Page 1

User Manual

1794 FLEX I/O Very High Speed Counter Module

Catalog Numbers

1794-VHSC

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous

environment, which may lead to personal injury or death, property damage, or economic loss.

available from

) describes some

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death,

property damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the

consequence

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that

surfaces may reach dangerous temperatures.

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Automation, FLEX I/O, ControlLogix, RSlogix, R SLinx, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Summary of Changes

This manual contains new and updated information. Changes throughout this

revision are marked by change bars, as shown to the right of this paragraph.

New and Updated Information

This table contains the major changes and additions made to this revision.

Topic Page

Updated Frequency Resolution/Enhancement section. 33

Updated Word 8 Bit/Word Definitions. 39, 40

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 iii

Page 4

Summary of Changes

Notes:

iv Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 5

Preface

Read this preface to familiarize yourself with the rest of the manual. It provides

information concerning:

• who should use this manual

• the purpose of this manual

• related documentation

Who Should Use this Manual

Purpose of this Manual

You must be able to program and operate an Allen-Bradley programmable

controller (PLC) to make efficient use of this module.

We assume that you know how to do this in this manual. If you do not, refer to

the appropriate programming and operations manual for the associated

programmable controller before you attempt to use this module.

This manual shows you how to use the FLEX I/O Very High Speed Counter

module with an Allen-Bradley programmable controller. It helps you install,

program, and troubleshoot your module.

For Information About See Page

Overview of the Very High Speed Counter Module 1

Install Your FLEX I/O VHSC Module 17

Programming Your Very High Speed Counter Module 55

Communicate With Your Module 29

Interpret Status Indicators for your FLEX I/O Module 47

Specifications 49

Additional Resources

These documents contain additional information concerning related Rockwell

Automation products.

Resource Description

FLEX I/O Selection Guide, publication 1794-SG002

Very High Speed Counter Module Installation Instructions,

publication 1794-IN067

ControlLogix System User Manual, publiation 1756-UM001

EtherNet/IP Modules Installation Instructions,

publication ENET-IN002

FLEX I/O DC Power Supply Installation Instructions,

publication 1794-IN069

EtherNet/IP Modules in Logix5000 Control Systems User Manual,

publication ENET-UM001

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 v

A description and overview of the 1794 series FLEX I/O, FLEX I/O XT and FLEX Ex

modules and compatible control platforms.

Information on installing the FLEX I/O Very High Speed Counter Module.

Detailed information on how to install, configure and troubleshoot the ControlLogix

module in your ControlLogix application.

Information on installing EtherNet/IP bridge modules.

Information on how to install the FLEX I/O DC Power Supply Catalog No. 1794-PS13,

1794-PS3.

Detailed information on how to use EtherNet/IP modules with Logix5000 controllers

and communicate with various devices on the Ethernet network.

Page 6

Preface

Resource Description

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-IN041

Product Certifications website, http://ab.com Provides declarations of conformity, certificates, and other certification details.

Application Considerations for Solid-State Controls,

publication SGI-1.1

Allen-Bradley Industrial Automation Glossary, publication AG-7.1

Provides general guidelines for installing a Rockwell Automation industrial system.

A description of important differences between solid-state programmable controller

products and hard-wired electromechanical devices.

A glossary of industrial automation terms and abbreviations.

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Rockwell Automation distributor or

sales representative.

Common Techniques Used in this Manual

The following conventions are used throughout this manual:

• Bulleted lists such as this one provide information, not procedural steps.

• Numbered lists provide sequential steps or hierarchical information.

• Italic type is used for emphasis.

vi Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 7

Table of Contents

Summary of Changes

Preface

Overview of the Very High

Speed Counter Module

New and Updated Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Common Techniques Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . vi

Chapter 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Module Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Module Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Encoder or Counter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Counter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Encoder Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Direction of Count . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Preset Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rollover Value. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Software Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gate/Reset Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Period/Rate Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Operation of Scaler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Connection to Counter Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Continuous/Rate Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Rate Measurement Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Sample Period . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Connection to Counter Inputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Pulse Width Modulation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Enabling and Forcing Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Assigning Outputs to Counter Windows . . . . . . . . . . . . . . . . . . . . . . . 13

Operation of Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Isolation of Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Connecting Outputs to Counters . . . . . . . . . . . . . . . . . . . . . . . . . .14

What the Module Does . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 2

Install Your FLEX I/O VHSC

Module

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 vii

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Before You Install Your Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Install the Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Mount on a DIN Rail . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Install the Terminal Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Mount on a Panel or Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Page 8

Mount the 1794-VHSC Module on the Terminal Base Unit . . . . . 21

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Connect Wiring to the FLEX I/O VHSC Input Module . . . . . . . . 24

Connect Wiring Using a 1794-TB3G, 1794-TB3GK or 1794-TB3GS

Terminal Base Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chapter 3

Communicate With Your

Module

Interpret Status Indicators for

your FLEX I/O Module

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Communication Over the

I/O Backplane . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Scheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Unscheduled Data-Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Module I/O Mapping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Application of New Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

I/O Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Adapter Input Status Word . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Safe State Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Device Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Communication Fault Behavior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Idle State Behavior. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Input Data Behavior upon Module Removal . . . . . . . . . . . . . . . . . . . . 33

Frequency/Resolution Enhancement. . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Chapter 4

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Diagnostic Codes Returned by the Module . . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter Summary. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix A

Specifications

Programming Your Very High

Speed Counter Module

Index

viii Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Appendix B

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Page 9

Overview of the Very High Speed

IMPORTANT

Counter Module

Chapter

1

Overview

Module Description

This chapter gives you information on features of the modules, how the module

communicates with controllers and how the module operates.

Topic Page

Module Description

Encoder or Counter Mode 2

Period/Rate Mode 8

Continuous/Rate Mode 10

Rate Measurement Mode 11

Pulse Width Modulation 12

Outputs 13

What the Module Does 14

The 1794-VHSC module performs high speed counting for industrial

applications. The module is an intelligent I/O module that interfaces signals with

any Allen-Bradley programmable controller that has Ethernet capability.

The 1794-VHSC module, once configured for its intended purpose, can

continue to operate without FlexBus power.

1

Customer power is required for the module, inputs and outputs.

After scanning the inputs and updating the outputs, the input data is converted to

a specified data type in a digital format to be transferred to the processor’s data

table on request. Command and configuration data is sent from the

programmable controller data tables to the module via Ethernet.

Module Features

The 1794-VHSC module counts pulses from encoders (such as Allen-Bradley

Bulletin 845), pulse generators or mechanical limit switches, or proximity

switches, and returns either a count or frequency in binary format.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 1

Page 10

Overview of the Very High Speed Counter Module

The module features include:

• 2 counters configurable for 3 encoder modes, counter mode, period/rate

mode, continuous/rate mode, rate measurement and pulse width

modulation (PWM)

• 4 outputs, isolated in pairs

• outputs are current-sourcing at 5 or 12…24V DC (0.5 mA max @ 5V; 1 A

max @ 12…24V)

• single-ended or differential inputs

• 2-phase encoder inputs up to a frequency of 250 KHz (X 4 mode)

• single-phase counter inputs up to a frequency of 1 MHz

• input voltage range of 5 or 24V DC

• returns input as count or frequency in binary format

• input counts as high as 16,777,215

• up to 1 MHz in period/rate or rate measurement frequency modes

• outputs can be tied to any or all counter windows

• each output has a user-selectable on-off value

• outputs can be tied back to an input for cascading

• each counter has a user-selectable preset and rollover value

• totalization is provided in period/rate, continuous/rate and rate

measurement modes

• module can continue counting without flexbus power (after configuration)

• outputs have safe state values which can be applied when there is a network

failure or the PLC is switched to PROGRAM mode

• pulse width modulation (PWM) mode is available

The 1794-VHSC module operates in the following modes:

• counter mode

• encoder X1 mode

• encoder X2 mode

• encoder X4 mode

• period/rate mode

• continuous/rate mode

• rate measurement frequency mode

• pulse width modulation (PWM)

Encoder or Counter Mode

2 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

The operation of encoder and counter modes is virtually identical. The only

difference between the two modes is in the type of feedback used.

Use the counter mode if you need the module to read incoming pulses from a

maximum of 2 encoders (single-ended or differential), counters, pulse generators,

mechanical limit switches, etc. and return them to the programmable controller

as a binary number (0…16,777,215).

Page 11

Overview of the Very High Speed Counter Module

Use the encoder modes if you need the module to read incoming quadrature

pulses and return them to the programmable controller as a binary number

(0…16,777,215). In these modes, the module accepts two-phase quadrature

feedback and counts up or down depending upon the condition of the phase B

input for each counter.

The operation of the module in the encoder/counter modes is as follows:

• counter mode – channel B is direction control (up or down). Channel A

input is used for pulse. The count is bidirectional with the direction

determined by channel B.

• encoder X1 – This is a bidirectional count mode; counting up or down,

using quadrature input signals.

• encoder X2 – This is a bidirectional count mode, using quadrature input

signals, with 2 times the resolution of X1.

• encoder X4 – This is a bidirectional count mode, using quadrature input

signals, with 4 times the resolution of X1.

Each of the counters in encoder/counter mode has values associated with it.

These are:

• preset value

• rollover value

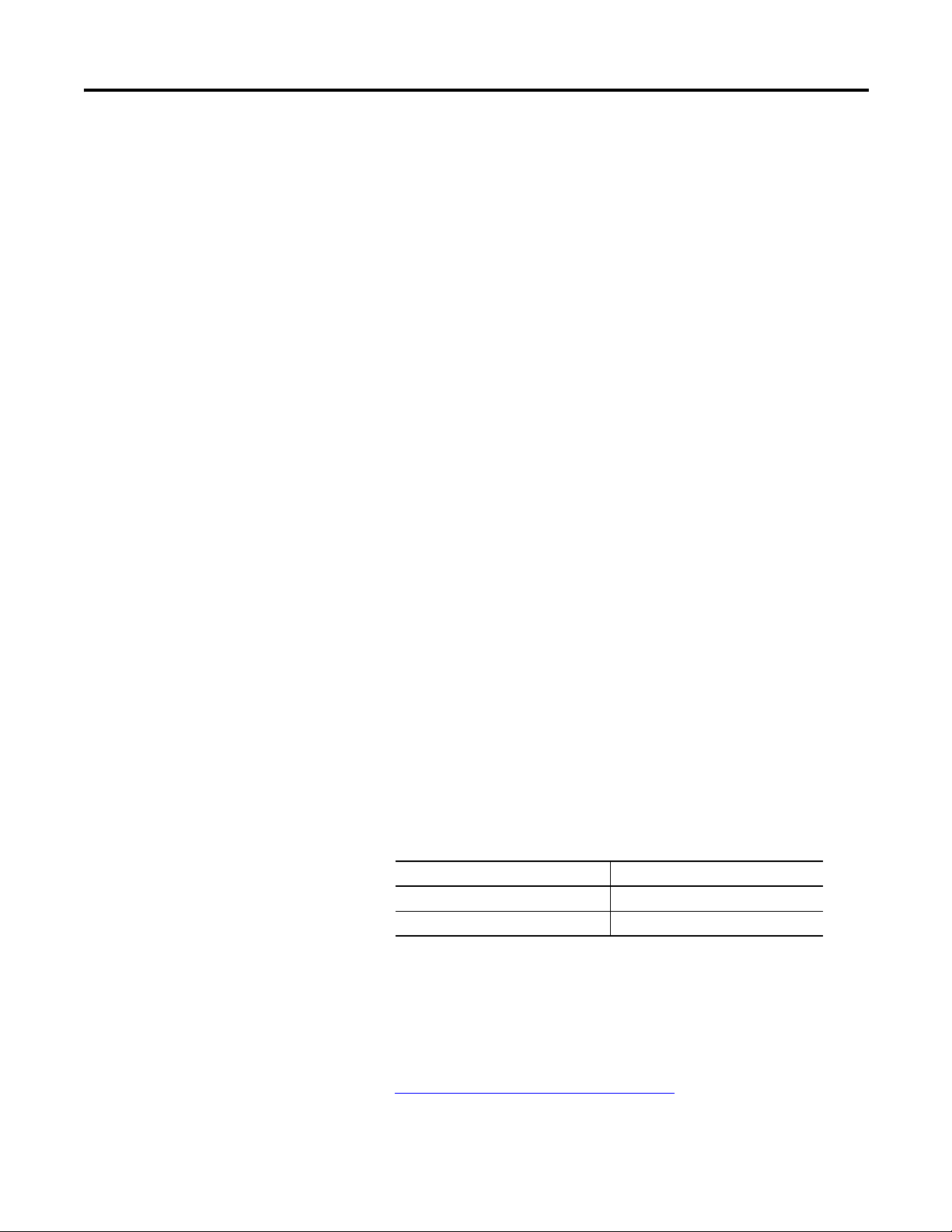

Counter Mode

The counter mode allows the module to read incoming pulses and return them to

the programmable controller processor as a binary number (0…16,777,215).

In the counter mode, direction (up counting or down counting ) is determined by

the phase B input, which can be a random signal. If Phase B is high, the counter

will count down. If phase B is low or floating, (that is, not connected), the

counter counts up.

Counter Mode Direction

Phase B Input Count direction

High Down

Low or floating (not included) Up

The module reads incoming pulses from a maximum of 2 encoders (single-ended

or differential), counters, pulse generators, mechanical limit switches, and so

forth and returns a count to the programmable controller processor in a binary

number (0-16,777,215).

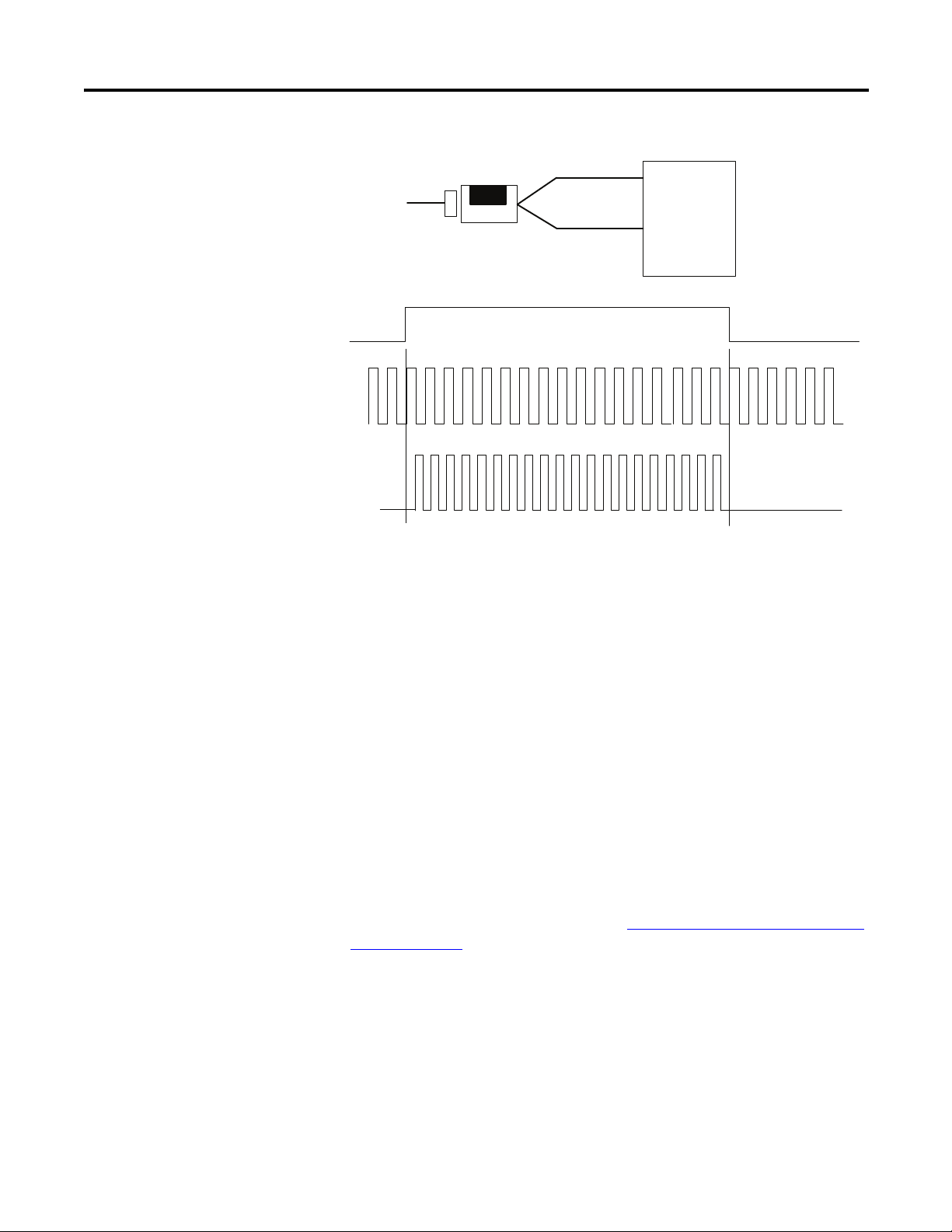

The counter mode accepts only one phase feedback. This relationship is shown in

Figure Block Diagram of Counter Mode

on page 4.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 3

Page 12

Overview of the Very High Speed Counter Module

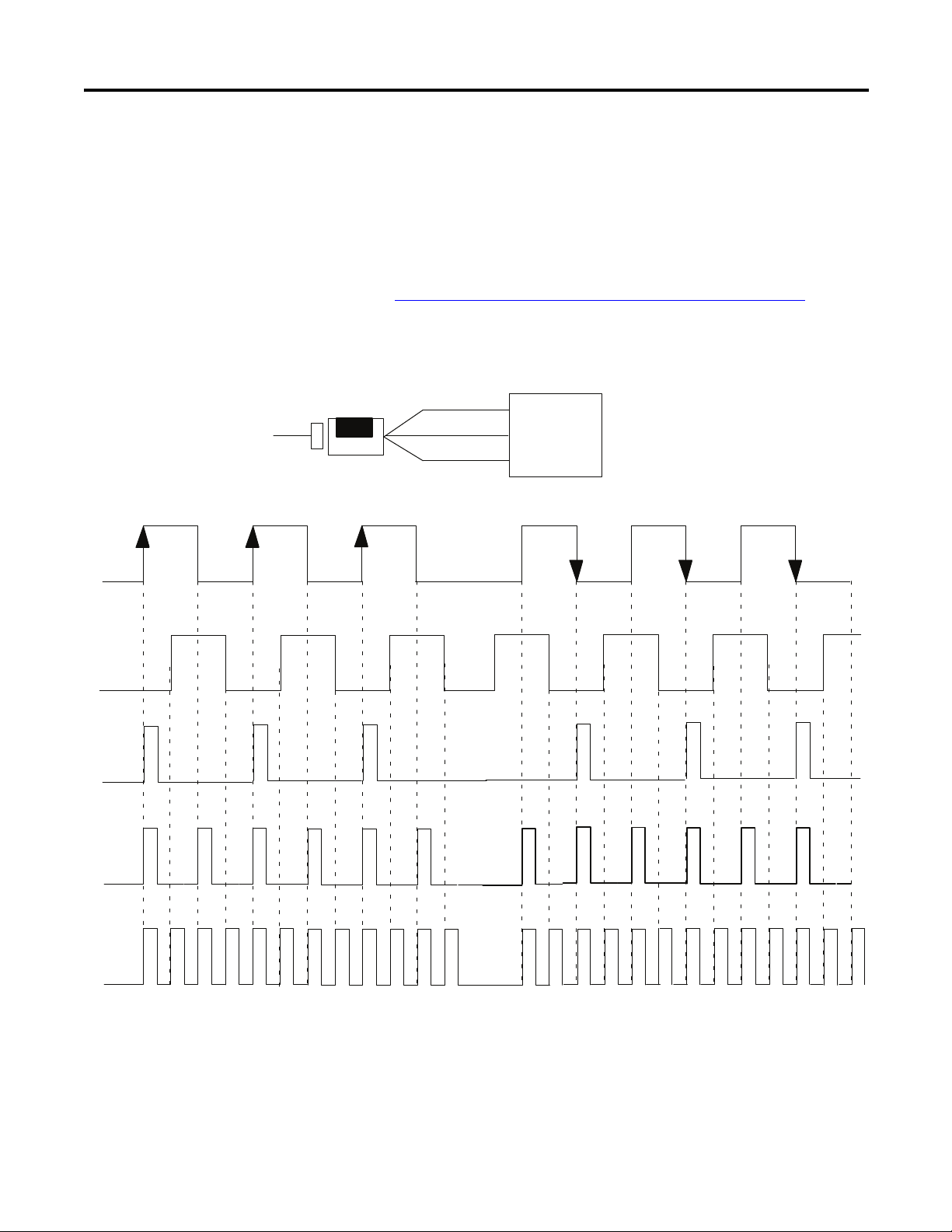

A

B

01 2 3 2 1 0

Input A

Input B

Z(Store count)

Single phase pulse generator

1794-VHSC

Input Z

(Gate/Reset)

