Page 1

M2

HIGH

LOW

P1

T1

T2

1

2

P

EV1

EV5

EV3

EV6

3F1

C

P2

HP

5

VU2

6

F2

9

4

EV7

10

7

V1

8

V3 V2V4

V6V5

M1

M3

13

12

11

EV10

VU3 VU1

EV8EV9

8

tuv7pqrs

0

1

4

ghi

V

abc

jkl

5

2

9

wxyz

def

mno

6

3

AC690PRO & variants

en

fr

pt

Original instructions

Notice originale

AC service units Appareil SAV pour la climatisation

Manual original

Aparelho de manutencao de

sistemas de ar condicionado

it

Istruzioni originali

Attrezzatura per assistenza

climatizzatore

Originalbetriebsanleitung

Klimaservicegerät

de

es

Manual original

Aparato de servicios de

aire acondicionado

Page 2

8

tuv7pqrs

0

1

4

ghi

V

abc

jkl

5

2

9

wxyz

def

mno

6

3

14 15 16

18

19

17

20

22

23

21

26

25

24

Page 3

It is forbidden to even partially this handbook in any way unless prior written authorisation has

been obtained from the manufacturer.

The data and characteristics indicated in this handbook are not binding. The manufacturer reserves

the right to make all those modifications as are considered necessary without being obliged to give

advance warning or make replacements.

All the names of brands and products and the trade marks are the property of the respective

owners.

S P00 D00 095 – 2014/02

Dear garage owner,

Thank you for having chosen one of our instruments for your workshop. We are

certain that it will give the utmost satisfaction and be a notable help on the job.

Please become fully familiar with the instructions in this user’s manual. It should

be kept ready to hand for consultation whenever required.

AC690PRO is an electronic unit for recovery, recycle, vacuum and charge of A/C

systems using R134a as refrigerant.

A simple but reliable connection system guarantees a safe work during all of the

operations: refrigerant recovery and recycle; vacuum and leak test; additive and

lubricant injection; circuit recharge and working pressure test.

The refrigerant flow is controlled and managed by an electronic scale so as to prevent

any tank overflow or the flow of a refrigerant quantity exceeding that allowed.

The quantity to be charged in the A/C system is set by the operator by the function

keyboard or by consulting the internal database.

A patented separator still allows to separate the refrigerant from the lubricant.

Page 4

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 45

Page 5

en AC690PRO ________________________________________________________________________________

46 OPERATING INSTRUCTIONS

INDEX

CAPTIONS 48

GENERAL INFORMATION FOR THE USER 49

Disposing of equipment 49

Disposing of batteries 49

1.0 - FOR A SAFE USE AC690PRO 50

1.1 - For a safe use 50

1.2 - Safety devices 51

1.3 - The work environment 52

1.4 - Tank test 52

2.0 - INTRODUCTION TO THE UNIT 53

3.0 - DESCRIPTION OF THE UNIT 54

3.1 - The Keyboard 54

4.0 - INSTALLATION OF THE UNIT 55

4.1 - Unpacking and checking components 55

4.2 - Machine handling and storage 55

4.3 - Preparation for use 56

4.4 - Loaded and recovered coolant storage 60

4.4.1 - Report management enabling 60

4.4.2 - Report printing 60

4.4.3 - Report management with ACUSB (optional) 60

4.5 - Bottle filling 61

4.6 - Tank display 62

4.7 - Oil scales reset 62

5.0 - USE OF THE UNIT 63

5.1 - Vehicle data entry 63

5.2 - Database 63

5.3 - Personalized Database 66

5.4 - Refrigerant recovery 67

5.5 - Evacuating the A/C system 68

5.6 - Oil injection and A/C system charge 69

5.7 - Automatic function 70

5.8 - Recycling function 72

5.9 - Incomplete charge 72

5.10 - Flushing (optional) 73

Page 6

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 47

6.0 - DISPLAYED MESSAGES 74

6.1 - Service messages 74

6.2 - Error messages 74

7.0 - MAINTENANCE 75

7.1 - Vacuum pump oil change 75

7.2 - Reset oil counter vacuum pump 75

7.3 - Filter dryer change 76

7.4 - Reset counter filter dryer 77

7.5 - Refrigerant scale calibration 78

7.6 - Oil replenishing scale calibration 79

7.7 - Oil purge scale calibration 80

8.0 - STOPPAGE FOR LONG PERIODS 81

9.0 - DEMOLITION/DISPOSAL 81

9.1 - Disposal of the equipment 81

9.2 - Disposal of the recycled materials 81

10.0 - TECHNICAL SPECIFICATIONS 82

11.0 - SPARE PARTS 82

12.0 - GLOSSARY OF TERMS 83

Page 7

en AC690PRO ________________________________________________________________________________

