Page 1

Bulletin 1494V Variable Depth Disconnect Switch Installation Instructions

(Cat 1494V-DS600 - Series D)

WARNING

WARNING

To prevent electrical shock, disconnect from power source before installing or servicing. Follow

NFPA 70E requirements. Install in suitable enclosure. Keep free from contaminants.

The following procedures are critical to the proper operation of the disconnect handle and switch.

Failure to follow these steps can result in damage to the equipment and/or serious injury or death to the

operator.

Table of Contents Page

Quick Installation Guide 2

-

Disconnect Switch Installation

- Disconnect Handle Installation

- Cutting Connecting Rod

Quick Installation Guide (continued) 3

Connecting Rod Installation

-

Connecting Rod Adjustment Procedure 4

Enclosure Without Handle Cutout 5

- Locate Handle

- Drill Handle Holes

Door Catch Mounting Bracket Installation 6

Disconnect Switch Installation 7

-

Locate Disconnect Switch

- Install Disconnect Switch

- Assemble and Install Line Terminal Guard

Conversion from Right Hand to Left Hand Operation 8

Trailer Fuse Block Installation 9

Fuse Clip Installation 10

Bulletin 1494V Disconnect Switch Kit 11

Bulletin 1494V Disconnect Switch Kit Optional Accessory List 12

42052-183-01

DIR 42052-183 (Version 03)

Printed in U.S.A.

