Rinnai RHFE-556FA, RHFE-556FTRA Owner's Operation And Installation Manual

~'l

...

·.

''il1

HOME OWNER I INSTALLER

FOR YOUR SAFETY

THIS MANUAL MUST BE READ IN ITS

ENTIRETY BEFORE OPERATING HEATER

RHFE-556FAlFTRA

ENERGYSAVER

GAS DIRECT VENT WALL FURNACE

Owner's Operation and Installation Manual

WARNING: IF THE INFORMATION IN THIS MANUAL IS NOT FOLLOWED

EXACTLY, A FIRE OR EXPLOSION MAY RESULT CAUSING PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS

OF

LIFE.

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS

AND LIQUIDS

IN

THE VICINITYOFTHIS OR ANY OTHER APPLIANCE.

WHAT TO DO IF YOU SMELL GAS

• DO NOTTRY

TO

LIGHT ANY APPLIANCE.

• DO NOT TOUCH ANY ELECTRICAL SWITCH; DO NOT USE ANY PHONE

IN YOUR BUILDING.

• IMMEDIATELY CALL YOUR GAS SUPPLIER FROM A NEIGHBOR'S

PHONE. 'FOLLOW THE GAS

SUPPI:IER'S INSTRUCTIONS.

•

. IF YOU CANNOT REACH YOUR GAS SUPPLIER, CALL THE FIRE

DEPARTMENT.

INSTALLATION AND SERVICE MUST BE PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

INSTALLER: MUST LEAVE MANUAL WITH UNIT AFTER INSTALLATION.

OWNER: RETAIN THIS MANUAL SAFELY,

FOR FUTURE REFERENCE.

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE

OR

MAINTENANCE

CAN CAUSE PROPERTY

DAMAGE,

PERSONAL

INJURY

OR

LOSS

OF

LIFE.

REFER

TO

THE

OWNER'S

INFORMATION

MANUAL

PROVIDED WITH THIS APPLIANCE. INSTALLATION AND

SERVICE

MUST

BE

PERFORMED

BY

A

QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

Rinnai Gas FF Heater

(Forced Flue)

ENERGYSAVER RHFE-556FAlFTRA

Table

of

Contents

Page

FEATURES OF THE RHFE-556 UNITS/SAFETY DEVICES 1

TECHNICAL DATA/GAS PRESSURE

SETIING

2

IMPORTANT POINTS/USAGE AND INSTALLATION MUST 3

DIMENSIONS 5

SPECIFICATIONS 6

SAFETY POINTS 8

GETIING

TO KNOW YOUR NEW RHFE-556FA/FTRA 10

CONTROL PANEL LAYOUT ,

11

REMOTE CONTROL 12

CUT-AWAY DIAGRAM 13

NOTICE BEFORE INSTALLATION 14

INSTALLATION INSTRUCTIONS

':

15

GAS CONNECTION 16

VENT LOCATION 17

FITIING

TOP SPACE+WALL CLIP 17

USA/CANADIAN VENT REGULATIONS 18

LOCATION/CLEARANCES 19

SLEEVE AND MANIFOLD INSTALLATION

21

OPERATING INSTRUCTION LABEL 25

ADDITIONAL CUSTOMER OPERATING INFORMATION 26

PROGRAMMING ON/OFF TIMERS/CLOCK(556FTRA ONLY) 32

OVERRIDE FUNCTION/USING THE REMOTE CONTROL(556FTRA ONLY) 36

TESTING/CHECK 37

PRE-SERVICE CHECK 38

TROUBLE SHOOTING 39

ERROR MESSAGES 40

MAINTENANCE/SERViCE

41

WIRING DIAGRAM 42

WARRANTY INFORMATION .43

SCHEMATIC DIAGRAM/PARTS LIST .45

RHFE-556 FLOW DIAGRAM :

5.5

,EXTENDED FLUE PIPE KIT 57

CONVERSiON 62

J

J

rJFEATURES OF THE RHFE-556FAlFTRA UNITSI

(

\"

.:..-_----------------------------.

• Clean Heating Forced Flue Type

• Easy Operation One-Touch

Ignition

• Sensible Temperature

Control

Feature

• Comfortable Room Temperature

Control

and

Display

• Warm

Air

OutletatFloor

Level (Keeps Your Feet Warm)

•

Child

Safety

Lock

• Room Temperature Setting Memory

•

Dirty

Air

Filter

Indicator

Lamp

• Energy-Saving

Economy

Setting

•

Humidifier

Tray

•

Air

Flow Directional

Louvers

• Direct Vent Easily Installed

•

Proportional

Heating Variable Capacity

• Hush! Quiet Operation )

• Modern Design Minimizes

Floor

Space Requirements

(

• Failure Message Display

• Dual Timers-556FTRA

only

"-~

/ •

Timer

Override Mode-556FTRA

only

(\,,_,_:__

~_~e_~_~_~e_at_cM_o_~_~re_~_I~_~5_6

6_7-r_R_:_A_o_~_~_ly

__1

Spark

Safety Device: Automatically shuts unit down when there is an abnormal spark at time

of ignition.

Flame Failure Device: Activated when burner flame fails. This prevents raw gas from being

released.

Overheat Switch:

Two Fusible

Links:

This device automatically cuts the gas off if the heater exceeds a

predetermined temperature. This

is

normally caused by an

obstruction

in

front of the louvers, or a blocked fan filter.

Backs up the overheat switch. If the fusible link cuts the unit off, a

service call by an authorized person is required to replace the link.

Overcurrent

Prevention Device: This is a 3 amp. glass fuse found on p.e; board. Design

to shut unit down in case of overcurrent. Iffuse

bloWs

all

indicator lamps will be "OFF".

Power Outage Safety Device:

This safety device cuts off gas passage and stops

operation.

-1-

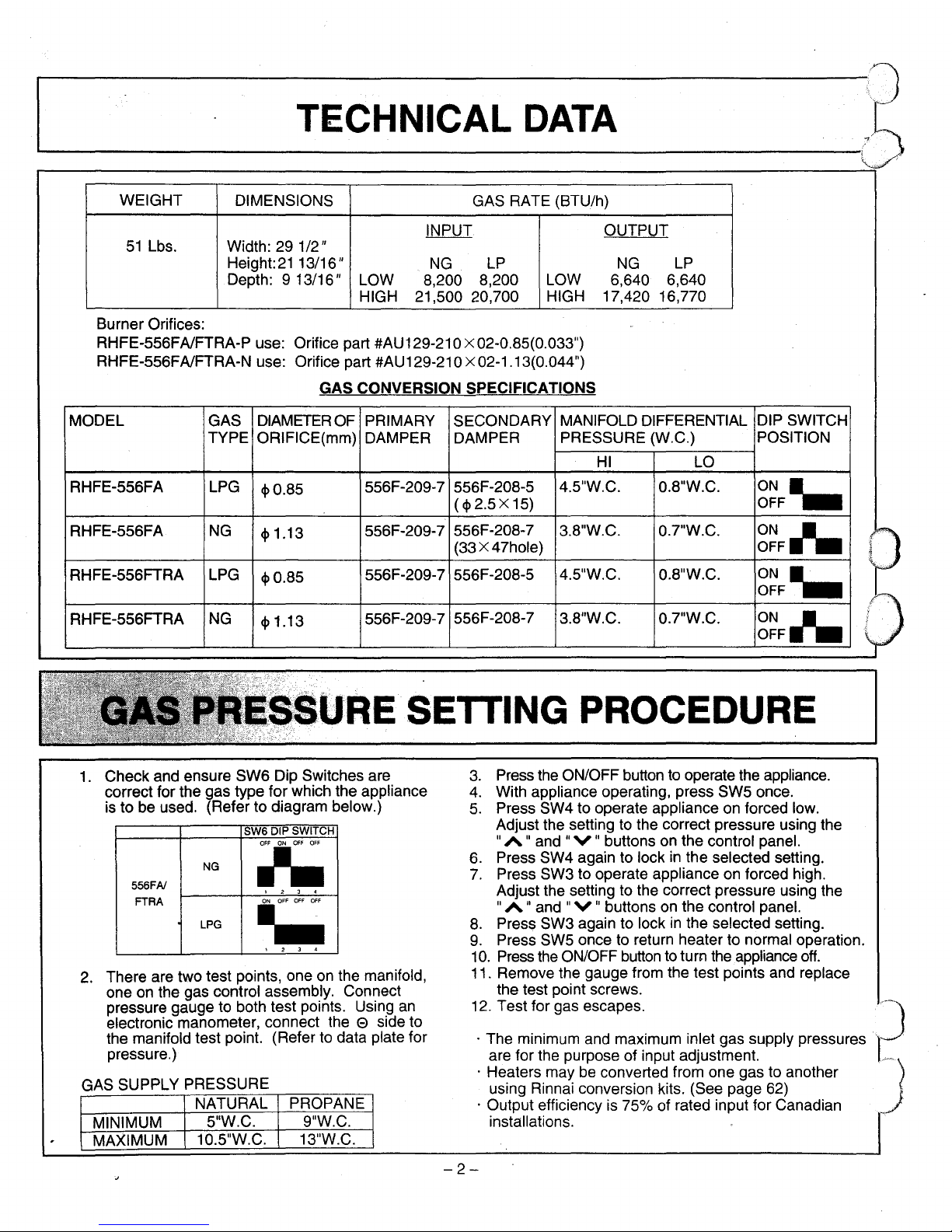

TECHNICAL

DATA

WEIGHT

DIMENSIONS GAS RATE (BTU/h)

INPUT OUTPUT

51

Lbs.

Width: 29 1/2"

Height:

21

13/16"

NG

LP

NG

LP

Depth: 9 13/16"

LOW

8,200

8,200

LOW

6,640

6,640

HIGH 21,500 20,700

HIGH 17,420 16,770

Burner Orifices:

RHFE-556FA/FTRA-P use: Orifice part #AU129-21 0

x 02-0.85(0.033")

RHFE-556FA/FTRA-N use: Orifice part #AU129-210

x02-1.13(0.044")

GAS CONVERSION SPECIFICATIONS

MODEL GAS

DIAMETER

OF

PRIMARY SECONDARY

MANIFOLD DIFFERENTIAL DIP SWITCH

TYPE ORIFICE(mm) DAMPER DAMPER

PRESSURE (W.C.) POSITION

HI

LO

RHFE-556FA LPG

<1>0.85

556F-209-7 556F-208-5

4.5"W.C. 0.8"W.C.

ON'"

(<I>

2.5 x 15)

OFF

RHFE-556FA

NG

<I>

1.13

556F-209-7

556F-208-7

3.8"W.C. 0.7"W.C.

ON

J'.

(33 x47hole)

OFF

RHFE-556FTRA LPG

<1>0.85

556F-209-7 556F-208-5

4.5"W.C. 0.8"W.C.

ON'"

OFF

RHFE-556FTRA

NG

<I>

1.13

556F-209-7

556F-208-7

3.8"W.C. 0.7"W.C.

ON

J'.

OFF

URE

SETTING PROCEDURE

1.

Check and ensure SW6 Dip Switches are

correct for the gas type for which the appliance

is

to be used. (Refer to diagram below.)

