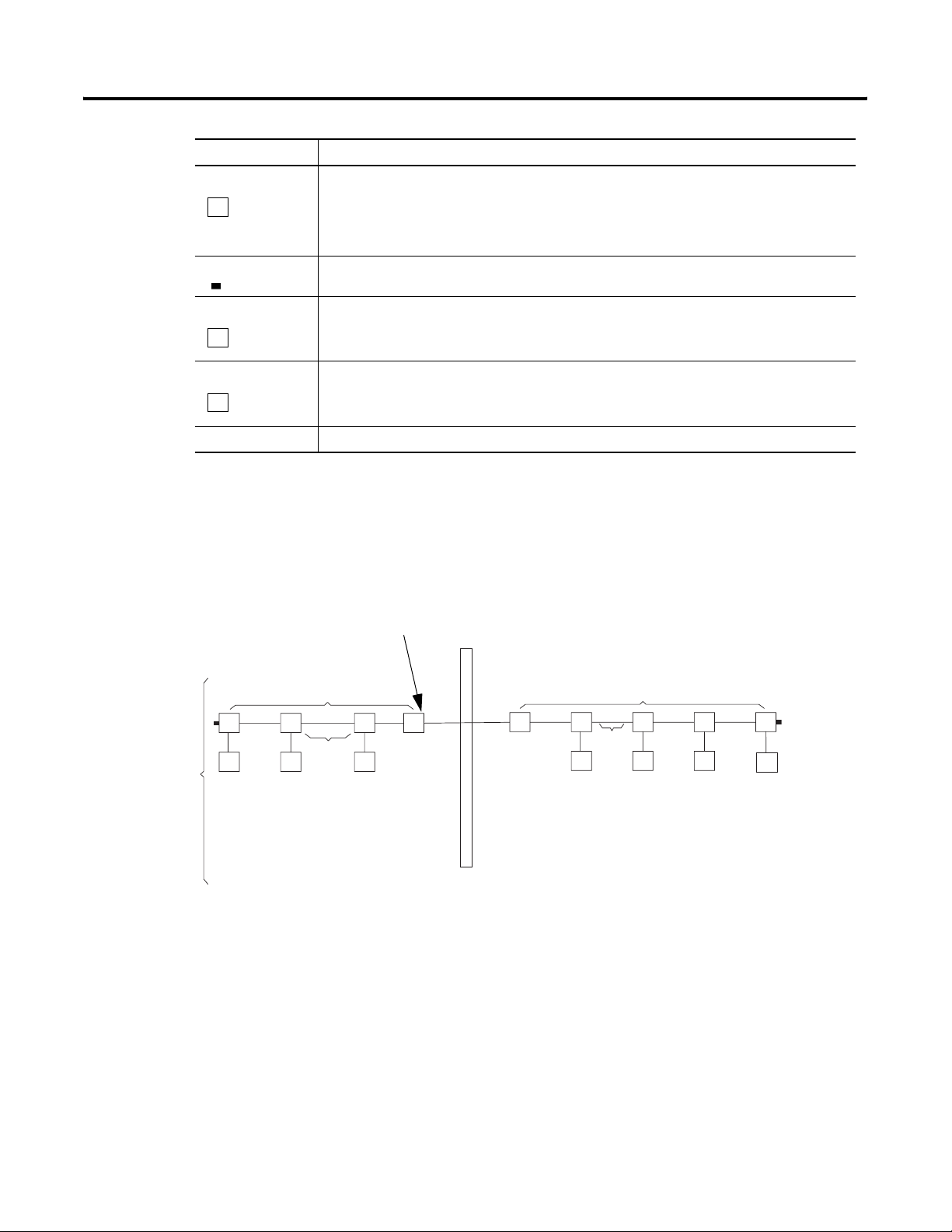

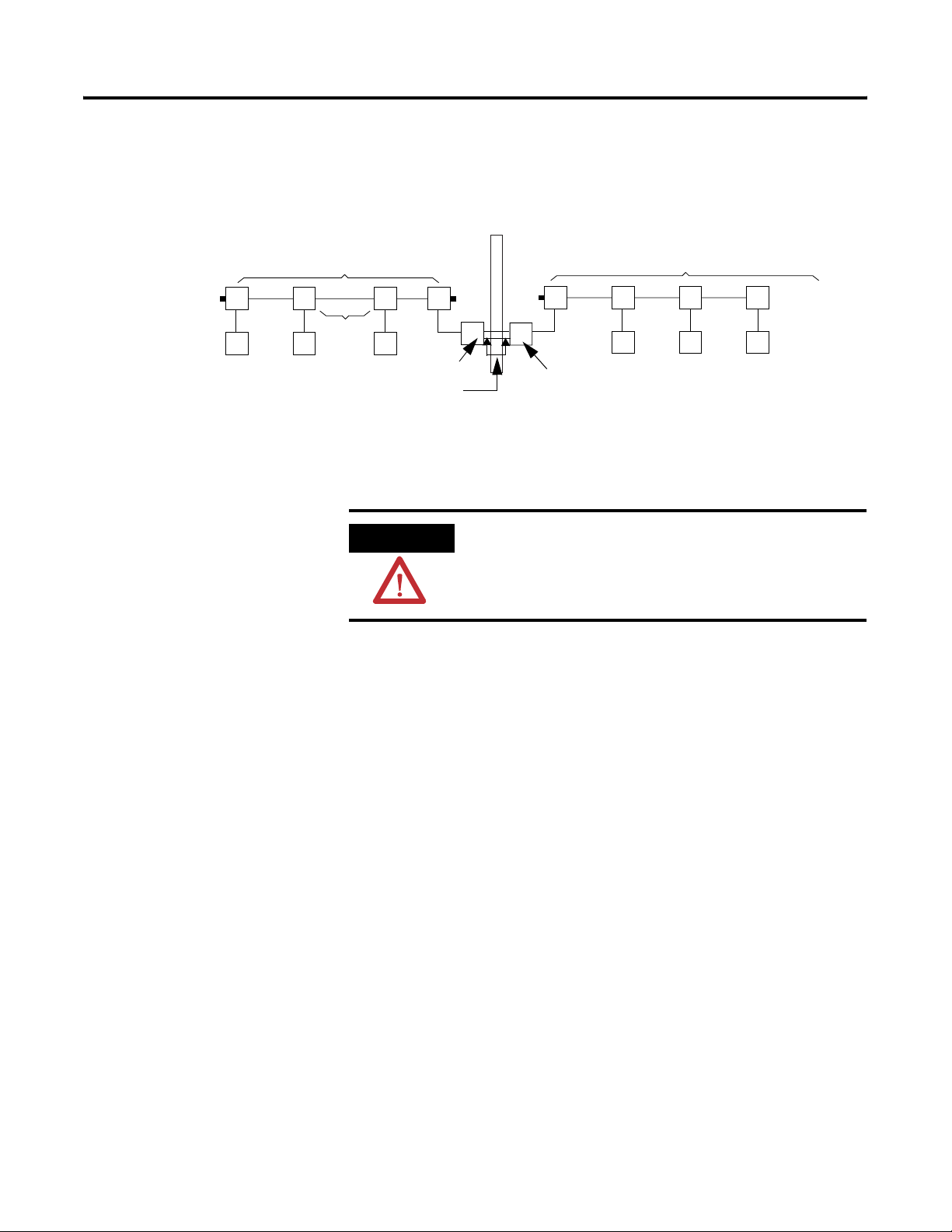

You can also use the 1797-BCNR FLEX Ex Redundant ControlNet

Barrier Module to interconnect between ControlNet coax and

ControlNet Ex networks. This module provides an alternative to

installing ControlNet Ex fiber repeater hubs.

Network

Figure 1.2 ControlNet Coax barrier system for FLEX Ex

1797-BCNR

Safe Area

Coax Segment

TT T

Trunk Cable

NN

N

B

Refer to Install the 1797-BCNR Module on page 3-28 for more

information.

Hazardous Area

Coax Segment

T

T

Trunk Cable

N

T

N

T

N

T

N

41326

Publication CNET-IN003A-EN-P - January 2006

Page 12

1-4 Overview of the ControlNet Ex Media System

Understand ControlNet Ex Components

The ControlNet Ex media system is comprised of these components:

• Nodes

• Taps

• Trunk cable

• Cable connectors

• Terminators

1

1

1

1

• Segments

• Fiber repeater hubs (option)

1

• Tap terminator

• Network

• Insulators

• Coax barrier

1

For information about purchasi ng t hese components see the Allen-Bradley C ontrolNet Media

Component List, publication AG-PA002.

(option)

1

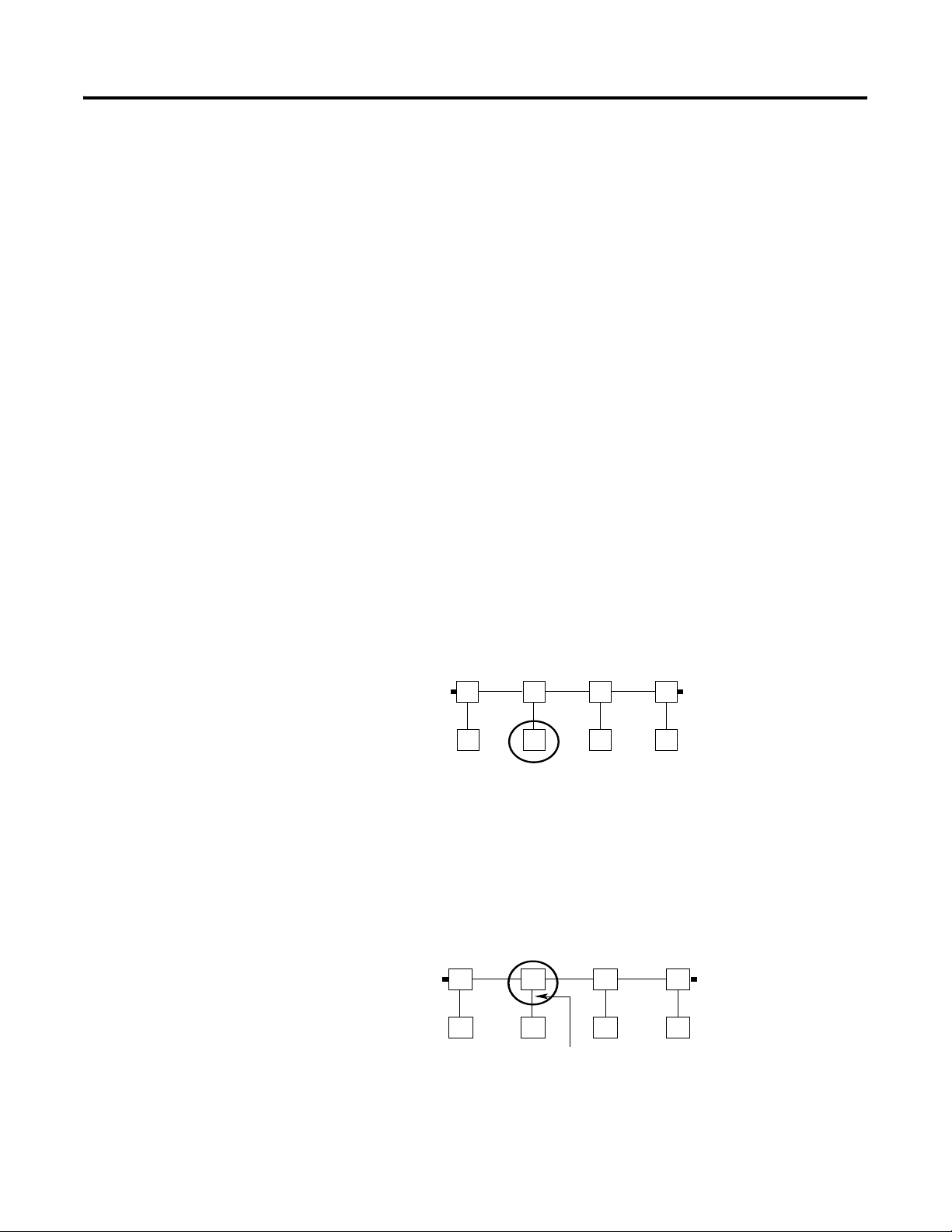

Nodes

Nodes are defined as physical devices connected to the ControlNet Ex

media system that require a network address to function on the

network.

