Page 1

Bulletin 1494V Variable Depth, Flange Operated Disconnect Switch Kits for 30 and

60 Amperes (Series A), 100 and 200 Amperes (Series B or Series C Switches)

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. Install

in suitable enclosure. Keep free from contaminants.

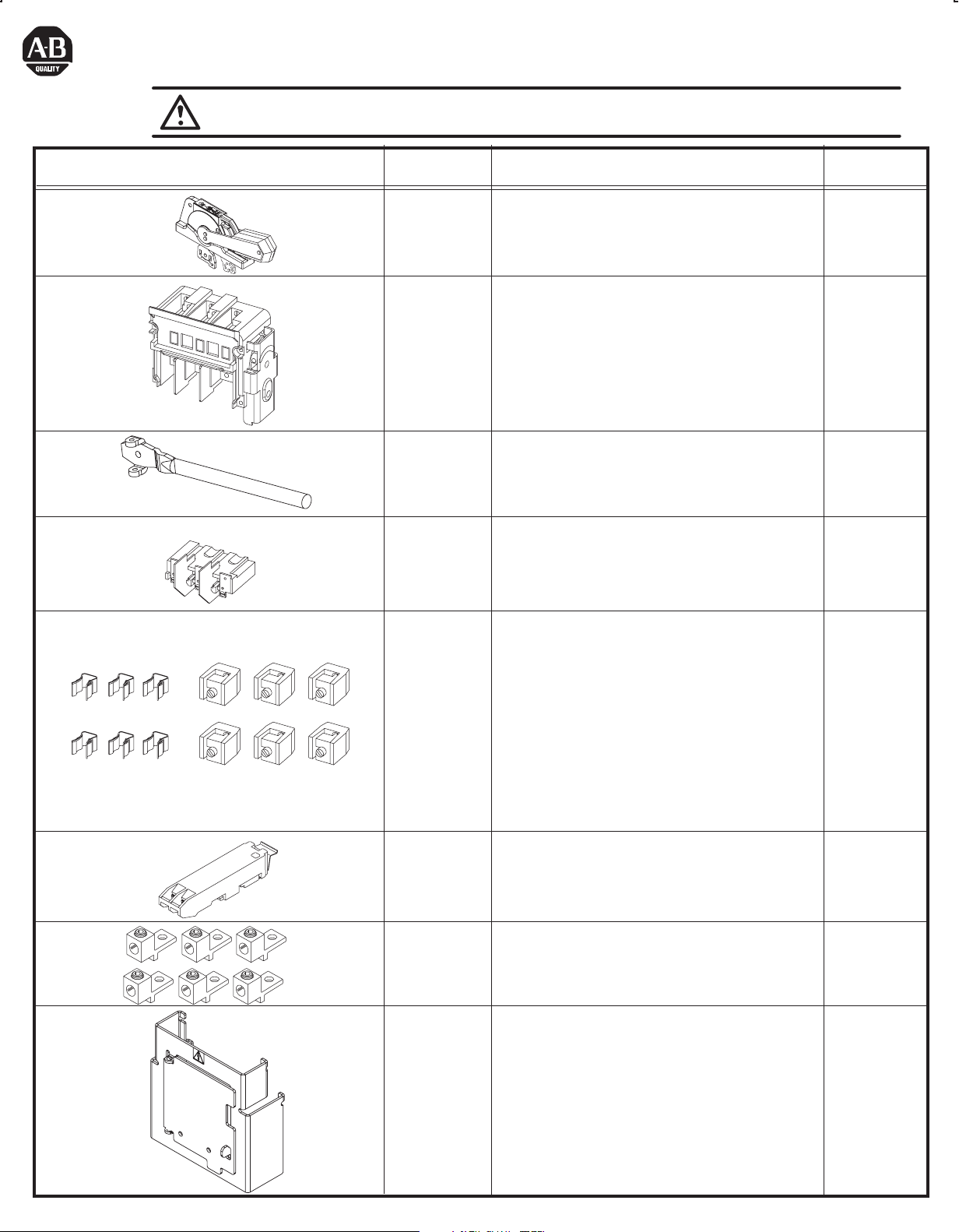

Components Cat No. Description

1494F-M1

1494F-P1

1494F-S1

1494V-DS30

1494V-DS60

1494V-DS100

1494V-DS200

1494V-RA3

1494V-RA4

1494V-FS30

1494V-FS60

1494V-FS100

1494V-FS200

5-1/2" Painted Metal Handle

5-1/2" Molded Handle

5-1/2" Stainless Steel Handle

30 Amp Switch

60 Amp Switch

100 Amp Switch

200 Amp Switch

Standard Connecting Rod

Enclosure Working Depth: 6-3/4" to 9-1/8"

Extended Connecting Rod

Enclosure Working Depth: 9-1/8" to 21-5/8"

30 Amp Fuse Block

60 Amp Fuse Block

100 Amp Fuse Block

200 Amp Fuse Block

Switch Rating

(Amps)

30...200

30

60

100

200

30...200

30

60

100

200

1401-N41

1401-N42

1401-N43

1401-N44

