Page 1

®

OPERATING

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

M

ANUAL

Model 92500

Transmission Fluid Exchanger

Page 2

®

Transmission Fluid Exchanger Unit

Model: 92500

SAFETY DEFINITIONS: Follow all WARNING, CAUTION, IMPORTANT, and NOTE messages in this manual.

These messages are defined as follows: WARNING means you may risk serious personal injury or death;

CAUTION means you may risk personal injury and property damage or serious unit damage; IMPORTANT means

you may risk unit damage; and NOTEs provide clarity and helpful tips. These safety messages cover situations

ROBINAIR is aware of. ROBINAIR cannot know, evaluate, and advise you as to all possible hazards. You must

make sure all conditions and procedures do not jeopardize your personal safety.

COPYRIGHT: No part of this manual may be reproduced, stored in a retrieval system, or transmitted in any form

or by any means (electronic, mechanical, photocopy, recorded, or otherwise) without the prior written permission of

ROBINAIR.

DISCLAIMER: All information, illustrations, and specifications contained in this manual are based on the latest

information available at the time of publication. The right is reserved to make changes at any time without

obligation to notify any person or organization of such revisions or changes. Further, ROBINAIR shall not be liable

for errors contained herein or for incidental or consequential damages (including lost profits) in connection with the

furnishing, performance, or use of this material. If necessary, obtain additional health and safety information from

the appropriate government agencies and the vehicle and oil manufacturers.

WARNINGSWARNINGS

WARNINGS

WARNINGSWARNINGS

To prevent personal injury and/or property damage,

Allow only qualified personnel to operate the unit.

Study, understand and follow all instructions and warnings before operating this

device. The operating instructions and safety precautions must be read and

discussed in the operator’s native language, if the operator cannot read these

instructions.

- Si el operador no puede leer o comprender estas instrucciones de funcionamiento

y las precauciones de seguridad, éstas deberán leerse y comentarse en el idioma

nativo del operador.

- Si l’utilisateur ne peut pas lire les directives relatives au fonctionnement et aux

mesures de sécurité, celles-ci doivent pouvoir être transmises à l’utilisateur dans sa

langue maternelle.

Wear protective equipment, including safety goggles. Disconnect hoses with

extreme caution.

Keep tools, electrical cords, and hoses away from moving engine parts.

Vent exhaust to the outside while running the vehicle. Never run a vehicle without

adequate ventilation in the work area.

Before starting the vehicle’s engine, verify the vehicle is in PARK or NEUTRAL, with

the emergency brake ON.

IMPORTANT!

Review current local, state, and federal statutes, cases, laws, and regulations to determine the current

status and appropriate disposal method for transmission oil. It is the responsibility of the user to

determine if a material is a hazardous waste at the time of disposal. Ensure that you are in compliance

with all applicable laws and regulations.

Page 3

Table of Contents

Safety Warnings ........................................................... inside front cover

Introduction ......................................................................................... 2

General Description ......................................................................................... 2

Glossary of Terms ............................................................................................2

Component Identification and Location ............................................................3

Unit Front View ......................................................................................... 3

Control Panel ............................................................................................4

Initial Setup .....................................................................................................5

Accessory Kit ............................................................................................5

Registering the Unit ..................................................................................5

Application Notes ......................................................................................5

Helpful Tips ...............................................................................................5

Operating Procedures ................................................................................... 6

Dipstick Only Mode ...................................................................................6

Dipstick/Cooler Mode ................................................................................8

Cooler Only Mode ...................................................................................10

Manual/Top-Off Mode .............................................................................11

Drain Waste Tank ...................................................................................12

Total Count ............................................................................................. 13

Changing Transmission Fluid Types.......................................................13

Error Messages .............................................................................................. 14

Maintenance...................................................................................................14

Replacement Adapters...................................................................................15

Replacement Parts.........................................................................................19

Warranty Statement ............................................................... inside back cover

Transmission Fluid Exchanger

11

1

11

Page 4

General Description

The 92500 provides an easy, efficient way of replacing automatic transmission

fluid in a vehicle. The Exchanger removes the used transmission fluid and

replaces it with new fluid, which reduces the harmful contaminants and

restores the fluid properties, extending the life of the vehicle’s transmission.

Glossary of Terms

ATF — Automatic transmission fluid (oil).

Unit — The transmission fluid exchanger.

Dipstick Only Mode —Transfers used ATF and new ATF through the

transmission’s dipstick tube by running a hose directly into the transmission

fluid pan. This mode eliminates the need to remove the cooler lines.

Dipstick/Cooler Mode — Initially transfers used ATF and new ATF through

the transmission’s dipstick tube. Then with the engine running, new ATF is

pumped into the transmission through the dipstick tube, while the used ATF is

evacuated through the cooler lines. This mode provides the quickest transfer of

used and new ATF.

Introduction

Cooler Only Mode — Transfers used ATF and new ATF through the oil cooler

lines. Use this mode if the transmission does not have a dipstick.

Manual/Top-Off Mode — Manually adds or removes fluid to or from the

transmission pan. Use this mode if it is necessary to remove the transmission

pan, or to add fluid when using another mode.

Drain Waste Tank — Transfers used ATF from the internal waste tank

through the nylon transfer hose to an external waste ATF holding tank.

Total Count — Displays the number of ATF exchanges performed.