Page 2

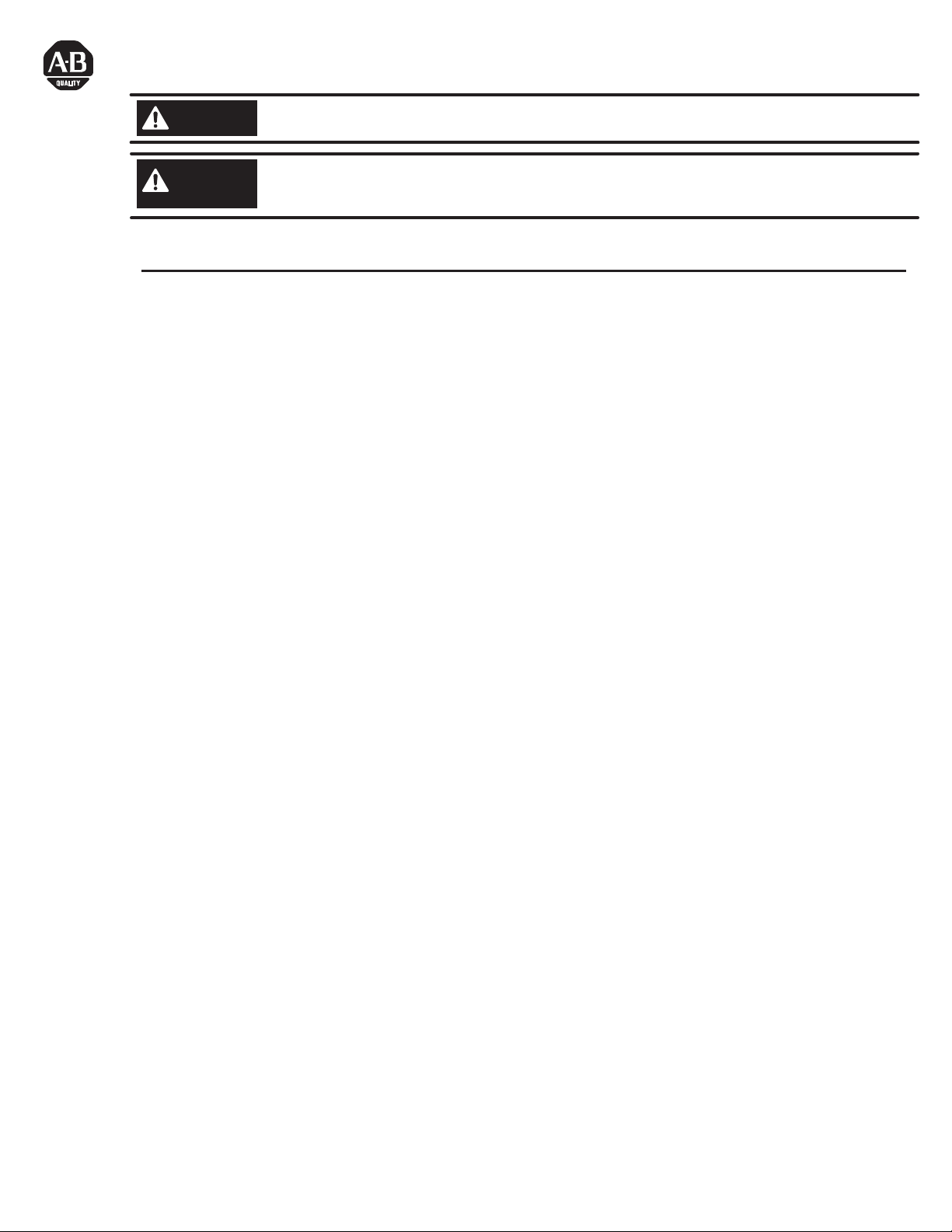

QUICK INSTALLATION GUIDE

Disconnect Switch Installation (Right hand installation shown. For left hand installation follow similar procedure.)

1

Use template D to locate handle holes on mounting plate.

4

2

OLE

TOP HANDLE H

MEASURE TO

INSIDE OF THE

HOLD FLUSH

TO INSIDE

TAPE

TOP OF ENCLOSURE

D

OF ENCLOSURE

BOTTOM HANDL

3

E HOLE

INSIDE OF THE

TOP OF ENCLOSURE

D

Disconnect Handle Installation

2

Install gasket.

1

MEASURE TO

HOLD FLUSH

TO INSIDE

OF ENCLOSURE

TOP

BOTT

11

2 3

Overlay template F (600 A) over D .

5

8-1/4"

4-1/8"

HOLD FLUSH

MEASURE TO

INSIDE OF THE

OF ENCLOSURE

TOP OF ENCLOSURE

Switch Mounting Holes

Center punch and drill (4) 9/32" holes for #5/16-18 thread

forming (TAP-TITE) screws provided with switch

15"

A

Disconnect Switch Hole Location Template (600A)

RIGHT Hand Installation

(Use opposite side for left hand installation)

6

Center punch

F

)

1

5-01 (

8

.

A

-1

S.

2

.

U

n

i

d

e

4205

int

r

P

and drill (4) holes

for 5/16-18 thread forming

screws provided with switch.

9/32" Dia.

Install handle and spring bracket.

TO INSIDE

Install disconnect switch.

7

/16"

1

2-

6-5/8"

TOP

6-1/2"

BOTT

90 -130 lb-in

Install defeater lever.

60-80 lb-in

IMPORTANT:

Apply grease to O-Ring

7-11 lb-in

to retain into handle groove.

Cutting Connecting Rod (Cut (2) Connecting Rods; first rod connects the handle to the switch, second rod provides

3

stiffening for the enclosure flange)

Measure working depth of enclosure.

1

Mounting

Plate

Enclosure

Working Depth

(Inside Flange

of Enclosure to

Mounting Plate)

Measure, mark and

2

cut (2) connecting rods.

N

N minus 3-3/4"

Remove burrs.

3

42052-183-01

DIR 42052-183 (Version 03)

(2)

