Page 1

Beacon 800 Gas Monitor

Operator’s Manual

Part Number: 71-0037RK

Revision: C

Released: 1/2/14

www.rkiinstruments.com

Page 2

Product Warranty

RKI Instruments, Inc. warrants gas alarm equipment sold by us to be free from defects in

materials, workmanship, and performance for a period of one year from date of shipment

from RKI Instruments, Inc. Any parts found defective within that period will be repaired or

replaced, at our option, free of charge. This warranty does not apply to those items, which

by their nature, are subject to deterioration or consumption in normal service, and which

must be cleaned, repaired, or replaced on a routine basis. Examples of such items are as

follows:

a) Absorbent cartridges d) Batteries

b) Pump diaphragms and valves e) Filter elements

c) Fuses

Warranty is voided by abuse including mechanical damage, alteration, rough handling, or

repair procedures not in accordance with the operator’s manual. This warranty indicates

the full extent of our liability , and we are not responsible for removal or replacement costs,

local repair costs, transportation costs, or contingent expenses incurred without our prior

approval.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ANY AND ALL OTHER

WARRANTIES AND REPRESENTATIONS, EXPRESSED OR IMPLIED, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART OF RKI

INSTRUMENTS, INC., INCLUDING BUT NOT LIMITED TO, THE WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE. IN NO

EVENT SHALL RKI INSTRUMENTS, INC. BE LIABLE FOR INDIRECT,

INCIDENTAL, OR CONSEQUENTIAL LOSS OR DAMAGE OF ANY KIND

CONNECTED WITH THE USE OF ITS PRODUCTS OR FAILURE OF ITS

PRODUCTS TO FUNCTION OR OPERATE PROPERLY.

This warranty covers instruments and parts sold to users by authorized distributors,

dealers, and representatives as appointed by RKI Instruments, Inc.

We do not assume indemnification for any accident or damage caused by the operation of

this gas monitor, and our warranty is limited to the replacement of parts or our complete

goods.

Beacon 800 Gas Monitor Operator’s Manual

Page 3

Table of Contents

Chapter 1: Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About the Beacon 800 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

About This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2: Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

External Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Internal Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Chapter 3: Installation & Startup. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Mounting the Beacon 800 Gas Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Wiring the Beacon 800 Gas Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Starting Up the Beacon 800 Gas Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Chapter 4: Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Normal Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Alarm Indications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Viewing & Resetting Min/Max Readings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Chapter 5: Configuration Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Enabling or Disabling Channels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Calibration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configure Channel Settings Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Chapter 6: Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Preventive Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Replacing the Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Chapter 7: Optional Recorder Output Board & Heavy Duty Relay Board . . . . . . . . . . 32

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Recorder Output Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Heavy Duty Relay Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Beacon 800 Gas Monitor Operator’s Manual

Page 4

Chapter 1: Introduction

Overview

This chapter briefly describes the Beacon 800 Gas Monitor. This chapter also describes

the Beacon 800 Gas Monitor Operator’s Manual (this document). Table 1 at the end of this

chapter lists the specifications for the Beacon 800.

About the Beacon 800 Gas Monitor

The Beacon 800 is a fixed-mounted, continuous-monitoring instrument. This multiple

channel gas monitor is capable of detecting gas at up to eight locations. The display

screens simultaneously display the gas readings of all active channels.

The Beacon 800 includes audible and visual alarms that warn you of hazardous gas

conditions. The alarm circuit includes two levels of gas alarms. The fail circuit alerts you to

failures in the gas tra nsmitter(s) or Beacon 800.

The Configuration menu allows you to change channel and calibration settings.

About this Manual

The Beacon 800 Gas Monitor Operator’s Manual is organized as follows:

• Chapter 1 is an introduction to the Beacon 800.

• Chapter 2 describes the components of the Beacon 800.

• Chapter 3 describes the installation and start-up procedures of the Beacon 800.

• Chapter 4 describes the operatio n of the Beaco n 800.

• Chapter 5 describes the configuration procedures of the Beacon 800.

• Chapter 6 describes the maintenanc e of the Beacon 800.

• Chapter 7 describes the optional Recorder Output and Heavy Duty Relay boards.

The Beacon 800 Gas Monitor Operator’s Manual uses the following conventions for notes,

cautions, and warnings:

NOTE: Describes additional or critical information.

CAUTION: Describes potential damage to equipment.

WARNING: Describes potential danger that can result in injury or death.

1 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 5

Specifications

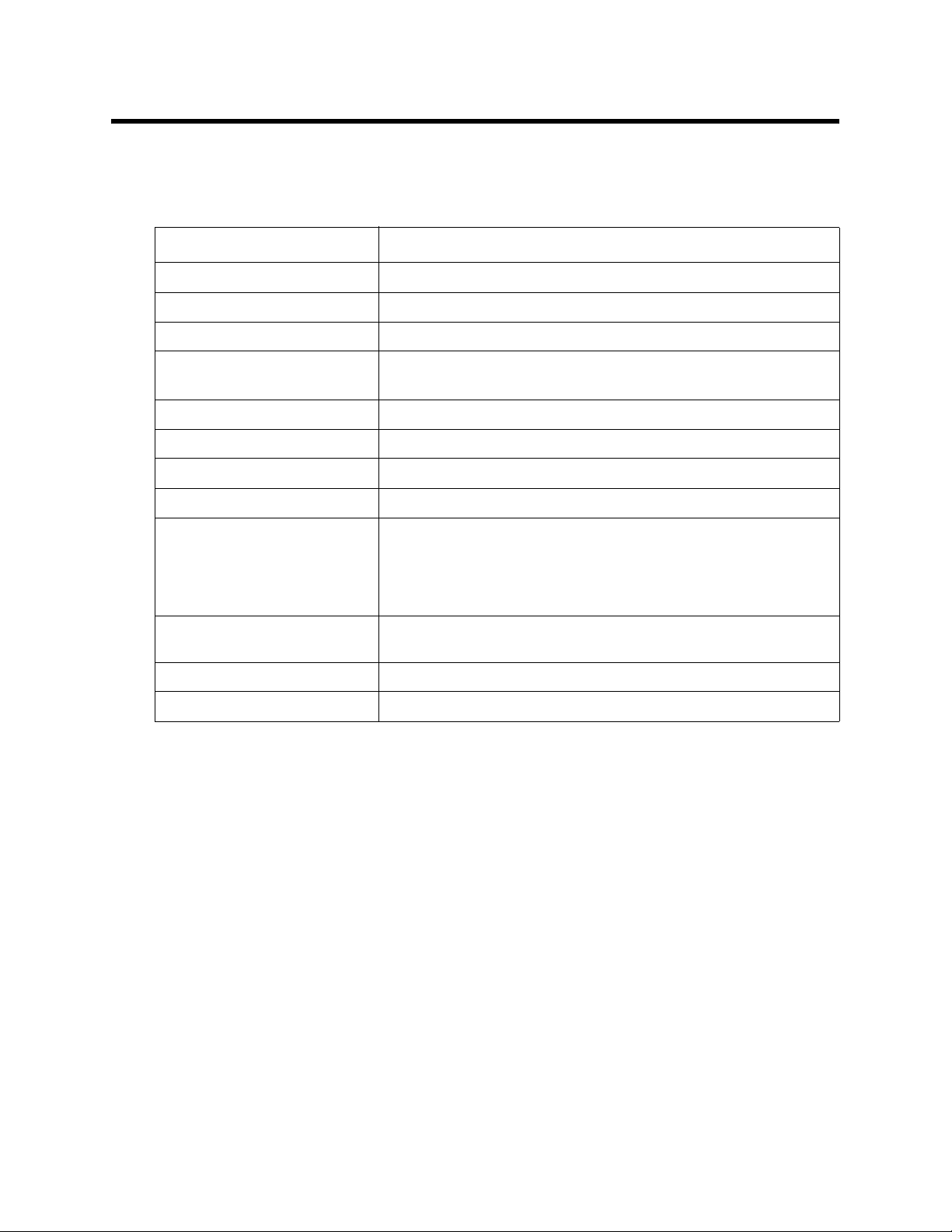

Table 1 lists specifications for the Beacon 800.

Description Specification

Input Power 100 to 240 VAC or 24 VDC

Detector Head Input Type 2 or 3 wire 4-20mA transmitters

Construc tion (housing) Fibergla ss/polyester with lexan window (NEMA 4X)

Dimensions 12.5 in. H x 11.0 in. W x 6.4 in. D

Weight 10.4 lbs. (without AC line cord)

Operating Temperature -4°F to 122°F (-20°C to 50°C)

Storage Temperature -4°F to 158°F (-20°C to 70°C)

Regulatory CSA, NRTL/C

T a ble 1: Beacon 800 Specifications

(31.8 cm H x 27.9 cm W x 16.3 cm D)

Environmental Conditions • For indoor or outdoor locations (Type 4X)

• 2000 meter max altitude

• Maximum humidity: 80% relative

• Pollution Degree 2

• Installation Category II

User Controls • Reset switch

• Program buttons: ESCAPE, UP (YES), DOWN (NO), and ENTER)

Relays CSA Rated for 3 amps at 115 VAC resistive, Form C

Standard Accessory Operator’s manual (this document)

Beacon 800 Gas Monitor Operator’s Manual Specifi cations • 2

Page 6

Chapter 2: Description

Overview

This chapter describes external and internal components of the Beacon 800 Gas Monitor.

External Description

This section describes the housing and all external components of the Beacon 800. For

the purposes of this description, the housing door is considered the front of the monitor.

Housing

The Beacon 800’s fiberglass housing is weather- and corrosion-resistant. It is suitable for

installation where general purpose equipment is in use. The housing door is hinged on the

left side and is secured by two latches on the right side. The display screens and status

lights are visible through windows in the housing door. Four mounting feet are attached to

the back of the housing (one at each corner). The mounting feet allow you to install the

housing to a vertical surface. Four conduit hubs on the bottom of the housing are for

external wiring connections.

CAUTION: To avoid electrical interference, do not route transmitter and power wiring

through the same conduit hub.

Reset Switch

The reset switch is on the bottom of the housing, in front of the buzzer. The reset switch

serves three functions:

• Resets the alarm circuits for “latched” alarms after an alarm 1 or alarm 2 condition

passes.

Y ou can set each channel for latched or self-resetting alarms in the channel setup program. See Chapter 5, Configuration, for more information.

• Silences the buzzer during an alarm 1 or alarm 2 condition. You cannot silence failure

alarms.

• Displays and resets the minimum and maximum gas concentration values.

Buzzer

The buzzer is on the bottom of the housing, behind the reset switch. The buzzer sounds

audible warnings to warn you of gas alarms and instrument failures.