TT

N

N

T

N

T

N

40953

Tap s

Taps connect each node on a network to the coax media system via

an integral 1 m (39.6 in.) drop cable.

T

N

T

N

Drop Cable

1 m (39.6 in.)

TT

NN

40944

Publication CNET-IN003A-EN-P - January 2006

Page 13

Overview of the ControlNet Ex Media System 1-5

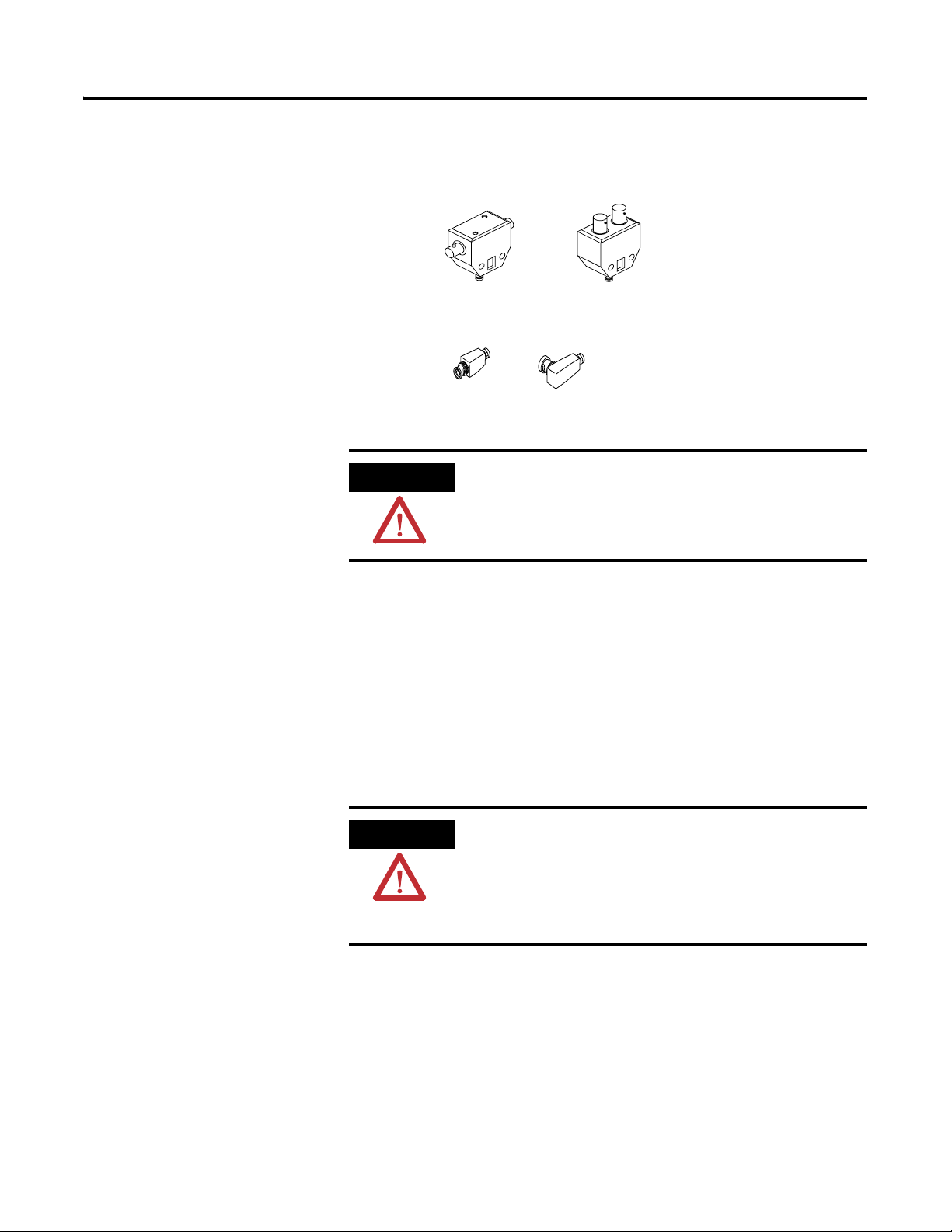

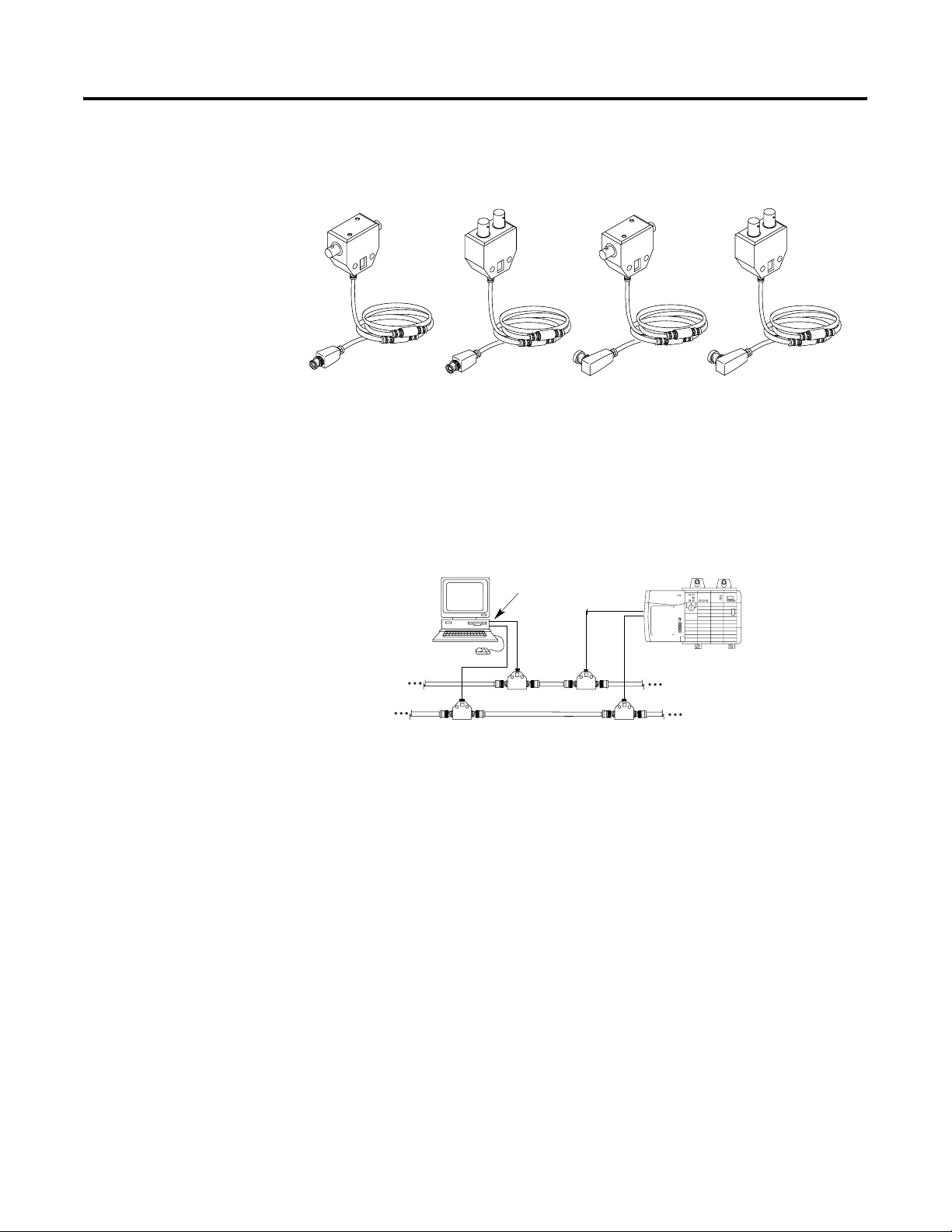

There are four styles of taps available with:

• T or Y placement of BNC connectors

T-tap

Y-tap

40955

• Straight or right-angle connector on the drop media

40956

ATTENTION

Straight

Right-angle

Use only intrinsically-safe taps in a ControlNet Ex

media system. Intrinsically-safe taps are marked

“ControlNet Ex Tap.”

See page 2-2 for detailed information on taps.

Trunk Cable

The trunk cable is the bus, or central part of the ControlNet Ex

coax media system. The trunk cable may be composed of multiple

sections of cable. Quad-shield RG-6 type coax cable can be used to

construct trunk cable sections.

ATTENTION

You must use either of these types of ControlNet Ex

trunk cable:

• 1797-RG6, Belden 3092A

• Belden 3092A blue quad-shield RG-6 type coax

cable

Publication CNET-IN003A-EN-P - January 2006

Page 14

1-6 Overview of the ControlNet Ex Media System

Cable Connectors

Use a cable connector (cat. no. 1786-BNC) to attach coax trunk cable

sections to the tap’s BNC connector.

T

N

T

Trunk Cable

NN

T

T

N

40957

Optional Connectors

Rockwell Automation also offers optional cable connectors for use in

your network configuration. See page 2-8 for available connectors.

Trunk Terminator

A 75 Ω terminator (cat. no. 1797-XT) must be installed on the tap at

each end of a segment.

T

N

T

Trunk Cable

NN

T

T

N

40958

Publication CNET-IN003A-EN-P - January 2006

ATTENTION

Use only intrinsically-safe trunk terminators in a

ControlNet Ex media system. Intrinsically-safe trunk

terminators are marked “CNet Ex Trk Trm.”

