Page 1

WARNING

FOR YOUR SAFETY

If you smell gas:

1. Open windows.

2. DO NOT try to light any appliance.

3. DO NOT use electrical switches.

4. DO NOT use any telephone in

your building.

5. Extinguish any open flame.

6. Leave the building.

7. Immediately call your local gas

supplier after leaving the building.

Follow the gas supplier’s

instructions.

8. If you cannot reach your gas

supplier, call the Fire Department.

Fire Hazard

Keep all flammable objects, liquids and

vapours the minimum required

clearances to combustibles away from

heater.

Some objects will catch fire or explode

when placed close to heater.

Failure to follow these instructions can

result in death, injury or property

damage.

WARNING

Installation must be done by a registered installer/

contractor qualified in the installation and service

of gas-fired heating equipment or your gas supplier.

Improper installation, adjustment, alteration, service

or maintenance can result in death, injury or property

damage. Read the installation, operation and service

manual thoroughly before installing or servicing

this equipment.

®

Combat

Compact Tubular Unit Heaters

Installation, Commissioning,

Operation & Service Manual

Models CTCU 7

CTCU 11

CTCU 15

CTCU 22

CTCU 27

CTCU 32

© 2012 Roberts-Gordon Europe Limited

Installer

Please take the time to read and understand

these instructions prior to any installation.

Installer must give a copy of this manual to the owner.

Owner

Keep this manual in a safe place in order to provide

your serviceman with necessary information.

Roberts-Gordon Europe Limited

Unit A, Kings Hill Business Park

Darlaston Road, Wednesbury

West Midlands WS10 7SH UK

Telephone: +44(0)121 506 7700

Fax: +44 (0)121 506 7701

Service Telephone: +44 (0)121 506 7709

Service Fax: +44 (0)121 506 7702

E-mail: uksales@rg-inc.com

E-mail: export@rg-inc.com

www.rg-inc.com

www.combat.co.uk

P/ N 1111 0 0 U K R ev F 03/12

Page 2

Page 3

© 2011

Roberts-Gordon Europe Ltd

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon Europe Ltd.

TABLE OF CONTENTS

SECTION 1: Heater Safety...................................................... 2

1.1 Manpower Requirements .............................................2

1.2 Safety Labels and Their Placement ............................. 2

SECTION 2: Installer Responsibility .....................................4

2.1 Clearances to Combustibles ........................................ 4

2.2 Corrosive Chemicals.................................................... 4

2.3 National Standards and Applicable Codes .................. 4

SECTION 3: Clearances to Combustibles.............................5

3.1 Required Clearances to Combustibles.........................5

SECTION 4: Critcal Considerations ......................................7

4.1 Ventilation .................................................................... 7

4.2 Gas Supply .................................................................. 7

4.3 Electrical Supply .......................................................... 7

4.4 Flue..............................................................................7

SECTION 5: Specifications ....................................................8

5.1 CTCUA (All Models) ....................................................8

5.2 General Technical Data Table (All Models)..................9

5.3 Technical Data Table (All Models)................................ 9

SECTION 6: Heater Installation............................................ 10

6.1 General...................................................................... 10

6.2 Basic Information....................................................... 10

6.3 Location and Suspension .......................................... 10

6.4 Handling .................................................................... 10

6.5 Suspension and Shelf Mounting ................................ 10

6.6 Wall Mounting............................................................ 10

SECTION 7: Flue Installation ...............................................13

7. 1 F l ue Installation .......................................................... 13

7.2 Changing Flue and Air Intake Orientation ..................13

7.3 Type C

7.4 Type B

SECTION 8: Air Supply......................................................... 16

8.1 Room Sealed Installation........................................... 16

8.2 Open Flued Installation.............................................. 16

8.3 Building Ventilation .................................................... 16

SECTION 9: Gas Pipe Work.................................................. 17

9.1 Connections............................................................... 17

SECTION 10: Wiring and Electrical Information................. 19

10.1 Electrical Supply ...................................................... 19

10.2 Remote Controls ...................................................... 19

10.3 CTCUA Wiring Diagram (Models 7-32) .................... 20

SECTION 11: Commissioning ..............................................21

11.1 Pre-Commission Checks .......................................... 21

11.2 Gas Supply ...............................................................21

11.3 Mechanical Checks................................................... 21

11.4 Begin Commissioning ...............................................22

11.5 Combustion Testing ..................................................23

11.6 Turning Off the Heater .............................................. 23

11.7 External Controls ...................................................... 23

11.8 Complete the Commissioning...................................24

11.9 Instruction to the User .............................................. 24

SECTION 12: User Instructions ...........................................25

12.1 User Instructions...................................................... 25

12.2 Heater Operation .....................................................25

12.3 Common User Controls ........................................... 25

12.4 Lighting Instructions.................................................26

12.5 Simple Fault Finding ................................................ 26

, C32 & C62 Appliance..................................... 13

12

Appliance ..................................................... 13

22

SECTION 13: Servicing.........................................................27

13.1 Servicing Instructions...............................................27

13.2 Burner Maintenance.................................................27

13.3 Fan/Motor Assembly Maintenance...........................27

13.4 Heat Exchanger Maintenance..................................27

13.5 Gas Control Valve Maintenance...............................28

13.6 Flue Fan ...................................................................28

13.7 Maintenance Checklist .............................................28

SECTION 14: Conversion Between Gases ..........................30

14.1 General ....................................................................30

14.2 Burner Conversion ...................................................30

14.3 Gas Valves...............................................................30

SECTION 15: Troubleshooting .............................................31

15.1 General ....................................................................32

15.2 Troubleshooting For Automatic Ignition Burner

Systems....................................................................33

15.3 Troubleshooting for Flame S

15.4 Troubleshooting for Solenoid Valves ........................34

15.5 Troubleshooting for Main Fan...................................35

SECTION 16: Removal and Replacement Parts..................36

16.1 Gas Valve.................................................................36

16.2 Burner Compartment ...............................................37

16.3 Ignition Electrode and Flame Probe.........................38

16.4 Flue Fan Vertical Installation (Models 7 - 15)...........39

16.5 Flue Fan Vertical Installation (Models 22 - 32).........40

16.6 Pressure Switch........................................................41

16.7 Ignition Control .........................................................42

16.8 CTCUA Axial Fan/Guard/Motor Assembly ...............42

16.9 Fan and Limit Thermostats ......................................42

upervision System .......34

Printed in U.K.