3 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 7

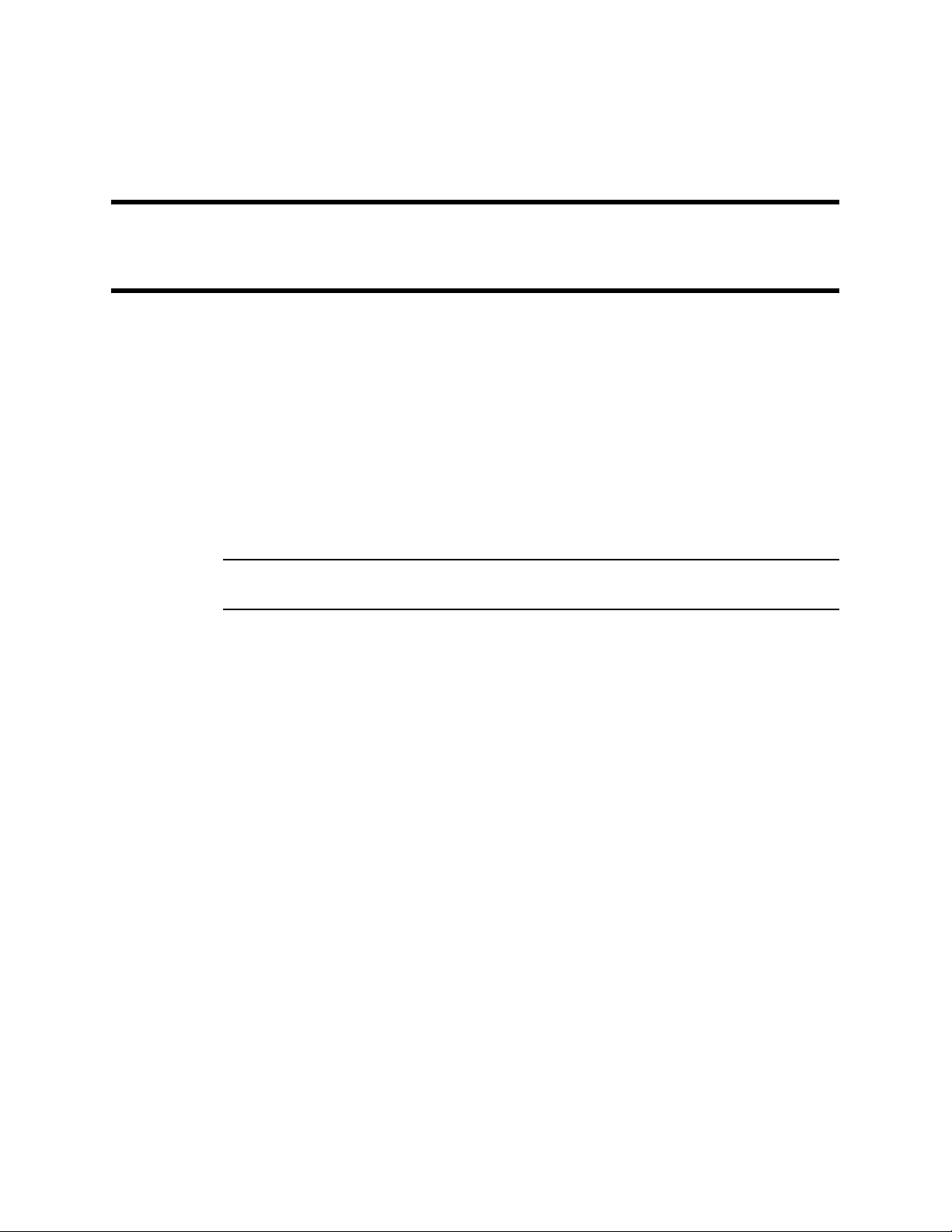

Internal Description

y

y

(

(

r)

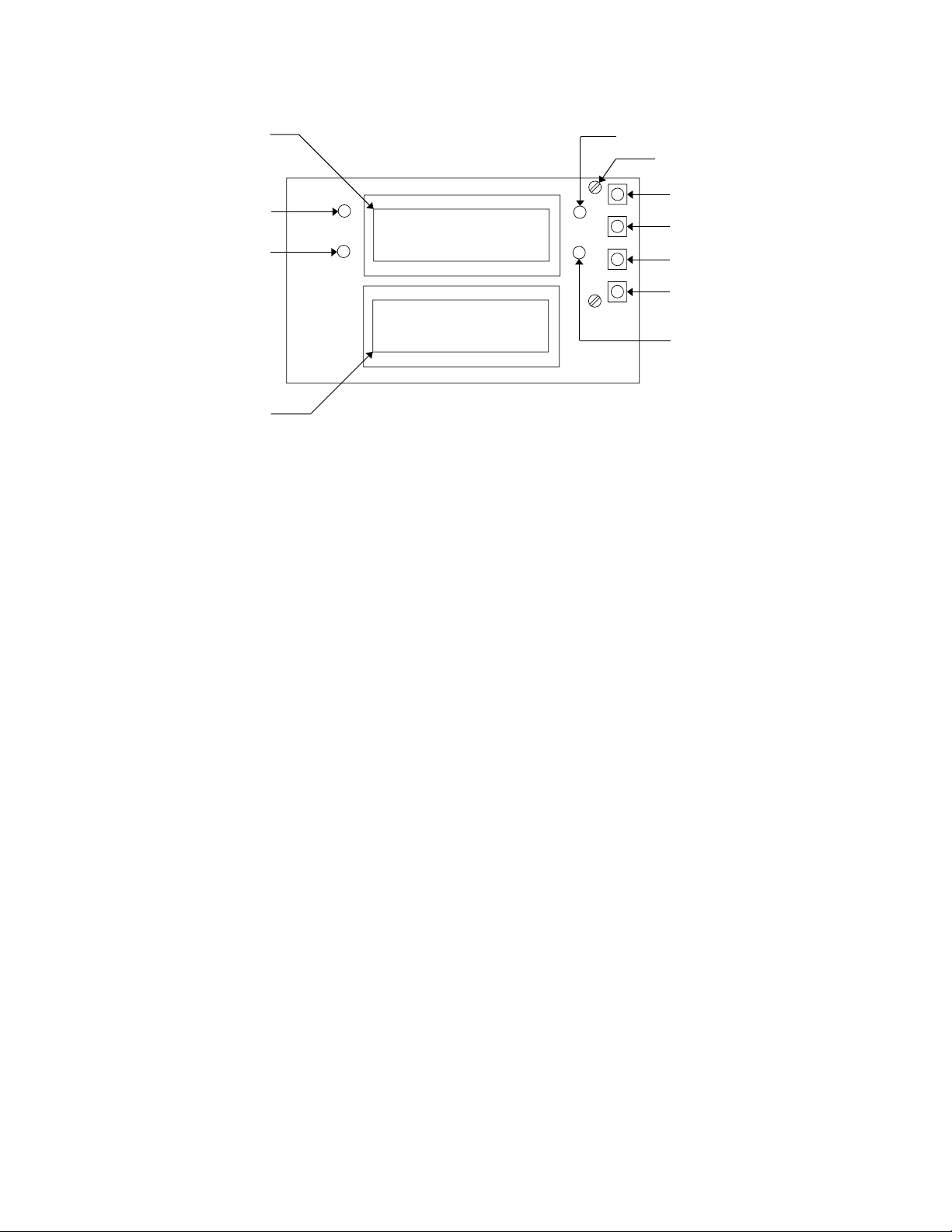

This section describes the internal components of the Beacon 800.

Main board

Power supply

Display board

(see Figure 2)

Housing

(shown without doo

Alarm 2 common rela

Alarm 1 common rela

Fail common relay

Power switch

Channel relays

(see Figure 3)

Alarm terminal strip

channels 1-4; alarm 2)

Transmitter terminal strip

(channels 5-8)

Transmitter terminal strip

(channels 1-4)

Alarm terminal strip

channels 1-4; alarm 1)

Conduit hub

(total of 4)

Display Screens

NOTE: The display screens, status lights, and program buttons are mounted to a

AC terminal strip

Controller

terminal strip

Alarm terminal strip

(channels 5-8; alarm 2)

Alarm terminal strip

(channels 5-8; alarm 1)

Ground Stud

Reset switch

Buzzer

(behind switch)

Figure 1: Beacon 800 Gas Monitor Component Location

secondary circuit board. This circuit board is mounted to the main circuit board by

standoffs.

The display screens simultaneously display the target gas, measuring unit, and current

gas reading of all active channels. The top screen displays channels 1 through 4; the

bottom screen displays channels 5 through 8.

The display screens also display messages, settings, and other data when you are

operating the configuration menu.

Beacon 800 Gas Monitor Operator’s Manual Internal Description • 4

Page 8

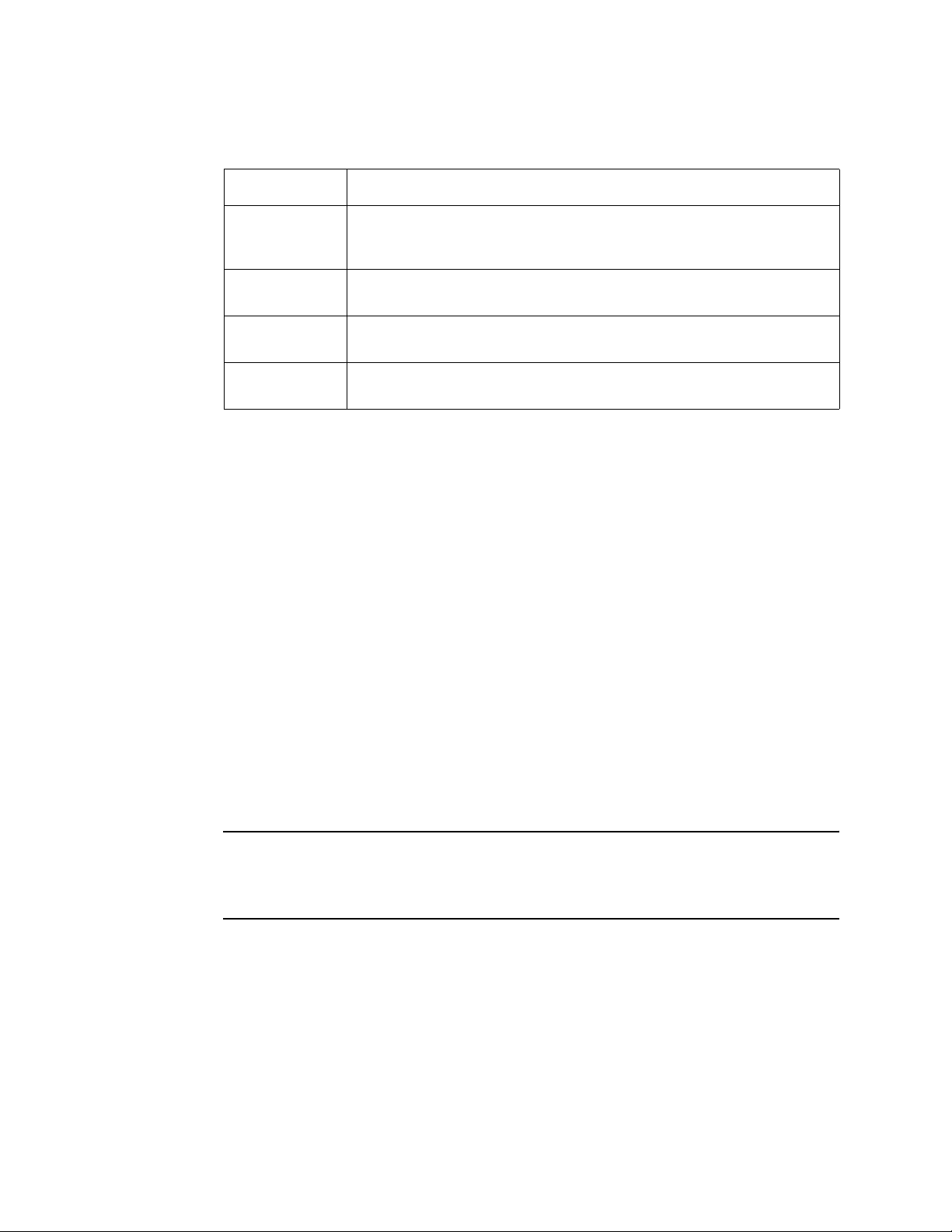

Display screen 1

(channels 1-4)

ALARM 2 light

ALARM 1 light

Display screen 2

(channels 5-8)

Status Lights

The Beacon 800 includes four status lights that indicate the current status of the monitor:

the ALARM 1 light, the ALARM 2 light, the FAIL light, and the PILOT light (see Figure 2).

PILOT Light

The PILOT light is on when the Beacon 800 is receiving incoming power, either AC or DC

power.

FAIL light

Thumbscrew

(total of 2)

Figure 2: Display Board Component Location

ESCAPE button

UP (YES) button

DOWN (NO) button

ENTER button

PILOT light

FAIL Light

The FAIL light turns on when the Beacon 800 is experiencing a fail condition. A fail

condition can be caused by a failure within the Beacon 800 or transmitter(s) wired to the

Beacon 800 (see “Chapter 6: Maintenance” on page 29).