Page 3

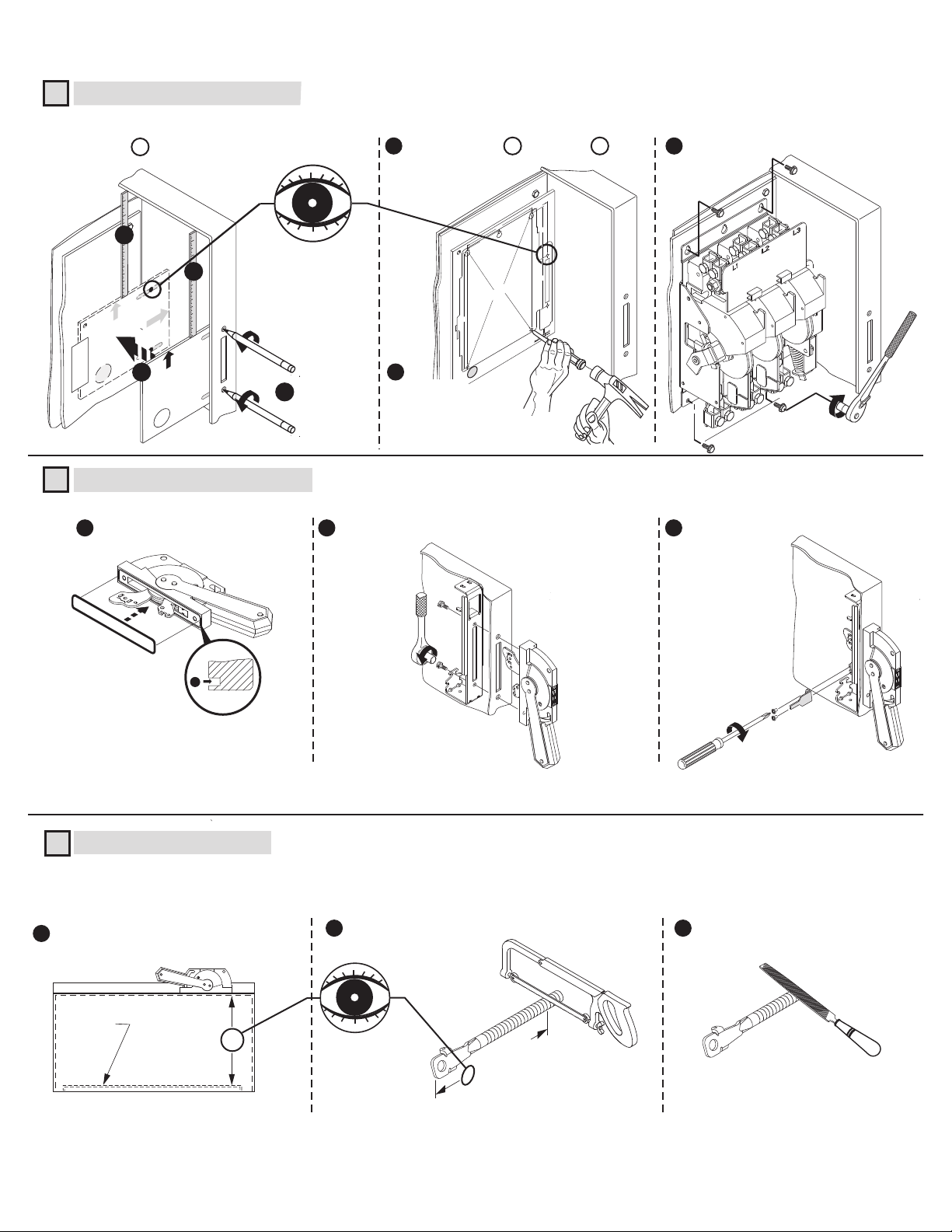

QUICK INSTALLATION GUIDE (CONTINUED)

Connecting Rod Installation

4

First rod connects the handle to the switch

Verify that disconnect switch and handle are in "OFF"

1

position. (Switch blades will be visible)

3

Pull rod up and verify if

rod is 1/2" away from

touching bottom of

spring bracket. (If not,

rotate rod accordingly)

4

O

P

E

N

Rotate connecting rod into

drive bar 15 turns.

2

Connecting

Rod

5

Drive Bar

Hitch Pin

6

Primary Link

1/2"

Clearance

7

8

42052-183-01

DIR 42052-183 (Version 03)

Second rod provides stiffening for the enclosure flange

11

150 - 200 lb-in

9

10

ATTENTION: CHECK FOR PROPER OPERATION

(3)

