Rinnai RHFE-201FA, RHFE-263FA, RHFE-431FA, RHFE-1004FA, RHFE-201RFA Service Manual

...

Direct Vent

Service Manual

RHFE-551FA

RHFE-1001FA

RHFE-1001FA/VA

RHFE-201FA

RHFE-263FA, FAII

RHFE-431FA, FAII, FAIII, WTA

RHFE-556FA, FAII, FAIII, FTRA, FTRAIII, WTA

RHFE-1004FA

ES08 RHFE-201RFA

ES11 RHFE-263RFA

ES17 RHFE-433RFA

EX17 RHFE-433RWTA

ES22 RHFE-558RFA

EX22 RHFE-558RWTA

ES38 RHFE-1004RFA, RHFE-1004FTA

EX08C RHFE-202FTA

EX11C RHFE-265FTA

EX17C RHFE-434FTA

EX22C RHFE-559FTA

200000014 Rev A

5/2012

Table of Contents

General Information .................................................... 3

Specifications ............................................................. 4

Sequence of Operations ............................................. 6

Fault Isolation

Accessing Fault Codes ............................................ 7

Fault Isolation Codes ............................................... 9

Fault Isolation - Other Issues ................................ 11

201FA, 201RFA

Troubleshooting .................................................... 12

Wiring Diagram ..................................................... 14

Ladder Diagram .................................................... 15

263FA, 263FAII, 263RFA

Troubleshooting .................................................... 16

Wiring Diagram ..................................................... 18

Ladder Diagram .................................................... 19

202FTA, 265FTA

Troubleshooting .................................................... 20

Wiring Diagram ..................................................... 21

Ladder Diagram .................................................... 22

431FA Series, 556FA/FTRA Series

Troubleshooting .................................................... 23

Wiring Diagrams

431FA Series, 556FA/FTRA ........................... 26

556FAIII .......................................................... 27

556FTRAIII...................................................... 28

431WTA, 556WTA

Troubleshooting .................................................... 29

Wiring Diagrams (431WTA) .................................. 32

Wiring Diagrams (556WTA) .................................. 33

433RFA, 558RFA

Troubleshooting .................................................... 34

Wiring Diagram ..................................................... 35

Ladder Diagram .................................................... 36

433RWTA, 558RWTA

Troubleshooting .................................................... 37

Wiring Diagram ..................................................... 38

Ladder Diagram .................................................... 39

434FTA, 559FTA

Troubleshooting ................................................... 40

Wiring Diagram ..................................................... 41

Ladder Diagram .................................................... 42

551FA, 1001FA, 1001FA/VA

Troubleshooting (551FA) ...................................... 43

Fault Finding Charts .............................................. 45

Wiring Diagram (551FA) ....................................... 55

Troubleshooting (1001FA) .................................... 56

Fault Finding Charts .............................................. 58

Wiring Diagram (1001FA) ..................................... 61

Troubleshooting (1001FA/VA) .............................. 62

Fault Finding Charts ............................................. 64

Wiring Diagram (1001FA/VA) ............................... 68

Lockout Check List ............................................... 69

1004FA, 1004RFA, 1004FTA

Troubleshooting Information ............................. 71

Wiring Diagram .................................................. 73

Ladder Diagram ................................................ 74

Lockout Check List ............................................ 75

Extension Installation Requirements ...................... 76

Vent Kits and Extension Sets .................................. 78

Vent Extension Covers ............................................ 79

Installations at Altitude ............................................. 79

Gas Pressure Setting Procedure

201FA, 263FA, 263FAII .................................... 80

201RFA, 263RFA .............................................. 82

202FTA, 265FTA ............................................... 85

431FA/WTA, 556FA/WTA ................................. 87

433RFA, 558RFA .............................................. 89

433RWTA, 558RWTA ....................................... 92

434FTA, 559FTA ............................................... 95

1004FA .............................................................. 97

1004RFA, 1004FTA .......................................... 98

Dip Switch Settings ................................................ 101

Checking Micro-Amps

(431, 556, 201, 263) .............................................. 102

Setting up the U Tube Manometer

(431, 556, 201, 263) .............................................. 103

Thermistor .............................................................. 104

Flame Rectification ................................................ 104

Setting a Maximum Temperature .......................... 105

Harmonic Noise (1004FA) ..................................... 105

Removal of “OF” on New PC Board

Installation .............................................................. 106

Wire Diagram Abbreviations .................................. 110

Serial Number Format ........................................... 111

2 Rinnai Direct Vent Service Manual

General Information

Safety Definitions

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and

others.

DANGER

WARNING

CAUTION

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Using this Manual

Repairs should be performed by a qualified service technician.

The following information can be referenced for additional information.