ALARM 1 Light

The ALARM 1 light is on when the Beacon 800 is experiencing a low-level (alarm 1) or

high-level (alarm 2) gas condition.

ALARM 2 Light

The ALARM 2 light is on when the Beacon 800 is experiencing a high-level (alarm 2) gas

condition.

Program Buttons

The Beacon 800 includes four program button that allow you to enter the Configuration

Menu, navigate through the menu, update instrument and channel settings, and save

changes to the settings. The program buttons, listed in Table 2, are near the right edge of

the display board (see Figure 2).

5 • Internal Description Beacon 800 Gas Monitor Operator’s Manual

Page 9

Table 2: Beacon 800 Program Button Functions

Button Function

ESCAPE • Moves backward through the Configuration Menu

• Cancels changes you make in the Configuration Menu

• Enters the Configuration Menu (press with ENTER button)

UP (YES) • Accepts the displayed setting and proceeds to the next setting

• Changes the displayed setting

DOWN (NO) • Allows you to update the displayed setting

• Changes the displayed setting

ENTER • Saves changes you make in the Configuration Menu

• Enters the Configuration Menu (press with ESCAPE button)

Ground Stud

The ground stud is used for connecting earth ground to the Beacon 800. The ground stud

is factory wired to the GND terminal on the AC terminal strip. The ground stud is located in

the lower right corner of the main board.

Terminal Strips

The Beacon 800 includes four terminal strips for external wiring connections. See “Wiring

the Beacon 800 Gas Monitor” on page 12 for detailed wiring procedures.

Transmitter Terminal Strips

Two transmitter terminal strips are mounted to the bottom left corner of the main circuit

board (see Figure 1). These two 12-point terminal strips facilitate wiring connections to the

detector heads. The bottom terminal strip is for channels 1 through 4; the top terminal strip

is for channels 5 through 8.

Alarm Terminal Strips

Four alarm terminal strips are to the right of the transmitter terminal strips (see Figure 1).

These four 12-point terminal strips facilitate wiring connections to external alarm devices

(horn, strobe, etc.). The bottom row of alarm terminals is for alarm 1 connections; the top

row of alarm terminals is for alarm 2 connection.

NOTE: The alarm terminal strips provide external alarm connections controlled by

individual channels. The Beacon 800 also provides common alarm terminals on

the controller terminal strip. The common alarm terminals are controlled by all

active channels.

Controller Terminal Strip

The 19-point controller terminal strip is to the right of the alarm terminal strips (see Figure

1). The controller terminal strip facilitates various internal and external wiring connections.

Table 3 lists the function of each terminal.

Beacon 800 Gas Monitor Operator’s Manual Internal Description • 6

Page 10

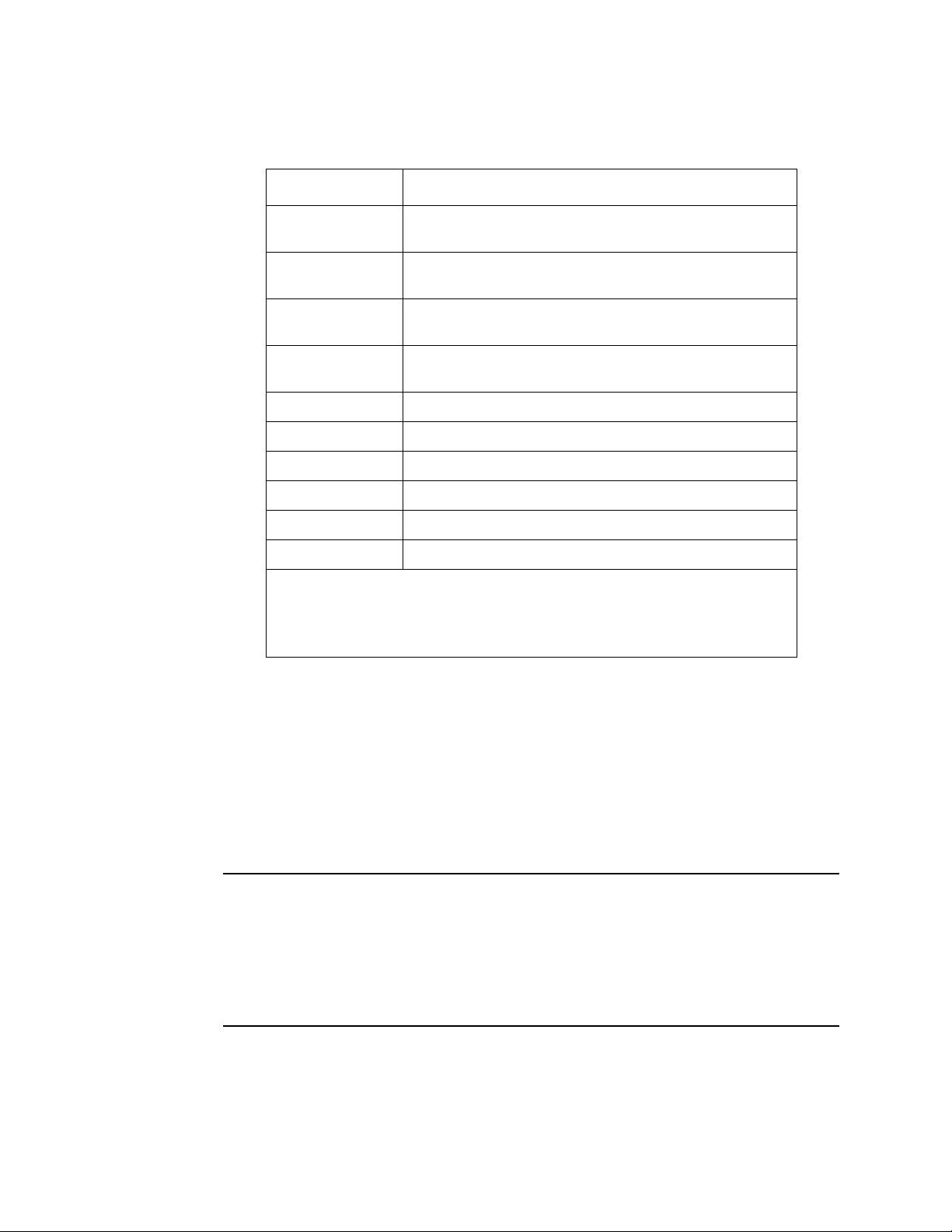

Table 3: Terminal Assignments for the Controller Terminal Strip

Terminal No. Connects to:

24VDC

(BAT-/BAT+)

ALM2

DC power source (you can use DC power as a primary or

backup power source.)

Common alarm 2 (external alarm)

1

2

(C, NO, NC)

ALM1

Common alarm 1 (external alarm)

3

(C, NO, NC)

FAIL

Common fail (external alarm)

4

(C, NO, NC)

+28V Communication

TX Communication

RX Communication

GND Communication

RESET (2) Reset switch (factory-wired)

BUZ-/BUZ+ Internal buzzer (factory-wired)

1

If used as primary power source do not make wiring connections to the AC terminal strip.

2

Activates if any gas channel recognizes an alarm 2 condition.

3

Activates if any gas channel recognizes an alarm 1 condition.

4

Activates if any gas channel or the Beacon 800 recognizes a fail condition.

AC Terminal Strip

The 3-point AC terminal strip is above the controller terminal strip (see Figure 1). The AC

terminal strip facilitates wiring connections to the AC power source. The GND terminal is

factory wired to the ground stud.

Relays

The Beacon 800 includes 16 channel relays and three common relays. Both sets of relay

contacts are single-pole, double-throw (SPDT) and are rated for 3 amps at 115 VAC

(resistive).

NOTE: In the Configuration menu, you can select normally energized, or normally de-

energized relays for each channel relay. This section describes the default

setting: normally de-energized.

The alarm 1 and alarm 2 common relays are factory-set as normally deenergized and the fail common relay is factory-set as normally energized. The

normally energized/normally de-energized setting for the alarm 1, alarm 2, and

fail common relays is not user-adjustable.

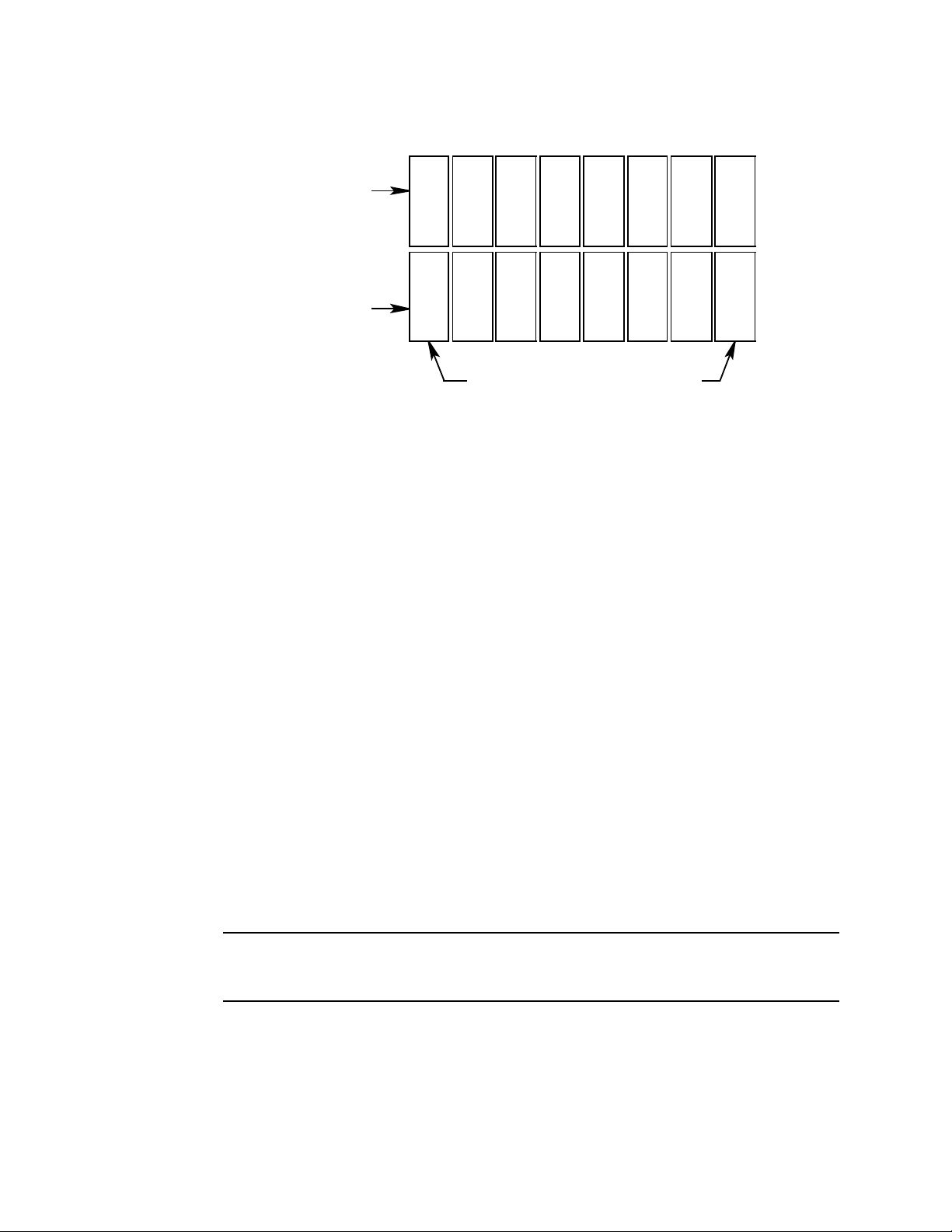

Channel Relays

The 16-channel relays are above the alarm terminal strips (see Figure 1). These relays

are dedicated to specific channels and alarm levels.

