Page 1

Bulletin 1494F Fixed Depth Disconnect Switch Installation Instructions

(Cat 1494F-N30; -N60; -N100; -N200) (Series B)

WARNING

WARNING

To prevent electrical shock, disconnect from power source before installing or servicing. Follow

NFPA 70E requirements. Install in suitable enclosure. Keep free from contaminants.

The following procedures are critical to the proper operation of the disconnect handle and switch.

Failure to follow these steps can result in damage to the equipment and/or serious injury or death to the

operator.

Table of Contents Page

Enclosure with Pre-Drilled Handle Cutout 2

Install Disconnect Switch

-

- Install Disconnect Switch Standoffs

Enclosure without Pre-Drilled Handle Cutout

Locate Handle

-

3

- Drill Handle Holes

Enclosure Requiring Door Catch Mounting Bracket

4

Fuse Block Adapter Plate Installation (Switch Rating 30A - 60A - 100A) 5, 6

Fuse Block Adapter Plate Installation (Switch Rating 200A) 7

Phase Barrier Replacement Kit and Fuse Clip Installation

(

Switch Rating 30A - 60A) 8

Phase Barrier Replacement Kit and Fuse Clip Installation

(

Switch Rating 100A) 9

Phase Barrier Replacement Kit (

Switch Rating 200A) 10

Fuse Clip Installation (

Switch Rating 200A)

11

Dimensions 12

Fuse Clip Installation (200A)

Installation--Vault Hardware Latching (1494F-L1)

12

13

Installation-- Vault Hardware Latching (1494F-L2, -L3, -L4) 14

Testing Vault Hardware Latching and Enclosure Seal 15

Installation-- Vault Hardware Latching (Non Pre-Drilled Enclosures) 16, 17

Bulletin 1494F Disconnect Switch Kits 18

Bulletin 1494F Disconnect Switch Kit Optional Accessory List 19

42052-195-01

DIR 10000075001 (Version 00)

Printed in U.S.A.

