Page 1

Bulletin 1494V Variable Depth, Flange Operated Circuit Breaker Kits for 125A, 150A

250A and 400A Frame Sizes

ATTENTION: To prevent electrical shock, disconnect from power source before installing or servicing. Install

in suitable enclosure. Keep free from contaminants.

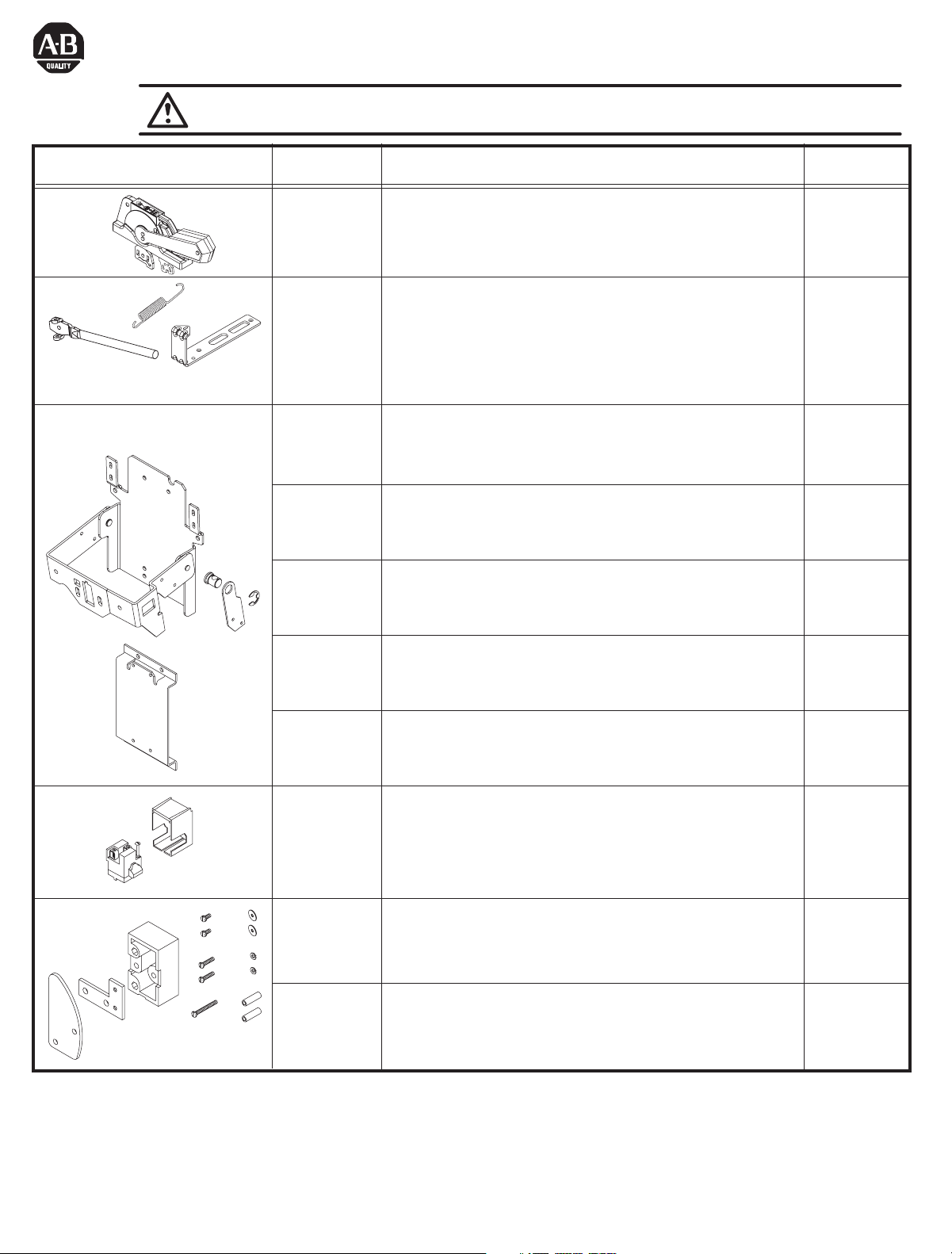

Components Cat No. Description

1494F-M1

1494F-P1

1494F-S1

1494V-RA3

1494V-RA4

5-1/2" Painted Metal Handle

5-1/2" Molded Handle

5-1/2" Stainless Steel Handle

Standard Connecting Rod

Enclosure Working Depth: 6-3/4" to 9-1/8"

Extended Connecting Rod

Enclosure Working Depth: 9-1/8" to 23"