• Operation and Installation Manual

• Conversion Manual

• Technical Bulletins

Technical Support

Technicians are available to assist in servicing issues. Contact Rinnai Technical Services at 1-800-621-9419.

Recommended Tools

• Volt/Ohm/Amp meter with test probes

• U tube type manometer with 14 inch water column (W.C.) scale, two hoses and two 1/8 inch taps

• assorted wrenches including a 3/16 Allen wrench

• assorted screw drivers

• leak solution or leak detector

WARNING

There are a number of live tests that are required when fault finding this product. Extreme care should be used at

all times to avoid contact with energized components inside the furnace. Before checking for resistance readings

disconnect the power source to the unit and isolate the item from the circuit (unplug it).

CAUTION

Label all wires prior to disconnection when

servicing controls. Wiring errors can cause

improper and dangerous operation.

Rinnai Direct Vent Service Manual 3

If any of the original wire as supplied with the appliance must

be replaced, it must be replaced with type 18 AWG wire or its

equivalent.

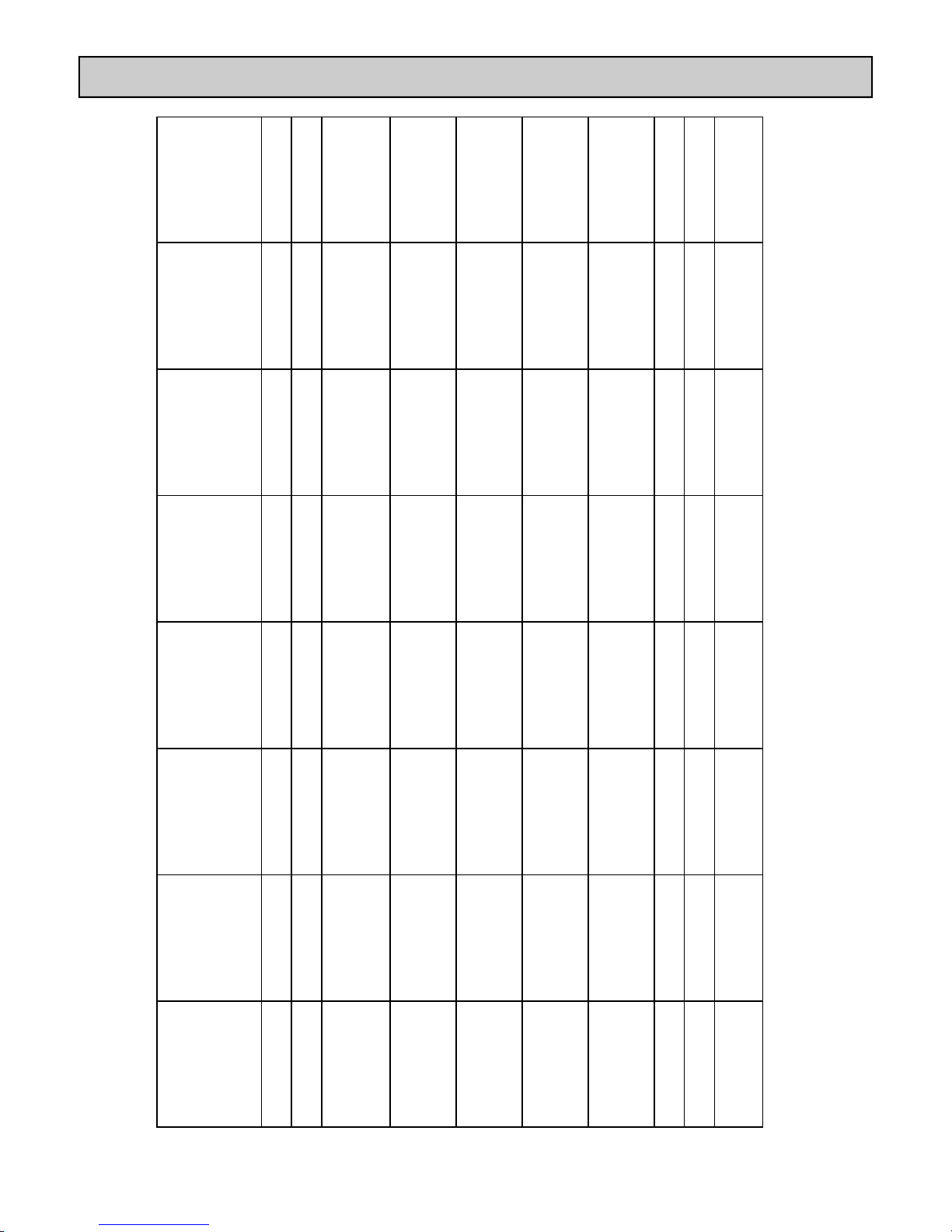

Specifications

1004FA

1001FA

551FA

(ES38)

1004RFA

265FTA

1001FA/VA

(ES38)

1004FTA

(EX11C)

11-13 in

-267 mm) W.C.