Count down

A input

B input

Count

Count up

+

-

Outputs updated continuously

45891

Block Diagram of Counter Mode

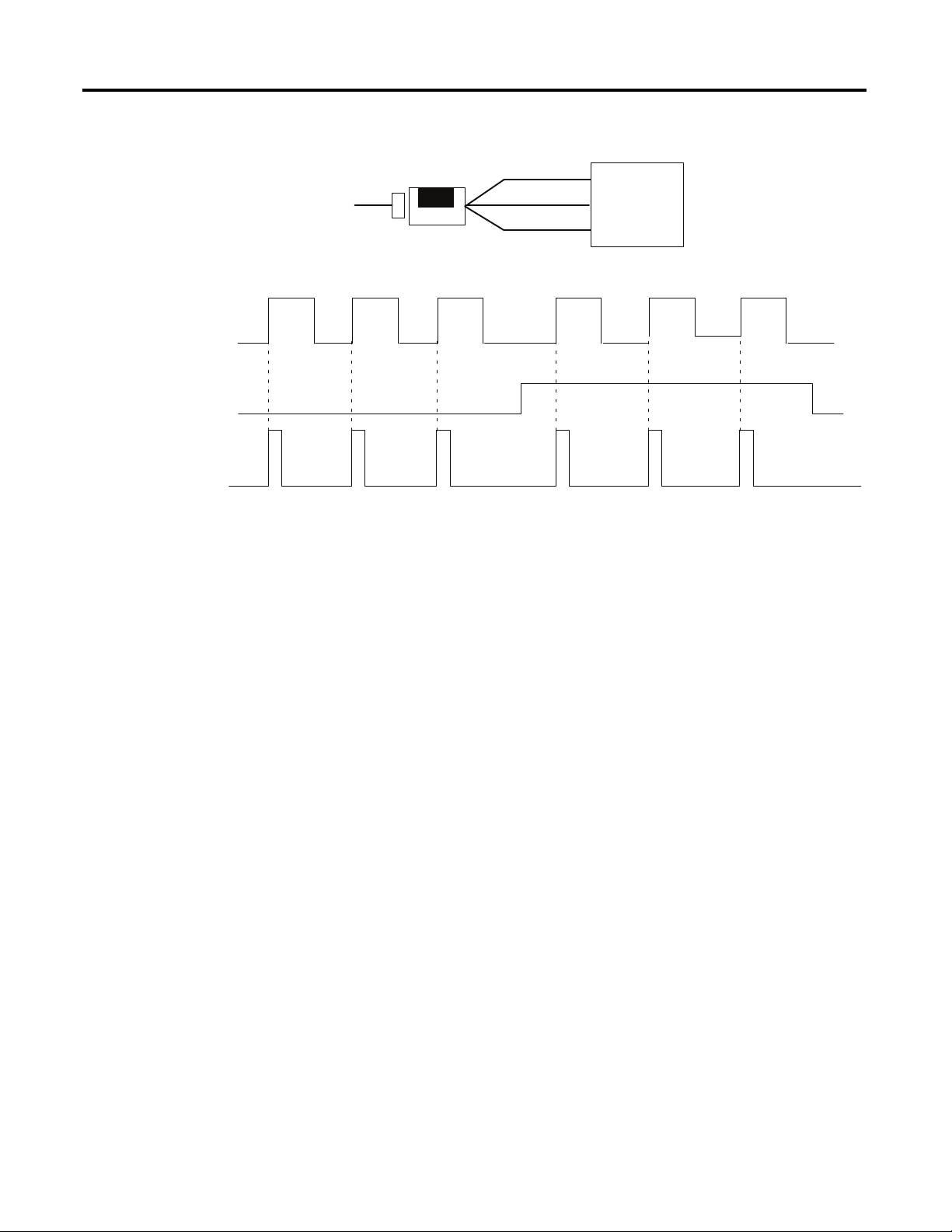

Encoder Mode

The encoder mode allows the module to read incoming pulses and return them to

the programmable controller processor as a binary number (0-16,777,215).

In this mode, the module will accept two phase quadrature feedback. The module

senses the relationship between the 2 phases and counts up or down accordingly.

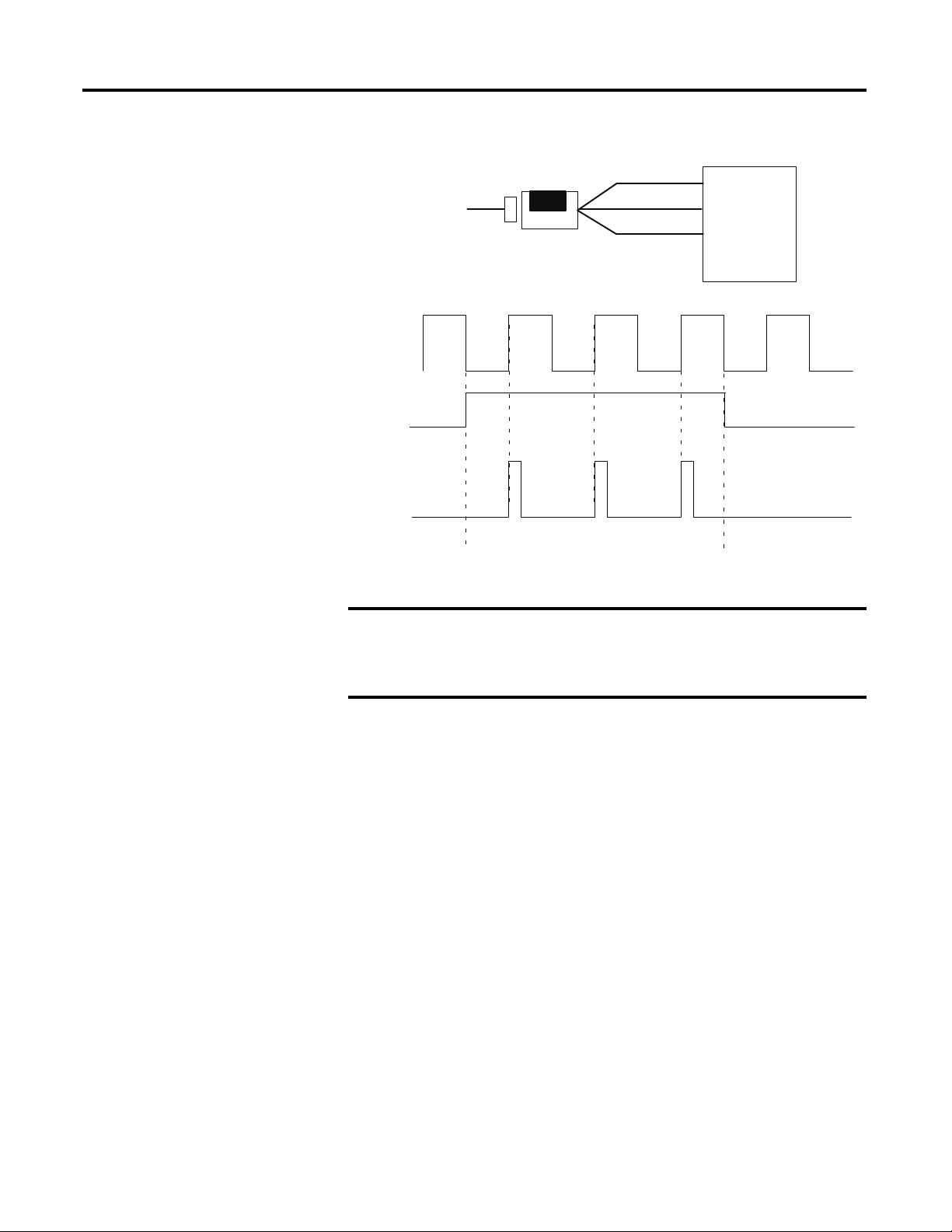

Encoder X1 mode – quadrature input signals count on the leading edge or the

trailing edge of channel A for a bidirectional count. The phase relationship

between Channel A and Channel B determines direction — channel A leading,

and channel B floating, the count direction is up; Channel A lagging, and

Channel B high, the count direction is down.

Encoder X2 mode – quadrature input signals count on the leading edge and the

trailing edge of channel A for a bidirectional count. Channel B determines

direction —B low (floating), the count direction is up; B high, the count

direction is down.

Encoder X4 mode – quadrature input signals count on the leading edge and the

trailing edge of channel A and channel B for a bidirectional count. Channel B

determines direction — B low (floating), the count direction is up; B high, the

count direction is down.

4 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 13

Overview of the Very High Speed Counter Module

A input

B input

X1

count

A

B

Input A

Input B

Reverse rotation

CW encoder rotation

Forward rotation

CCW encoder rotation

120

312

1 2 3 4 5 6 7 8 9 10 11 1 2

1234567

8

9101112

0

1 2 3 4 5 6 7 8 9 10 11 1 2

1234567

8

9101112

0

Z(Store count)

Quadrature encoder

1794-VHSC

Input Z

(Gate/Reset)

45892

Direction of Count

The module can count either up or down, depending upon the condition of the B

input for each counter. In encoder applications, the counter will increment on the

leading edge of input A, while input B determines the direction of the count.

You also have the option of X1, X2 and X4 multiplying of the input pulses. See

Figure Phase Relationship for Forward or Reverse Directions

relationships between inputs A and B for forward and reverse directions in

encoder applications.

Phase Relationship for Forward or Reverse Directions

on page 5 for the

The following paragraphs apply to both encoders and counters.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 5

Page 14

Overview of the Very High Speed Counter Module

Preset Value

Each of the 2 counters has one preset value associated with it. In the encoder or

counter modes, the preset value represents a reference point (or count) from

which the module begins counting. The module can count either up or down

from the preset value. Preset values are loaded into the count registers through the

preset count bits. Preset values can range from 0 to 16,777,215 binary.

Rollover Value

Each of the 2 counters has one rollover value associated with it. When the

rollover value is reached by the encoder/counter, it resets to 0 and begins

counting again. The rollover values range from 1 to 16,777,216 binary. The

rollover value is circular. For example: if you program 360, the count will be from

358, 359, 0, 1, and so on, in a positive direction and from 1, 0, 359, 358, and so

on, in a negative direction.

Software Reset

The counters can also be reset by the Reset Count bits found in Word 0, bits 0

and 4 of the Counter Control word. When one of these bits is set to 1, the

associated counter is reset to zero and begins counting. The module can also be

reset with the gate/reset as explained below. For more details, .

Gate/Reset Input

There is one gate/reset input for each of the 2 counters. The gate/reset input,

when active, will function in one of the 4 store count modes outlined below.

Scaling Input Count at the Gate/Reset Terminal

You can scale the incoming count at the gate/reset terminal. Scaling allows the

incoming pulses at gate/reset to be divided by a number in the range of 1, 2, 4, 8,

16, 32, 64 and 128.

Store Count

The store count feature allows the module to store the current count value of the

associated counter. The store count feature is triggered by the state of the gate/

reset terminal on the module. The stored count of each counter is placed in a

separate word in the Read Data file. The stored count value will remain in the

Read Data file until a new trigger pulse is received at the Gate/Reset terminal.

When a new trigger pulse is received, the old count value will be overwritten by

the new value.