7 • Internal Description Beacon 800 Gas Monitor Operator’s Manual

Page 11

For example, the channel 1, alarm 1 relay energizes if channel 1 recognizes an alarm 1

condition. Figure 3 illustrates the allocation of the channel relays.

Alarm 2

Alarm 1

Channel 1

Figure 3: Beacon 800 Channel Relay Allocation

Channel 8

Common Relays

The three common relays are above the AC terminal strip (see Figure 1). These relays are

common for all channels.

For example, the alarm 1 common relay energizes if any channel recognizes an alarm 1

condition.

Power Switch

The power switch is to the left of the fuses (see Figure 1). The power switch turns the

incoming power source on and off at the Beacon 800. When the switch is up, the power is

on.

Power Supply

The power supply is near the top edge of the main circuit board. The power supply

receives the AC input from the external power source and converts it to a DC voltage that

is usable by the Beacon 800 circuitry.

Fuses

The Beacon 800 includes two AC fuses and one DC fuse. The fuses are housed in

extractor-type fuse holders behind the display board and to the left of the common relays.

• The AC fuses are the two 3A fuses. The AC fuses protect the AC line circuitry from

short circuit or overload.

• The DC fuse is the 6A fuse. The DC fuse protects the DC line circuitry from short

circuit or overload.

NOTE: If your Beacon 800 includes the optional Recorder Output Board or the Heavy

Duty Relay Board, please see “Chapter 7: Optional Recorder Output Board &

Heavy Duty Relay Board” on page 32 for a complete description of these options.

Beacon 800 Gas Monitor Operator’s Manual Internal Description • 8

Page 12

Chapter 3: Installation and Start Up

Overview

This chapter describes procedures showing how to mount the Beacon 800 Gas Monitor, to

make wiring connections to the monitor, and to start up the monitor.

WARNING: Perform all installation and start-up procedures in a “fresh air”

environment of normal oxygen content, and known to be free of

combustible and toxic gas. The Beacon 800 is not in operation as a

gas monitoring system until the start-up procedure is complete.

Mounting the Beacon 800 Gas Monitor

Perform the following procedure to install the Beacon 800 at the mounting site.

1. Select the mounting site. When you select the mounting site, consider the following

factors:

• Is an AC or DC power source available?

• Is there enough room to open the housing door and make wiring connections

through the conduit hubs at the bottom of the housing?

• Are the display screens and status lights visible?

2. Close and latch the housing door.

3. Position the monitor on a vertical surface at eye level (4 1/2 to 5 feet from the floor).

4. The Beacon 800 is shipped with the mounting feet positioned under the housing.

Loosen the screws that secure the feet to the housing, rotate the feet to their mounting

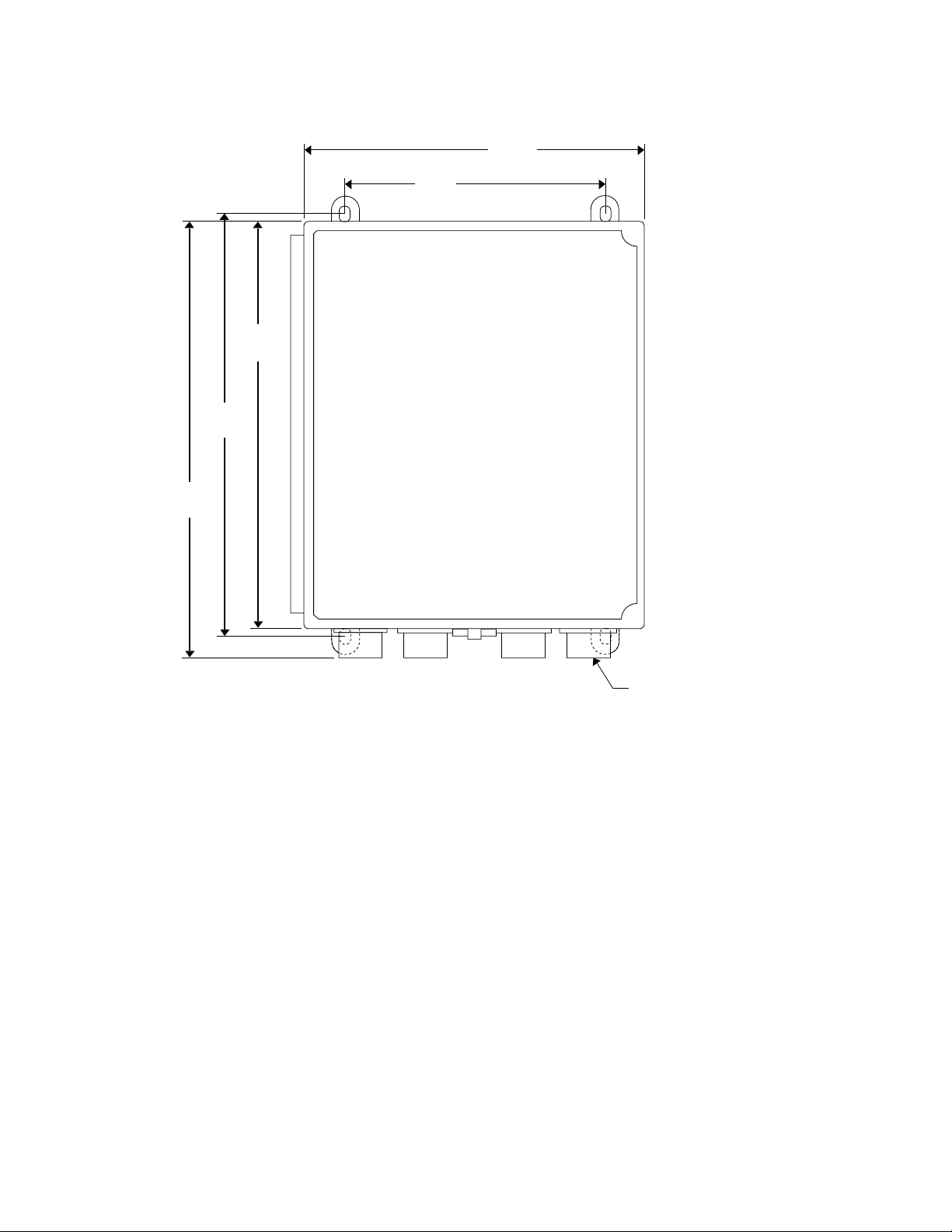

position (as shown in Figure 4), then tighten the screws.

5. Insert 1/4 in. screws through the slots in the mounting feet at each corner of the

housing to secure the housing to the mounting surface (see Figure 4).

9 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 13

(32.8 cm)

13.4 in.

(34.0 cm)

12.9 in.

12.5 in.

(31.8 cm)

8.0 in.

(20.3 cm)

10.5 in.

(26.7 cm)

Note:

The housing is

6.25 in. (15.9 cm) deep.

3/4 in. conduit hub

(total of 4 hubs)

Figure 4: Beacon 800 Gas Monitor Outline and Mounting Dimensions

Beacon 800 Gas Monitor Operator’s Manual Mounting the Beacon 800 Gas Monitor • 10

Page 14

power if 24 VDC i s the

prim ary power s our ce.

100-240 V AC

Note: Do n otconnect AC

ContactRating of 10 Amps

Resistive at 2 50 VAC for Eac h

Alarm 1 T erminalStrip f or

Channels 1 - 4 ( typical wiring)

Stud

Ground

Line (Hot)

Neutral

Ground

Set of Al arm R elay C ontac ts.

AC Power Wiring

(factory wired)

+

Alarm

Power

Device

Battery

24 VD C

Buzzer

Reset Switch

(factory wired)

(for future u se)

Communication

Powe r

Alarm D ev ice

(typical wiring)

(factory wired)

2wire4-20mA

Transm itter Termi nals

(typical)

FB (4 - 2 0 m A)

+24VDC

Devices

3wire4-20mA

Transm iter Ter minals

(typical)

Common AlarmR elay Wirin g

(DC G round)

-

Alarm

Devices

+24VDC

FB (4 - 2 0 m A) Alarm

Transmitter Wiring Individual Alarm Relay Wiring

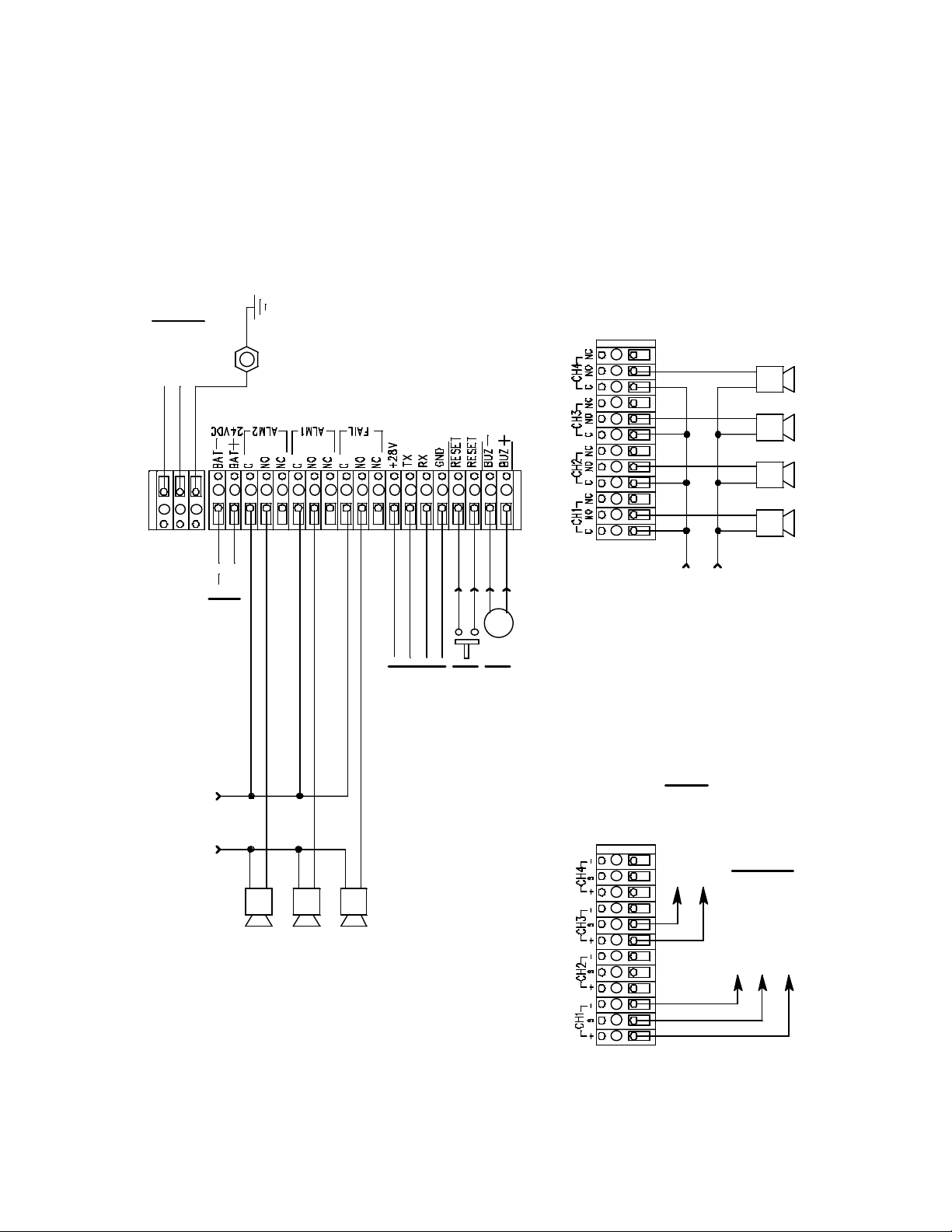

Figure 5: Beacon 800 Gas Monitor External Wiring Diagram

11 • Mounting the Beacon 800 Gas Monitor Beacon 800 Gas Monitor Operator’s Manual

Page 15

Wiring the Beacon 800 Gas Monitor

This section describes procedures to connect the AC power source, DC power source,

external alarms, and detector heads. See Figure 5 for a general wiring diagram of all

external wiring to the Beacon 800.