Page 4

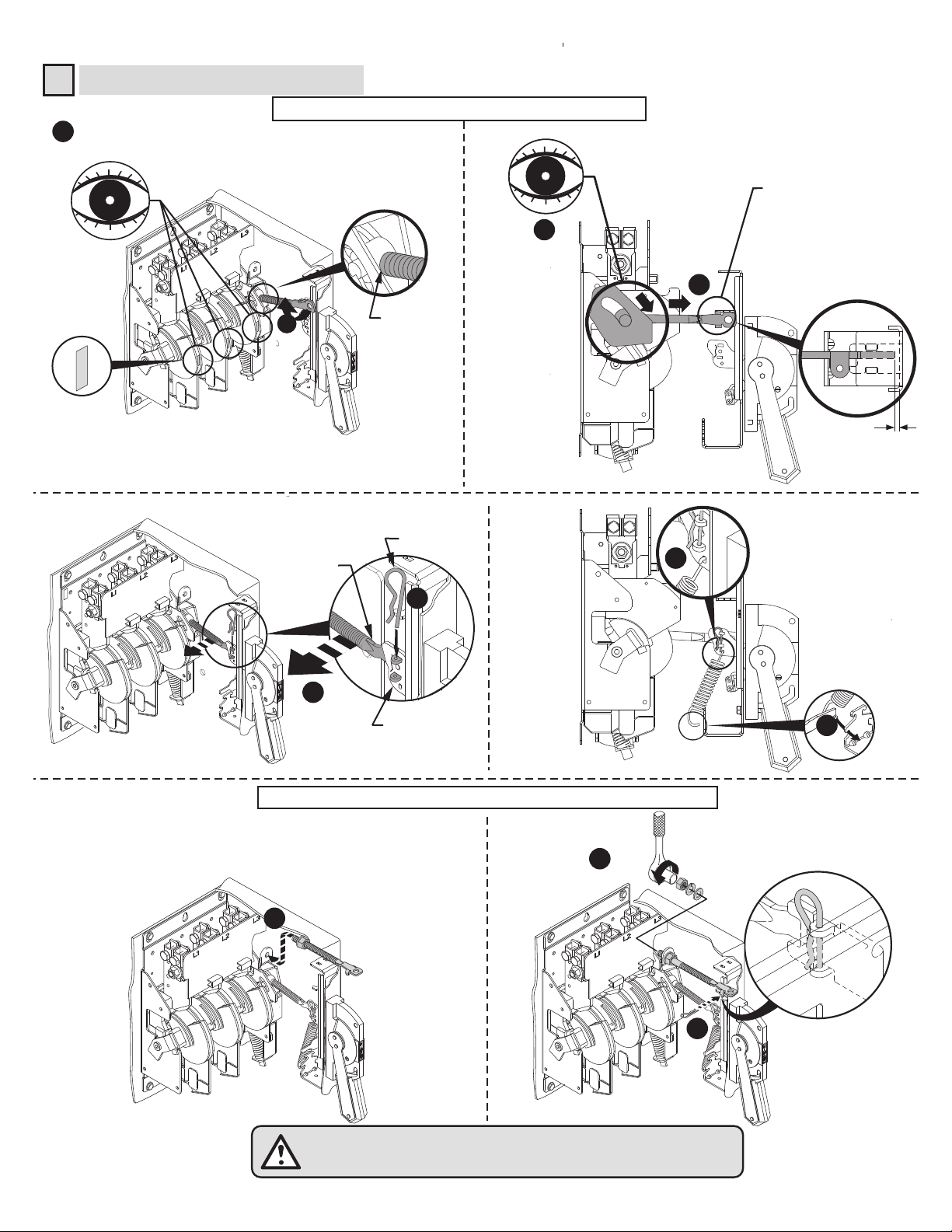

Connecting Rod Adjustment Procedure

2

Drive Bar

Hitch Pin

Connecting

Rod

6

5

Primary Link

"ON" Position

1

Move disconnect handle to the "ON" position.

Ê

If switch does not fully close, return handle to "OFF" position.

Ê

Remove link spring hitch pin and disengage the connectiong rod from the primary link.

Ê

Turn connecting rod counter-clockwise (1 or more) full turns.

Ê

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test

Ê

Repeat Ê - Ê as necessary.

Ê

Re-install link spring

Ê

"OFF" Position

2

Move disconnect handle to the "OFF" position.

Ê

If switch does not fully open, return handle to "ON" position.

Ê

Remove hitch pin and link spring, then disengage the connectiong rod from the primary link.

Ê

Turn connecting rod clockwise (1 or more) full turns.