1401-N45

1401-N50

1401-N51

1401-N52

1401-N53

1401-N54

595-A

595-B

(Included)

1494R-N1

1494R-N2

1494R-N3

1495-N59

Fuse Clip, Class H, 30A - 250V

Fuse Clip, Class H,J, 30A - 600V,

Class H, 60A-250V

Fuse Clip, Class H,J, 60A - 600V

Fuse Clip, Class H,J, 100A-250V, 100A-600V

Fuse Clip, Class H,J, 200A-250V, 200A-600V

Fuse Clip, Class R, 30A - 250V

Fuse Clip, Class R, 30A - 600V, 60A-250V

Fuse Clip, Class R, 60A - 600V

Fuse Clip, Class R, 100A - 250V, 100A-600V

Fuse Clip, Class R, 200A-250V, 200A-600V

(1) N.O. Auxiliary Contact

(1) N.C. Auxiliary Contact

Lug Connector: Wire Size #14 . . . #8 AWG

Lug Connector: Wire Size #14 . . . #4 AWG

Lug Connector: Wire Size #14 . . . #1/0 AWG

Lug Connector: Wire Size #6 . . . #4/0 AWG

Fuse Cover with Door

(only for Right-Hand Installation)

30

30 - 60

60

100-200

100-200

30

30 - 60

60

100-200

100-200

30...200

30

60

100

200

30...100

1495-N60

Fuse Cover with Door

(only for Right-Hand Installation)