Pause/Abort — Pauses or aborts a transfer. Press button once to pause.

Press and hold button to abort.

itself. All measurements will be cancelled.

Note: When abort is selected, the unit resets

IMPORTANT!

Review current local, state, and federal statutes, cases, laws, and regulations

to determine the current status and appropriate disposal method for the

automatic transmission fluid. It is the responsibility of the user to determine

if a material is a hazardous waste at the time of disposal. Ensure that you are

in compliance with all applicable laws and regulations.

22

2

22

© 2004 SPX Corporation

Page 5

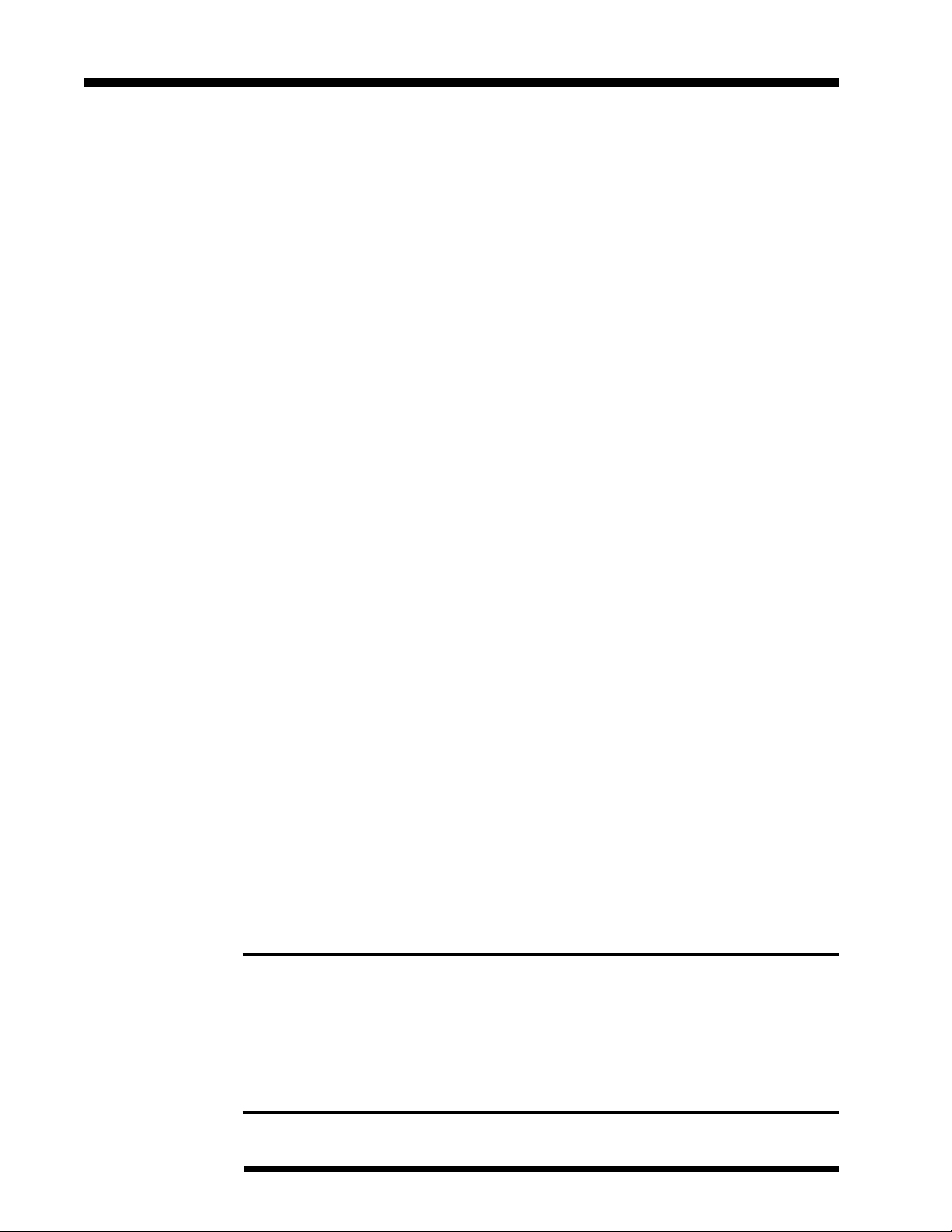

Component Identification and Location

Introduction

Unit Front View

Control Panel

Shelf for tools and

accessories

Indicator Light

Selector Valve

Assembly

Nylon Hose

Hose Hanger

Dipstick Wand Assembly

Hose Hanger

Built-in Handle

Tank for new oil

Polypropylene

Cabinet for

durability and light

weight

Locking Casters

Large Wheels for

ease of mobility

Transmission Fluid Exchanger

33

3

33

Page 6

Introduction

Component Identification and Location

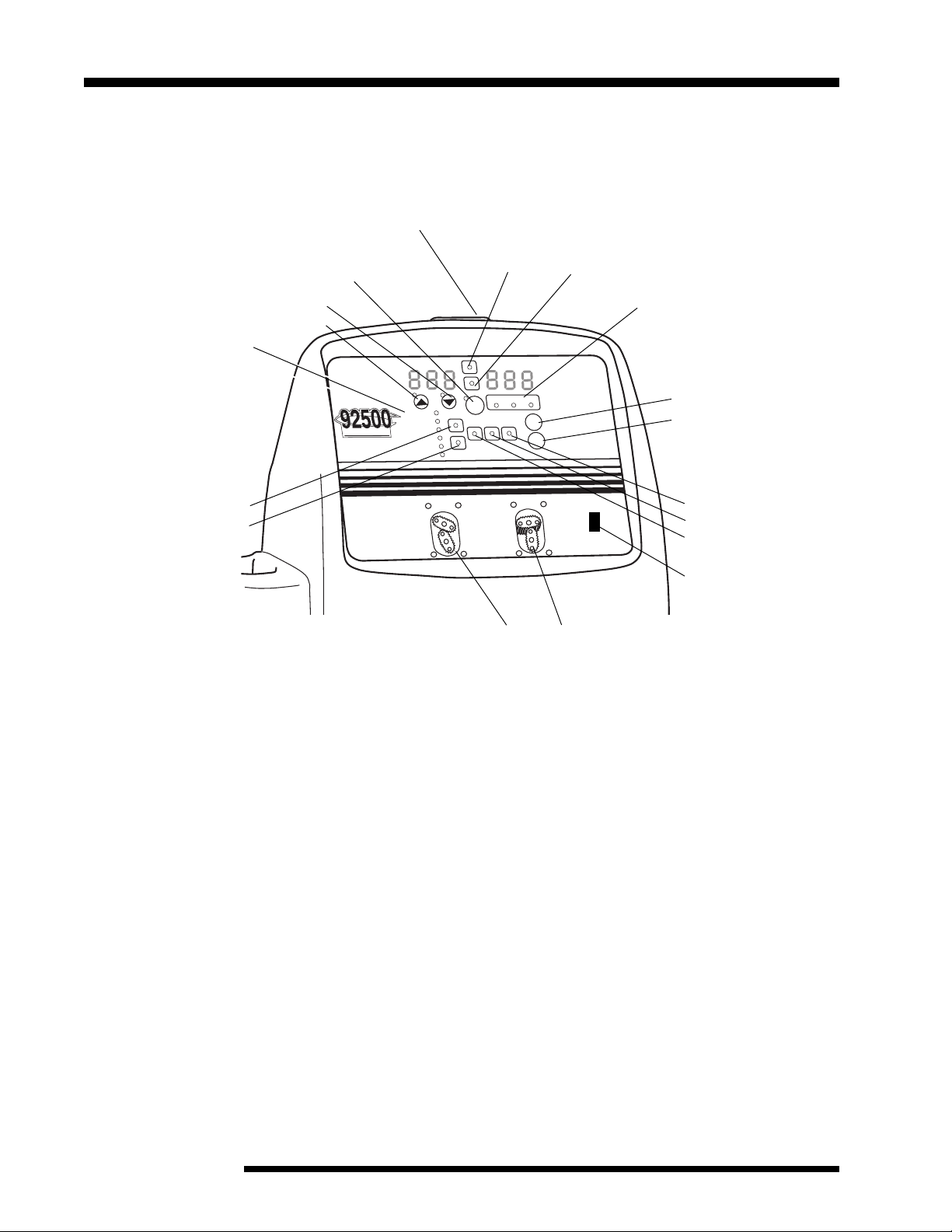

Control Panel

ON/OFF Indicator Light

Pause/Abort

Down

Up

Button

N

e

w

s

s

i

m

s

n

a

r

T

n

i

.

.

d

i

.

u

l

F

DIPSTICK ONLY

START