Page 4

Page 5

TABLE OF FIGURES

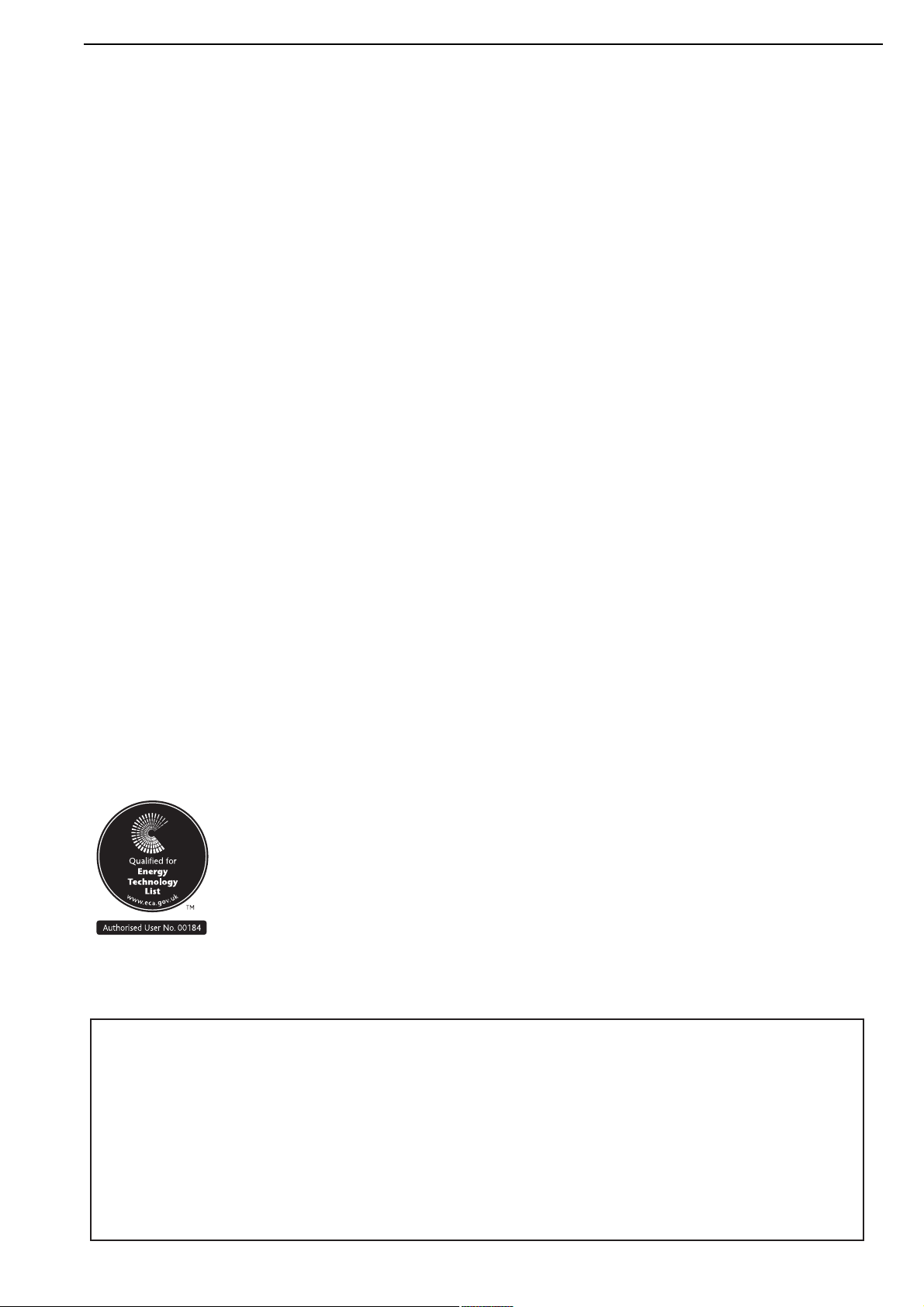

Figure 1: Front and Back Panel Label Placement ..................... 2

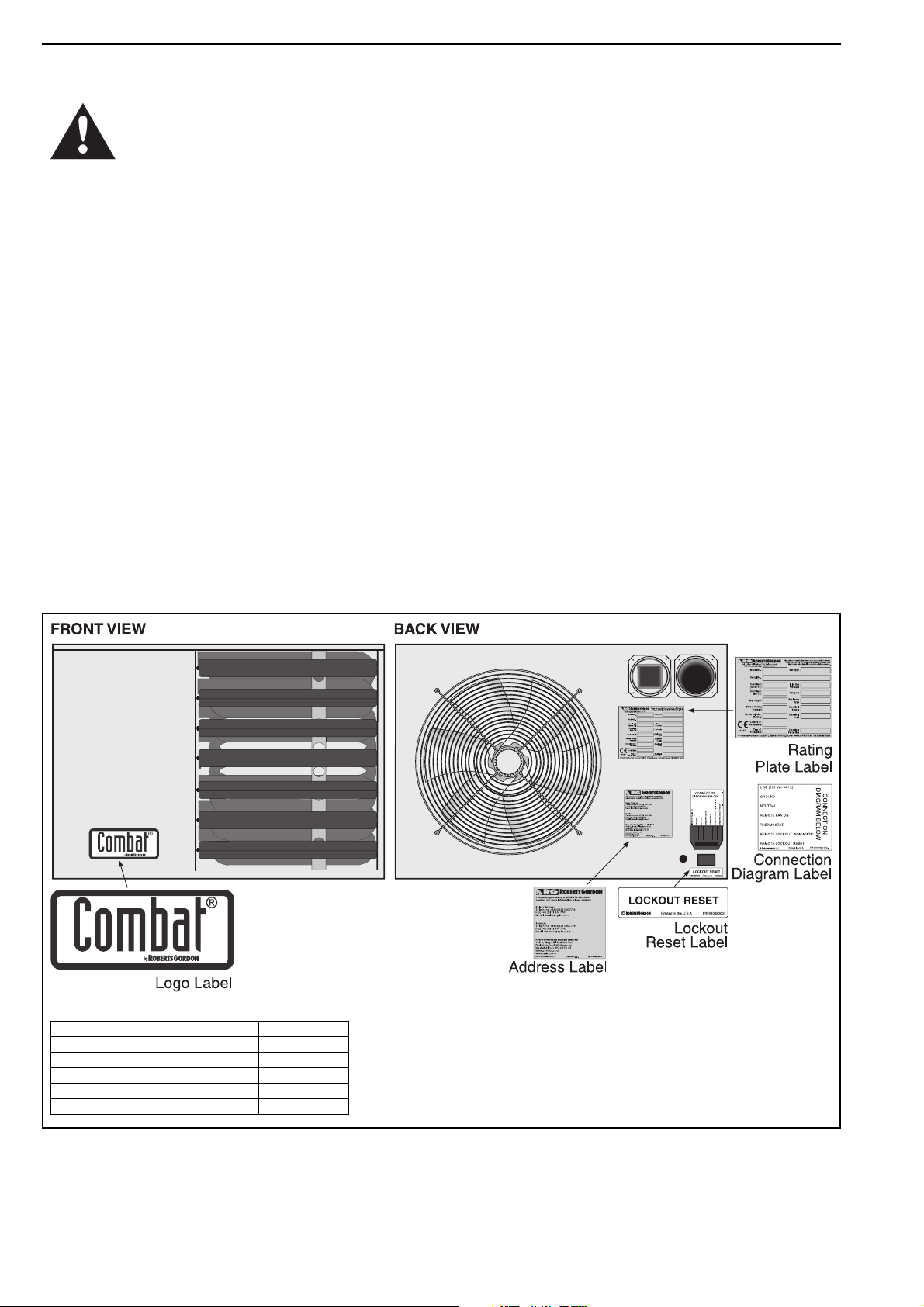

Figure 2: Side Panel Label Placement......................................3

Figure 3: Installation Clearances and Clearances to

Combustibles............................................................. 6

Figure 4: Suspension Methods ............................................... 11

Figure 5: Shelf Mounting and Hanging Suspension................12

Figure 6: Vertical Louvres (Optional) ...................................... 12

Figure 7: Flue and Roof Detail ................................................ 14

Figure 8: Vertical and Horizontal Flue Termination -

Type B

Figure 9: Vertical and Horizontal Flue Termination -

Type C

Figure 10: Gas Connection with Stainless Steel Flex

Figure 11: Automatic Burner Control Box Sequence............... 22

Figure 12: Gas Valve for Heater (Models 7 - 32)..................... 23

Figure 13: Heater Operating Sequence .................................. 25

Appliance .................................................. 14

22

& C62 Appliances.................................15

12 C32

Connector .............................................................. 18

Page 6

Page 7

ROBERTS GORDON® appliances have been tested and CE certified as complying with the essential

requirements of the Gas Appliance Directive, the Low Voltage Directive, the Electromagnetic

Compatibility Directive and the Machinery Directive for use on natural gas and LPG when installed,

commissioned and maintained in accordance with these instructions.

These instructions refer to appliances designed to operate in the European Union.

Appliances designed for other countries (Non-European Union) are available on request.

This appliance must be installed in accordance with the local and national codes in force and used

only in a sufficiently ventilated space, as specified in these instructions.

Before installation, check that the local gas distribution systems, nature of gas and pressure, and

adjustment of the appliance are compatible.

®

COMBAT

Compact Tubular Unit Heaters are high efficiency heaters and are listed on

the Enhanced Capital Allowance Scheme ’Energy Technology Product List’. The ETL

symbol is a UK registered certification mark of The Carbon Trust.

Product Approval

1 of 42

Page 8

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Description Part Number

Logo Label 91040030

Address Label 91040006

Lockout Reset Label 91038303

Rating Plate Label 91040001

Connection Diagram Label 91040022

SECTION 1: HEATER SAFETY

Yo ur Safety is Important to Us!

This symbol is used throughout the

manual to notify you of possible fire,

electrical or burn hazards. Please pay

special attention when reading and

following the warnings in these sections.

Installation, service and annual inspection of heater

must be done by a registered installer/contractor

qualified in the installation and service of gas-fired

heating equipment.

Read this manual carefully before installation,

operation, or service of this equipment.

Before installation, check that the local distribution

conditions, nature of gas and pressure, and

adjustment of the appliance are compatible.

The heater must be applied and operated under the

general concepts of reasonable use.

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given

supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they

do no play with the appliance.

This heater is designed for heating non-residential

indoor spaces. Do not install in residential spaces.

These instructions, the layout drawing, local codes

For additional copies of the Installation, Operation

and Service Manual, please contact Roberts-

Gordon Europe Limited.

and ordinances, and applicable standards that apply

to gas piping, electrical wiring, venting, etc. must be

thoroughly understood before proceeding with the

installation.

1.1 Manpower Requirements

To p re vent personal injury and damage to the

heater, two persons will be required for installation

Protective gear is to be worn during installation,

operation and service. Thin sheet metal parts have

sharp edges. To prevent injury, the use of work

ves is recommended. The use of gloves will also

glo

prevent the transfer of body oils from the hands.

.

1.2 Safety Labels and Their Placement

Product safety signs or labels sho

the product user when they are no longer legible.

Contact Roberts-Gordon for obtaining replacement

signs or labels. See Page 2, Figure 1 through Page

3, Figure 2.

Figure 1: Front and Back Panel Label Placement

uld be replaced by

2 of 42

Page 9

Figure 2: Side Panel Label Placement

Description Part Number

Lighting Label 91040002

Wiring Diagram Label 91040020

SECTION 1: HEATER SAFETY

3 of 42

Page 10

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

CAUTION

Product Damage Hazard

Do not use heater in area containing

corrosive chemicals.

Refer to appropriate Material Safety Data

Sheets (MSDS).

Failure to follow these instructions can result

in product damage.

SECTION 2: INSTALLER RESPONSIBILITY

• To install the heater, as well as the gas and electrical supplies, in accordance with applicable

specifications and codes. Roberts-Gordon

recommends the installer contact a local

building inspector, Fire Officer or insurance

company for guidance.

•To use the information given in the manual

together with the local and national codes to

perform the installation.

• To install the heater in accordance with the

clearances to combustibles of this heater.

•To furnish all needed materials not furnished

as standard equipment.

• To plan location of supports, flues and air

intakes.

•To provide access to burners for servicing.

•To provide the owner with a copy of this

installation, commissioning, operation and

service manual.

•To never use heater as support for ladder or

other access equipment and never hang or

suspend anything from heater.

• To ensure that there is sufficient ventilation in the

area to comply with the requirements of

all relevant local and national codes.

• To safely and adequately install heater using

materials with a minimal working load of 33 kg.

• To ensure the heater is placed in an approved

application.

2.1 Clearances to Combustibles

A laminated wall tag is available for the heater as a

permanent reminder of the safety instructions and

the importance of the required clearances to

combustibles. Affix the tag by peeling off the backing

of the adhesive strips on the rear surface and

position the tag on a wall near the heater (e.g.

®

thermostat or ROBERTS GORDON

Controller).

A copy of the wall tag (P/N 91040029) is illustrated

on the back cover. Know your model number and

installed configuration. Model number and installed

configuration are found on the burner and in the

Installation, Operation and Service Manual. Write

the largest clearance dimensions with permanent

ink according to your model number and

configuration in the open spaces on the tag.

2.2 Corrosive Chemicals

Roberts-Gordon cannot be responsible for ensuring

that all appropriate safety measures are undertaken

prior to installation; this is entirely the responsibility

of the installer. It is essential that the contractor, the

sub-contractor, or the owner identifies the presence

of combustible materials, corrosive chemicals or

halogenated hydrocarbons* anywhere in the

premises.