48 OPERATING INSTRUCTIONS

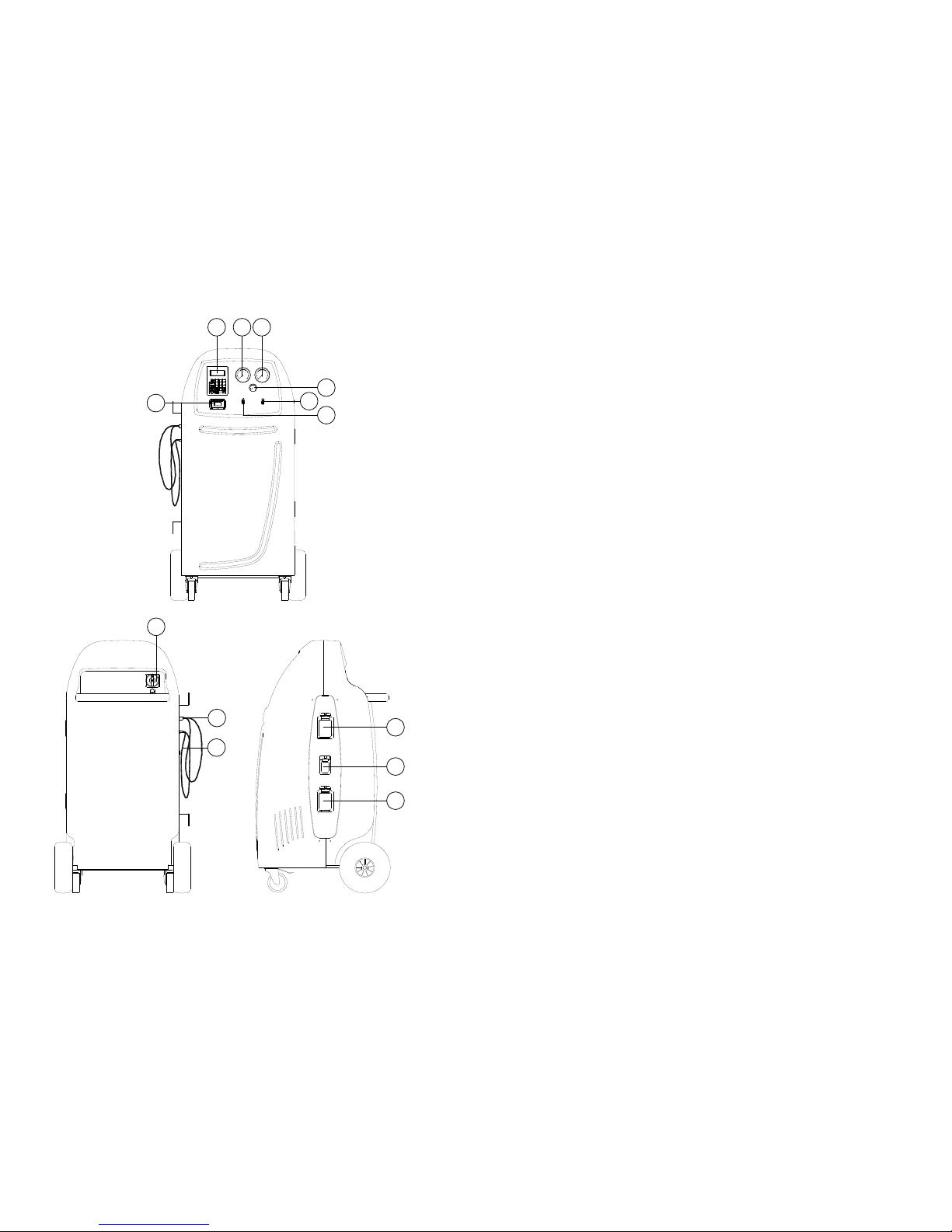

CAPTIONS

M1 Low pressure gauge

M2 High pressure gauge

M3 Inside tank pressure meter

T1 Low pressure service hose

T2 High pressure service hose

LOW Manifold set low pressure valve

HIGH Manifold set high pressure valve

V1 Tank vapour side hose valve

V2 Tank liquid side hose valve

V3 Tank vapour side valve

V4 Tank liquid side valve

V5 Safety valve

V6 Non condensable drain valve

VU1 Oil protection unidirectional valve

VU2 Separator-still check valve

VU3 UV dye protection unidirectional valve

F1 Recovery line mechanic filter

F2 Dehydrating filter

EV1 Vacuum line solenoid valve

EV3 Circuit separation solenoid valve

EV5 Recovery/Recycle solenoid valve

EV6 Charge solenoid valve

EV7 Oil purge solenoid valve

EV8 Oil addition solenoid valve

EV9 UV dye injection solenoid valve

EV10 High/low pressure separation solenoid valve

1 Oil replenishing bottle

2 Vacuum pump

3 Pressure adjuster

4 Separator-still for recovered oil

5 Separator-still for compressor oil

6 Compressor

7 Storage tank

8 Electronic scale

9 Oil purge bottle

10 Heat exchanger

11 UV dye charge bottle

12 Oil replenishing scale

13 Oil purge scale

P1 Pressure transducer

P2 High pressure switch

Page 8

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 49

GENERAL INFORMATION FOR THE USER

Disposing of equipment

Do not dispose of this equipment as miscellaneous solid municipal waste but

arrange to have collected separately.

The re-use or correct recycling of the electronic equipment (EEE) is important in

order to protect the environment and the wellbeing of humans.

In accordance with European Directive WEEE 2002/96/EC, special collection points

are available to witch to deliver waste electrical and electronic equipment.

The public administration and producers of electrical and electronic equipment are

involved in facilitating the processes of the re-use and recovery of waste electrical

and electronic equipment through the organisation of collection activities and the

use of appropriate planning arrangements.

Unauthorised disposal of waste electrical and electronic equipment is punishable by

law with appropriate penalties.

Disposing of batteries

Batteries must be recycled or disposed of properly. Do not throw batteries

away as part of normal refuse disposal.

Do no throw batteries into open flame!

Page 9

en AC690PRO ________________________________________________________________________________

50 OPERATING INSTRUCTIONS

1.0 - FOR A SAFE USE AC690PRO

The advanced technology adopted in the design and production of the AC690PRO make

this equipment extremely simple and reliable in the performance of all procedures.

Therefore, the user is not exposed to any risk if the general safety rules reported below

are followed with proper use and maintenance of the equipment.

NOTA BENE:

This unit can be exclusively used by professionally trained operators who have to know

the principles of refrigeration, refrigerating systems and gases and the possible

damages which might be caused by pressurized equipment.

Every user has to read carefully this manual for a correct and safe use of the

equipment.

1.1 - For a safe use

It is necessary to wear suitable protections such as goggles and gloves, the

contact with the refrigerant can cause blindness as well as other injuries to the

operator. Please make reference to the symbols below:

Carefully read the instructions.

Do not use open air in case of rain or high humidity.

Use gloves.

Use protection goggles.

Avoid the contact with the skin, the low boiling temperature (about -30 °C) may

provoke freezing.

Do not inhale refrigerating gases fumes.

Before connecting the AC690PRO unit to an A/C system or to an external tank,

make sure all the valves are closed.

Page 10

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 51

Ensure that the phase has been completed and that all valves are closed before

disconnecting the unit AC690PRO. This will prevent release of the refrigerant into

the atmosphere.

Do not change the safety valve or control system settings.

Do not use external tanks or other storage tanks that have not been

type-approved or that lack safety valves.

Never leave the unit live if an immediate use is not scheduled, stop the electrical

supply before a long period of unit inactivity or before internal maintenance

interventions.

Be careful while servicing the unit since connecting hoses may contain pressurized

refrigerant.

Do not use the unit in explosive environments.

Extraordinary maintenance interventions have to be performed by authorized staff only.

Pressure of leaks of the HCF-134a service equipment or of the air conditioning

systems of the vehicle must not be tested by using compressed air.

Some air/HCF-134a mixtures can burn at high pressures. These mixtures can be

dangerous and may cause fires or explosions and subsequent injuries or damages.

Further information on the operators’ health and safety can be obtained from the

refrigerant producers.

1.2 - Safety devices

The AC690PRO is equipped with the following safety devices:

Overpressure valves.

Besides the overpressure valve a maximum pressure switch has been fitted

which stops the compressor in case of excessive pressure.

CAUTION:

Any type of tampering with the safety devices mentioned above is

hereby prohibited.

Page 11

en AC690PRO ________________________________________________________________________________

52 OPERATING INSTRUCTIONS

1.3 - The work environment

The unit has to work in a sufficiently ventilated environment.