SW6 DIP SWITCH

2.

There are two test points, oneonthe manifold,

one

on

the gas control assembly. Connect

pressure gauge to both test points. Using

an

electronic manometer, connect the e side to

the manifold test point. (Refer to data plate for

pressure.)

GAS SUPPLY PRESSURE

1 2 J 4

3.

Press the ON/OFF button to operate the appliance.

4.

With appliance operating, press SW5 once.

5.

Press SW4 to operate applianceonforced low.

Adjust the setting to the correct pressure using the

"A " and

"V

" buttons

on

the control panel.

6.

Press SW4 again to lockinthe selected setting.

7.

Press SW3 to operate applianceonforced high.

Adjust the setting to the correct pressure using the

"A " and

"V

" buttons

on

the control panel.

8.

Press SW3 again to lockinthe selected setting.

9.

Press SW5 oncetoreturn heater to normal operation.

10.

Press

the

ON/OFF

buttontoturn the appliance

off.

11. Remove the gauge from the test points and replace

the test point screws.

12.

Test for gas escapes.

J'~~

· The minimum and maximum inlet gas supply pressures

·1··

.

are for the purpose of input adjustment.

r._·

J

'·.·.·

.

· Heaters maybeconverted from one gas to another

using Rinnai conversion kits. (See page

62)

· Output efficiency is 75% of rated input for Canadian

installations.9"W.C.

13"W.C.

PROPANE

~

I 2 J 4

NG

LPG

556FAI

FTRA

NATURAL

MAXIMUM 10.5"W.C.

MINIMUM 5"W.C.

-2-

~

.~

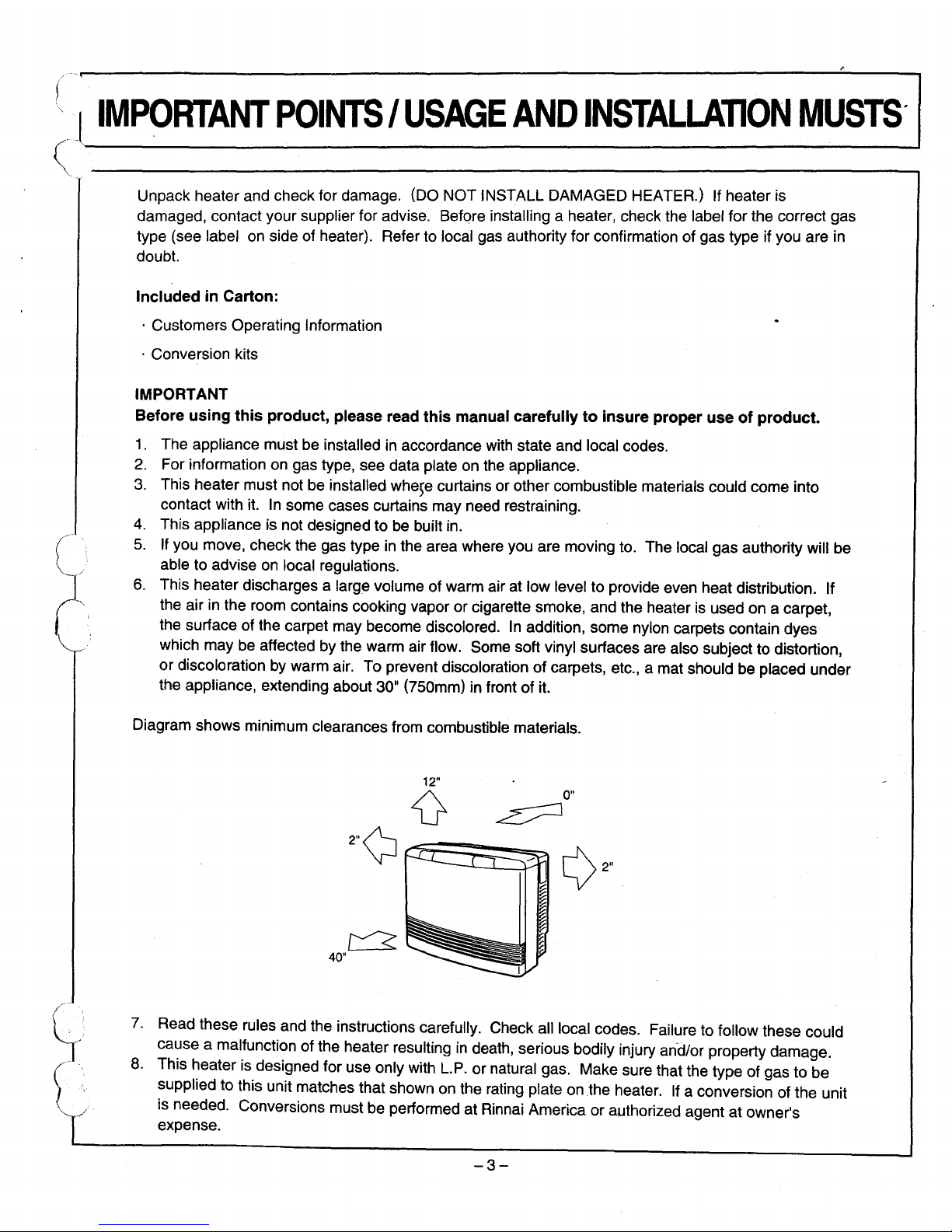

IMPORTANT

POINTSIUSAGE

AND

INSTALLATION

MUSTS-I

Unpack heater and check for damage. (DO NOT INSTALL DAMAGED HEATER.) If heater is

damaged, contact your supplier for advise. Before installing a heater, check the label for the correct gas

type (see label on side of heater). Referto local gas authority for confirmation of gas type if you are in

doubt.

Included in Carton:

. Customers Operating Information

. Conversion kits

IMPORTANT

Before using

this

product, please read

this

manual carefullytoinsure proper useofproduct.

1.

The appliance must be installedinaccordance with state and local codes.

2.

For information on gas type, see data plate on the appliance.

3.

This heater must not be installed whese curtains or other combustible materials could come into

contact with it.

In

some cases curtains may need restraining.

4.

This appliance is not designed to be built in.

5.

If you move, check the gas typeinthe area where you are moving to. The local gas authority will be

able to advise on local regulations.

6.

This heater discharges a large volume of warm air at low level to provide even heat distribution. If

the air in the room contains cooking vapor or cigarette smoke, and the heater is used on a carpet,

the surface of the carpet may become discolored.

In

addition, some nylon carpets contain dyes

which may be affected by the warm air flow. Some soft vinyl surfaces are also subject to distortion,

or discoloration by warm air. To prevent discoloration

of

carpets, etc., a mat should be placed under

the appliance, extending about 30" (750mm) in front

of

it.

Diagram shows minimum clearances from combustible materials.

~

40"

12"

{}

0"

~

7.

Read these rules and the instructions carefully. Check all local codes. Failure to follow these could

cause a malfunction of the heater resulting

in

death, serious bodily injury and/or property damage.

8.

This heater is designed for use only with L.P. or natural gas. Make sure that the type of gas to be

supplied to this unit matches that shown on the rating plate on the heater. If a conversion of the unit

is needed. Conversions must be performed at Rinnai America or authorized agent

at

owner's

expense.

-3-

9.

WARNING: Any change to this heater or its controls canbedangerous.

10. If a gas leak is suspected,

turf} heater off, turn gas supply valve off at appliance connector valve.

Open windows to ventilate area immediately and contact your dealer or gas company.

11

.00

not place clothing or flammable materials, gasoline and other flammable vapors and liquids, on or

near the heater.

12. Young children should be carefully supervised when they are

in

the same room with the heater.

13. LPG containers must not

be

installed indoors.

14. Do not use this room heater if any part has been under water. Immediately cal! a qualified service

technician to inspectthe room heater and to replace any part of the control system and any gas

control which has been under water.

15. Adequate clearances for accessibility for purposes of servicing and proper operation should

be

provided.

16. Adequate clearances around air openings should be provided.

17. Do not install

in

areas where curtains, drapes, clothing, or other moving flammables are within 12

inches of this unit.

18. Periodic examination of the venting system is required.

19. The flow of combustion and ventilation air should not be obstructed.

20. "This appliance must

be

installed in accordance with the manufacturer's instructions and the

Manufactured Home Construction and Safety Standard, Title 24 CFR, Part 3280, or a standard for

manufactured home ANSI A 22512/NFPA

501

A"

21. "This appliance must be installedinaccordance with the current standard CSA Z240.4 GAS

EQUIPPED RECREATIONAL VEHICLES AND MOBILE HOUSING. Cet appareil doit ette installe

conformement aux, exigences de la norme Z240.4 en vigeuer de I'ACNOR, Installations de gaz dans

les constructions mobiles et vehicules recreatifs."

GENERAL INFORMATION

THIS SERIESISDESIGN CERTIFIEDBY THE AMERICAN GAS

ASSOCIATION LABORATORIES (AGA) AND INTERNATIONAL

APPROVAL SERVICES (lAS).

ALTERATION OF THE ORIGINAL DESIGN INSTALLED OTHER

THAN AS SHOWN

IN

THESE INSTRUCTIONS OR USED WITH

A TYPE OF GAS NOT SHOWN

ON

THE RATING PLATE, IS

THE

RESPONSIBILITY

OF THE PERSON AND COMPANY

MARKING THE CHANGE.

· Rinnai is continually updating and improving products. Therefore, specifications are subject to

change without notice.

· Thank

you=for

purchasing Rinnai force flue gas heater.

· Please read the warranty thoroughly and keep it

in

a safe place.

