Page 1

®

CoRayVac

Custom Engineered,

Gas-Fired, Low-Intensity

Infrared Heating System

CRV-B-2

CRV-B-4

CRV-B-6

CRV-B-8

CRV-B-10

CRV-B-12

CRV-B-12A

Design Manual

All designs must be installed in strict accordance with the CORAYVAC®

Installation, Operation and Service Manual (P/N 127102NA).

Roberts-Gordon LLC

1250 William Street

P.O . B o x 44

Buffalo, New York 14240-0044

Telephone: 716.852.4400

Fax: 716.852.0854

Toll Free: 800.828.7450

CRV-B-9

© 2009 Roberts-Gordon LLC

www.rg-inc.com

www.radiantheaters.com

www.corayvac.com

P/N 127500NA Rev D 05/09

Page 2

Page 3

© 2009

Roberts-Gordon LLC

All rights reserved. No part of this work covered by the copyrights herein may be reproduced

or copied in any form or by any means - graphic, electronic, or mechanical, including

photocopying, recording, taping or information storage and retrieval systems - without the

written permission of Roberts-Gordon LLC.

TABLE OF CONTENTS

SECTION 1: Concept ..............................................................1

SECTION 2: The CRV-Series System.....................................2

2.1 Safety...........................................................................2

2.2 Zero Regulator ............................................................. 2

2.3 Fuel Savings and Comfort ...........................................4

SECTION 3: Clearances to Combustibles.............................5

3.1 Required Clearances to Combustibles.........................5

SECTION 4: Sizing and Design Considerations...................9

4.1 Radiant Adjustment to Heat Loss ................................9

4.2 Radiant Height Adjustment Factor...............................9

4.3 Selecting the Burners ................................................ 10

4.4 Radiant Distribution ................................................... 10

SECTION 5: Flow Loading.................................................... 12

5.1 Radiant Branch Flow .................................................12

5.2 Pump Capacity ..........................................................14

5.3 Tailpipe Flow.............................................................. 14

SECTION 6: Radiant Tube and Tailpipe............................... 15

6.1 Radiant Tube Length.................................................. 15

6.2 Tailpipe.......................................................................15

6.3 Design Parameters .................................................... 16

6.4 CRV-Series Design Methods ..................................... 16

6.5 Tailpipe Design Method ............................................. 18

SECTION 7: Example CRV-Series System Layouts............21

7.1 Example System Layout (Option 1) ............................ 21

7.2 Example System Layout (Option 2) ............................ 22

7.3 Example System Layout (Option 3) ............................ 22

7.4 Example System Layout (Option 4) ............................ 23

7.5 Example System Layout (Option 5) ............................ 23

7.6 Example System Layout (Option 6) ............................ 24

7.7 Example System Layout (Option 7, 8 and 9)............... 25

SECTION 8: Control Methods .............................................. 26

8.1 ROBERTS GORDON

(P/N 02770002) .........................................................26

8.2 ROBERTS GORDON® ULTRAVAC™..........................26

8.3 SPST Transformer Relay (P/N 90417600K)...............27

8.4 DPST Transformer Relay (P/N 90436300).................27

8.5 Pressure Switch .........................................................27

SECTION 9: Air Supply System ...........................................28

9.1 Pressurized................................................................28

9.2 Non-Pressurized ........................................................ 28

9.3 Outside Air System Design Requirements.................28

SECTION 10: ROBERTS GORDON

Requirements.................................................31

SECTION 11: CRV-Series Equipment Specifications......... 32

11.1 Burner and Burner Controls......................................32

11.2 Equipment ................................................................32

®

System Control

®

ULTRAVAC™ Design

Printed in U.S.A.

Page 4

Page 5

TABLE OF FIGURES

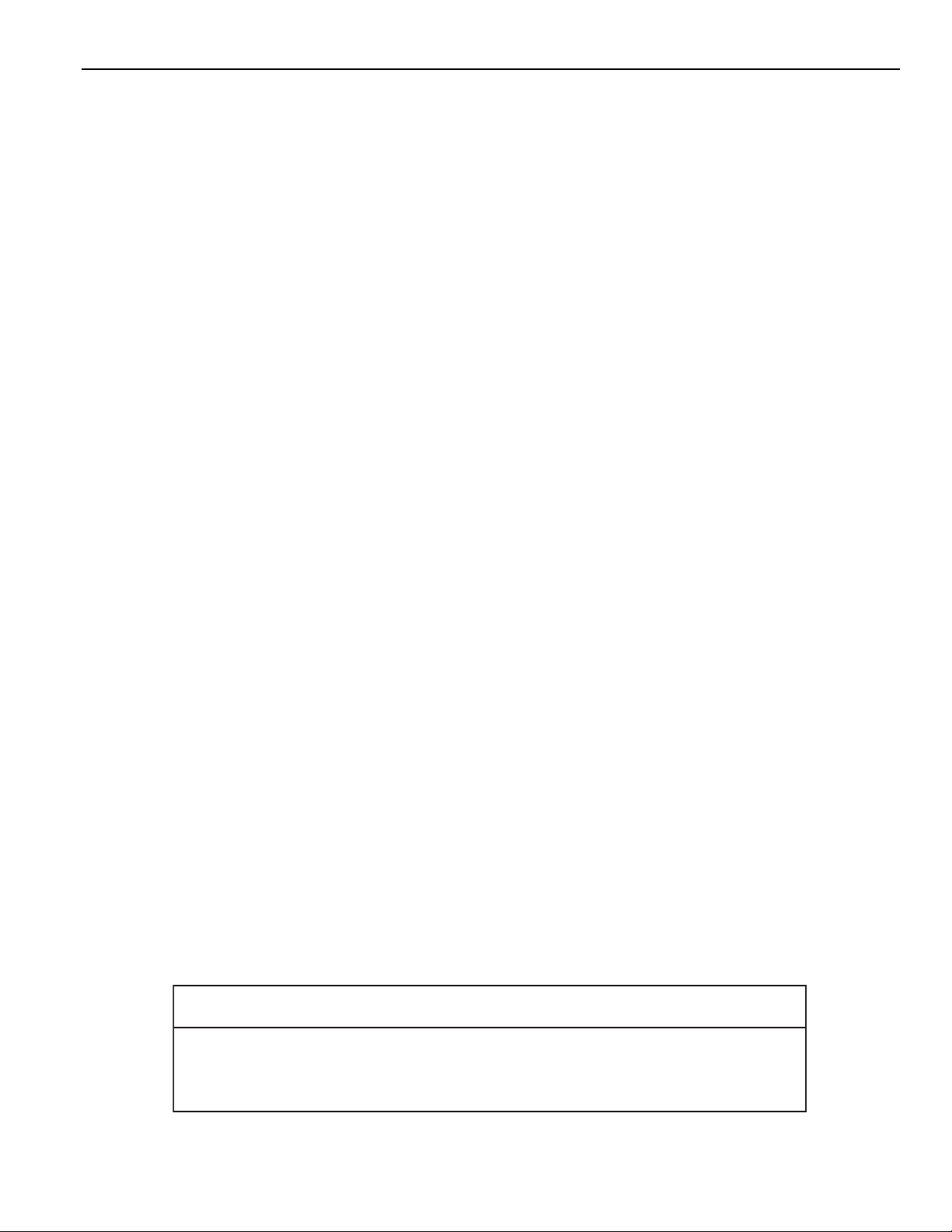

Figure 1: Assembly Overview (Two Branch System Shown).....3

Figure 2: Standard Reflector .....................................................6

Figure 3: One Side Reflector.....................................................6

Figure 4: Two Side Reflectors ...................................................6

Figure 5: Universal Shield, Position 1 .......................................7

Figure 6: Universal Shield, Position 2 .......................................7

Figure 7: Universal Shield, Position 3 .......................................7

Figure 8: 2-Foot Deco Grille......................................................8

Figure 9: Barrier Shield .............................................................8

Figure 10: Protective Grille........................................................8

Figure 11: Radiant Distribution (Average Coverage)............... 11

Figure 12: Radiant Distribution (Increased Coverage) ............ 11

Figure 13: Radiant Distribution (Heavy Coverage).................. 11

Figure 14: Burner Flow Units .................................................. 13

Figure 15: Vacuum Loss Curve for 4" Shared Tailpipe...........14

Figure 16: Tube Length vs. Efficiency...................................... 16

Figure 17: Possible Damper Coupling Locations ....................20

Figure 18: Example System Layout (Option 1)....................... 21

Figure 19: Example System Layout (Option 2)....................... 22

Figure 20: Example System Layout (Option 3)....................... 22

Figure 21: Example System Layout (Option 4)....................... 23

Figure 22: Example System Layou

Figure 23: Example System Layout (Option 6)....................... 24

Figure 24: Example System Layout (Option 7)....................... 24

Figure 25: Example System Layout (Option 8)....................... 24

Figure 26: Example System Layout (Option 9)....................... 25

Figure 27: Air Supply System Capacity by Duct Length and

Diameter ................................................................28

Figure 28: Outside Air Blower .................................................29

Figure 29: Sample Layout for Pressurized Outside Air

Systems..................................................................30

t (Option 5).......................23

LIST OF TABLES

Table 1: CORAYVAC® Design Parameters ............................12

Table 2: Pump Capacity..........................................................14

Table 3: Pump Exhaust Requirements ...................................14

Table 4: Allowable Tailpipe Lengths .......................................17

Table 5: Operating Characteristics; Condensing or

Non-Condensing ......................................................18

Page 6

Page 7

SECTION 1: CONCEPT

The concept of CRV-Series is easy to understand.