CAUTION:

Work far from free flames and hot surfaces; at high temperatures the

refrigerant decomposes freeing toxic and aggressive substances

which are noxious for the user and the environment.

For a correct functioning the unit has to work on an even surface; during short

handling do not shake it.

Do not subject the AC690PRO unit to vibration.

CAUTION:

While operating do not disperse the refrigerant in the environment.

Such a precaution, besides being required by the international rules

for the environment protection, is necessary to prevent the possible

presence of refrigerant in the working environment from making it

difficult to detect possible leaks.

Work in environments with sufficient lighting.

Avoid inhalation of the refrigerants and oils in the A/C systems. Exposure may

cause irritation to eyes and the respiratory tract. To remove R134a from the

A/C system, use only the special recycling-units for R134a. If the refrigerant is

accidentally released into the atmosphere, ventilate the work area before resuming

service.

Do not use the unit under direct sunrays; sun exposure can cause excessive

temperatures and malfunctioning. Working temperatures indicated refer to the unit

being not directly exposed to the sun.

1.4 - Tank test

The tank has to be re-tested or substituted every 10 years. Check the re-testing

date (1) written on the neck of the tank.

1

Page 12

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 53

2.0 - INTRODUCTION TO THE UNIT

The AC690PRO unit fits all of the air-conditioners functioning with R134a refrigerant

located on cars, trucks and industrial vehicles.

The AC690PRO unit microprocessor allows the managing of all functions by means of

an electronic scale, a LCD to display the weight or minute values and the help

messages of the various procedures which can be set, a control board with

alphanumeric keyboard.

By connecting the AC690PRO unit to an A/C system the refrigerating gas can be

recovered and recycled to enter the system itself again after a correct vacuum.

The amount of lubricant taken from the A/C system during the recovery can be

measured and, afterwards, reintegrated in the system.

The unit is equipped with a two-stage pump for high vacuum and a manifold set to

continuously monitor the operations in process.

Tightness test on the A/C units is carried out through the manometers the unit is

equipped with.

The unit is equipped with special connectors to avoid cross-mixing with systems using

R12.

CAUTION:

Do not try to adapt this unit for air conditioning systems using R12.

Page 13

en AC690PRO ________________________________________________________________________________

54 OPERATING INSTRUCTIONS

3.0 - DESCRIPTION OF THE UNIT

14. Keyboard.

15. Low pression gauge.

16. High pression gauge.

17. Inside tank pressure meter.

18. High pression valve.

19. Low pression valve.

20. Printer.

21. Main power switch.

22. High side connection hose.

23. Low side connection hose.

24. Oil injector glass.

25. UV dye injector glass.

26. Oil drain glass.

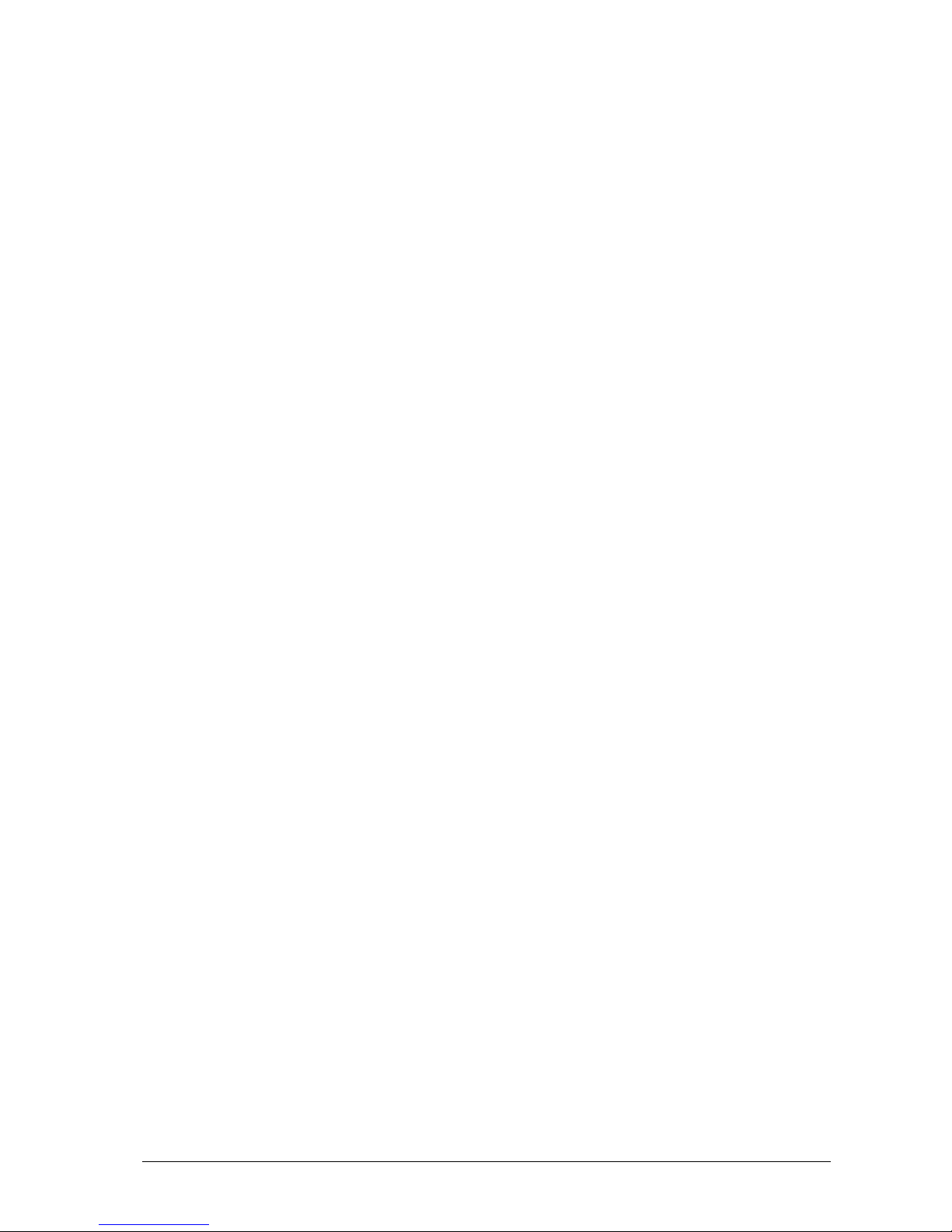

3.1 - The Keyboard

27. RECOVERY function Led.

28. RECOVERY function key.

29. VACUUM function Led.

30. VACUUM function key and cursor shifting upwards.

31. CHARGE function Led.

32. CHARGE function key and cursor shifting to the right.

33. AUTOMATIC function Led.

34. AUTOMATIC function key and cursor shifting to the left.

35. FLUSHING function Led.

36. FLUSHING function key and cursor shifting downwards.

37. MENU key (menu, cancellation, by-pass and pause).

38. VEHICLE DATA and DATABASE function key.

39. Port for software updates.

40. STOP key.

41. ENTER key.

42. Display.

Page 14

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 55

4.0 - INSTALLATION OF THE UNIT

Please find below operations to perform to start the unit.