* Halogenated Hydrocarbons are a family of chemical

compounds characterized by the presence of halogen

elements (fluorine, chlorine, bromine, etc.). These compounds are frequently used in refrigerants, cleaning

agents, solvents, etc. If these compounds enter the air

supply of the burner, the lifespan of the heater components will be greatly reduced. Warranty will be invalid if

the heater is exposed to halogenated hydrocarbons.

2.3 National Standards and Applicable Codes

All appliances must be installed in accordance with

the latest revision of applicable standards and local

and national codes. This refers also to the electric,

gas and venting installation. Note: Additional

standards for installations in public garages, aircraft

hangars, etc. may be applicable.

4 of 42

Page 11

SECTION 3: CLEARANCES TO COMBUSTIBLES

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapours the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 3: CLEARANCES TO COMBUSTIBLES

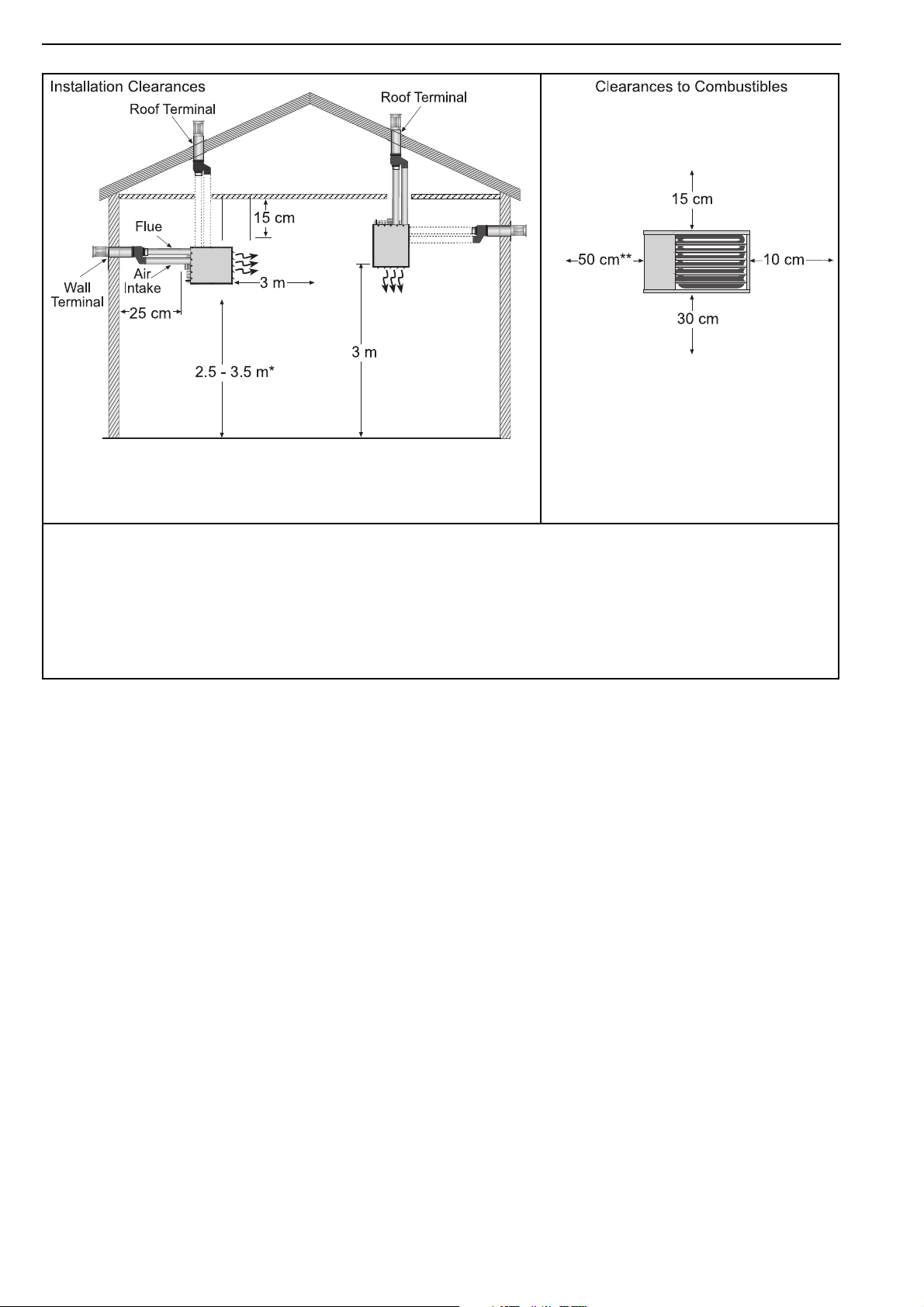

3.1 Required Clearances to Combustibles

Clearances are the required distances that

combustible objects must be away from the heater

to prevent fire hazards. Caution should be used

when running the system near combustibles.

Combustibles are materials, which may catch on fire

and include common items such as wood, paper,

rubber, fabric, etc. Maintain clearances to

combustibles at all times for safety.

Clearances around the heater and flue must be as

indicated on Page 6, Figure 3, to ensure access for

servicing, and correct operation. If clearances to

combustibles are not indicated, then installation

clearances apply.

Check the clearances on each burner for the model

heater being installed to make sure the product is

suitable for your application and the clearances are

maintained. Read and follow the safety guidelines

below:

• Keep petrol or other combustible materials

including flammable objects, liquids, dust or

vapours a

ance.

• The stated clearances to combustibles represents a surface temperature of 32°C (90° F)

above room temperature. Building materials with

a low heat tolerance (such as plastics, vinyl sid-

ing, canvas, tri-ply, etc) may be subject to degradation at lower temperatures. It is the installer’s

responsibility to assure that adjacent materials

are protected from degradation.

• Maintain clearances from heat sensitive equip-

ment and workstations.

• Maintain clearances from vehicles parked below

the heater.

• Maintain clearances from swinging and over-

head doors, overhead cranes, vehicle lifts, parti-

way from this heater or any other appli-

tions, storage racks, hoists, building

construction, etc.

• In locations used for the storage of combustible

materials, signs must be posted to specify the

maximum permissible stacking height to maintain required clearances from the heater to the

combustibles. Signs must be posted adjacent to

the heater thermostat. In the absence of a thermostat, signs must be posted in a conspicuous

location.

• Consu

Carrier or other authorities for approval of pro-

posed installation when there is a possibility of

exposure to combustible airborne materials or

vapours.

• Hang heater in accordance to the minimum

suspension requirements on Page 10, Section 6

and Page 11, Figure 4 through Page 12, Figure

5.

• Affix the tag on a wall near the heater.

lt local Building Inspector, Fire Insurance

5 of 42

Page 12

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

If installed at low levels where individuals can come in contact with hot heat exchanger components,

adequate guarding must be provided.

All distances are minimum clearance requirements for service access, air flow and safety.

The heater must always be installed at least 1.8 m above the floor.

The flue pipe must have clearance from combustibles by 5 cm.

* Heaters may be mounted at a higher level if destratification

fans are installed.

**80 cm is necessary to service

heater.

Figure 3: Installation Clearances and Clearances to Combustibles

6 of 42

Page 13

SECTION 4: CRITCAL CONSIDERATIONS

WARNING

Carbon Monoxide Hazard

Heaters may be installed vented or unvented.

Vented heaters must be vented outdoors.

Unvented heaters must be installed in

buildings with ventilation rates as per

section 7.

Failure to follow these instructions can result

in death or injury.

4.1 Ventilation

It is important to ensure that there is adequate air

circulation around the heater to supply air for

combustion, ventilation and distribution in

accordance with local and national codes.

4.2 Gas Supply

SECTION 4: CRITCAL CONSIDERATIONS

4.3 Electrical Supply

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly grounded.

Failure to follow these instructions can result

in death or electrical shock.

A permanent 230 V 50 Hz 1Ø electrical supply is

required at the main electrical terminals. The heater

also requires suitable energy controls in accordance

with Section 10.

4.4 Flue

Choose heater siting to allow for the proper location

of the flue. Each heater must be fitted with an

individual and correctly sized sealed flue system

(See Page 13, Section 7).

No other appliance may be connected to the flue.

For room sealed installation, the air intake must be

the same size sealed system and the flue/air intake

must terminate at an approved concentric wall or

roof terminal.

It is important that the gas supply pipe is sized

correctly to provide the inlet pressure as stated on

the heater data plate. The gas supply pipe and

electrical connections must not support any of the

heater's weight.