Ê

Re-engage connecting rod in primary link of handle, insert hitch pin and re-test.

Ê

Repeat Ê - Ê as necessary.

Ê

Re-install link spring

Ê

42052-183-01

DIR 42052-183 (Version 03)

(4)

Page 5

Enclosure without Handle Cutout

L Enclosures with a Flange Thickness less than 3/16" use dimensions below to install disconnect handle.

Locate Handle

1

1 - 1/8" Max.

1 - 3/8" Min.

1 - 3/8" Min.

1 - 1/8" Max.

Drill Handle Holes

2

18 - 3/16" Min.

18 - 3/16" Min.

Top Handle Hole

Right Hand Flange Left Hand Flange

(2) .328 Dia. Holes

Top Handle Hole

5/16"

42052-183-01

DIR 42052-183 (Version 03)

Square corners or up to 1/4" radius

1/4"

(5)

1/2"

5 - 1/2"

6 - 1/2"

Page 6

Door Catch Bracket Installation

Right hand installation shown (for left hand installation follow similar procedures)

Door Catch Mounting Bracket:

L Provided with projections for welding.

L Projections can also be used as a guide for drilling holes.

L Can be used as a template to drill corresponding holes in the enclosure door.

L User to supply the hardware for fastening the bracket.

LFasteners must provide the degree of ingress protection for the environmental rating of the enclosure.

L The bracket hardware must be inaccessible to unauthorized personnel.

L Dimension K (3/4" to 1")

L When using large disconnect handle kit only (1494F-M2 or -S2), use door catch provided with handle kit.

L When using large disconnect handle kit and small door hardware kits (1494V-L1, -LL1, -L2 or -LL2), use door catch

provided with door hardware kit.

Dimension K (1-1/8" to 1-3/8")

L When using large disconnect handle kit only (1494F-M2 or -S2), use door catch (40492-080-02) which can be ordered

from factory.

L When using large disconnect handle kit and large door hardware kits (1494V-L3 or -LL3), use door catch provided with

door hardware kit.

Door Catch

Mounting Bracket

Top

Enclosure Door

Door Catch

Mounting Bracket

Door Catch

C

E

TOP VIEW

NEMA

SIZE

600A

18 - 3/16"

B

A

22 - 37 lb-in

Flange

Thickness

C

D

B

Enclosure Dimensions

A

(min)

B

(min)

1 - 3/8"

Top Handle Hole

C

(max)

1 - 5/8"

Door Catch

K

Enclosure

Base

DE

3 - 3/4"1 - 1/8"

C

B

A

E

Door Catch

Mounting

Bracket

Right Hand Flange Left Hand Flange

42052-183-01

DIR 42052-183 (Version 03)

Door Catch

Mounting

D

D

(6)

Bracket

Page 7

Disconnect Switch Installation

Locate Disconnect Switch

1

CC

AAAAAAAA

AA

EE

AAAAAAAA

CC

DD

FF

BB BB

Top Handle Hole

GG

GG

Right Hand Flange Left Hand Flange

Panel Mounting Dimensions

Switch

Size

600A

AA BB CC DD

2 - 1/16" 8 - 1/4"6 - 5/8" 15" 2 - 1/16" 8 - 1/4"9/32" Dia.

EE

(4 Mounting Plate Holes)

FF

GG

FF

DD

Install Disconnect Switch

2

90 - 130 lb-in

Line Terminal Guard

3

42052-183-01

DIR 42052-183 (Version 03)

(7)