However, it means discarding old ideas because CRVSeries is a different kind of heating system.

CRV-Series is a gas-fired, vacuum-operated, low-

intensity infrared heating system incorporating a patented incremental burner system.

Gas-Fired means it uses clean-burning Natural or

Propane gas.

Vacuum-Operated means that the pump draws all

the products of combustion through the system and

expels them outdoors.

Low-Intensity means the radiant surfaces of the

tubes do not glow red; instead they operate at a lower

temperature (less than 900° F or 482.2° C) and radiate

heat at lower intensity per square foot of radiating sur-

face. Area coverage is provided by long runs of 4" (10

cm) O.D. tubing which hang from the ceiling or roof

supports. Reflectors direct the radiant heat downward

to occupied areas.

SECTION 1: CONCEPT

Radiant refers to the heat radiated by the CRV-Series

system. Because this heat is in the form of infrared

rays, it does not directly heat the air. Instead, the rays

heat objects such as floors, people, walls, cars,

machines, tools, etc. The warm objects, in turn, heat

the air throu

gh convection.

Incremental Burner System means that several

burners can operate in-series and fire into the same

run of steel tube that carries the combustion gases

from upstream burners. Each of these burners in a

radiant branch may have different firing rates; also, the

space between burners may vary. This allows the

designer to match heat gain to heat loss for each area

of the building. Firing burners in-series provides higher

thermal and radiant efficiency.

In a properly designed low-intensity radiant system,

the occupants should be barely aware of the radiant

heat when the system is firing. They will feel little or no

change when the thermostat is satisfied and the system is not firing. This combines with warm floors,

warm walls and draft-free operation to improve the

mean radiant temperature of the space. This is the key

to the exceptional comfort and fuel efficiency provided

by the CRV-Series system.

1

Page 8

CRV-SERIES DESIGN MANUAL

SECTION 2: THE CRV-SERIES SYSTEM

A CRV-Series system consists of one pump, a control

system, and a number of burners, see Page 3, Figure

1. It also includes an extended tube surface (4" (10

cm) steel tubing) covered by highly efficient reflectors

to direct the radiant heat downward to the floor. The

tubing nearest the burners radiates with the most

intensity and is called radiant tube. This should be

located over areas with the greatest heat loss. The

rest of the tubing surface (located between the radiant

tube and the pump) radiates with less intensity and is

called tailpipe. This can be located in areas with

lower heat loss.

While it is important to locate radiant tubes over areas

with high heat loss, such as the perimeter of the build-

ing, it is not essential to cover all areas directly with

radiant heat. Center areas (away from external walls)

and other areas of low heat loss can be adequately

heated without direct coverage as long as the input of

the system is adequate for the total building heat loss.

However, to achieve the highest degree of comfort and

fuel savings, it is recommended that the CRV-Series

system be located to provide as complete and even a

distribution as is practical. In addition, several different

reflector and shield configurations are available to

direct the radiant heat to or away from desired areas.

With CRV-Series, all equipment and controls are

C.S.A. design certified, both as individual parts and

also as a complete heating system. Also, individual

electrical component parts are listed as applicable.

2.2 Zero Regulator

CRV-Series uses a 100% pre-mix burner with the input

dependent on system vacuum. With no vacuum, the

zero regulator prevents gas flow. When vacuum is

present, the burner fires and input increases as vac-

uum increases. As the input increases, the amount of

air also increases. Over the normal range of operating

vacuum, the gas/air ratio is essentially linear.

This unique and patented feature provides optimum

combustion conditions at all times. Combustion condi-

tions are unaffected by fluctuations in fuel pressure,

vacuum, dirty air filters, changes in atmospheric pressure, wind velocity or other climate conditions.

Page 3, Figure 1 illustrates the components of a typi-

cal CRV-Series system. The system shown is a four

burner system composed of two branches. A branch

consists of a single run of tubing, including an end

burner, followed by any burners downstream. A

branch ends at a tee or a cross (where other branches

connect). For a single branch system, the branch ends

at the pump.

2.1 Safety

Safety is a prime consideration of CRV-Series. First,

there is a pre-purge of the complete tube network prior

to flame ignition. Then, to ensure that there will be no

gas flow unless the pump is operating, a pressure

switch located at the pump must activate prior to igni-

tion. After the pressure switch has closed, there are

two valves in-series in each burner that must be ener-

gized, as well as a zero regulator. Additionally, slow

opening gas valves provide smooth ignition and

enhance reliability. Once the thermostat has been satisfied, the burners turn off and the pump continues to

run for two minutes to purge the entire system of flue

gases.

2

Page 9

FIGURE 1: Assembly Overview (Two Branch System Shown)

Pump

End

Vent

Combustion

Chamber

End Burner

Radiant

Tube

Coupling

Reflector

End Cap

Reflector

Support

Burner

Tube &

Reflector

Hanger

Reflector

Reflector

with Hole

End Vent

Exhaust to

Outside

Shared Tailpipe

End Burner

Tailpipe

Tailpipe

1. Radiant tubing between burners, and 20-50' (6-15 m)

downstream of the last burner is normally hot rolled steel or

heat-treated aluminized steel. All tailpipe tubing must be por-

celain coated steel or heat-treated aluminized steel.

2. Damper couplings are required when layout has unequal

branches. Unequal branches are achieved by unequal

geometry, burner quantity or burner firing rates.

3. Plain couplings are used to connect combustion chambers

to radiant tubing and radiant tubing to tailpipe tubing. All

tailpipe couplings must be lined.

SECTION 2: THE CRV-SERIES SYS TEM

3

Page 10

CRV-SERIES DESIGN MANUAL

2.3 Fuel Savings and Comfort

Space heating can be accomplished with less input

capacity when a radiant heating system is utilized,

rather than with a conventional convective heating

system. Why is this so?

A conventional, convective heating system, such as a

unit heater or central furnace works by heating the air,

which then indirectly heats the area and

occupants. CRV-Series utilizes infrared energy to heat

objects, people and surfaces directly, not the air. The

warm objects and floor create a heat reservoir, which

then re-radiates to the surroundings and also heats

the air by convection.

The radiant energy received by the occupants, directly

from the heater or indirectly from the

surroundings via re-radiation, serves to increase the

mean radiant temperature (MRT) of the space. In a

manner similar to direct sunlight, the increased MRT

allows the occupant to perceive a comfort condition at

a reduced air temperature. The resulting reduced air

temperature within the space provides the

following fuel-saving advantages:

• Reduced stratification of air in the space.

• Reduced transmission heat loss due to lower temperature inside than assumed design

condition.

• Redu

ced air change heat loss, to the extent that

exfiltration through cracks or openings near the

roof will be decreased because of decreased

stack effect.

• Decreases the actual degree days experienced.

4

Page 11

SECTION 3: CLEARANCES TO COMBUSTIBLES

WARNING

Fire Hazard

Keep all flammable objects, liquids and

vapors the minimum required clearances to

combustibles away from heater.

Some objects will catch fire or explode when

placed close to heater.

Failure to follow these instructions can result

in death, injury or property damage.

3.1 Required Clearances to Combustibles

Clearances are the required distances that combusti-

ble objects must be away from the heater to prevent

serious fire hazards. Combustibles are materials,

which may catch on fire and include common items

such as wood, paper, rubber, fabric, etc. Maintain

clearances to combustibles at all times for safety.

Clearances for all heater models are located on the

burner assembly and on Page 6, Figure 3 through

Page 8, Figure 10 in this manual. Check the clear-

ances on each burner for the model heater being

installed to make sure the product is suitable for your

application and the clearances are maintained. Read

and follow the safety guidelines below:

• Keep gasoline or other combustible materials

including flammable objects, liquids, dust or

vapors away from this heater or any other appli-

ance.

SECTION 3: CLEARANCES TO C OMBUSTIBLES

• Hang heater in accordance to the minimum sus-

pension requirements.

• If the radiant tubes must pass through the building

structure, be sure that adequate sleeving and fire

stop is installed to prevent scorching and/or fire

hazard.

•

The stated clearances to combustibles represents

a surface temperature of 90° F (32° C) above

room temperature. Building materials with a low

heat tolerance (such as plastics, vinyl siding, canvas, tri-ply, etc) may be subject to degradation at

lower temperatures. It is the installer’s responsibility to assure that adjacent materials are protected

from degradation.

• Maintain clearances from heat sensitive

equipment and workstations.

• Maintain clearances from vehicles parked below

the heater.

• Maintain clearances from swinging and overhead

doors, overhead cranes, vehicle lifts, partitions,

storage racks, hoists, building construction, etc.

• In locations used for the storage of combustible

materials, signs must be posted to specify the

maximum permissible stacking height to maintain

required clearances from the heater to the combustibles. Signs must be posted adjacent to the

heater thermostat. In the absence of a thermostat, signs must be posted in a conspicuous location.