7 of 42

Page 14

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Rear View

Top View

Air Intake

on Model 22

728

A

Gas Supply

B

171

Lockout Reset

Electrical

Connection

Flue

Air Intake

45

85

D

448

120

End View

660

514

Mounting

Holes

422

Mounting

Holes

448 26514

C

171

120

Air Intake

(Optional Position)

Flue

(Optional Position)

4 x M10 Captive Nuts Provided

463

4 x M10 Captive Nuts Provided

*

* 140 for 27 - 32

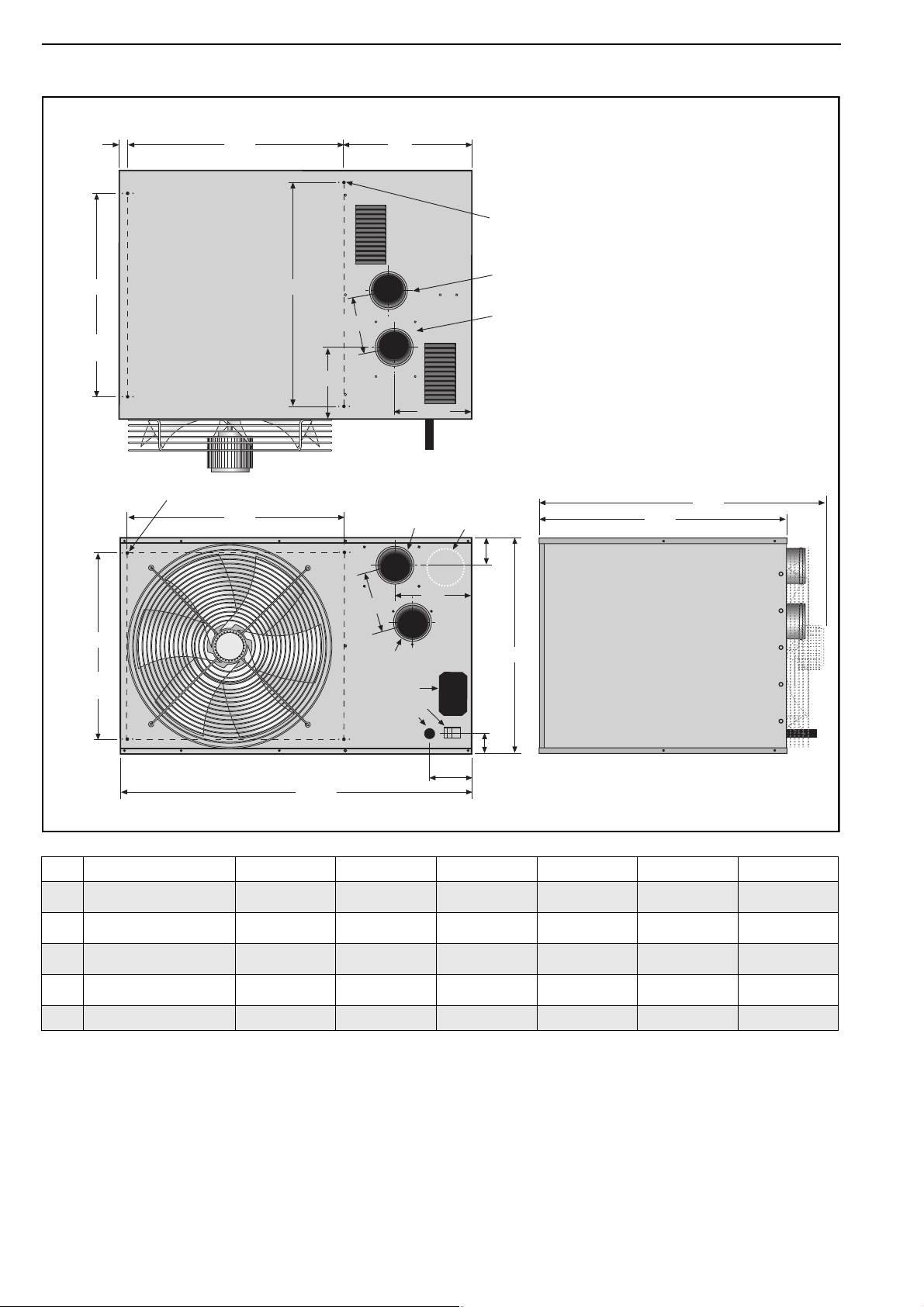

SECTION 5: SPECIFICATIONS

5.1 CTCUA (All Models)

Dimension Data - CTCUA (All Models)

Model CTCU-7 CTCU-11 CTCU-15 CTCU-22 CTCU-27 / 32

Height

A

Mounting Hole Spacing

B

Centre of Flue (Top Option)

C

Centre of Flue

D

Weight kg 28 30.5 38.5 41 52.3

mm

(in)

mm

(in)

mm

(in)

mm

(in)

(12.0)

(9.4)

(5.9)

(2.7)

304

239

151

68

304

(12.0)

239

(9.4)

151

(5.9)

68

(2.7)

450

(17.7)

385

(15.2)

151

(5.9)

68

(2.7)

450

(17.7)

385

(15.2)

172

(6.8)

46

(1.8)

578

(22.8)

513

(20.2)

149

(5.9)

59

(2.3)

8 of 42

Page 15

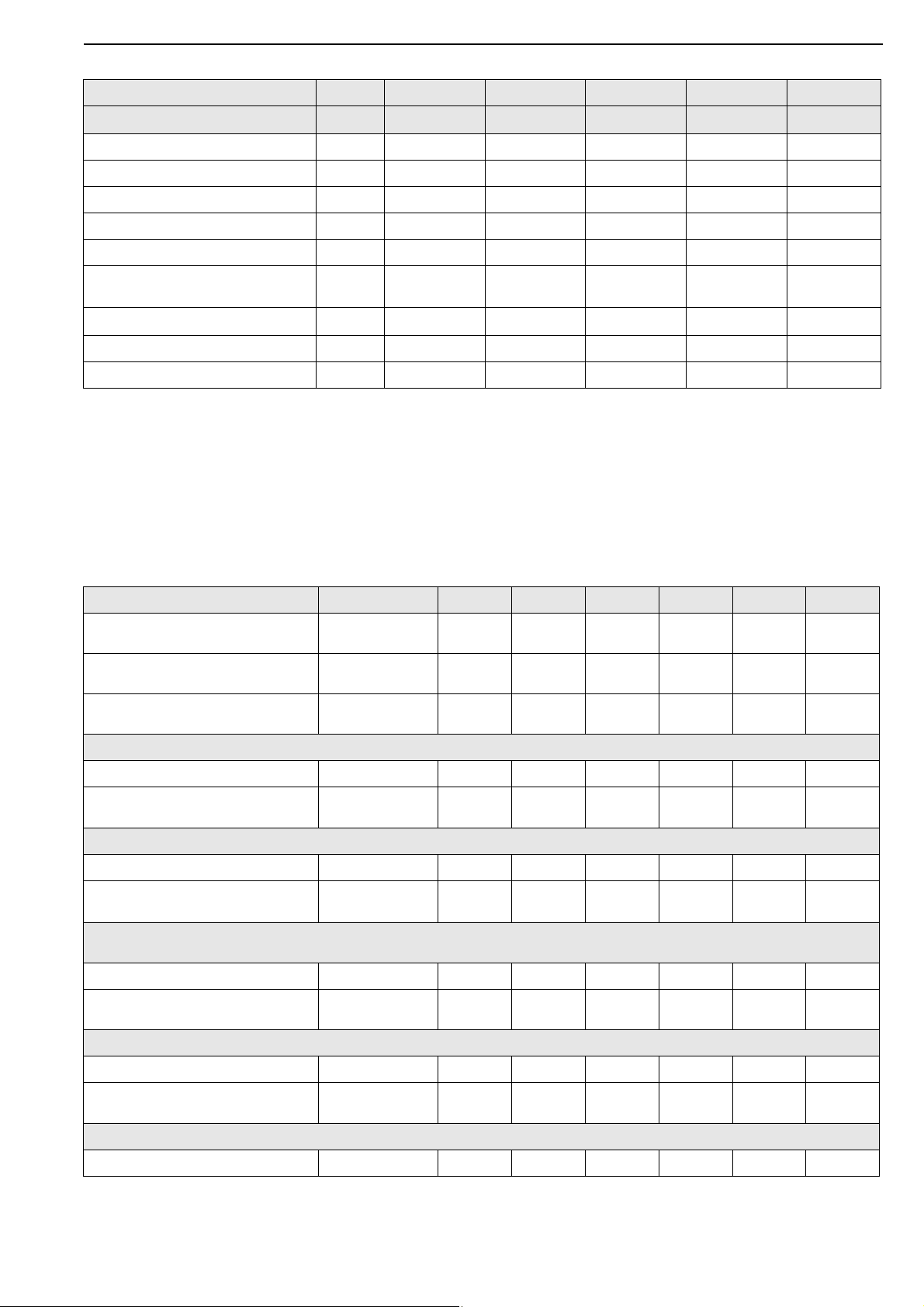

SECTION 5: SPECIFICATIONS

5.2 General Technical Data Table (All Models)

Model CTCU-7 CTCU-11 CTCU-15 CTCU-22 CTCU-27 / 32

CTCUA, Axial Fans

Total Electrical Load W 260 274 336 384 345

Run Cur r e n t A 1. 1 1. 2 1. 5 1. 7 1. 5

Start Current A 1.7 1.8 2.5 2.9 2.6

3

Air Flow m

/h 1120 1220 2710 2750 4474

Air Throw m 9 12 14 16 16

Sound Pressure Level at 3 m

[NR]

dB(A)

[31]

37

[35]

41

[39]

45

[42]

48

[42]

48

Flue and AIr Intake

Flue and Air Intake Size mm Ø 80 80 80 80 100

*Maximum Straight Flue/Air Intake m 2.5 4 5 5 5

Electrical load at 230 V 50 Hz measured by calculating from total run current of appliance.

* Do not exceed the maximum length of flue stated or heater may not operate properly.

Reduce the maximum length stated by 1 m for each 90° bend installed.