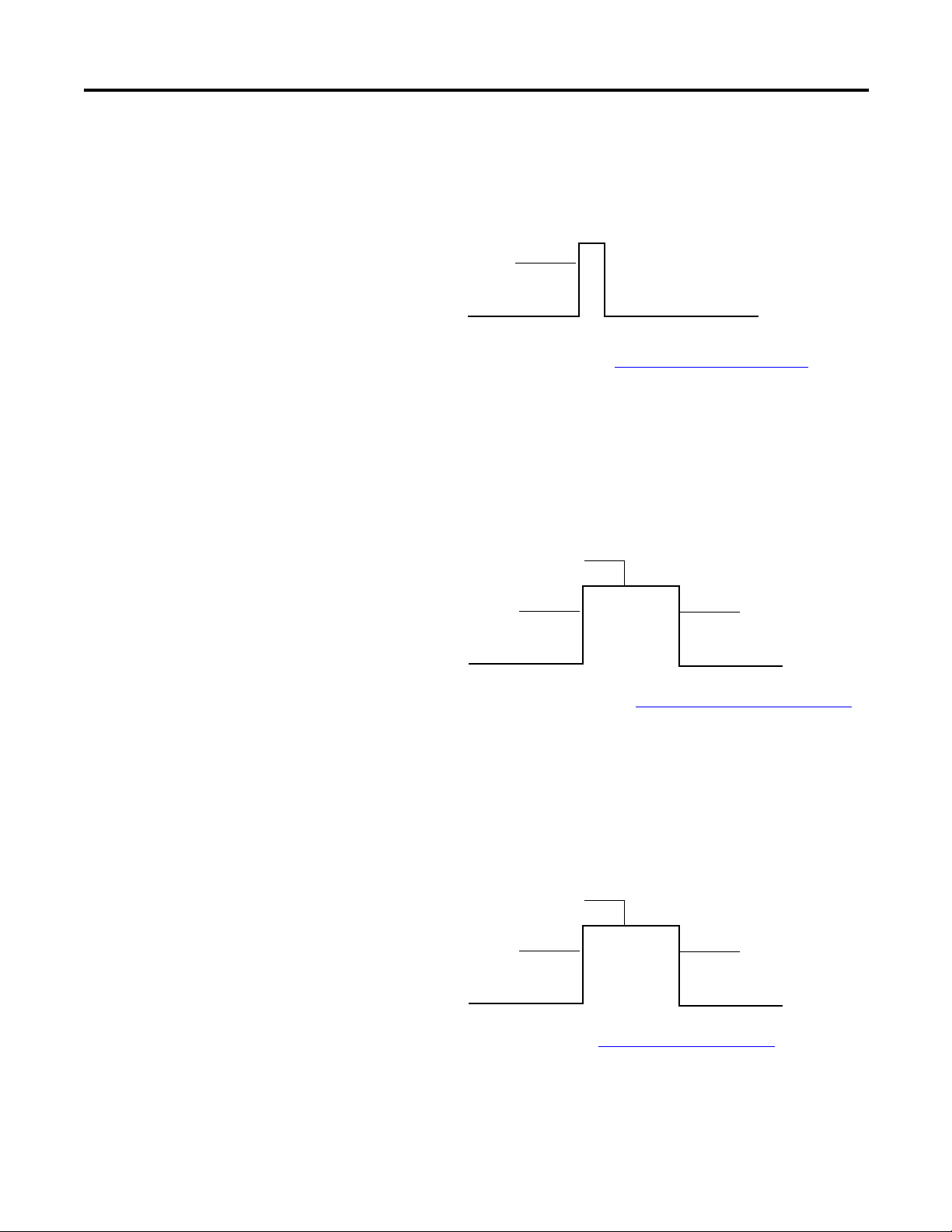

In mode 1, store/continue (see Figure Store/Continue

edge of a pulse input on input Z (gate/reset) terminal causes the current value in

6 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

on page 7), the leading

Page 15

Overview of the Very High Speed Counter Module

Read, Store Count and

continue counting.

Store Count

Stop counting

Resume counting

Stop count, store

and reset to zero

Counter has stopped counting

Start counting

from zero

the counter to be read and stored. The counter will continue counting. The

stored count will be available in the Read Data file. The stored count information

will remain in the block transfer read file until it is overwritten by new data.

Store/Continue

In mode 2, store/wait/resume (see Figure Store/Wait/Resume on page 7), a rising

edge of a pulse input on the Z input (gate/reset) terminal reads and stores the

current counter value in the Read Data file, and inhibits counting while the gate/

reset input is high. Counting resumes when the input goes low.

Mode 2 does not reset the counter, although it does store the count value. The

stored count is available in the Read Data file. The stored count remains in the

Read Data file until it is overwritten with new data.

Store/Wait/Resume

In mode 3, store-reset/wait/start (see Figure Store-Reset/Wait/Start on page 7),

the rising edge of the pulse on input Z (gate/reset) terminal causes the counter to

stop counting, store the current count value in the Read Data file and reset the

count to zero. The counter does not count while the Z input on the gate/reset

terminal remains high. Counting resumes from zero on the falling edge of the

pulse at the Z (gate/reset) terminal. The stored count is available in the Read

Data file. The stored count remains in the Read Data file until it is overwritten

with new data.

Store-Reset/Wait/Start

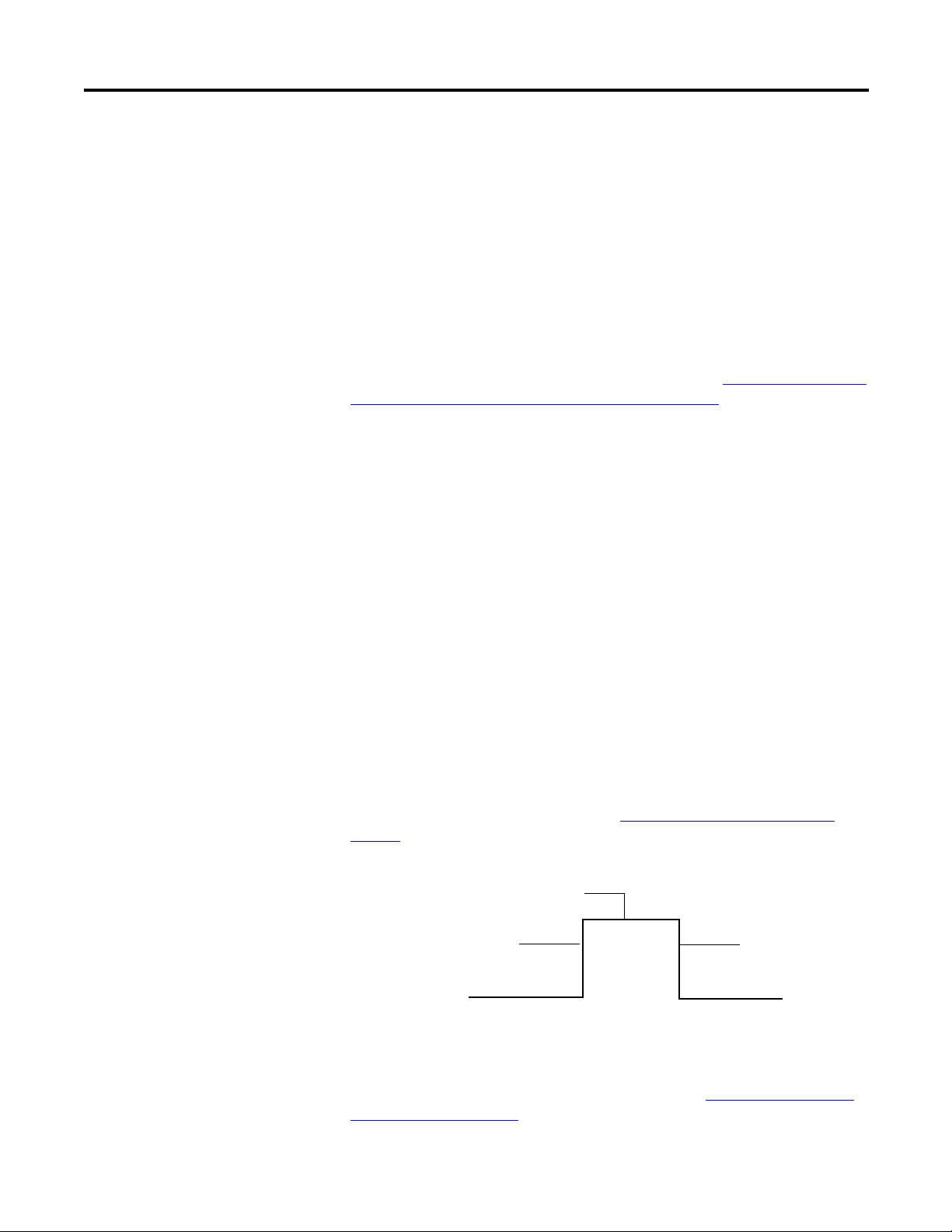

In mode 4, store-reset/start (see Figure Store-Reset/Start on page 8), on the rising

edge of a pulse input at the Z (gate/reset) terminal causes the counter to store the

accumulated count value in the Read Data file, and reset the counter to zero. The

counter continues counting while the Z gate/reset input is high. The stored count

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 7

Page 16

Overview of the Very High Speed Counter Module

Store Count,

reset to zero,

start counting

Rising edge

Store Count,

reset to zero,

start counting

Falling edge

is available in the Read Data file. The stored count remains in the Read Data file

until it is overwritten with new data.

Store-Reset/Start

The figures show the store count feature operating on the rising edge of the gate/

reset pulse. The user has the option of electing these same features using the

falling edge of the gate/reset pulse. The gate invert bit is active in the store count,

continuous/rate and period/rate modes.

Period/Rate Mode

Use the period/rate mode to determine the frequency of input pulses by counting

the number of internal 5MHz clock pulses over a user-specified number of input

signal pulses. At the end of the specified number of pulses, the module returns the

frequency and the total number of pulses received.

A channel configured for period/rate mode acts as a period rate counter. An

internal 5MHz clock is used as a frequency reference. This clock is gated by the

incoming pulse train at the gate/reset input. The results of this gating action are

the number of pulses or a frequency. The frequency is returned in input file words

0 (LSW) and 1 (MSW) for channel 0 and word 2 (LSW) and 3 (MSW) for

channel 1. The total pulses received is stored in input file words 4 (LSW) and 5

(MSW) for channel 0 and words 6 (LSW) and 7 (MSW) for channel 1. Select

the period/rate mode by setting the appropriate bits in word 0 of the

configuration block.

1794-VHSC modules count the total number of pulses occurring at the Z (gate/

reset) pin. This function is frequency-limited to 200Hz X the scaler value. You

can reset this count by setting the VR bit.

Figure Period/Rate Mode

on page 9 shows a diagram of the module used in the

period/rate mode.

8 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 17

Period/Rate Mode

Assumes symmetrical pulse, 50% duty cycle, so period = sample time on X 2 (on and off)

Frequency = 1/period

If count = 25, scaler = 1, and clock period = (1/5 MHz)

Frequency = 1 / [(25/1) X (1/5 MHz) X 2] = 100 KHz

45893

Overview of the Very High Speed Counter Module

Incoming pulse train at Z

(gate/reset terminal)

5 MHz internal clock

Accumulated count

Single phase pulse generator

1

A (not used)

B (not used)

Z (gate/reset)

10 20

Input A

Input B

Input Z

scaler

5 MHz clock

1794-VHSC

Frequency and outputs

updated here

In Figure Period/Rate Mode on page 9, the incoming pulse train from the gate/

reset terminal is used to sample pulses from the 5 MHz internal clock. As the

frequency of the incoming pulse train at the gate/reset terminal increases, the

number of sampled pulses from the 5 MHz clock decreases. This relationship is

shown in NO TAG. Since accuracy is related to the number of pulses received

over the sample period, the accuracy will decrease with increasing input

frequencies at the Gate/Reset terminal.