DIPSTICK/COOLER

COOLER ONLY

r

e

g

n

a

h

c

x

E

d

i

u

l

F

n

o

i

MANUAL/TOP-OFF

DRAIN WASTE TANK

TOTAL COUNT

SERVICE

START

ENGINE

SERVICE

END

Arrow Buttons:

Mode LED Indicators:

Dipstick Only

Dipstick/Cooler

Cooler Only

Manual/Top-Off

Drain Waste Tank

Total Count

Start Service LED

Start Engine LED

continued

Transfer LEDs:

To Trans From Trans

d

e

c

.

a

.

l

.

p

R

e

u

o

t

d

i

u

l

F

RETURN

REVERSED

SUPPLY

LINE

LINE

POLARITY

SELECT

FINISH

CHECK

LEVEL

ENTER

I

O

Light Indicators:

Reversed Polarity

Supply Line

Return Line

Select Button

Enter Button

Finish LED

Check Trans Level LED

End Service LED

ON/OFF

Switch

Transfer Indicators: ATF In ATF Out

New Fluid In — Displays amount of fluid added.

Replaced Fluid Out — Displays amount of fluid extracted.

UP/DOWN Arrows — Adjusts amount of fluid in or out.

Pause/Abort — Pauses or aborts a transfer.

Error Message Indicators — Displays error message.

Mode Indicators — Identifies procedures available.

Select Button — Selects the desired mode or procedure.

Enter Button — Accepts mode selected and starts the ATF exchange.

Display Screens — Displays operational or error information.

Transfer Indicators and LEDs — Indicates the transfer that is presently

taking place.

ON/OFF Power Switch — Turns the unit on.