-4-

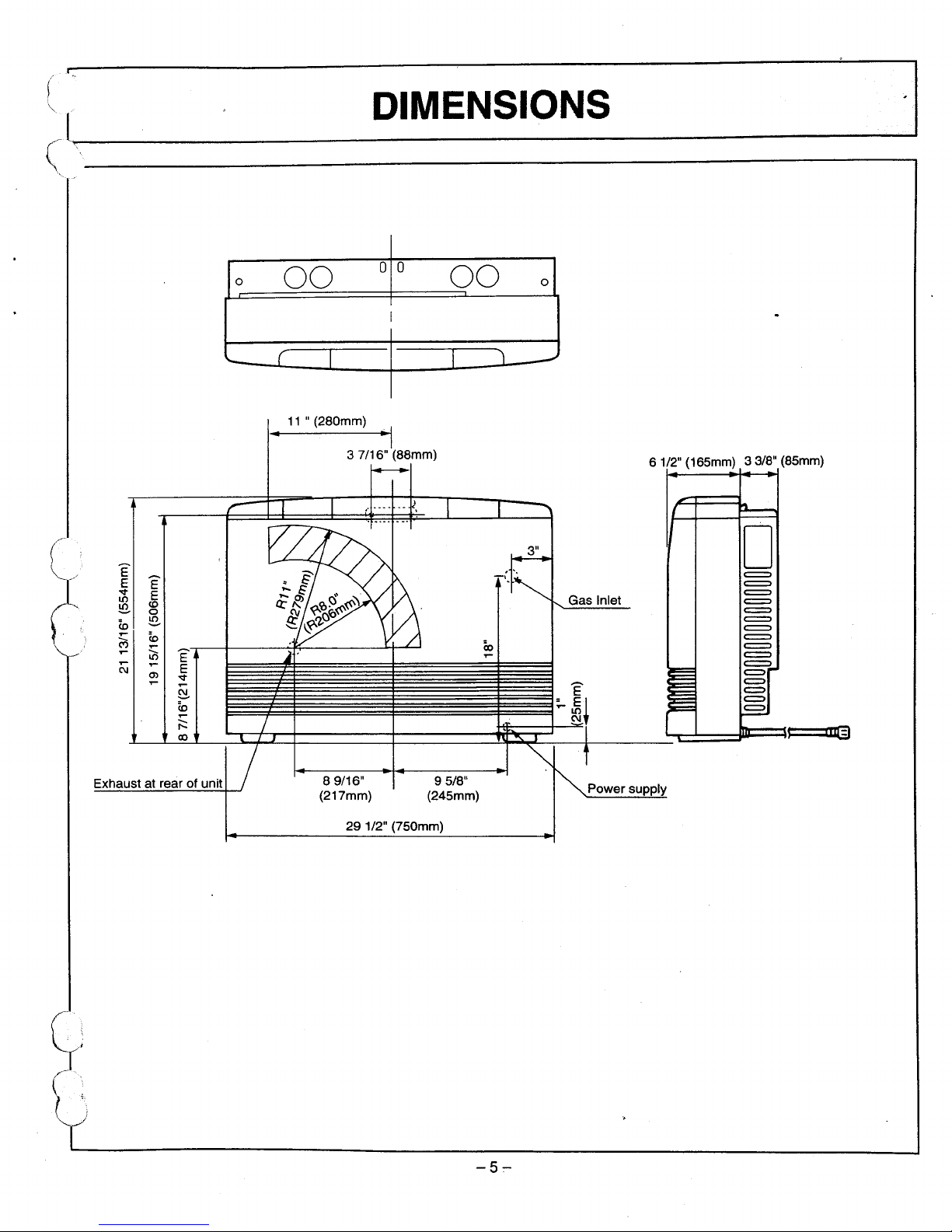

(;~~

•..

D-IM-E-N-S-IO-N-S-----........;.....·I

00

o 0

00

01

0

I

'---

(

I r

'1

.-

iJT€)

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

=

o

61/2"

(165mm)

33/8"

(85mm)

Power supply

Gas Inlet

9 5/8"

(245mm)

89/16"

(217mm)

11

"(280mm)

•

-I

3 7/16" (88mm)

E

E

E

v

E

III

!£.

(0

0

<0

!£.

....

<0

M

....

....

LO

E

N

....

E

OJ

v

....

....

~

<0

....

r:::

co

Exhaust at rear of unit

(

(

291/2"

(750mm)

-5,..-

'I

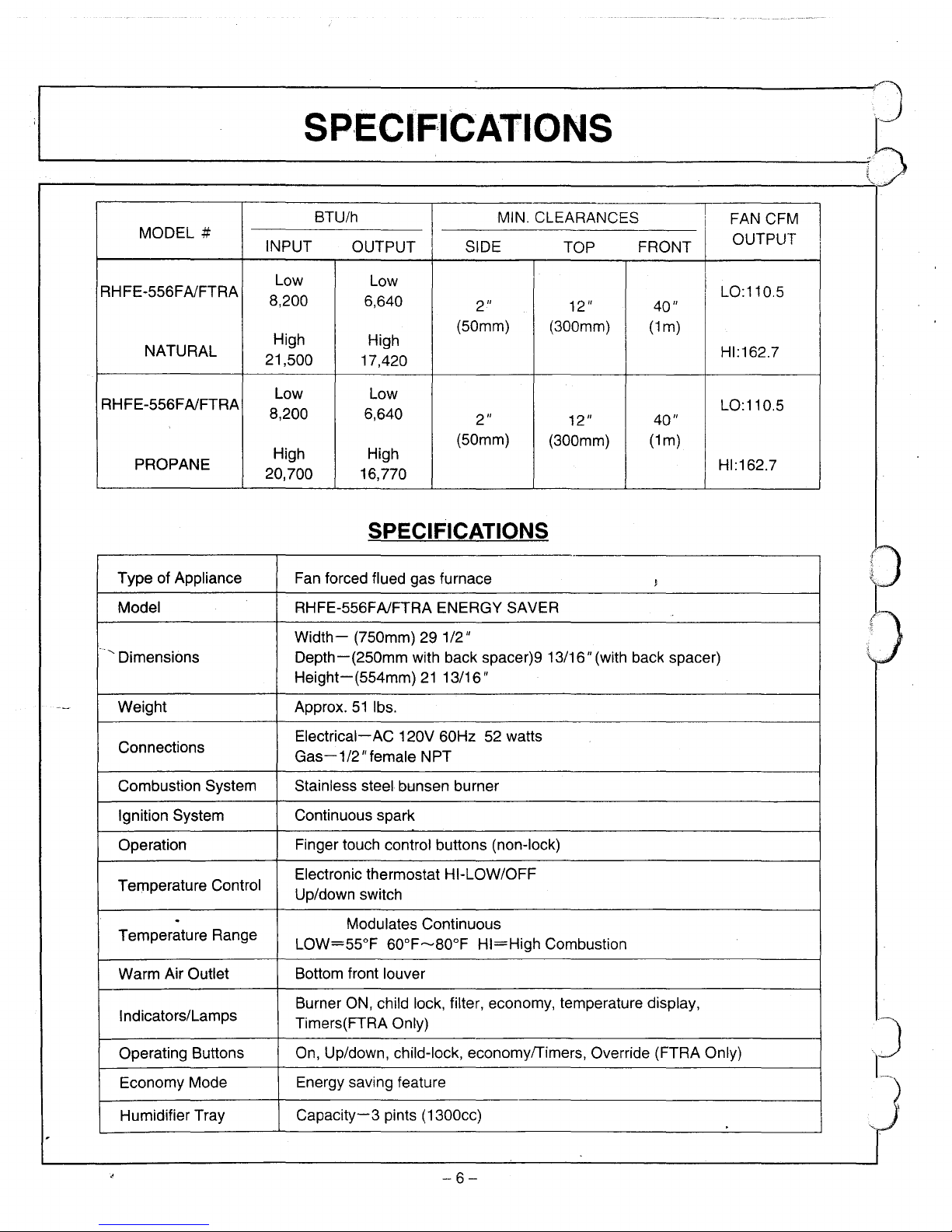

SP_

.•.

,E_C_F--.:-.,C_A_

..

~_IO_·.·

N_S---.:-

~(g

BTU/h

MIN. CLEARANCES

I

FAN

CFM

I

i

MODEL #

OUTPUT

INPUT

OUTPUT SIDE

TOP

FRONT

!

RH

FE-556FAlFTRA

Low

Low

LO:110.5

8,200

6,640

2"

12"

40"

High

(50mm)

(300mm)

(1

m)

NATURAL

High

HI:162.7

21,500

17,420

RHFE-556FAlFTRA

Low Low

LO:110.5

8,200

6,640

2"

12"

40"

High High

(50mm)

(300mm)

(1m)

PROPANE

20,700 16,770

HI:162.7

SPECIFICATIONS

Type of Appliance

Fan forced flued gas furnace

J

Model

RHFE-556FAlFTRA ENERGY SAVER

Width-

(750mm) 29 1/2"

'."

Dimensions

Depth-(250mm

with back spacer)9 13/16" (with back spacer)

Height-(554mm)2113/16"

Weight Approx.

51

Ibs.

Connections

Electrical-AC

120V 60Hz 52 watts

Gas-1/2/1female NPT

Combustion System Stainless steel bunsen burner

Ignition System

Continuous spark

Operation Finger touch control buttons (non-lock)

Temperature Control

Electronic thermostat HI-LOW/OFF

Up/down switch

.

Modulates Continuous

Temperature Range

LOW=55°F

60°F-80°F

HI=High

Combustion

Warm Air Outlet

Bottom front louver

Indicators/Lamps

Burner ON, child lock, filter, economy, temperature display,

Timers(FTRA Only)

Operating Buttons

On, Up/down, child-lock, economy/Timers, Override (FTRA Only)

Economy Mode

Energy saving feature

Humidifier Tray

Capacity-3

pints (1300cc)

,J

1.--

-6-

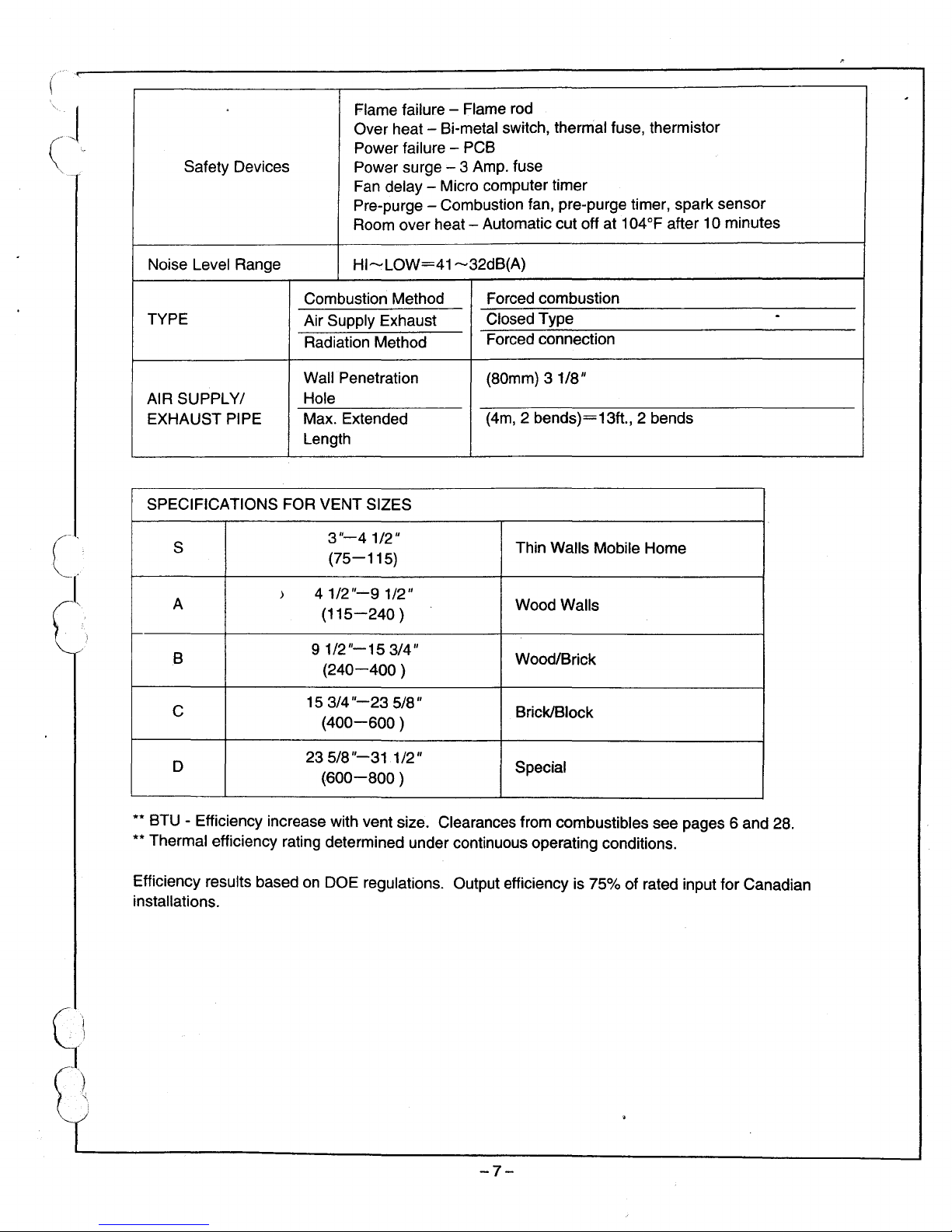

Flame failure - Flame rod

Over heat - Bi-metal switch, thermal fuse, thermistor

Power failure - PCB

Safety Devices Power surge - 3 Amp. fuse

Fan delay - Micro computer timer

Pre-purge - Combustion fan, pre-purge timer, spark sensor

Room over heat - Automatic cut off at 104°F after 10 minutes

Noise Level Range

HI-LOW=41-32dB(A}

Combustion Method

Forced combustion

TYPE

Air Supply Exhaust

Closed Type

.