200

Page 2

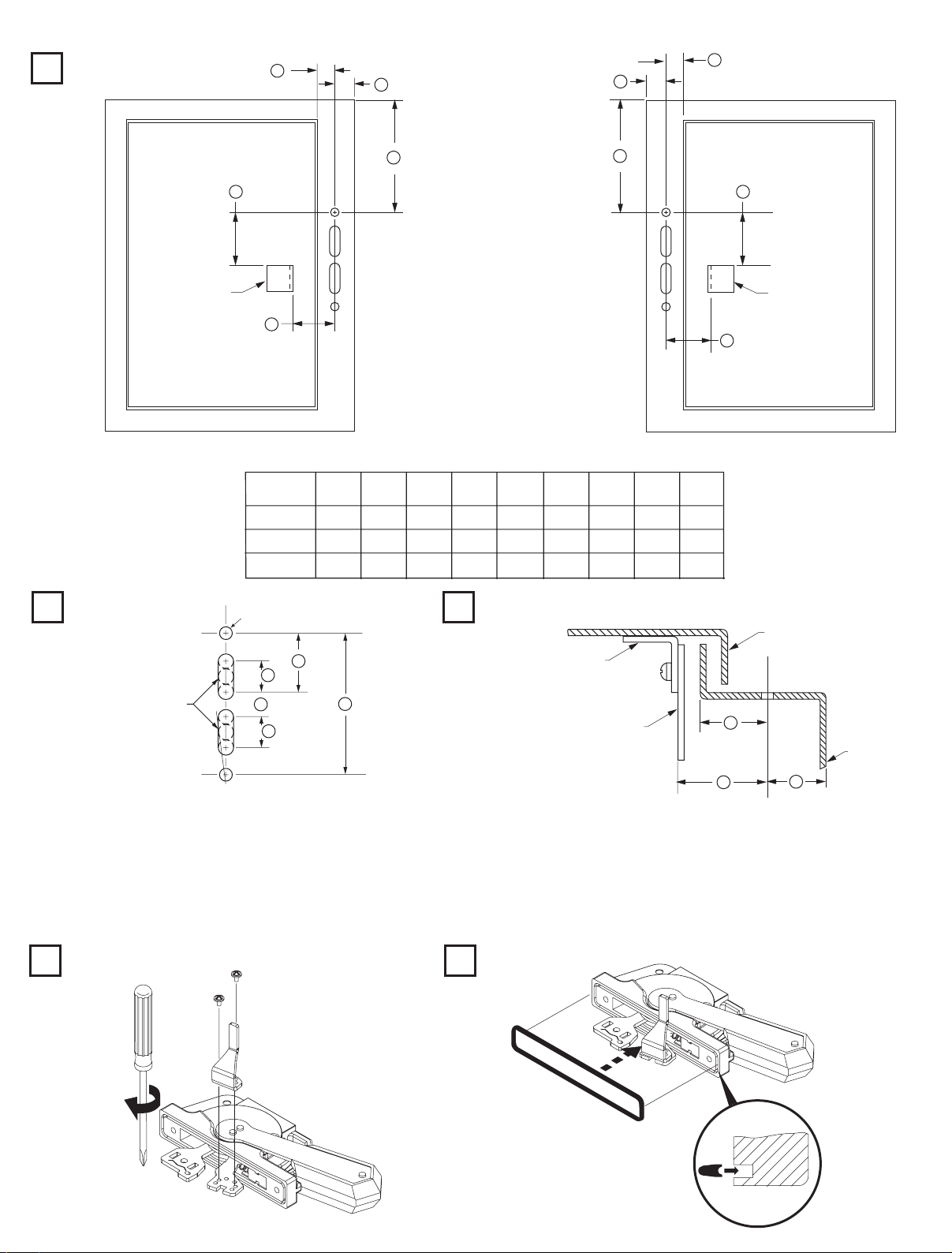

Handle Installation

Locate Handle

1

C

B

B

C

Drill Handle Holes

2

E

Door Catch

Mounting

Bracket

D

Right Hand Flange

NEMA

SIZE

30A, 60A

100A

200A

(2) .265 Dia. Holes

A

(min)

4 - 5/8"

5 - 13/16"

10 - 1/8"

B

(min)

29/32"

29/32"

29/32"

A

A

E

Door Catch

Mounting

D

Bracket

Left Hand Flange

D

E

F

G

H

C

(max)

1 - 3/32"

1 - 3/32"

1 - 3/32"

1 - 5/8"

1 - 5/8"

1 - 5/8"

Locate Door Catch

3

2 - 11/32"

2 - 11/32"

2 - 11/32"

4 - 11/16"

4 - 11/16"

4 - 11/16"

1 - 9/16"

1 - 9/16"

1 - 9/16"

J

1"

7/8"

1"

7/8"

1"

7/8"

Enclosure Door

Door Catch

Mounting Bracket

Door Catch

C

To make slot drill

(3) 1/2" diameter holes

and remove burrs

G

H

J

H

F

Enclosure

D

B

Base

Notes:

A) Enclosures with a Flange Thickness less than 3/16" use dimensions above.

B) Enclosures with a Flange Thickness 3/16" and greater use dimensions in Mounting Kit 1494V-H3.

C) Multi-Door Enclosures use dimensions in Channel Support Kit 1494V-H4, if handle is mounted atop channel.

D) The door catch mounting bracket is provided with projections for welding; however, holes can be drilled in the bracket using the

projections for locating hole centers. After proper location, use the bracket as a template and drill corresponding holes in the

enclosure door. Fasten the bracket with hardware supplied by user. If properly assembled, the hardware should not be accessible for

tampering with by unauthorized personnel.