• Consult local Fire Marshal, Fire Insurance Carrier

or other authorities for approval of proposed

installation when there is a possibility of exposure

to combustible airborne materials or vapors.

5

Page 12

CRV-SERIES DESIGN MANUAL

B

C

D

A

A

B

C

D

A

B

C

D

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream from

where the combustion chamber and the tube connect.

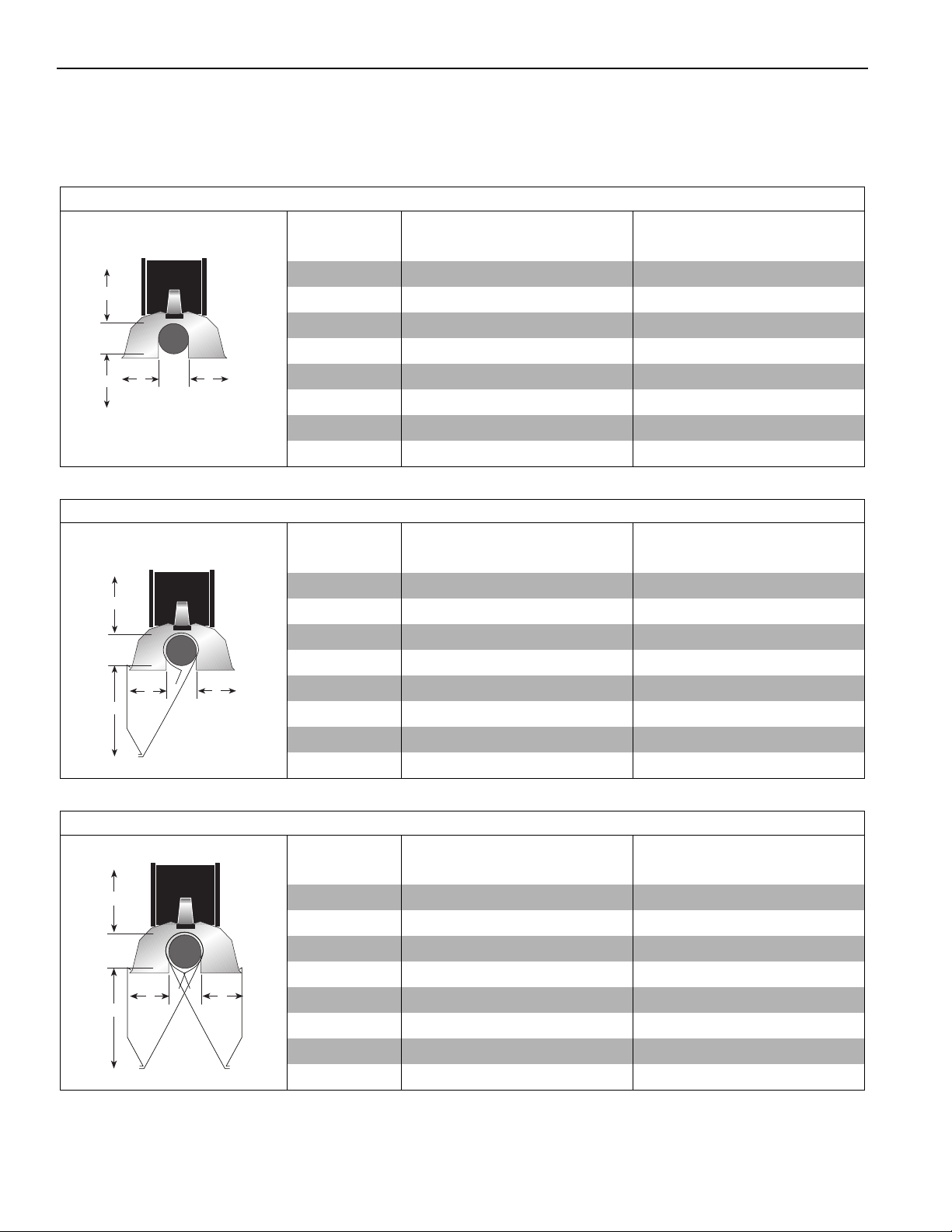

FIGURE 2: STANDARD REFLECTOR

Model A B C D A B C D

CRV-B-2 4 20 48 20 11 51 122 51

CRV-B-4 4 20 48 20 11 51 122 51

CRV-B-6 4 20 48 20 11 51 122 51

CRV-B-8 4 20 48 20 11 51 122 51

CRV-B-9 4 36 60 36 11 92 153 92

CRV-B-10 4 366036119215392

CRV-B-12 4 36 60 36 11 92 153 92

CRV-B-12A 4 36 60 36 11 92 153 92

.

(inches) (centimeters)

FIGURE 3: ONE SIDE REFLECTOR

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 56 20 11 31 143 51

CRV-B-4 4 12 56 20 11 31 143 51

CRV-B-6 4 12 56 20 11 31 143 51

CRV-B-8 4 12 56 20 11 31 143 51

CRV-B-9 4 12 60 42 11 31 153 107

CRV-B-10 4 12 60 42 11 31 153 107

CRV-B-12 4 12 60 42 11 31 153 107

CRV-B-12A 4 12 60 42 11 31 153 107

FIGURE 4: TWO SIDE REFLECTORS

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 56 12 11 31 143 31

CRV-B-4 4 12 56 12 11 31 143 31

CRV-B-6 4 12 56 12 11 31 143 31

CRV-B-8 4 12 56 12 11 31 143 31

CRV-B-9 4 12 60 12 11 31 153 31

CRV-B-10 4 12 60 12 11 31 153 31

CRV-B-12 4 12 60 12 11 31 153 31

CRV-B-12A 4 12 60 12 11 31 153 31

6

Page 13

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

C

A

B

D

C

A

B

D

C

A

B

D

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream from

where the combustion chamber and the tube connect.

FIGURE 5: UNIVERSAL SHIELD, POSITION 1

Model A B CDABCD

CRV-B-2 4 12 12 12 11 31 31 31

CRV-B-4 4 12 12 12 11 31 31 31

CRV-B-6 4 12 12 12 11 31 31 31

CRV-B-8 4 12 12 12 11 31 31 31

CRV-B-9 8 18 24 18 21 46 61 46

CRV-B-10 8 18241821466146

CRV-B-12 8 18 24 18 21 46 61 46

CRV-B-12A 8 18 24 18 21 46 61 46

SECTION 3: CLEARANCES TO C OMBUSTIBLES

(inches) (centimeters)

FIGURE 6: UNIVERSAL SHIELD, POSITION 2

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 24 48 24 11 61 122 61

CRV-B-4 4 24 48 24 11 61 122 61

CRV-B-6 4 24 48 24 11 61 122 61

CRV-B-8 4 24 48 24 11 61 122 61

CRV-B-9 4 36 48 36 11 92 122 92

CRV-B-10 4 36 48 36 11 92 122 92

CRV-B-12 4 36 48 36 11 92 122 92

CRV-B-12A 4 36 48 36 11 92 122 92

FIGURE 7: UNIVERSAL SHIELD, POSITION 3

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 56 30 11 31 143 77

CRV-B-4 4 12 56 30 11 31 143 77

CRV-B-6 4 12 56 30 11 31 143 77

CRV-B-8 4 12 56 30 11 31 143 77

CRV-B-9 8 12 60 42 21 31 153 107

CRV-B-10 8 12 60 42 21 31 153 107

CRV-B-12 8 12 60 42 21 31 153 107

CRV-B-12A 8 12 60 42 21 31 153 107

7

Page 14

CRV-SERIES DESIGN MANUAL

A

B

C

D

C

A

B

D

A

B

C

D

NOTE: 1. All dimensions are from the surfaces of all tubes, couplings, elbows, tees and crosses.

2. Clearances B, C and D can be reduced by 50% after 25' (7.5 m) of tubing downstream from

where the combustion chamber and the tube connect.

FIGURE 8: 2-FOOT DECO GRILLE

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 48 12 11 31 122 31

CRV-B-4 4 12 48 12 11 31 122 31

CRV-B-6 4 12 48 12 11 31 122 31

CRV-B-8 4 12 48 12 11 31 122 31

CRV-B-9 4 18 56 18 11 46 143 46

CRV-B-10 4 18 56 18 11 46 143 46

CRV-B-12 4 18 56 18 11 46 143 46

CRV-B-12A 4 18 56 18 11 46 143 46

FIGURE 9: BARRIER SHIELD

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 12 12 12 11 31 31 31

CRV-B-4 4 12 12 12 11 31 31 31

CRV-B-6 4 12 12 12 11 31 31 31

CRV-B-8 4 12 12 12 11 31 31 31

CRV-B-9 - UNAPPROVED - - UNAPPROVED -

CRV-B-10 - UNAPPROVED - - UNAPPROVED -

CRV-B-12 - UNAPPROVED - - UNAPPROVED -

CRV-B-12A - UNAPPROVED - - UNAPPROVED -

FIGURE 10: PROTECTIVE GRILLE

(inches) (centimeters)

Model A B CDABCD

CRV-B-2 4 20 48 20 11 51 122 51

CRV-B-4 4 20 48 20 11 51 122 51

CRV-B-6 4 20 48 20 11 51 122 51

CRV-B-8 4 20 48 20 11 51 122 51

CRV-B-9 4 36 60 36 11 92 153 92

CRV-B-10 4 36 60 36 11 92 153 92

CRV-B-12 4 36 60 36 11 92 153 92

CRV-B-12A 4 36 60 36 11 92 153 92

8

Page 15

SECTION 4: SIZING AND DESIGN CONSIDERATIONS

Given a building with a calculated heat loss of

350,000 (Btu/h), what is the installed capacity

required of a CORAYVAC

®

system mounted at

30' (9 m)?