Radiation Method

Forced connection

Wall Penetration

(80mm) 3

1/8"

AIR SUPPLY/

Hole

EXHAUST PIPE

Max. Extended

(4m,

2 bends}=13ft., 2 bends

Length

SPECIFICATIONS FOR VENT SIZES

S

3"-41/2"

Thin Walls Mobile Home

(75-115)

A

>

4

1/2"~9

1/2"

Wood Walls

(115-240

)

B

91/2"-153/4"

Wood/Brick

(240-400

)

C

15 3/4

"-23

5/8"

Brick/Block

(400-600

)

D

235/8"-31

1/2"

Special

(600-800

)

** BTU - Efficiency increase with vent size. Clearances from combustibles see pages 6 and 28.

** Thermal efficiency rating determined under continuous operating conditions.

Efficiency results based

on

DOE regulations. Output efficiency is 75% of rated input for Canadian

installations.

-7-

SAFETY·POINTS

i/l

l)

'------------'---------1f~)

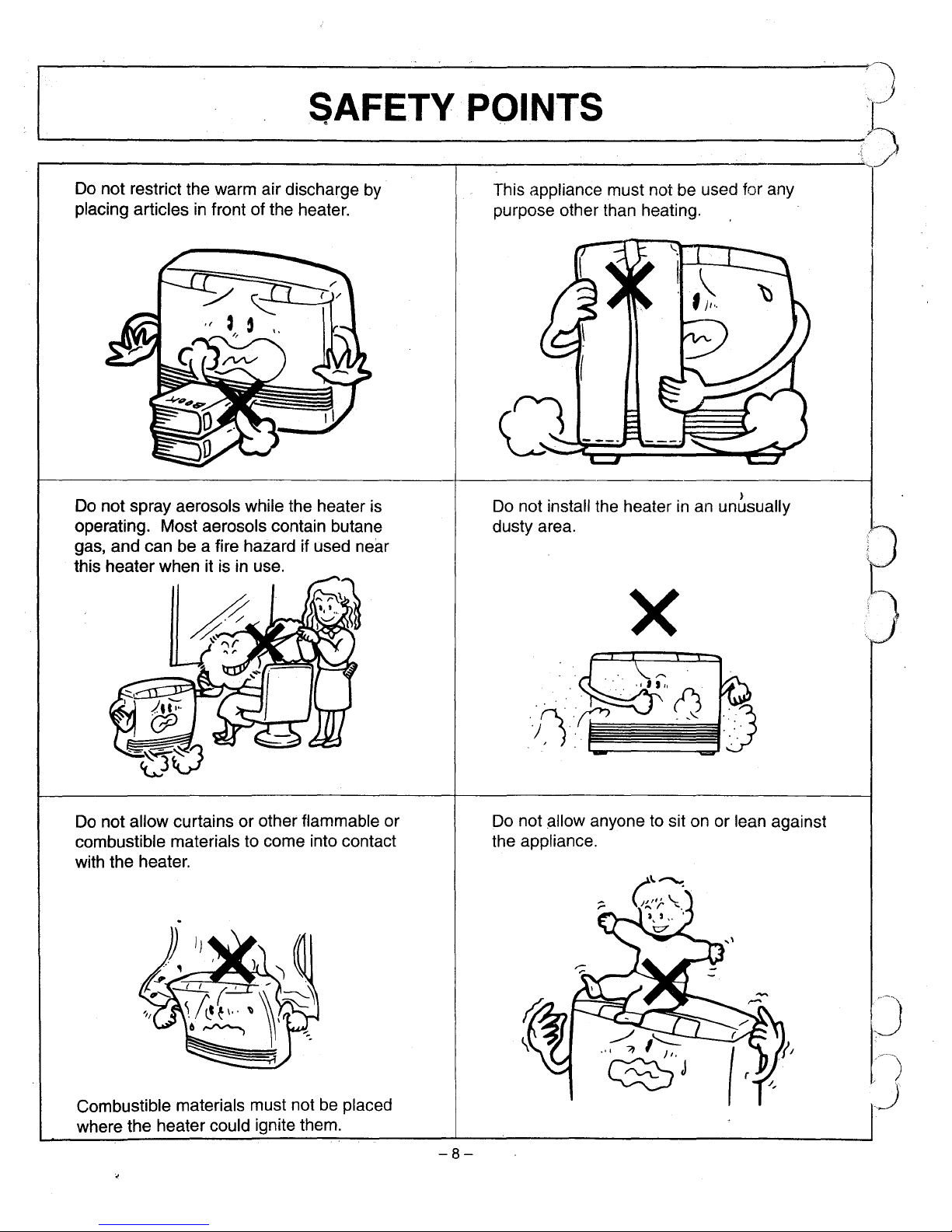

Do not restrict the warm airdischarge by

placing articles

in

front of the heater.

Do not spray aerosols while the heater is

operating. Most aerosols contain butane

gas, and can be a fire hazard if used

near

this heater when it isinuse.

Do not allow curtains or other flammable or

combustible materials to come into contact

with the heater.

Combustible materials must not

be

placed

where the heatercould ignite them.

-8-

This appliance must not be used for any

purpose other than heating.

Do not install the heater

in

an un6sually

dusty area.

x

Do not

allOW

anyone to sit on or lean against

the appliance.

,J

/)

/J

~;_,

S_A_F_E_T_y_P_O_IN_T_S

-1

"

("

~l

c:

s

·····;·:

..

·1

[

..

--.'.\

"

;1

/

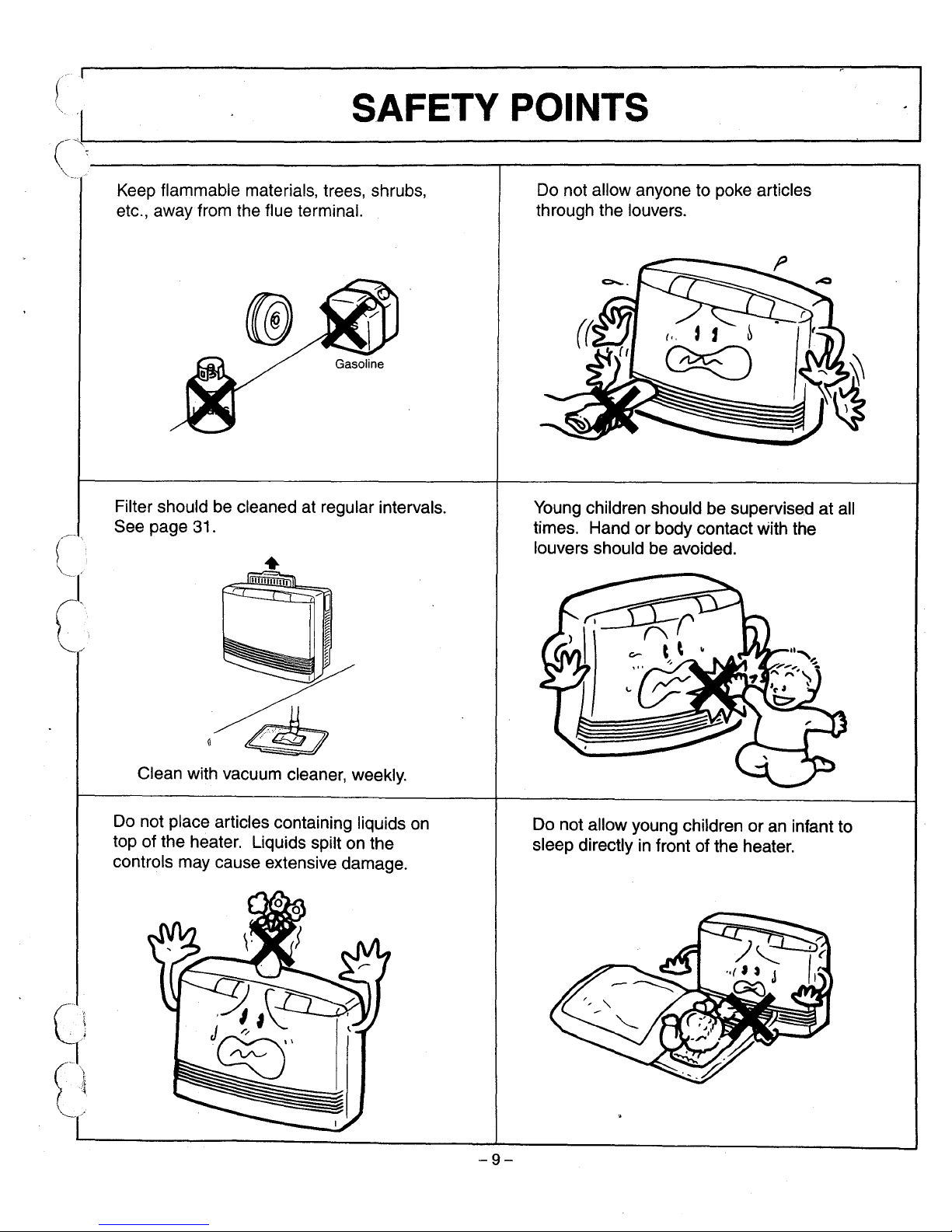

Keep flammable materials, trees, shrubs,

etc., away from the flue terminal.

Filter should be cleaned at regular intervals.

See page 31.

Clean with vacuum cleaner, weekly.

Do not place articles containing liquids on

top of the heater.

liquids

spilt on the

controls may cause extensive damage.

-9-

Do not allow anyone to poke articles

through the louvers.

Young children should be supervised at all

times. Hand

or

body contact with the

louvers should be avoided.

Do not allow young children

or

an infantto

sleep directly

in

front of the heater.