Install Defeater Lever

4

7-11 lb-in

Install Gasket

5

(2)

Page 3

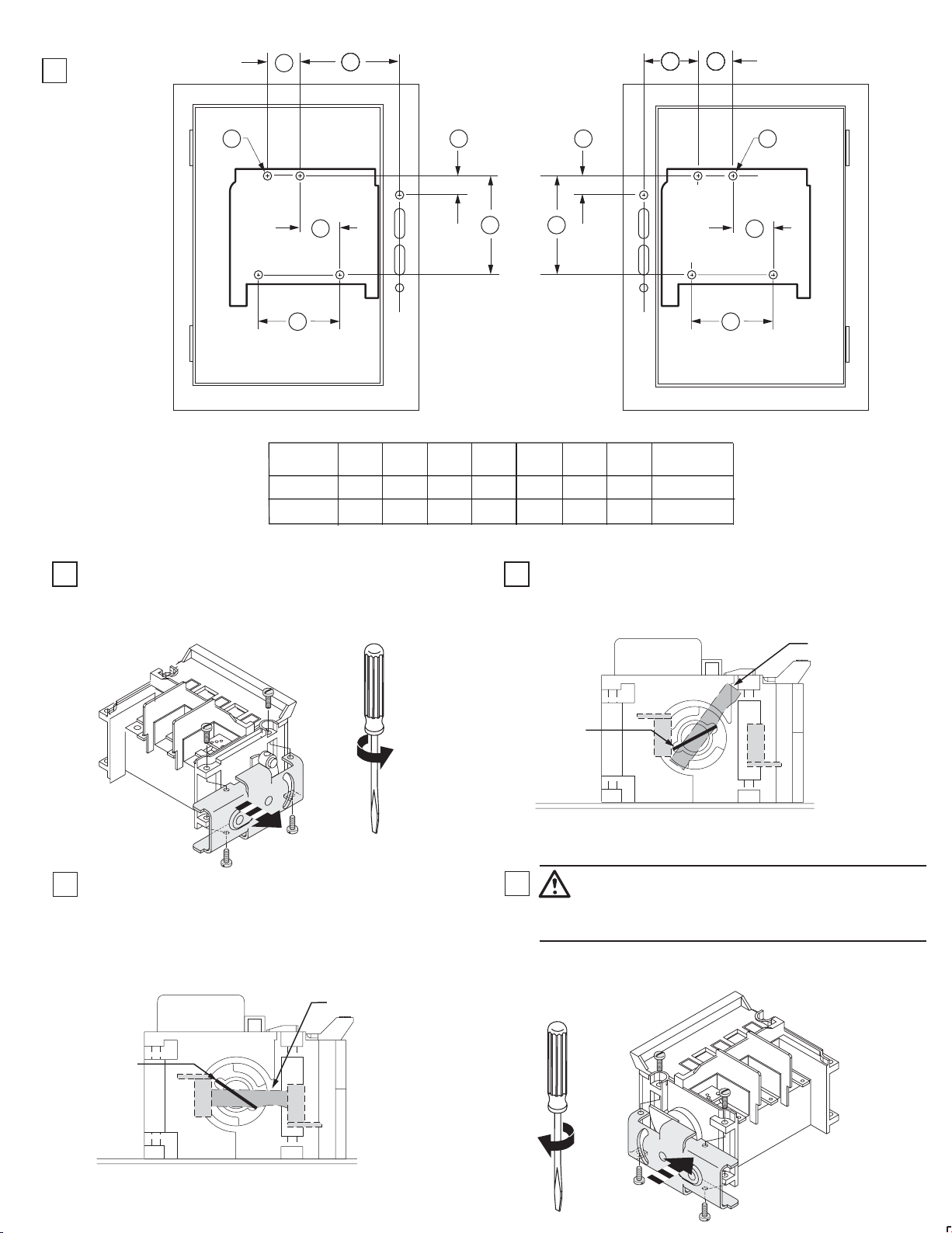

Disconnect Switch Installation

Locate

1

Disconnect

Switch

CC

AAAAAAAAAAAA

AAAAAAAAAAAAAAAAAAAAAAGG AAAAAAAAAAAAAAAAAAAAAACC

HH

EE

FF

BB BB

DD DD

Right Hand Flange Left Hand Flange

SIZE

30A, 60A,100A

200A

AA BB CC DDNEMA

3 - 29/64" 1 - 27/32" 1 - 31/32" 4 - 21/64" 1" 3 - 15/16"