44

4

44

© 2004 SPX Corporation

Page 7

Initial Setup

Accessory Kit

Unpack Accessory Kit located inside the rear door

of unit. Accessory Kit includes: Adapter set,

warranty card, and hose hanger bracket.

Attach Hose Hanger Bracket

1.

Drop tube all the way down over existing tube

on unit.

2. Rotate to align holes.

3. Insert screw into the middle hole.

Hose Hanger Bracket

Align holes

Application Notes

Ford Taurus with a 3.0 liter V6 requires the

removal of the vent cap located behind the

shifter linkage on top of transmission before

service. This will minimize “overfilling” due to

lack of headroom in the transmission housing.

Low pressure transmissions require the

transmission be left in neutral with the parking

brake secured during the “dynamic” (engine

running) phase of the ATF service.

Import vehicles, with small dipstick tube

openings, require the 529740 flexible nylon

hose, which has a smaller blue section at the

end, in place of the 529734 hose.

Helpful Tips

To avoid oil spillage, turn unit on before removing

the flexible nylon hose from its storage area.

Press the Pause/Abort once to pause an opera-

Nylon Hose

Storage

Registering the Unit

To validate the warranty provided by SPX

ROBINAIR, complete the warranty card included

in the accessory kit, and mail it within ten days

from the date of purchase.

tion; press ENTER to continue the operation.

Press and hold the Pause/Abort button to

discontinue an operation and to reset the unit.

For the quickest and most accurate exchange,

ensure transmission is warmed to normal

operating temperatures.

IMPORTANT: To prevent damage to the

vehicle, ensure all hoses are correctly

connected before transferring fluid.

WARNING

This manual contains important procedures concerning the setup, operation, and

maintenance of the unit. Study and follow all warnings at the beginning of this manual. Do

not operate the unit until you have read and understand the contents of this manual. If you

do not understand any of the contents of this manual, notify your supervisor. If the operator

cannot read English, all instructions and safety precautions must be read and discussed in the

operator’s native language.

Transmission Fluid Exchanger

55

5

55

Page 8

Operating Procedures

Dipstick Only Mode

The Dipstick Only mode transfers used ATF and

new ATF through the transmission’s dipstick

tube by running a hose into the transmission

fluid pan, emptying it of its contents, and then

with engine running, adding ATF. ATF is then

subtracted until a user specified amount of new

ATF has been added.

Note: Confirm vehicle and transmission are at

operating temperature before initiating service.

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light, the flexible nylon

hose evacuates ATF, and the software

version displays.

3. Remove dipstick from the transmission tube.

4. Insert the unit’s flexible nylon hose into the

transmission dipstick tube as far as possible

to reach the bottom of the oil pan. The

Dipstick Only, Dipstick/Cooler, Cooler Only,

Manual/Top-Off, Drain Waste Tank, and

Total Count

button LEDs are still lit and flashing.

5. Press the SELECT button until the

Only

LED is lit.

6. Pause until the ENTER LED lights and

flashes (about one second).

7. Press ENTER to confirm the selection. The

left display (

default quantity in quarts of new ATF to be

run into the system).

8. Use the arrow keys to select the amount of

quarts to be transferred. (12 quarts is the

default; minimum is 6 quarts, maximum is 32

quarts.)

indicators, and the

New Fluid In

Reversed Polarity

SELECT

Dipstick

) reads 12 (the

LED

9. Press ENTER to confirm the quantity

displayed. The alarm sounds, and the

Service

and ENTER LEDs flash.

Start

Start Service

1. With the vehicle engine off, press ENTER to

start the ATF exchange. The following takes

place:

a. The unit purges its internal fluid lines.

b. Used ATF is then extracted from the

transmission pan until empty.

c. The cumulative volume extracted

on the

d. Through the nylon transfer hose, the unit

pumps back into the transmission fluid pan

the same volume of new ATF that appears

on the

e. The volume of new fluid yet to be pumped

into the transmission pan is shown on

Fluid In

“Power Up” step 8 minus the amount

transferred in “Start Service” step 1d.)

f. The

2. Start the vehicle’s engine to circulate the new

ATF through the transmission system (torque

converter and cooler lines).

3. Press ENTER to confirm the engine is

running.

The exchanger extracts one quart of diluted ATF

and returns one quart of new ATF through the

hose and back into the transmission fluid pan.

The

respectively the amount of fluid extracted and

the amount of new fluid to be added. This

recycling continues until the selection made in

step 8 under “Power Up” is met (i.e., using the

12 quart default,

and

New Fluid In

Replace Fluid Out

Replace Fluid Out

display. (The amount designated in

Start Engine

Replace Fluid Out

Replace Fluid Out

will be 0).

display.

display.

and ENTER LEDs flash.

and

New Fluid In

appears

New

displays

will be 12

66

6

66

© 2004 SPX Corporation

Page 9

Operating Procedures

Dipstick Only Mode

When the selection in step 8 is met, the buzzer

sounds and the

light.

4. Press ENTER to confirm that the correct

amount of ATF has been replaced.

Trans Level

End Service

LED lights.

continued

and ENTER LEDs

Check

Check the ATF Level in the Pan

1. Remove the flexible nylon hose.

2. Insert the dipstick.

3. Remove dipstick to check level of fluid.

If the fluid level needs to be adjusted, continue

on to “Adjust the ATF Level.” If the level is

satisfactory, go to step 4 under “Adjust the ATF

Level.”