NOTE: All connections to building electrical systems must be installed in accordance

with local requirements and must be installed by qualified personnel.

WARNING: Make all connections to the Beacon 800 before you plug in or turn on

the AC or DC power source. Before you make any wiring adjustments,

always verify that all power sources are not live.

Accessing the Terminal Strips

Perform the following procedure to gain access to the AC and controller terminal strips,

which are located behind the display board.

1. Turn off or unplug all incoming power to the Beacon 800 at the power source end.

2. Open the housing door, then place the power switch in the OFF position.

3. Loosen the two captive thumbscrews (on the right side of the display board) that

secure the board to the standoffs, until the screws are disengaged from the standoffs.

4. Gently pull the right side of the display board out toward the housing door. (The

standoffs under the left side of the display board are hinged, which allows the display

board to move in this manner.)

Connecting the AC Power Source and Earth Ground

NOTE: If you are using DC power as the primary power source, go to the next section,

“Connecting the DC Power Source.”

Perform the following procedure to connect the AC power source to the Beacon 800.

WARNING: Verify that the power source is unplugged or turned off at the power

source end before you continue with this procedure.

1. Locate the AC terminal strip (see Figure 1 on page 4).

2. Install an appropriately rated cable bushing or conduit in the right-most conduit hub on

the bottom of the Beacon 800 housing.

3. Guide the AC power cord or wires in conduit through the right-most conduit hub on the

bottom of the Beacon 800 housing.

CAUTION: Do not route power and detector head wiring through the same conduit hub.

The power wiring may disrupt the transmission of the detector head signal to

the monitor.

Beacon 800 Gas Monitor Operator’s Manual Wiring the Beacon 800 Gas Monitor • 12

Page 16

4. Connect the AC power wires to the AC terminal strip and the earth ground wire to the

ip

A

S

Terminal Strip

# 10 ground stud as shown in Figure 6.

Hot

Neutral

GND Factory Wired to Ground Stud

LINE

NEUT

GND

C Power

ource

Earth Ground

Figure 6: AC Power Wiring

AC Terminal Str

Connecting the DC Power Source

WARNING: Verify that the power source is unplugged or turned off at the power

source end before you continue with this procedure.

DC power may be used as a primary power source. It may also be used as a backup

power source with a 24 VDC battery if AC power is the primary power source. If DC power

is the primary power source, DO NOT connect AC power.

1. Locate the controller terminal strip (see Figure 1 on page 4).

2. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800 housing.

3. Guide a DC power cord or two wires in conduit through the selected conduit hub on

the bottom of the Beacon 800 housing.

CAUTION: Do not route power and detector head wiring through the same conduit hub.

The power wiring may disrupt the transmission of the detector head signal to

the monitor.

4. Connect the DC line to the controller terminal strip as shown in Figure 7.

BAT-

BAT+

+

DC Power

Source

Figure 7: DC Power Wiring

13 • Wiring the Beacon 800 Gas Monitor Beacon 800 Gas Monitor Operator’s Manual

Controller

24VDC

Page 17

Connecting External Alarms

Perform the following procedure to connect external alarm devices to the Beacon 800.

NOTE: The alarm terminal strips include terminals that are dedicated to individual

channels and levels of alarm. The controller terminal strip includes terminals for

common alarms (dedicated to all channels).

The example used in this procedure describes connecting an external alarm

device to the channel 1, alarm 1 terminals on the alarm terminal strip.

1. Locate the applicable alarm terminal strip (see Figure 1 on page 4).

2. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800.

3. Guide the wiring of the external alarm device through the selected conduit hub on the

bottom of the Beacon 800 housing.

CAUTION: Do not route the external alarm wiring and detector head wiring through the

same conduit hub. The external alarm wiring may disrupt the transmission of

the detector head signal to the Beacon 800.

4. Connect the leads from the external alarm device to the alarm terminal strip as shown

in Figure 8.

Beacon 800

Alarm Terminal Strip

(H) +

(N) -

External

Power Source

External

Alarm Device

CH1

CNONC

(H) +

(N) -

Figure 8: External Alarm Wiring

5. Repeat steps 3 and 4 for additional external alarm devices.

Connecting RKI Detector Heads

Perform the following procedure to connect an RKI detector head to the Beacon 800.

1. Turn off Power to the Beacon 800 at the power source.

2. Open the Beacon 800 door and place the power switch in the off position.

3. See the detector head instruction manual for instructions on how to connect wires to

the detector head.

4. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800 housing.

5. Route the wires in conduit or shielded cable from the detector head through the

selected conduit hub into the Beacon 800. See Table 4 below for wire size and

Beacon 800 Gas Monitor Operator’s Manual Wiring the Beacon 800 Gas Monitor • 14

Page 18

distance guidelines. Shielded cable or wires in conduit are recommended for the 2wire and 3-wire 4 - 20 mA transmitter detector heads.

NOTE: If using shielded cable, do not connect the cable shield’s drain wire to earth

ground at the detector head. The drain wire is only connected to earth ground at

the Beacon 800.

6. Connect the wires from the detector head to the appropriate transmitter terminal strip.

See the detector head instruction manual for controller terminal connections.

CAUTION: Do not route power and detector head wiring through the same conduit hub.

The power wiring may disrupt the transmission of the detector head’s signal

to the Beacon 800.

Table 4: Wire Size Guidelines for RKI Detector Head Wiring

Number of

Detector Head Type

2-Wire 4 - 20 mA Transmitter 2 2,500 ft. 5,000 ft. 8,000 ft.

3-Wire 4 - 20 mA Transmitter 3 2,500 ft. 5,000 ft. 8,000 ft.

Wires to

Controller

Max Distanc e to

Controller w/18

Gauge Wire

Max Distance to

Controller w/16

Gauge Wire

Max Distance to

Controller w/14

Gauge Wire

Connecting User-Supplied 4 - 20 mA Transmitters

The Beacon 800 may be used with a user supplied 2-wire or 3-wire 4 - 20 mA transmitter

which runs on 24 VDC nominal (the Beacon 800 supplies 28VDC). When this is done, the

Beacon 800 is normally setup at RKI Instruments with the following channel parameters:

unit of measure, item name, and full scale. For example, “PSI AIR” with a full scale of 10

PSI.

Perform the following procedure to connect a 4 - 20 mA transmitter, which you supply, to

the Beacon 800.

1. Turn off power to the Beacon 800 at the power source.

2. Open the Beacon 800 door and turn off the power switch.

3. See the transmitter’s instruction manual for instructions on how to connect wires to the

transmitter.

4. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800 housing.

5. Route the wires from the transmitter through the selected conduit hub into the Beacon

800.

6. Connect the wires from the transmitter to the appropriate transmitter terminal strip.

See the transmitter instruction manual for controller terminal connections.

CAUTION: Do not route power and transmitter wiring through the same conduit hub. The

power wiring may disrupt the transmission of the transmitter’s signal to the

Beacon 800.

15 • Wiring the Beacon 800 Gas Monitor Beacon 800 Gas Monitor Operator’s Manual

Page 19

Figure 9 below illustrates typical transmitter wiring connections.

3-Wire Connection

2-Wire Connection

Transmitter Terminal Strip

(24 VDC)

(4 - 20 mA)

(DC Ground)

Transmitter

Beacon 800

+

FB

-

CH1

+S-

Figure 9: Generic 4 to 20 mA Transmitter Output Wiring

NOTE: If your Beacon 800 includes the recorder output board or heavy duty relay board,

see “Chapter 7: Optional Recorder Output Board & Heavy Duty Relay Board” on

page 32 for wiring instructions.

Starting Up the Beacon 800 Gas Monitor

Perform the following procedure to place the Beacon 800 into normal operation.

1. Complete the mounting and wiring procedures described earlier in this chapter.

CH1

+S-

Beacon 800

Transmitter Terminal Strip

(24 VDC)

+

(4 - 20 mA)

FB

Transmitter

2. Complete all installation procedures described in the detector head or user supplied 4

- 20 mA transmitter instruction manual.

3. Verify that all wiring connections are correct and secure and that the Beacon 800’s

power switch is in the OFF position.

4. Plug in or turn on the incoming power source (AC or DC) at the power source end.

5. Place the Beacon 800’s power switch in the ON position. RKI INSTRUMENTS

appears on the top display and BEACON 800 appears on the bottom display for a few

seconds, then WARMING UP appears for each active channel. The warm-up period

will last for one minute.

NOTE: To prevent unwanted alarms during warm up, the alarm circuits are not active

while the WARMING UP message is displayed.

6. Verify that the PILOT light is on. If the PILOT light is not on, see the troubleshooting

guide in Chapter 6, Maintenance.

7. Perform the start-up procedure for each detector head or user supplied 4 - 20 mA

transmitter as described in the detector head or transmitter instruction manual.

NOTE: If your Beacon 800 includes the optional Recorder Output Board or the Heavy

Duty Relay Board, please see “Chapter 7: Optional Recorder Output Board &

Heavy Duty Relay Board” on page 32 for a complete description of these

components.

Beacon 800 Gas Monitor Operator’s Manual Starting Up the Beacon 800 Gas Monitor • 16

Page 20

Chapter 4: Operation

Overview

This chapter describes the Beacon 800 Gas Monitor in normal operation. This chapter

also describes the Beacon 800 in alarm 1, alarm 2, and fail conditions, and suggests

responses to these conditions.

Normal Operation

Normal operation is defined as follows:

• the start-up procedure is complete.

• the Beacon 800 is not indicating an alarm 1, alarm 2, or fail condition.

• the Beacon 800 is not running the Configuration menu.

During normal operation, the Beacon 800 simultaneously displays the target gas, unit of

measure, and current gas reading for all active channels. The top screen displays

channels 1 through 4; the bottom screen displays channels 5 through 8.

:

1

2

:

3

:

4

:

:

5

6

:

7

:

8

:

The PILOT light is on indicating that the Beacon 800 is receiving incoming power.

20.9

20.9

0

%

%

0

PPM

0

PPM

0

%

%

0

PPM

0

PPM

Figure 10: Target Gas Display

E

L

OXY

E

L

OXY

CH4

L

CO

H2S

CH4

L

CO

H2S

17 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 21

Alarm Indications

This section describes the Beacon 800 in alarm 1, alarm 2, and fail conditions, and

suggests responses to these conditions. Table 4 lists the alarm indications for each

condition.

NOTE: The Beacon 800 includes alarm on and alarm off delay settings for each channel

and level of gas alarm. The alarm indications described in this section operate

according to the default delay settings. See Chapter 5: Configuration Menu for

detailed information on displaying or changing the alarm on and alarm off delay

settings.

Table 5: Visual and Audible Alarm Indications

Condition Cause Visual Indication(s)

Alarm 1 Increasing (decreasing for O2) gas

reading at or above the alarm 1

setpoint

Alarm 2 Increasing gas reading at or above

Fail • Disconnected or misconnecte d

Low

2

Battery

the alarm 2 setpoint

transmitter wiring

• Display reading below -10% of

fullscale or lower

• Malfunctioning components

No AC power and DC power

source (primary or backup) less

than 21.5 volts.

• ALARM 1 light is on

• Gas reading flashes and

alternates with ALARM-1

message

• ALARM 1 and ALARM 2

lights are on

• Gas reading flashes and

alternates with ALARM-1

and ALARM-2 messages

• FAIL light is on

• FAIL message flashes in

place of gas reading

• FAIL light is on

• Top screen displays

SUPPLY VOLTAGE IS

TOO LOW message

• Bottom screen displays LOW POWER

STANDBY- message

and actual voltage of

incoming DC power

1

Audible

Indication

Stead y tone

Stead y tone

Stead y tone

None

1

The ALARM 1 light is not on for oxygen channels.

2

If DC power is used as primary or backup power source.