4.1 - Unpacking and checking components

Remove the machine packaging.

Check to ensure that all of the accessory components are present:

Operating instructions.

1 Graduated beaker.

2 cylinder connectors.

Bottle safety valve conformity certificate.

4.2 - Machine handling and storage

Remove the unit from the base pallet of the packaging.

The unit is moved on the four wheels. The two front wheels have brakes.

On rough terrain, the AC690PRO can be moved by tilting it and balancing the weight on

the two rear wheels.

In spite of the fact that the heaviest components have been assembled on the base in

order to lower the centre of gravity, it has not been possible to eliminate the

risk of overturning completely.

Page 15

en AC690PRO ________________________________________________________________________________

56 OPERATING INSTRUCTIONS

4.3 - Preparation for use

Before starting to use the AC690PRO unit, it is possible to personalize it.

These settings are not compulsory on the standard models.

To personalize the A/C unit comply with the following procedure:

Turn on the unit and wait until the STAND-BY page is displayed (date and time).

Simultaneously press the 3 and FLUSHING keys (36) for some seconds.

The display shows 0000.

Enter the code 2222.

A menu is displayed containing the operations that may be carried out.

Press the cursor shifting key upwards (30) or downwards (36) to scroll the menu.

Select the wished function and press ENTER to enter.

Press STOP to go back to the STAND-BY page.

LANGUAGE CHANGE

Select the LANGUAGE CHANGE function and press ENTER.

The list of languages available in memory is displayed.

Press the cursor shifting key upwards (30) or downwards (36) to scroll the menu

and press ENTER (41) to set the selected language.

Then the main menu is displayed again.

UNITS OF MEASURE

Select the UNITS OF MEASURE function and press ENTER.

The list of units of measure being available in memory is displayed.

Press either the upwards cursor shifting key (30) or the downwards cursor shifting

key (36) to scroll the menu and press ENTER (41) to set the selected unit of

measure.

Then the main menu is displayed again.

Page 16

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 57

DATE AND TIME

Select the DATE AND TIME function and press ENTER.

The current date and time are displayed and the cursor positions on the date.

Enter the date and press ENTER to confirm.

The cursor positions on the time.

Enter the time and press ENTER to confirm.

Then the main menu is displayed again.

PIPES LENGTH

It is possible to supply, on demand, longer service pipes (optional); if this is the case it

is necessary to set the machine so that during the charge it counterbalances the

variation of coolant remaining in the pipes. The standard pipes that are supplied

standard are 2,5 m long.

Select the PIPES LENGTH function and press ENTER.

The standard length of the optional pipes is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to scroll the menu and press ENTER to set the selected length.

Then the main menu is displayed again.

GARAGE DATA

To enter the workshop data there are 8 lines of 20 characters each.

The data entering is carried out through the keyboard, in a way similar to that used for

mobile phones:

Select the GARAGE DATA function and press ENTER.

Press the numerical keys to select the letters and the characters.

Press the cursor shifting keys to shift among the lines.

Press the MENU key (37) to erase the character that precedes the cursor.

Press ENTER to memorize the garage data entry.

Then the main menu is displayed again.

Page 17

en AC690PRO ________________________________________________________________________________

58 OPERATING INSTRUCTIONS

CONTRAST

Select the CONTRAST function and press ENTER.

A numerical index of the contrast degree is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to modify the contrast and press ENTER to confirm.

Then the main menu is displayed again.

FLUSHING

It is possible to install on the A/C unit the optional kit for the flushing of components.

If the unit is equipped with this kit, it is necessary to insert it in the internal parameters

so that it enables the function.

Select the FLUSHING function and press ENTER.

The display displays the messages ENABLED and DISABLED.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either ENABLED or DISABLED and press ENTER to confirm.

Then the main menu is displayed again.

OIL SCALES

In case of malfunction the oil refilling and discharge scales can be disabled to prevent

the station stop.

Select the OIL SCALES function and press ENTER.

The display displays the messages ENABLED and DISABLED.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either ENABLED or DISABLED and press ENTER to confirm.

Then the main menu is displayed again.

Page 18

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 59

UV DYE

This menu is used to display the request of dye injection before the charge.

Select the UV DYE function and press ENTER.

The display displays the messages ENABLED and DISABLED.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either ENABLED or DISABLED and press ENTER to confirm.

Then the main menu is displayed again.

CAUTION:

To avoid any problems due to chemical incompatibilities with the

internal components of the service station, use only UV dyes selected

and supplied by Robinair. Problems resulting from the use of any

different types of dyes, will cancel the unit warranty.

DATABASE UPDATE

This menu is used to update the car manufacturers’ database.

Enter the key in the card slot on the front panel.

Select the DB UPDATE function and press ENTER

At the end of the operation the board resets automatically.

Extract the key.

NOTA BENE:

Do not switch off the A/C unit during the updating.

ENTRY OF THE SERIAL NUMBER

Select the SERIAL NUMBER function and press ENTER.

Enter the station serial number (engraved on the technical data plate applied to

the station rear panel) by the numerical keys and then press ENTER.

Then the main menu is displayed again.

NOTA BENE:

Only the last 5 digits of the number have to be entered since the first one is entered

automatically by the program.

Page 19

en AC690PRO ________________________________________________________________________________

60 OPERATING INSTRUCTIONS

4.4 - Loaded and recovered coolant storage

If you want to storage and then print the data of the loaded and recovered coolant you

have to enable the “Report Management” function. Once all data of the loaded and

recovered coolant are enabled they are automatically stored.

4.4.1 - Report management enabling

To enable the report management proceed as follows:

Simultaneously press the 3 and FLUSHING keys for some seconds.

The displays shows 0000.

Set the value 5599.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either REPORT MANAGEMENT and press ENTER to confirm.

Select ENABLE and press ENTER.

4.4.2 - Report printing

CAUTION:

The station has a big memory that is able to contain more data than

those you can print on a 12m long roll of paper.

To print the stored data proceed as follows:

Press the MENU key from the STAND-BY page.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either REPORT MANAGEMENT and press ENTER to confirm.

Select the PRINT REPORT function and press ENTER.

The display shows the stored records quantity.

Press the ENTER key to print. Afterwards any record can be deleted.

Before printing, be sure to have enough paper. It is recommended to print the stored

records at least once a week in order to avoid a too long print which would also be

difficult to consult.