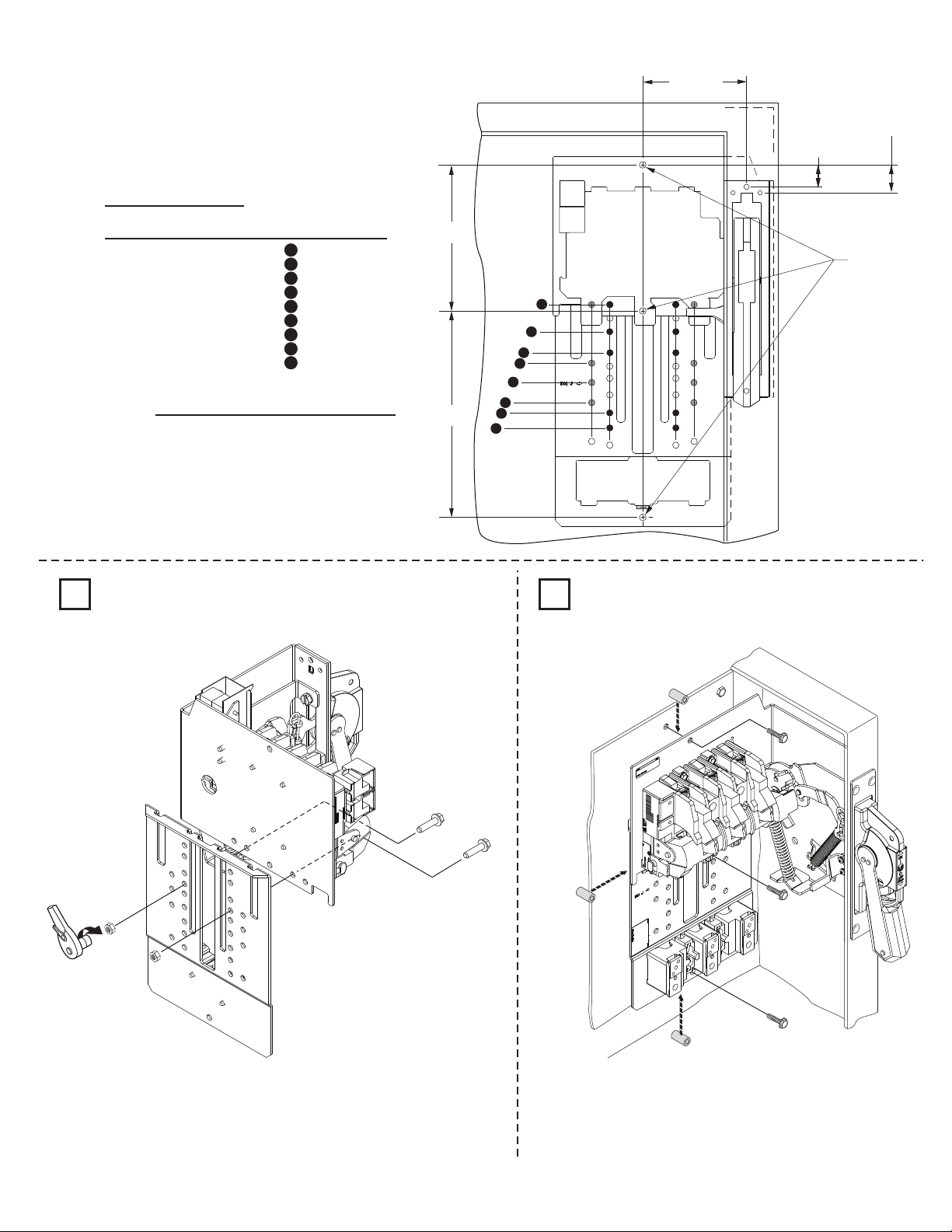

Page 2

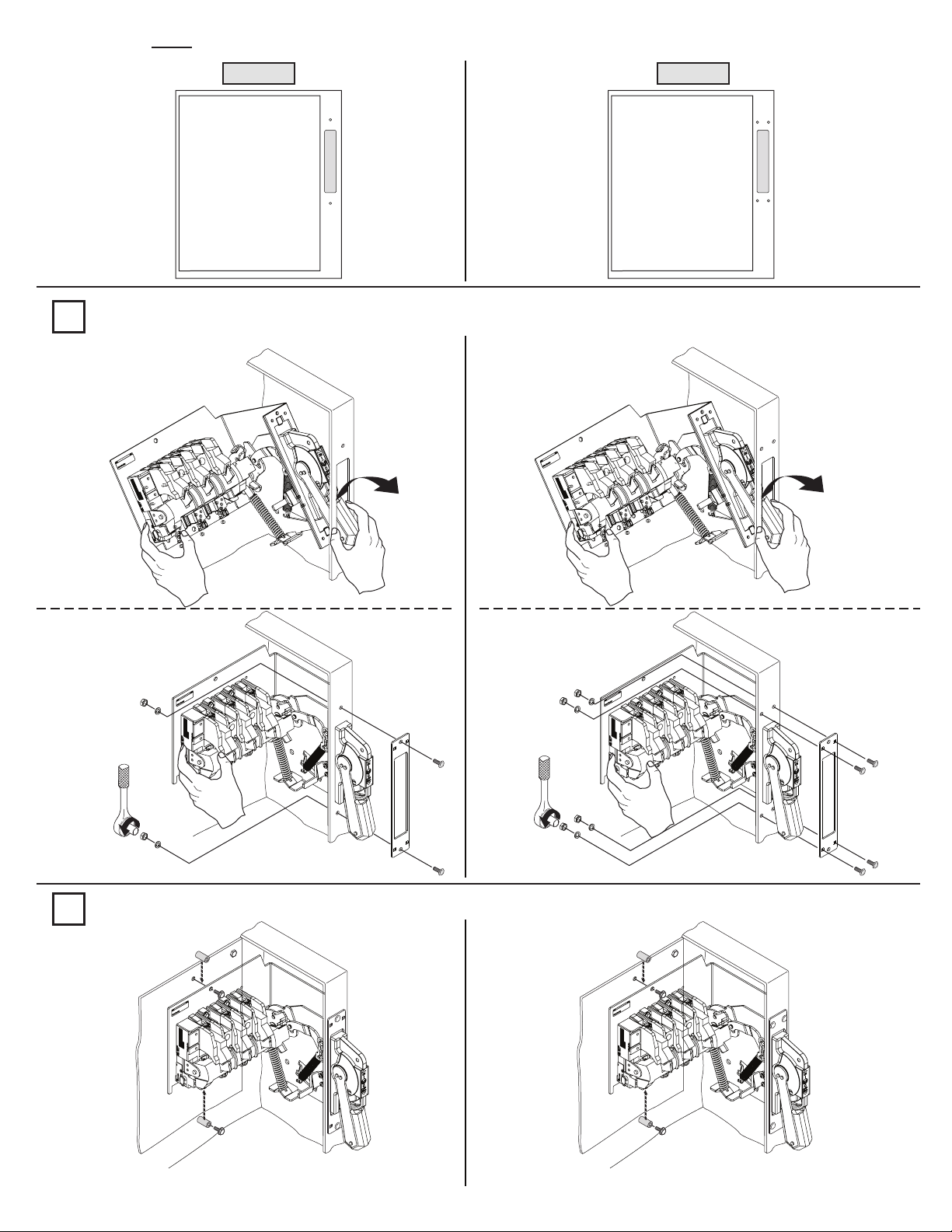

Enclosure with Pre-Drilled Handle Cutout

Option 1

Install Disconnect Switch (Left-hand installation unavailable.)

1

Option 2

35-45 lb-in

Install Disconnect Switch Standoffs

2

Standoffs & Bolts to be

Provided by User or

Enclosure Manufacturer

42052-195-01

DIR 10000075001 (Version 00)

23-37 lb-in

Standoffs & Bolts to be

Provided by User or

Enclosure Manufacturer

(2)