CORAYVAC

®

Installed Capacity = Heat Loss x

Radiant Adjustment x Height Adjustment

For CORAYVAC

®

systems, a .80 radiant adjust-

ment factor is used.

The height adjustment is 1% per foot over 20'

(3% per meter over 6 meters), or 1.10.

∴CORAYVAC

®

Installed Capacity = 350,000

(Btu/h) x .80 x 1.10 = 308,000 (Btu/h)

A 12% reduction in installed capacity vs. a

conventional heating system.

The building heat loss must be calculated in accor-

dance to accepted energy load calculation methods.

ASHRAE (American Society of Heating, Refrigeration

and Air-Conditioning Engineers) offers in-depth information that is useful in calculating energy loads. The

CRV-Series system input is determined in concert with

the required radiant adjustment to heat loss and height

adjustment factors.

4.1 Radiant Adjustment to Heat Loss

The practice of applying an adjustment factor to heat

loss calculations for radiant heating systems is well

known within the radiant heating industry, having been

used by manufacturers for over 25 years. A number of

studies have been conducted to identify the values of

the adjustment factor in the range of 0.8 to 0.85

depending on efficiency (higher efficiency uses lower

factor). This adjustment can be more thoroughly

understood when considering the following radiant

effect issues:

• Infrared energy heats objects, not the air.

• Lower ambient temperatures reduce the amount

of air infiltration.

• Less air stratification with radiant heat.

heating system. The ability of a radiant system to provide the advantages of these radiant effects rests

largely with the ability of this system to establish a

reserve heat capacity in the floor. Without this reserve

capacity, radiant comfort cannot be achieved. (The

exception is station heating/spot heating applications

where sufficiently high levels of direct radiation are

received from the heater.) The height adjustment factor is a means to insure adequate floor level radiant

intensity to “charge” the floor heat reservoir.

Proportionately larger wall surfaces also remove

energy from the floor to a larger degree, decreasing

the heat reservoir.

The increased input capacity recommended by a

height adjustment factor is not extraneous as compared to the heat loss calculation. Rather, it is a realization that in order to maintain radiant comfort

conditions (and the economic benefits), a minimum

radiant level must be maintained at the floor.

It is recommended that an adjustment to the heat loss

of 1% per foot (3% per meter) for mounting heights

above 20' (6 m), be added up to 60' (18 m). Above this

height, additional correction overstates the BTU

requirement as determined by the heat loss.

• Lower ambient air temperatures reduce the trans-

EXAMPLE 1:

mission heat loss through walls and roof.

SECTION 4: SIZING AND DESIGN C ONSIDERATIONS

• Elevated floor temperature provides a thermal

reserve capacity.

• Increased mean radiant temperature allows occu-

pants to perceive thermal comfort at the reduced

air temperature.

Each of these issues impacts favorably on the reduc-

tion of the installed capacity of the radiant heating system. This fact, together with the realization that the

standard ASHRAE heat loss calculation methods

(particularly the transmission heat loss coefficients)

have been developed specifically for conventional hot

air systems, demonstrates the need for the heat loss

adjustment factor.

• In general, a .80 adjustment factor should be

used for CRV-Series systems.

4.2 Radiant Height Adjustment Factor

As discussed above, the installed input capacity of

radiant heating systems is typically reduced as compared to the calculated heat loss due to the radiant

effects associated with a properly designed radiant

9

Page 16

CRV-SERIES DESIGN MANUAL

Given a building with a calculated heat loss

of 500,000 Btu/h, what is the installed capacity required of a CRV-Series system mounted

at 50' (15 m)?

CORAYVAC

®

Installed Capacity = Heat Loss x

Radiant Adjustment x Height Adjustment.

For CORAYVAC

®

systems, a .80 radiant adjust-

ment factor is used.

The height adjustment is 1% per foot over 20'

(3% per meter over 6 meters), or 1.30.

∴ CORAYVAC

®

Installed Capacity = 500,000

(Btu/h) x .80 x 1.30 = 520,000 (Btu/h).

EXAMPLE 2:

Note in Example 2, if equipment had been conventionally sized based on thermal output only, a nearly identical input requirement would result. For mounting

heights above 60' (18 m), no further correction is generally necessary if the floor level radiant intensity is

sufficient to establish a reserve capacity (hence, radiant comfort), and the heat loss

requirement is satisfied based on thermal output.

Due to the complexity of installations with mounting

heights over 60' (18 m), it is advisable to contact Roberts-Gordon for further information regarding the specific application.

4.3 Selecting the Burners

The number of burners and input for each must be

specified in the design layout. The following

factors should be considered when selecting burner

input:

• Heat gain and distribution required.

• Mounting height.

• Flow loading restrictions.

• Length of radiant branches.

• Distance required between burners.

• Desired radiation intensity.

In general, lower burner inpu

ts can be used for lower

mounting heights and where lower heat gains are

required. Higher burner inputs are used primarily with

higher mounting heights and where high heat gain is

required.

The number of burners required can be calculated by

dividing the input rating of the selected sizes into the

10

calculated CRV-Series system required installed

capacity.

4.4 Radiant Distribution

Radiant heat distribution at occupant level must be

considered in the burner and design selection

process.

Distribution of heat between radiant branches at floor

level is more critical at the perimeter of buildings. This

is where the heat loss is highest. Therefore, it may be

possible to combine different applications of distribu-

tion within the same building. The following figures

show three different applications of rules to determine

distribution.

4.4.1 Radiant Distribution (Average Coverage)

The aim of this distribution is to provide average or

lighter than average radiant intensity and works well

for general b

uilding heating. See Page 11, Figure 11.

The distance between radiant branches can vary

between 2.5 to 4 (or more) times the mounting height.

This distribution is commonly used in applications

such as warehouses and lower heat loss areas of a

building.

Lighter coverage can be used in areas where occu-

pant traffic is low.

4.4.2 Radiant Distribution (Increased Coverage)

The aim of this distribution is to provide continuous

radiant intensity. See Page 11, Figure 12. The

distance between radiant branches is about 2 times

the mounting height.

This distribution is commonly used in areas bordering

high heat loss areas or areas requiring increased radi-

ant intensity to achieve occupant comfort.

4.4.3 Radiant Distribution (Heavy Coverage)

The aim of this distribution is to provide increased radiant intensity in areas that range from sedentary work

to spot heating for loading docks. See Page 11, Figure

13. The y dimensions in the diagram is the height

above floor level where overlap of the radiant output

will occur.

In practice, y = 6' (1.83 m) is commonly used in areas

where occupant comfort doing sedentary work is an

important factor. In loading bays, spot heating and

areas of high heat loss, the horizontal distance (x)

between branches can be as little as 0.5 times the

mounting height.

Page 17

FIGURE 11: Radiant Distribution (Average Coverage)

H

90°

3 H

H= mounting height

2 H

H

90°

H= mounting height

H

90°

y

x=2H-2y

x

y= height above the

floor level where

overlap of radiant

output will occur

H= mounting height

FIGURE 12: Radiant Distribution (Increased Coverage)

SECTION 4: SIZING AND DESIGN C ONSIDERATIONS

FIGURE 13: Radiant Distribution (Heavy Coverage)

11

Page 18

CRV-SERIES DESIGN MANUAL

SECTION 5: FLOW LOADING

The patented CRV-Series burner system allows a

number of burners to be installed in-series, in the

same radiant tube, resulting in a long, continuous radiant emitting surface to give even heat distribution

within the building.

To enable the burners to be correctly located within the

system, to maintain system operating vacuum and

obtain design flue gas temperatures at the pump, the

design layout is based on a simplified flow principle

using a “flow unit.”

The flow unit is defined as the amount of fuel/air mixture for a heat input of 10,000 (Btu/h). This corresponds to a flow rate of 1.83 cfm at 65-70°F.

For the purpose of design, flow units enter the CRVSeries system in one of two ways:

• Through the burner.

• Through the end vent plate.

Flow units exit the system as spent produ

cts of com-

bustion via the pump.

The purpose of the end vent air is to dilute the hot

combustion gases at the burner, thereby promoting

uniform heating of the tube while avoiding excessive

heating of the combustion chamber.

For the end burner, the burner inlet flow consists of the

end vent air and combustion air. For all other

burners, the burner inlet flow consists the of the total of

the end vent air plus the combustion gases from all

upstream burners.

The requirement for minimum burner inlet flow is met if

the total flow units entering the combustion chamber

meets or exceeds the minimum as shown on Page 12,

Table 1.

5.1 Radiant Branch Flow

The flow in a radiant branch consists of the end vent

flow units plus the flow units of combustion air from all

burners. Page 13, Figure 14 shows a representation

of flow

units for various types of branches.

The limiting factor for maximum flow in the radiant section has been determined experimentally in terms of

the maximum burner inlet flow units that can be tolerated without degradation of combustion characteris-

tics at the last downstream burner. If more than the

maximum number of burners are installed per radiant

branch, the vacuum loss across the additional burners

will increase appreciably.