Circuit breaker mechanism for use with

1494V-M41

Allen-Bradley: 140U-H (MCCP), 140M-H (MCP)

Cutler-Hammer: EF, HMCPE

Circuit breaker mechanism for use with

1494V-M40

Allen-Bradley: 140M-I (MPCP and MCP)

Cutler-Hammer: EHD, FD, FDB, FDC, HFD, HMCP

Circuit breaker mechanism for use with

1494V-M51

Allen-Bradley: 140U-J (MCCB), 140M-J (MPCB and MCP)

Cutler-Hammer: EF

Switch Rating

(Amps)

125A...400A

125A...400A

125A

150A

250A

Circuit breaker mechanism for use with

1494V-M50

Cutler-Hammer: JD, JDB, JDC, HJD, HMCP

250A

Circuit breaker mechanism for use with

1494V-M60

Allen-Bradley: 140U-K (MCCB), 140M-K (MPCB and MCP)

400A

Cutler-Hammer: KD, KDB, KDC, HKD, HMCP

TERMINAL

GUARD

N.O.

1495-N8

1495-N9

(1) N.O. Auxiliary Contact

125A...400A

(1) N.C. Auxiliary Contact

1495-N21 Auxiliary Contact Adapter Kit 125A...150A

1495-N23 Auxiliary Contact Adapter Kit 250A...400A

42052-074-01 (1)

Printed in U.S.A.