To some extent, the decrease in accuracy can be lessened by scaling the input

frequency through the use of a scaler. A scaler value of 1 will only return an

accurate input frequency if incoming pulses have a 50% duty cycle.

Relationship Between Sampled Pulses and Input Frequency

Input Frequency at Z

(Gate/Reset)

Terminal in Hz

21.25M

5500K

10 250K

20 125K

50 50K

100 25K

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 9

Sampled Pulses for 1/2 Cycle of Z

(Gate/Reset) Pulse

Page 18

Overview of the Very High Speed Counter Module

Relationship Between Sampled Pulses and Input Frequency

Input Frequency at Z

(Gate/Reset)

Terminal in Hz

200 12.5K

500 5K

1 KHz 2.5K

2 KHz 1.25k

5 KHz 500

10 KHz 250

20 KHz 125

50 KHz 50

100 KHz 25

Sampled Pulses for 1/2 Cycle of Z

(Gate/Reset) Pulse

Operation of Scaler

In period/rate mode, the scaler lets the incoming pulse train at the Z (gate/reset)

terminal be divided by a user defined number. Acceptable values for the scaler are

1, 2, 4, 8, 16, 32, 64 and 128. There is one scaler value for each counter.

ATTENTION: Sample period times scaler must be less than 6.71 s in

order to avoid a zero frequency detect indication.

Continuous/Rate Mode

Connection to Counter Inputs

The only input to the module in the period/rate mode is made to the Z (gate/

reset) terminal. The counter inputs (channel A and B) are not used in the period/

rate mode.

The continuous/rate mode is similar to the period/rate mode previously

described except the outputs in this mode are dynamic outputs. Use this mode to

determine the frequency of input pulses by counting the number of internal

5 MHz clock pulses over a user-specified number of input signal pulses. Each

output is turned on as soon as the turn-on count is reached, and turned off as

soon as the turn-off count is reached. As the internal 5 MHz clock is counted, the

outputs dynamically track the 5 MHz count. This allows you to turn an output

on a certain number of 5 MHz counts after the gate/reset pin goes active, and

turn it off a certain number of 5 MHz counts later.

1794-VHSC module counts the total number of pulses occurring at the Z (gate/

reset) terminal. This function is frequency-limited to 200 Hz X the scaler value.

This total count is returned in input file words 4 (LSW) and 5 (MSW) for

channel 0 and 6 (LSW) and 7 (MSW) for channel 1. You can reset this count by

setting the VR bit.

10 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 19

Overview of the Very High Speed Counter Module

Incoming pulse train at Z

(gate/reset terminal)

5 MHz internal clock

A (not used)

B (not used)

Input A

Input B

Z

Encoder/Pulse generator

1794-VHSC

Input Z

(Gate/Reset)

scaler

5 MHz clock

1

Accumulated count

Outputs updated continuously

Frequency

updated here

10 20

Assumes symmetrical pulse, 50% duty cycle, so period = sample time on X 2 (on and off)

Frequency = 1/period

If count = 25, scaler = 1, and clock period = (1/5 MHz)

Frequency = 1 / [(25/1) X (1/5 MHz) X 2] = 100 KHz

45894

Period/Rate and Continuous/Rate Output Operation with Scaler of 1

Rate Measurement Mode

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 11

Use the rate measurement mode to count incoming pulses for a user-specified

time interval. At the end of the interval, the module returns a value representing

the sampled number of pulses and a value indicating the incoming frequency.

When the count and frequency are updated, any associated outputs are checked

against their associated presets.

The value representing the total number of pulses is returned in input file words 4

(LSW) and 5 (MSW) for channel 0 and 6 (LSW) and 7 (MSW) for channel 1,

and the value indicating the incoming frequency is returned in words 0 (LSW)

and 1 (MSW) and 2 (LSW) and 3 (MSW). The total count equals the running

sum of the number of pulses received during the sample period. The operation of

rate measurement mode is shown in Figure Operation of the Rate Measurement

Mode on page 12.

Page 20

Overview of the Very High Speed Counter Module

If sample period is 50 ms, and count = 3, then frequency = 3/50 ms = 60 Hz

45895

EXAMPLE

A Input (pulse)

Internal sampling gate

Accumulated count

Operation of the Rate Measurement Mode

Encoder/Pulse generator

123

A Input

B (not used)

Z (not used)

(Gate/Reset)

Input A

Input B

Input Z

Time base

1794-VHSC

Frequency calculated,

outputs updated here

In , three counts have been accumulated during the user-selected time

period. If you had selected 50 ms as the sample period, the frequency

returned to the programmable controller processor would be:

Frequency = Counts/Sample period = 3 counts/50 ms = 60 Hz

Sample Period

You can set the sample period used in the frequency calculation in the rate

measurement mode. Allowable values are 10 ms to 3 s in 10 ms increments. The

default value is 1 s.

Connection to Counter Inputs

The only user connections used in the rate measurement mode are to phase A of

the module. The Z (gate/reset) and channel B terminals are not used in

this mode.

Pulse Width Modulation

The module can generate a pulse width modulation signal that may be tied to any

output. By specifying a period (configuration word 2) and gate interval

(configuration word 2 or 3) together with the PWM configuration word 2 or 3, a

counter and its first ON/OFF window comparator is assigned and the signal

generated. The actual duty cycle is specified by output words 2 and 3.

12 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 21

Overview of the Very High Speed Counter Module

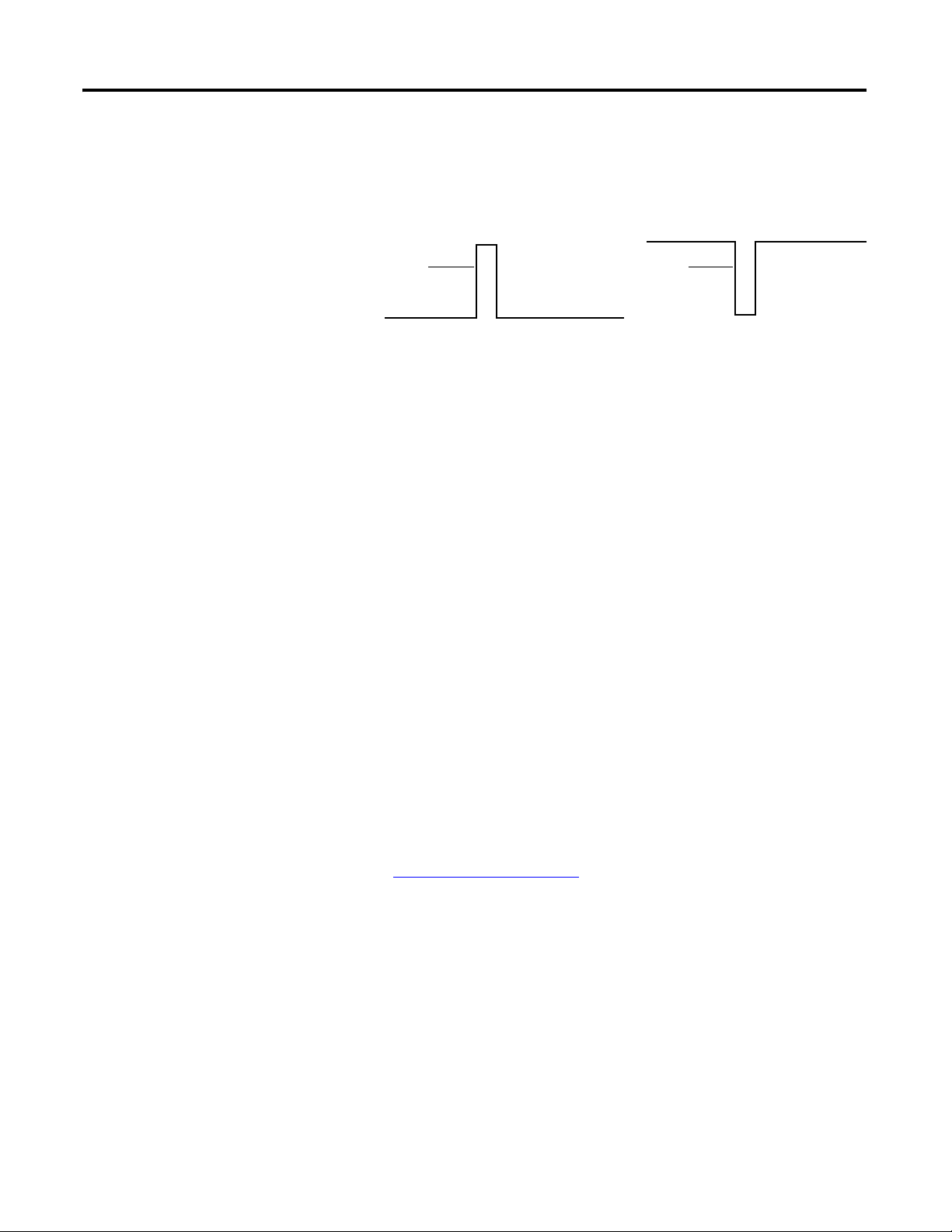

Output turns on at

count value of 2000

Output remains energized for

3000 additional counts

Output turns off at

count value of 5000

Outputs

The 1794-VHSC module has 4 outputs, isolated in groups of 2. Each of the

outputs is capable of sourcing current and will operate between 5 and 24V DC.

You must connect an external power supply to each of the outputs. The outputs

can source 1 A DC alone or in combination. The outputs are hardware-driven

and will turn on in about 25 s when the appropriate count value has been reached.

Enabling and Forcing Outputs

Outputs may be forced on or off independent of count or frequency value. To

force the outputs, they must first be enabled. Enabling the outputs is done

through a data table word 1, bits 1, 5, 9 and 13 (see Figure 1794-VHSC — High

Speed Counter Module Image Table Mapping on page 35). Once the outputs

have been enabled, they may be forced on by setting bits 0, 4, 8 or 12 in word 1.

The outputs can be forced off by setting the enable bit to 0.

Assigning Outputs to Counter Windows

By setting bits in the configuration block, you can assign the outputs on the

module to any of the various counter windows. You can assign any output to any

count window with no restrictions.

Operation of Outputs

When the outputs for the 1794-VHSC module are enabled and assigned to a

counter window they operate in an ON-OFF fashion. For example, assume that

the module were programmed to turn ON an output when a count value of 2000

was reached. Further, assume that the user desired to have the output remain

energized for a period of 3000 counts and then turn OFF. The end result would

be that the outputs would turn ON at count of 2000, would remain energized for

3000 additional counts, and would turn OFF at 5000 counts. The ON and OFF

values are circular around zero (see Figure On-Off Operation of Output

page 13).