NOTE: You can set the channel relays to be normally energized or normally de-

energized in the Configuration menu. The following sections describe the default

setting: normally de-energized.

Common alarm 1 and alarm 2 relays are factory-set as normally de-energized,

and the common fail relay is factory-set for normally energized. The common

relays are not user adjustable.

Beacon 800 Gas Monitor Operator’s Manual Alarm Indications • 18

Page 22

Alarm 1 Condition

This section describes the audible and visual indications for an alarm 1 condition and

suggests responses to an alarm 1 condition.

Alarm 1 Condition Indications

When the gas reading of an active channel reaches the alarm 1 setpoint, the Beacon 800

senses an alarm 1 condition. The Beacon 800 alerts you to an alarm 1 condition as

follows:

• the ALARM 1 light turns on;

• the gas reading in alarm 1 condition flashes and alternates with the ALARM-1

message;

• the buzzer sounds a steady tone;

• the common alarm 1 relay energizes;

• the applicable alarm 1 channel relay energizes.

Responding to an Alarm 1 Condition

This section suggests the following responses to an alarm 1 condition:

1. Follow your established procedure for a low-level combustible or toxic gas condition or

a decreasing oxygen condition.

2. Oxygen alarms are factory set as self-resetting and will automatically clear when the

oxygen reading rises above the alarm 1 setpoint.

3. Alarms for all other gas types are factory set as latching. After the gas reading falls

below (rises above for oxygen) the alarm 1 setpoint, press the reset switch to reset the

alarm 1 circuit. Resetting the alarm 1 circuit silences the buzzer, turns off the ALARM

1 light, resets the channel display, and de-energizes the common and channel alarm 1

relays.

NOTE: To silence the buzzer while in an alarm 1 condition, press the reset switch.

Y ou cannot de-energize the alarm 1 relays until the gas reading falls below (rises

above for oxygen) the alarm 1 setpoint.

Alarm 2 Condition

This section describes the audible and visual indications for an alarm 2 condition and

suggests responses to an alarm 2 condition.

Alarm 2 Condition Indications

When the gas reading of an active channel reaches the alarm 2 setpoint, the Beacon 800

senses an alarm 2 condition. The Beacon 800 alerts you to an alarm 2 condition as

follows:

• the ALARM 2 light turns on;

• the gas reading during an alarm 2 condition continues to flash and alternates with the

ALARM-1 and ALARM-2 messages;

• the buzzer sounds a steady tone;

• the common alarm 2 relay energizes;

• the applicable alarm 2 channel relay energizes.

19 • Alarm Indications Beacon 800 Gas Monitor Operator’s Manual

Page 23

Responding to an Alarm 2 Condition

This section suggests responses to an alarm 2 condition.

1. Follow your established procedure for a high-level combustible or toxic gas condition,

or an increasing oxygen condition.

2. Oxygen alarms are factory set as self-resetting and will automatically clear when the

oxygen reading rises above the alarm 2 setpoint.

3. Alarms for all other gas types are factory set as latching. After the gas reading falls

below the alarm 2 setpoint, press the reset switch to reset the alarm circuit. Resetting

the alarm circuit turns off the ALARM 2 light, and de-energizes the common and

channel alarm 2 relays.

NOTE: To silence the buzzer while in an alarm 2 condition, press the reset switch.

You cannot de-energize the alarm 2 relays until the gas reading falls below the

alarm 2 setpoint.

Fail Condition

This section describes the audible and visual indications for a fail condition and suggests

responses to a fail condition.

Fail Condition Indications

The Beacon 800 senses a fail condition for any of the following:

• the transmitter wiring is disconnected or incorrectly connected;

• the display reading is -10% of full scale or lower;

• the Beacon 800 or transmitter is malfunctioning.

When the Beacon 800 senses a fail condition, it alerts you as follows:

• the FAIL light turns on;

• the gas reading for the failing channel is replaced by the FAIL message;

• the buzzer sounds a steady tone;

• the common fail relay de-energizes.

NOTE: If you elected to use the channel’s alarm 2 relay as an individual fail relay in the

Configuration menu, the relay de-energizes in a fail condition. See Chapter 5:

Configuration Menu.

Responding to a Fail Condition

This section suggests responses to a fail condition.

1. Verify that the transmitter wiring is correctly and securely connected.

2. See the troubleshooting guide in Chapter 6, Maintenance.

Low Battery Condition

This section describes the audible and visual indications for a low battery condition and

suggests responses to a low battery condition. This condition only applies when DC power

is used as a primary or backup power source.

Beacon 800 Gas Monitor Operator’s Manual Alarm Indications • 20

Page 24

NOTE: When a 24 VDC battery is used as a backup power source, the Beacon 800

keeps the battery charged by providing a trickle charge from the AC power

source. If AC power is interrupted, the Beacon 800 will operate from the DC

backup battery until the battery voltage drops to 21.5 volts or less.

Low Battery Condition Indications

The Beacon 800 senses a low battery condition when:

• AC power is disconnected, misconnected, or interrupted

AND

• the DC power source is 21.5 volts or less.

When the Beacon 800 senses a low battery condition, it alerts you as follows:

• the FAIL light turns on;

• the top screen displays the SUPPLY VOLTAGE IS TOO LOW message;

• the bottom screen displays the -LOW POWER STANDBY- message and actual

voltage of incoming DC power.

Responding to a Low Battery Condition

This section suggests responses to a low battery condition.

• If DC power is the primary power source:

1. For a temporary DC power source, disconnect primary DC power at the Beacon

800, then connect a 24 VDC backup battery;

2. Determine and correct the cause of primary DC power loss.

When the DC power source rises above 22.0 volts, the Beacon 800 begins the warm

up process.

• If DC power is the backup power source:

1. Replace or recharge the 24 VDC backup battery to resume backup power

capability;

2. Determine and correct the cause of primary AC power loss.

When backup DC or primary AC power is restored, the Beacon 800 begins the warm

up process. When AC power is restored, the Beacon 800 charges the battery until it is

fully recharged. Charge time varies depending on the battery size and how much the

battery was depleted. Once the battery is fully charged, the Beacon 800 reverts to a

trickle charge to maintain the battery charge.

21 • Alarm Indications Beacon 800 Gas Monitor Operator’s Manual

Page 25

Viewing & Resetting Min/Max Readings

The Reset switch may be used to view and reset the minimum and maximum gas

readings for all active channels.

1. While the Beacon 100 is in normal operation, press and hold the Reset switch button

for 3 seconds.

2. The display will indicate MIN / MAX Display on the top display and the bottom display

will indicate Press RESET when done viewing . . . for 5 seconds before displaying

the minimum and maximum readings for all active channels. The minimum reading is

on the left and the maximum is on the right side of the display for each channel.

3. Press and release the Reset switch button to exit the min/max screen. The top display

will indicate To RESET Min/MAX Values and the bottom display will indicate Press

and HOLD RESET Button for 10 seconds and then return to normal operation.

• To return to normal operation without resetting the minimum and maximum read-

ings, do not press the Reset switch button and allow the unit to return to normal

operation.

• To reset the minimum and maximum readings, before the unit returns to normal

operation press and hold the Reset switch button until the display indicates Min/

Max Values Have Been Reset. Release the Reset switch button. The unit will

then return to normal operation.

Beacon 800 Gas Monitor Operator’s Manual Viewing & Resetting Min/Max Readings • 22

Page 26

Chapter 5: Configuration Menu

Overview

This section describes how to use the Beacon 800s Configuration menu.

With the Configuration menu, you can:

• enable/disable channels

• enter calibration mode to calibrate a detector head

• set channel parameters

• program the heavy duty relay relays (optional feature)

NOTE: Channels included with the original shipment of the Beacon 800 are set up at the

factory. If you are adding a channel to an existing Beacon 800, the channel must

be configured as described in this section before it can be an active monitoring

channel.

The Configuration menu consists of four sub menus as described in Table 6. If the heavy

duty relay board option is not installed, then the Configure Power Relays menu does not

appear.

NOTE: See “Chapter 7: Optional Recorder Output Board & Heavy Duty Relay Board” on

page 32 for a description of the Configure Power Relays menu.

Table 6: Configuration Menu Functions

Submenu Function

Enable/Disable Channel(s) Configures channels as enabled, disabled,

Calibration Mode Disables alarms so calibration

Configure Channel Settings Configures units, gas type, fullscale, and

Configure Power Relays (optional) Programs the heavy duty relays

or not used

can be performed without

unwanted alarms

alarm settings for each channel

* NOTE: This menu item only appears

if the optional heavy duty re lay board

is installed.

23 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 27

Enabling or Disabling Channels

1. To enter the Configuration menu, simultaneously press and hold the ESCAPE and

ENTER buttons for approximately 5 seconds. Release the buttons when the

Entered the Configuration Menu...

NOTE: The Configuration menu includes a 5-minute time-out feature. If you do not

perform an action within 5 minutes of the previous action, the Beacon 800

automatically returns to normal operation.

2. Press the UP (YES) button to continue.

3. Press the UP (YES) or DOWN (NO) button until the

message appears on the bottom display screen, then press the ENTER button.

4. Use the UP (YES) and DOWN (NO) buttons to select the channel (or all channels) you

want to enable or disable, then press the ENTER button.

5. Press the DOWN (NO) button. The CHANNEL USAGE setting displays on the bottom

display screen .

6. Use the UP (YES) and DOWN (NO) buttons to display the setting you want, then

press the ENTER button to select the setting. Table 6 describes the three available

settings.

Table 7: Beacon 800 Channel Usage Settings

Yo u H a ve

message appears on the top display screen.

1) Enable/Disable Channel(s)

Setting Description

CHANNEL ENABLED The Beacon 800 displays gas readings and initiates gas and channel

CHANNEL DISABLED The Beacon 800 displays DISABLED for the channel and the channel’s

CHANNEL NOT USED The Beacon 800 leaves the channel blank on the display screen.

failure alarms when appropriate.

Use this setting for normal operation when the channel has a transmitter

wired to it.

alarm circuit is not active.

Use this setting when the channel has a transmitter wired to it, but gas

readings and alarms are not required for the channel (for example if the

transmitter requires maintenance or is malfunctioning).

Use this setting when the channel does not have a transmitter wired to i t.

7. Press the ESCAPE button, then press the DOWN/NO button to return to normal

operation.

Beacon 800 Gas Monitor Operator’s Manual E nabling or Disabling Channels • 24

Page 28

Calibration Mode

This section describes how to use calibration mode to calibrate a detector head.

WARNING: The Beacon 800 is not an active gas monitoring device during the

Entering Calibration Mode

1. Assemble the calibration kit(s). See the instruction manual for each detector head for

procedures specific to that detector head.

2. Open the Beacon 800’s housing door, and locate the program buttons to the right of

the display screens.

3. Simultaneously press and hold the ESCAPE and ENTER buttons for approximately

5 seconds to enter the Configuration menu. Release the buttons when the

Entered the Configuration Menu...

NOTE: The Configuration menu includes a 5-minute time-out feature. If you do not

calibration procedure.

You Have

message displays.

perform an action within 5 minutes of the previous action, the Beacon 800

automatically returns to normal operation.

4. Press the UP (YES) button to continue.

5. Press the UP (YES) or DOWN (NO) button until the

message appears on the bottom display screen, then press the ENTER button.

The calibration time-out setting displays. If necessary, adjust this setting using the UP/

YES and DOWN/NO buttons.

NOTE: Once you enter Calibration mode, the alarm lights, buzzer, and relays are

disabled for the amount of time indicated by this setting or until you exit

Calibration mode.

The Beacon 800 automatically exits Calibration mode if you do not exit before the

calibration time-out expires. If necessary , adjust the setting from this screen.

6. Press the ENTER button to enter Calibration mode. The gas readings will alternate

with a message showing that the unit is in Calibration mode.

2) Enter Calibration Mode

Calibrating the Detector Head(s)

NOTE: All calibration adjustments must be made at the detector head.