Page 3

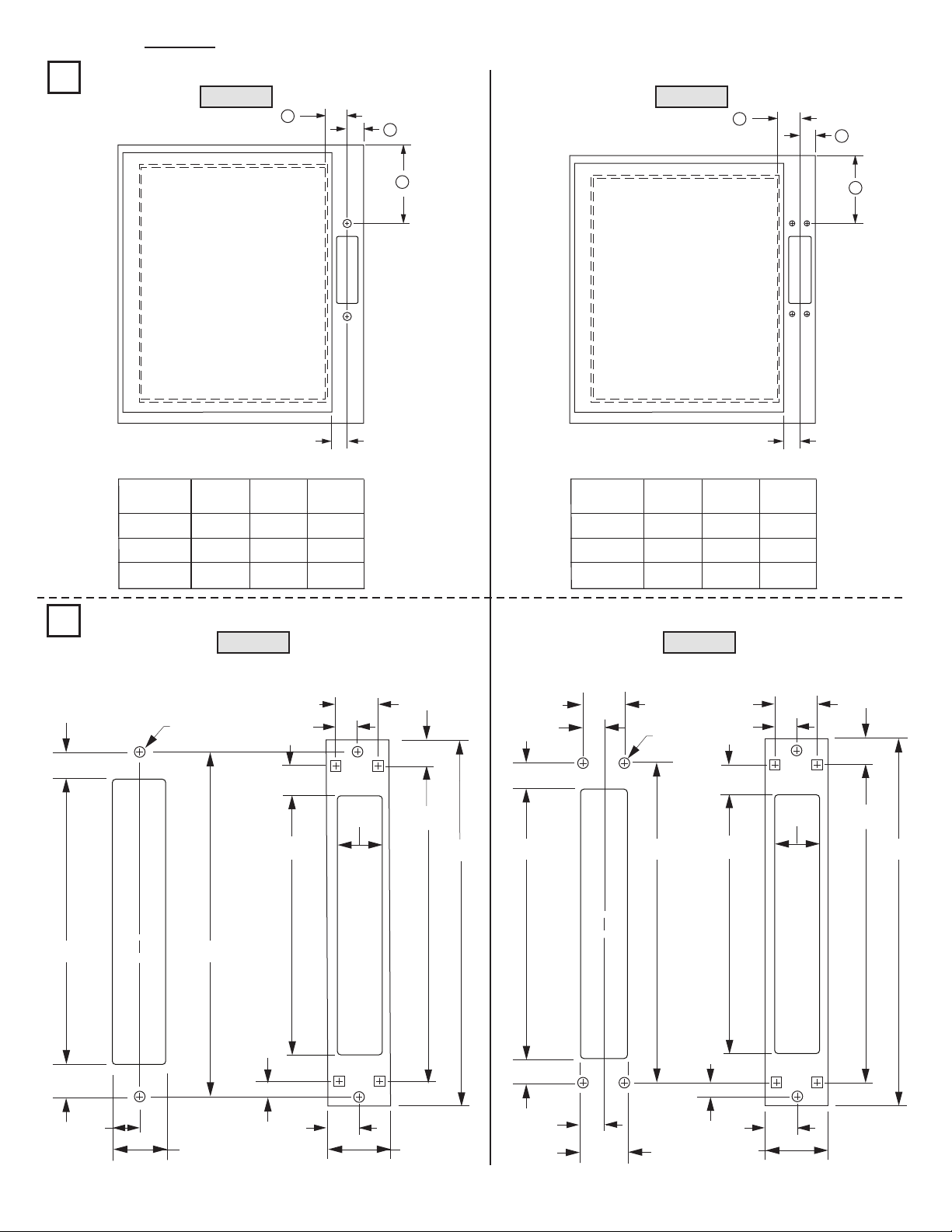

Enclosure without Pre-Drilled Handle Cutout

Locate Handle

1

Option 1

C

B

Option 2

F

E

NEMA

SIZE

30A, 60A

100A

200A

Drill Handle Holes

2

ENCLOSURE FLANGE

HANDLE CUT-OUT

15/32”

A

(min)

2-3/4"

4-1/4"

8-1/4"

Option 1

(2) .265” Dia.

Holes

B

(min)

1 - 3/16"

1 - 3/16"

1 - 3/16"

9/16”

13/16”

5/8” Min.

C

(min)

1 - 1/16"

1 - 1/16"

1 - 1/16"

FLANGE MOUNTED

COVER PLATE

1 - 1/8”

A

D

5/8” Min.

Enclosure Flange Cut-Out Dimensions (Option 2)Enclosure Flange Cut-Out Dimensions (Option 1)

NEMA

SIZE

30A, 60A

100A

200A

D

(min.)

3

4-1/2"

8-1/2"

E

(min.)

1 - 3/16"

1 - 3/16"

1 - 3/16"

F

(min.)

1 - 1/16"

1 - 1/16"

1 - 1/16"

Option 2

FLANGE MOUNTED

COVER PLATE

1 - 1/8”

9/16”

9/16”

13/16”

9/16”

ENCLOSURE FLANGE

HANDLE CUT-OUT

1-1/8”

9/16”

13/32”

(4) .203” Dia.

Holes

7 - 3/16”

27/32”

21/32”

8 - 1/2”

1 - 5/16”

42052-195-01

DIR 10000075001 (Version 00)

1/4”

6-3/8”

25/32”

1 - 3/16”

8”

1 - 9/16”

9-1/8”

(3)

7-3/16”

13/32”

21/32”

1-5/16”

1 - 3/16”

8”

6-3/8”

1/4”

25/32”

1 - 9/16”

8”

9-1/8”