GETTING

TOKNO\lvYOUR

NEW RHFE-556 i

J

'-------------'------:;()

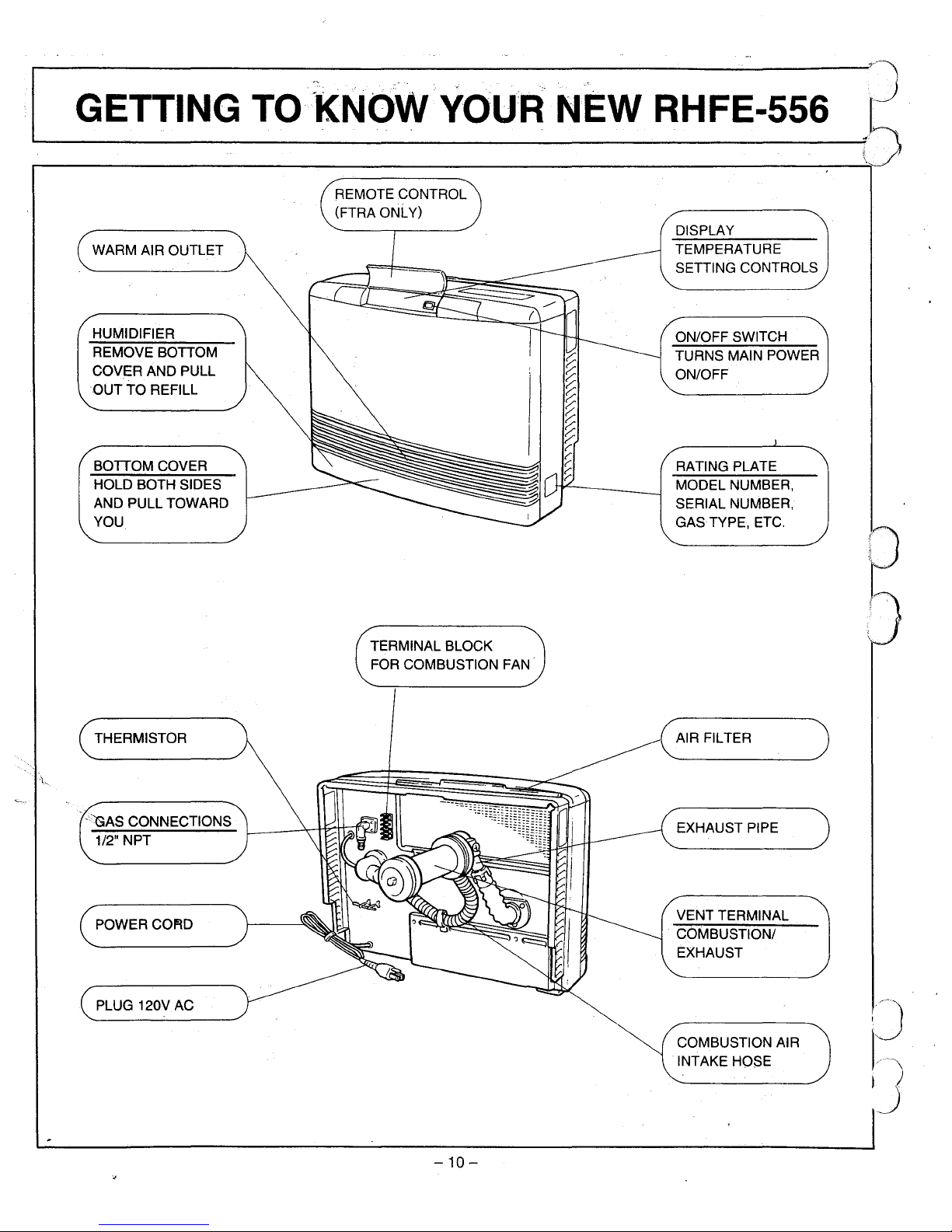

REMOTE CONTROL

(FTRA ONLY)

WARM AIR OUTLET

HUMIDIFIER

REMOVE BOTTOM

COVER AND PULL

OUT

TO REFILL

BOTTOM COVER

HOLD BOTH SIDES

AND PULL TOWARD

YOU

TERMINAL BLOCK

FOR COMBUSTION FAN'

DISPLAY

TEMPERATURE

SETTING CONTROLS

ON/OFF SWITCH

TURNS MAIN POWER

ON/OFF

RATING PLATE

MODEL NUMBER,

SERIAL NUMBER,

GASTYPE, ETC.

THERMISTOR

(AIR

FILTER

)

POWERCOfitD

PLUG 120V AC

-10

-

EXHAUST PIPE

VENT TERMINAL

COMBUSTION/

EXHAUST

COMBUSTION AIR

INTAKE HOSE

(1"...--..

C_O_N_T_RO_L_··

_PA_N_E_L_L_/4_~_O_U_T

'1

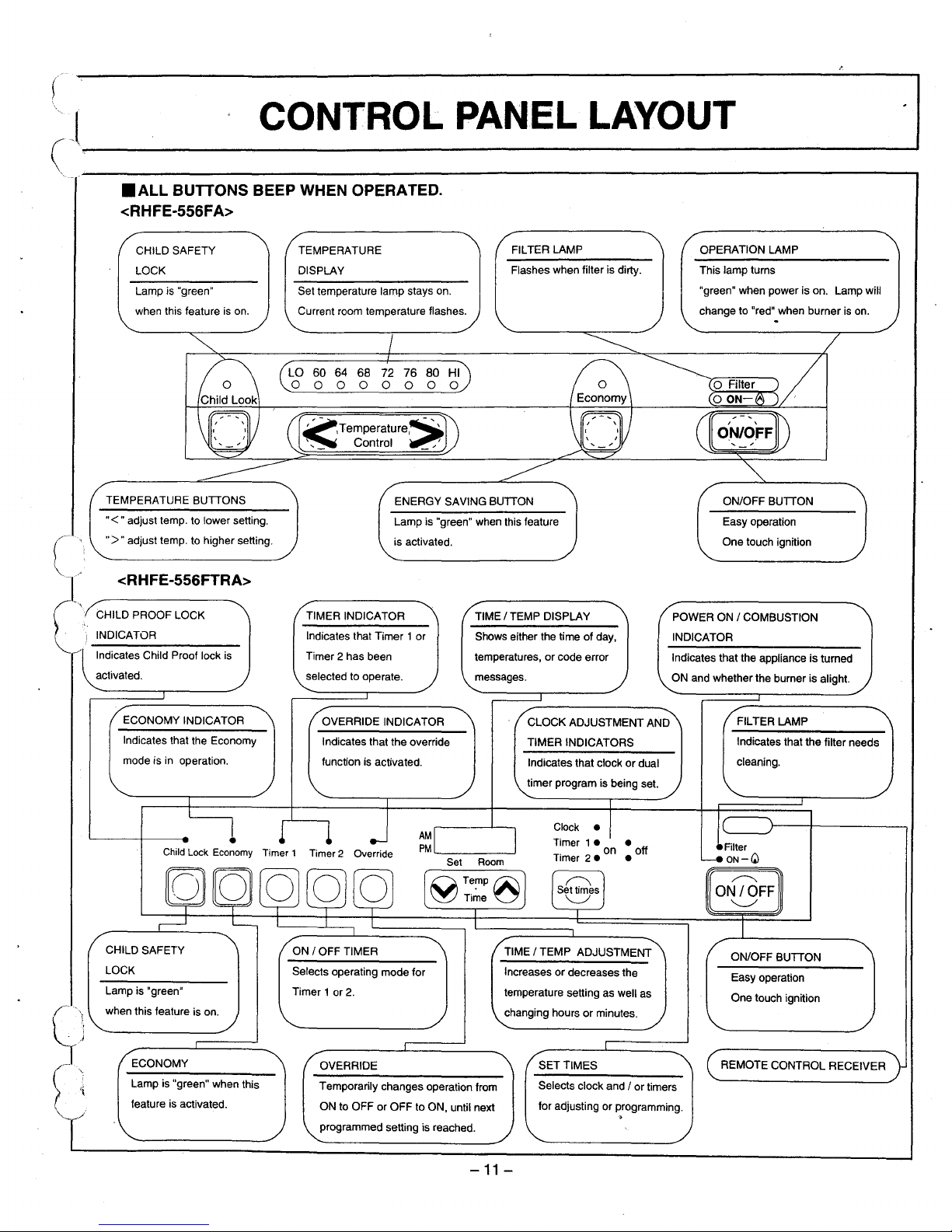

• ALL BUTTONS BEEP WHEN OPERATED.

<RHFE-556FA>

CHILD SAFETY

LOCK

Lamp is "green"

when this feature

is

on.

TEMPERATURE

DISPLAY

Set temperature lamp stays on.

Current room temperature flashes.

FILTER LAMP

Flashes when filter is dirty.

OPERATION LAMP

This lamp turns

"green" when power is on. Lamp will

change to "red" when burner

is

on.

60 64 68

000

ENERGY SAVING BUTTON

Lamp is "green" when this feature

is activated.

TEMPERATURE BUTTONS

"<"

adjust temp. to lower selling.

">

..

adjust temp. to higher selling.

<RHFE-556FTRA>

CHILD PROOF LOCK

INDICATOR

Indicates Child Proof lock is

activated.

TIMER INDICATOR

Indicates that Timer 1 or

Timer

2 has been

selected to operate.

TIME / TEMP DISPLAY

Shows either the time

of

day,

temperatures, or code error

messages.

ON/OFF BUTTON

Easy operation

One touch ignition

POWER ON / COMBUSTION

INDICATOR

Indicates that the appliance is turned

ON and whether the burner is alight.

Indicates that the filter needs

cleaning.

ON/OFF BUTTON

FILTER LAMP

Easy operation

One touch ignition

REMOTE CONTROL RECEIVER

Clock

•

Timer

1 •

on

• off

Timer

2.

•

Selects clock and / or timers

for adjusting or programming.

.

Indicates that clockordual

timer program is being set.

CLOCK ADJUSTMENT AND

TIMER INDICATORS

SET TIMES

TIME / TEMP ADJUSTMENT

Increases or decreases the

temperature selling as well as

changing hours

or

minutes.

AM

PM

'--

--'

OVERRIDE INDICATOR

Indicates that the override

function is activated.

Temporarily changes operation from

ON to OFF or OFF to ON, until next

programmed selting is reached.

OVERRIDE

Selects operating mode for

Timer

lor

2.

ON / OFF TIMER

•

Child

Lock

Economy

Timer 1 Timer 2 Override

ECONOMY

Lamp is "green" when this

feature is activated.

Indicates that the Economy

mode is

in

operation.

ECONOMY INDICATOR

Lamp is "green"

when this feature is on.

CHILD SAFETY

LOCK

-11-

""":,.REMOTE

CONTROL

"""~

[J

L..-.-

;")

o

w

en

a:

w

>

w

a:

~

U>

•

iii

~.~

Z

::>

WI-

cal:'

C

Ql Ql

§

ca

C:

z

~

U>

E

~~

~ ~

(j;

"::>

c:li;

~ -

lD

o

f1

iii

~;;

U>

Ql

LL

Ql

QlC-

LL

.r:

:::i:c

U>

E

0

U>

~<

~~

c-

o

U

Ql

CiS

E£

~

i

.r:

Ql

:5

~-~

-ca

f1

::>

Ql C

c-ca

OE

••

!