Page 15

Overview of the ControlNet Ex Media System 1-7

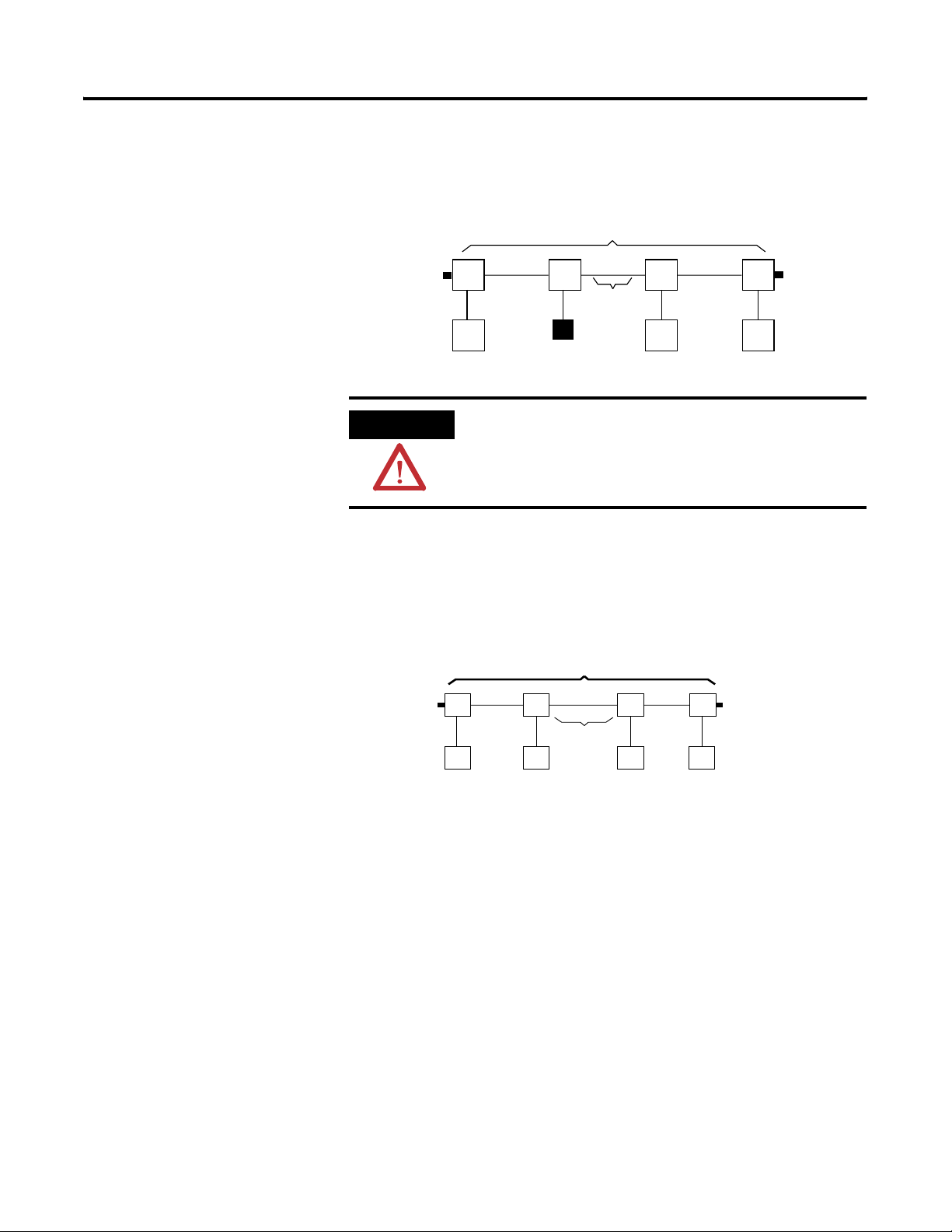

Tap Terminator

A tap terminator (cat. no. 1797-TCAP) is available to terminate unused

taps.

Segment

1797-TCAP

T

Trunk Cable

TT

T

ATTENTION

N

Use only intrinsically-safe tap terminators in a

N

N

40959

ControlNet Ex media system. Intrinsically-safe tap

terminators are marked “CNet Tap Trm.”

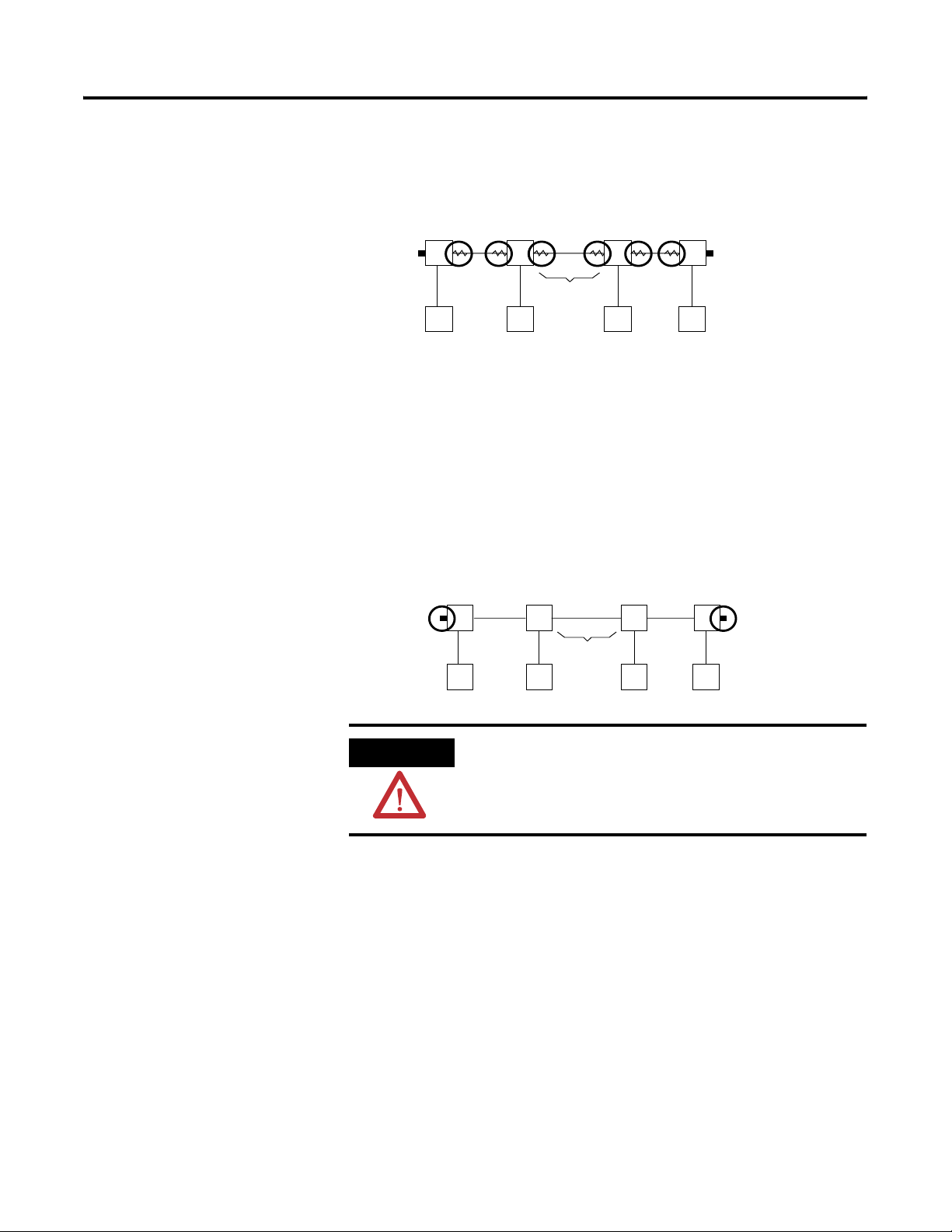

Segments

A segment is a collection of coax trunk cable sections, taps, and two

terminators.

Segment

T

NN

T

Trunk Cable

TT

N

N

40959

The total allowable length of a segment depends upon the number of

taps in your segment and the coax cable type used.

See page 2-1 for detailed information.

Fiber Repeater Hubs

You can use fiber as the connector from your safe area to your

hazardous area. Use fiber repeaters to connect the coax cable to the

fiber. Fiber repeater hubs increase the number of taps, extend the total

length of your segment, or create a star configuration (go off in

multiple directions from one point). The number of fiber repeater

Publication CNET-IN003A-EN-P - January 2006

Page 16

1-8 Overview of the ControlNet Ex Media System

hubs and cable length total are limited depending on your network

topology. You can have a maximum of 5 repeaters in series.

Safe Area

Coax Segment

T

NN

TTT T

Trunk Cable

Coax (1786) Fiber Hubs

Hazardous Area

Coax Segment

T

NN

Fiber Segment

HH

Ex (1797) Fiber Hubs

TT

NN

41327

When you insert a fiber repeater hub into your cable system, you

create a new segment. The same restrictions on the number of taps

and cable length apply to this new segment.

ATTENTION

Use only the intrinsically-safe 1797 version of the

fiber repeater hub in the hazardous area.

Network

A ControlNet network is the collection of connected segments, fiber

repeater hubs, and nodes.

Insulators

The ControlNet Ex media system must maintain isolation from ground.

Many of the connectors have metal parts. These parts must be

insulated from ground contact by 500V insulation material. Insulators

are provided with ControlNet Ex media system components that

require insulation. For example, the ControlNet Ex taps are supplied

with an insulator kit.

A large variety of BNC connectors are available for use with the

ControlNet Ex media system. As a result, insulators for all types of

connectors are not available. In these cases, wrapping the exposed

metal with 500V insulation electrical tape is acceptable.

Publication CNET-IN003A-EN-P - January 2006

Page 17

Overview of the ControlNet Ex Media System 1-9

Two insulator kits are available:

• Catalog number 1797-BOOT provides standard BNC trunk cable

insulators.

• Catalog number 1797-INS provides a variety of the preformed

boots and insulators used with the ControlNet Ex system

products.

ControlNet Ex System Installation Requirements

You can connect a maximum of 48 ControlNet Ex taps with a total of

250m of coax cable when using fiber hub architecture. The maximum

distance increases to 1000m when you use only 2 taps.

Refer to Determine Trunk Cable Section Lengths on page 2-4 and see

the table below for more information.

Catalog

Number

1797-RPA ControlNet Ex

1797-RPFM ControlNet Ex

1797-ACNR15 Redundant

1797-BCNR FLEX Ex

1797-TCAP ControlNet Ex

1797-TPx ControlNet Ex

1797-XT ControlNet Ex

Catalog Name Description

Represents one ControlNet Ex

Modular

Repeater Adapter

Fiber Repeater

Module, Medium

Distance

Media

ControlNet Ex

Adapter

Redundant

ControlNet

Barrier Module

Tap (Dummy)

Terminator

Coax Tap

Trunk Terminator

node and must be connected to a

coax trunk cable by

1797-TPx

Allows connection of a maximum

of two devices per 1797-RPA and

is powered directly by 1797-RPA

Represents one ControlNet Ex

node and must be connected to a

coax trunk cable by

1797-TPx -each one with two

redundant output channels that

are connected to different

ControlNet Ex networks (coax

cables and 1797-TPx)

Galvanic isolation barrier for

signal between the non-intrinsic

ControlNet system an

intrinsically-safe ControlNet Ex

system.

Represents one ControlNet Ex

node and is a simple capacitor

(56pF) with a coax connector

Four types of connections

available: S (straight T-tap), R

(right angle T-tap), YS (straight

Y-tap), and YR (right angle Y-tap) -

a maximum of 48 taps can be

connected by coax trunk cable

Simple resistor (75 Ω) with coax

connector that must be on each

end of the ControlNet Ex coax

trunk for termination

Publication CNET-IN003A-EN-P - January 2006

Page 18

1-10 Overview of the ControlNet Ex Media System

Catalog

Number

1786-RG6 Quad-Shield,

1786-BNCP,

-BNCJ, BNCJI

1797-BOOT FLEX Ex Boot

Catalog Name Description

Maximum (functional) length

RG-6 75Ω Coax

Trunk Cable

Standard Coax

Trunk Cable BNC

Couplers

Insulator Kit

between two 1797-TPx is 3280ft

(1000m) - each 1797-TPx reduces

the (functional) coax cable length

by 16.3 m (53.4 ft)

Standard cable couplers

Replacement insulators

You can install fiber connecting the 1797-RPFM module with any

approved associated device throughout the safe location.

All cables and fiber media that are not light blue must be marked as IS

using the 1797-EXMK marking kit or other locally approved IS

identification or segregation method.

ATTENTION

You must isolate all metallic parts during the

installation of the ControlNet Ex system to prevent

an earth connection. Use dielectric-strength isolating

material. The isolating material must withstand

voltages > 500V ac.