3 - 53/64" 2 - 63/64" 2 - 23/64" 4 - 59/64" 1 - 7/64" 4 - 23/32" (4) 1/4-20 2 - 61/64"

Conversion from Right-Hand Installation to Left-Hand Installation

With the disconnect switch in the "OFF" position, (blades visible)

2 3

loosen and remove the (4) screws.

Remove the drive mechanism from the right-hand side of the

disconnect switch.

Save the (4) 1/4-20 pan head screws shown below.

HH

EE

FF

EE FF GG HH

2 - 37/64"

(4) #10-32

Insert the rectangular metal plate provided with the hardware kit

into the crossbar end slot on the right-hand side as shown below.

Movable

Blades

Rotate the crossbar assembly in a clockwise direction to the

4

"ON" position (blades fully engaged - not visible).

(Use any convenient adjustable wrench or pliers to aid in

rotating the crossbar & moveable blades.)

Moveable Blades

Rectangular

Metal Plate

Rectangular

Metal Plate

5

ATTENTION: Do not attempt to change the position of the

drive mechanism after removal from the disconnect assembly.

Use the rectangular metal plate to rotate the crossbar from the

"OFF" position to the full "ON" positiom.

Remove the rectangular metal plate and discard, (not required for

switch operation.)

Position the drive mechanism assembly as shown below and install

the (4) screws.

40-60 lb-in

(3)