Page 2

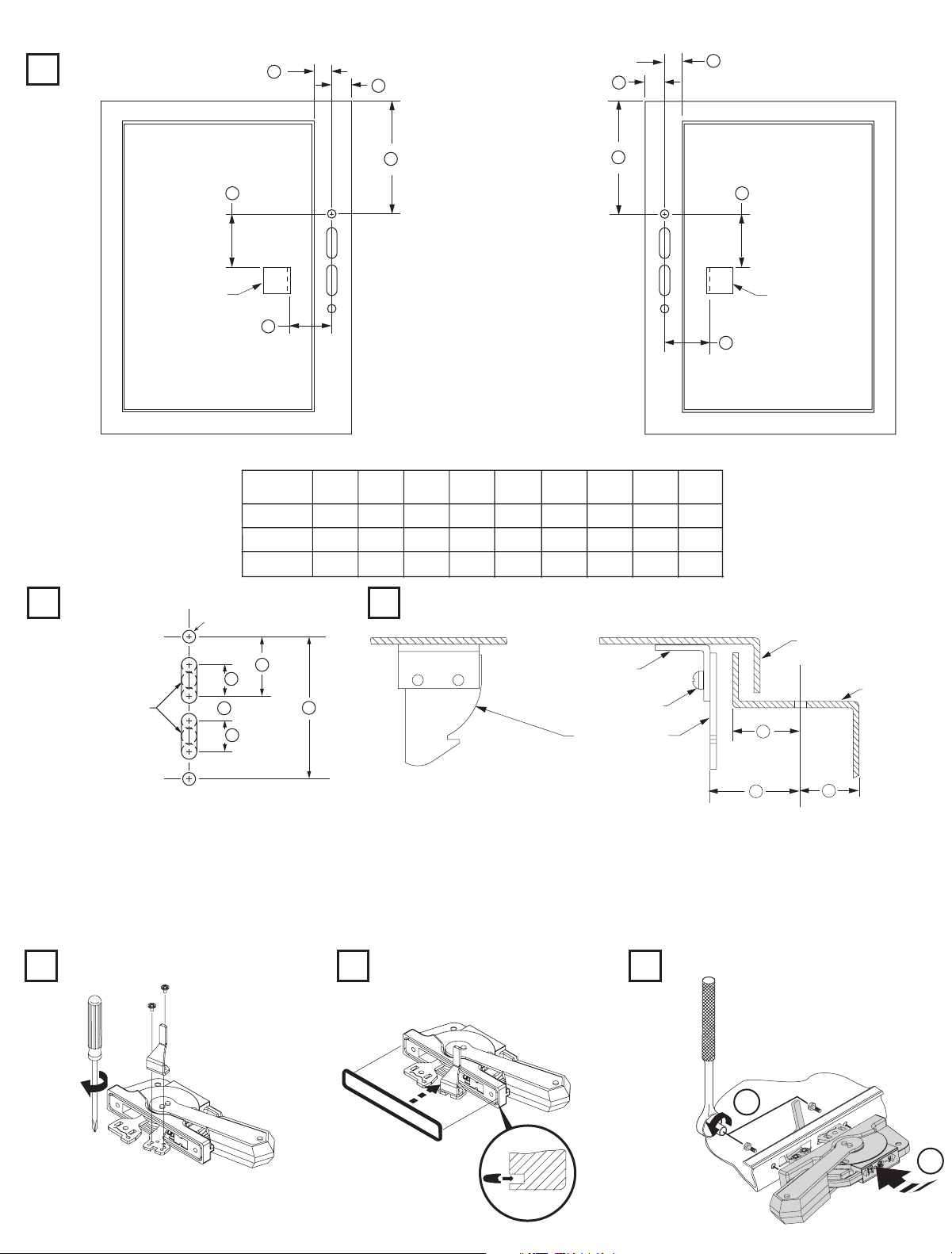

Handle Installation

Locate Handle

1

C

B

B

C

Drill Handle Holes

2

To make slot drill

(3) 1/2" diameter holes

and remove burrs

E

Door Catch

Mounting

Bracket

D

Right Hand-Flange

FRAME

SIZE

125A, 150A

250A

400A

(2) .265 Dia. Holes

G

H

J

H

(min)

3 - 1/2"

10 - 29/32"

13 - 3/32"

F

A

A

E

Door Catch

Mounting

D

Bracket

Left Hand-Flange

D

E

F

G

H

A

(max)

(min)

1 - 3/32"

29/32"

1 - 3/32"

29/32"

1 - 3/32"

29/32"

Locate Door Catch

3

1 - 5/8"

1 - 5/8"

1 - 5/8"

2 - 11/32"

2 - 11/32"

2 - 11/32"

4 - 11/16"

4 - 11/16"

4 - 11/16"

1 - 9/16"

1 - 9/16"

1 - 9/16"

C

B

Door Catch

Mounting Bracket

30 lb-in

Door Catch

J

1"

7/8"

1"

7/8"

1"

7/8"

Enclosure Door

Enclosure

Base

C

Notes:

D

B

A) Enclosures with a Flange Thickness less than 3/16" use dimensions above.

B) Enclosures with a Flange Thickness 3/16" and greater use dimensions in Mounting Kit 1494V-H3.

C) Multi-Door Enclosures use dimensions in Channel Support Kit 1494V-H4, if handle is mounted atop channel.

D) The door catch mounting bracket is provided with projections for welding; however, holes can be drilled in the bracket using the

projections for locating hole centers. After proper location, use the bracket as a template and drill corresponding holes in the

enclosure door. Fasten the bracket with hardware supplied by user. If properly assembled, the hardware should not be accessible for

tampering with by unauthorized personnel.

Install Defeater Lever

4

7-11 lb-in

Install Gasket

5

Install Handle to Flange

6

2

23-37 lb-in

(2)

1

Page 3

Circuit Breaker Mechanism Installation

1 2

1494V-M41

1494V-M51

(Only)

2

1

16 - 22 lb-in

3

LL

3

Threaded Rod

N

Enclosure

Working Depth

(Flange to

Mounting Plate)

Connecting

Rod

Standard

Extended

Catalog Number

1494V-RA3

1494V-RA4

N - 3"

"N"

Min. Max.

6-3/4" 9-1/8"

9-1/8" 23"

Locate Circuit Breaker Mechanism (125A and 150A Frame Circuit Breakers)

4a

AAAAAAAAAABB

CC

EE

AA

DD

Frame

Size

125A

150A

AA BB CC DD

1/4" 2 - 7/64" 1 - 3/8" 4 - 1/2"

1/4" 2 - 7/64" 1 - 3/8" 4 - 1/2"

EE

Wire

Bending

Space

6

6

Mechanism

Mounting

Hole (Tapped)

KK

(4) - #8-32

(4) - #8-32

AAAAAAAAAA

BB

Left Hand-FlangeRight Hand-Flange

Mechanism

Mounting

Hole (Tapped)

lb-in

20

20

CC

(3)

Page 4

Circuit Breaker Mechanism Installation (Cont'd)

Locate Circuit Breaker Mechanism (250A and 400A Frame Circuit Breaker)

4b

BB

CC

BB

CC

Frame

Size

250A

400A

MM

HH

EE

DD

KK

JJ

AA BB CC DD

13/16" 2 - 9/32" 1 - 3/8" 7 - 1/4" - - - - - 1 - 7/32" - - - - -

- - - - - 2 - 13/16" 1 -23/32" - - - - - 8 - 7/16" 1 - 13/32" 1/4"

LL

EE FF GG

GG

FF

GG

AA

HH

10 - 5/8"

10 - 3/4"

MM

LL

2 - 31/32"

3 - 43/64"

LL

MM

Wire

Bending

Space

10

12

HH

EE

DD

KK

JJ

Left Hand-FlangeRight Hand-Flange

Mechanism

Mounting

Hole (Tapped)