Certified Equivalent ControlNet Ex System Components

You may use these items as equivalents for system components.

Component Catalog Number Source

Coax Trunk Cable 1797-RG6 Rockwell Automation

1

3092IS

3092A with blue jacket Belden Wire & Cable Co.

1 Belden Wire & Cable 1189A may be used, but with functional loss of communication distance

or nodes.

Belden Wire & Cable Co.

Publication CNET-IN003A-EN-P - January 2006

Page 19

Overview of the ControlNet Ex Media System 1-11

UL, cUL I/O Entity Parameters and Requirements

TIP

For more information on UL and cUL installation

requirements, refer to publication 1797-RM001, FLEX

Ex System Certification Reference Manual.

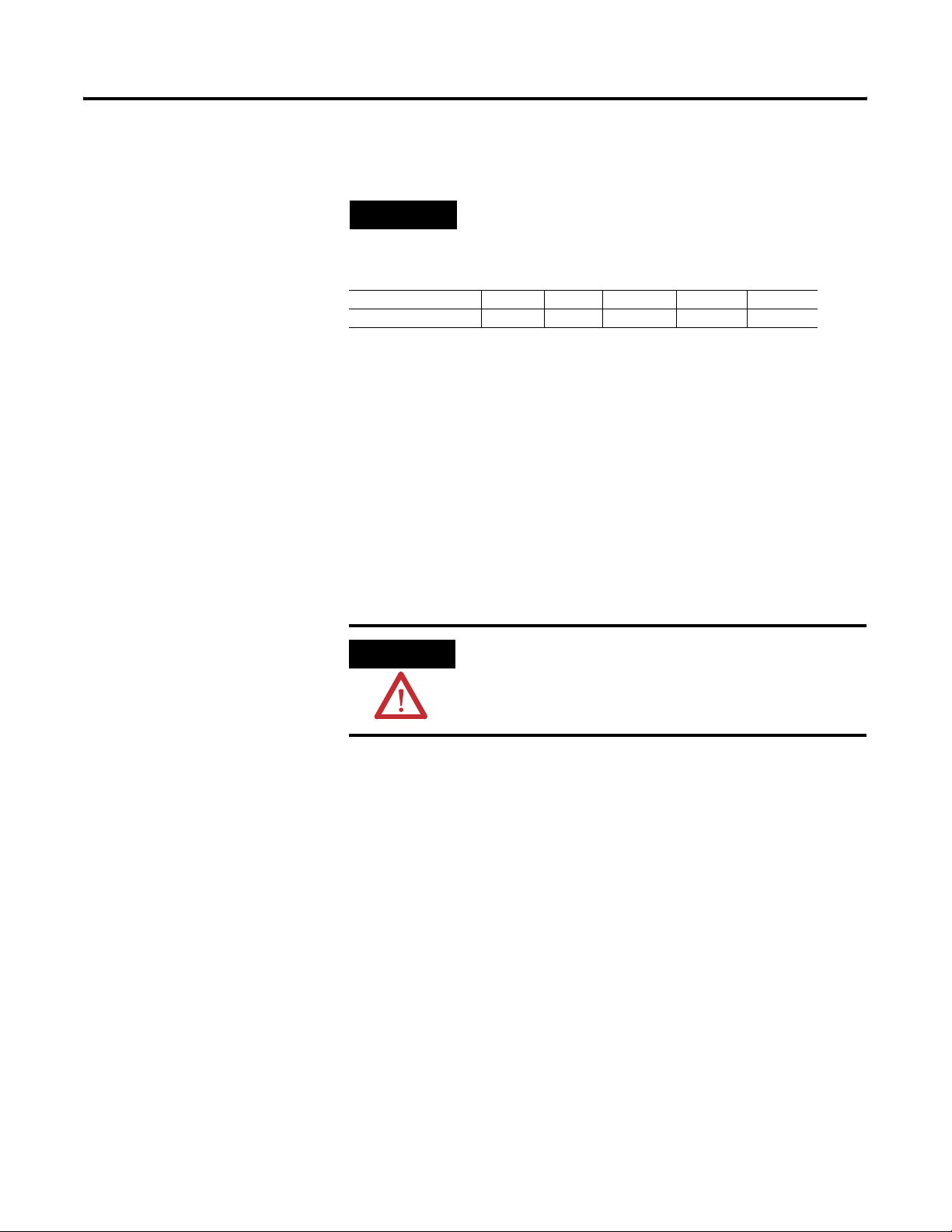

Te rm in al s Vt (V) It (mA) Groups C

Male Bus Connector 5.8 400 A-G 3.0 3.0

(µF) La (µH)

a

The entity concept allows interconnection of intrinsically-safe

apparatus with associated apparatus not specifically examined in

combination as a system when the approved values of V

of the associated apparatus are less than or equal to V

and I

t

of the intrinsically-safe apparatus and the approved values of Ca

I

max

of the associated apparatus are greater than Ci + C

and L

a

respectively for the intrinsically-safe apparatus.

L

cable

and I

oc

cable

or V

sc

and

max

and L

+

i

Wiring methods must be in accordance with the National Electric

Code, ANSI/NFPA 70, Article 504 and 505 or the Canadian Electric

Code CSA C22.1, Part 1, Appendix F. For additional information refer

to ANSI/ISA RP12.6.

WARNING

Substitution of components may impair the intrinsic

safety of this system.

AVERTISSEMENT: La substitution de composant peut

compromettre la securite intrinseque.

t

Publication CNET-IN003A-EN-P - January 2006

Page 20

1-12 Overview of the ControlNet Ex Media System

If fiber optic cable is provided with a metal shield, it must be

connected to a dedicated intrinsic safety ground in the

intrinsically-safe location and isolated in the non-intrinsically-safe

location or be connected to a ground in the hazardous location and

isolated in the intrinsically-safe location.

The glass fiber must have a minimum diameter of 6µm.

European Community Directive Compliance

The ControlNet Ex System has the CE mark. It is approved for

installation within the European Community or EEA regions. It has

been designed and tested to meet the following directives.

EMC Directive

The ControlNet Ex System is tested to meet the Council Directive

89/336/EC Electromagnetic Compatibility (EMC) by applying the

following standards, in whole or in part, documented in a technical

construction file:

• EN50081-2 — EMC - Generic Emission Standard, Part 2 -

Industrial Environment

• EN50082-2 — EMC - Generic Immunity Standard, Part 2 -

Industrial Environment

The ControlNet Ex System is intended for use in an industrial

environment.

Publication CNET-IN003A-EN-P - January 2006

Page 21

Overview of the ControlNet Ex Media System 1-13

Ex Directive

The ControlNet Ex System is tested to meet the Council Directive 94/9

EC (ATEX 100a) Equipment and Protective Systems Intended for Use

in Potentially Explosive Atmospheres by applying the following

standards:

• EN50014:1992, Electrical Apparatus for Potentially Explosive

Atmospheres

• EN50020:1994, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsic Safety “i”

• EN50039:1980, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsically-safe Electrical Systems “i”

• pr EN50284:1997, Special requirements for construction, test,

and marking of electrical apparatus of equipment group II,

category 1 G

What Is Next?

Now that you have a general understanding of the ControlNet Ex

media system, you are ready to go to Chapter 2 to design a ControlNet

Ex media system for your specific requirements.

Publication CNET-IN003A-EN-P - January 2006

Page 22

1-14 Overview of the ControlNet Ex Media System

Notes:

Publication CNET-IN003A-EN-P - January 2006

Page 23

Plan a ControlNet Ex Media System

Chapter

2

What This Chapter Contains

Read this chapter to determine your network requirements.

For See Page

Determine How Many Taps You Need 2-2

Connect Programming Devices in Safe Areas 2-3

Coax Cable Type 2-3

Fiber Media Type 2-4

Determine Trunk Cable Section Lengths 2-4

Estimate Fiber Media Lengths 2-7

Determine How Many Trunk Terminators You Need 2-7

Determine What Type of Connectors You Need 2-8

Use Redundant Media in a Hazardous Area 2-10

Application Considerations 2-13

Ferrite Beads 2-15

Order Components 2-17

After reading this chapter, consult engineering drawings of your

facility for specific information concerning the best location for

installing your network.

TIP

1 Publication CNET-IN003A-EN-P - January 2006

The ControlNet Ex media system is a ground-isolated

network. To help prevent accidental grounding:

• Properly select cable, connectors, and

accessories. Local agencies require use of these

items for instrinsically safe system certification.

• Use the supplied ight-blue intrinsically-safe

insulators and dust caps to cover exposed metal

parts.

• Any accessories should have a dielectric rating of

greater than 500V.

• Use good installation techniques.

• Use blue tape to help prevent metal-to-ground

connections.

Page 24

2-2 Plan a ControlNet Ex Media System

Determine How Many Taps You Need

The number of taps you need depends on the number of devices you

want to connect to the network. You need a tap for each node,

repeater, or fiber hub on the network.

If you plan to add nodes later, you should consider ordering and

installing the cable and connectors for these additional nodes when

you install the initial network. This will minimize disruption to the

network during operation.

TIP

A disconnected drop cable can cause noise to enter

the network. Because of this, we recommend that

you have only one unconnected tap per network

for maintenance purposes. Use a tap terminator,

catalog number 1797-TCAP, on any unconnected

drop cable.

TIP

If you are planning future installation of additional

nodes, and can tolerate losing communication for a

short time, do not install the tap. Instead, install a

BNC bullet connector, catalog number 1786-BNCJ.

See page 2-8 for more information on the 1786-BNC

bullet connector.

Ex Insulator Kit

With Intrinsically-safe

Insulators

30394-M

Each tap kit contains the following pieces:

Tap (1797-TPS, -TPR, -TPYS, -TPYR)

Dust Cap

For noise suppression, ferrite beads

are molded on the drop cable.

TIP

BNC Connector Kits

ControlNet Ex

Cable Labels

Screws

Universal Mounting Bracket

41329

We provide the light-blue intrinsically-safe insulators

and dust caps to cover exposed metal parts. Use

these items for instrinsically safe system certification

by local agencies.

Publication CNET-IN003A-EN-P - January 2006

Page 25

Plan a ControlNet Ex Media System 2-3

These tap kits are available (dust caps not shown):

Connect Programming Devices in Safe Areas

Straight T-Tap Straight Y-Tap Right-Angle T-tap

1797-TPS

1797-TPYS

Connect programming devices in safe areas to the ControlNet cable

system through a 1784-KTCX15 communication card. Use a

ControlNet tap to connect the communication card to the network.

Figure 2.1 Use a 1784-KTCX15 Communication Card on Coax Media

Programming

Terminal

1784-KTCX15

Right-Angle Y-Tap

1797-TPR 1797-TPYR

Node

41330

Coax Cable Type

41331

You must use 1786-RG6, Belden 3092A, or Belden 3092A blue quadshield RG-6 coax cable as the ControlNet Ex trunk cable.

Publication CNET-IN003A-EN-P - January 2006

Page 26

2-4 Plan a ControlNet Ex Media System

Fiber Media Type

Determine Trunk Cable Section Lengths

Trunk Terminator

With

Intrinsically-safe

Insulator

Fiber media type specifications are listed below.