On-Off Operation of Output

Using output 0 as an example, when the value in Counter ON Value is less than

the value in Counter OFF Value, the output turns on at 2000 and off at 5000. If

the value in Counter ON Value is greater than the value in Counter OFF Value,

the output turns off at 2000 and on at 5000 (see Figure Effect of Values in On/

Off Operation on page 14).

on

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 13

Page 22

Overview of the Very High Speed Counter Module

Output turns on at

count value of 2000

Output remains energized for

3000 additional counts

Output turns off at

count value of 5000

Output turns off at

count value of 2000

Output turns on at

count value of 5000

When values in Counter On Value are less than

values in Counter Off Value.

When values in Counter On Value are greater

than values in Counter Off Value.

Effect of Values in On/Off Operation

Isolation of Outputs

The module provides 850V DC isolation between each of the outputs and

the FlexBus.

Connecting Outputs to Counters

You can connect any of the outputs to any of the counter inputs. In this way, it is

possible to use the outputs to reset a counter or to cascade counters. If using the

outputs this way, make certain that the output voltage is compatible with the

chosen input.

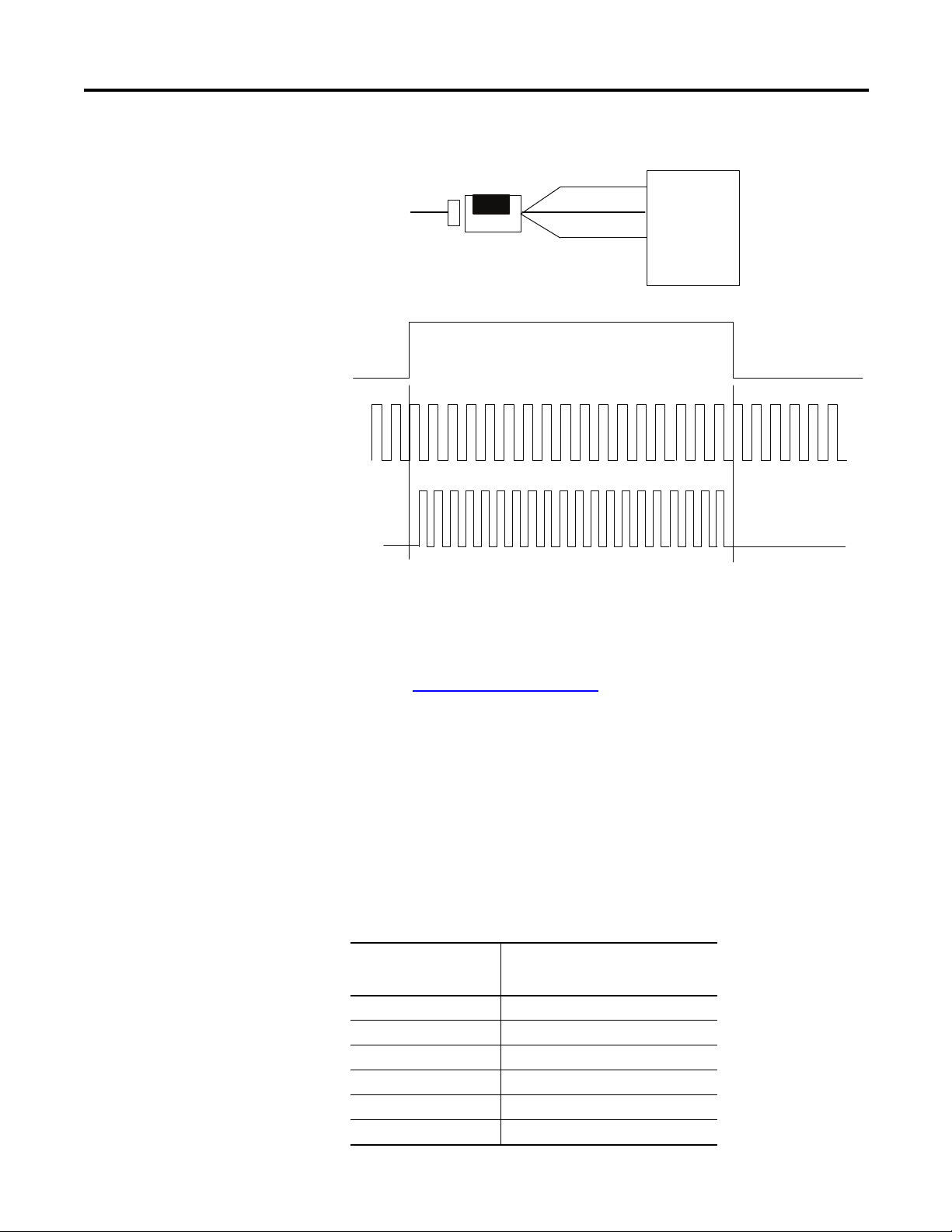

What the Module Does

The very high speed counter module performs high-speed scaling calculation

operations for various industrial applications. The module interfaces with a

FLEX I/O family EtherNet/IP adapter which then communicates with a

programmable controller processor.

The adapter/power supply transfers data to and from the module over the

FlexBus. Instructions in the programmable controller facilitate this

communication and let you write output values and configure the module’s mode

of operation. Figure FLEX I/O Communication Process on page 15 describes the

communication process.

14 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 23

FLEX I/O Communication Process

The adapter transfers your configuration

data to the module.

The adapter transfers the

data over the FlexBus.

The adapter and module determine

that the transfer was made without

error and input values are within a

specified range.

EtherNet/IP transfers the data to the

programmable controller data table.

The module converts

frequency signals into

binary format and stores

these values until the

adapter requests their

transfer.

External devices transmit

frequency signals to the module.

FlexBus

45896

Overview of the Very High Speed Counter Module

1

Allen-Bradley

4

VERY HIGH SPEED COUNTER MODULE

1794-VHSC

1

ok

5

2

3

6

1. The adapter transfers your configuration data and commands to the

module.

2. External devices generate input signals that are transmitted to the module.

3. The module converts these signals into binary format, and stores these

values and controls their output until the adapter requests their transfer.

4. The adapter transfers the data over the FlexBus.

5. The adapter and module determine that the transfer was made without

error and inputs values are within a specified range.

6. EtherNet/IP transfers the data to the programmable controller data table.

Chapter Summary

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 15

In this chapter you learned how your module operates, and how your module

communicates with the programmable controller.

Page 24

Overview of the Very High Speed Counter Module

Notes:

16 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 25

Install Your FLEX I/O VHSC Module

Chapter

2

Overview

Before You Install Your Module

This chapter describes how to physically install the 1794-VHSC adapter on the

DIN rail and connect it to the EtherNet/IP network.

Topic Page

Before You Install Your Module

Power Requirements 17

Install the Module 18

Mount on a DIN Rail 18

Mount on a Panel or Wall 20

Mount the 1794-VHSC Module on the Terminal Base

Unit

Wiring Information 23

Connect Wiring to the FLEX I/O VHSC Input Module 24

Connect Wiring Using a 1794-TB3G, 1794-TB3GK or

1794-TB3GS Terminal Base Unit

Before installing your 1794-VHSC very high speed counter module, you need to:

• Calculate the power requirements of all modules in the FLEX I/O system,

and,

• Position the keyswitch on the terminal base.

17

21

24

Power Requirements

The wiring of the terminal base unit is determined by the current draw through

the terminal base. Make certain that the current draw does not exceed 10 A.

ATTENTION: Total current draw through the terminal base unit is

limited to 10 A. Separate power connections may be necessary.

Methods of wiring the terminal base units are shown in Wiring Inform

page 23.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 17

ation on

Page 26

Install Your FLEX I/O VHSC Module

1

2

3

4

6

7

7

8

9

0

2

+

2

+

45319

Install the Module

Installation of the module consists of:

• mount the terminal base unit

• install the 1794-VHSC module into the terminal base unit

• install the connecting wiring into the terminal base unit

If you are installing your module into a terminal base unit that is already installed,

proceed to See Mount on a DIN Rail

on page 18.

Mount on a DIN Rail

ATTENTION: Do not remove or replace a terminal base unit when

power is applied. Interruption of the FlexBus can result in unintended

operation or machine motion.

Install the Terminal Base Unit

1. Remove the cover plug in the male connector of the unit to which you are

connecting this terminal base unit.

2. Check to make sure that the 16 pins in the male connector on the adjacent

device are straight and in line so that the mating female connector on this

terminal base unit will mate correctly.

Make certain that the female FlexBus connector is fully retracted into the

base unit.

18 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 27

Install Your FLEX I/O VHSC Module

2

+

2

+

45320

2

+2+

45321

2

+

2

+

45322

3. Position the terminal base at a slight angle and hooked over the top of the

35 x 7.5 mm DIN rail A (Allen Bradley part number 199-DR1; 46277-3).

4. Slide the terminal base over tight against the adapter, or proceeding

terminal base. Make sure the hook on the terminal base slides under the

edge of the adapter, or proceeding terminal base, and the FlexBus

connector is fully retracted.

5. Pivot the terminal base onto the DIN rail with the top of the rail hooked

under the lip on the rear of the terminal base.

Use caution to make sure that the female FlexBus connector does not strike

any of the pins in the mating male connector.

6. Press down on the terminal base unit to lock the terminal base on the DIN

rail. If the terminal base does not lock into place, use a screwdriver or

similar device to open the locking tab, press down on the terminal base

until flush with the DIN rail and release the locking tab to lock the base in

place.

Gently push the FlexBus connector into the side of the adapter, or

proceeding terminal base to complete the backplane connection.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 19

Page 28

Install Your FLEX I/O VHSC Module

(1.4)

35.5

0

1

7

2

3

4

6

7

8

9

2

+

2

+

1

2

3

4

45323

Millimeters

(inches)

For specific wiring information, refer to the installation instructions for the

module you are installing in this terminal base unit.

7. Repeat the above steps to install the next terminal base unit.

Ensure that the cover of the FlexBus connector on the last terminal base

unit is in place.

Mount on a Panel or Wall

Installation of a FLEX I/O system on a wall or panel consists of:

• laying out the drilling points on the wall or panel.

• drilling the pilot holes for the mounting screws.

• mounting the adapter mounting plate.

• installing the terminal base units and securing them to the wall or panel.

Use the mounting kit Cat. No. 1794-NM1 for panel or wall mounting.

1794-NM1 Mounting Kit

Description Description

1 Mounting plate for adapter 3 Terminal base unit (not included)

2 #6 Self-tapping screws 4 Adapter module (not included)

To install the mounting plate on a wall or panel:

Lay out the required points on the wall or panel as shown in the Figure Drilling

Dimensions for Panel or Wall Mounting on page 21.

20 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 29

Drilling Dimensions for Panel or Wall Mounting

45327

IMPORTANT

Install Your FLEX I/O VHSC Module

Millimeters

(Inches)

21 (0.83)

35.5

(1.4)

58.5

(2.3)

35.5

(1.4)

58.5

(2.3)

35.5

(1.4)

8. Drill the necessary holes for the #6 self-tapping mounting screws.

9. Mount the mounting plate for the adapter module using two #6 self-

tapping screws – 18 screws are included for mounting up to 8 modules and

the adapter.