1. Verify that the detector head is in a fresh-air environment. (If necessary, use a zeroemission air cylinder, also known as zero air, to introduce a fresh-air sample when

adjusting the zero reading below.)

2. Adjust the detector head’s zero (fresh air reading for oxygen) reading. See the

detector head’s instruction manual for instructions on how to adjust the zero reading

(fresh air reading for oxygen).

3. Apply calibration gas to the detector head’s detector and adjust the detector head’s

span reading (zero reading for oxygen). See the detector head’s instruction manual for

25 • Calibration Mode Beacon 800 Gas Monitor Operator’s Manual

Page 29

instructions on how to adjust the span (zero reading for oxygen) reading.

4. Repeat steps 1 through 3 for each detector head you wish to calibrate.

NOTE: Allow all the gas readings to decrease below the alarm points (increase above for

oxygen) before returning to normal operation to avoid unwanted alarms.

5. Press the ESCAPE button to return to normal operation.

Configure Channel Settings Menu

This section describes how to view and change channel parameters for the installed gas

channels.

1. To enter the Configuration menu, simultaneously press and hold the ESCAPE and

ENTER buttons for approximately 5 seconds to enter the Configuration menu.

Release the buttons when the

appears on the top display screen.

NOTE: The Configuration menu includes a 5-minute time-out feature. If you do not

perform an action within 5 minutes of the previous action, the Beacon 800

automatically returns to normal operation.

You Have Entered the Configuration Menu... message

2. Press the UP (YES) button to continue.

3. Press the UP (YES) or DOWN (NO) button until the

message appears on the bottom display screen, then press the ENTER button.

4. Use the UP (YES) and DOWN (NO) buttons to select the channel (or all channels) for

which you want to set parameters, then press the ENTER button.

5. Press the UP (YES) button until the parameter you want to set appears on the top

display screen. The bottom screen will ask if the current setting is O.K. Table 7 lists

the parameters you can set for a channel, and the factory set value for each

parameter.

NOTE: Use the ESCAPE button to go backwards in the menu.

6. Press the DOWN (NO) button to display the parameter on the bottom screen.

(The parameter is adjustable when it is displayed on the bottom screen.)

7. Use the UP (YES) or DOWN (NO) button to update the parameter, then press the

ENTER button to continue.

8. Repeat steps 5 through 7 to set any other channel parameters.

9. Press the UP (YES) button until the following message appears on the top display

screen.

3) Configure Channel Setting(s)

Beacon 800 Gas Monitor Operator’s Manual Configure Channel Settings Menu • 26

Page 30

Con f iguration for

CHANNEL 1

has nbee

completed

eSav These Se t t i ngs?

Press YES to SAVE

Or NO t o ABORT

Figure 11: Save/Abort Selection

10. Press the UP (YES) button to save the Configuration, then press the DOWN (NO)

button to return to normal operation.

Table 8: Channel Setting Parameters

Parameter

(Factory-Set Value)

UNITS and GAS TYPE

(Factory setting depends on

Detector Head.)

FULL SCALE

(Factory setting depends on

Detector Head.)

ALARM-1 Level

(See the Beacon 800 Detector

Head S pecifica tion sh eet for the

detector head install ed on this

channel.)

ALARM-1 ON DELAY

(1 sec)

ALARM-1 OFF DELA Y

(0 sec)

ALARM-1 (activation)

(DECREASING for oxygen,

INCREASING for all other

channel types)

ALARM-1 Relay (action)

(NORMALLY DE-ENERGIZED)

Description

The unit of measure and target gas. Select from a list of settings.

You can also create your own setting by selecting User Will

Specify.

CAUTION: Contact RKI before creating your own setting.

The maximum gas re ad ing di sp lay ed for this channel. Select from

a list of settings. Select User W ill Specify to select a full scale not

in the list.

CAUTION: Contact RKI before updating this parameter.

The gas reading at which the Beacon 800 initiates an alarm 1

condition for this channel.

The amount of time the Bea con 80 0 delay s activat ion of the ala rm

1 circuit once an alarm 1 condition is initiated.

The amount of time th e Be ac on 800 delays turning off the alarm 1

circuit once an alarm 1 condition passes.

Indicates if the alarm 1 circuit is activated by gas readings

INCREASING or DECREASING to the ALARM-1 Level.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 1

relay is de-energized in normal operation and energizes when an

alarm 1 condition is initiated.

If set as NORMALL Y ENERGIZED, the channel’s alarm 1 relay is

energized in normal operation and de-energizes when an alarm 1

condition is initiated.

ALARM-1 Relay (reset)

(SELF RESETTING for oxygen,

LA TC HIN G for al l othe r cha nn el

types)

27 • Configure Channel Settings Menu Beacon 800 Gas Monitor Operator’s Manual

If set as LATCHING, you must press the RESET button to reset

the alarm 1 circuit after the alarm 1 condition passes.

If set as SELF RESETTING, the Beacon 800 automatically resets

the alarm 1 circuit after the alarm 1 condition passes.

Page 31

Table 8: Channel Setting Parameters (Continued)

Parameter

(Factory-Set Value)

ALARM-2 Relay (used for)

(ALARM-2 Condition)

ALARM-2 Level

(See the Beacon 800 Detector

Head S pecifica tion sh eet for the

detector head install ed on this

channel.)

ALARM-2 ON DELAY

(2 min for oxygen, 1 sec for all

other channel types)

ALARM-2 OFF DELA Y

(0 sec)

ALARM-2 (activation)

(INCREASING)

ALARM-2 Relay (action)

(NORMALLY DE-ENERGIZED)

Description

If set as ALARM-2 Condition, the channel’s alarm 2 relay

activates when an alarm 2 conditi on is ini tiated for the channel.

If set as FAIL Condition, the channel’s alarm 2 relay activates

when a fail condition is initiated for the channel.

The gas reading at which the Beacon 800 initiates an alarm 2

condition for this channel.

The amount of time the Bea con 80 0 delay s activat ion of the ala rm

2 circuit once an alarm 2 condition is initiated.

The amount of time th e Be ac on 800 delays turning off the alarm 2

circuit once an alarm 2 condition passes.

Indicates if the alarm 2 circuit is activated by gas readings

INCREASING or DECRESING to the ALARM-2 Level.

If set as NORMALLY DE-ENERGIZED, the channel’s alarm 2

relay is de-energized in normal operation and energizes when an

alarm 2 condition is initiated.

If set as NORMALL Y ENERGIZED, the channel’s alarm 2 relay is

energized in normal operation and de-energizes when an alarm 2

condition is initiated.

ALARM-2 Relay (reset)

(SELF RESETTING for oxygen,

LA TC HIN G for al l othe r cha nn el

types)

NOISE FILTER

(2)

ZERO SUPPRESSION

(0.0% of the detection range in

terms of the detection units for

carbon dioxide channel types;

0.5% oxygen for oxygen

channels; 2.0% of the detection

range in terms of the detection

units for all other channel

types.)

If set as LATCHING, you must press the RESET button to reset

the alarm 2 circuit after the alarm 2 condition passes.

If set as SELF RESETTING, the Beacon 800 automatically resets

the alarm 2 circuit after the alarm 2 condition passes.

The noise filter feature helps “smooth out” jumpy or noisy signals

from the detector head. You can set the noise filter from1 to 8.

A setting of 8 produces the gre atest amoun t of sm oothin g but a lso

responds slowest to changes in the response reading.

A setting of 1 responds fa stest to c hanges in the response reading

but produces the least amount of smoothing.

The zero suppression feature helps prevent “jumpy” rea dings n ear

the normal reading.

For example, if the zero suppression sett ing is 1.0 % of f ull s cale ,

the Beacon 800 will display a reading of 0 %LEL for gas readings

from -1 %LEL to 1 %LEL.

* NOTE: The zero suppression for oxygen channels is

defined in % oxygen. For all othe r type s of channels, it is

defined in % of full scale.

Beacon 800 Gas Monitor Operator’s Manual Configure Channel Settings Menu • 28

Page 32

Chapter 6: Maintenance

Overview

This chapter describes corrective maintenance procedures for the Beacon 800 Gas

Monitor. The chapter includes a troubleshooting guide for problems you may encounter

with the Beacon 800. Procedures to replace components of the Beacon 800 are at the end

of this chapter.

Preventive Maintenance

Preventive maintenance of the Beacon 800 consists of daily, monthly, and quarterly

procedures to ensure that the detector heads remain on zero (20.9 for oxygen) in fresh air

and are responsive to the target gas. See the detector head instruction manual(s).

Troubleshooting

Table 8 describes symptoms, probable causes, and recommended actions for the most

common problems you may encounter with the Beacon 800.

NOTE: This troubleshooting guide describes controller problems only. See the detector

head instruction manual(s) for preventive maintenance procedures that apply to

the detector head(s) supplied with your Beacon 800.

Table 9: Troubleshooting the Beacon 800

Condition Symptom(s) Probable Causes Recommended Action

No Power • The PILOT light is

off.

• The display screens

are blank.

• The power wiring is

disconnected or

misconnected.

• The AC or DC fuse is

blown.

• The display cable is

disconnected or

misconnected.

1. Verify that the wiring to the power

source is correct and secure.

2. At the Beacon 800, verify that the

wiring to the AC terminal strip is

correct and secure.

3. Check the continuity of the ap pli ca ble

(AC or DC) fuse.

4. Verify that the display cable is

connected.

The display (ribbon) cable plugs into

connectors on the top left corner of

the display board (label ed J1) and on

the left edge of the main circuit board

(labeled Front Panel/Power Relay).

5. If the power difficulties continue,

contact RKI for further instruction.

29 • Overview Beacon 800 Gas Monitor Operator’s Manual

Page 33

Table 9: Troubleshooting the Beacon 800 (Continued)

Condition Symptom(s) Probable Causes Recommended Action

Frequent or

Suspect

Alarms

Flickering

Display

• The Beacon 800

alerts you to

frequent or suspect

alarms.

• The transmitter’s

fresh air readings

remain on zero

(20.9 for oxygen).

• The display

readings flicker

often.

• The Beacon 800 is

experiencing false

readings due to RFI or

EMI.

• The transmitter wiring

is disconnected,

misconnect ed, or

intermittent.

• The Beacon 800 is

experiencing false

readings due to RFI or

EMI.

• The noise filter setting

is too low.

• The zero suppression

setting is too low.

• The display screen is

malfunctioning.

1. Verify that the transmitter wiring is

properly shielded.

2. Verify that the transmitter wiring is

correct and secure.

3. Verify that power and transmitter

wiring is routed through separate

conduit hubs on the bottom of the

Beacon 800 housing.

4. Increase the alarm on delay settin g in

the Configuration menu.

5. If the frequent or suspect alarm

difficulties continue, contact RKI for

further instruction.

1. Verify that the transmitter wiring is

properly shielded.

2. Verify that the transmitter wiring is

correct and secure.

3. Verify that power and transmitter

wiring is routed through separate

conduit hubs on the bottom of the

Beacon 800 housing.

4. Increase the noise filter setting in the

Configuration menu.

5. Increase the zero suppressio n set ting

in the Configuration menu.

6. If the display difficulties continue,

contact RKI for further instruction.

Buzzer not

Working

Reset Switch

not Working

• The buzzer does not

sound an audible

alarm during alarm

conditions.

• The buzzer sounds

weak or broken.

• The buzzer does not

silence when you

press the reset

switch.

• The applicable

alarm circuit does

not reset when you

press the reset

switch after an

alarm condition

passes.

• The buzzer is

disconnected or

misconnected.

• The buzzer is

malfunctioning.

• The reset switch is

disconnected or

misconnected.

• The reset switch is

malfunctioning.

1. Verify that the wiring to the BUZ- and

BUZ+ terminals of the controller

terminal strip is correct and secure.

2. If the buzzer difficulties continue,

contact RKI for further instruction.

1. Verify that the wiri ng to the RESET (2)

terminals of the controller terminal

strip is correct and secure.