I-

Z

o

a:

LL

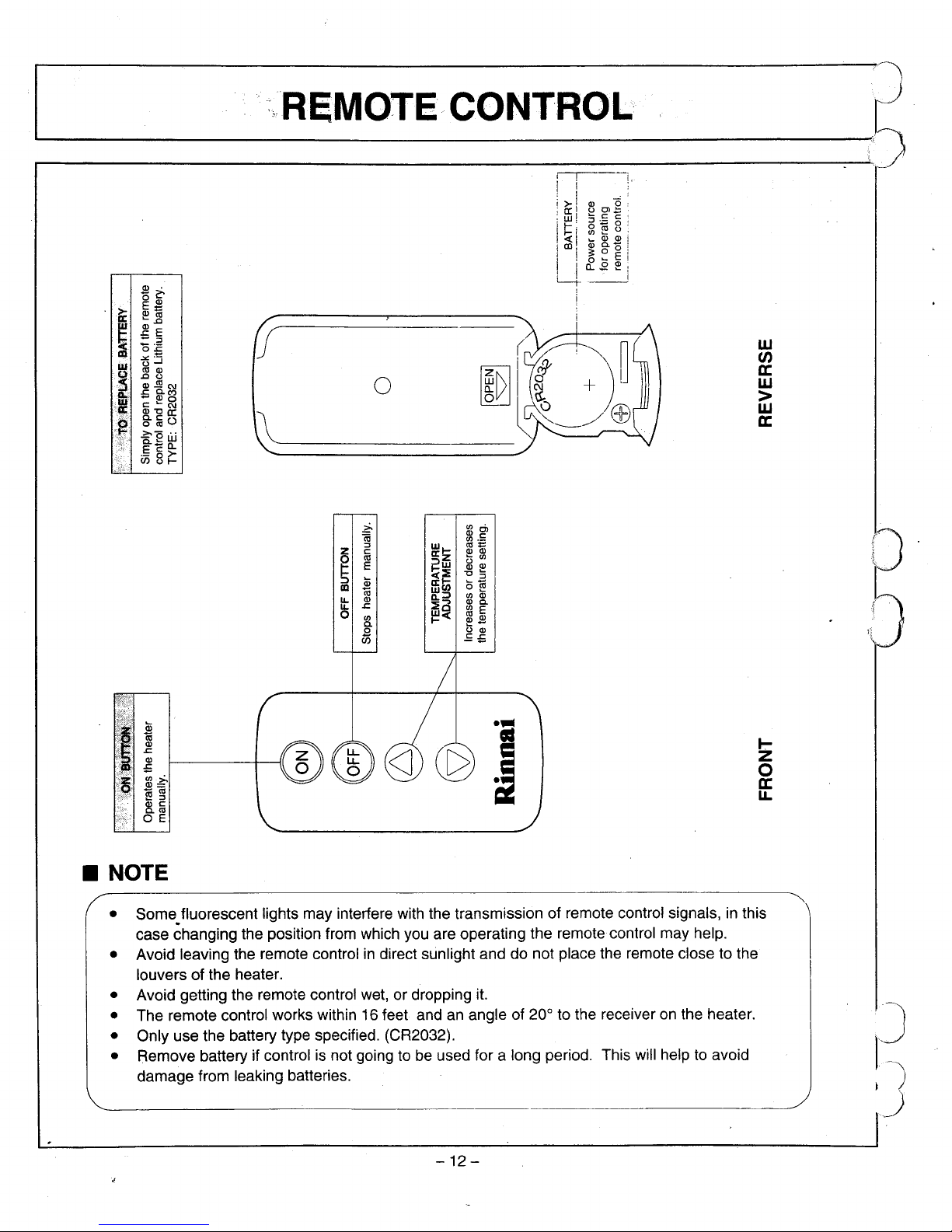

• NOTE

• Some.fluorescent lights may interfere with the transmission of remote control signals,inthis

case changing the position from which you are operating the remote control may help.

• Avoid leaving the remote control

in

direct sunlight and do not place the remote close to the

louvers of the heater.

• Avoid getting the remote control wet, or dropping it.

• The remote control works within 16 feet and

an

angle of 20° to the receiveronthe heater.

• Only use the battery type specified. (CR2032).

• Remove battery if control

is

not going to be used for a long period. This will help to avoid

damage from leaking batteries.

-12

-

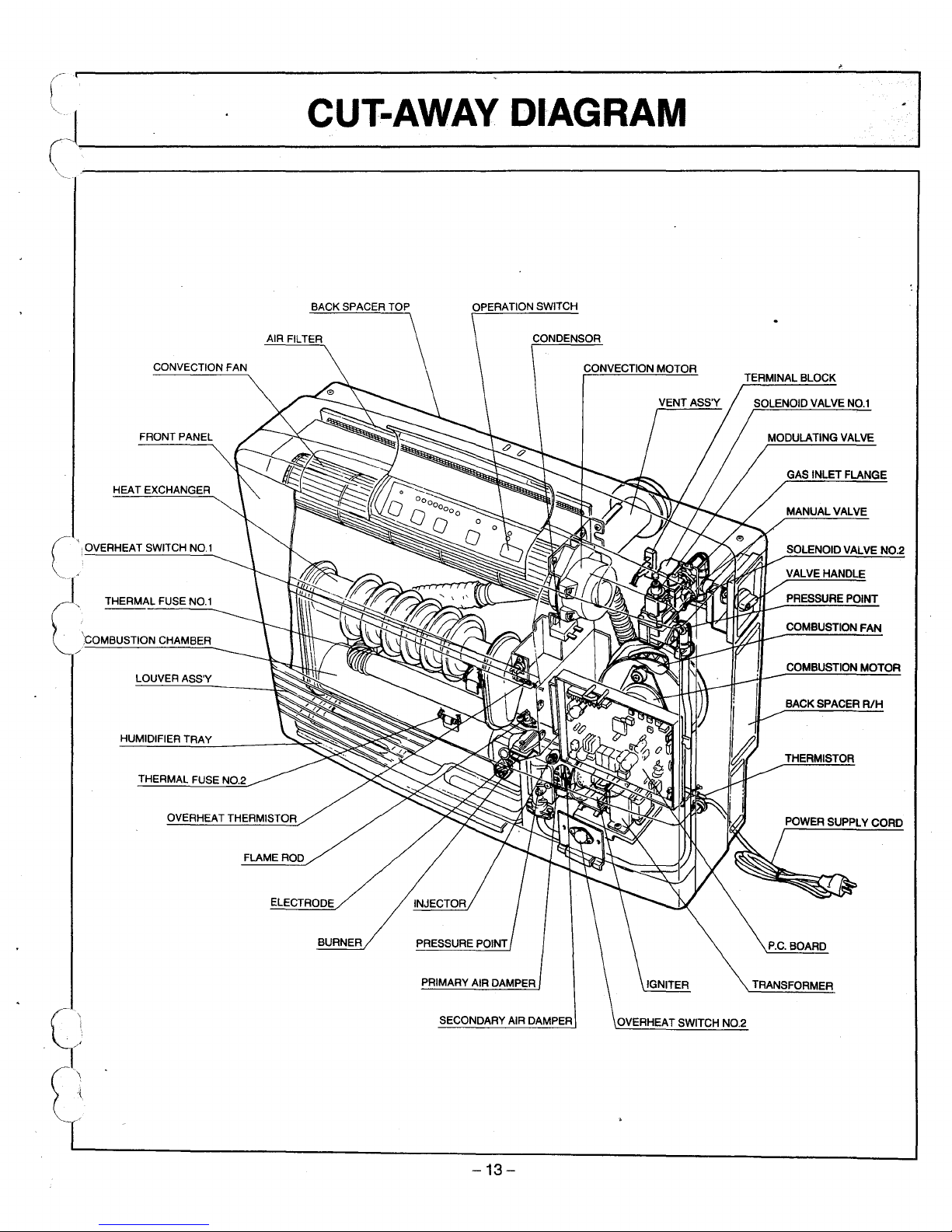

~;"""'---"

C_UT:_-_AW_,_AY_"