**If minimum air flow requirements are not met, then temperature limit devices will shut down the heater.

5.3 Technical Data Table (All Models)

Appliance Category II

Heat Input

Gross CV

Heat Input

Net CV

Approximate

Heat Output

Natural Gas (G20) Data - Inlet Pressure 20 mbar (7.8 in WG) Min. 17 mbar (6.8 in WG) Max. 25 mbar (10 in WG)

Burner Pressure mbar 9.59.59.59.59.09.0

Gas Rate

Natural Gas (G25) Data - Inlet Pressure 25 mbar (10 in WG) Min. 20 mbar (7.8 in WG) Max. 30 mbar (12 in WG)

Burner Pressure mbar 9.09.09.59.29.29.3

Gas Rate

LPG / Propane (G31) Data - Inlet Pressure 37 mbar (14.6 WG) Min. 25 mbar (10 in WG) Max. 45 mbar (18 in WG)

Alternative where permitted 50 mbar (20 in WG) Min. 42.5 bar (17 in WG) Max. 57.5 mbar (23 in WG)

Burner Pressure mbar 25.6 29.4 29.4 28.6 29.9 29.9

Gas Rate

LPG / Butane (G30) Data - Inlet Pressure 29 mbar (11,4 in WG) Min. 20 mbar (7.8 in WG) Max. 35 mbar (13.8 WG)

Burner Pressure mbar 19.2 21.9 22.9 21.4 21.4 22.4

Gas Rate

CTCUA R - 1/2" R - 1/2" R - 1/2" R - 1/2" R - 1/2" R - 1/2"

2H/L 3B/P

Model CTCU-7 CTCU-11 CTCU-15 CTCU-22 CTCU-27 CTCU-32

kW

(Btu/h) x (1000)

kW

(Btu/h) x (1000)

kW

(Btu/h) x (1000)

3

/h

m

3

ft

/h

3

/h

m

3

ft

/h

3

/h

m

kg/h

3

/h

m

kg/h

8.5

29

7. 7

26

7. 1

24

0.8

29

0.9

33

0.3

0.59

0.2

0.6

13.4

46

12.1

41

11.1

38

1. 3

45

1. 5

52

0.5

0.93

0.4

0.94

18.3

6227.5 9433

16.5

24.8

56

15.1

52

1. 7

2.6

62

2.0

72

108

0.7

1. 2 7

0.5

1. 2 8

1. 9 1

0.8

1. 9 3

85

23

78

93

3

1

Gas Connection

Gas rates corrected to standard conditions 1013.25 mbar 15° C

113

29.7

101

27.2

93

3.1

110

3.6

127

1. 2

2.3

.9

2.31

38.5

131

34.7

118

31.7

108

3.6

127

4.2

148

1. 4

2.68

1. 1

2.7

9 of 42

Page 16

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

WARNING

Crush Hazard

Use 10 mm steel drop rod minimum.

Failure of the supports can result in death,

injury or property damage.

SECTION 6: HEATER INSTALLATION

6.1 General

Heaters are designed for installation above 2.5 m.

These heaters must be installed within the heated

space. Duct delivery systems are not permitted with

axial fans. When handling or supporting the heater

from below, ensure that the weight is taken at the

support points.

6.2 Basic Information

CTCU heaters have automatic ignition burners for

ON/OFF operation only.

6.3 Location and Suspension

All models:

•Must be installed indoors.

•Must be installed in a level position, with

horizontal or vertical discharge.

• May be mounted on a shelf of non-combustible

material. (See Page 6, Figure 3 and Page 11,

Figure 4 for support points)

• May be suspended from above (See Page 11,

Figure 4 and Page 12, Figure 5) or from wall

brackets of sufficient strength to support the

heater as listed in the Dimension Data Table on

Page 8, Section 5.1. Drop rods must be a minimum of 10 mm diameter mild steel. Four suspension points (M10 nuts) are located on top of

the heater.

•Must be installed in a manner which allows the

hinged door to be fully opened to provide access

to all serviceable components.

6.4 Handling

All CTCU heaters are supplied secured to a wooden

pallet and shrink wrapped. Use the pallet to support

the heater during handling and installation. When

handling or supporting the heater from below,

ensure that the weight is taken at the support points.

6.5 Suspension and Shelf Mounting

For typical suspension See Page 11, Figure 4.

The gas or electrical supply lines must not be used

to support the heater.

Do not locate the gas or electrical supply lines

directly over the path of the flue products from the

heater.

The heater must be installed in a location that is

readily accessible for servicing.

The heater must be installed in accordance with

clearances to combustibles as indicated on the wall

tag and in this manual.

6.6 Wall Mounting

For typical suspension, See Page 11, Figure 4 and

Page 12, Figure 5. Wall mo

parallel to the wall can only be installed with the

service door away from the wall.

The wall mounting brackets must be attached to a

suitable wall using all mounting holes. Screw sizes

less than 3/8" may not be used. In order for the wall

mounting brackets to adequately carry the weight of

the heater, it must be installed according to best

building practices.

unted heaters blowing

10 of 42

Page 17

Figure 4: Suspension Methods

Cone Point

Set Pin

Window

Clamp

Unistrut

10 mm

Steel

Drop Rod

Nut

Washer

Riv

Nut

Support Points

Ensure all suspension hardware

is torqued to a minimum

of 27 Nm (20 ft lbs).

NOTE: For vertical installations, use the mounting points on the rear of the unit.

10 mm

Steel

Drop Rod

Washer

Nut

Unistrut

Channel Nut

Shelf Mounting

Brackets

Description Part Number Qty.

Shelf Mounting Bracket

Kit

111115 10K 1

Shelf Mounting B r a c ket ( 2 ) 111111510 2

Screw #10 x 1/2"

Type AB Phil HWH Z (2)

94311008 2

SECTION 6: HEATER INSTALLATION

Existing cabinet screws must be re-used.

11 of 42

Page 18

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Shelf

Mounting

Brackets

(Fasten to

Wall Mounting

Bracket)

M8 Bolt

Washer

Lock Washer

M8 Locknut

Torque to 4.5 Nm (40 in lb)

Shelf Mounting

Wall Mounting

Bracket Arm

(Right & Left)

Hanging

Wall Mounting

Bracket Vertical

Wall Mounting

Bracket Diagonal

M10 Fasteners

Description Part Number Qty.

Wall Shelf Mounting Bracket Kit 11111512K 1

Wall Suspension Mounting Bracket Kit 1111510K 1

Shelf Moun ting B r a c ket K i t 11111511K 1

Description Part Number Qty.

Wall Suspension Mounting Bracket Kit 11111511K 1

Wall Mounting Bracket Arm Left 111WALL1L 1

Wall Mounting Bracket Arm Right 111WALL1R 1

Wall Mounting Bracket Vertical 111WAL2 2

Wall Mounting Bracket Diagonal 111WAL3 2

M8 x 85 mm Hex Head Bolt 97311405 6

M8 Lock Nut with Nylon Insert 92204504 6

M8 Flat Washer 95204502 6

M8 Lockwasher 96404502 6

Push in

Louvre and compress

spring to remove

(opposite end first)

Install Vertical

Louvre Brackets

(top and bottom)

with supplied

screws.

Install Vertical

Louvres and Springs

into Brackets

with Springs at Top

Remove Horizontal

Louvres

Description Part Number Qty

Vertical Louvre Kit CTCU 7

& 11

111119 01 K 1

Vertical Louvre B r a cke t 111119 0 3 2

#10 Screw S103 4

CTCU 7-11 Vertical Louvre s 11111 901 5

Louver Spring 90901200 2

Instruction Sheet 91040021 1

Description Part Number Qty

Vertical Louvre Kit

CTCU 15 and 22

111119 0 0K 1

Vertical Louvre B r a cke t 1111190 3 2

#10 Screw S103 4

Instruction Sheet 91040021 1

Description Part Number Qty

Vertical Louvre Kit

CTCU 27 and 32

11111902K 1

Vertical Louvre B r a cke t 111119 0 3 2

#10 Screw S103 4

27-32 Vertical Louv r e 111119 0 2 5

Instruction Sheet 91040021 1

Figure 5: Shelf Mounting and Hanging Suspension

Hardware provided to construct mounting bracket assembly only.

Figure 6: Vertical Louvres (Optional)

For models 15 and 22, horizontal louvres are re-used.

12 of 42

Page 19

SECTION 7: FLUE INSTALLATION

WARNING

Carbon Monoxide Hazard

Heaters installed unvented must be interlocked

with sufficient building exhaust.

Heaters must be installed according to the

installation manual.

Failure to follow these instructions can result

in death or injury.

WARNING

Cut/Pinch Hazard

Wear protective gear during installation,

operation and service.

Edges are sharp.

Failure to follow these instructions can result

in injury.

7.1 Flue Installation

WARNING

SECTION 7: FLUE INSTALLATION

connections are required, follow the instructions on

Page 39, Section 16.4 through Page 40, Section

16.5.

The flue must terminate outside of the building.

Flues and air intakes must be a fully sealed system

and correctly sized for the model. Flues should be

assembled as detailed on Page 14, Figure 7 through

Page 15, Figure 9. The joints between the flue

terminal and the roof or wall must be properly

sealed. If the flue passes through a wall or ceiling of

combustible material, it must be enclosed by a

sleeve of non-combustible material and be

separated from the sleeve by at least a 25 mm air

gap.

Flues and air intakes must be adequately

supported so that the heater does not bear the

weight of the pipes.

For flue termination See Page 14, Figure 7 through

Page 15, Figure 9.

Fire Hazard

Keep all flammable objects, liquids and

vapours the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

7. 3 T y p e C

Room Sealed.

The heaters are designed to be installed as room

sealed appliances. The flue and air intake are run as

separate pipes to the special concentric wall or roof

terminal. See Page 15, Figure 9. The wire mesh

inside the fresh air adapter on the heater must be

removed prior to installation.

7. 4 T y p e B

The flue must terminate outside the building and be

fitted with a low resistance terminal.

See Page 14, Figure 7 through Page 14, Figure 8.

, C32 & C62 Appliance

12

Appliance

22

7. 2 C h a n ging Flue and Air Intake Orientation

The heater is sold with horizontal flue and fresh air

connections as standard. If vertical flue and fresh air

13 of 42

Page 20

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Roof

Flue

Terminal

Metal Sleeve

Masterflash

Soaker Flashing

or Rain Collar.

Flue

25 mm Air Gap to

Combustible Material

Wall

Terminal

Flue

Masterflash

Masterflash

Roof Terminal

Vertical

Option

Horizontal

Option

Flue

Figure 7: Flue and Roof Detail

Figure 8: Vertical and Horizontal Flue Termination - Type B

Appliance

22

14 of 42

Page 21

SECTION 7: FLUE INSTALLATION

Wall

Plate

Wall

Terminal

Flue

Roof Terminal

Flue

Air Intake

Air Intake

Manifold

Manifold

Vertical

Option

Plastic Cup

Masterflash

Horizontal

Option

Remove Internal

Wire Mesh

Remove Internal

Wire Mesh

Figure 9: Vertical and Horizontal Flue Termination - Type C

& C62 Appliances

12 C32

15 of 42

Page 22

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 8: AIR SUPPLY

8.1 Room Sealed Installation

When installed as a room sealed heater, the air for

combustion is drawn in from outside the building. It

is important to ensure that there is adequate

ventilation to provide air for the distribution fan/s.