Adjust the ATF Level

a. If the level is too low, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to add (each press

indicates one-tenth of a quart).

b. If the level is too high, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to take out (each

press indicates one-tenth of a quart).

3. When transfer is complete, go to “Check the

ATF Level in the Pan.”

4. If the level is satisfactory, press SELECT

until

Finish

LED lights.

a. Wait for one second.

b. Press ENTER to confirm the function.

c. Press ENTER again.

The display reads SR FIN, indicating the service

is finished.

To Trans

From Trans

1. Place the flexible nylon hose in the dipstick

tube.

2. Press ENTER. The

and

Finish

LEDs light.

To Trans, From Trans

Transmission Fluid Exchanger

77

7

77

Page 10

Operating Procedures

Dipstick/Cooler Mode

Initially transfers used ATF and new ATF

through the transmission’s dipstick tube. Then

with the engine running, new ATF is pumped

into the transmission through the dipstick tube,

while the old ATF is evacuated through the

cooler lines. This mode provides the quickest

transfer of used and new ATF.

Note: Confirm vehicle and transmission are at

operating temperature before initiating service.

Identify Cooler Lines

1. Disconnect cooler lines, and attach adapters

to the input and output connectors. These

adapters may be open hoses and/or snap or

threaded fittings.

Note: To minimize the total time of the ATF

service, this step may be performed during

the “static” (engine not running) phase, when

the used ATF in the transmission pan is

being exchanged with the new ATF.

6. Insert the unit’s flexible nylon hose into the

transmission dipstick tube as far as possible

to reach the bottom of the transmission fluid

pan. The

Cooler Only, Manual/Top-Off, Drain Waste

Tank, Total Count

SELECT button LEDs are still lit and

flashing.

7. Press the SELECT button until only the

Dipstick/Cooler

8. Pause until the ENTER LED lights and

flashes (about one second).

9. Press ENTER to confirm the selection. The

left display (

default quantity in

run into the system).

10. Use the arrow keys to select the amount of

quarts to be transferred. (12 quarts is the

default; minimum is 6 quarts, maximum is 32

quarts.)

Dipstick Only, Dipstick/Cooler,

indicators, and the

LED is lit.

New Fluid In

quarts of new ATF to be

) reads 12 (the

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light and flash, the

flexible nylon hose evacuates ATF, and the

software version displays.

3. Attach the adapters to the unit’s cooler line

selector valve assembly.

can be connected to either coupler

4. Confirm connections are secure.

5. Remove the dipstick from the transmission

tube.

Reversed Polarity

Note: The adapters

.

LED

11. Press ENTER to confirm the quantity

displayed. The alarm sounds and the

Service

and ENTER LEDs flash.

Start

Start Service

1. Press ENTER to start the ATF exchange.

The following takes place:

a. The unit purges its internal fluid lines.

b.

Used ATF is then extracted from the

transmission fluid pan until empty.

c. The cumulative volume extracted appears

on the

d. Through the flexible nylon hose, the unit

pumps back into the transmission fluid pan

the same volume of new ATF that appears

on the

Replace Fluid Out

Replace Fluid Out

display.

display.

88

8

88

© 2004 SPX Corporation

Page 11

Operating Procedures

Dipstick/Cooler Mode

e. The volume of new fluid yet to be pumped

into the transmission pan is shown on

Fluid In

“Power Up” step 10 minus the amount

transferred in “Start Service” step 1d).

f. The

2. Start the vehicle’s engine to circulate the

ATF through the transmission system (torque

converter and cooler lines).

3. Press ENTER to confirm the engine is

running.

The unit extracts used ATF from the cooler lines

and returns new ATF through the nylon transfer

hose and back into the transmission fluid pan.

The

Replace Fluid Out

displays respectively the amount of ATF

extracted and the amount of new ATF added.

This recycling continues until the selection made

in step 10 under “Power Up” is met.

When the preset amount is met, the buzzer

sounds and the

light.

4. Press ENTER to confirm that the correct

amount of ATF has been replaced.

Trans Level

display (the amount designated in

Start Engine

End Service

LED lights.

and ENTER LEDs flash.

and

continued

New

New Fluid In

and ENTER LEDs

Check

Check the ATF Level in the Pan

1. Remove the flexible nylon transfer hose.

Adjust the ATF Level

1. Place the flexible nylon hose in the dipstick

tube.

Note: An alternative method is to disconnect

the red hose from the dipstick wand

assembly, and connect it to the selector

valve assembly.

Adapters

Red Hose

Selector Valve

Assembly

2. Press ENTER. The

and

Finish

LEDs light.

a. If the level is too low, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to add (each press

indicates one-tenth of a quart).

b. If the level is too high, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to take out (each

press indicates one-tenth of a quart).

3. When transfer is complete, go to “Check the

ATF Level in the Pan.”

4. If the level is satisfactory, press SELECT

until

Finish

LED lights.

To Trans, From Trans

To Trans

From Trans

2. Insert the dipstick.

3. Remove the dipstick to check fluid level.

If the fluid level needs to be adjusted, continue

on to “Adjust the ATF Level.” If the level is

satisfactory, go to step 4 under “Adjust the ATF

Level.”

Transmission Fluid Exchanger

a. Wait for one second.

b. Press ENTER to confirm the function.

c. Press ENTER again.