Page 4

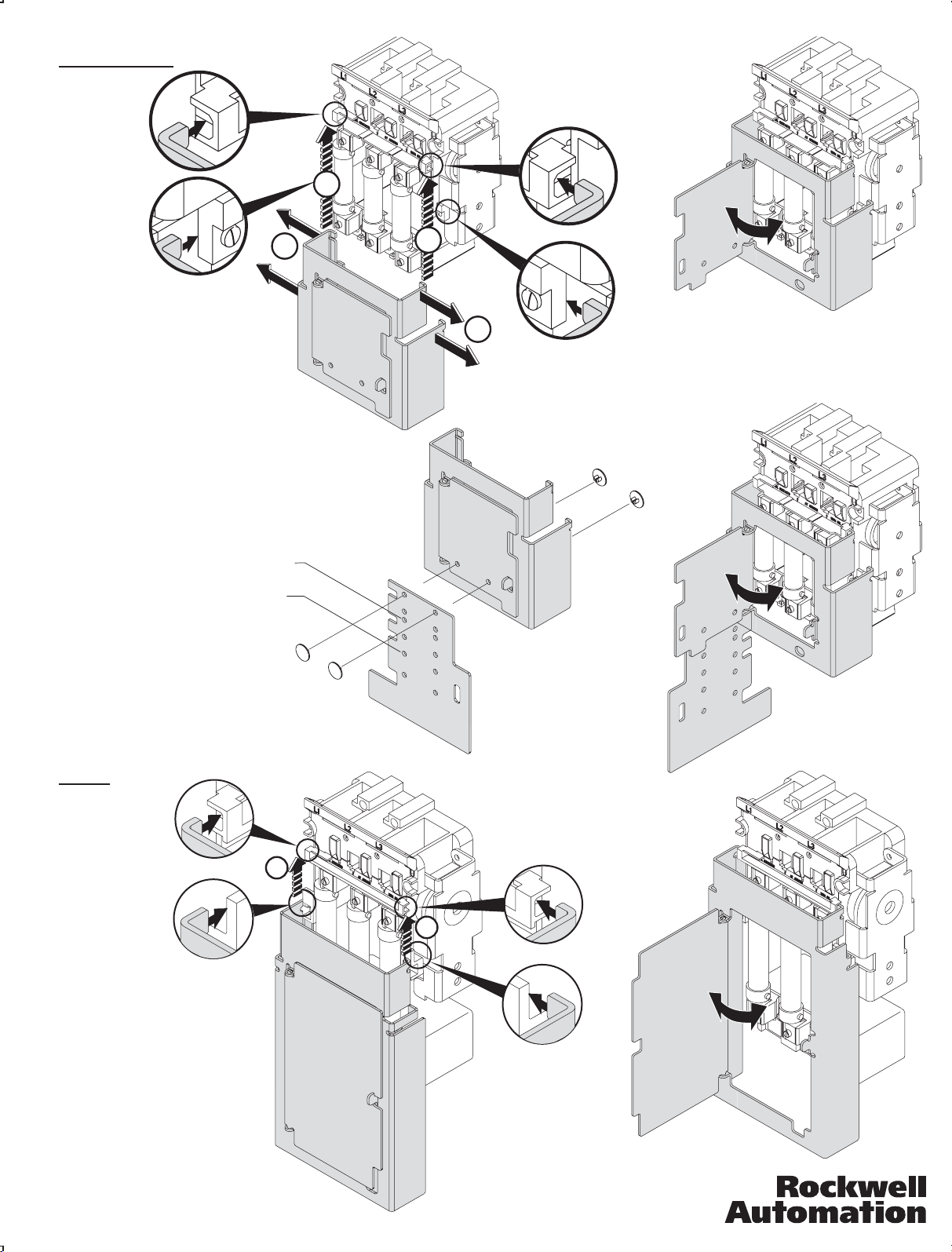

Trailer Fuse Block and Fuse Clip Installation

Install Trailer Block

1

Q

Install Fuse Clips

2

30A ....... 60A 100A ....... 200A

R

Y

Z

W

V

X

40 lb-in

R

Install Wire Lugs to Terminals

3

2

1

S

4

Install Wire to Lugs

4

T

3

10 - 15 lb-in

1

2

(4)

Page 5

Switch Fuse Fuse Block Clip Block Mtg. Screw Mtg. Screw Termina l Lug

Trailer Fuse Fuse Fuse Block Fuse Clip Lug to Wire to

Rati ng Ra ting F use Cata log Cata log V W X Y Z Mounting Torque Torque Torque Torque

(Amps) Amps/Volts Class Number Number inches inches inches inches inches Hole lb-ins. lb-ins. lb-ins. lb-ins.