5.0-10.5 in (127

11-13 in

267 mm) W.C.

4.5-10.5 in (114-

11-13 in

267 mm) W.C.

5.0-10.5 in (127-

W.C.

3.5-10.5 in

(89-267 mm)

8-13 in

W.C.

(279-330 mm)

W.C.

(279-330 mm)

W.C.

(279-330 mm)

W.C.

(203-330 mm)

60 Hz,

120 watts

AC 120V,

60 Hz,

120 watts

AC 120V,

60 Hz,

121 watts

AC 120V,

60 Hz,

44 watts

AC 120V,

202FTA

(EX08C)

201FA 263FA, FAII

80.6% 80% 81% 80% 80.6% NA NA

3,000-8,000 5,500-11,000 3,000-8,000 5,500-11,000 10,500-38,400 22,000 (max) 38,400 (max)

3,000-8,000 5,700-11,000 3,000-8,000 5,700-11,000 10,500-36,500 21,000 (max) 36,500 (max)

BTU Input NG

BTU Input LP

AFUE Rating

W.C.

4.5-10.5 in

(114-267 mm)

W.C.

3.5-10.5 in

(89-267 mm)

83.4% 80% 82% 81% 82% NA NA

NG

AFUE Rating

LP

W.C.

4.5-10.5 in

(114-267 mm)

Gas Supply

Pressure (NG)

W.C.

8-13 in

(203-330 mm)

W.C.

8-13 in

(203-330 mm)

W.C.

8-13 in

(203-330 mm)

Gas Supply

Pressure (LP)

4 Rinnai Direct Vent Service Manual

60 Hz,

41 watts

AC 120V,

60 Hz,

47 watts

AC 120V,

60 Hz,

42 watts

AC 120V,

Electrical

Connection

(at high fire)

48.3-78.6 96.4-128.5 48.3- 78.6 96.4-128.5 203.4-360.6 135-189 179-289

27-34 dB(A) 31-38 dB(A) 27-36 dB 31-38 dB 37-47 dB(A) 35-44 dB(A) 35-46 dB(A)

Sound Level

Fan CFM

37 lbs (17 kg) 46 lbs (21 kg) 46 lbs (21 kg) 90 lbs (41 kg) 74 (34 kg) 110 (50 kg)

39.4 lbs

(17.9 kg)