Page 4

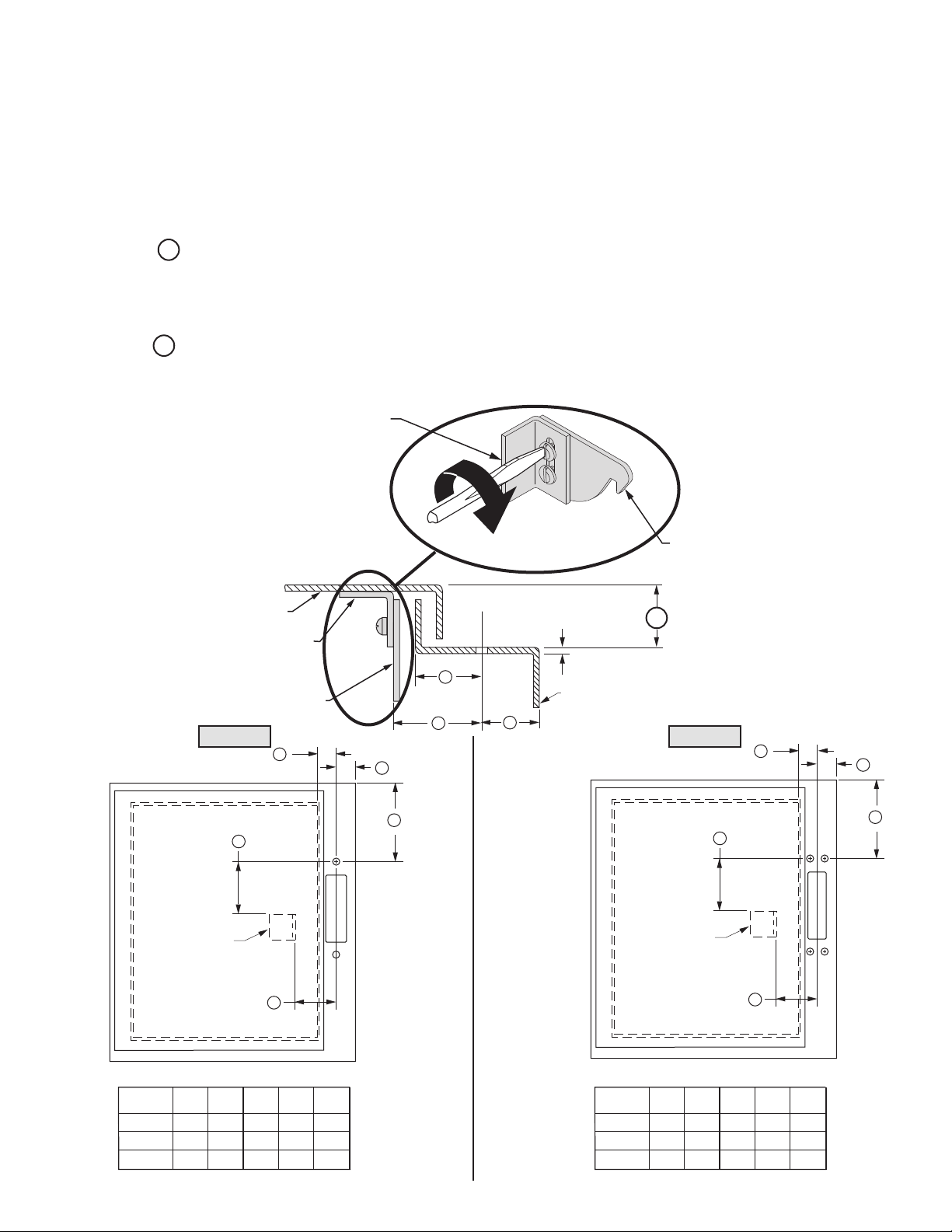

Enclosure Requiring Door Catch Bracket

Right-hand installation shown with or without enclosure door vault hardware

(Left-hand installation unavailable)

Door Catch Mounting Bracket:

L Provided with projections for welding.

L Projections can also be used as a guide for drilling holes.

L Can be used as a template to drill corresponding holes in the enclosure door.

L User to supply the hardware for fastening the bracket.

L The bracket hardware must be inaccessible to unauthorized personnel.

L Fasteners must provide the degree of ingress protection for the environmental rating of the enclosure.

Dimension K (3/4" to 1")

L When installed in any size enclosure without door vault hardware, use door catch provided with disconnect switch kit.

L When installed in small and intermediates size enclosures (15 inches to 40 inches) using door vault hardware kits

(1494F-L1, 1494F-L2 and 1494F-L3), use door catch with pivot lever provided with disconnect switch kit. Discard the door catch

supplied with the door vault hardware kit.

Dimension K (1-1/8" to 1-3/8")

L When installed in large enclosure using door vault hardware kit (1494F-L4), use the door catch assembly with the pivot lever

included with the disconnect switch. Discard the door catch supplied with the door vault hardware kit.

Mounting Bracket

Enclosure Door

Door Catch

Mounting Bracket

Door Catch

Option 1

C

E

Door Catch

TOP VIEW

Top

Door Catch (used without door

vault hardware kits)

Flange

Thickness

C

K

Enclosure

Base

D

B

Option 2

H

B

A

K

G

F

Door Catch

Mounting

Bracket

Enclosure Dimensions

NEMA

SIZE

30A, 60A

100A

200A

42052-195-01

DIR 10000075001 (Version 00)

A

(min)

2 - 3/4"

4 - 1/4"

8 - 1/4"

B

(min)

1 - 3/16"

1 - 3/16"

1 - 3/16"

C

(max)

1 - 1/16"

1 - 1/16"

1 - 1/16"

Door Catch

Mounting

Bracket

H

(max)

1 - 1/16"

1 - 1/16"

1 - 1/16"

J

J

2 - 1/8"

2 - 1/8"

2 - 1/8"

K

3 - 9/16"

3 - 9/16"

3 - 9/16"

D

Enclosure Dimensions

D

2 - 1/8"

2 - 1/8"

2 - 1/8"

E

3 - 13/16"

3 - 13/16"

3 - 13/16"

NEMA

SIZE

30A, 60A

100A

200A

F

(min)

3"

4 - 1/2"

8 - 1/2"

G

(min)

1 - 3/16"

1 - 3/16"

1 - 3/16"

(4)