JJ

(2) - #10-32 (4) - 1/4-20 60

(2) - #10-32 (4) - 1/4-20 60

Mechanism

Mounting

Hole (Tapped)

KK

Hole (Tapped)

Mechanism

Mounting

lb-in

5

6

2

On

Off

Toggle

Adjustment

Plate

UP

1

3

16 - 20 lb-in

Toggle

Adjustment

Plate

25 - 30 lb-in

150A

125A

(4)

125A / 150A

Circuit Breaker

250A / 400A

Circuit Breaker

Page 5

Circuit Breaker Installation (Cont'd)

2

87

2

3

1

3

1

Hitch Pin

Testing of Circuit Breaker

1. Verify that the circuit breaker can be turned on by moving the defeater lever downward and moving the disconnect

handle to the ON position.

2. If the circuit breaker does not turn on, loosen the (2) screws and adjust the toggle adjustment plates toward the line

terminals until the circuit breaker turns on when the disconnect handle is in the ON position. Tighten the (2) toggle

adjustment plate screws to 25 - 30 lb-in.

3. If the circuit breaker still can not be turned on unhook the spring, remove hitch pin and separate threaded rod and

handle link. Turn threaded rod one full turn counterclockwise. Reattach threaded rod and handle link, hitch pin and

spring. Repeat Step 1 and if necessary Step 2.

4. Verify that the circuit breaker can be turned off by moving the disconnect handle to the OFF position.

5. If the circuit breaker can not be turned off, loosen the (2) screws and adjust the toggle adjustment plates toward the

load terminals until the circuit breaker turns off when the disconnect handle is in the OFF position. Tighten the (2)

toggle adjustment plate screws to 25 - 30 lb-in.

6. If the circuit breaker still can not be turned off and if no adjustment of the threaded rod was made in Step 3 then

unhook the spring, separate threaded rod and handle link and remove hitch pin. Turn threaded rod one full turn

clockwise. Reattach threaded rod and handle link, hitch pin and spring. Repeat Step 4 and if necessary Step 5.

7. Verify that the circuit breaker can be reset after manually tripping when circuit breaker is in the ON position.

8. Manually trip the circuit breaker while in the ON position, then move the disconnect handle to the Off-Reset

position.

9. If the circuit breaker does not reset, loosen the (2) screws and adjust the toggle adjustment plates in small

increments toward the load terminals.

Note: Repeat this procedure until the circuit breaker can be reset.

Note: Do not adjust the toggle adjustment plate too far: this will prevent the disconnect handle from moving to the full OFF-

Reset position.

10.Tighten the (2) adjustment plate screws to 25 - 30 lb-in.

11.Verify that the circuit breaker can still be turned on following the above steps.

Note: Twisting of the bail mechanism is acceptable when the handle is in the full ON or full OFF position.

4

(5)

Page 6

Auxiliary Installation

Safety Guards

On

Off

5

Bulletin 1495

1

Auxiliary

Contacts

Slot B

Slot A

Base

Assembly

3

Bail

Support

Bracket

4

Support

Bushings

Plate

Safety Guard

Cam

2

Bulletin 1495

Auxiliary

Contacts

1. Move the disconnect handle on the combination starter to the OFF position.

2. Fasten the cam and bushings to the bail with (2) flat washers, (2) lock washers, and (2) screws Tighten to 12 - 16 lb-in.

3. Fasten the base assembly to the support bracket with (2) screws. Tighten to 7 - 10 lb-in.

4. Attach the assembly from Step 3 to the ear on the support plate with (2) screws. Tighten to 7 - 10 lb-in.

5. Attach the auxiliary contact with the safety guard to the base assembly.

Note: If a single auxiliary contact is used, it must be positioned nearest the cam, in slot A shown above. A second auxiliary contact

would be positioned in slot B.

Testing of Auxiliary Contacts

1. Make sure the auxiliary contact and adapter kit (circuit breaker) have been installed in the proper position.

2. If the auxiliary contact (circuit breaker) is N.O., place the probes of the continuity tester across both terminals with the

disconnect handle in the OFF position; there should be no continuity.

3. Move the disconnect handle to the ON position and place the probes of the continuity tester across both terminals; there

should be continuity.

4. If the auxiliary contact (circuit breaker) is N.C., place the probes of the continuity tester across both terminals with the

disconnect handle in the OFF position; there should be continuity.

5. Move the disconnect handle to the ON position and place the probes of the continuity tester across both terminals; there

should be no continuity.

42052-074-01 (1)

Printed in U.S.A.

Loading...

Loading...