Page 1

40134A, 40152, 40153, 41600, 41700 SERIES

MANIFOLD OPERATING INSTRUCTIONS

WARNING

Always wear safety goggles when working with refrigerants. Contact with refrigerant can cause eye injury.

Disconnect hoses with extreme caution!

Pressurized refrigerant may be present in

hoses. Always point hoses away from you

and anyone nearby.

Your manifold is designed so that all three lower fittings are

connected to each other by internal passages. Separate passages

from the low and high side fittings to their respective gauges

give you pressure and vacuum readings whether the handwheels

are open or closed. For your convenience and safety, handwheels

and gauges are color-coded with the blue compound gauge on

the left or low side, and the red pressure gauge on the high or

right side.

Connecting Field Service Couplers (40134A)

Field service couplers are provided to access the vehicle’s

service ports. The service coupler should be in the closed

position before connecting to the external fitting on the vehicle.

1. To close, turn the handle counterclockwise until finger

tight.

2. Place the service coupler on the external fitting.

3. Push in on the handle of the service coupler with your

thumb, while pulling up on the sleeve, until it bottoms on

the external fitting; then release. Check to see if it is

correctly seated by pulling up on the service coupler.

4. For maximum flow, turn the handle clockwise until it

stops.

Diagnosing System Operation

1. Connect the blue low side hose to the A/C system’s low

side service port. Connect the red high side hose to the

A/C system’s high side service port.

2. With the manifold handwheels closed, read the pressures

on the gauge face.

3. Use the temperature/pressure chart stored on the back of

the gauge holster to find the corresponding temperature

for the refrigerant in the system (41600, 41700).

4. Compare these pressures and temperatures to the A/C

system manufacturer’s specifications for proper operation.

5. If the system is within the correct operating guidelines,

disconnect the manifold hoses from the system. If

repairs are necessary, follow the steps for recovering,

evacuating, and recharging the system.

Recovering Refrigerant

Note: According to federal law, refrigerant should not be

exhausted to the atmosphere.

1. Be sure the blue low side hose is connected to the A/C

system’s low side service port and that the red high side

hose is connected to the A/C system’s high side service

port.

Note: Typically, the yellow center hose is connected to the

inlet of the recovery unit.

2. Follow the instructions provided with the recovery unit

for proper recovery of refrigerant from the A/C system.

Evacuating and Charging a Refrigerant System

1. Connect the blue low side hose to the A/C system’s low

side service port. Connect the red high side hose to the

A/C system’s high side service port.

2. Check the manifold gauge pressure reading to be sure

the A/C system has been recovered properly. If it is not,

follow steps under “Recovering Refrigerant.” If it is,

connect the center yellow charging hose to a vacuum

pump.

3. Open the high and low side handwheels and start the

vacuum pump.

4. After evacuating the system according to the manufacturer’s specifications, close both the high and low

side handwheels and turn off the vacuum pump.

5. Disconnect the yellow hose from the vacuum pump and

connect it to the refrigerant supply.

6. Slightly open the refrigerant supply valve. Purge air

from the yellow charging hose at the manifold, then

close the supply valve.

7. You can now charge the A/C system according to the

manufacturer’s specifications.

• If the system specifications call for charging on the high

side, close the manifold’s blue low side handwheel, open

the refrigerant supply valve and open the manifold’s red

high side handwheel. After dispensing the proper

amount of refrigerant, close the manifold’s red high side

handwheel and close the refrigerant supply valve.

• If the system specifications call for charging on the low

side, close the manifold’s red high side handwheel, open

the refrigerant supply valve and open the manifold’s

blue low side handwheel. After dispensing the proper

amount of refrigerant, close the manifold’s blue low side

handwheel and close the refrigerant supply valve.

(continued)

Page 2

8. When you have charged the system, close both manifold

handwheels. Let the compressor run and check the

manifold’s gauge pressure readings to be sure the

system is operating properly. If it is not, adjust the

system as necessary. To disconnect the manifold when

the system is operating correctly, see the steps below for

your specific manifold.

• For the 40134A manifold, first close the high side

coupler valve. Open the low side coupler valve. Then

disconnect the red high side hose from the A/C system.

After disconnecting, go to step 9.

• For all other manifolds, close both handwheels on the

manifold. Carefully remove the charging hoses from the

system. Charging is now complete.

9. Restart the A/C system, then open both manifold

handwheels. Refrigerant from both hoses will be drawn

quickly into the A/C system through the blue low side

hose.

10. When both gauges show the lowest operating pressure

recommended by the manufacturer, close the low side

valve and turn off the A/C system.

11. Close the low side coupler valve and disconnect the low

side hose from the A/C system.