2. If the reset switch difficulties c ontinue,

contact RKI for further instruction.

Beacon 800 Gas Monitor Operator’s Manual Troubleshooting • 30

Page 34

Replacing the Fuses

The Beacon 800 includes up to three fuses. This section applies to all three fuses. To

replace other components of the Beacon 800, contact RKI Instruments, Inc. for further

information.

1. Turn off or unplug all incoming power to the Beacon 800 at the power source end.

2. Open the housing door of the Beacon 800, then place the power switch in the OFF

position. Loosen the two captive thumbscrews on the right side of the display board,

until the thumbscrews are disengaged from the standoffs.

3. Pull the right side of the display board out toward the housing door. (The standoffs

under the left side of the display board are hinged, which allow the display board to

move in this manner.)

4. Use a flat-blade screwdriver to rotate the applicable fuse holder 1/4 turn counter

clockwise. The fuse holder releases from the socket.

5. Remove the fuse holder from the socket, then remove the fuse from the fuse holder.

CAUTION: Verify that the replacement fuse is the same type and rating as the fuse you

are replacing.

6. Install the appropriate replacement fuse in the fuse holder, then place the fuse holder

in the socket.

7. Push the fuse holder into the socket, then turn the holder 1/4 turn clockwise to secure

it in the socket.

8. Place the display board in its original position, then secure the board to the standoffs

with the two screws you loosened in Step 2.

9. Plug in or turn on all incoming power to the Beacon 800 at the power source end.

10. Place the Beacon 800’s power switch in the ON position, then verify that the PILOT

light is on.

11. Close and secure the housing door.

31 • Replacing the Fuses Beacon 800 Gas Monitor Operator’s Manual

Page 35

Chapter 7: Optional Recorder Output Boar d

& Heavy Duty Relay Board

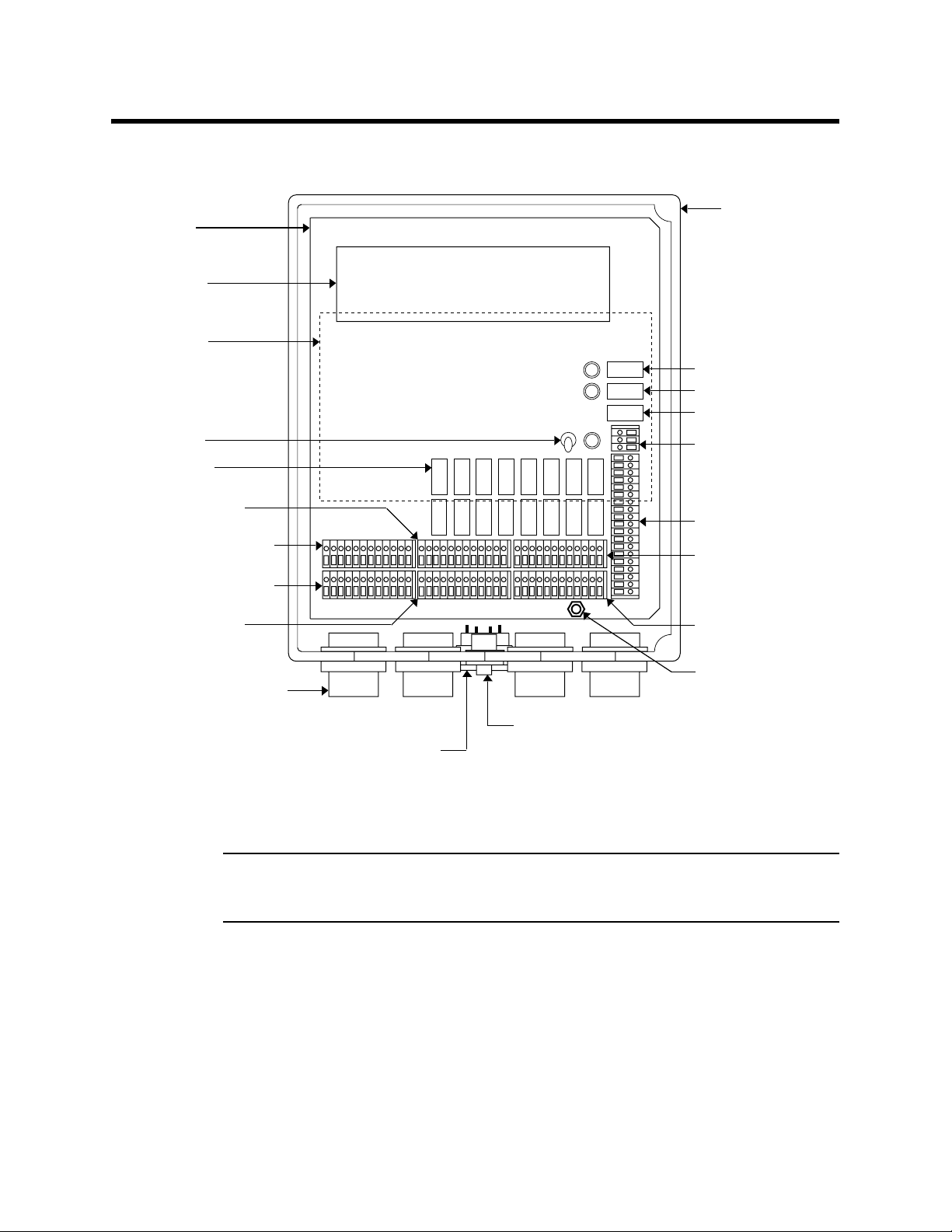

Overview

This chapter describes the optional Recorder Output Board and the optional Heavy Duty

Relay Board. It also includes procedures for wiring to the boards and instructions on

programming the heavy duty relay board’s relays. Either board may be installed alone or

both may be installed together. Figure 12 below shows both boards installed. The boards

are not field installable and must be specified at the time a Beacon 800 is ordered so that

they may be factory installed.

NOTE: Display Board Not Shown

Heavy Duty Relay Board

Recorder Output Board

Figure 12: Beacon 800 with Recorder Output and Heavy Duty Relay Board

Beacon 800 Gas Monitor Operator’s Manual Overview • 32

Page 36

Recorder Output Board

Recorder Output Board

NOTE: Display Board Not Shown

J1

TB3

J2

Recorder Output

Terminal Strip, 8X

Figure 13: Beacon 800 with Recorder Output Board

Description

When installed, the recorder output board is located below the display board and extends

out from under it so the terminal strips are accessible for wiring. When it is installed along

with a heavy duty relay board, the heavy duty relay board is installed below the display

board and the recorder output board is below the heavy duty relay board (see Figure 12).

The recorder output board connects to the main board with two cables. One 34 position

ribbon cable runs from the connector labell ed J2 in the lowe r left of the recorder outp ut

board to the analog expansion connector on the left side of the main board just above the

transmitter terminal strips. The other cable has a three position connector on each end,

but one position is unused. This two wire cable runs from J1 in the upper right of the

33 • Recorder Output Board Beacon 800 Gas Monitor Operator’s Manual

Page 37

recorder output board to TB3 on the main board below the power supply. If the heavy duty

of

Current and Voltage Output

relay board is also installed, this cable has an additional section which connects to TB5 on

the heavy duty relay board.

The recorder output board provides a two linear analog signal outputs for each active

channel, giving the reading for the channel. They are a current output and a voltage

output: 4-20 mA (milliamps) and 1-5 V (volts). Either one or both may be monitored by a

chart recorder or any other appropriate device. A current monitoring device must have

have 500 ohms resistance maximum and a voltage monitoring device must have 500

ohms resistance mini mu m.

Wiring

Perform the following procedure to connect a recording device to the recorder output

board.

1. Turn off Power to the Beacon 800 at the power source.

2. Open the Beacon 800 door and place the power switch in the off position.

3. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800 housing.

4. Route wires in conduit or shielded cable from the recording device through the

selected conduit hub into the Beacon 800.

When wiring to the 4 - 20 mA output, keep in mind that the maximum allowable

resistance including the current monitoring device and wiring can be no greater than

500 ohms.

When wiring to the 1 - 5 V output, keep in mind that the minimum allowable

resistance of the voltage monitoring device and wiring is 500 ohms.

5. Connect the wires to the recorder output board as illustrated in Figure 14. See the

monitoring device’s instruction manual for connections at the monitoring device.

Recorder Output Board

J2

(Installed in Beacon 800)

Voltage

Monitoring

Device

T ypical Wiring

Beacon 800 Gas Monitor Operator’s Manual Recorder Output Board • 34

Current

Monitoring

Device

Optional Wiring for Simultaneous Monitoring

Figure 14: Recorder Output Board Wiring

Voltage

Monitoring

Device

Current

Monitoring

Device

Page 38

6. Start up the Beacon 800 as described in “Chapter 3: Installation and Start Up” on

page 9. When the Beacon 800 start up is complete, the recorder output board will be

generating the analog output signals for all active channels.

Operation

The output of the board for a channel directly mirrors the signal from the detector head

installed on that channel at all times regardless of whether the Beacon 800 is in normal

operation or in the configuration menu. 4 mA and 1 V correspond to a gas concentration of

0; 20 mA and 5 V correspond to a full scale reading. In the case of an oxygen channel, a

normal concentration of oxygen, 20.9%, corresponds to 17.38 mA and 4.34 V. The output

at terminals for any inactive or uninstalled channels is 0 mA and 0 V.

35 • Recorder Output Board Beacon 800 Gas Monitor Operator’s Manual

Page 39

Heavy Duty Relay Board

NOTE: Display Board Not Shown

J1

Heavy Duty Relay Terminal Strip, 4X

Energized Relay Indication LED, 4X

Heavy Duty Relay Board

TB5

TB3

Figure 15: Beacon 800 with Heavy Duty Relay Board

Description

When installed, the heavy duty relay board is located below the display board. The

terminals are not accessible unless the display board, which is hinged on its left side, is

swung open. If the heavy duty relay board is installed with a recorder output board, it is

located below the display board and above the recorder output board (see Figure 12). The

heavy duty relay board connects to the main board with two cables. One 34 position

ribbon cable runs from the connector labelled J1 in the upper left of the heavy duty relay

board to the analog front panel/power relay connector on the left side of the main board

Beacon 800 Gas Monitor Operator’s Manual Heavy Duty Relay Board • 36

Page 40

and to J1 on the upper left of the display board. The other cable has a three position

connector on each end, but one position is unused. This two wire cable runs from TB5 in

the upper right of the heavy duty relay board to TB3 on the main board below the power

supply. If the recorder output board is also installed, this cable has an additional section

which connects to J1 on the recorder output board.

The heavy duty relay board provides four extra sets of relay contacts which can be used to

control devices drawing too much current to use the Beacon 800’s standard relay

contacts. The four relay contact terminal strips are located along the bottom of the heavy

duty relay board. An LED is located just to the right of each terminal strip which indicates

when that relay is energized. The relay contacts are rated 30 A at 240 VAC, and 30 A at

125 VAC. A typical use for the heavy duty relay board is controlling ventilation fans in a

parking garage.

Wiring

Perform the following procedure to connect external devices to the heavy duty relay

board.

1. Turn off Power to the Beacon 800 at the power source.

2. Open the Beacon 800 door and place the power switch in the off position.

3. Install an appropriately rated cable bushing or conduit in an unused conduit hub on

the bottom of the Beacon 800 housing.

4. Loosen the two captive thumbscrews (on the right side of the display board) that

secure the board to the standoffs, until the screws are disengaged from the standoffs.

5. Flip the right side of the display board out toward the housing door. (The standoffs

under the left side of the display board are hinged, which allows the display board to

move in this manner.)

6. Route wires in conduit or cable from a device through the selected conduit hub into

the Beacon 800.

CAUTION: Use wire or cable that is appropriately rated for the voltage and current draw

of the device(s) being used.

7. Connect the wires to the heavy duty relay board, a power source, and the device as

illustrated in Figure 16.