Page 5

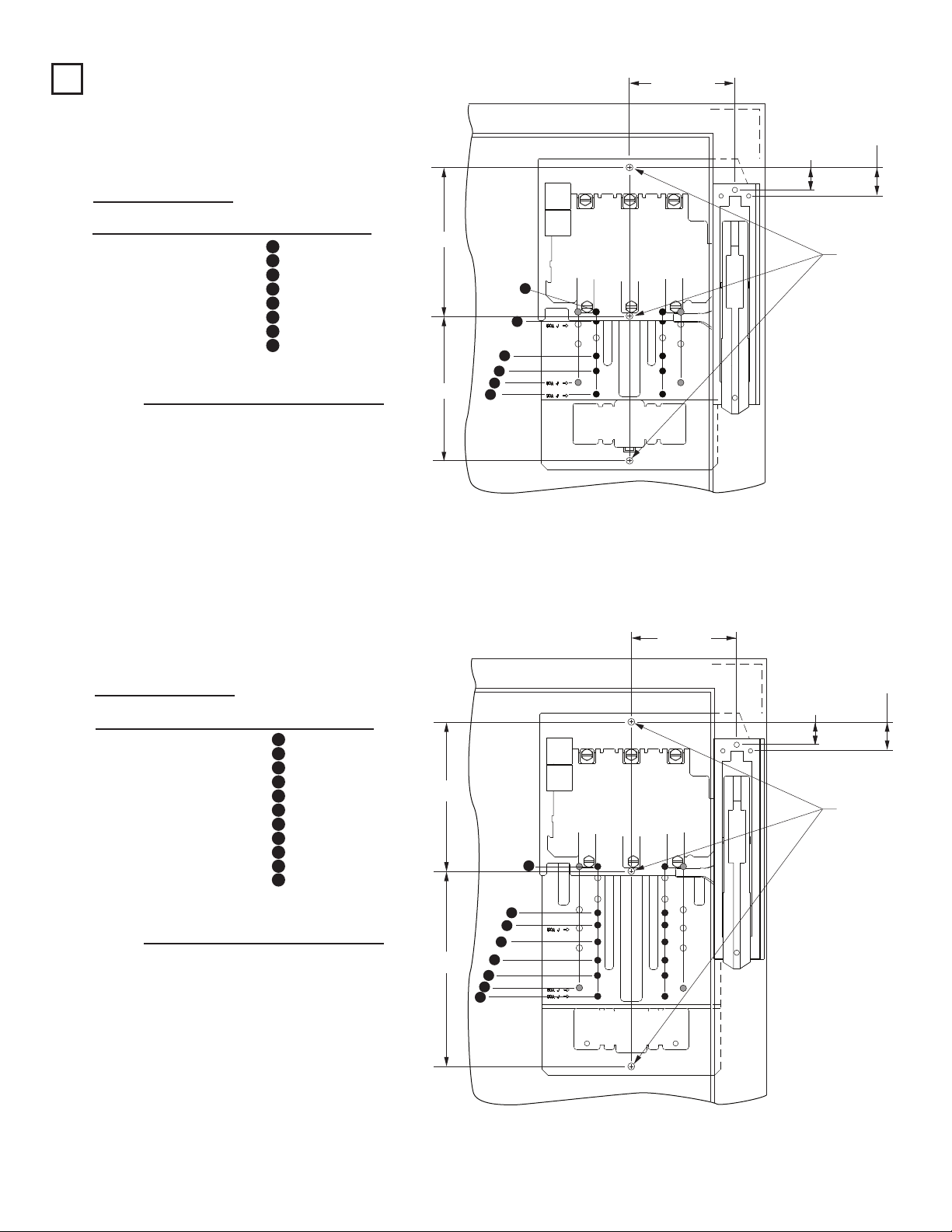

Fuse Block Adapter Plate Installation (Switch Rating 30A - 60A - 100A)

30 Amp Fuse Block Adapter Plate Kit (1494F-F30)

1

Fuse

Amps

30

30

30

30

60

60

60

60

Voltage Class

250

600

600

600

250

600

600

600

H/R

H/R

HRCII-C

H/R

H/R

HRCII-C

Position D

J

J

6

2

6

3

4

1

5

3

2 - 13/16”

5 - 5/8”

2 - 13/16”

4

-

3/16”

3 - 5/8”

6 - 1/8”

3”

4 - 3/16”

Hardware Torque (lb-in)

30

60

Fuse Block

Adapter Kit

Fuse

Clip

Lug to

Terminal

into Lug

40-60 22-37 20-25 20-25

Wire

Fuse

Amps

6”

4 - 5/16”

1 - 3/16”

15/16”

(Option 2)

(Option 1)

(3) - 9/32 Dia.

1

2

3

4

D

5

6

60 Amp Fuse Block Adapter Plate Kit (1494F-F60)

Fuse

Amps Voltage Class Position

30

30

30

30

60

60

60

60

100

100

100

250

600

600

600

250

600

600

600

250

600

600

H/R

H/R

J

HRCII-C

H/R

H/R

J

HRCII-C

H/R

J

H/R

8

3

8

5

6

2

7

5

2

4

1

Hardware Torque (lb-in)

30

60

100

Fuse Block

Adapter Kit

Fuse

Clip

Terminal

40-60 22-37 40-60 45-50

40-60 16-22 40-60 45-50

Fuse

Amps

Lug to

D

2 - 13/16”

5 - 5/8”

2 - 13/16”

4 - 3/16”

3

-

5/8”

6

-

1/8”

3”

4 - 3/16”

6 - 1/8”

4 - 15/16”

8 - 1/8”

Wire

into Lug

6”

4

-

5/16”

1

-

3/16”

15/16”

(Option 2)

(Option 1)

(3) - 9/32 Dia.

1

2

3

4

D

5

6

7

8

42052-195-01

DIR 10000075001 (Version 00)

(5)

Page 6

Fuse Block Adapter Plate Installation (Switch Rating 30A - 60A - 100A) - (Cont’d)

a

100 Amp Fuse Block Adapter Plate Kit (1494F-F100)

100 Amp Trailer Fuse Block (1494F-F100)

Fuse

Amps Voltage Class

60

60

60

60

100

100

100

100

200

Fuse

Amps

100

200

60

250

600

600

600

250

600

600

600

600

Fuse Block

Adapter Kit

H/R

J

H/R

HRCII-C

H/R

H/R

J

HRCII-C

J

Hardware Torque (lb-in)

40-60 22-37 90-110 150-165

40-60 16-22 90-110 150-165

Fuse

Clip

7

8

3

6

3

1

5

2

4

Lug to

Terminal

DPosition

4 - 3/16”

3 - 9/16”

6 - 11/16”

4 - 11/16”

6 - 11/16”

8 - 11/16”

5

-

1/2”