Delete the already printed records so that they will not be accumulated with those

stored afterwards (otherwise they would be printed again in a new print).

4.4.3 - Report management with ACUSB (optional)

The stored records can be downloaded to a PC by means of the ACUSB reader.

To transfer data on the PC, please refer to the ACUSB reader’s operating manual.

Page 20

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 61

4.5 - Bottle filling

Before being able to use the unit, after personalizing it, it is necessary to inject some

coolant in the inner bottle. Comply with the following procedure:

Connect the service pipe to an external container full of coolant

(use the supplied unions).

NOTA BENE:

There are two types of source tanks: one with a liquid outlet and one without.

Tanks with liquid outlets must remain in an upright position in order to transfer the

liquid refrigerant. Use the LIQUID valve connection for this type of tank.

Tanks without liquid outlets are usually equipped with only one valve and have to be

overturned to transfer the liquid refrigerant.

Open the valve on the external bottle and on the service pipe.

Open the high and low pressure valves on the unit.

Press the MENU key (37) from the STAND-BY page.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select the BOTTLE FILLING and press ENTER to confirm.

The display shows the tank available capacity.

Set the amount of coolant that you wish to inject (it is advisable to inject at

least 4-5 kg).

Press ENTER to start the operation.

Some massages prompt the operator for the pipes connection, then the function

starts.

The unit automatically stops once reached the set value.

Close the valve on the source tank.

Press ENTER to complete the operation and empty the pipes and the still

separator.

NOTA BENE:

Usually the final amount of recovered coolant exceeds the set value by about

500-700 g, since also the still separator is emptied.

The function stops automatically when pressure is over in the system.

The STAND-BY page is displayed.

Close the valves on the unit.

Page 21

en AC690PRO ________________________________________________________________________________

62 OPERATING INSTRUCTIONS

4.6 - Tank display

From the STAND-BY page it is possible to display the weight of the coolant in the tank.

Press ENTER to display the weight.

Press STOP to go back to the STAND-BY page.

4.7 - Oil scales reset

NOTA BENE:

It is advisable to carry out this operation at regular intervals since it is useful to correct

the zero point deviation of the oil loading cells (this operation is similar to that carried

out for the kitchen scales). Should this operation not be carried out, the unit operation

is not compromised since the software works only by weights difference.

Press the MENU key from the STAND-BY page.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select the SCALES RESET and press ENTER to confirm.

The display requires the oil bottle disconnection.

Press the ENTER key to continue.

The display waits for some seconds before carrying out the automatic reset.

At the end of the reset the display requires the oil bottle reconnection.

Press ENTER to go back to the STAND-BY page.

Page 22

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 63

5.0 - USE OF THE UNIT

Find below the description of the unit functions.

5.1 - Vehicle data entry

This function enables the display of the vehicle data into the print-out.

Press the VEHICLE DATA key (38).

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either VEHICLE DATA and press ENTER (41) to confirm.

Enter the vehicle data with the alphanumeric keyboard.

Press the MENU key (37) to erase the character that precedes the cursor.

Press ENTER to confirm the entered datum and shift to the next line.

Repeat the data entry and confirmation operation for all the items; in the end the

main menu will be displayed again.

5.2 - Database

Charge data can be taken directly from the internal database. The database also

contains further pieces of information that may be displayed or printed.

Press the DATABASE key (38).

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either DATABASE and press ENTER to confirm.

By the alphanumerical keys select the first letter of the car’s make. Use the cursor

keys to select the make of the tested car and press ENTER to confirm.

By the alphanumerical keys select the first letter of the car’s model. Use the

cursor keys to select the model of the tested car and press ENTER to confirm.

After scrolling all data the display shows two selection options:

Digit 1 to store data and use them during the next service. Then the program

displays the STAND-BY page again.

Digit 2 to display data. Use the cursor shifting keys to scroll the data

concerning the vehicle.

Press the ENTER key to print.

Press STOP (40) to go back to the DATABASE menu.

Page 23

en AC690PRO ________________________________________________________________________________

64 OPERATING INSTRUCTIONS

DIAGNOSIS

It is important to note that the vehicle to be tested should be in a place that is not in

direct sunlight and away from any adverse wind/drafty conditions. The most

insignificant air currents can falsify the performance values drastically.

To evaluate the air conditioning system it is important to follow the procedure below:

LOWER Bonnet.

START engine (engine to be at normal operating temperature).

Stabilise engine rpm at approximately 1500-2000 rpm.

Air conditioning system ON.

Centre face vent OPEN.

Heating setting to maximum COLD.

Interior fan set to HIGH.

Recirculation OFF.

Doors and windows OPEN.

It is recommended to confirm the compressor clutch is engaged before carrying out any

performance tests.

Before recording or inputting any data it is important to note the position of the HVAC

controls, engine temperature / rpm and adequate time has been given to allow the a/c

system to Stabilise (no less than 3 minutes).

Ambient Temperature - To record the ambient temperature, it is important to take

the temperature of the ambient air at approximately 1metre in front of the car.

Inputting the temperature of the air around the engine compartment may lead to

incorrect diagnosis.

High Side Pressure – With the compressor clutch engaged record the highest high

pressure gauge reading. It is important to note a cycling clutch system will cause the

compressor to cut in and out, thus, the high side pressure will rise and fall. It is the

highest pressure reading that should be recorded.

Low Side Pressure - With the compressor clutch engaged record the lowest low

pressure gauge reading. It is important to note a cycling clutch system will cause the

compressor to cut in and out, thus, the low side pressure will rise and fall. It is the

lowest pressure reading that should be recorded.

Centre Vent Temperature – When taking the centre face vent temperature input a

mean value.

Page 24

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 65

CAUTION:

Air conditioning diagnostic software is designed to assist and guide

professional and competent technicians diagnose air

conditioning/climate control faults. The diagnosis and rectification

offered is to be used for guidance purposes only and in no way should

result in the replacing of components without first being inspected by

the technician and established to be faulty.

Press the MENU key from the STAND-BY page.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select the DIAGNOSIS and press ENTER to confirm.

NOTA BENE:

Diagnostics function only work if a vehicle from the database is selected. Otherwise the

program enters directly the database enabling the selection and memorization of a

vehicle before moving to the diagnostics.

Entered the ambient temperature measured value and press ENTER.

Entered the high pressure measured value and press ENTER.

Entered the low pressure measured value and press ENTER.

Entered the flap air temperature measured value and press ENTER.

The display shows two selection options:

Digit 1 to select the result and display entered data with their status: OK, high,

low.

Press the ENTER key to print.

Digit 2 to select hints and display the list of possible causes of the defect and

the operation to carry out to solve the problem.