8.2 Open Flued Installation

It is important to ensure that there is adequate air

supply at all times for both combustion and heating

requirements in accordance with local and national

codes. When installed in this mode, the air supply to

the heater must also be fitted with a low resistance

terminal to prevent the ingress of debris. See Page

14, Figure 8.

8.2.1 Heaters Installed Within the Heated Space

Where the volume of the heated space is greater

than 4.7 m

3

per kilowatt of total rated heat input and

the air change rate is at least 0.5/h, additional high

and low level ventilation will not be required.

For a building having an air change rate less than

0.5/h, ventilation will be necessary in accordance

with local and national codes. Ventilation direct to

outside must be provided as follows:

• Heaters up to 70 kW heat input: 5.0 cm

2

per kW

of rated heat input

8.3 Building Ventilation

Where ventilation is required, air must be taken from

an outside point where it is not likely to be

contaminated or obstructed.

Where natural ventilation is used, suitable ventilation

with outside air at low level must be provided in

accordance with Section 8.2.1 and local and

national codes.

Where mechanical ventilation is used, extract rate

must be 5% - 10% less than the inlet rate. The

mechanical ventilation must be interlocked with the

burner on the heater.

16 of 42

Page 23

SECTION 9: GAS PIPE WORK

WARNING

Explosion Hazard

Leak test all components of gas pipe work

before operation.

Gas can leak if pipe work is not installed

properly.

Do not high pressure test gas pipe work with

heater connected.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 9: GAS PIPE WORK

• The gas supply pipe is adequately sized to carry

the total volume of gas for the complete

installation.

• An isolating valve and union connection should

be used and fitted into the supply adjacent to the

heater.

•For suspended heaters, u

flexible connection between the isolating valve

and the heater. To reduce pressure loss, use

one pipe size larger than the heater gas

connection.

IMPORTANT - The complete installation must be

purged and tested for gas soundness in accordance

with local and national codes.

• Check the pipe and tubing ends for leaks

before placing heating equipment into service. When checking for gas leaks, use a

soap and water solution; never use an open

flame

se an approved metal

It is important that the gas supply pipe and the

electrical connections do not support any of the

heater’s weight.

A gas meter is connected to the service pipe by the

gas supply company. An existing meter should be

checked, preferably by the company, to ensure that

the meter is adequate for the rate of gas supply

required.

Installation pipes must be fitted in accordance with

local and national codes. Pipe work from the meter

to the heater(s) must be of adequate size.

9.1 Connections

Connect the heater to the gas supply ensuring that

the final connections are as follows:

•Gas supply pipe work is run in medium or heavy

gauge tubing in compliance with local and

national codes.

17 of 42

Page 24

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Figure 10: Gas Connection with Stainless Steel Flex Connector

18 of 42

Page 25

SECTION 10: WIRING AND ELECTRICAL INFORMATION

10.2.3 Remote Frost Thermostat

DANGER

When required, connect to L

room thermostat.

Locate within the heated space adjacent to the most

vulnerable equipment that requires protection.

See Page 20, Section 10.3.

SECTION 10: WIRING AND ELECTRICAL INFORMATION

and T2 parallel to the

1

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly grounded.

Failure to follow these instructions can result

in death or electrical shock.

10.1 Electrical Supply

All heaters need a constant 230 V 50 Hz single

phase supply connected to terminals L, N & Earth.

Polarity "L & N" must be correct. The voltage

between neutral and earth should be 0 and never

exceed 15 volts.

All heaters and controls must be correctly earthed.

All external wiring must comply with the relevant

local codes. Wire specification H05VV-F.

External controls must have the same constant

230 V 50 Hz supply.

An isolator with a contact separation of at least

3 mm on all poles must be installed adjacent to, but

not attached to, the heater to disconnect all supplies

to the heater and any remote control. This switch

should be fused to 5 A.

10.2.4 Remote Fan Controls

The fan will operate automatically providing there is

a constant 230 V supply to the main terminals.

A switch or control wired between terminals Y & T

1

in the terminal block will allow external control of the

fan(s).

The fan may be controlled to operate continuously

from an external control, with the burner cycling on

and off, providing that the fan run-on at close down

is not impaired.

The final connection to the heater should be made

by flexible cable or conduit to the 7 pole plug on the

inside of the heater using 1 mm

2

cable on all

models.

10.2 Remote Controls

The heater is designed to be operated by controls

installed remote from the heater. See Page 20,

Section 10.3.

10.2.1 Burner Controls (Thermostat)

Controls to operate the burner must be connected

between L

and T2.

1

10.2.2 Positioning Room Thermostats or

®

ROBERTS GORDON

A room thermostat or ROBERTS GORDON

Control

®

control should be mounted on a wall or column at a

height of approximately 1.5 metres from the floor to

measure the ambient temperature. It should be clear

of both cold draughts and the direct path of warm air

from the heater.

19 of 42

Page 26

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

NOTE:

If any of the original wire supplied with the heater must be replaced, it must be replaced with

wiring material having a temperature rating of at least 105° C and 600 volts.

10.3 CTCUA Wiring Diagram (Models 7-32)

20 of 42

Page 27

SECTION 11: COMMISSIONING

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

DANGER

Electrical Shock Hazard

Disconnect electric

before service.

More than one

disconnect switch may

be required to

disconnect electric from

heater.

Heater must be

connected to a properly

grounded electrical

source.

SECTION 11: COMMISSIONING

Gas Fired Heater

Installation Code and Annual Inspections:

All installation and service of ROBERTS GORDON

equipment must be performed by a contractor

qualified in the installation and service of equipment

sold and supplied by Roberts-Gordon and conform

to all requirements set forth in the ROBERTS

GORDON

governmental authorities pertaining to the

installation, service and operation of the equipment.

To help facilitate optimum performance and safety,

Roberts-Gordon recommends that a qualified

contractor conduct, at a minimum, annual

inspections of your ROBERTS GORDON

equipment and perform service where necessary,

using only replacement parts sold and supplied by

Roberts-Gordon.

Installation, service, commissioning and annual

inspection of the heater must be done by a

contractor qualified in the installation and service of

gas-fired heating equipment. Read this manual

carefully before installation, commissioning,

operation, or service of this equipment. All

components are accessed via the hinged door.

Opening the door exposes live electrical

connections and hot components.

11.1 Pre-Commission Checks

All pre-commission checks must be carried out

before lighting the heater.

Ensure that the heater and all controls are suitable

for the gas, pressure and electrical supply to which

they are to be connected.

®

manuals and all applicable

®

11.1.1 Louvres

Where fitted, the air delivery louvres need to be set

®

during commissioning to give the required air

distribution.

11.1.2 Electrical Checks

All pre-commission checks must be carried out

before commissioning the heater.

1. Check that all site wiring is connected in

accordance with the appropriate wiring diagrams on Page 20, Section 10.3.

2. Check the correct f

See Page 19, Section 10.1.

11.2 Gas Supply

All aspects of the gas installation including the gas

meter must be inspected, tested for soundness and

purged in accordance with local and national codes.

Ensure that the air is fully purged from the heater

inlet pipe up to the main gas valve inlet test nipple.

11.3 Mechanical Checks

1. Check that the fan(s) are free to run and

delivery louvres are turned to give required air

deflection.

2. Check that the flue (and air intake for room

sealed) is installed in accordance with these

instructions and local regulations.

3. The thermostat limit thermodisc is preset and

sealed at the factory and is not adjustable.

use size is fitted;

21 of 42

Page 28

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

P

P

Fan Neon

Burner Neon

Neon

Ignition

Gas

Valve

Flame

Sensing

Pressure

Switch

Fan

Thermostat

KEY TO

SYMBOLS

T0 T1 T2 T3 T4 T5 T6 T7

10 sec

Tp

40 sec max.

Interruption of main

Tp

10 sec

Ts

10 sec

flame sensing

11 sec typical

T8

Lockout Alarm

Signal (optional)

Burner Lockout

signal received after

3 ignition trial

failures

11.4 Begin Commissioning

11.4.1 Before Operating the Heater

To ensure that all the controls are in safe working

order, operate the heater for the first time with the

isolating gas valve turned off.

1. Turn off the gas isolating valve

Figure 11: Automatic Burner Control Box Sequence

2. Using the installed external control, turn on the

burner. The automatic sequence will now begin

as described on Page 22, Figure 11.

There will be no ignition of the burner and lockout

will occur, which proves the controls are operating

correctly.

NOTE: If the heater operates for more than 24 hours continuously, the ignition module will automatically

recycle the burner to ensure that all safety functions are still in working condition.

22 of 42

Page 29

Figure 12: Gas Valve for Heater (Models 7 - 32)

SECTION 11: COMMISSIONING

11.4.2 Commissioning the Gas Valves (all gases)

11.4.2.1 Check Burner Gas Pressure

1. Loosen the screw cover of the outlet (burner)

pressure test point and connect a manometer.

2. With the burner firing, measure the pressure on

the manometer. To adjust the burner pressure,

remove the regulator cover from the valve and

turn the regulator adjustment screw to set the

required burner pressure as stated in the Technical Data Tables for the correct gas and model

on Page 9, Section 5.3.

NOTE: If the correct burner pressure cannot be

reached, then check the inlet pressure to the valve,

with the burner firing. See Technical Data Tables on

Page 9, Section 5.3 for inlet pressure requirement.

Do not continue to adjust the regulator if the

pressure is not changing.

If the inlet pressure is too lo

w to allow correct burner

pressure setting, then the gas inlet pressure must be

corrected before completing the commission.

Check Gas Rate

1. Af t e r b urner pressure adjustment, allow the

heater to operate for at least 15 minutes and

then re-check settings.

2. Remove the manometer and refit all covers to

the valve and tighten the screw of the outlet

pressure tap.

3. Check gas flow rate at gas meter.

11.5 Combustion Testing

The only adjustment to alter combustion

performance is burner pressure. Combustion quality

must be tested to prove correct heater operation.