30A, 250V 1494V-FS30 1401-N41 2-1/4 1-13/16 1-31/32 31/32 9/16

30A, 250V 1494V-FS30 1401-N50 2-1/4 1-13/16 1-31/32 31/32 9/16

30A, 600V 1494V-FS30 1401-N42 2-1/4 1-13/16 1-31/32

30A, 600V 1494V-FS30 1401-N42 2-1/4 1-13/16 1-31/32

30

30A, 600V 1494V-FS30 1401-N42 2-1/4 1-13/16 1-31/32

30A, 60 0V 1494V-FS30 1401-N51 2-1/4 1-13/16 1-31/32

60A, 250V 1494V-FS30 1401-N42 2-1/4 1-13/16 1-31/32

60A, 250V 1494V-FS30 1401-N51 2-1/4 1-31/32

60A, 600V 1494V-FS30 1401-N43 2-1/4 1-31/32

60A, 600V 1494V-FS30 1401-N43 2-1/4 1-31/32

60A, 600V 1494V-FS30 1401-N52 2-1/4 1-31/32

H

R

3-47/64

31/32

31/32 9/16J

3-47/64

1-47/64

1-47/64

4-15/64

1-3/32

4-15/64

3-21/64

9/16

3-21/64

1-11/32

1-11/32

3-27/32

23/32

3-27/32

#10-32

3030

H

J

R

H

R

H

J

R

1-13/16

1-13/16

1-13/16

1-13/16

Term

Screw

#10-322030

60A, 250V 1494V-FS60 2-1/4 1-31/32

60A, 600V 1494V-FS60 2-1/4 1-31/32

60A, 600V 1494V-FS60 2-1/4 1-31/32

60A, 600V 1494V-FS60 2-1/4 1-31/32

60A, 600V

60A, 600V

60A, 600V 1494V-FS60 2-1/4 1-31/32 1-21/64

60

60A, 600V

60A, 600V 1494V-FS60 2-1/4 1-31/32 11/16

60A, 600V 1494V-FS60 2-1/4 1-31/32 3-53/64R 1401-N52 1-13/16 4-15/64

100A, 250V

100A, 250V

100A, 600V

100A, 600V 1494V-FS6 0 2-1/4 1-31/32 2-9/16J 1401-N44 2-31/32 1-13/16

100A, 60 0V

**

60A, 600V 1494V-FS100 1401-N43 2-1/ 8 1-31/32 6-17/64

60A, 600V

** 1494V-FS100 1401-N43 2-1/8 1-11/16 1-31/32 4-63/64 J 5-3/8

**

60A, 600V

100A, 250V 1494V-FS100 1401-N44 2-1/8 1-11/16 1-31/32H 4-5/8 4-15/64

100A, 250V 1494V-FS100 1401-N53 2-1/8 1-11/16 1-31/32R 4-5/8 4-15/64

100

100A, 250V 1494V-FS100 1401-N44 2-1/8 1-11/16 1-31/32H 6-5/8 6-15/64

100A, 600V 1494V-FS100 1401-N44 2-1/8 1-11/16 1-31/32J 3-3/8 2-63/64

100A, 600V 1494V-FS100 1401-N53 2-1/8 1-11/16 1-31/32

*

200A, 600V 1494V-FS100 1401-N45 7/16 1-11/16 1-31/32J 4-1/8 3-47/64 #10-32 9030

H

R

H

J

R

1494V-FS60 2-1/4 1-31/32

H

1494V-FS60 2-1/4 1-31/32 1-21/64

R

H

1494V-FS60 2-1/4 1-31/32 3-53/64

J

1494V-FS60 2-1/4 1-31/ 32 3-27/32

H 1401-N44 1-13/16 4-1/4

1494V-FS60 2-1/4 1-31/ 32 3-27/32R 1401-N53 1-13/16 4-1/4

H

1494V-FS60

R

1494V-FS60 2-1/4 1-31/32 5-13/16

H

1494V-FS100

R

R

1401-N41

1401-N50

1401-N42

1401-N42

1401-N51

1401-N42

1401-N51

1401-N43

1401-N43

1401-N44

1401-N53

1401-N52 2-1/ 8 1-11/16 1-31/32 6-17/64

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

1-13/16

2-1/4 1-31/32 5-13/16

1-13/16

1-11/16

31/32

31/32

3-47/64

31/32

3-47/64

1-47/64

1-47/64

4-15/64

1-3/32

6-7/32

6-7/32

6-5/8

6-5/8

6-5/8

9/16

9/16

3-11/32

1-11/32

3-11/32

6-15/64

#10-32

#10-32

#10-32

#10-32

3030

#1/4-284550

30

30

20

30

#5/16/2415090

2030

100A, 600V 1494V-FS200 1401-N44 1-41/64 1-1/4 2-23/64

100A, 600V 1494V-FS200 1401-N44 1-41/64 1-1/4 2-23/64

100A, 600V 1494V-FS200 1401-N53 1-41/64 1-1/4 2-23/64

200A, 250V 1494V-FS200 1401-N45 1-41/64 1-1/4 2-23/64

200A, 250V 1494V-FS200 1401-N54 1-41/64 1-1/4 2-23/64R 7-27/64 5-43/ 64

200

200A, 600V 1494V-FS200 1401-N45 1-41/64 1-1/4 2-23/64H 9-59/64 8-13/ 64

200A, 600V 1494V-FS200 1401-N45 1-41/64 1-1/4 2-23/64

200A, 600V 1494V-FS200 1401-N54

*

400A, 600V 1494V-FS200 1401-N46 1-41/64 1-1/4 2-23/64 1/4-20J 8-17/32 6-13/64 17540

*

FUSE BOLTS DIRECTLY TO THE SWITCH AND FUSE BLOCK TERMINALS

H

J

R

H

J

1-41/64 1-1/4 2-23/64R 9-59/64 8-13/64

**FUSE ADAPTER KIT CATALOG NUMBER 1401-N170 REQUIRED.

8-35/64

5-19/64

8-35/64

7-27/64

6-3/64

(5)