The display reads SR FIN, indicating the service

is finished.

99

9

99

Page 12

Operating Procedures

Cooler Only Mode

Transfers used ATF and new ATF through the

cooler lines.

Note: Confirm vehicle and transmission are at

operating temperature before initiating service.

Identify Cooler Lines

1. Disconnect cooler lines, and attach adapters

to the input and output connectors.

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light and flash, the

dipstick tube holder evacuates ATF, and the

software version displays.

Reversed Polarity

LED

8. Press ENTER to confirm the selection. The

left (

New Fluid In

default quantity in

run into the system).

9. Use the arrow keys to select the amount of

quarts to be transferred. (12 quarts is the

default; minimum is 6 quarts, maximum is 32

quarts.)

10. Press ENTER to confirm the quantity

displayed. The alarm sounds and the

Engine

11. Start the vehicle’s engine.

and ENTER LEDs flash.

) display reads 12 (the

quarts of new ATF to be

Start

Start Service

1. Press ENTER to start the ATF exchange.

The following takes place:

a. The unit extracts used ATF from one of

the cooler lines.

3. Attach the adapters to the unit’s cooler line

selector valve assembly.

can be connected to either coupler.

4. Disconnect the red hose from the dipstick

wand assembly, and connect it to the

selector valve assembly.

Adapters

Selector Valve

Assembly

5. Confirm connections are secure.

6. Press the SELECT button until only the

Cooler Only

7. Pause until the ENTER LED lights and

flashes (about one second).

LED is lit and flashing.

Note: The adapters

Red Hose

b.

The amount of ATF extracted appears on

the

Replaced Fluid Out

selected in

were extracted in step 1a above,

Fluid Out

c. The unit replaces the ATF taken out with

new ATF through the other cooler line.

This recycling continues until the selection in

step 9 under “Power Up” is met. When the

selection is met, the buzzer sounds and the

Service

2. Press ENTER to confirm that the correct

and ENTER LEDs light.

amount of oil has been replaced.

Trans Level

“Power Up”

will display 9).

LED lights.

display (i.e., if 12 was

step 9, and 3 quarts

Replaced

Check

End

1010

10

1010

© 2004 SPX Corporation

Page 13

Operating Procedures

Cooler Only Mode

continued

Check the ATF Level in the Pan

1. Remove the dipstick to check level of fluid in

transmission fluid pan. If the vehicle does not

have a dipstick, refer to the vehicle’s service

manual for the method required to check the

fluid level.

If the fluid level needs to be adjusted, continue

on to “Adjust the ATF Level.” If the level is

satisfactory, go to step 4 under “Adjust the ATF

Level.”

Adjust the ATF Level

1. Press ENTER. The

and

Finish

LEDs light.

a. If the level is too low, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to add (each press

indicates one-tenth of a quart).

b. If the level is too high, select

LED. Press ENTER. Press the up arrow key

to select how much fluid to take out (each

press indicates one-tenth of a quart).

2. When transfer is complete, go to “Check the

ATF Level in the Pan.”

3. If the level is satisfactory, press SELECT

until

Finish

LED lights.

To Trans, From Trans

To Trans

From Trans

Manual/Top-Off Mode

Transfers used ATF and new ATF through the

transmission’s dipstick tube. This mode is

commonly used when the transmission fluid pan

needs to be removed (to change gaskets or

replace a filter). When using another mode, this

mode is required to top off the ATF fluid level.

Note: Confirm vehicle and transmission are at

operating temperature before initiating service.

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Remove the dipstick from the transmission

noting ATF level, which will determine

whether additional ATF needs to be added

or withdrawn.

3. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light and flash, the

flexible nylon hose evacuates ATF, and the

software version displays.

4. Insert the unit’s flexible nylon transfer hose

into the transmission dipstick tube as far as

possible to reach the bottom of the oil pan.

Reversed Polarity

LED

a. Wait for one second.

b. Press ENTER to confirm the function.

c. Press ENTER again.

The display reads SR FIN, indicating the service

is finished.

Transmission Fluid Exchanger

5. Press the SELECT button until only the

Manual/Top-Off

6. Pause until the ENTER LED lights and

flashes (about one second).

7. Press ENTER to confirm the selection. The

Check Trans Level, To Trans,

Trans

display.

LEDs light

LED is lit and flashing.

and

From

. Drn Pan

appears on the

1111

11

1111

Page 14

Operating Procedures

Manual/Top-Off Mode

continued

Adjust the ATF Level

1. In step 2 under “Power Up,” the ATF level

was determined noting whether ATF needed

to be added, subtracted, or it was satisfactory.

a.

If the level is too low, select

(1) Press Enter.

(2) Press the arrow key to select how

much fluid to add (each press indicates onetenth of a quart).

(3) Pause after the correct volume is

selected. The ENTER key lights and flashes.

(4) Press ENTER to start the service.

b. If the level is too high, select

Trans

LED.

(1) Press Enter.

(2) Press the arrow key to select how

much fluid to take out (each press indicates

one-tenth of a quart).

(3) Pause after the correct volume is

selected. The ENTER key lights and flashes.

(4) Press ENTER again to start the

service.

c. If the transmission fluid pan needs to

be removed, press SELECT until

appears on the display.

To Trans

From

Drn Pan

LED.