This maximum flow in the radiant branch can be

expressed for each burner firing rate by either a maximum number of burners per branch or the maximum

number of flow units. See Page 12, Table 1.

Table 1: CORAYVAC® Design Parameters

Burner Model B-2 B-4 B-6 B-8 B-9* B-10 B-12A B-12

Input (Btu/h) x (1000) 20 40 60 80 90 100 110 120

Flow Units per Burner 2 4 6 8 9 10 12 12

Flow Units per End Vent

(minimum flow units entering combustion chamber)

Maximum Number of Burners per Branch 6 4 4 4 2 4 3 3

Maximum Number of Flow Units per Branch 18 26 39 52 33 60 56 56

Radiant Tube Length (average distance between burners)

Minimum (ft) 10 12.5 20 20 20 30 35 35

Recommended (ft) 15 20 25 30 30 40 50 50

Maximum (ft) 20 25 35 45 50 60 70 70

Minimum Distance from Burner to Downstream Elbow (ft) 5 5 10 10 10 15 15 15

Suggested Minimum mounting Height (ft) 8 8 8 10 10 15 15 15

6 10152015202020

* CRV B-9 requires first downstream tube from burner to be aluminized heat-treated.

12

Page 19

FIGURE 14: Burner Flow Units

B-10 Burner #1

End Burner

End Vent Air

+ 20 Flow Units

Combustion Gas

+ 10 Flow Units

Coupling

B-10 Burner #2

Downstream Burner

Combustion Gas

+ 10 Flow Units

B-10 Burner #3

Downstream Burner

Combustion Gas

+ 10 Flow Units

Burner 1

Burner 2

Burner 3

1

2

3

1

2

3

1

2

3

1

2

3

1

2

1

2

3

1

2

3

1

2

3

End Vent

Flow Units

Burner Firing Rate

Btu/h

Burner #

Burner #1

Flow Units

Burner #2

Flow Units

Burner #3

Flow Units

Total Flow

Units

6

20,000

20,000

20,000

40,000

40,000

40,000

60,000

60,000

60,000

80,000

80,000

80,000

90,000

90,000

100,000

100,000

100,000

120,000 (or 110,000)

120,000 (or 110,000)

120,000 (or 110,000)

120,000

100,000

80,000

10

15

20

15

20

20

20

2

2

2

12

4

4

4

22

6

6

6

33

8

8

8

44

9

9

33

10

10

10

50

12

12

12

56

12

10

8

50

Total Flow

Units

20 + 10 + 10 + 10

= 50 Flow Units

SECTION 5: FLOW LO ADING

13

Page 20

CRV-SERIES DESIGN MANUAL

NOT OK

OK

SIDE

10

20

30

40

50

60

70

80

90

100

120

130

Length of Tailpipe Section (feet)*

Maximum Flow Units per Single Tailpipe Section

30

40

50 60 70

80

90 100

110

120

5.2 Pump Capacity

The flow unit capacity of the pump is indicated on

Page 14, Table 2, as a function of installed altitude.

When the CRV-Series system is designed in accordance with this set of instructions and is in proper

operating condition, a vacuum from 2-3" w.c. will be

obtainable at each end vent (i.e. at all burners).

Table 2: Pump Capacity

Installed Altitude Maximum Flow Units

Feet Above

Sea Level

' - 2000'

0

2001' - 3000'

3001' - 4000'

4001

' - 5000'

5001' - 6000'

6001' - 7000'

7001

' - 8000'

8001' - 9000'

Meters Above

Sea Level

0 m - 609 m 66 112 224

610 m - 914 m 63 105 215

915 m - 1219 m 60 100 206

1220 m - 1524 m 57 95 197

1525 m - 1828 m 54 90 188

1829 m - 2134 m 51 84 180

2135 m - 2438 m 48 80 170

2439 m - 2743 m 45 75 161

EP-100

EP-200

Series

EP-300

Series

number of flow units carried in the tube.

See Figure 15. Readings for length and flow when

plotted on the graph must fall on OK side to avoid

excessive vacuum losses.

FIGURE 15: Vacuum Loss Curve for 4" Shared

Tailpipe

There are a number of design requirements which, if

not met, will reduce the vacuum obtainable and

thereby the effective flow capacity of the pump. These

include:

• Minimum Length of Tailpipe - If less than the

minimum length of tailpipe is provided per radiant

branch, there will be insufficient cooling of the com-

bustion gases and improper operation of the pump.

• Line Loss Check for Tailpipe is applicable to

sections of tailpipe which are common to two or

more radiant branches (i.e. shared lengths). See

Page 14, Figure 15.

• Excessive back pressure on discharge line of

pump can be caused by partial blockage or too

much flow for length. See Section 5.3.1

• More than maximum number of burners or flow

units per radiant branch. See Page 14, Table 2.

• Excessive number of elbow or tee fittings

which increases vacuum loss.

5.3 Tailpipe Flow

Excessive flow loading in a single section of tailpipe

can cause low vacuum and lower effective pump

capacity. For the pump to develop the proper vacuum,

the length of tailpipe m

14

ust not be excessive for the

NOTE: For 6" (15 m) tailpipe, length is limited to a

maximum of 100’ (30 m). See Page 16, Section 6.3

for more details.

Lengths shown include allowance for 1 elbow every

50' (15 m); deduct 15% of length for each additional

elbow used per 50' (15 m) length.

5.3.1 Pump Exhaust Length Requirements

The tube length on the exhaust side of the pump is

considered excessive if not within the following condi-

tions:

Table 3: Pump Exhaust Requirements

Pump Series Exhaust Tube Length Exhaust Tube Diameter

EP-100 Up to 25' (7.6 m) 4" 3 Elbows

EP-100 Up to 50' (15 m) 5" 3 Elbows

EP-200 Up to 10' (3 m) 4" 0 Elbows

EP-200 Up to 25' (7.6 m) 5" 3 Elbows

EP-200 Up to 50' (15 m) 6" 3 Elbows

EP-300 Up to 10' (3 m) 6" 1 Elbows

EP-300 Up to 25' (7.6 m) 7" 3 Elbows

EP-300 Up to 50' (15 m) 8" 3 Elbows

Page 21

SECTION 6: RADIANT TUBE AND TAILPIPE

The main purpose of the tailpipe and the radiant tube

is to provide sufficient tube surface to transfer the heat

from the flue gases to the tube wall where it radiates

from the tube. Radiant tube is defined as the tubing

between burners firing in a radiant branch, plus the

radiant tubing immediately following the last down-

stream burner. Tailpipe is defined as all tubing

between the radiant tube and the pump.

Most of the radiant heat supplied by each burner is

released from the radiant tube; the balance is released

by the tailpipe. The placement of radiant tube to correspond to areas of major heat loss is the key to providing uniform comfort levels. The use of adequate

tailpipe is the key to high combustion efficiency and

proper operation of the pump.

6.1 Radiant Tube Length

The considerations in the selection of the length of

radiant tube include the following:

SECTION 6: RADIANT TUBE AND TAILPIPE

Page 16, Figure 16 relates the effect on system thermal efficiency of variations in radiant and tailpipe

lengths. The chart was created based on test data

obtained in accordance with methodology developed

by the National Bureau

of Standards (NBSIR 80-2110)

and recommendations on flue loss calculation contained in ANSI Z83.20/CSA 2.34 (latest edition).

Actual installation variables (gas BTU content, air temperature and operation cycle, etc.) may effect efficiencies (positively or negatively). Page 16, Figure 16 is

presented as a guide to the designer for information

only.

NOTE: When accounting for the required tailpipe

lengths during the design process, it is important to

verify that the tailpipe for each branch is at least equal

to the specified minimum.

6.1.1 Minimum Radiant Tube Length

Provides for the highest level of intensity per length of

radiant tube and good radiant heat uniformity between

b

urners. More tailpipe length is required to maintain

operating efficiency and pump capacity.

6.1.2 Maximum Radiant Tube Length

Provides the lowest level of intensity per length of radi-

ant tube, and consequently the largest span between

burners. The radiant intensity will be reduced slightly

for the last 5'-10' (2-3 m) of radiant tube before the

next burner.

The length of radiant tube required varies according to

the burner input. Consideration has been given to the

use of a standard 10' (3 m) length of tube or lengths

that can be cut from same without waste. See Page

12, Table 1.

When positioning radiant tube to give the required

radiant distribution, it is important to consider:

• Clearances to combustible materials.

• Lighting equipment and other suspended objects.

6.2 Tailpipe

Tailpipe provides a low level of radiant intensity per

length. The length of tailpipe for systems can be varied

according to the flow units in the system and the

designed radiant length. Longer lengths of tailpipe will

attain higher operating efficiencies and therefore condensation will occur.

15

Page 22

CRV-SERIES DESIGN MANUAL

Length of Tailpipe per Flow Unit (feet)

3.0

2.5

2.0

1.5

1.0

83% 84% 85% 86% 87% 88% 89% 90%

Steady State Thermal Efficiency (%)

M

a

x

i

m

u

m

R

a

d

i

a

n

t

P

i

p

e

M

i

n

i

m

u

m

R

a

d

i

a

n

t

P

i

p

e

N

o

m

i

n

a

l

R

a

d

i

a

n

t

P

i

p

e

NOTE: Thermal efficiency values shown do not include the contribution due to condensing conditions when

operating in cyclic fashion. To estimate cyclic efficiencies, add 2-3% to the values obtained from the graph.