7 - 9/16”

6

-

1/4”

Wire

into Lug

6”

D

4 - 5/16”

1

-

3/16”

15/16”

(Option 2)

(Option 1)

(3) - 9/32 Di

1

2

3

4

5

6

7

8

2 3

40 - 60 lb-in

Standoffs & Bolts to be

Provided by User or

Enclosure Manufacturer

42052-195-01

DIR 10000075001 (Version 00)

(6)

Page 7

Fuse Block Adapter Plate Installation (Switch Rating 200A)

200 Amp Fuse Block Adapter Plate Kit (1494F-F200)

1

200 Amp Trailer Fuse Block (1494F-F200)

Fuse

Amps Voltage Class

100

100

100

100

200

200

200

200

400

Fuse

Amps

100

200

400

250

600

600

600

HRCII-C

250

600

600

600

HRCII-C

600

Fuse Block

Adapter Kit

40-60 16-22 160-190 275-305

40-60 16-22 160-190 275-305

Position

Fuse

Clip

5

2

7

7

3

1

6

6

4

Terminal

Lug to

5 - 7/8”

7 - 7/8”

4 - 5/8”

4

6 - 3/4”

9 - 1/4”

5 - 3/8”

5 - 3/8”

6

-

H/R

H/R

J

H/R

H/R

J

J

Hardware Torque (lb-in)

D

5/8”

1/4”

into Lug

Wire

8 - 3/16”

D

1

2

3

4

5

6

7

400A J

200A J

100A J

4 - 23/32”

1 - 3/16”

(Option 2)

15/16”

(Option 1)

(3) - 9/32 Dia.

2

40 - 60 lb-in

3

Standoffs & Bolts to be

Provided by User or

Enclosure Manufacturer

42052-195-01

DIR 10000075001 (Version 00)

(7)

Page 8

Phase Barrier Replacement Kit (Switch Rating 30A - 60A)

1494F-PH2

1 2

1

2

Disconnect Switch

Phase Barrier

Part No. 40392-097

30 Amp Disconnect Switch and Fuse Block Shown

Fuse Block

Phase Barrier

Part No.

40392-098

Fuse Clip Installation (Switch Rating 30A - 60A)

1

23 - 37 lb-in

2

2

CLICK

1

CLICK

2

Class R

Fuses Shown

42052-195-01

DIR 10000075001 (Version 00)

Class R

Fuse Clips

Shown

1

30 Amp Disconnect Switch and Fuse Block Shown

(8)

Page 9

Phase Barrier Replacement Kit (Switch Rating 100A)

R

1494F-PH3

Switch Phase Barrier

Trailer Block Phase Barrier

1

2

CLICK

Fuse Clip Size and Class

60 A

100 A

200 A

200 A

600V H - R

600V H - R

600V H - R

250V H - R

2

2

Fuse Clip Size and Class

60 A

1

60 A

100 A

100 A

250V H - R

600V J

250V H - R

600V J

600V J200 A

1

CLICK

3

1

2

Fuse Clip Installation (Switch Rating 100 Amp)

1

16 - 22 lb-in

2

2

CLICK

1

1

CLICK

2

100 Amp Class

Fuses Shown

2

23 - 37 lb-in

42052-195-01

DIR 10000075001 (Version 00)

1

(9)

Page 10

Phase Barrier Replacement Kit (Switch Rating 200A)

1494F-PH4

1

1

2

5

40 - 60 lb-in

3

2

CLICK

4

1

2

3

CLICK

42052-195-01

DIR 10000075001 (Version 00)

(10)

Page 11

Fuse Clip Installation (Switch Rating 200A)

1

16 - 22 lb-in

2

2

1

1

Fuse Clip Installation (Switch Rating 200A) for 400A Class J Fuses (Cat. No. 1401-N171)

23 - 37 lb-in

2

1

2

16 - 22 lb-in

2

150 - 200 lb-in

1

42052-195-01

DIR 10000075001 (Version 00)

(11)

Page 12

Dimensions

Spacers /

Standoffs

Provided by

User or

Enclosure

Manufacturer

H

(Min)

J Q

Non-Fusible Disconnect Switch

R

E

D

Fusible Disconnect Switch

A

B

1-1/8”

M

C

F

1/4”

K LG

(2) - 9/32 Dia.

Spacers /

Standoffs

Provided by

User or

Enclosure

Manufacturer

Switch

Size

H

(Min)

J

ABC EFGH

R

Q

E

D

See Fuse Block

Adapter Plate Section

See Fuse Block

Adapter Plate Section

(Min)

A

B

1-1/8”

N

P

JD

KMNPQRL

M

C

F

1/4”

K LG

(3) - 9/32 Dia.

30A

60A

100A

200A

9 - 3/16”

9

9

-

3/16”

-

-

9

3/16”

5/8”

4

-

5/16”

4

-

5/16”

-

5/16”

4

-

3/4”

4

42052-195-01

DIR 10000075001 (Version 00)

1

-

1/8”

1

-

1/8”

-

1/8”

1

-

5/32”

1

-

8

6”

6”

6”

3/16”

3/8”

3/8”

3/8”

1

1

1

-

-

-

9/16”

9/16”

9/16”

2”

10

10

10

10

-

-

-

-

29/32”

1/2”

1/2”

1/2”

8

8

9

9

-

-

-

-

1/2”

1/2”

3/4”

3/4”

6

-

7/8”

6-

7/8”

-

1/8”

8

-

1/8”7/16”

8

8”

8 - 1/2”

8”

8

8”

8

8

8”

15/16”

3 - 21/32”

15/16”

15/16”

3

3

-

1/2”

-

1/2”

-

1/2”

-

21/32”

-

21/32”

-

3

3/4”

7

7

7

7

-

5/16”

-

5/16”

-

5/16”

-

1/2”

5

3”

-

7/16”

3”

5

-

7/16”

3”

-

7/16”

5

-

3”1 - 5/16”

7/16”

5

(12)

Page 13

Installation--

)

Vault Hardware Latching (1494F-L1) - Top and Side Latching

(40 Inches Maximum Enclosure Height)

1

Latching rod may be supplied

by enclosure manufacturer

2

2

Drive-Lok Pin

1

(Optional screw

and nut included

with kit)

3 4

3

40 - 60 lb-in

Gasket to be installed inside door.