Make certain that the mounting plate is properly grounded to the

panel. Refer to Industrial Automation Wiring and Grounding

Guidelines, publication 1770-IN041

.

10. Hold the adapter at a slight angle and engage the top of the mounting plate

in the indention on the rear of the adapter module.

11. Press the adapter down flush with the panel until the locking lever locks.

12. Position the terminal base unit up against the adapter and push the female

bus connector into the adapter.

13. Secure to the wall with two #6 self-tapping screws.

14. Repeat for each remaining terminal base unit.

Mount the 1794-VHSC Module on the Terminal Base Unit

The 1794-VHSC module mounts on a 1794-TB3G or 1794-TB3GS terminal

base unit.

1. Rotate keyswitch (3) on terminal base unit (4) clockwise to position 1 as

required for the module.

Do not change the position of the keyswitch after wiring the terminal base

unit.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 21

Page 30

Install Your FLEX I/O VHSC Module

1

2

3

4

5

6

7

8

Label here or under here

40231

FLEX I/O Terminal Base and Very High Speed Counter Parts

Description Description

1 FlexBus connector 5 Base unit

2 Latching mechanism 6 Alignment groove

3 Keyswitch 7 Alignment bar

4 Cap plug 8 Module

2. Make certain the FlexBus connector (1) is pushed all the way to the left to

connect with the neighboring terminal base or adapter.

You cannot install the module unless the connector is fully extended.

3. Make sure the pins on the bottom of the module are straight so they will

align properly with the connector in the terminal base unit.

ATTENTION: If you remove or insert the module while the

backplane power is on, an electrical arc can occur. This could

cause an explosion in hazardous location installations. Be sure that

power is removed or the area is nonhazardous before proceeding.

4. Position the module (8) with its alignment bar (7) aligned with the groove

(6) on the terminal base.

5. Press firmly and evenly to seat the module in the terminal base unit.

The module is seated when the latching mechanism is locked into the

module.

6. Remove cap plug and attach another terminal base unit to the right of this

terminal base unit if required.

Make sure the last terminal base has the cap plug in place.

22 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 31

Install Your FLEX I/O VHSC Module

IMPORTANT

Digital input

module

Digital input

module

Digital output

module

VHSC

module

VHSC

module

Frequency input

module

VHSC

module

VHSC

module

Daisy-chaining

Individual

24V DC

24V DC

24V DC

24V DC

Wiring when total current draw is less than 10 A

Wiring when total current draw is greater than 10 A

Note: Do not use any digital modules in this configurations.

Note: Use this configuration if using any digital output

modules that could couple transients to the 24V supply.

1794-VHSC module wiring separate from digital wiring.

45897

The adapter is capable of addressing eight modules. Do not exceed a

maximum of eight terminal base units in your system.

Wiring Information

This section provides essential wiring information for the 1794-TB3G, 1794TB3GK, and 1794-TB3GS terminal base units. It also includes instructions for

connecting wiring to the FLEX I/O module.

Wire the Terminal Base Units (1794-TB3G shown)

ATTENTION: Take note of the following considerations when wiring

your terminal base units:

· AIl modules must be frequency or analog modules for the daisychain

configuration.

· Use the individual type of configuration for any "noisy" DC digital I/O

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 23

Wiring the FLEX I/O VHSC Input module is done using the 1794-TB3G,

1794-TB3GK or the 1794-TB3GS terminal base unit.

modules in your system.

· All modules powered by the same power supply must be frequency or

analog modules for the combination type of configuration.

Page 32

Install Your FLEX I/O VHSC Module

0123456789101112131415

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

A

B

C

A

B

C

1794-TB3G or 1794-TB3GK

1794-TB3GS

0...15

34...51

16...33

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

18 19 20 21 22 23 3324 25 26 27 28 29 30 31 3217

35 36 37 38 47 48 49 5034 51

16

39 40 41 42 43 44 45 46

Label placed at top of wiring area

34 and 50 = 24V DC

35 and 51 = common

16 and 33 = chassis

40…45 = chassis ground

35 and 51 = common

34 and 50 = 24V DC

16 and 33 = chassis ground

40…45 = chassis ground

45328

1794-TB3G, 1794-TB3GK and 1794-TB3GS Wiring Connections

Connect Wiring to the FLEX I/O VHSC Input Module

24 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Wiring to the 1794-VHSC Input module is made through the terminal base unit

on which the module mounts.

The module is compatible with the 1794-TB3G, 1794-TB3GK and 1794TB3GS terminal base units.

Connect Wiring Using a 1794-TB3G, 1794-TB3GK or 1794-TB3GS Terminal Base Unit

1. Connect the individual signal wiring to numbered terminals on the 0…15

row (A) for 24V inputs (terminals 0…5 and 8…13) and 17…32 row (B) for

5V inputs (terminals 17…22 and 25…30) on the terminal base unit.

Connect the input devices as shown in Ta b l e

1794-VHSC High Speed Counter Module on page 26.

ATTENTION: Do not connect 24V signals to the 5V input terminals.

Permanent damage to the module will result.

2. Connect individual output wiring to terminals 6, 7 and 14, 15 on the

0…15 row (A) and terminals 23, 24 and 31, 32 on the 16…32 row (B) on

the terminal base unit. Connect output return wiring for channels 0, 1, 2,

and 3 to terminals 23, 24 31 and 32 respectively. Connect the output

devices as shown in Ta b l e

Speed Counter Module on page 26

3. Terminate shields to terminals 16 or 33 on row B, or 40…45 on row C.

Wiring connections for the 1794-VHSC High

Wiring connections for the

Page 33

Install Your FLEX I/O VHSC Module

4. Connect 24V DC to terminal 34 on the 34…51 row (C), and 24V

common to terminal 35 on the 34…51 row (C).

ATTENTION: To reduce susceptibility to noise, power frequency

modules and digital modules from separate power supplies. Do not

exceed a length of 10 m (33 ft) for DC power cabling.

5. If daisychaining the 24V DC power to the next 1794-TB3G, 1794-

TB3GK or 1794-TB3GS base unit, connect a jumper from terminal 50

(24V) on this base unit to terminal 34 and from terminal 51 (24V DC

common) to terminal 35 on the next 1794-TB3G, 1794-TB3GK or

1794-TB3GS base unit.

6. Connect output power wiring to terminals 37 (+) and 39 (-) for outputs

0 and 1, and terminals 46 (+) and 48 (-) for outputs 2 and 3.

ATTENTION: Use extreme care when connecting wiring to an

adjacent terminal base unit. Wiring for the 1794-TB3G and

1794-TB3GS terminal base units is different from other 1794 terminal

base units.

ATTENTION: Do not daisychain power or ground from the 1794TB3G, 1794-TB3GK or 1794-TB3GS terminal base unit to any AC or DC

digital module terminal base unit.

ATTENTION: 24V DC power must be applied to your module before

operation. If power is not applied, the module position will appear to

the adapter as an empty slot in your chassis. If the adapter does not

recognize your module after installation is completed, cycle power to

the adapter.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 25

Page 34

Install Your FLEX I/O VHSC Module

17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16

35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

34

COM

6 Chassis ground

for shields

Chassis GND

Chassis GND

AAB

BZ

O1O0 O3O2

O1O0

O3

O2

Z

A

AB

BZ

ZAAB

BZ

Z

AAB

BZ

Z

24V inputs

24V inputs

5V inputs

5V inputs

-V+V-V+V

+24V

COM

+24V

24V DC

base power

24V DC

base power

A, A - incremental encoder input A (+5 or +24V DC)

B B

- incremental encoder input B (+5 or +24V DC)

Z, Z - incremental encoder input Z (+5 or +24V DC)

O = sourcing outputs

R = returns for sourcing outputs

+V = +5 or +24V DC isolated power externally supplied for outputs (1 A max)

-V = negative isolated power connection (1 A max)

+24V DC = 24V DC terminal base power for module

COM = return for +24V DC terminal base power for module

Chassis Gnd = chassis ground for input or output cable shields

45898

Where:

Connections for Terminal Base 1794-TB3G or 1794-TB3GK shown

Wiring connections for the 1794-VHSC High Speed Counter Module

Incremental

Encoder Input

Input A 0 8

26 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Input A

Input B 2 10

Input B

Input Z 4 12

Input Z

Input A 17 25

Input A

Input B 19 27

Terminal Base Units 1794-TB3G, 1794-TB3GK,

1794-TB3GS

Channel 0 Channel 1

+24V Inputs

19

311

513

+5V Inputs

Channel 0 Channel 1

18 26

Page 35

Install Your FLEX I/O VHSC Module

Wiring connections for the 1794-VHSC High Speed Counter Module

Input B

Input Z 21 29

Input Z 22 30

Output Sourcing Out Return Output Sourcing Out Return

O0 6 23 O1 7 24

O2 14 31 O3 15 32

+24V DC

Base power

+24V DC COM Terminals 35 and 51

+5V or +24V

Output power

-V Output power Terminals 39 and 48

Chassis GND Terminals 16, 33, and 40…45

20 28

Outputs

Terminals 34 and 50

Terminals 37 and 46

ATTENTION: Total current draw through the terminal base unit is

limited to 10 A. Separate power connections to the terminal base unit

may be necessary.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 27

Page 36

Install Your FLEX I/O VHSC Module

45899

Example of Quadrature Encoder Differential Wiring to a 1794-TB3G or 1794-TB3GK

Terminal Base Unit

A

B

Z(Store count)

(Gate/reset)

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

0

0 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33

34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51

1794-TB3G

Quadrature encoder

(for example: 845H-SJ__24DRY__ )

Mechanical switch

0…15

16…33

34…51

A

B

C

24V Base power

Chapter Summary

12V

+-

Solenoid

ATT ENTI ON: Keep exposed area of inner conductor as short

as possible.

This chapter provided you with instructions on how to install the module in an

existing programmable controller system and how to wire to a terminal

base unit.

28 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 37

Communicate With Your Module

45900

Chapter

3

Overview

Communication Over the I/O Backplane

Read this chapter to familiarize yourself with configurable features on the

1794-VHSC Very High Speed Counter module

For Information About See Page

Communication Over the I/O Backplane

I/O Structure 31

Safe State Data 32

Device Actions 32

1794-VHSC — High Speed Counter Module Image

Table Mapping

Input Status Word Bits 32

Bit/Word Definitions 37

Configuration Word Definition 42

29

35

One 1794-AENT or 1794-AENTR EtherNet/IP adapter can interface up to

eight terminal base units with installed FLEX I/O modules, forming a FLEX I/O

system of up to eight slots. The adapter communicates to other network system

components (typically one or more controllers or scanners, and/or programming

terminals) over the EtherNet/IP network. The adapter communicates with its

I/O modules over the backplane.

0

EtherNet/IP

Adapter

Read

Write

Inputs

Status

Outputs

Configuration

Read

Words

Write

Words

15

Inputs

Status

Outputs

Configuration

Inputs

Status

Outputs

Configuration

Data is exchanged scheduled when mapped, or unscheduled using EtherNet/

IP instructions.