• Fiber type 62.5/125

µ

• Connector type ST (plastic or ceramic)

• Operating wavelength 1300 nm

• Optical power budge 13.3 dB

You should install all fiber for your ControlNet Ex cable system in

accordance with the regulations contained in applicable country

codes, state codes, and applicable municipal codes (for example,

National Electric Code). All metal connectors must be insulated

from the ground. Use blue ControlNet cable or the ControlNet Ex

Cable Marking Kit (1797-EXMK) to mark cable as intrinsically-safe.

When you use the 1797-EXMK, be certain to place one marker at

every meter of length.

A segment is comprised of several sections of trunk cable separated

by taps. The total cable length of a segment is equal to the sum of all

of the trunk cable sections, including taps.

Tap TapTap

IS Insulators

Trunk Cable Section

Trunk Cable Section

Trunk Terminator

With

Intrinsically-safe

Insulator

30094-m

TIP

When determining the length of trunk cable sections,

measure the actual cable path as it is routed in your

network. Consider vertical dimensions as well as

horizontal dimensions. You should always calculate

the three-dimensional routing path distance when

determining cable lengths.

Cover all exposed metal on connectors with either

the intrinsically-safe insulators or other forms of

insulation.

Select the shortest path for routing the cable to

minimize the amount of cable you need. The specific

details of planning such a cable route depends upon

the needs of your network.

The total allowable length of a segment containing standard RG-6

quad-shield cable depends upon the number of taps in your

segment. There is no minimum trunk cable section length

Publication CNET-IN003A-EN-P - January 2006

Page 27

Plan a ControlNet Ex Media System 2-5

requirement. The maximum allowable total length of a segment is

1,000 m (3,280 ft) with two taps connected. Each additional tap

decreases the maximum length of the segment by 16.3 m (53.4 ft). The

maximum number of taps allowed on a segment is 48 with a

maximum length of 250 m (820 ft).

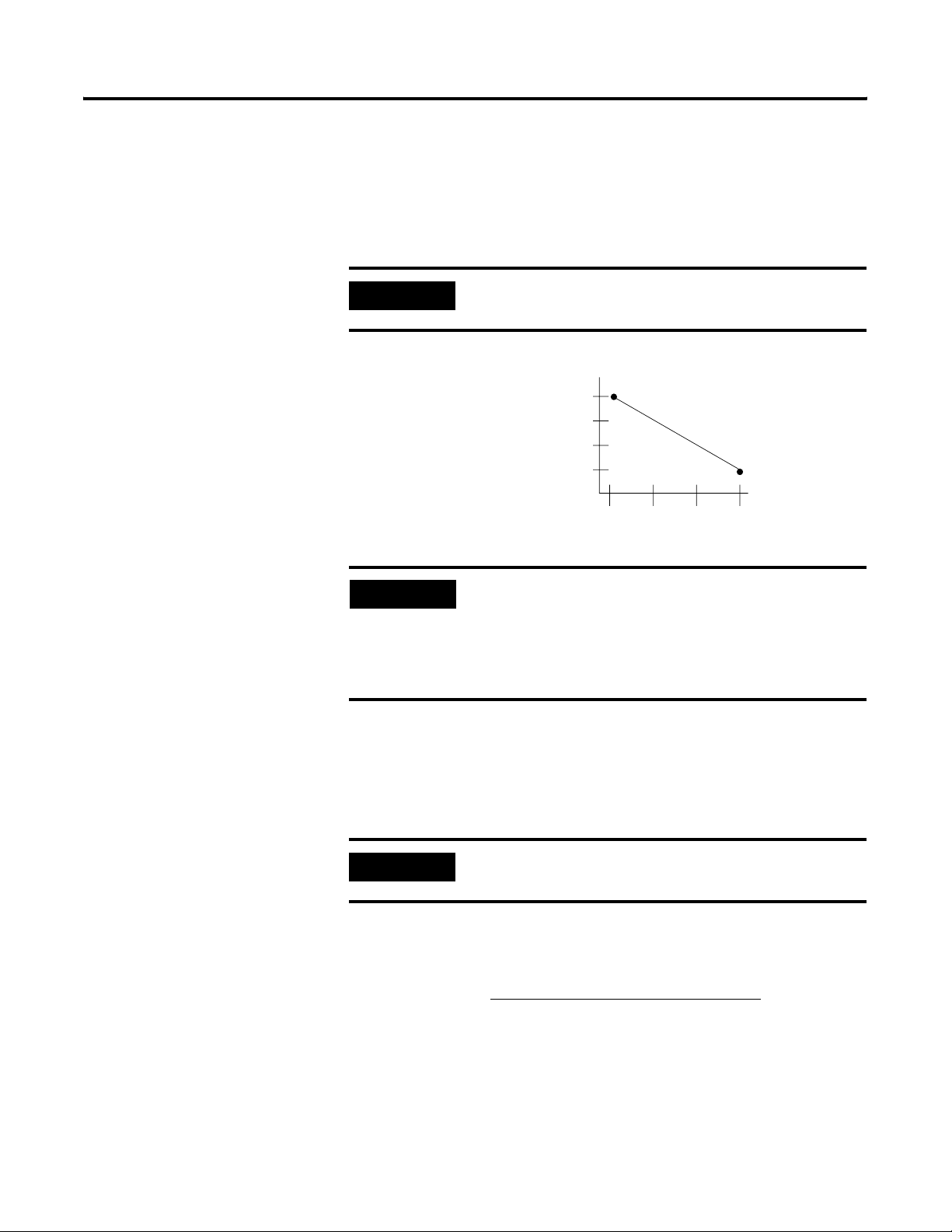

IMPORTANT

Figure 2.2 ControlNet Single Media Derating Curve

Maximum Allowable Segment Length

for FLEX Ex on ControlNet =

1000 m (3280 ft) - 16.3 m (53.4 ft) X

[Number of Taps - 2]

EXAMPLE

An allowable total length of RG-6 cable segment in your application

can be determined by using the equation below. Each additional tap

decreases the maximum length of the segment. The maximum

number of taps allowed on a segment is 48. Each additional tap

decreases the maximum length of the segment.

The derating curve is applicable only when the cable

meets ControlNet attenuation specifications.

)

t

1000 (3280)

(f

m

h

750 (2460)

t

g

n

e

500 (1640)

L

t

n

e

250 (820)

m

g

e

S

32 48

16

2

Number of Taps

30014-m

If your segment requires 10 taps, the maximum

segment length is:

1000m (3280 ft) - 16.3 m (53.4 ft) x [10 - 2]

1000m (3280 ft) - 130.4 m (427.7 ft)= 869.6 m

(2852.3 ft)

IMPORTANT

This equation applies when the cable does not meet

ControlNet attenuation specifications.

Maximum Allowable Segment Length of Cable =

(20.29 db - Number Of Taps in Segment *.32 db)

Cable Attenuation @ 10 MHz per 304 m (1000 ft)

Note: Cable attenuation is defined as the signal loss measured at 10 MHz per

304 m (1000 ft) of cable. Cable attenuation for ControlNet Ex cables is listed

in the ControlNet Ex Media Component List, publication AG-PA002.

X 304 m (1000 ft)

Publication CNET-IN003A-EN-P - January 2006

Page 28

2-6 Plan a ControlNet Ex Media System

EXAMPLE

IMPORTANT

For redundant media, decrease the number of taps by half, as shown

in the derating curve.

Figure 2.3 ControlNet Redundant Media Derating Curve

Maximum Allowable Segment Length

for FLEX Ex on ControlNet =

1000 m (3280 ft) - 16.3 m (53.4 ft) X

[Number of Taps - 2]

If your segment requires 3 taps using 1786-RG6

cable, the maximum segment length is:

([20.29 db - 3*.32 db] / 5.99 db] * 304)

(19.33 db / 5.99 db) * 304 = 982 m (3227 ft)

The total trunk cable length or number of taps can

be increased by installing a repeater hub on the

segment. This creates another segment.

)

t

1000 (3280)

(f

m

h

750 (2460)

t

g

n

e

500 (1640)

L

t

n

e

250 (820)

m

g

e

S

816 24

2

Number of Taps

30014-m

Publication CNET-IN003A-EN-P - January 2006

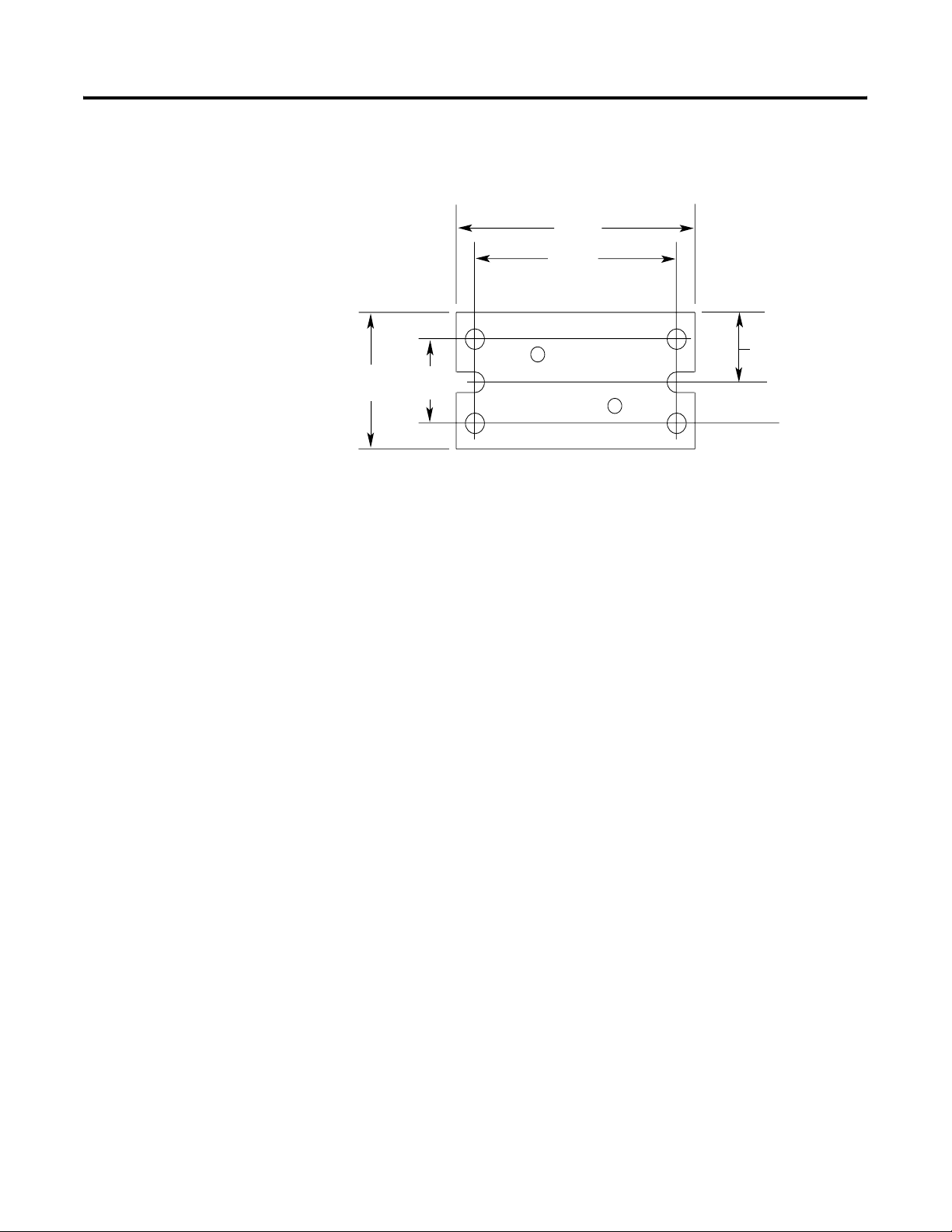

Determine Trunk Cable Section Length When You Use a FLEX Ex Redundant ControlNet Barrier Module

When you use a FLEX Ex Redundant ControlNet Barrier Module

(catalog no. 1797-BCNR), the total allowable length of a segment

containing standard RG-6 quad-shield cable depends upon the

number of taps in your segment. There is no minimum trunk cable

section length requirement. The maximum allowable length of a

segment that contains a 1797-BCNR module is 500 m. (1640 ft) with

two taps connected. Each additional tap decreases the maximum

length of the segment according to the derating curve. The maximum

number of taps allowed on a segment is 20 with a maximum length of

250 m (820 ft).