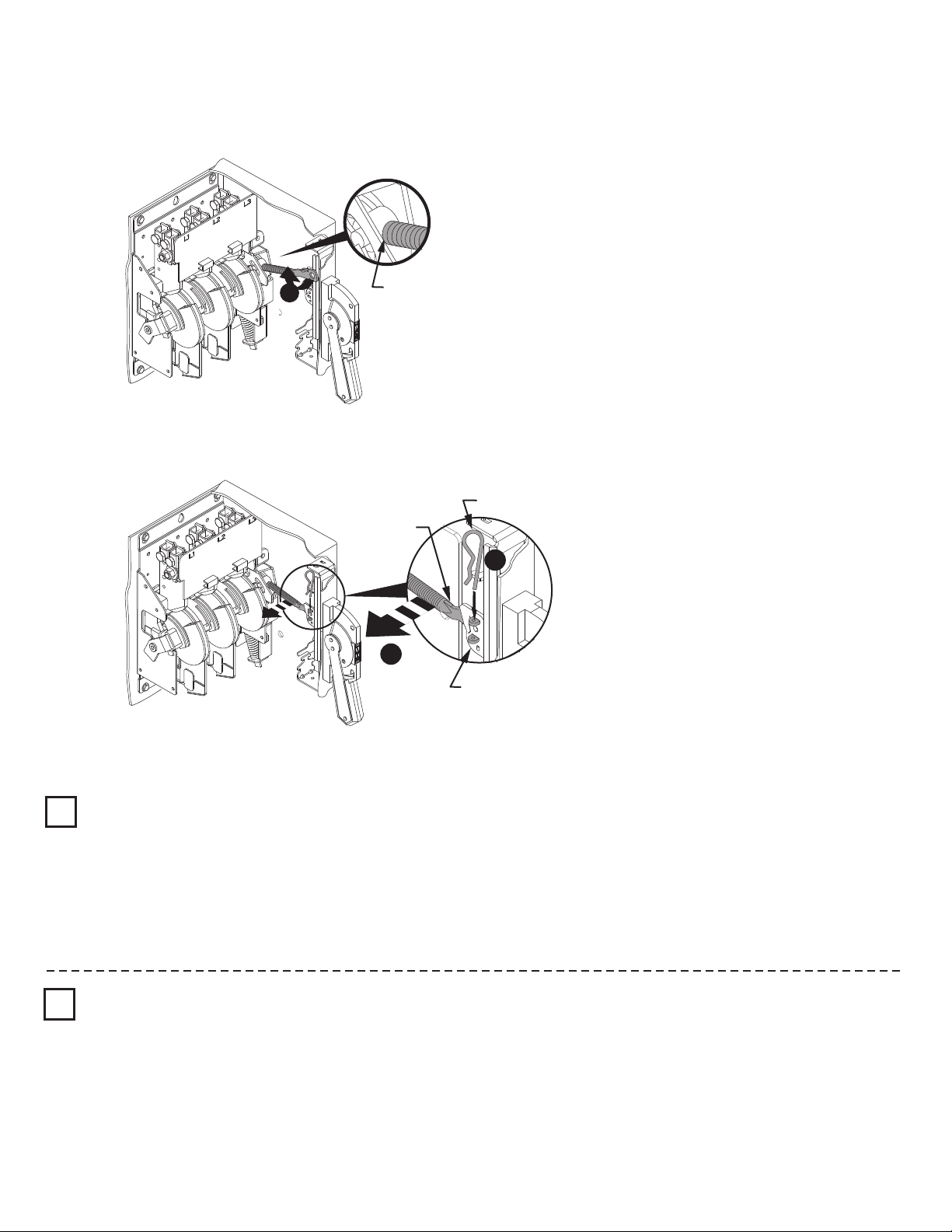

Page 8

Conversion from Right Hand to Left Hand Operation (If Required)

Remove drive mechanism from right side of switch

1

(3) 5/16 - 18 Hex Head Screws

Rotate crossbar to closed position.

2

Reinstall drive mechanism

3

on left side of switch

42052-183-01

DIR 42052-183 (Version 03)

90 -130 lb-in

(8)

Page 9

Trailer Fuse Block Installation (Switch Rating 400A)

Trailer Fuse Block Location

1

(400A Class H, J, R Fuses)

Note: Not required for non-fusible disconnect switch applications.