2. Press ENTER. The amount removed will

display on the

3. Adjust the

Replaced Fluid Out

4. Press ENTER.

New Fluid In

Replaced Fluid Out

display to match the

display.

display.

Drain Waste Tank

Transfer used ATF from the internal waste tank

to an external waste ATF reservoir.

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Ensure the unit’s hoses are disconnected

from the vehicle.

3. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light and flash, the

flexible nylon hose evacuates ATF, and the

software version displays.

4. Disconnect the red hose from the wand

assembly. Connect the drain waste adapter

(#546763) to the red hose, and place into an

external waste ATF reservoir.

Reversed Polarity

LED

(1) Pause until ENTER LED lights (about

one second).

(2) Press ENTER to confirm the function.

(3) Press ENTER again to start draining

the pan. The unit will stop when pan is empty.

Refill Transmission Fluid Pan

To refill the transmission fluid pan,

1. Press SELECT until the

1212

12

1212

To Trans

LED is lit.

Start Service

1. Press the SELECT button until only the

Drain Waste Tank

2. Pause until the ENTER LED lights and

flashes (about one second).

3. Press ENTER to confirm the selection. The

display reads DRN (XXX), which is the

amount left to be drained.

When the waste tank is drained, the display

reads SR FIN, indicating service is finished.

LED is lit and flashing.

© 2004 SPX Corporation

Page 15

Operating Procedures

Total Count

Displays the number of ATF exchanges

performed.

Power Up

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Turn the unit on. The

lights if the power is connected incorrectly.

The unit self-tests: The buzzer sounds, all

LEDS and displays light and flash, the

flexible nylon hose evacuates ATF, and the

software version displays.

Start Service

1. Press the SELECT button until only the

Count

LED is lit and flashing.

2. Pause until the ENTER LED lights and

flashes (about one second).

Reversed Polarity

LED

Total

Changing Transmission

Fluid Types

To change transmission fluid type in a new tank:

1. Connect the power cord to a 12V DC

battery: red to the positive post and black to

the negative post.

2. Insert the flexible nylon hose into a clean

ATF container.

3. Press the SELECT button until

Off

LED lights.

4. Press ENTER.

5. Press the SELECT button until

LED

lights.

6. Press ENTER.

7. Press the UP arrow key until display reads

an amount more than what is in the new

tank.

Manual/Top-

To Trans

3. Press ENTER to confirm the selection.

The total number of services performed is

displayed; the

4. Press ENTER to return to mode selection

after noting the total number of services.

Finish

LED flashes.

8. Press ENTER. The unit will pump ATF from

the new tank into the clean ATF container.

9. Turn the unit off when completed. The unit

will clear the lines when it is restarted.

Transmission Fluid Exchanger

1313

13

1313

Page 16

Error Messages

ER FLO — Return Line is lit. No oil is returning.

ER FLO — Supply Line is lit. Check new oil reservoir.

Reversed Polarity is lit. Check battery connections.

Maintenance

•

•

Check the flexible nylon hose for cuts and/or kinks.

Filter screens may need to be cleaned. Locate the filter screens inside the

unit; clean if necessary.

Cabinet can be kept clean by wiping it down with a clean cloth.

•

Check wires for cuts and/or damage.

•

1414

14

1414

© 2004 SPX Corporation

Page 17

Replacement Adapters

529567 - Complete adapters kit. All replacement adapters described

below are included in the kit.

Part Order No. Description Application

Original No.

529568 1/4" (M6) Barb Assembly General

6304-06

529569 5/16" (M8) Barb Assembly General

6304-08

529570 3/8" (M10) Barb Assembly General

6304-10

529571 1/4" (M6) Open End Hose General

6303-06

529572 5/16" (M8) Open End Hose General

6303-08

529573 3/8" (M10) Open End Hose General

6303-10

529574 1/2" (M13) Open End Hose General

6303-12

529575 5/16" x 90 Internal Domestic

6306-03

529576 3/8" External x 5/16" External Domestic

6310-10

and Import

529577 3/8" Internal Snap Lock Domestic

6306-05

Qty. 2

529578 1/2" External Snap Lock Chrysler

6310-12

529579 1/2" External Angle Step GM

6312-01

Transmission Fluid Exchanger

529580 3/8" External Angle Step GM

6311-01

1515

15

1515

Page 18

Replacement Adapters contd.

Part Order No. Description Application

Original No.

529581 5/16" Flare, 1/2" - 20 Assembly Domestic

6318-05

529582 1/2" - 20 External (Long End SAE) Ford

6308-04

529583 1/2" - 20 Internal x SAE 45 Degrees Domestic

6313-01

529584 5/8" - 18 Internal x SAE IN Ford

6307-04

529585 3/8" Flare, 5/8" - 18 Assembly Domestic

6318-06

and Import

and Import

and Import

529586 5/8" - 18 Internal x SAE 45 Degrees Domestic

6301-01

and Import

529587 M14 Banjo Fitting Import

6308-14

(2 fittings included in 529567 Kit)

529588 M16 Internal Swivel Import

6310-16

529589 5/8" - 18 Internal x 45 Degrees Domestic

6302-02

and Import

529590 S/25 x 1/4" NPTM Plug Domestic

2025-13

(2 plugs included in 529567 Kit)

529591 S/25 x 3/8" NPTM Plug Domestic

2025-33

1616

16

1616

© 2004 SPX Corporation

Page 19

Replacement Adapters contd.