Page 29

500 m

(1640 ft)

250 m

(820 ft)

Plan a ControlNet Ex Media System 2-7

Segment Length m (ft)

Estimate Fiber Media Lengths

2

Number of Taps With One FLEX Ex Redundant ControlNet Barrier Module

20

The maximum length of a fiber media section for the 1797-RPFM

module is dependent on the quality of the fiber, number of splices,

and the number of connectors. The total attenuation for a cable

section must be less than 13.3 dB.

Typically, cable attenuation for a wavelength of 1300 nm is less than

1.5 dB/km.

IMPORTANT

Avoid joining cable with connectors as much as

possible. Connectors can cause considerable

attenuation and limit the maximum length of your

system. Be sure to check the attenuation of each

cable sections after the cable is installed.

Determine How Many Trunk Terminators You Need

You must use 75 Ω trunk terminators equipped with intrinsically-safe

insulators (cat. no. 1797-XT) at the end of each segment in the

ControlNet Ex cable system.

1797-XT

Intrinsically-safe Insulator

Publication CNET-IN003A-EN-P - January 2006

Page 30

2-8 Plan a ControlNet Ex Media System

After you have determined the number of segments in your network,

multiply this number by two to determine how many terminators you

need for your network.

IMPORTANT

To comply with intrinsic safety standards, be sure to

cover the exposed metal with the intrinsically-safe

insulator provided with each terminator.

Determine What Type of

Use the foll owing table to determine what type of connectors you need.

Connectors You Need

Use This BNC Connector To Cat. No.

cable connector Attach trunk cable sections to a tap’s BNC connector 1786-BNC

Use This Optional BNC Connector To Cat. No.

Bullet (Jack-to-jack) Reserve a space in the trunk cable for future installation of a

tap or to splice a trunk cable

Barrel (Plug-to-plug) Connect two adjacent taps without a trunk cable section

between them

1786-BNCJ

1786-BNCP

Isolated-bulkhead

(Jack-to-jack)

Tap Terminator Cap off installed taps that have yet to be connected to a node 1797-TCAP

Right Angle

(Jack-to-plug)

Go through grounded panel walls while maintaining the shield

isolation of the trunk cable

Provide a 90° bend in your cable (prevent bending your cable

excessively)

See Chapter 3 for the bend radius specification

1786-BNCJI

Refer to the ControlNet

Media System

Component List,

publication AG-PA002 for

the part number

Publication CNET-IN003A-EN-P - January 2006

Page 31

In This Example, ControlNet Ex

Cable:

• Enters and exits the panel

enclosure from the side

using isolated-bulkhead

connectors

• Contains two adjacent

taps connected by a barrel

connector

• Reserves one future tap

location with a bullet

Panel Wall

Bullet Connector

Right Angle

Connectors

Plan a ControlNet Ex Media System 2-9

Cable Enters and Exits

From the Side

Isolated-bulkhead

Connectors

Barrel

Connector

Taps

20091m

ATTENTION

TIP

Do not let any metallic surfaces on the BNC

connectors, plugs, or optional accessories touch

grounded metallic surfaces. This contact could cause

noise on the network. All exposed metal must be

covered with either intrinsically-safe blue insulators

or another form of insulation, such as tape with a

500V rating.

If you install a bullet connector for future tap

installations, count the bullet as one of the tap

allotments on your segment (and decrease the

maximum allowable cable length by 16.3 m [53.5 ft]).

This helps you avoid reconfiguring your network

when you install the tap.

Publication CNET-IN003A-EN-P - January 2006

Page 32

2-10 Plan a ControlNet Ex Media System

Use Redundant Media in a Hazardous Area

Safe Area

1786 Fiber

Repeater Hub

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

1797 - RPA

Net Ex

Control

Comm

Module

REPEATER ADAPTER

Status

Status

.

PWR

.

.

Coax Trunk Cable A =

Chan 1

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

You can run a second trunk cable between your ControlNet Ex nodes

for redundant media. With redundant media, nodes send signals on

two separate segments. The receiving node compares the quality of

the two signals and accepts the better signal to permit use of the best

signal. This also provides a backup cable should one cable fail.

Trunk cables on a redundant cable network are defined by the

segment number and the redundant trunk cable letter.

Actual ControlNet Ex products are labeled with these icons

(the shaded icon represent redundant media).

In this figure, the redundant cable trunk cable is trunk cable B.

Hazardous Area

1797 Fiber

Repeater Hub

.

1797 - RPFM

Net Ex

Control

FIBER MODULE

MEDIUM RANGE

.

Chan 2

.

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

Comm

Module

Status

Status

.

.

1797 - RPFM

1797 - RPA

Net Ex

Control

Net Ex

Control

FIBER MODULE

REPEATER ADAPTER

MEDIUM RANGE

.

PWR

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

Trunk Cable A =

Coax Trunk Cable B =

1786 Fiber

Repeater Hub

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

1797 - RPA

Net Ex

Control

Comm

Module

REPEATER ADAPTER

Status

Status

.

PWR

.

.

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

Trunk Cable B =

1797 Fiber

Repeater Hub

.

.

Chan 1

Chan 2

.

B-A

Allen-Bradley

QUALITY

1797 - RPFM

Net Ex

Control

FIBER MODULE

Comm

Module

MEDIUM RANGE

Status

Status

.

.

.

B-A

Allen-Bradley

QUALITY

1797 - RPFM

1797 - RPA

Net Ex

Control

Net Ex

Control

FIBER MODULE

REPEATER ADAPTER

MEDIUM RANGE

.

PWR

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

Node

Observe the following guidelines when planning a redundant media

system in a hazardous area.

• Route the two trunk cables (trunk cable A and trunk cable B)

differently to reduce the chance of both cables being damaged

at the same time.

• Each node on a redundant-cable network must support

redundant coax connections and be connected to both trunk

cables at all times. Any nodes connected to only one side of a

redundant-cable network will result in media errors on the

unconnected trunk cable.

41346

Publication CNET-IN003A-EN-P - January 2006

Page 33

Plan a ControlNet Ex Media System 2-11

• Install the cable system so that the trunk cables at any physical

device location can be easily identified and labeled with the

appropriate icon or letter. Each redundant ControlNet Ex device

is labeled so you can connect it to the corresponding trunk

cable.

• Both trunk cables (trunk cable A and trunk cable B) of a

redundant-cable network must have identical configurations.

Each segment must contain the same number of taps, nodes and

fiber repeaters. Connect nodes and fiber repeaters in the same

relative sequence on both trunk cables.

• Either side of a redundant-cable network may differ in cable

length. The total difference in length between the two trunk

cables must not exceed 800 m (2640 ft).

Trunk Cable A =

Trunk Cable B =

Trunk Cable B =

Trunk Cable A =

Segment 1

1

Node

1

Node

1

Node Supporting Redundant Media

Hazardous Area

Node

1

Node

Segment 2

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

Comm

Module

Status

Status

.

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

1797 - RPA

Control

Net Ex

Control

Comm

Module

REPEATER ADAPTER

Status

Status

.

PWR

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

1

1797 - RPA

Net Ex

Control

REPEATER ADAPTER

.

PWR

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

1797 - RPFM

Net Ex

FIBER MODULE

MEDIUM RANGE

.

1797 Fiber

Repeater

B-A

Allen-Bradley

QUALITY

Comm

Module

Status

Status

.

1797 - RPFM

1797 Fiber

Net Ex

Control

FIBER MODULE

MEDIUM RANGE

.

Repeater Hub

.

B-A

Allen-Bradley

QUALITY

1797 - RPA

Net Ex

Control

REPEATER ADAPTER

.

PWR

.

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

Comm

Module

Status

Status

.

.

Control

FIBER MODULE

MEDIUM RANGE

Chan 1

Chan 2

.

1797 - RPFM

1797 - RPA

Net Ex

Control

Net Ex

Control

FIBER MODULE

REPEATER ADAPTER

MEDIUM RANGE

.

PWR

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

1797 - RPFM

Net Ex

.

Node

1

41683

Publication CNET-IN003A-EN-P - January 2006

Page 34

2-12 Plan a ControlNet Ex Media System

Segment 1

1786 Node

• Avoid connecting a single node’s redundant trunk cable

connections on different segments; this will cause erratic

operation.

Hazardous AreaSafe Area

1786 Fiber

Repeater Hubs

B-A

Allen-Bradley

QUALITY

Comm

Module

Status

Status

.

B-A

Allen-Bradley

QUALITY

Comm

Module

Status

Status

.

.

Control

REPEATER ADAPTER

12

+V -V +V -V

.

.

Control

REPEATER ADAPTER

12

+V -V +V -V

.

.

B-A

Allen-Bradley

QUALITY

1797 - RPA

Net Ex

.

PWR

.

Chan 1

Chan 2

1

43

Recv Xmit Recv Xmit

.

.

B-A

Allen-Bradley

QUALITY

1797 - RPA

Net Ex

.

PWR

.

Chan 1

Chan 2

1

43

Recv Xmit Recv Xmit

.

1797 Fiber

Repeater Hubs

1797 - RPFM

Net Ex

Control

FIBER MODULE

MEDIUM RANGE

.

1797 - RPFM

Net Ex

Control

FIBER MODULE

MEDIUM RANGE

.

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

1797 - RPFM

1797 - RPA

Net Ex

Control

Net Ex

Control

FIBER MODULE

Comm

Module

REPEATER ADAPTER

MEDIUM RANGE

Status

Status

.

PWR

.

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

.

.

B-A

B-A

Allen-Bradley

Allen-Bradley

QUALITY

QUALITY

1797 - RPFM

1797 - RPA

Net Ex

Control

Net Ex

Control

FIBER MODULE

Comm

Module

REPEATER ADAPTER

MEDIUM RANGE

Status

Status

.

PWR

.

.

.

Chan 1

Chan 2

1

43

12

+V -V +V -V

Recv Xmit Recv Xmit

.

.

1797 Node

Segment 2

41348

A node supporting redundant trunk cable connections will function

even if trunk cable A is connected to the B connector on the node and

vice-versa. This makes cable fault indications (on the hardware or in

software) difficult to interpret and makes locating a bad cable segment

very difficult.

ATTENTION

Never connect parts of a ControlNet cable system to

those of a ControlNet Ex cable system. The 1786

fiber repeater hub and 1797 fiber repeater hub are

used to isolate the two sections of a ControlNet

network.

ATTENTION

ControlNet Ex products cannot be used in an

intrinsically-safe environment after they have been

exposed to non-intrinsically-safe signals.

Publication CNET-IN003A-EN-P - January 2006

Page 35

Plan a ControlNet Ex Media System 2-13

Application Considerations

The following guidelines coincide with the guidelines for the

installation of electrical equipment to minimize electrical noise inputs

to controllers from external sources contained in IEEE standard

518-1982. When planning your cable system keep these installation

considerations in mind.