40 - 60 lb-in

1

Optional number of

1

150 - 200 lb-in

2

shims used (0 - 3).

More shims, more

gasket compression

23 - 37 lb-in

2

23 - 37 lb-in

3

23 - 37 lb-in

Assemble door catch

and defeater lever

actuator in center of

slots. (Parts included

with the disconnect

switch).

Adjustment may be

required (up or down

1

for interlocking to

work properly.

42052-195-01

DIR 10000075001 (Version 00)

(13)

Page 14

Installation--

c

f

Vault Hardware Latching (1494F-L2, -L3) -

(40 Inches Maximum Enclosure Height-1494F-L2)

(60 Inches Maximum Enclosure Height-1494F-L2, -L3)

Top and Bottom Latching or Top, Side and Bottom Latching

Vault Hardware Latching (1494F-L4 for Large Enclosures) -

(84 Inches Maximum Enclosure Height)

1

3

2

Latching rod may be

supplied by

enclosure manufacturer

1

Drive-Lok Pin

(Optional screw and

nut included with kit)

Top, Side and Bottom Latching

4

Drive-Lok Pin

(Optional screw and

nut included with kit)

2

3

4

3

40 - 60 lb-in

3

23 - 37 lb-in

Gasket to be

installed inside door.

Assemble door cat

and defeater lever

actuator in center o

slots. (Parts include

with the disconnect

switch).

Adjustment may be

required (up or dow

1

for interlocking to

work properly.

40 - 60 lb-in

1

1

3

40 - 60 lb-in

2

150 - 200 lb-in

23 - 37 lb-in

Optional number

of shims used

(0 - 3).

More shims,

more gasket

compression

2

23 - 37 lb-in

42052-195-01

DIR 10000075001 (Version 00)

(14)

Page 15

Installation-- Vault Hardware Latching (Non Pre-Drilled Enclosures)

2

Option 2Option 1

1 - 3/8”

1

-

1/8”

9/16”

(1494F-L1)

-

1/4”

3

G

(Min)

(1494F-L2,

1494F-L4)

H *

(Min)

C

(Min)

J *

(Min)

C + 1/16” *

(Min)

4 - 3/4”

Bracket

Guide

Bracket

2 - Holes

9/32” Dia.

3 - 1/4”

2 - 3/8”

13/16”

2 - Holes

13/32” Dia.

Guide

1 - 3/8”

B

1/4”

A

D

F

E

(Min)

1/4”

3/4” Dia.

B

M

Guide Bracket

Door Catch Bracket

(1494F-L1, 1494F-L2)

E + 3 - 1/2”

(1494F-L4)

-

3/8”

E + 3

N

Guide Bracket

M

3/4”

5/16”

N

3/4”

6 - Holes

+.000

.193” Dia.

-.003

3/8”

K

L

1/2”

2 - Holes

#10-32

5/16”

3/8”

(1494F-L1, 1494F-L

G minus 3/4”

(1494F-L4)

-

G minus 1

1/8”

(1494-L2)

H minus 3/4”

(1494-L4)

H minus 1 - 1/8”

* Non applicable for 1494F-L1

Vault Hardware

Kits

Switch

Size

AB C

(Min)

E

(Min)

FG

(Min)H(Min)

J

(Min)

KLD

M

N

Small and Intermediate Enclosures

4

-

1/2”

1494F-L1 *

1494F-L2 *

1494F-L3 *

30A

60A

100A

200A

3

-

3

-

-

3

-

3

7/8”

7/8”

7/8”

7/8”

3/8”

3/8”

3/8”

3/8”

3

-

1/16”

-

1/8”

2

3

-

1/16”

2 - 1/8”

-

1/16”

3

-

3

1/16”

-

1/8”

2

2

-

1/8”

3

-

13/16”

-

1/2”

4

3

-

13/16”

-

1/2”

4

4

-

1/2”

-

3

-

3

13/16”

13/16”

18

23 - 25/32”

13”

14”

-

7/8”

8

-

1/8”

8

-

1/8”

-

1/8”

8

-

1/8”

8

5”

1/2”

5”

1/2”

5”

1/2”

5”

1/2”

1/4”

1/4”

1/4”

1/4”

11/16”

11/16”

11/16”

11/16”

1/2”

1/2”

1/2”

1/2”

Large Enclosures

5”

3

-

13/16”

13 - 1/8”

5”

3

-

5”

-

3

5”

-

3

13/16”

13/16”

13/16”

13

18

23 - 13/32”

-

13/16”

9

9

-

5/8”

-

13/16”

-

1/2”

-

13/16”

9

-

13/16”

9

6”

6”

6”

6”

5/8”

5/8”

5/8”

5/8”

5/16”

5/16”

5/16”

5/16”

1-1/4”

1-1/4”

1-1/4”

1-1/4”

3/4”

3/4”

3/4”

3/4”

1494F-L4 *

30A

60A

100A

200A

1/2”

4”

4”

4”

4”

1/2”

1/2”

1/2”

3 - 3/4”

3

-

3/4”

-

3/4”

3

-

3/4”

3

2

-

1/8”

2

-

1/8”

-

1/8”

2

-

1/8”

2

* When using 1494F-L1, -L2, -L4 vault hardware kits with Series A 1494F-N30, 1494F-NF30, 1494F-N60, 1494F-NF60, 1494F-N100, 1494F-NF100, 1494D-N4,

1494D-N5, 1494M-N30, 1494M-NF30, 1494M-N60, 1494M-NF60, 1494M-N100 or 1494M-NF100 it may be necessary to order adapter 1494F-N13. (Required for

Hoffman A22 Series B or later enclosures.)