Part Order No. Description Application

Original No.

529592 1/2" to 29/32" x 5/16" Band Clamp General

2102-07

529593 M14 Banjo Bolt Long Import

6007-14

529594 M14 Cap Nut Import

1419-98

529595 M14 Copper Washer Import

1602-14

529596 S/25 x 3/8" NPTF Plug Domestic

2025-32

529597 1/2" x 20 Internal Inverted Domestic

6308-02

(3 clamps included in 529567 Kit)

(3 washers included in 529567 Kit)

and Import

529598 1/2" x 20 Internal SAE Inverted Ford

6308-03

529599 5/8" x 18 Ford

6307-03

529600 1/2" x 20 External x 45 Degrees Domestic

6313-02

and Import

529601 S/25 x 1/4" NPTF Plug Domestic

2025-12

529734 75" x 5/16" OD Dipstick Tube Adapter Assembly

6300-00-75

with compression fitting connection

547222 75" x 5/16" OD Dipstick Tube Adapter Assembly

6300-00-75

with push-to-connect fitting connection

529740 42" x 1/4" OD Dipstick Tube Adapter

6300-00-42

with compression fitting connection

547223 42" x 1/4" OD Dipstick Tube Adapter

6300-00-42

with push-to-connect fitting connection

Transmission Fluid Exchanger

1717

17

1717

Page 20

Replacement Adapters contd.

Part Order No. Description Application

Original No.

546763 S/48 x 9" Hose - Drain Hose Assy. Drain

2030-31

546764 1/2" Female Snap Lock Domestic

6306-08

546765 3/8" Male Snap Lock Ford

6319-06

546766 1/2" Push-on Barb Ford

6304-12

Waste

Tank

1818

18

1818

© 2004 SPX Corporation

Page 21

Replacement Parts

Illustration Part Number Description

92501 Pump Assembly Replacement

92501RBK Pump Head

90516 New Oil Reservoir Cap

B

A

92509

(A in illustration) 2 Required

92510 Directional Valve Assembly

(Entire assembly shown at left)

92511 Quick Disconnect Plug, S/48 x 1/4" External NPT

(B in illustration)

92513 Pressure Hose (Red; 92" x 3/8" Barb Assembly)

92514 Recovery Hose (Black; 92" x 3/8" Barb Assembly)

92515 Cooler Hose (Black; 92" x 3/8" Barb Assembly)

92516 Power Cord Assembly

Quick Disconnect Coupler, S/25 x 1/4" Internal NPT

Transmission Fluid Exchanger

92517 Quick Disconnect Coupler,

(A in illustration)

92518 Quick Disconnect Plug,

(D in illustration)

92521 Replacement Wand Assembly

(Entire assembly shown at left)

S/48 x 3/8" External NPT

S/48 x 3/8" External NPT

1919

19

1919

Page 22

Limited Warranty

Robinair Limited Warranty Statement

Rev. November 1, 2005

This product is warranted to be free from defects in workmanship, materials, and components for a

period of one year from date of purchase. All parts and labor required to repair defective products

covered under the warranty will be at no charge. The following restrictions apply:

1. The limited warranty applies to the original purchaser only.

2. The warranty applies to the product in normal usage situations only, as described in the Operating

Manual. The product must be serviced and maintained as specified.

3. If the product fails, it will be repaired or replaced at the option of the manufacturer.

4. Transportation charges for warranty service will be reimbursed by the factory upon verification of

the warranty claim and submission of a freight bill for normal ground service. Approval from the

manufacturer must be obtained prior to shipping to an authorized service center.

5. Warranty service claims are subject to authorized inspection for product defect(s).

6. The manufacturer shall not be responsible for any additional costs associated with a product

failure including, but not limited to, loss of work time, loss of refrigerant, cross-contamination of

refrigerant, and unauthorized shipping and/or labor charges.

7. All warranty service claims must be made within the specified warranty period. Proof-of-purchase date must be supplied to the manufacturer.

This Limited Warranty does NOT apply if:

• The product, or product part, is broken by accident.

• The product is misused, tampered with, or modified.

© 2004 SPX Corporation Transmission Fluid Exchanger

Page 23

Visit our web site at

www.robinair.com

or

%

Call our Toll-Free

Technical Support Line at

800-822-5561

in the continental U.S. or Canada.

In all other locations, contact your local distributor. To help us serve

you better, be prepared to provide the model number, serial number,

and date of purchase of your unit.

To validate your warranty, complete the warranty card attached to your

unit, and return it within ten days from date of purchase.

NATIONWIDE NETWORK OF AUTHORIZED SERVICE CENTERS

If your unit needs repair or replacement parts, contact the service

center in your area. For help in locating a service center, call the

toll-free technical support line.

Due to ongoing product improvements,

we reserve the right to change design,

specifications, and materials without notice.

®

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Technical Services: 1-800-822-5561

Fax: 1-412-690-2001

Customer Service: 1-800-533-6127

Fax: 1-800-322-2890

Web Site: www.robinair.com

526233 Rev. C (December 20, 2007) 92500 Transmission Fluid Exchanger © 2004 SPX Corporation

Loading...

Loading...