Press the ENTER key to print.

Press STOP to go back to the STAND-BY page. When quitting, the program asks

whether to cancel the vehicle data set in memory or not.

Page 25

en AC690PRO ________________________________________________________________________________

66 OPERATING INSTRUCTIONS

5.3 - Personalized Database

It is possible to create a personalized database where you can enter the data of the

new vehicles that are not present in the database standard.

Press the DATABASE key (38).

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either PERSONALIZED DATABASE and press ENTER to confirm.

Enter the required data through the alphanumeric keyboard.

NOTA BENE:

Four lines of 20 characters each are available for the description of the car. We suggest

entering Make, Model, etc. since descriptions are entered in alphabetical order.

The following lines are available: one 20 character line for the coolant amount, one

20 character line for the type of oil and one 20 character line for the amount of oil.

Press the MENU key to erase the character that precedes the cursor.

Press the cursor shifting keys to shift the cursor on the display.

Press ENTER to confirm the entered datum and shift to the next line.

NOTA BENE:

If necessary, it is possible to avoid entering all of the required data; if this is the case,

press ENTER to shift to the next line and the field relating to that specific datum will

not be filled in.

Repeat the data entry and confirmation operation for all the items; in the end the

main menu will be displayed again.

Page 26

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 67

5.4 - Refrigerant recovery

CAUTION:

Always wear protection goggles and gloves when working with

refrigerant. Read and comply with warnings at the beginning of this

manual before using the unit.

NOTA BENE:

Run the A/C system for some minutes before starting recovery. Tests proved that a

bigger amount of refrigerant is sucked if this operation is performed. Turn off the

A/C system before servicing.

In order to recover the coolant present in the A/C system, carry out the following

procedure:

Some messages prompt the operator for the pipes connection. Press ENTER to go

to the next message.

Connect the T1 low pressure and T2 high pressure hoses of the A/C system.

Open the valves on the hose quick couplers T1 and T2.

Open the high and low pressure valves on the unit.

Press the RECOVERY key (28), and the self-cleaning function is started.

The function is not started in case of lack of pressure in the system; in this case a

message is displayed to inform the operator.

NOTA BENE:

This function is useful to ensure a correct weighing of the recovered coolant.

The self-cleaning function can be passed by pressing the MENU key.

When the self-cleaning is over, the refrigerant recovery starts.

NOTA BENE:

The function stops automatically when the pressure inside the system drops below

0 bar.

At the end of recovery the oil is automatically drained and the pressure values are

checked.

The scale located on the oil bottle stores the weight of the discharged oil.

When the waiting time is over:

The function restarts automatically, if pressure has increased.

The display shows the amount of recovered coolant and oil if the pressure was

stable.

Close the valves on the unit.

Page 27

en AC690PRO ________________________________________________________________________________

68 OPERATING INSTRUCTIONS

Press the ENTER key to print.

Press STOP to go back to the STAND-BY page. When quitting, the program asks

whether to cancel the vehicle data set in memory or not.

Some messages prompt the operator for the pipes disconnection.

Select the wished option.

5.5 - Evacuating the A/C system

NOTA BENE:

If the vacuum pump has run for more than 10 hours the message CHANGE OIL

appears. Carry out the maintenance according to the procedures described in the

relevant section.

Some messages prompt the operator for the pipes connection. Press ENTER to go

to the next message.

Open the high and low pressure valves on the unit.

Press the VACUUM key (30).

The function is not started in case of pressure presence in the system; in this case

a message is displayed to inform the operator.

Enter the wished vacuum time.

Press ENTER to confirm and start the function.

When the vacuum time is over the pressure values check time starts. At the end of

this time the check result is displayed showing whether leaks have been detected

on the system.

Close the valves on the unit.

Press the ENTER key to print.

Press STOP to go back to the STAND-BY page. When quitting, the program asks

whether to cancel the vehicle data set in memory or not.

Some messages prompt the operator for the pipes disconnection.

Select the wished option.

Page 28

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 69

5.6 - Oil injection and A/C system charge

CAUTION:

This function must be performed only on A/C systems under vacuum

(following a system evacuation function). At the end of the oil

injection function, following a filling function.

Charge the oil from the high side only. In case of systems equipped

with low side fitting only (LOW), wait at least 10 minutes before

starting the A/C system after the charge.

Some messages prompt the operator for the pipes connection. Press ENTER to go

to the next message.

Check that the service pipes are connected and that their valves are open.

Press the CHARGE key (32).

The UV dye injection request is displayed.

Digit 1 to inject the UV dye.

Digit 2 not to inject the UV dye.

The display requires whether to carry out the oil charge.

Digit 1 to charge oil. Select the amount of oil to be charged by means of

numerical keys (the display shows by default the value of the discharged oil)

and use the MENU key to change the default value; press ENTER to confirm.

Digit 2 to avoid oil injection.

The display requires the entry of the amount of refrigerant to be charged.

NOTA BENE:

If cars are selected through the Database, the display shows automatically the amount

of coolant to be charged for the selected car.

Enter the amount of refrigerant to be charged and press ENTER to confirm.

The station carries out all operations in sequence and in the end it displays the

coolant and charged oil value.

To verify if the circuit is efficient, you need to check the functioning pressures.

Close the valves on the unit.

CAUTION:

Failure to close the valves may cause errors, malfunction or damage

of the internal components.

Switch On the car and the A/C system.

Check pressure values.

Switch Off the A/C system and the car.

Page 29

en AC690PRO ________________________________________________________________________________

70 OPERATING INSTRUCTIONS

Close the valves on the service pipes.

Press the ENTER key to print.

Press STOP to go back to the STAND-BY page. When quitting, the program asks

whether to cancel the vehicle data set in memory or not.

Some messages prompt the operator for the pipes disconnection.

Select the wished option.

5.7 - Automatic function

This function allows carrying out recovery, vacuum, and charge functions in automatic

function.

CAUTION:

For cars equipped with a single service fitting the charge function

should be carried out manually by following the procedure suggested

by the manufacturer.

To carry out the automatic function:

Some messages prompt the operator for the pipes connection. Press ENTER to go

to the next message.

Connect the T1 low pressure and T2 high pressure hoses of the A/C system.

Open the valves on the hose quick couplers T1 and T2.

Open the high and low pressure valves on the unit.

Press the AUTOMATIC function key (34).

The display requires the entry of the vacuum time.

Enter the value and press ENTER to confirm.

The UV dye injection request is displayed.

Digit 1 to inject the UV dye.

Digit 2 not to inject the UV dye.

The display requires whether to carry out the oil charge.

Digit 1 to confirm. A message on the display asks whether some more oil has

to be added to the amount recovered. Select the amount of oil by the

numerical keys and press ENTER to confirm.