_D_IA_G_R_A_M

'/

\

~~-

FRONT

PANEL

LOUVER

ASS'Y

GAS

INLET FLANGE

COMBUSTION

MOTOR

COMBUSTION

FAN

PRESSURE

POINT

SOLENOID

VALVE

NO.2

VALVE

HANDLE

BACK

SPACER

R/H

THERMISTOR

P.C.BOARD

MODULATING

VALVE

TRANSFORMER

OVERHEAT

SWITCH

NO.2

CONVECTION MOTOR

SECONDARY

AIR

DAMPER

PRIMARY

AIR

DAMPER

ELECTRODE

BURNER

CONVECTION

FAN

OVERHEAT

THERMISTOR

FLAME

ROD

THERMAL

FUSE

NO.2

HUMIDIFIER

TRAY

HEAT

EXCHANGER

THERMAL

FUSE

NO.1

':COMBUSTION

CHAMBER

r\

OVERHEAT

SWITCHNO1

I

-13-

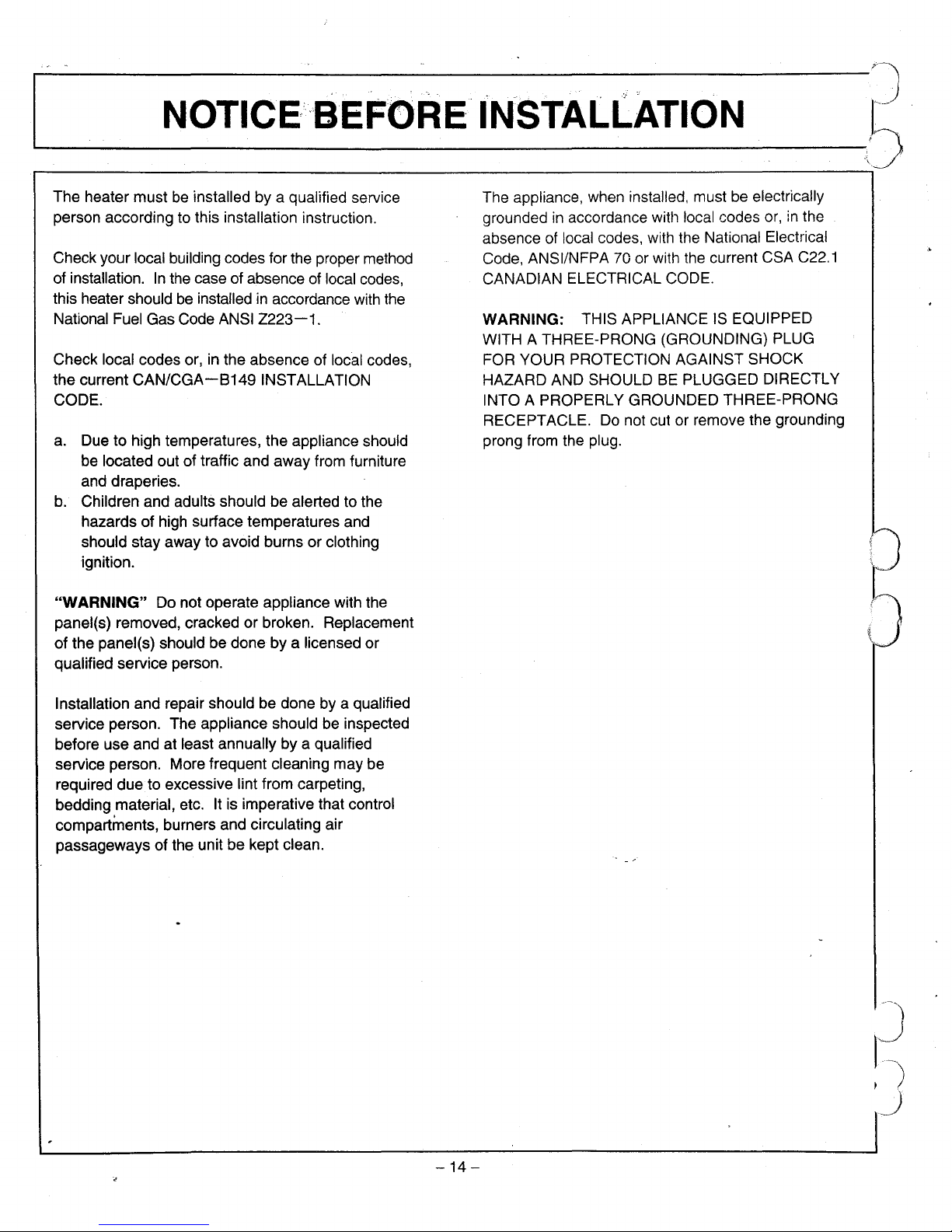

NOTICE/BEFORE INSTALL.ATION

;J

'------------\')

The heater mustbeinstalled by a qualified service

person according to this installation instruction.

Check your local building codes for the proper method

of installation.

In

the case of absence of local codes,

this heater should

be

installedinaccordance with the

National Fuel Gas Code ANSI

Z223-1.

Check local codes or,inthe absence of local codes,

the current

CAN/CGA-B149

INSTALLATION

CODE.

a.

Due to high temperatures, the appliance should

be located out of traffic and away from furniture

and draperies.

b.

Children and adults should be alerted to the

hazards of high surface temperatures and

should stay away to avoid burns or clothing

ignition.

"WARNING" Do not operate appliance with the

panel(s) removed, cracked or broken. Replacement

of the panel(s) should be done by a licensed or

qualified service person.

The appliance, when installed, must

be

electrically

grounded

in

accordance wittl local codes

or,inthe

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 or with the current CSA

C22.1

CANADIAN ELECTRICAL CODE.

WARNING: THIS APPLIANCE

IS

EQUIPPED

WITH A THREE-PRONG (GROUNDING) PLUG

FOR YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD

BE

PLUGGED DIRECTLY

INTO A PROPERLY GROUNDED THREE-PRONG

RECEPTACLE. Do not cut or remove the grounding

prong from the plug.

2

~(J

..

'

\".'

.

Installation and repair should be done by a qualified

service person. The appliance should be inspected

before use and at least annually by a qualified

service person. More frequent cleaning may be

required due to excessive lint from carpeting,

bedding material, etc. It is imperative that control

compartments, burners and circulating air

passageways of the unit be kept clean.

-14

-

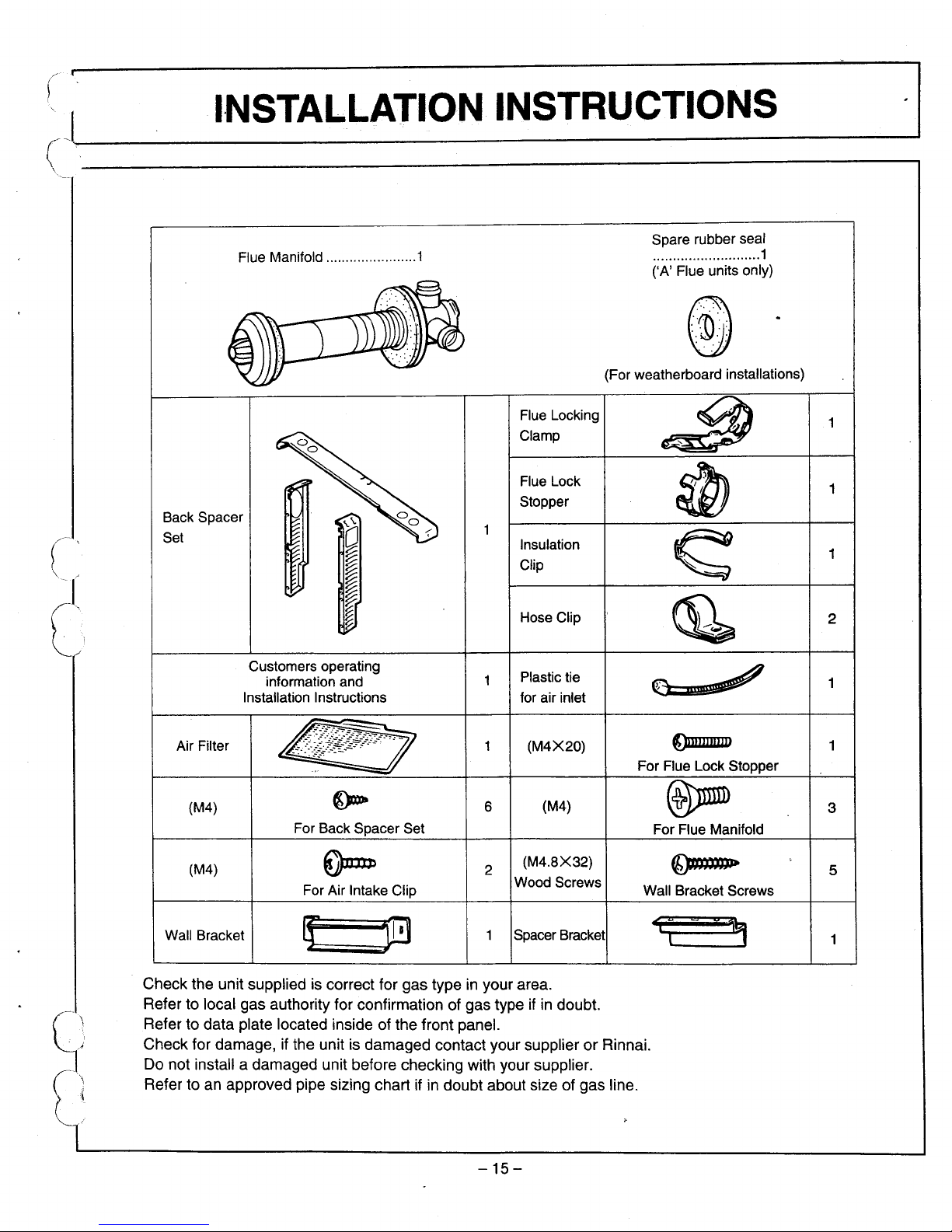

~.~l,.-.

I.N_S_T:_A_LL_A_T_IO_N_.

_IN_S_T_R_U_C_TI_O_N_S

__

-----"

I

,

Flue Manifold 1

Spare rubber seal

...........................1

('A' Flue units only)

5

2

1

3

1

1

()nJlUIIIJIJ

For Flue Manifold

e=",,~

f/;)JtttJm

..

Wall Bracket Screws

For Flue Lock Stopper

(For weatherboard installations)

Flue Locking

Clamp

Flue Lock

Stopper

Insulation

Clip

Hose Clip

Plastic tie

for air inlet

(M4X20)

6

(M4)

2

(M4.8X32)

Wood Screws

(M4)

For Air Intake Clip

Air Filter

Customers operating

information and

Installation Instructions

(M4)

For Back Spacer Set

Back Spacer

Set

('

('

Wall Bracket Spacer Bracket

o

.?:t

(-

...• )

':1'

\

Check the unit supplied is correct for gas typeinyour area.

Refer to local gas authority for confirmation of gas type

ifindoubt.

Refer to data plate located inside of the front panel.

Check for damage, if the unit is damaged contact your supplier

or

Rinnai.

Do not install a damaged unit before checking with your supplier.

Refer to an approved pipe sizing chart if

in

doubt about size of gas line.

-15-

'--

G_AS_···_C_ON_'

N_·

..

·

E_C_T_IO_N

,5

1.

The gas supply line shall be gas-tight, sized and so installed as to provide a supply of gas sufficient

to meet the maximum demand of the heater without loss of pressure.

..

2.

A shut off valve (and appliance connector valve) shouldbeinstalledinthe upstream of the gas line

to permit servicing.

3.

Flexible pipe and any appliance connector valve used for gas piping shall be types approved by

nationally recognized agencies.

4.

Any compound used on the threaded joint of the gas piping shall be a type which resists the action

of liquefied petroleum gas.

5.

Supplied gas pressure mustbewithin the limits showninthe specifications.

6.

After completion of gas pipe connections, all joints including the heater must be checked for gas

tightness by means of leak detector solution, soap and water, or an equivalent nonflammable

solution, as applicable.

CAUTION: Since some leak test solutions, including soap and water, may cause corrosion or stress

cracking, the piping shall be rinsed with water after testing, unless it has been determined that the

leak test solution

is

noncorrosive.

7.

The appliance and its individual shut off valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressure

in

excess of 1/2 psig.

The appliance must be isolated from the gas supply piping system by closing its individual manual

shut off valve during any pressure testing of the gas supply system at test pressures equal to or less

than 1/2 psig.

8.

A 1/8" test plug is provided for testing of manifold pressure see schematic for location.

At time of installation installer must supply a

1/8 inch N.P.T. plugged tapping, accessible for test

gauge connection of the appliance.