Incorrect results will indicate faults with the

installation or appliance.

Combustion testing must be carried out with all

covers in place. The flue gas is sampled in the flue,

within 1 meter of the heater. The valu

es of CO

2

should be between 5.7% to 8.0% for natural gas and

6.8% to 9.2% for LPG dependant upon model.

The CO will be up to 80 ppm (0.008%) dry, air free

dependant upon model. Temperature rise of the flue

gases above ambient should be approximately

130° C to 160° C. Seal test hole in flue after testing.

Pressure Switch:The pressure switch is factory preset for each model and is not adjustable.

11.6 Turning Off the Heater

Set the external controls to the off position and the

main burner will stop.

The fans will run until they are stopped automatically

by the fan thermostat.

Do not use electrical isolator for control of

heater. Electrical isolator will switch off the fan.

Heat exchanger could be damaged. Warranty will

not cover damage to the heat exchanger if

operated improperly.

11.7 External Controls

External controls may include time switch, room

thermostat and frost thermostat. Operate each

control to ensure that they function correctly. Set the

time switch (if fitted) and room thermostat to the

users’ requirements.

23 of 42

Page 30

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

11.8 Complete the Commissioning

Ensure that all covers are fitted correctly and all test

points are properly sealed.

11.9 Instruction to the User

Explain the controls of the heater to the user

including how to turn it on and off, using the controls

fitted on site.

Give this manual to the user.

Ensure that the user is shown and understands the

importance of maintaining clearances to

combustibles and the user instructions on Page 25,

Section 12 through Page 26, Section 12.5 and all

warnings defined in this manual.

24 of 42

Page 31

SECTION 12: USER INSTRUCTIONS

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly grounded.

Failure to follow these instructions can result

in death or electrical shock.

Fire Hazard

Keep all flammable

objects, liquids and

vapors the minimum

required clearances to

combustibles away

from heater.

Some objects will catch

fire or explode when

placed close to heater.

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

SECTION 12: USER INSTRUCTIONS

12.1 User Instructions

The CTCU heaters are fully automatic and operate

from the external controls fitted on site.

The only user controls at the heater are the:

Burner Lockout Reset Button:

See Page 26, Section 12.3.2

Limit Thermostat Reset Button:

See Page 25, Section 12.3.1

12.2 Heater Operation

When the heater has been switched on by the

remote controls installed on site, the main burner will

automatically turn on.

The burner control box will control the safe ignition

of the flame.

All heaters require a constant gas and electricity

supply which must not be interrupted during the

normal operation of this heater.

Figure 13: Heater Operating Sequence

12.3 Common User Controls

12.3.1 Fan Thermostat

The fan thermostat is located inside the access door

at the top of the heater. See Page 38, Section 16.3.

This control ensures the heater does not blow cold

air in the normal heating cycle.

25 of 42

Page 32

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Press to reset

These are hand reset devices to give further

protection against fan failure.

NOTE: To reset, the heat exchanger must be cool.

Description Part Number

Limit Thermostat 90412100

12.3.2 Limit Thermostat

The limit thermostat is located inside the access

door of the heater. See Page 38, Section 16.3. This

control protects the heat exchanger against

overheating.

12.3.3 Burner Lockout Reset Button

The red warning light at the front of the heater will

illuminate when the control has gone to lockout. This

may be caused by flame failure. Press the reset

button on the back of the heater, (See Page 8,

Section 5.1), or the remote reset if installed on site.

If control locks out, do not make more than three

attempts to restart the heater. Dangerous fuel

mixtures can build up. The fault must be traced and

repaired by a registered installer or service

engineer.

3. The time and/or temperature controls are not

“ON”.

4. The thermostat limit thermodisc may have

operated. This may be caused by an interrup-

tion of the electrical supply or failure of the

distribution fan.

If the thermostat limit thermodisc persistently

operates, there is a fault which must be investigated

by a contractor qualified in the installation and

service of gas-fired heating equipment.

12.5.1 Simple Fault Finding (Burner Faults)

If the burner fails to ignite for any reason, it will go to

locko

ut. This will be indicated by the red light on the

heater or at the remote indicator (if fitted).

1. Press in and release the lockout reset button. If

a remote reset is not fitted, a reset button is on

the rear panel of the heater.

See Page 8, Section 5.1.

Lockout should not occur during normal operation of

the heater and indicates there is a fault condition

which must be corrected.

12.4 Lighting Instructions

12.4.1 To Turn On Heater

1. E n s ure that the electrical and gas supplies to

the heater are on. Check that the on site

controls are “ON”.

NOTE: The thermostat setting must be above the

ambient temperature for the heater to operate.

2. The automatic firing sequence will begin as

described on Page 22, Figure 11. The heater

will now operate automatically under the control

of the on site controls. Following long shu

t

down periods, the control may go to lockout.

See Page 26, Section 12.3.3.

12.4.2 To Turn the Heater Off

Set the installed remote controls to the “OFF”

position.

The burner will turn off immediately.

The fan will continue to run for a few minutes.

To restart, turn the control used above to “ON”.

12.5 Simple Fault Finding

Some possible reasons for the heater not operating

are:

1. Ga s s upply not turned “ON”.

2. Electricity supply not turned “ON”.

26 of 42

Page 33

SECTION 13: SERVICING

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

DANGER

Electrical Shock Hazard

Disconnect electric

before service.

More than one

disconnect switch may

be required to

disconnect electric from

heater.

Heater must be

connected to a properly

grounded electrical

source.

SECTION 13: SERVICING

13.1 Servicing Instructions

After commissioning, the heater will require

maintenance to be carried out annually. If the heater

is used in a dirty or dusty area, more frequent

maintenance may be necessary.

Installation, service and annual inspection of

heater must be done by a contractor qualified

in the installation and service of gas-fired heating

equipment.

WARNING

Severe Injury Hazard

Turn off gas and electrical supply before

service.

Fan can start automatically at any time.

Failure to follow these instructions can

result in severe injury or product damage.

NOTE 1: After any maintenance or repair work

always test fire the heater in accordance with the

commissioning instructions on Page 21, Section 11

through Page 24, Section 11.9 to ensure all safety

systems are in working order before leaving the

heater to operate. Minor faults may be traced by

using the troubleshooting charts on Page 31,

Section 15 through Page 35, Section 15.5.

NOTE 2: Check all gas pipes and pipe joints to

ensure there are no cracks or gas leaks. Any cracks

in the pipes or pipe joints must be repaired.

NOTE 3: Inspect all suspended components and

hardware. Insure that they are in good condition,

properly tightened, and corrosion free.

13.2 Burner Maintenance

1. Open the hinged door and remove the burner

compartment cover.

2. Clean any deposits from the main burner which

may have formed in the injectors or venturi of

the burner. See Page 37, Section 16.2.

3. Remove the ignition electrode and flame probe.

Check condition of ignition electrode and flame

probe. Clean off any deposits which may have

been formed, check condition of ceramic

insulators. Replace as necessary.

13.3 Fan/Motor Assembly Maintenance

The main fan bearings are permanently sealed and

do not need lubrication. Before cleaning, turn off gas

and electrical supply. Remove the fan(s) and use a

small brush or duster to clean the fan blades from

each side. Replace fan(s) when done.

13.4 Heat Exchanger Maintenance

The heat exchanger will remain clean unless a

problem has developed with combustion. Inspect the

See Page 37, Section 16.2.

27 of 42

Page 34

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

heat exchanger. Look for signs of overheating at the

front tubes which may indicate burner over firing or

persistently low air flows.

13.5 Gas Control Valve Maintenance

No regular maintenance is required on these

devices. To change gas control valves, See Page

36, Step 16.1.

Do not repair or disassemble on site.

Replace faulty gas valves with genuine

replacement parts sold and supplied by

Roberts-Gordon.

13.6 Flue Fan

The flue fan should not require maintenance.

However, if the air pressure switch is causing burner

lockout, then remove the flue fan from the vent box

by unscrewing the screw at the outlet flange and the

flue fan mounting plate (See Page 39, Section 16.4

through Page 40, Section 16.5). Ensure that the fan

is free to run and that the fan wheel is clean.

13.7 Maintenance Checklist

Installation Code and Annual Inspections: All

installations and service of ROBERTS GORDON

®

equipment must be performed by a contractor

qualified in the installation and service equipment

sold and supplied by Roberts-Gordon and conform

to all requirements set forth in the ROBERTS

GORDON

®

manuals and all applicable

governmental authorities pertaining to the

installation, service and operation of the equipment.

To help facilitate optimum performance and safety,

Roberts-Gordon recommends that a qualified

contractor conduct, at a minimum, annual

inspections of your ROBERTS GORDON

®

equipment and perform service where necessary,

using only replacement parts sold and supplied by

Roberts-Gordon.

The Vicinity of the Heater Do not store or use flammable objects, liquids or vapors near the heater.

Immediately remove these items if they are present.

Maintain the clearances to combustibles.

Do not hang anything from, or place anything on, the heater.

Immediately remove objects in violation of the clearances to combustibles.

See Page 5, Section 3.

Vent Pipe/Terminals Venting must be intact. Using a flashlight, look for obstructions, cracks on the

pipe, gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Remove any carbon deposits or scale using a wire brush.

If the vent terminal has a screen built in, remove any dirt, dust or deposits

from the screen.

See Page 16, Section 8.

Combustion Air Intake

Pipe

Intake pipe and inlet must be intact. Look for obstructions, cracks on the pipe,

gaps in the sealed areas or corrosion.

The area must be free of dirt and dust.

Clean and reinstall as required.

Heat Exchanger Make sure there are no cracks.

Make sure there is no sagging, bending or distortion.

Clean or replace as required.

Gas Line and Shut-off

Valves

Check for gas leaks.

See Page 17

, Section 9.

28 of 42

Page 35

SECTION 13: SERVICING

Burner Observation

Window

Flue Blower Scroll, Wheel

Make sure it is clean and free of cracks or holes.

Clean and replace as required.