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 29

Page 38

Communicate With Your Module

Scheduled Data-Transfer

Scheduled data transfer:

•is continuous

• is asynchronous to the ladder-logic program scan

• occurs at the actual rate displayed in the Actual Packet Interval field on the

programming software I/O mapping (monitor) screen

Unscheduled Data-Transfer

Unscheduled operations include:

• unscheduled non-discrete I/O data transfers — through I/O transfer

instructions

• peer-to-peer messaging — through Message (MSG) instructions

• messaging from programming devices

Unscheduled messaging on an EtherNet/IP network is non-deterministic. Your

application and your configuration — number of nodes, application program,

NUT, amount of scheduled bandwidth used, and so on — determine how much

time there is for unscheduled messaging.

Module I/O Mapping

The I/O map for the 1794-VHSC module is divided into read words and write

words. Read words consist of input and status words, and write words consist of

output and configuration words. The number of read words or write words can

be 0 or more. The length of each I/O modules read words and write words vary in

size depending on module complexity. Each I/O module will support at least 1

input word or 1 output word. Status and configuration are optional, depending

on the module. The 1794-VHSC module has 9 input words, no status words, 4

output words and 56 configuration words.

Application of New Configurations

When a configuration is sent to the 1794-VHSC module, it is checked for

consistency before being applied. If an error is found in the configuration, the PE

bit (input word 8, bit 15) is asserted and the module locally retains its previous

configuration. To isolate any problems an improperly configured module may

have, the user application program (ladder program, for instance) should monitor

this error.

30 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 39

Communicate With Your Module

45901

I/O Module Fault Bits

Not used

Node Address Changed Bit

Bit: 15 01413121110987654321

Slot 0

Slot 1

Slot 2

Slot 3

Slot 4

Slot 5

Slot 6

Slot 7

Node Address Changed Bit

Created by controller

{

45902

If the configuration is considered acceptable, the counter application specific

integrated circuit (ASIC) is disabled — counting is suspended and outputs are

shut off — while the ASIC is loaded with the new operational parameters.

I/O Structure

Output data is received by the adapter in the order of the installed I/O modules.

The Output data for Slot 0 is received first, followed by the Output data for Slot

1, and so on up to slot 7.

The first word of input data sent by the adapter is the Adapter Status Word. This

is followed by the input data from each slot, in the order of the installed I/O

modules. The Input data from Slot 0 is first after the status word, followed by

Input data from Slot 2, and so on up to slot 7.

EtherNet/IP adapter

Adapter Status

Slot 0 Input Data

Slot 1 Input Data

Slot 7 Input Data

Adapter Status

Slot 0 Output Data

Slot 1 Output Data

Read

Write

Slot 0 Slot 1 Slot 7

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 31

Adapter Input Status Word

The input status word consists of:

• I/O module fault bits — 1 status bit for each slot

• node address changed — 1 bit

•I/O status — 1 bit

Slot 7 Output Data

Page 40

Communicate With Your Module

The adapter input status word bit descriptions are show in Table Input Status

Wor d Bi ts on page 32.

Input Status Word Bits

Bit Description Bit Explanation

I/O Module Fault 0 This bit is set (1) when an error is detected in slot position 0.

1 This bit is set (1) when an error is detected in slot position 1.

2 This bit is set (1) when an error is detected in slot position 2.

3 This bit is set (1) when an error is detected in slot position 3.

4 This bit is set (1) when an error is detected in slot position 4.

5 This bit is set (1) when an error is detected in slot position 5.

6 This bit is set (1) when an error is detected in slot position 6.

7 This bit is set (1) when an error is detected in slot position 7.

Node address

changed

I/O state 9 Bit = 0 – idle

8 This bit is set (1) when the node address switch setting is changed

since power up.

Bit = 1 – run

10…15 Not used – set to 0.

Safe State Data

Device Actions

Possible causes for an I/O module fault are:

• transmission errors on the FLEX I/O backplane

•a failed module

• a module removed from its terminal base

• an incorrect module inserted in a slot position

• an empty slot

• a non-discrete module in the slot

The EtherNet/IP adapter does not provide storage for alternate module output

data during communication faults or processor idle state. This safe state data is

stored in the 1794-VHSC module and may be defined using configuration

software. Safe state data assures that a known output will be applied to the output

devices to maintain a previously designated safe operating condition during the

previously mentioned failure modes. This data is sent in the configuration block.

For more information, Table 1794-VHSC — High Speed Counter Module

Image Table Mapping on page 35.

Device actions include:

• communication fault behavior

• idle state behavior

• input data behavior upon module removal

32 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 41

Communicate With Your Module

Communication Fault Behavior

You can configure the 1794-VHSC response to a communication fault. Upon

detection of a communication fault, the module can:

• leave the module output data in its last state (hold last state)

• reset the module output data to zero (reset)

• apply safe state data to the module output

Idle State Behavior

The 1794-VHSC module responds to idle state according to the

Communication Fault Behavior described above. The module can:

• leave the module output data in its last state (hold last state)

• reset the module output data to zero (reset)

• apply safe state data to the module output

Input Data Behavior upon Module Removal

I/O module input data sent by the adapter upon module removal is configurable.

The adapter can:

• reset the module output data to zero (reset)

• leave the module output data in the last state before module removal (hold

last state)

Frequency/Resolution Enhancement

This mode is only for use in modules with firmware revision D or later.

Frequency/Resolution Enhancement is a precise configuration which handles the

decimal position adjustment to frequency count. Using this mode allows the

module to read the frequency up to two positions to the right or left of the

decimal place. For example, a rounded frequency of 13 Hz can be displayed as

1257 or 12.57. The mode is only valid when the module is configured for Period

Rate or Continuous Rate.

Frequency Resolution/Enhancement reports the frequency back as a floating

point value in a single word and allows configuration of decimal places of

resolution.

The upper byte of the counter control word (output word 0) is reserved for

special mode, Enhancing Frequency/Resolution. In this mode, you can change

significant digits of frequency display based on output word 2 for channel 0 and

output word 3 for channel 1. Decimal point placement is absolute positioning. -2

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 33

Page 42

Communicate With Your Module

moves decimal point left 2 places dividing the frequency value by 100; +1 moves

the decimal point 1 place, multiplying by 10, and so on. This allows frequency

values to fit in a single word.

Applying the Frequency/Resolution Enhancement

To use this mode, proceed as follows.

ATTENTION: Use this enhancement mode with caution since no

checks are performed to verify data. Unintended operation can occur.

1. Power up the FLEX chassis, or put the controller into RUN mode, or

both. Let the 1794-VHSC module initialize as normal. Wait for the OK

indicator on the module to go solid green.

2. You must place ladder logic in your PLC that performs the following:

a. Set a value between -4 and +2 into output word 2 and/or 3.

b. Then set (1) the M11 bit in the upper byte of control word 0.

When the upper byte of the output word is not zero, the status

indicator flashes red, and the TF bit (bit 12, input word 8) is asserted.

c. Next, reset (0) the M11 bit in the upper byte of output control word 0.

Clearing the upper byte of output word 0 restores the module to an

operational state, clears the TF bit in input word 8 and returns the

indicator to green. The module is now in enhanced mode.

3. To tu rn th is f ea t ur e o f f :

a. Set output word 2 or 3 to zero (no value)

b. Set (1) the M11 bit

c. Then reset (0) the M11 bit

34 Rockwell Automation Publication 1794-UM010D-EN-E - July 2013

Page 43

Communicate With Your Module

45903

1794-VHSC — High Speed Counter Module Image Table Mapping

I/O Image

Input Size

1…9Words

Output Size

0…4Words

Configuration Size

56 Words

0

1

2

3

4

5

6

7

PE FP NR TF OS OS OS OS C1 C0 ZF ZS C1 C0 ZF ZS

8

0

1

Reserved

0 LC OE FO 0 LC OE FO 0 LC OE FO 0 LC OE FO

2

3

0

1

2

3

4

Channel 0 Current Count (least significant word)

Channel 0 Current Count (most significant word)

Channel 1 Current Count (least significant word)

Channel 1 Current Count (most significant word)

Channel 0 Stored/Accumulated Count (least significant word)

Channel 0 Stored/Accumulated Count (most significant word)

Channel 1 Stored/Accumulated Count (least significant word)

Channel 1 Stored/Accumulated Count (most significant word)

M11

Reserved

VRCPCR0 VRCP CR

0

Channel 0 PWM Output Value (0…95.00%)

Channel 1 PWM Output Value (0…95.00%)

Counter Configuration

Filter Selection

Time Base Value/PWM Period

Channel 0 Gate Interval

Channel 1 Gate Interval

5

6

7

8

9

10

11

12

13

Channel 0 Rollover Value (least significant word)

Channel 0 Rollover Value (most significant word)

Channel 1 Rollover Value (least significant word)

Channel 1 Rollover Value (most significant word)

Channel 0 Preset Value (least significant word)

Channel 0 Preset Value (most significant word)

Channel 1 Preset Value (least significant word)

Channel 1 Preset Value (most significant word)

14

15

16

00000000 S3S4S2 S1F4F3F2F1

Reserved

Channel 0 Scaler

Channel 1 Scaler

Rockwell Automation Publication 1794-UM010D-EN-E - July 2013 35

Page 44

Communicate With Your Module

45904

Configuration Size

(continued)

56 Words

17

00000000 S3S4S2 S1F4F3F2F1

18

00000000 S3S4S2 S1F4F3F2F1

19

00000000 S3S4S2 S1F4F3F2F1

20

21

22

23

24

25

26

27

28

29

30

31

32

First Counter 1st On Value (least significant word)

First Counter 1st On Value (most significant word)

First Counter 1st Off Value (least significant word)

First Counter 1st Off Value (most significant word)

First Counter 2nd On Value (least significant word)

First Counter 2nd On Value (most significant word)

First Counter 2nd Off Value (least significant word)

First Counter 2nd Off Value (most significant word)

First Counter 3rd On Value (least significant word)

First Counter 3rd On Value (most significant word)

First Counter 3rd Off Value (least significant word)

First Counter 3rd Off Value (most significant word)

First Counter 4th On Value (least significant word)

33

34

35

36

37

38

39

40

41

42

43

44

46

47

48

First Counter 4th On Value (most significant word)

First Counter 4th Off Value (least significant word)

First Counter 4th Off Value (most significant word)

Second Counter 1st On Value (least significant word)

Second Counter 1st On Value (most significant word)

Second Counter 1st Off Value (least significant word)

Second Counter 1st Off Value (most significant word)

Second Counter 2nd On Value (least significant word)

Second Counter 2nd On Value (most significant word)

Second Counter 2nd Off Value (least significant word)

Second Counter 2nd Off Value (most significant word)

Second Counter 3rd On Value (least significant word)

45

Second Counter 3rd On Value (most significant word)

Second Counter 3rd Off Value (least significant word)

Second Counter 3rd Off Value (most significant word)

Second Counter 4th On Value (least significant word)

49

econd Counter 4th On Value (most significant word)

S