42052-195-01

DIR 10000075001 (Version 00)

(15)

Page 16

Testing Vault Hardware Latching and Enclosure Seal

Close door against enclosure base. The door handle should

1 2

be in the 6 o’clock position in line with the length of the door

when fully latched and the enclosure is sealed.

Turn release screw counterclockwise and hold screw in that

position to release initial catch from beneath enclosure flange.

Handle should rotate clockwise to approximately the 9 o’clock

3 4

position under spring action. The locking bars should have

retracted from top and bottom of door and center latch cleared

right hand flange.

Reclose door against enclosure base. Turn door handle

counterclockwise to the 6 o’clock position. You should

hear two distinct clicks as you turn the handle.

Handle should remain in this position.

“Click”

“Click”

42052-195-01

DIR 10000075001 (Version 00)

(16)

Page 17

Testing Vault Hardware Latching and Enclosure Seal (Cont’d)

Return to Step 3 to open door. Close the

5 6

door on the base and turn the handle to

the 6 o’clock position. Door should be

sealed securely to the enclosure base.

Close the door and turn the door handle counterclockwise until the first “click”

is heard. Move the disconnect handle to the ON position (do not force). If the

disconnect handle can be moved, the defeater lever actuator is properly adjusted.

Continue rotating door handle to fully closed position (6’oclock).

“Click”

Move defeater lever actuator upward

to allow disconnect handle to be turned

to on position later.

Move door catch downward to allow

operation of handle relative to door

latching handle sooner.

42052-195-01

DIR 10000075001 (Version 00)

(17)

Page 18

Bulletin 1494F Disconnect Switch Kit

Disconnect Kit

Disconnect Switch and Handle

with Mechanism

Fuse Block

with Adapter Plate

Cat No.

Switch and Handle with Right Hand Mechanism

(Non-Fusible and Fusible)

1494F-N30 (30A)

1494F-N60 (60A)

1494F-N100 (100A)

1494F-N200 (200A)

1494F-F30 (30A)

1494F-F60 (60A)

1494F-F100 (100A)

1494F-F200 (200A)

42052-195-01

DIR 10000075001 (Version 00)

Fuse Clips

1401-N41 (Class H, 30A - 250V)

1401-N42 (Class H,J, 30A - 600V,

Class H, 60A-250V)

1401-N43 (Class H,J, 60A - 600V)

1401-N44 (Class H,J, 100A-250V, 100A-600V)

1401-N45 (Class H,J, 200A-250V, 200A-600V)

1401-N50 (Class R, 30A - 250V)

1401-N51 (Class R, 30A - 600V, 60A-250V)

1401-N52 (Class R, 60A - 600V)

1401-N53 (Class R, 100A - 250V, 100A-600V)

1401-N54 (Class R, 200A-250V, 200A-600V)

1401-N171 (Class J, 400A-250V / 600V)

(18)

Page 19

Bulletin 1494F Disconnect Switch Optional Accessory List

Optional Accessories

(Installation Instructions

Included with Accessory Kits)

Electrical

Interlock

Terminal

Adapter Kit

Use with Switch with Right Hand Mechanism

1495-N34 (1-N.O./N.C.) (30A - 60A - 100A)

1495-N35 (2-N.O./N.C.) (30A - 60A - 100A)

1495-N43 (1-N.O./N.C.) (200A)

1495-N44 (2-N.O./N.C.) (200A)

1494R-N16 (30A)

1494R-N17 (60A)

1494R-N18 (100A)

1494R-N19 (200A)

Cat No.

Line Side

Cover

Auxiliary

Contact

Lug

Connectors

Phase

Barrier

Fuse

Cover

with Door

1495-N80 (30A - 60A - 100A)

1495-N81 (200A)

1495-N8 (1-N.O.) (30A - 60A - 100A - 200A)

1495-N9 (1-N.C.) (30A - 60A - 100A - 200A)

Low Energy

1495-N8X (1-N.O.) (30A - 60A - 100A - 200A)

1495-N9X (1-N.C.) (30A - 60A - 100A - 200A)

(Saddle Clamps Included)

(CU Wire Size #14 . . #8 AWG) (30A)

1494R-N1

(CU Wire Size #14 . . #4 AWG) (60A)

1494R-N2

(CU Wire Size #8 . . #1/0 AWG) (100A)

1494R-N3

(CU Wire Size #6 . . #4/0 AWG) (200A)

1494F-PH2 (30A - 60A)

1494F-PH3 (100A)

1494F-PH4 (200A)

Switch

Rating

30A

30A

60A

30A

60A

60A

100A

30A

60A

100A

100A

200A

Fuse

Class

Non-Fusible

H, R

H, R

J

J

Non-Fusible

Non-Fusible

H, R

H, R

J

H, R

J

Non-Fusible

H, J, R

J

Fuse Clip

Rating

250V 600V

----

----

30A

----

60A

----

30A

30A

60A

60A

----

----

----

----

----

30A

----

60A

100A

100A

100A

100A

200A

200A

----

----

200A

200A

400A

400A

Cat No.

1495-N64

1495-N65

1495-N66

1495-N67

42052-195-01

DIR 10000075001 (Version 00)

(19)

Page 20

42052-195-01

DIR 10000075001 (Version 00)

Print in U.S.A.

Loading...

Loading...