Compressed air or a vacuum cleaner may be used to clean dust and dirt.

and Motor

Inshot Burners and

Orifices

Clear obstructions (even spider webs will cause problems).

Carefully remove any dust and debris from the burner.

Direct-Spark Igniter Replace if there are cracked ceramics, excessive carbon residue, or erosion

of the electrode.

The electrode gap should be 1/8" (3.2 mm).

Thermostat There should be no exposed wire or damage to the device or wiring.

See Page 19, Section 10.

Suspension Points Make sure the heater is hanging securely.

Look for signs of wear on the suspension materials or ceiling.

See Page 11, Figure 4 and Page 12, Figure 5.

Silicone Tubing Ensure tight, secure fit on all pressure fittings at pressure switch,

burner partition, and blower outlet.

Gas Valve Verify that cap covering pressure regulator adjustment screw is secure and

has not been tampered with.

Verify all wiring connections.

Condensate Drain

Flush drain and clear any obstructions.

(when installed)

Ductwork Consult an indoor air quality professional for proper cleaning procedures

Air Circulation Blower For a complete inspection, refer the manufacturers Installation, Operation and

Service manual.

Wall Tag If wall tag is present, make sure it is legible and accurate. Please contact

Roberts-Gordon LLC or your ROBERTS-GORDON

®

independent distributor if

you need a wall tag. See Page 4, Section 2.1.

29 of 42

Page 36

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

SECTION 14: CONVERSION BETWEEN GASES

14.1 General

Conversion between gases will require a change of

burner injectors and the gas valve re-commissioning

to the new conditions.

14.2 Burner Conversion

Conversion of the burner assembly from one gas to

the other is the same for all types of heaters.

1. R e m o ve the burner compartment cover as

shown on Page 37, Section 16.2.

2. Remove the connection between the gas valve

outlet and the manifold. See Page 36, Section

16.1 for gas valve removal.

3. Remove the manifold from the burner assembly

by removing the screws at the top and bottom.

See Page 37, Section 16.2.1.

4. Remove the main burner injectors.

5. Replace with the injectors for the new gas

ensuring a gas tight seal.

6. Refit all components in reverse order.

14.3 Gas Valves

All gas valves used on the unit ha

ve pressure

regulators that may be set to operate on natural gas

or LPG.

Conversion is carried out by re-setting the burner

pressure to the value in the data table during

commissioning. See Page 9, Section 5.3.

Ensure that the gas inlet pressure to the heater is

correct for the new gas, and that the gas supply has

been purged of the old gas.

30 of 42

Page 37

SECTION 15: TROUBLESHOOTING

DANGER

Electrical Shock Hazard

Disconnect electric before service.

Heater must be properly grounded.

Failure to follow these instructions can result

in death or electrical shock.

Fire Hazard

Keep all flammable

objects, liquids and

vapors the minimum

required clearances to

combustibles away

from heater.

Some objects will catch

fire or explode when

placed close to heater.

Cut/Pinch Hazard

Wear protective gear

during installation,

operation and service.

Edges are sharp.

WARNING

Failure to follow these instructions can result in death, injury or property damage.

Burn Hazard

Allow heater to cool

before service.

Tubing may still be hot

after operation.

Explosion Hazard

Turn off gas supply to

heater before service.

SECTION 15: TROUBLESHOOTING

31 of 42

Page 38

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

For your safety and optimum heater performance, use only ROBERTS GORDON® replacement parts.

Conduct Commissioning procedure as shown on Page 21, Section 11.

15.1 General

32 of 42

Page 39

15.2 Troubleshooting For Automatic Ignition Burner Systems

For your safety and optimum heater performance,

use only ROBERTS GORDON

®

replacement parts.

Conduct Commissioning procedure as shown

on Page 21, Section 11.

SECTION 15: TROUBLESHOOTING

33 of 42

Page 40

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

NOTE: Minimum flame probe current 1 µA DC.

To measure flame current, connect a 0 - 50 µA DC meter in

series with the flame probe. If the meter reads negative

values, then reverse the test leads.

15.3 Troubleshooting for Flame Supervision System

15.4 Troubleshooting for Solenoid Valves

34 of 42

Page 41

15.5 Troubleshooting for Main Fan

For your safety and optimum heater performance, use only genuine ROBERTS GORDON® replacement

parts.

Conduct Commissioning procedure as shown on Page 21, Section 11.

SECTION 15: TROUBLESHOOTING

35 of 42

Page 42

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Carbon Monoxide Hazard

WARNING

Use only genuine ROBERTS GORDON

®

replacement parts per this installation, operation and

service manual.

Failure to follow these instructions can result in death, electric shock, injury or property damage.

Explosion Hazard

DANGER

Electrical Shock Hazard

Fire Hazard

Description Part Number

Gas Valve 90033102

Ignition Control 90434021

SECTION 16: REMOVAL AND REPLACEMENT PARTS

See warnings and notes on Page 27, Section 13

before removing or replacing parts.

Burner Components

All serviceable burner parts are accessed by the

door on the right side of the heater. Use a

screwdriver to turn the latch 90°. See Page 8,

Section 5.

16.1 Gas Valve

Remove the gas supply pipe at the heater inlet.

16.1.1 Models 7 - 32

16.1.2 All Models

Replace in reverse order. Verify that the gas flow

direction of the valve is correct. Use a minimum

amount of gas seal on the thread joint. Re-use the

"O" ring seal in the outlet flange where fitted. Check

that all the joints are leak free. Reset gas valve. See

Page 23, Section 11.4.2.

36 of 42

IT IS IMPORTANT THAT ONLY THE CORRECT

GAS VALVES SPECIFIED FOR EACH MODEL

TYPE ARE USED WHEN REPLACING THESE

CONTROLS.

Page 43

16.2 Burner Compartment

Remove flexible

air duct from spigot

Viewing port

for flame probe

Flame Probe

Burner

Compartment

Cover

Ignition Electrode

Remove screws and

pull off burner cover

The burner compartment is a sealed

compartment. Following any work,

re-seal the compartment with the gas

pipe rubber seal fully in place and all

screws fitted and tight.

Remove manifold

screws and pull

out manifold.

Manifold

Burners

Injectors

Manifold

Mounting

Bracket

Gromet

Unscrew

Injectors

Manifold

Marking

Ensure gas tight fitting of injectors.

Ensure correct alignment with burners.

Ensure all pipe joints are gas tight.

16.2.1 Burner Injectors

SECTION 16: REMOVAL AND REPLACEMENT PARTS

MODEL CTCU-7 CTCU-11 CTCU-15 CTCU-22 CTCU-27 CTCU-32

Injector Quantity 2 3 4 5 6 7

Natural Gas (G20)

Injector size mm Ø 1.78 1.85 1.85 2.06 2.057 2.057

in Ø 0.070 0.073 0.073 0.081 0.081 0.081

Marking 504949464646

RG P/N 91930050 91930049 91930049 91930046 91930046 91930046

Natural Gas (G25)

Injector size mm Ø 1.99 2.06 2.06 2.26 2.261 2.261

in Ø 0.0785 0.081 0.081 0.089 0.089 0.089

Marking 474646434343

RG P/N 91930047 91930046 91930046 91930043 91930043 91930043

LPG Propane (G31) and LPG Butane (G30)

Injector size mm Ø 1.18 1.18 1.18 1.25 1.25 1.25

Marking 5656561.251.251.25

RG P/N 91930056 91930056 91930056 91930125 91930125 91930125

in Ø 0.0465 0.0465 0.0465 0.049 0.049 0.049

37 of 42

Page 44

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL

Burners

.120

(3 mm)

spark

gap

Ignition

Electrode

Burner Compartment

Front Views

Limit

Thermostat

Ignition

Electrode

Flame

Probe

Fan

Thermostat

Flame

Probe

Burners

Description Part Number

Spark Electrode 90427411

Automatic Ignition Flame Probe 90439300

Burners 92000002

Fan Thermostat 90412102

Limit Thermostat 90412100

To replace the ignition electrode or flame probe, remove the electrical lead and screw.

Pull out from mounting. Refit in reverse ensuring that the gap to burner is as shown in the

front view of the burner compartment.

16.3 Ignition Electrode and Flame Probe

38 of 42

Page 45

16.4 Flue Fan Vertical Installation (Models 7 - 15)

1. To r e m o ve the fan, remove 3

screws securing the fan/

mounting plate to the vent box.

2. To remove the fan from the

mounting plate, remove the 4

screws.

3. Refit in reverse order.

4. To change the flue and air

intake orientation from back to

top, remove the fan/mounting

plate as explained in Steps 1

and 2.

5. Remove intake and exhaust

cover(s) from top of the heater.

6. Rotate the fan, mounting plate

and gasket clockwise until the

flue adapter lines up with the

top hole. Secure with 3 screws.

7. R e m o ve the flexible duct from

the air intake adapter on the

back.

8. Remove the air intake adapter

from the back of the heater.

Install in the appropriate hole

on top.

9. Reconnect the flexible duct.

10.Install intake and exhaust

cover(s) over the holes on the

back of the heater.

11. E ns ure sealed joints. Ensure

mounting plate orifice is clear

and not obstr

ucted.

SECTION 16: REMOVAL AND REPLACEMENT PARTS

MODEL CTCU-7 CTCU-11 CTCU-15

Flue Fan

RG P/N 90710470 90710470 90710470

Air Plate mm Ø 35 44 57

in Ø 1. 3 8 1. 7 5 2.25

RG P / N 111112 10 11112 2 1 0 11113 2 1 0

Fasco

7021-11767

IT IS IMPORTANT THAT ONLY THE CORRECT FLUE FAN SPECIFIED FOR EACH MODEL TYPE IS

USED WHEN REPLACING THESE ITEMS.

Carry out a commission after working on or changing a flue fan. See Page 25, Section 12.

Fasco

7021-11767

7021-11767

Fasco

39 of 42

Page 46

COMBAT® CTCU UNIT HEATERS INSTALLATION OPERATION AND SERVICE MANUAL