Digit 2 to avoid oil injection.

The display requires the entry of the amount of refrigerant to be charged.

Page 30

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 71

NOTA BENE:

If cars are selected through the Database, the display shows automatically the amount

of coolant to be charged for the selected car.

Enter the amount of refrigerant to be charged and press ENTER to confirm.

The function starts and continues automatically til the end.

NOTA BENE:

In case of errors, the station stops and displays the relevant error message.

To verify if the circuit is efficient, you need to check the functioning pressures.

Close the valves on the unit.

CAUTION:

Failure to close the valves may cause errors, malfunction or damage

of the internal components.

Switch On the car and the A/C system.

Check pressure values.

Switch Off the A/C system and the car.

Close the valves on the unit.

Press the ENTER key to print.

Press STOP to go back to the STAND-BY page. When quitting, the program asks

whether to cancel the vehicle data set in memory or not.

Some messages prompt the operator for the pipes disconnection.

Select the wished option.

Page 31

en AC690PRO ________________________________________________________________________________

72 OPERATING INSTRUCTIONS

5.8 - Recycling function

Press the MENU key from the STAND-BY page.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either RECYCLING and press ENTER to confirm.

The function is self-limited to 60 minutes.

Press STOP to stop the function.

The function stops automatically after the complete draining of the internal circuit.

5.9 - Incomplete charge

Close the high side quick coupler valve on the T2 service hose on the A/C system.

Start the vehicle system.

Open the high and low pressure valves on the unit.

Press ENTER to complete the charge.

Let the residual refrigerant be sucked until manifold gauges show a pressure of

about 1-2 bar.

Close the low side quick coupler valve on the T1 service hose on the A/C system.

Turn off the vehicle and disconnect the unit from the vehicle.

Close the valves on the unit.

CAUTION:

Disconnect the flexible hoses with extreme caution. All of the flexible

hoses can contain liquid refrigerant under pressure. Before using the

equipment read and follow carefully the instructions at the beginning

of this manual.

Page 32

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 73

5.10 - Flushing (optional)

NOTA BENE:

Carefully read the flushing kit instructions for the correct connection and use of

accessories.

To use the flushing kit follow instructions below:

Connect the flushing kit and the part to be flushed following instructions of the

flushing kit manual.

Open the low side valve and press ENTER to continue.

Select the vacuum time and press ENTER to drain the component.

After the vacuum phase a test is carried out to be sure of the absence of leaks.

If the leak test is positive, open the flushing valve.

Wait until the flushing time is over or, if the cleaning is correct, press the MENU

key.

Close the flushing valve and press ENTER to drain the circuit.

Press ENTER to print the flushing report.

Press STOP to terminate.

Page 33

en AC690PRO ________________________________________________________________________________

74 OPERATING INSTRUCTIONS

6.0 - DISPLAYED MESSAGES

6.1 - Service messages

CHANGE OIL

Vacuum pump oil change (see chapter 7.1).

CHANGE FILTER

Change filter dryer (see chapter 7.3).

6.2 - Error messages

HIGH PRESSURE

Out feed pressure from compressor is excessively high. Switch off the unit and wait for

about 30 minutes. If the problem persists, apply to the Technical Service.

SOFTWARE ERROR

Error in the software, apply to the Technical Service.

FULL BOTTLE

Coolant level in the bottle reached the maximum capacity level, carry out some charges

to reduce the amount of coolant inside.

SCALE RECALIBRATION

Error in scale calibration, reset it. If the error persists, apply to the Technical Service.

HIGH RECOVERY TIME

The recovery time exceeds the set safety limit. Make sure there are no leaks in the A/C

system. If no leaks are detected, apply to the Technical Service.

EMPTY SYSTEM

There is no refrigerant in the A/C system.

BOWL FULL

The oil discharge bowl is full and has to be drained.

BOWL EMPTY

The oil injection bowl is empty and has to be charged.

FULL SYSTEM

The A/C system is charged with refrigerant.

INCOMPLETE CHARGE

Excessive charge time; this proves that the pressure inside the bottle is equal to the

pressure inside the A/C system (see chapter 5.9).

OIL CHARGE TIME HIGH

The A/C system is not under vacuum and the station cannot suck oil.

Page 34

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 75

7.0 - MAINTENANCE

The AC690PRO is a highly reliable unit built with top-quality components with the use of

today's most advanced production techniques.

For these reasons, maintenance is reduced to a minimum and marked by a very low

frequency of intervention. In addition, owing to the electronic control system, all

periodic maintenance procedures are signalled at the prescribed time.

CHANGE OIL Change vacuum pump oil (10 hours).

CHANGE FILTER Change filter dryer (150 kg of fluid).

7.1 - Vacuum pump oil change

The oil of the vacuum pump must be changed frequently in order to assure higher

performances of the unit.

When the oil has to be changed, the display shows CHANGE OIL.

To change the oil, follow carefully these instructions:

Disconnect the unit from the power supply.

Put a beaker under the cap (45), open the cap and discharge the oil contained in

the vacuum pump.

When the pump is empty, screw in the cap (45) and open the upper cap (43).

Fill the pump with the oil through the upper hole. Check the oil level in the pump

through the inspection glass (44); level has to reach the sight glass middle line.

When the pump is filled, close the upper cap.

7.2 - Reset oil counter vacuum pump

After having changed the oil of the vacuum pump, reset the counter.

To reset the counter follow carefully these instructions:

Simultaneously press the 3 and FLUSHING keys for some seconds.

The display shows the message 0000.

Digit 5555 on the keypad and press ENTER.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either OIL CHANGE and press ENTER to confirm.

Page 35

en AC690PRO ________________________________________________________________________________

76 OPERATING INSTRUCTIONS

The display shows a value which corresponds to the working hours of the vacuum

pump.

Press the MENU key and keep it pressed.

When the display shows 0000 release the MENU key.

The display displays the functions menu again.

Press STOP to go back to the STAND-BY page.

7.3 - Filter dryer change

The filter dryer of this unit has been designed in order to eliminate all acid residues and

the high water content of the refrigerant R134a.

The filter has to be changed when the display shows the message CHANGE FILTER.

To change correctly the filter dryer, follow carefully these instructions.

Connect the unit to the electrical power supplied and press the RECOVERY key.

Open the high and low pressure valves on the unit.

Wait for the end of self-cleaning.

Let the compressor operate until the pressure indicated on the manometers has

not decreased under the 0 (zero) bar value.

Press the STOP key to stop the compressor. Now all the refrigerant has been

drained from the filter and no pressure should be present.

Close the valves on the unit.

Disconnect the unit from the electrical power supply and remove the lower front

panel.