-16

-

l.l..·

..•

t

D

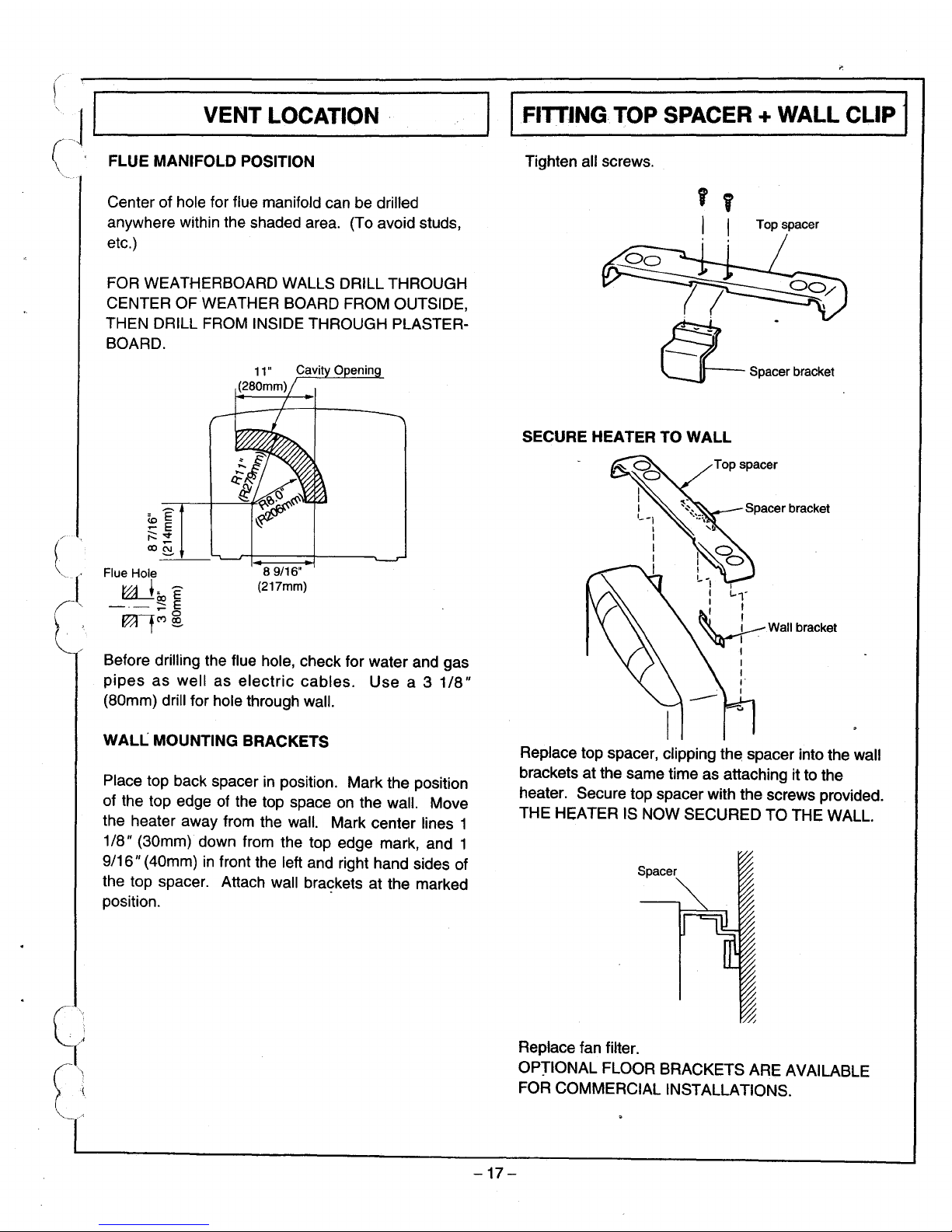

JI VENT LOCATION

( FLUE MANIFOLD POSITION

IFITTING TOP SPACER + WALL CLIP I

Tighten all screws.

Top spacer

Spacer bracket

Top spacer

Replace top spacer, clipping

th~

spacer into the wall

brackets at the same time as attaching it to the

heater. Secure top spacer with the screws provided.

THE HEATER IS NOW SECURED TO THE WALL.

Spacer

SECURE HEATER TO WALL

89/16"

(217mm)

Center of hole for flue manifold can be drilled

anywhere within the shaded area. (To avoid studs,

etc.)

FOR WEATHERBOARD WALLS DRILL THROUGH

CENTER OF WEATHER BOARD FROM OUTSIDE,

THEN DRILL FROM INSIDE THROUGH PLASTER-

BOARD.

Flue Hole

raja,

E

-.-

;:: E

~tC')

@.

WALL MOUNTING BRACKETS

Before drilling the flue hole, check for water and gas

pipes

as

well as

electric

cables.

Use

a 3

1/8"

(80mm) drill for hole through wall.

Place top back spacer

in

position. Mark the position

of the top edge of the top space on the wall. Move

the heater away from the wall. Mark center lines 1

1/8" (30mm) down from the top edge mark, and 1

9/16" (40mm)

in

front the left and right hand sides of

the top spacer. Attach wall

braqkets at the marked

position.

Replace fan filter.

OPTIONAL FLOOR BRACKETS ARE AVAILABLE

FOR COMMERCIAL INSTALLATIONS.

-17-

.CJ\NADIAN VENT REGULATIONS

CAN/CGA-B149.1-M91

A vent shall not terminate:

(a) Directly above a paved sidewalk or paved driveway which is located between two

singlefamily dwellings and serves both dwellings;

(b) less than 7ft(2.13m) above a paved sidewalk or a paved driveway located on

public property;

(c) within 6

ft.

(1.8m) of a mechanical air supply inlet to any building;

(d) above a meter/regulator assembly within 3

ft.

(900mm) horizontally of the vertical

centerline of the regulator;

(e) within 6

ft.

(1.8m) of

any

gas service regulator vent outlet;

(f) less than 1

ft.

(300mm) above grade level;

(g) within the following distances of a windowordoor which can be openedinany

building, any non-mechanical air supply inlet to any building or the combustion air

inletofany other appliance;

(i) 1ft(300mm) for inputs up to and including 100,000 Btuh (30kW),

(ii) 3ft(900mm) for inputs exceeding 100,000 Btuh (30kW); and

(h) underneath a veranda, porch or deck, unless

(i) the veranda, porch or deck is fully open on a minimum of two sides beneath the

floor, and

(ii) the distance between the top of the vent termination and the underside of the

veranda, porch or deck is greater than 1

ft.

(300mm).

FOR COMPLIANCE

TO

NFPA54OR Z223-1-1992 U.S.A.

Vent

terminal

mustbelocatedatleast

3 feet

above

any

forced

air

inlet

location

within10feet

away.

Vent

terminal

must

notbelocated

over

public

walk

waysorbe

detrimentaltoregulators

and

equipment.where

condensate

couldbea

problem.

Vent

terminal

mustbekept

clearofsnow

at all

times.

The

bottomofthe

vent

terminal

and

the

air

intake

mustbelocatedatleast12inches

above

grade.

The

vent

terminalofa

direct

vent

appliance

withaninputof50,000

Btu

per

hourorless

shall

be

locatedatleasl9

inches

from

any

opening

through

which

flue

gases

could

enterabuilding,

and

suchanappliance

withaninput

over

50,000

Btu

per

hour

shall

requirea12inches

vent

termination

clearance.

The

bottomofthe

vent

terminal

and

the

air

intake

shallbelocatedatleast

12

inches

above

grade.

-18

-

~~J

J

~;~,

L_O_CA_J_IO_N_/C_L_E_A_R_A_N_C_E_S~_-----J-I

(

[I

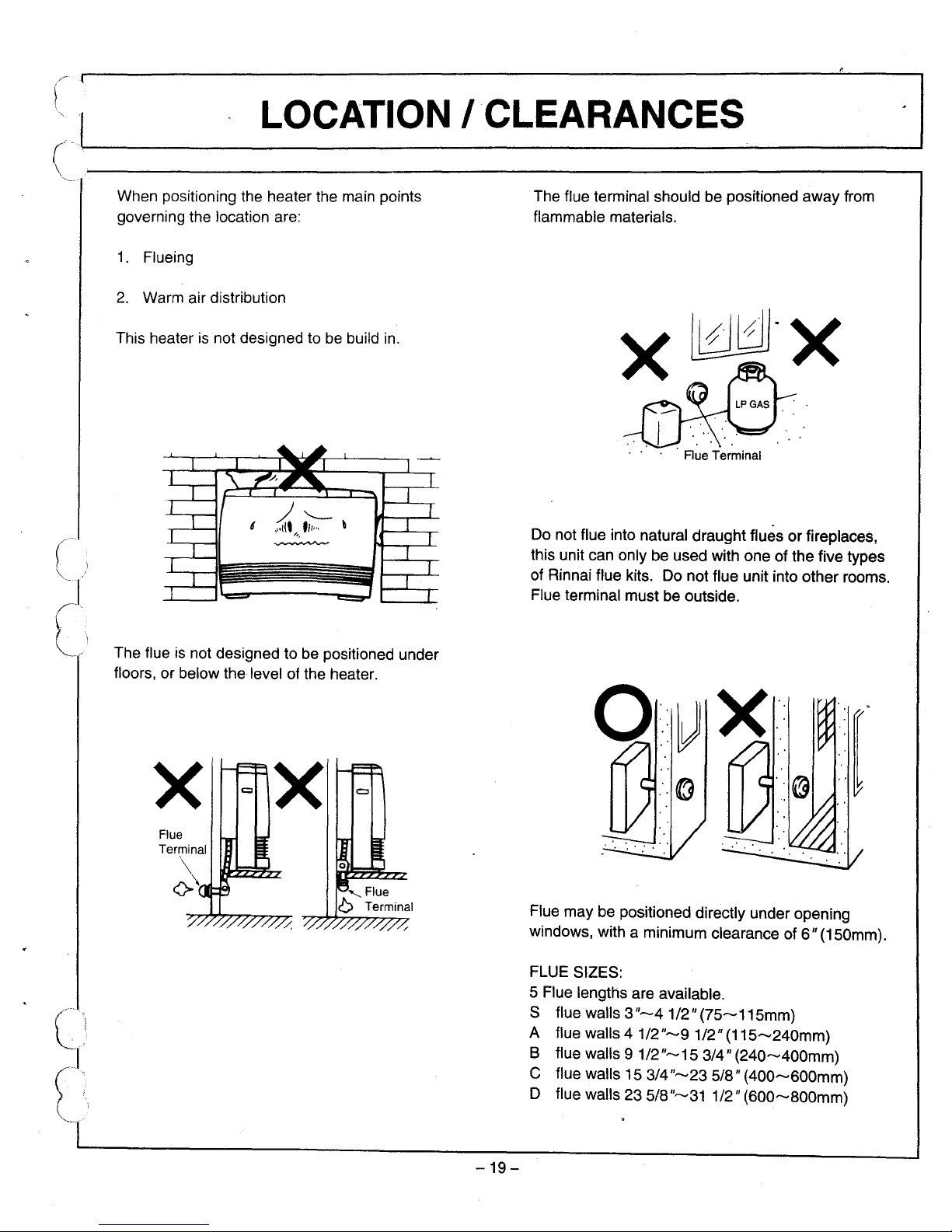

When positioning the heaterthe main points

governing the location are:

1.

Flueing

2.

Warm air distribution

This heater is not designed to be build in.

The flue is not designed to be positioned under

floors, or below the level of the heater.

The flue terminal should be positioned

away

from

flammable materials.

x~-x

Flue Terminal

Do not flue into natural draught fluesorfireplaces,

this unit can only be used with one of the five types

of Rinnai flue kits. Do not flue unit into other rooms.

Flue terminal must be outside.

c

(

x

Flue

Terminal

x

-19-

Flue may be positioned directly under opening

windows, with a minimum clearance of6"(150mm).

FLUE SIZES:

5 Flue lengths are available.

S flue walls 3

"-4

1/2"

(75-115mm)

A flue walls

41/2"-91/2"

(115-240mm)

B flue walls

91/2"-15

3/4"

(240-400mm)

C flue walls 15

3/4"-23

5/8"

(400-600mm)

D flue walls 23

5/8"-31

1/2"

(600-800mm)

Loading...

Loading...