6-53/64

3-37/64

6-53/64

5-43/64

4-21/64

1/4-20

40

20 #3/8-24275175

Page 6

Connecting Rod Installation

1

Connecting

N

Enclosure

Working Depth

(Flange to

Mounting Plate)

Right Hand Operation

Install connecting rod in mechanism and

2

thread in clockwise (12) full turns

Standard

Extended

Rod

Catalog Number

1494V-RA3

1494V-RA4

N - 3"

Front

"N"

Min. Max.

6-3/4" 9-1/8"

9-1/8" 21-5/8"

Place the disconnect handle in the "OFF" position. Insert the

3

ears of rod into the primary link of the handle and install the

hitch pin as shown below

Connecting Rod Adjustment Procedure

"ON" Position

4 5

a) Move disconnect handle to the "ON" position.

b) If switch does not fully close, return handle to "OFF"

position.

c) Remove hitch pin and disengage the connectiong rod from the

primary link.

d) Turn connecting rod counter-clockwise (1) full turn.

e) Re-engage connecting rod in primary link of handle, insert

hitch pin and re-test

f) Repeat 4a - 4e as necessary.

(6)

"OFF" Position

g) Move disconnect handle to the "OFF" position.

h) If switch does not fully open, return handle to "ON"

position.

j) Remove hitch pin and disengage the connectiong rod from

the primary link.

k) Turn connecting rod clockwise (1) full turn.

l) Re-engage connecting rod in primary link of handle, insert

hitch pin and re-test

m) Repeat 5g - 5l as necessary.

Page 7

Left Hand Operation

Install connecting rod in mechanism and thread in

6

clockwise (9) full turns.

Connecting Rod Adjustment Procedure

"ON" Position

8 9

a) Move disconnect handle to the "ON" position.

b) If switch does not fully close, return handle to "OFF"

position.

c) Remove hitch pin and disengage the connectiong rod

from the primary link.

d) Turn connecting rod counter-clockwise (1) full turn.

e) Re-engage connecting rod in primary link of handle,

insert hitch pin and re-test

f) Repeat 4a - 4e as necessary.

7

Place the disconnect handle in the "ON" position. Insert the

ears of rod into the primary link of the handle and install the

hitch pin as shown below.

"OFF" Position

g) Move disconnect handle to the "OFF" position.

h) If switch does not fully open, return handle to "ON" position.

j) Remove hitch pin and disengage the connectiong rod from the

primary link.

k) Turn connecting rod clockwise (1) full turn.

l) Re-engage connecting rod in primary link of handle, insert

hitch pin and re-test

m) Repeat 5g - 5l as necessary.

Auxiliary Contact Installation

Important: Before installing auxiliary contact, disconnect switch must be in "Off" position.

1 2

Align

Arrows

(7)

Click

Page 8

Fuse Cover Installation

30 A ... 100 A

2

30 A ... 100 A Non-Fused

30 A, 250 V, Class H, R Fuses

30 A, 600 V, Class J Fuses

60 A, 250 V, Class H, R Fuses

60 A, 600 V, Class J Fuses

100 A, 600 V, Class J Fuses

100 A, 600 V, Class H, R Fuses

30 A, 600 V, Class H, R Fuses

60 A, 600 V, Class H, R Fuses

100 A, 250 V, Class H, R Fuses

200 A, 600 V, Class J Fuses

1

2

1

200 A

200 A Non-Fused

100 A, 250 V, Class H, R Fuses

100 A, 600 V, Class H, J, R Fuses

200 A, 250 V, Class H, R Fuses

200 A, 600 V, Class H, J, R Fuses

400 A, 600 V, Class J Fuses

42052-064-01 (1)

Printed in U.S.A.

2

2

Loading...

Loading...