ATTENTION

These guidelines apply only to noise coupling.

Intrinsic safety requirements for cable mounting are

of the highest priority.

Understand Conductor Categories

Conductors can be divided into three categories.

Category Includes

1 ac power lines

High-power digital ac I/O lines

High-power digital dc I/O lines

Power connections (conductors) from motion drives to motors

2 Analog I/O lines and dc power lines for analog circuits

Low-power digital ac/dc I/O lines

Low-power digital I/O lines

ControlNet Ex communication cables

3 Low-voltage dc power lines

Communication cables to connect between system components

within the same enclosure

Publication CNET-IN003A-EN-P - January 2006

Page 36

2-14 Plan a ControlNet Ex Media System

General Wiring Guidelines

Follow these guidelines with regard to noise coupling. Following

intrinsic safety requirements should prevent most or all of these

situations from occurring. These guidelines are provided as a general

reference for wiring.

• If wiring must cross power feed lines, it should do so at right

angles.

• Route wiring at least 1.5 m (5 ft) from high-voltage enclosures,

or sources of rf/microwave radiation.

• If the conductor is in a metal wireway or conduit, each section

of that wireway or conduit must be bonded to each adjacent

section so that it has electrical continuity along its entire length,

and must be bonded to the enclosure at the entry point.

For more information on general wiring guidelines, see the

Industrial Automation Wiring and Grounding Guidelines, publication

1770-4.1.

Wire External to Enclosures

Cables that run outside protective enclosures are relatively long.

To minimize cross-talk from nearby cables, you should maintain

maximum separation between the ControlNet Ex cable and other

potential noise conductors. Route your cable following these

guidelines:

Cable in a Contiguous

Metallic Wireway or

Conduit?

Yes 0.08 m (3 in.) Category-1 conductors of less than 20A

No 0.15 m (6 in.) Category-1 conductors of less than 20A

Route Your

Cable At Least

0.15 m (6 in.) ac power lines of 20A or more, up to 100 KVA

0.3 m (12 in.) ac power lines greater than 100 KVA

0.3 m (12 in.) ac power lines of 20A or more, up to 100 KVA

0.6 m (24 in.) ac power lines greater than 100 KVA

From Noise Sources of This Strength

Wire Inside Enclosures

Cable sections that run inside protective equipment enclosures are

relatively short. As with wiring external to enclosures, you should

maintain maximum separation between your ControlNet Ex cable and

Category-1 conductors.

Publication CNET-IN003A-EN-P - January 2006

Page 37

Plan a ControlNet Ex Media System 2-15

When you run cable inside an enclosure, route conductors external to

all raceways in the same enclosure, or in a raceway separate from

Category-1 conductors.

Route Your Cable At Least From Noise Sources of This Strength

0.08 m (3 in.) Category 1 conductors of less than 20 A

0.15 m (6 in.) ac power lines of 20A or more, up to 100 KVA

0.6 m (24 in.) ac power lines greater than 100 KVA

Surge Suppression

Transient electromagnetic interference (emi) can be generated

whenever inductive loads such as relays, solenoids, motor starters, or

motors are operated by hard contacts such as push-button or selector

switches. These wiring guidelines assume you guard your system

against the effects of transient emi by using surge-suppressors to

suppress transient emi at its source.

Inductive loads switched by solid-state output devices alone do not

require surge suppression. However, inductive loads of ac output

modules that are in series or parallel with hard contacts require

surge-suppression to protect the module output circuits as well as to

suppress transient emi.

Ferrite Beads

Ferrite beads provide additional suppression of transient emi.

Fair-Rite Products Corporation manufactures a ferrite bead

(part number 2643626502) that can be slipped over Category-2 and

Category-3 (RG-6 type trunk cable) conductors. You can secure them

with heat-shrink tubing or tie-wraps. A cable transient emi induced

onto the cable can be suppressed by a ferrite bead located near the

end of the cable. The ferrite bead will suppress the emi before it

enters the equipment connected to the end of the cable.

Required Ferrite Beads

Five ferrites come with each ControlNet Ex adapter. Four are identical

and are for use on the ControlNet Ex trunk cable (two for Segment 1

and two for Segment 2). The fifth ferrite is longer. You use this ferrite

on the adapter power cable.

Publication CNET-IN003A-EN-P - January 2006

Page 38

2-16 Plan a ControlNet Ex Media System

Add Ferrite Beads

Wrap the IS power input cable

two turns around the ferrite bead

before connecting the terminal

block to the adapter.

Five ferrite beads come with the

adapter. Four are short and

identical. Use these on the

ControlNet Ex trunk cable. The

fifth, longer ferrite bead is for the

adapter power cable.

42206

Add ferrite beads on the

ControlNet Ex trunk cable inside the

cabinet wherever the trunk cable

goes into or out of the cabinet.

Ferrite Beads

30890-M

Publication CNET-IN003A-EN-P - January 2006

Page 39

Plan a ControlNet Ex Media System 2-17

Order Components

Now that you are ready to begin ordering components, use these

guidelines to help you select components.

General Planning

The ControlNet Ex cable system is isolated from earth and must be

protected from inadvertent ground connections.

Plan a Segment

Refer to this list when you plan a segment.

• All connections to the trunk cable require a tap

• Taps may be installed at any location on the trunk cable

• Tap drop-cable length must not be changed

• Maximum number of taps = 48, with 250 m (820 ft) of standard

RG-6 trunk cable

• Maximum trunk cable length of RG-6 trunk cable = 1000 m

(3280 ft), with 2 taps

• 75 Ω trunk terminators are required on both ends

• One tap with an unconnected drop cable may be installed for

maintenance purposes

• Use BNC bullet connectors at future tap locations

• Do not mix redundant and non-redundant nodes

• Use ControlNet Ex tap terminators (1797-TCAP) for all other

unconnected drop cables

• Avoid high noise environments when routing cables

• A supplied ferrite toroid should be used on the ControlNet Ex

trunk as it enters and leaves control cabinets

Publication CNET-IN003A-EN-P - January 2006

Page 40

2-18 Plan a ControlNet Ex Media System

Plan Your Network

Refer to this list when you plan your network.

• Maximum of 99 nodes (excluding fiber repeater hubs)

• Fiber repeater hubs require a tap but are not counted as nodes

(they are included in the number of devices allowed per

segment [48])

• Fiber repeater hubs may be installed at any tap location along a

segment

• There can be only one path between any two points on a

network

• The configuration of both sides of a redundant segment must be

the same

• The total cable difference between the two sides of a redundant

network cannot exceed 800 m (2640 ft)

Order Parts

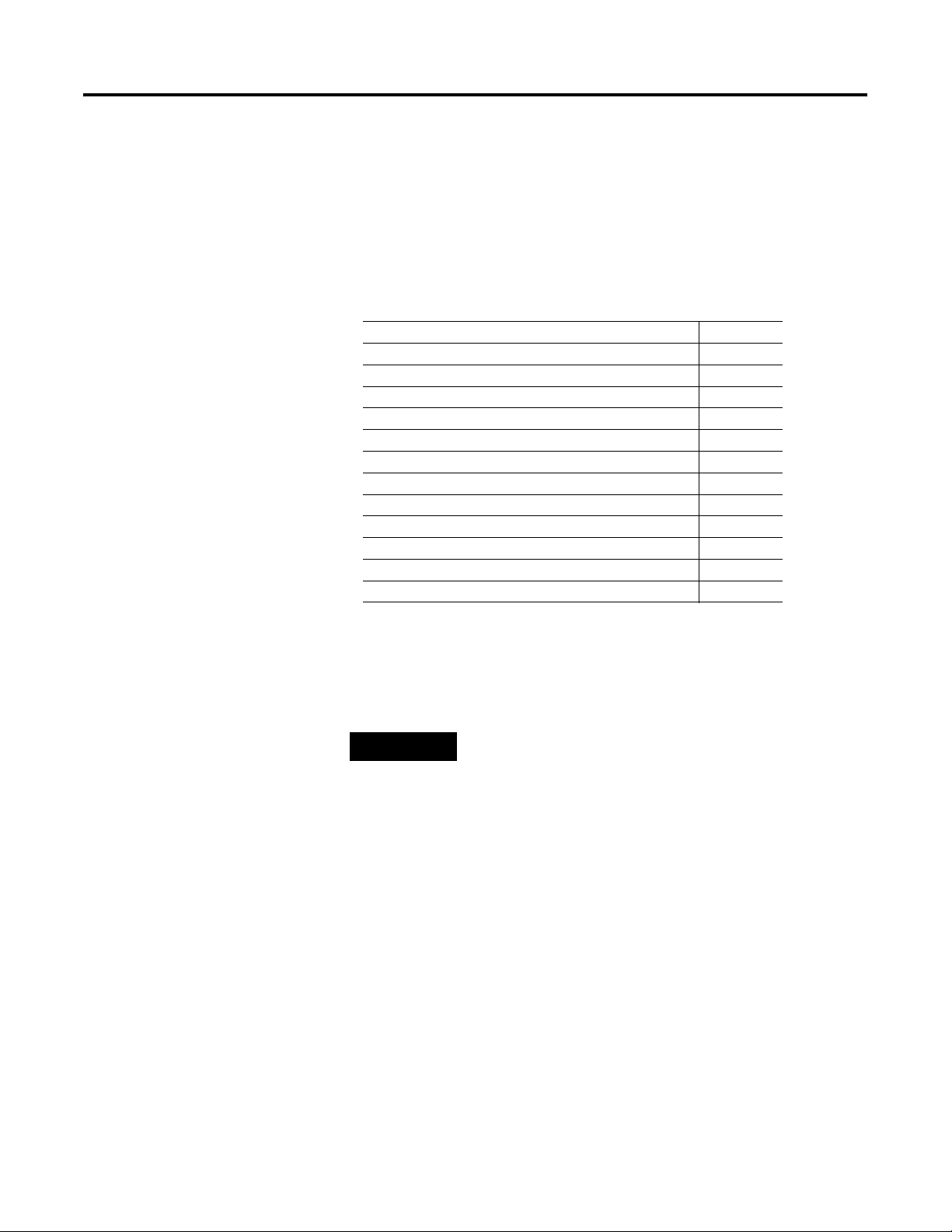

The following table contains a list of ControlNet Ex Components.

Refer to the ControlNet and ControlNet Ex Media System Components

List, publication AG-PA002, for a list of other ControlNet parts.

Item Cat. No. Guidelines

Taps

Straight T-tap

Straight Y-tap

Right-angle T-tap

Right-angle Y-tap

Trunk Terminators 1797-XT

Trunk Cable Use the ControlNet Ex Media System

Tap Terminator 1797-TCAP

1797-TPS

1797-TPYS

1797-TPR

1797-TPYR

(quantity of 50)

(quantity of 5)

You need a tap for each connection to the

trunk cable (nodes and repeaters).

Each tap kit contains: two BNC connector

kits, one dust cap, one universal mounting

bracket, ControlNet Ex cable labels and

two screws

You need a terminator for each end

of each segment.

Component List, publication AG-PA002,

to order your required length of cable.

Use the dummy load to plug into drop

cables that are not attached to a node.

Required Quantity

Number of repeaters x 2

Number of nodes

Number of segments x 2

Follow guidelines on page 2-4

of this document to determine

cable length

One for every drop cable that is

not attached to a node

1

+

Publication CNET-IN003A-EN-P - January 2006

Page 41

Plan a ControlNet Ex Media System 2-19

Item Cat. No. Guidelines

Coax Tool Kit 1786-CTK Use the tool kit to create your trunk cable

Required Quantity

One

to your specifications.