CAUTION:

During the following phase it will be necessary to open the refrigerant

circuit of the unit. Wear goggles and gloves.

Disconnect the filter with caution and replace it with a new one.

CAUTION:

Check that the sealing rings are in the right position.

Set up the plastic protection again.

Page 36

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 77

7.4 - Reset counter filter dryer

After the change of the filter dryer, reset the counter.

To reset the counter follow carefully these instructions:

Simultaneously press the 3 and FLUSHING keys for some seconds.

The display shows the message 0000.

Digit 5555 on the keypad and press ENTER.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either FILTER CHANGE and press ENTER to confirm.

The display displays a value, either in kg or in Pounds, corresponding to the amount of

coolant that has been filtered.

Press the MENU key and keep it pressed.

When the display shows 0000 release the MENU key.

The display displays the functions menu again.

Press STOP to go back to the STAND-BY page.

Page 37

en AC690PRO ________________________________________________________________________________

78 OPERATING INSTRUCTIONS

7.5 - Refrigerant scale calibration

Required equipment:

2 Sample weights.

After removing the rear cover, remove the container to the scale plate.

NOTA BENE:

The hoses from the internal container do not have to be disconnected. If you wish to

disconnect them, close the valves on the pipes and on the bottle.

Simultaneously press the 3 and FLUSHING keys for some seconds.

The displays shows 0000.

Set the value 1111.

Press the ENTER key.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either BOTTLE CALIBRATION and press ENTER to confirm.

The displays shows ZERO WEIGHT.

With the scale pan being completely empty, insert the numerical value 00.00 and

press the ENTER key.

The displays shows SAMPLE WEIGHT.

Position the sample weight on the scale plate (the suggested weight ranges

between 10 and 15 kg).

Enter the sample weight value and press the ENTER key.

The display displays the functions menu again.

Press STOP to go back to the STAND-BY page.

Page 38

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 79

7.6 - Oil replenishing scale calibration

Required equipment:

2 Sample weights.

Simultaneously press the 3 and FLUSHING keys for some seconds.

The displays shows 0000.

Set the value 1111.

Press the ENTER key.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either IN OIL CALIBRATION and press ENTER to confirm.

The displays shows ZERO WEIGHT.

With the scale pan being completely empty (bowl disconnected), insert the

numerical value 00.00 and press the ENTER key.

The displays shows SAMPLE WEIGHT.

Position the sample weight on the scale plate (the suggested weight ranges

between 200 and 1000 g).

NOTA BENE:

It is possible to weigh one of the bottles containing the oil and use it as sample weight.

Enter the sample weight value and press the ENTER key.

The display displays the functions menu again.

Press STOP to go back to the STAND-BY page.

Page 39

en AC690PRO ________________________________________________________________________________

80 OPERATING INSTRUCTIONS

7.7 - Oil purge scale calibration

Required equipment:

2 Sample weights.

Simultaneously press the 3 and FLUSHING keys for some seconds.

The displays shows 0000.

Set the value 1111.

Press the ENTER key.

The functions menu is displayed.

Press the upwards cursor shifting key (30) or the downwards cursor shifting key

(36) to select either OUT OIL CALIBRATION and press ENTER to confirm.

The displays shows ZERO WEIGHT.

With the scale pan being completely empty (bowl disconnected), insert the

numerical value 00.00 and press the ENTER key.

The displays shows SAMPLE WEIGHT.

Position the sample weight on the scale plate (the suggested weight ranges

between 200 and 1000 g).

NOTA BENE:

It is possible to weigh one of the bottles containing the oil and use it as sample weight.

Enter the sample weight value and press the ENTER key.

The display displays the functions menu again.

Press STOP to go back to the STAND-BY page.

Page 40

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 81

8.0 - STOPPAGE FOR LONG PERIODS

The unit must be kept in a safe place

Ensure that the valves on the internal tank are closed.

To resume use, follow the activation process only after reopening the internal tank

valves.

9.0 - DEMOLITION/DISPOSAL

9.1 - Disposal of the equipment

At the end of the equipment's lifetime, the following procedures must be performed:

Detach and vent the gas from the unit circuit: be sure the refrigerant tank too is

completely discharged, in compliance with the rules in force.

Deliver the unit to a disposal center.

9.2 - Disposal of the recycled materials

The refrigerants recovered from A/C systems and which cannot be reused, must be

delivered to gas suppliers for disposal as required.

The lubricants extracted from systems must be delivered to used oil collection

centres.

Page 41

en AC690PRO ________________________________________________________________________________

82 OPERATING INSTRUCTIONS

10.0 - TECHNICAL SPECIFICATIONS

Refrigerant:

R134a

Coolant electronic scale resolution:

5 g

M1 M2 gauges:

Kl. 1.0

M3 gauge:

Kl. 2.5

Container capacity:

27 l

Maximum weight that can be stored:

20 kg

Filtering station:

1 spin-on filter dryer

Supply voltage:

230 V/50 Hz

Power:

800 W

Working temperature:

10°C + 50°C

Humidity: 20 75%

Transport and storage temperature:

- 25°C + 60°C

Dimensions:

1270 690 660 mm

Weight:

110 kg approx with empty tank

Noise:

<70 dB (A)

11.0 - SPARE PARTS

Components indicated below are those necessary for routine maintenance.

Dehydrating filter 5117399

N°1 Vacuum pump oil bottle 5604052

Thermal paper roller 5607069

Page 42

________________________________________________________________________________ AC690PRO en

OPERATING INSTRUCTIONS 83

12.0 - GLOSSARY OF TERMS

Refrigerant: A refrigerant solely of the type for which the unit has been created

(ex. R134a).

A/C system: Air-conditioning system in the motor vehicle.

Unit or Station: AC690PRO equipment for the recovery, recycling, evacuation

and filling of the A/C system.

External tank: Non-refillable fresh refrigerant (ex. R134a) cylinder, used to fill

the refrigerant tank.

Refrigerant tank: The tank specifically designed for the unit.

Function: Execution of an individual function.

Recovery/Recycling: Function in which the refrigerant is recovered by an

A/C system and stored in the internal container.

Evacuation: Function in which incondensables and moisture are evacuated from

an A/C system solely by means of a vacuum pump.

Oil injection: Introduction of oil inside an A/C system for the purpose of

maintaining the amount of oil specified by the manufacturer.

Filling: Function during which refrigerant is introduced into an A/C system in the

amount specified by the manufacturer.

Page 43

Page 44

Page 45

Bosch Automotive Service Solutions S.r.I.

Via ProvinciaIe 12

43038 Sala Baganza (PR)

ITALIA

http://de-ww.bosch-automotive.com

bosch.prueftechnik@bosch.com

S P00 D00 095 | 2014-02-07

Loading...

Loading...