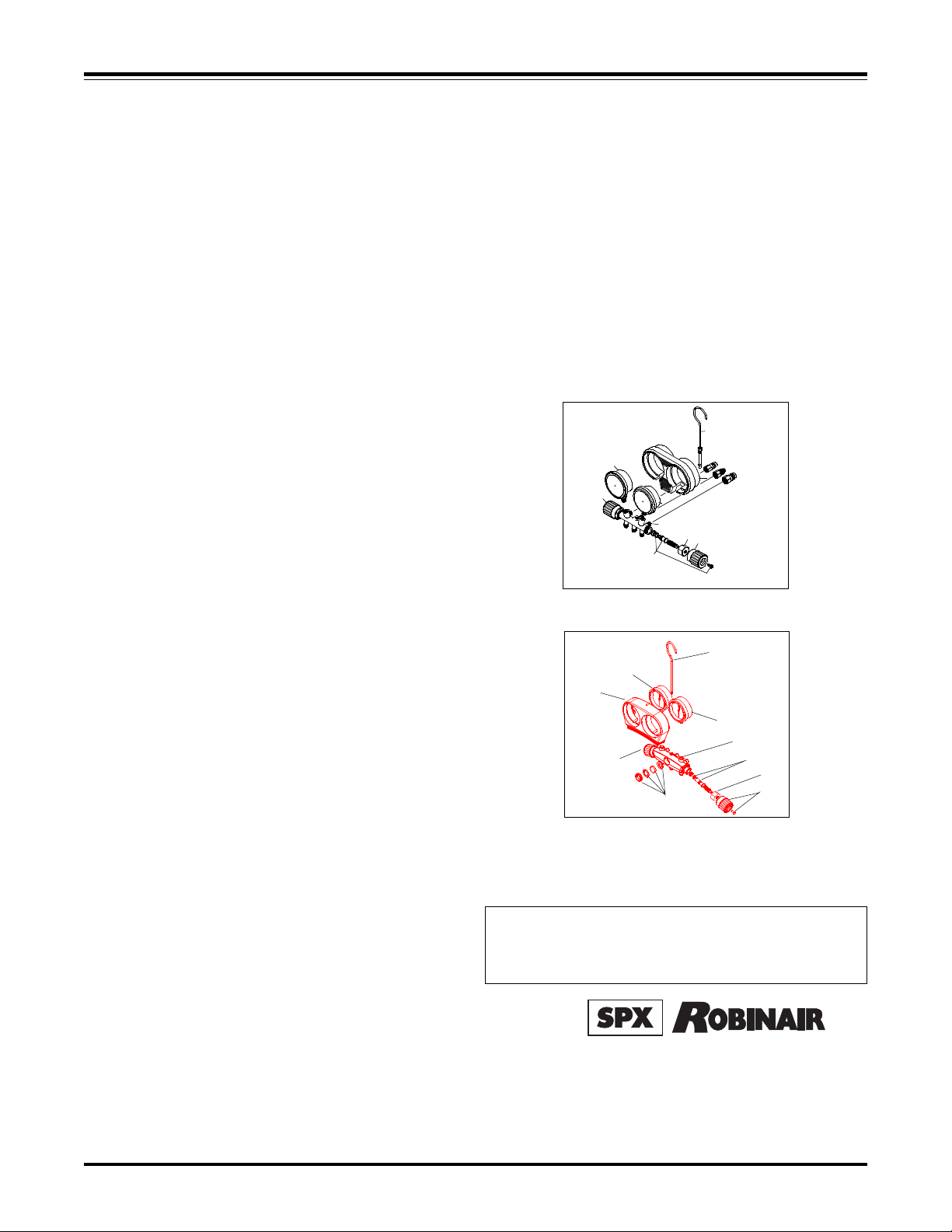

REPLACEMENT PARTS LIST

MAINTAINING YOUR MANIFOLD

To keep your manifold in top operating condition:

• Periodically replace O-rings and valve seats.

• Be sure to lubricate O-rings with Robinair’s High

Vacuum Grease (part number 13033).

WARRANTY COVERAGE

Your manifold is covered by our One Year Limited Warranty. We guarantee your manifold to be free from defects in

material and workmanship under normal use and service for

one year from the date of sale. See your distributor for details.

4

3

1

9

6

5

2

8

7

1 Blue Barrel Handwheel Set 41698

2 Manifold Bar without Gauges (41600) 41694

(41700) 19690

3 Compound Gauge, blue case, °F

40134a, 40152, 40153, 41600, 41700 Series 11794

3 Compound Gauge, blue case, °C

40151, 41612, 42134A 11797

4 Hanging Hook 41697

5 Pressure Gauge, red case, °F

40134a, 40152, 40153, 41600, 41700 Series 11795

5 Pressure Gauge, red case, °C

40151, 41612, 42134A 11798

6 Flexible Holster (41600) 41691

Flexible Holster (41700) 19691

7 Red Barrel Handwheel Set 41698

8 Hex Nut 41616

9 Complete Stem Assembly,

2 required (41600 includes seat and O-rings) 41617

41700 19695

10 Sight Glass Assembly (41700) 19693

High Pressure Gauges for Model 41670:

Compound Gauge, psi 41675

Pressure Gauge, psi 41676

40134A, 41600

4

4

3

6

5

5

2

1

9

8

7

10

41700

Because of ongoing product improvements, we reserve the right

to change design, specifications, and materials without notice.

INST 0740

For more information call toll-free

1-800-822-5561 in the continental U.S. and

Canada. In all other locations, contact your local

distributor.

SPX Corporation

655 Eisenhower Drive

Owatonna, MN 55060-0995 USA

Technical Services: 1-800-822-5561

Fax: 1-800-822-7805

Customer Service: 1-800-533-6127

Fax: 1-800-322-2890

Web Site: www.robinair. com

122420 (Rev B, 6/03) Manifold Operating Instructions © SPX Corporation

Loading...

Loading...