1

You will need to double your quantities when ordering components for a redundant cable system.

2

The connector kit may be shipped with two ferrules. The smaller diameter ferrule should not be used with ControlNet Ex applications.

1

Publication CNET-IN003A-EN-P - January 2006

Page 42

2-20 Plan a ControlNet Ex Media System

What Is Next?

After you gather all of the parts for your ControlNet Ex media system,

you are ready to go to Chapter 3 to begin the installation of your

network.

Publication CNET-IN003A-EN-P - January 2006

Page 43

Install a ControlNet Ex Media System

Chapter

3

What This Chapter Contains

Install the Trunk Cable

Follow the instructions in this chapter to install your ControlNet Ex

media system.

For See Page

Install the Trunk Cable 3-1

Mount the Taps 3-2

Specifications 3-6

Install Fiber Hubs 3-6

Install Cable Connectors 3-13

Connect Cable Sections 3-25

Terminate Segments 3-25

Connect Devices 3-27

Install the 1797-BCNR Module 3-28

TIP

When installing your trunk cable, observe your cable supplier’s

installation instructions and these guidelines.

You should read Chapter 2, Plan a ControlNet Ex

Network, before you install your network.

Wire External to Enclosures

When the RG-6 type coax cable is being pulled through multiple

conduit bends, follow these specifications.

For This Coax

Cable

PVC 42.75 kg (95 lbs) 76.2 mm (3.0 in.)

1 Publication CNET-IN003A-EN-P - January 2006

The Pull Strength Should Not

Exceed

The Bend Radius Should Not

Exceed

Page 44

3-2 Install a ControlNet Ex Media System

Wire Inside Enclosures

When the RG-6 type coax cable is not being pulled through conduit,

follow these specifications.

For This Coax Cable The Bend Radius Should Not Exceed

PVC 38.1 mm (1.5 in.)

Tap drop-cable 25.4 mm (1.0 in.)

The 1797-EXMK Cable Marking kit is available for clearly marking

drop cables and trunk cables as intrinsically-safe.

Mount the Taps

First select where you want to mount the taps, then use this mounting

procedure.

Select Where to Mount the Taps

There is no spacing requirement between taps; you can install two

adjacent taps if necessary by using a barrel connector (1786-BNCP).

IMPORTANT

Be certain that:

• you choose a convenient location to mount and route the cable.

• the location does not cause any cable bend-radii to exceed the

limits listed on pages 3-1 and 3-2.

If the barrel connector (1786-BNCP) is used, use an

intrinsically-safe insulator, the light-blue dust caps

we provide, or tape having a 500V insulation rating

to cover exposed metal parts. Local agencies require

their use for intrinsically-safe certification.

Publication CNET-IN003A-EN-P - January 2006

• you route the cable in accordance with intrinsically-safe cable

routing specifications.

• you do not mount the tap in a position that routes the drop

cable over any ac power terminals on nearby modules.

Page 45

Install a ControlNet Ex Media System 3-3

ATTENTION

Do not allow any metal portions of the tap, such as

the universal mounting bracket screws or

connectors, to contact any conductive material. This

contact could cause noise on the network.

Also be certain all exposed metal is covered by

either the intrinsically-safe insulators or tape having a

500V dielectric rating.

Mount the Taps

You can mount your ControlNet Ex taps (Y-tap and T-tap):

• to a universal mounting bracket, and then mount the tap and

bracket as an assembly.

• through the body holes in the tap using screws, flat washers,

and a tie wrap.

Once you have mounted your taps, you can store or discard any

unused universal mounting brackets.

TIP

See Appendix A for universal mounting bracket and

tap mounting dimensions.

Publication CNET-IN003A-EN-P - January 2006

Page 46

3-4 Install a ControlNet Ex Media System

Mount a Tap with a Universal Mounting Bracket

1. Align the universal mounting bracket with the mounting holes

on the tap.

2. Use the screws provided with the tap to attach the tap to the

universal mounting bracket.

Universal Mounting Bracket

Y-Ta p

Universal Mounting Bracket

(Provided With Tap)

Use only the screws that are packaged with the tap. They are the proper length and head style.

20084-M

ATTENTION

ATTENTION

Dust Cap

Dust Cap

T-Ta p

Do not over-tighten the screws. Over-tightening the

screws can damage the tap. The applied torque

should be 0.2-0.4 Nm (1-2 ft-lbs).

Do not remove the intrinsically-safe dust cap unless

the tap drop is connected to a ControlNet Ex

product.

20080-M

Publication CNET-IN003A-EN-P - January 2006

Page 47

Install a ControlNet Ex Media System 3-5

3. Mount the tap and bracket assembly to a DIN rail or another

mounting surface.

DIN Mounting Rail Another Mounting Surface

Universal Mounting Bracket

Universal Mounting Bracket

Use four screws to attach the universal

mounting bracket to another mounting

surface.

DIN Rail

Suitable Fixture

20081-M

Mount the universal mounting bracket on specified Allen-Bradley mounting rails or #3 style symmetrical DIN rails (35 mm X 7.5 mm [1.38 in. x 0.30 in.])

20082-M

Type of Rail Cat. No. Type of Rail Cat. No.

A-B rail 1492-N1 DIN rail #3 199-DR1

1492-N22 1492-DR5

1492-N44 1492-DR6

1492-DR7

ATTENTION

Use an intrinsically-safe insulator, the light-blue dust

caps we provide, or tape having a 500V insulation

rating to cover exposed metal parts. Local agencies

require their use for intrinsically-safe certification.

Publication CNET-IN003A-EN-P - January 2006

Page 48

3-6 Install a ControlNet Ex Media System

Mount a Tap Through the Body Holes

TIP

A suitable fixture (mounting surface) can be

conductive or grounded because the mounting holes

are electrically isolated.

Mount the tap to a suitable fixture by using a tie wrap, or screws and

flat washers.

Tie Wrap Screws and Flat Washers

Screws and Flat Washers

41645

Body Holes

ATTENTION

Tie Wra p

You can use a variety of screw types.

Do not over-tighten the screws. Over-tightening the

Body Holes

screws can damage the tap. The applied torque

should be 0.2-0.4 Nm (1-2 ft-lbs). Do not use screws

larger than #8 in these holes.

(Not Supplied)

41646

Specifications

Install Fiber Hubs

Publication CNET-IN003A-EN-P - January 2006

The following table lists the specifications for the ControlNet Ex taps.

Operating temperature -20 to 70 °C (-4 to 158 °F)

Storage temperature -40 to 85 °C (-40 to 185 °F)

Relative humidity 5 to 95% noncondensing

Read the following sections before installing a fiber repeater hub.

To Install a Fiber Repeater Hub, You Should See Page

Apply the Installation in Zone 1 and related intrinsically-safe

warnings and standards

Select where to mount the fiber repeater hub 3-8

Mount the fiber repeater hub 3-9

3-7

Page 49

Install a ControlNet Ex Media System 3-7

Installation in Zone 1

The 1797-RPA and 1797-RPFM modules must not be exposed to the

environment. You must install these modules in a metal enclosure.

This repeater hub has a protection factor of IP20.

Attention: Avoid electrostatic charge.

ATTENTION

These modules cannot be used in a hazardous

environment after they have been exposed to

non-intrinsically-safe signals.

Electrostatic Charge

Protect the system against electrostatic charge. Post a sign near this

module. The sign should read

Attention! Avoid electrostatic charge.

For your convenience, see page C-1 for signs that you can cut out.

European Community Directive Compliance

If this product has the CE mark it is approved for installation within

the European Community or EEA regions. It has been designed and

tested to meet the following directives.

EMC Directive

This product is tested to meet the Council Directive 89/336/EC

Electromagnetic Compatibility (EMC) by applying the following

standards, in whole or in part, documented in a technical construction

file:

• EN50081-2 EMC — Generic Emission Standard, Part 2 —

Industrial Environment

• EN50082-2 EMC — Generic Immunity Standard, Part 2 —

Industrial Environment

This product is intended for use in an industrial environment.

Publication CNET-IN003A-EN-P - January 2006

Page 50

3-8 Install a ControlNet Ex Media System

Ex Directive

This product is tested to meet the Council Directive 94/9 EC (ATEX

100a) Equipment and Protective Systems Intended for Use in

Potentially Explosive Atmospheres by applying the following

standards:

• EN50014:1992, Electrical Apparatus for Potentially Explosive

Atmospheres

• EN50020:1994, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsic Safety “i”

• EN50039:1980, Electrical Apparatus for Potentially Explosive

Atmospheres - Intrinsically-safe Electrical Systems “i”

• pr EN50284:1997, Special requirements for construction, test,

and marking of electrical apparatus of equipment group II,

category 1 G

Inputs/Outputs

Do not apply any non-intrinsically-safe signals to the fiber modules.

When you use an intrinsically-safe electrical apparatus according to

EN50020, the European directives and regulations must be followed.

Select a Fiber Repeater Hub Mounting Location

The fiber repeater hub should be mounted:

• so that air can flow in and out of the air holes on the top and

bottom of the coax repeater.

For proper ventilation, be certain that there is a minimum of 5.1

cm (2 in.) from surrounding equipment.

• in a NEMA enclosure to provide protection from dust, moisture,

or corrosive atmospheres to a grounded metal plate, if possible.

ATTENTION

Be certain that the adapter and fiber modules are

secured together with DIN-rail anchors. Failure to do

so may result in the loss of communications or cause

damage to the modules.

Publication CNET-IN003A-EN-P - January 2006

Page 51

Install a ControlNet Ex Media System 3-9

Mount the Fiber Repeater Hub

Follow this procedure to mount the fiber repeater hub.

1. Position the module on a 35 mm x 7.5 mm (1.38 in. x 0.30 in.)

DIN rail (A-B part number 199-DR1) at approximately a 30°

angle.

41167

2. Hook the lip on the rear of the adapter onto the top of the DIN

rail, and rotate the module onto the rail.

41166

3. Press the adapter down onto the DIN rail until flush.

The locking tab should snap into position and lock the module

to the DIN rail.

Publication CNET-IN003A-EN-P - January 2006

Page 52

3-10 Install a ControlNet Ex Media System

4. If the adapter does not snap into position, use a screwdriver or

similar device to move the locking tab down while pressing the

module flush onto the DIN rail. Release the locking tab to lock

the module in place. If necessary, push up on the locking tab to

lock.

41168

5. Remove the adapter backplane connector cover.

6. Follow steps 1 through 4 to attach fiber modules to the DIN rail.

7. Once attached to the DIN rail, slide fiber modules to the left to

mate with the adapter.

Publication CNET-IN003A-EN-P - January 2006

41169

IMPORTANT

A DIN-rail end anchor (A-B part number 1492-EA35)

must be used on the left side of the adapter and to

the right side of the fiber module to keep the units

from moving.

8. Be certain the last fiber module has its backplane connector

cover in place.

9. Connect the adapter wiring as shown on page 3-11.

IMPORTANT

You can attach only two media modules to the

repeater adapter. If you exceed the module limit, you

may cause damage to the adapter or fiber modules

and void the intrinsically-safe certification.

Page 53

Install a ControlNet Ex Media System 3-11

Connect the Fiber Repeater Hub to a ControlNet Ex Network

1. Connect to the ControlNet Ex coax network with the drop line

of the Ex coax tap to the adapter BNC connector.

Intrinsically-safe

Insulator

41170