Flow Units Per Branch

Branch 1 +

Branch 2 +

Branch 3 +

Branch 4 +

Branch 5 +

Branch 6 +

To t a l S ys te m

Flow Units =

FIGURE 16: Tube Length vs. Efficiency

6.3 Design Parameters

When designing branches of 4 B-8 or larger burners

in-series, the following limitation to the pump capacity

applies:

Pump Model Series

Maximum Loading

EP-100:Not Allowed

EP-200:1 Branch of 4 burners

EP-300:2 Branches of 4 burners

For systems that are designed above 90% pump

capacity, the following limitations of shared tailpipe

apply:

• 4" (10 cm) tailpipe: limited to maximum of 2 combined branches and length limited to maximum of

20' (6 m). See Page 14, Figure 15 for all other

tailpipe considerations.

• 6" (15 cm) tailpipe limited to maximum of 4 combined branches and length limited to maximum of

100' (30 m).

• When calculating required tailpipe length 1' (.3 m)

of 6" manifold tube is equivalent to 1.3' (.4 m) of 4"

tailpipe.

in insufficient vacuum to burners.

6.4 CRV-Series Design Methods

1. L ay o ut the system to suit the BTU input

required.

2. Calculate the system design for each branch

individually.

3. Calculate the number of flow units per branch of

burners. Add the flow units for each branch

together to get the total system flow units. See

Page 12, Table 1 for the r

model. See Page 13, Figure 14 for example flow

unit calculations.

ules for each burner

Failure to comply with the above parameters will result

16

Page 23

4. Select pump model series for total system flow

Burner

Radiant Tube Length

After Each Burner

1+

2+

3+

4+

5+

6+

Total Radiant Tube

Length in Branch =

Average Radiant

Length Per Burner =

units:

EP-100: up to 66 flow units

EP-200: up to 110 flow units

EP-300: up to 224 flow units

5. See Page 14, Table 2 for altitudes greater than

2000'.

6. For each branch, add the length of radiant tube

after each heater:

SECTION 6: RADIANT TUBE AND TAILPIPE

Repeat this calculation for each branch in the

system.

7. Divide the total radiant tube length in the branch

by the number of burners in the branch to get

the average radiant length per burner.

Repeat this calculation for each branch in the

system.

8. Using the average radiant length per burner

(Calculated in Step 7) See Page 17, Table 4 to

select the allowable tailpipe lengths per flow

unit.

Table 4: Allowable Tailpipe Lengths

Radiant Tube Length (average distance between burners)

Minimum (ft) 10 12.5 20 20 20 30 35

Recommended (ft) 15 20 25 30 30 40 50

Maximum (ft) 20 25 35 45 50 60 70

Tailpipe length per flow unit

Minimum (ft)* 1.2 1.2 1.2 1.2 1.2 1.2 1.2

Recommended (ft) 1.5 1.5 1.5 1.5 1.5 1.5 1.5

Maximum (ft) 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Maximum (ft) for EP-100 only 1.7 1.7 1.7 1.7 1.7 1.7 1.7

*Minimum tailpipe lengths can only be used if radiant tube length is recommended or greater.

B-2 B-4 B-6 B-8 B-9 B-10 B-12/B-12A

Burner Model

17

Page 24

CRV-SERIES DESIGN MANUAL

For a B-10 burner system of 200 flow units and an average of 40' radiant tube length per burner, See

Page 17, Table 4 for the tailpipe lengths per flow unit that can be used and the corresponding

operating characteristic.

From Table 4, we can use between 1.2' per flow unit and 2.5' per flow unit when the average radiant length

per B-10 burner is 40'. By multiplying the number of flow units in the system (200 flow units) by the mini-

mum tailpipe length from the chart (1.2' per flow unit), we see that we will need a minimum of 240' of tailpipe

for this system. Likewise, by multiplying the number of flow units in the system (200 flow units) by the maxi-

mum tailpipe length from the chart (2.5' per flow unit), we see that maximum system, tailpipe length is 500'.

Tailpipe length range for a B-10 burner system with 200 flow units and an average radiant tube length of 40’

is 240'-500'. The length of the tailpipe will determine whether the system is condensing or non-condensing.

Given a certain radiant tube length and tailpipe length, the operating characteristic can be determined

u

sing Table 5.

Total tailpipe ' (includes 1 elbow / 50').

Total tailpipe - 10' = Optimum unshared

tailpipe per branchNumber of branches

Total system tailpipe

= Tailpipe ft/flow unit

To t a l f l ow units

EXAMPLE 3: B-10 Radiant Tube vs. Tailpipe Length

Table 5: Operating Characteristics; Condensing or Non-Condensing

Radiant Tube Length (average distance between burners)

Minimum N/A NC Borderline C

Recommended NC Borderline C C

Maximum Borderline C C C

N/A=Not Allowed NC=Non Condensing C=Condensing

Minimum Recommended 1.7 ft/flow unit Maximum

Tailpipe Length per Flow Unit

6.5 Tailpipe Design Method

Given the overall length of tailpipe for the system, the

following section provides the method for ensuring the

design will function correctly.

the section of tailpipe.

If flow units entering a shared tailpipe system exceed

90% of pump capacity, the length of 4" diameter

tailpipe must not exceed 20'.

System with EP-300 Series Pump

6.5.1 Rule of Thumb Unshared Calculations

For shared tailpipe up to 115 flow units, 4" diameter

tailpipe can be used. See Page 14, Figure 15 for max-

imum permissible length of tailpipe for the number of

flow units entering the section of tailpipe.

Select a pump discharge location and plan the route of

the tailpipe. For example system layouts See Page 21,

Figure 18 through Page 25, Figure 26 for different

pump and system efficiency requirements. If these layouts are not suitable, it is necessary to customize the

layout for the CRV-Series system to the individual

building requirements.

For multiple branch systems, always plan to connect

the unshared tailpipe together as close to the pump as

possible for better system efficiency.

6.5.2 Shared Tailpipe Calculation

System with EP-100 or EP-200 Series Pump

Shared tailpipe greater than 115 flow units use 6"

diameter tube. Note that all tailpipe lengths for the pur-

poses of calculation are expressed in terms of 4"

diameter tube.

Effective length: 10' (3 m) of 6" (15 cm) diameter

tube = 13' (4 m) of 4" diameter tube.

6.5.3 To Calculate the Total System Tailpipe

To ta l unshared tailpipe + shared 4" branch tailpipe +

effective length of shared 6".

6.5.4 To Check Performance Criteria

See Page 14, Figure 15 for maximum permissible

length of tailpipe for the number of flow units entering

Compare the results to Page 17, Table 4 and Page 18,

18

Page 25

Table 5 for the burner model to ensure that the result-

ing tailpipe lengths maintain intended operating characteristic.

6.5.5 Damper Couplings

Damper couplings are needed:

• In any tailpipe branch that carries less flow units

than other tailpipe branches connected to the

same pump

• In unsymmetrical layouts with branches having

the same number of flow units, the damper cou-

pling is placed in every branch except for the

longest branch.

The purpose of the damper coupling is to adjust the

end vent vacuum down to the desired level. These are

to be placed in the tailpipe section and not the radiant

branch. The recommended location is before the first

tee fitting or 10'-40' from the end of the radiant pipe.

See Page 20, Figure 17; Page 23, Figure 21, Page

24, Figure 25, and Page 25, Figure 26 for placement

examples.

SECTION 6: RADIANT TUBE AND TAILPIPE

19

Page 26

CRV-SERIES DESIGN MANUAL

Damper Coupling

Damper

NOTE: Damper setting

will vary

Zone 1

Zone 2

Zone 3

Zone 1

End Vent

Zone 3

End Vent

Zone 2

End Vent

Zone 1

Damper

Coupling

Zone 2

Damper

Coupling

Zone 3

Damper

Coupling

Pump

Damper

FIGURE 17: Possible Damper Coupling Locations

20

Page 27

SECTION 7: EXAMPLE CRV-SERIES SYSTEM LAYOUTS

CORAYVAC

®

Burner

LEGEND

Pump

Damper

Radiant Tube

Tailpipe

6" Tailpipe

30'

(9 m)

30'

(9 m)

30'

(9 m)

20'

(6 m)

20'

(6 m)

20'

(6 m)

10' (3 m)

Systems that are symmetrical are preferred because

FIGURE 18: Example System Layout (Option 1)

the vacuum available in the system branches are balanced as a function of design (damper couplings are

not needed).

Where radiant tube lengths are variable in a single

branch, the average length shall be used to determine

the total radiant tube length. Tailpipe will begin after

the last radiant tube following the last burner in the

branch.

CRV-Series is most effective when there are at least 3

burners in the radiant branch.

To assist with the selection of burners and system

designs, the following figures show system layouts that

have been used extensively with CRV-Series since

1962. Designing systems using these layouts will

mean altering the dimensions to suit the individual

building.