2

Trailer Fuse Block Location

(600A Class J Fuses)

8-1/4"

6-3/4"

A

3-15/16"

Amps Voltage Class Fuse

400

400

400

250

600

600

3/16"

2-13/16"

400 Amp Trailer Fuse Block (1494V-FSV400)

H/R

H/R

J

A

1-3/4"

4-1/4"

1-1/8"

3-3/16"

3"

6-3/4"

22-37

Clip

Torque (lb-in)Fuse

Fuse

Block

90-130

Lug to

Terminal

175

-

200 275-305

Wire

into Lug

8-1/4"

6-3/4"

A

3/8"

3-15/16"

2-13/16"

600 Amp Trailer Fuse Block (1494V-FS600)

Amps Voltage Class Fuse

3-3/16"

3"

6-3/4"

A

Bolt

4-3/8"600 250 / 600 J

300-350

Torque (lb-in)Fuse

Fuse

Block

90-130

Lug to

Terminal

175

-

200 275-305

Wire

into Lug

Trailer Fuse Block Location

3

(600A - 250V / 600V Class H, R Fuses)

Note: Refer to instructions provided with separately mounted fuse blocks (Catalog Numbers 1491-N621 and 1491-R621).

42052-183-01

DIR 42052-183 (Version 03)

(9)

Page 10

Fuse Clip Installation (Switch Rating 600A)

400A Fuses (Class H, J, R) 600A Fuses (Class J)

300 - 350 lb-in

1

40 - 55 lb-in

2

2

1

600A Fuses (Class H, R)

300 - 350 lb-in

4

3

Note: Refer to instructions provided with separately mounted fuse blocks (Catalog Numbers 1491-N621 and 1491-R621).

42052-183-01

DIR 42052-183 (Version 03)

(10)

Page 11

Bulletin 1494V Disconnect Switch Kit

Disconnect Kit

Switch

Handle

Connecting

Rod

Catalog Number and Description

Switch with Right Hand Mechanism

1494V-DS600 (600A)

Convertible in the field for Left Hand operation

1494F-M2 (7-1/2" Painted Metal) (400A / 600A)

1494F-S2 (7-1/2" Stainless Steel) (400A / 600A)

1494V-RB3 (Standard) (400A / 600A)

Enclosure Working Depth: 9-1/2" to 10"

1494V-RB4 (Extended)(400A / 600A)

Enclosure Working Depth: 9-1/2" to 23"

Fuse

Block

Fuse

Clips

Mounted with Switch

1494V-FSV400 (400A Class H, J, R)

1494V-FS600 (600A Class J)

Separately Mounted

1491-N621 (600A Class H)

1491-R621 (600A Class R)

400A Fuses

1401-N46 (Class H, J, 400A-250V, 400A-600V)

1401-N55 (Class R, 400A-250V, 400A-600V)

600A Fuses

Class J - Bolts directly to switch and fuse block

(no clips required)

Class H, R - Fuse clips included with separately

mounted fuse blocks Cat. Nos.1491-N621

and 1491-R621

42052-183-01

DIR 42052-183 (Version 03)

(11)

Page 12

Bulletin 1494V Disconnect Switch Optional Accessory List

Optional Accessories

(Installation Instructions

Included with Accessory Kits)

Electrical

Interlock

Catalog Number and Description

Switch with Right Hand Mechanism

1495-N34 (1-N.O./N.C.) *

1495-N35 (2-N.O./N.C.) *

*Requires Adapter Kit 1495-N36

Auxiliary

Contact

Lug

Connectors

595-A (1-N.O.) (600A) *

595-B (1-N.C.) (600A) *

*Requires Adapter Kit 595-N1

Switch and Fuse Block

1494R-N10

(CU Wire (2) - #1/0 -350 MCM)

(600A or 400A Fuse Block)

(3 per kit)

1494R-N12

(CU Wire (1) - #1/0 -500 MCM)

(600A or 400A Fuse Block)

(3 per kit)

Separately Mounted Fuse Blocks

1494R-N11

(CU Wire (2) - #1/0 -350 MCM)

(600A)

(2 per kit)

Switch

Rating

Fuse

Class

Fuse Clip

Rating

250V 600V

Cat No.

42052-183-01

DIR 42052-183 (Version 03)

Printed in U.S.A.

Fuse

Cover

with Door

Available only for R.H. mounted

disconnect switch.

600A ----

Non-Fusible 1495-N61

H, J, R600A 1495-N61

Ê Switch with right hand mechanism

ÊSwitch with left hand mechanism

400A 400A

600A 600AJ600A 1495-N61

600A 600AH,R600A N/A

----

Loading...

Loading...