SECTION 7: EXAMPLE CRV-SERIES SYSTEM L AYOUTS

Generally, shared tailpipe reduces the available system vacuum. See Page 14, Section 5.3 for shared

tailpipe design rules.

7.1 Example System Layout (Option 1)

Six B10 burners at minimum radiant tube length and

2.5 ft/flow unit tailpipe, the recommended pump for

this system is an EP-200 Series p

ump.

This system provides maximum radiant intensity on

the left and right and adds supplemental radiant

effects through the center creating very even radiant

effects over the coverage area.

Layout to provide high system efficiency, condensed

radiant output and good uniformity of distribution.

Adjust the lengths as necessary for different input systems and to change the efficiency levels.

21

Page 28

CRV-SERIES DESIGN MANUAL

40'

(12 m)

40'

(12 m)

40'

(12 m)

40'

(12 m)

40'

(12 m)

20' (6 m)

10' (3 m)

30'

(9 m)

30'

(9 m)

40'

(12 m)

40'

(12 m)

30'

(9 m)

50'

(15 m)

6" Tailpipe

FIGURE 19: Example System Layout (Option 2)

7.2 Example System Layout (Option 2)

FIGURE 20: Example System Layout (Option 3)

Six B10 burners at recommended radiant tube length

and 1.2'/flow unit tailpipe, the recommended pump for

this system is an EP-200 Series pump.

Layout will minimize up front equipment cost of tubing

by implementing minimum tailpipe length.

Layout will exhibit minimum system efficiency. Adjust

the lengths as necessary for different input systems

and to increase the efficiency levels.

7.3 Example System Layout (Option 3)

Twelve B10 burners at minimum radiant tube length

and 1.56'/flow unit tailpipe, the pump for this system is

an EP-300 Series Pump.

All shared tailpipe is 6" diameter.

Layout will provide maximum radiant intensity

between burners.

Layout will exhibit minimum system efficiency. Adjust

the lengths as necessary for different input systems

and to increase the efficiency levels.

22

Page 29

SECTION 7: EXAMPLE CRV-SERIES SYSTEM L AYOUTS

30'

(9 m)

40'

(12 m)

30'

(9 m)

40'

(12 m)

40'

(12 m)

40'

(12 m)

30'

(9 m)

6" Tailpipe

70'

(21 m)

10'

(3 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

FIGURE 21: Example System Layout (Option 4)

FIGURE 22: Example System Layout (Option 5)

7.4 Example System Layout (Option 4)

Nine B10 burners at recommended radiant tube length

and 1.58'/flow unit tailpipe, the pump for this system is

an EP-300 Series Pump.

All shared tailpipe is 6" diameter.

Layout will exhibit nominal system efficiency. Adjust

the lengths as necessary for different input systems

and to increase the efficiency levels.

7.5 Example System Layout (Option 5)

Six B10 burners at minimum radiant tube length and

1. 5 ' / f l o w unit tailpipe, the pump for this system is an

EP-200 Series pump.

23

Page 30

CRV-SERIES DESIGN MANUAL

100'

(30 m)

10' (3 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

10' (3 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

negligible

180'

(55 m)

10' (3 m)

30'

(9 m)

30'

(9 m)

30'

(9 m)

10' (3 m)

Layout to provide minimum system efficiency. Adjust

the lengths as necessary for different input systems

and to increase the efficiency levels.

This system is generally accompanied by an additional system, as shown, so that the radiant output of

the additional system supplements the lack of radiant

intensity from the tailpipe of the first system. This layout method is used in high heatloss and perimeter

heating applications.

FIGURE 23: Example System Layout (Option 6)

This layout method is often used effectively in heatloss

and perimeter heating applications.

FIGURE 24: Example System Layout (Option 7)

7.6 Example System Layout (Option 6)

Six B10 burners at minimum radiant tube length and

2.3'/flow unit tailpipe, the pump for this system is an

EP-200 Series pump.

FIGURE 25: Example System Layout (Option 8)

Layout to provide high system efficiency, condensed

radiant output and good uniformity of distribution.

Adjust the lengths as necessary for different input systems and to change the efficiency levels.

24

Page 31

SECTION 7: EXAMPLE CRV-SERIES SYSTEM L AYOUTS

30'

(9 m)

30'

(9 m)

10'

(3 m)

30'

(9 m)

10'

(3 m)

30'

(9 m)

30'

(9 m)

6"

Tailpipe

FIGURE 26: Example System Layout (Option 9)

Layout to provide condensed radiant output and good

uniformity of distribution. Layout will exhibit minimum

system efficiency.

7.7 Example System Layout (Option 7, 8 and 9)

These systems are for B9 burners only, this burner is

specially rated for 2 burners in-series applications in

the systems shown.

Option 7 is a 180' (55 m) straight system connected to

an EP-100 pump.

Option 8 is a system connected to an EP-200 Series

pump.

Option 9 is a system connected to an EP-300 Series

pump.

These layouts show minimum allowed lengths. Addi-

tional tubing may be added. The distance between the

burners can be varied from 30' (9 m) to 20’ (6 m), but

the overall system lengths must remain the same.

Layout will minimize upfront equipment cost of tubing

by implementing special shortened minimum tailpipe

lengths.

25

Page 32

CRV-SERIES DESIGN MANUAL

DANGER

Electrical Shock Hazard

Disconnect electric before service or

maintenance.

More than one disconnect switch may be

required to disconnect electric to the unit.

Control must be properly grounded to an

electrical source.

Failure to follow these instructions can

result in death or electrical shock.

WARNING

Explosion Hazard

Turn off gas supply to heater before service.

Failure to follow these instructions can result

in death, injury or property damage.

SECTION 8: CONTROL METHODS

Electronic 24 Vac thermostats and mechanical thermostats with heat anticipator can be used. The system control offers a 24 Vac power supply to power

electronic thermostats.

Roberts-Gordon offers a selection of low voltage

thermostats approved for use with the system

control.

A System Control operated system has two minutes

post purge pump operation to completely exhaust

products of combustion from the system. A system

control provides indication of power to the pump and

zones and indicates the status of the pressure switch

with lights.

The System Control is ETL listed in accordance with

UL873 – Standard for Temperature Indicating and

Regulating Equipment.

8.2 ROBERTS GORDON

®

ULTRAVAC

™

The ROBERTS GORDON® ULTRAVAC™ is a micro

processor based control package designed for modu-

lating control of CRV-Series heaters based on outdoor

temperatures. The controls offer full modulation

between 60% and 100% of system maximum rated

input.

There are several methods of controlling CRV-Series

systems. The options are as follows:

8.1 ROBERTS GORDON

®

System Control (P/N

02770002)

®

The ROBERTS GORDON

System Control is an

electronic controller designed for the control of

CORAYVAC

systems.

®

and VANTAGE® NP (multiburner only)

The System Control is capable of giving four zones of

burners' temperature control and power. The control

will also give power output to as many as two pumps,

provided that the load is not greater than 20 A and 1

Ø. For additional electrical specifications see the

System Control Installation, Operation and Service

manual (P/N 10091601NA).

This controller is capable of giving control outputs to

one pump and three heating zones. The controller

also features inputs which are used for indoor and out-

door signal condition monitoring.

System status and settings are viewed and altered

from a PC (not supplied) running ROBERTS GOR-

®

DON

ULTRAVAC™ Software.

®

ROBERTS GORDON

a PC (not supplied) running Windows

with a Pentium

®

class processor and at least 64k of

ULTRAVAC™ Software requires

®

95 or higher,

RAM.

Special design requirements apply for CRV-Series

®

systems using the ROBERTS GORDON

™

VAC

Controller, See Page 31, Section 10.

ULTRA-

26

Page 33

SECTION 8: CONTROL METHODS

Buildings today demand all sorts of control options

based on the user’s preference. ULTRAVAC™

controls offer a host of communication options for

integration with controls’ networks to best serve

individual needs:

BACnet

®

: Interface ULTRAVAC™ with other building

management control platforms with our BACnet

option.

TCP/IP (LAN): Connect to ULTRAVAC™ via your

local area network of computers. Load ULTRAVAC™

software onto any computer on the network and

control and view your heating system from your

computer.

MODEM: Dial into ULTRAVAC™ from anywhere in

the world via modem. Supplied as standard on all

central controllers!

RS-485: Hard wire ULTRAVAC™ directly to your

computer.

There are references in this manual to various trademarks. All

trademarks mentioned herein, whether registered or not, are the

property of their respective owners. Roberts-Gordon is not

sponsored by or affiliated with any of the trademark or registered

trademark owners, and make no representations about them,

their owners, their products or services.

Roberts-Gordon LLC is not sponsored by or affiliated with

BACnet®.

indication of operating conditions. The transformer

relay wiring diagram is shown in the CORAYVAC

®

Installation, Operation and Service Manual (P/N

127102NA).

8.5 Pressure Switch

A pressure switch is required to confirm pump operation on all systems.

A pressure switch is also required on the inlet duct of a

non-pressurized air supply.

8.3 SPST Transformer Relay (P/N 90417600K)

The transformer relay can be used to control an EP100 or EP-201 pump CORAYVAC

®

system. The single

pole relay can only be used to control one zone of

burners. The electrical circuit is a 120 V AC (20 A)

supply. The transformer 24 V AC output for the thermostat is rated at 40 V A. Thermostats used with the

transformer must not exceed this power requirement.

A transformer relay operated system will not give any

post purge pump operation to completely exhaust

products of combustion from the system or provide

indication of operating conditions. The transformer

relay wiring diagram is shown in the CORAYVAC

®

Installation, Operation and Service Manual (P/N

127102NA).

8.4 DPST Transformer Relay (P/N 90436300)

The transformer relay can be used to control an EP100 or EP-201 pump CORAYVAC

®

system. The double

pole relay can only be used to control two zones of

burners. The electrical circuit is a 120 V AC (20A) sup-

ply. The transformer 24 V AC output for the thermostat

is rated at 40 VA. Thermostats used with the trans-

former must not exceed this power requirement. A

transformer relay operated system will not give any

post purge pump operation to completely exhaust

products of combustion from the system or provide

27

Page 34

CRV-SERIES DESIGN MANUAL

140

120

100

80

60

40

20

0

0 50 100 150 200 250

Flow Units

Straight Duct Length (feet)

4"

5"

6"

7"

NOTE: For capacity requirements larger than shown, use 8" duct.

Duct Diameter

SECTION 9: AIR SUPPLY SYSTEM

An air supply free of dust and corrosive contaminants

is essential for proper operation and best life expectancy with any heating system. With CRV-Series, there

are two alternatives available to the designer for providing the air supply. These are:

• Room air, a filter is standard for each burner.

• Outside air system to duct air from an uncontami-

nated source. The outside air system can be

designed as a pressurized or non-pressurized

system.

The first alternative above is usable when the dust

load is not excessive and there is no usage of corrosive contaminants such as solvents or vapors inside

the building.

The outside air system must be used in all applica-

tions where corrosive contaminants may be present in

the air even in trace amounts (few parts per million).

It is important for designers and owners of heating

systems to note that the presence of contaminants in

the combustion air supply will greatly accelerate the

rate of corrosion on tube surfaces and will shorten the

useful life of the heating system. This is true regard-

less of whether the heating system is CRV-Series,

other infrared systems or conventional gas or oil-fired

equipment such as u

nit heaters, central boiler plant,

etc.

With the unique vacuum powered burners, the fuel/air

mix remains constant, even if combustion air filters are

dirty. It can be expected that the use of an outside air

system will reduce but not eliminate the potential for

corrosion due to contamination.

®

ULTRAVAC™ or relay transformer, a separate

DON

load relay package is required. Wire the control for the

relay in parallel with the pump. The outside air blower

must have a separate 20 A, 120 V power supply.

9.2 Non-Pressurized

For a non-pressurized outside air supply, a 4" O.D. single wall pipe duct may be attached to the burner and

end vent. For length and duct sizing requirements See

Section 9.3. To prevent condensation, insulate the

outside air duct.

9.3 Outside Air System Design Requirements

9.3.1 Non Pressurized

• 6" diameter duct must not exceed 90' (27 m)

• 4" diameter duct must not exceed 90' (27 m)

• Elbows are equivalent to 10' (3 m) of duct length.

• See the CRV-Series Installation, Operation, and

Service Manual (P/N 127102NA) for ducting

installation details.

9.3.2 Pressurized Systems

• 6" diameter duct must not exceed 120' (36 m) total

per system.

• 4" diameter duct must not exceed 120' (36 m) per

radiant branch.

• See the CRV-Series Installation, Operation, and

Service Manual (P/N 127102NA) for ducting

installation details.

FIGURE 27: Air Supply System Capacity by Duct

Length and Diameter

In a way similar to the CRV-Series pump system, the

design of the air supply system also involves considerations of total flow units and acceptable combinations

of duct lengths (and diameters) versus flow units car-

ried. In certain circumstances, it may be desirable to

introduce an outside air blower to pressurize the system. A small positive pressure is desirable and necessary to prevent the system from drawing in

contaminated air.

9.1 Pressurized

For pressurized outside air supplies, the outside air

blower motor has a pressure switch that must be used.

Wire this switch in-series with the pu

switch. When using an outside air blower with a ROB-

ERTS GORDON

28

®

System Control, ROBERTS GOR-

mp pressure

Page 35

9.3.3 Pipe sizing

To size each section of pipe proceed as follows:

• Calculate the required flow units at each outlet of

the supply system.

• Measure the longest run of pipe from the blower

to the most remote outlet. Use only this distance

in Figure 27 (or the next longer distance if the

exact distance is not shown). This is to provide

assurance that the pressure drop to the most

remote outlet will not exceed 0.25" w.c. when all

outlets are supplied.

• See Figure 27, find the intersection point on the

graph for the appropriate duct length and number

of flow units. The duct size above this intersection

point indicates what size duct work should be

used. Proceed in a similar manner for each outlet

and each section of duct. For each section of

duct, determine the total flow unit capacity sup-

plied by that section.

SECTION 9: AIR SUPPL Y SYS TEM

Duct Design Rules

• System should be designed so that the blower is

positioned closest to the highest flow require-

ments (end vents).

• When a duct is carrying more than 40 flow units, it

must be at least 6" diameter.

Blower (P/N 90707501) Performance 112 Flow

Units:

One outside air blower is required per each EP-100 or

EP-200 series pump and two outside air blowers may

be required for each EP-300 series pump. Outside air

blowers cannot be shared between two separate

CRV-Series systems.

FIGURE 28: Outside Air Blower

29

Page 36

CRV-SERIES DESIGN MANUAL

*NOTE: up to 10' (3 m) max. from blower

inlet can be neglected for pressure drop

calculations.

4

4

4

10

20 8

8

8

110'

(33 m)

(44)

15 6

66

(22)

(33)

P

100'

(30 m)

15'

(4.5 m)

B

50'

(15 m)

10'

(3 m)

max.*

4" duct

4" duct

Branch A

Branch B

Walls

Branch C

4" duct

6" Duct

4" Duct

6" duct

FIGURE 29: Sample Layout for Pressurized Outside Air Systems

30

Page 37

®

SECTION 10: ROBERTS GORDON

ULTRAVAC™ DESIGN REQUIREMENTS

CRV-B-2 and CRV-B-4 are not available for use with

ROBERTS GORDON

®

ULTRAVAC™ controls.

CRV-Series systems designed with minimum

radiant tube lengthshall have 1.5' - 2.0' per flow unit of

tailpipe length.

-OR-

CRV-Series systems with recommended radiant tube

length shall have 1.2' - 1.5' per flow unit of tailpipe

length.

SECTION 10: ROBERTS GORDON® ULTRAVAC™ DESIGN R EQUIREMENTS

31

Page 38

CRV-SERIES DESIGN MANUAL

SECTION 11: CRV-SERIES EQUIPMENT SPECIFICATIONS

The total heating system supplied shall be design cer-

tified by the CSA International per American National

Standard ANSI Z83.20/CSA 2.34 (latest edition).

11.1 Burner and Burner Controls

11.1.1 Burners shall be designed to operate simulta-

neously in series without adverse effects from com-

11.2 Equipment

11.2.1 Burner

Each burner assembly shall consist of heavy-duty

cast-iron burner heads, pre-wired gas controls with

electronic, three-try direct spark ignition and combus-

tion air filter.

bustion gases from upstream burners.

11.2.2 Pump

11.1.2 Burners shall be capable of firing on:

Natural Gas, or LP Gas.

11.1.3 Burners shall be supplied to fire at any one of

the input firing rates as specified:

CRV-B-2-20,000 (Btu/h)

CRV-B-4-40,000 (Btu/h)

CRV-B-6-60,000 (Btu/h)

CRV-B-8-80,000 (Btu/h)

CRV-B-9-90,000 (Btu/h)

CRV-B-10-100,000 (Btu/h)

CRV-B-12A-110,000 (Btu/h)

CRV-B-12-120,000 (Btu/h)

When using ROBERTS GORDON

®

ULTRAVAC™ controls, burner rates will modulate between 60% and

100% rated input (CRV-B-2 and CRV-B-4 are not available for use with ROBERTS GORDON

®

ULTRAVAC™

controls).

11.1.4 The design of burners supplied shall provide

for maintaining a constant proportion of fuel gas to filtered combustion air. These conditions are met for

burners in which the pressure of both the fuel gas

and the combustion air are introduced at zero (atmospheric) pressure and the flow of each is established

by a vacuum on the downstream side of the flow

The pump model supplied will vary with the capacity of

the system. See the pump technical specification

sheet or the installation, operation and service manual

for product description and specification.

The pump shall be acoustically isolated from the system with a flexible connector with temperature rating of

350°F minimum. The motor in the vacuum pump shall

be secured with rubber mounts for acoustical isolation.

11.2.3 Heat Exchanger

Radiant tubing (between burners and 10’ - 70’ down-

stream of last burner) shall be of 4" O.D. steel or heat

treated aluminized tubing.

As an option, the balance of the tubing shall be 4"

O.D. steel tubing w

of acid-resistant porcelain.

All heat exchanger (tubing) connections shall be made

with stainless steel coupling assemblies. Standard

couplings will be used in radiant sections. Lined cou-

plings will be used in tailpipe sections.

11.2.4 Outside Air

When specified, in contaminated environments, the

system shall be capable of supplying air from the out-

side to each burner and end vent for the support of

combustion.