Weight

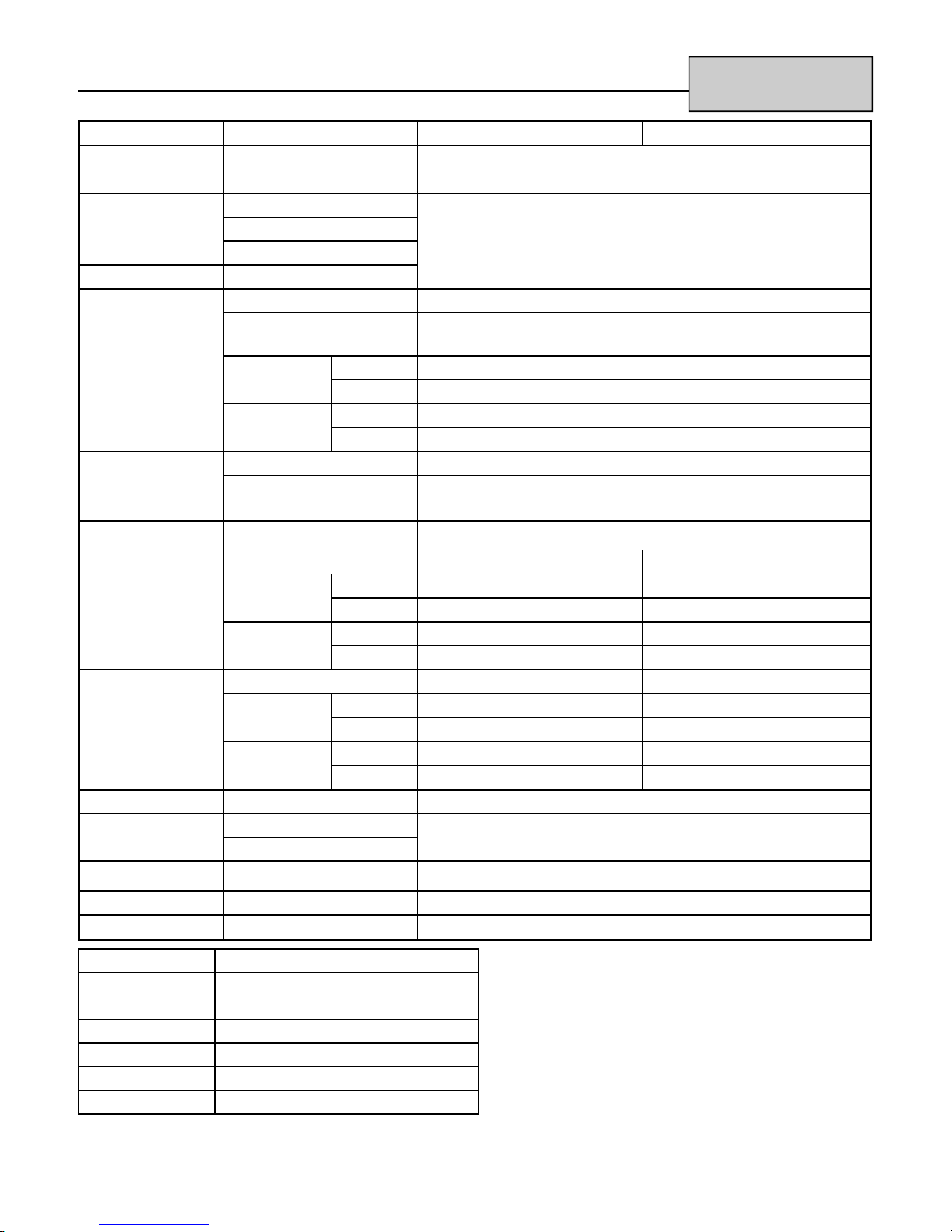

Specifications

559FTA

(EX22C)

434FTA

(EX17C)

(EX22)

558RWTA

(EX17)

433RWTA

80%

8,200-21,500

8,200-20,700

82%

W.C.

W.C.

W.C.

W.C.

8-13 in

8-13 in

8-13 in

8-13 in

3.5-10.5 in

(89-267 mm)

3.5-10.5 in

(89-267 mm)

3.5-10.5 in

(89-267 mm)

3.5-10.5 in

(89-267 mm)

W.C.

(203-330 mm)

W.C.

(203-330 mm)

W.C.

(203-330 mm)

W.C.

(203-330 mm)

60 Hz,

46 watts

AC 120V,

60 Hz,

46 watts

AC 120V,

60 Hz,

47 watts

AC 120V,

60 Hz,

47 watts

AC 120V,

110.5-162.7

33-42 dB

57 lbs (26 kg)

(ES22)

558RFA

(ES17)

433RFA

Series, WTA

556FA/FTRA

431FA

Series, WTA

8,200-16,700 8,200-21,500 8,200-16,700 8,200-21,500 8,200-16,700 8,200-21,500 8,200-16,700

8,200-16,700 8,200-20,700 8,200-16,700 8,200-20,700 8,200-16,700 8,200-20,700 8,200-16,700

W.C.

3.5-10.5 in

(89-267 mm)

W.C.

3.5-10.5 in

(89-267 mm)

W.C.

5.0-10.5 in

(127-267 mm)

80.8% 80.6% 81% 81% 81% 80.6% 81%

81% 81% 80% 80% 81% 81% 82%

W.C.

3.5-10.5 in

(89-267 mm)

W.C.

8-13 in

(203-330 mm)

W.C.

8-13 in

(203-330 mm)

W.C.

8-13 in

(203-330 mm)

W.C.

8-13 in

(203-330 mm)

60 Hz,

50 watts

AC 120V,

60 Hz*,

45 watts

AC 120V,

60 Hz*,

55 watts

AC 120V,

60 Hz*,

40 watts

AC 120V,

32-38 dB(A) 32-41 dB(A) 32-42 dB 32-39 dB 32-41 dB 32-41 dB 33-38 dB

110.5-141.3 110.5-162.7 110.5-141.3 110.5-162.7 110.5-141.3 110.5-162.7 110.5-141.3

51 lbs (23 kg) 51 lbs (23 kg) 53 lbs (24 kg) 53 lbs (24 kg) 51 lbs (23 kg) 51 lbs (23 kg) 57 lbs (26 kg)

BTU Input

BTU Input LP

NG

Rinnai Direct Vent Service Manual 5

AFUE Rating

NG

AFUE Rating

LP

Gas Supply

Pressure

(NG)

Gas Supply

Pressure

(LP)

Electrical

Connection

(at high fire)

Sound Level

Weight

Fan CFM

* 60 Hz must be maintained or the sound levels (dB) may change.

Sequence of Operations

1. The blower (combustion) motor fan starts and purges the combustion and heat exchanger

chambers making sure that they are clear. The green LED light is on.

2. The blower stages down and the ignition module powers the spark igniter and spark

occurs. When the spark is sensed as being correct, the PCB allows voltage to the

solenoid gas valves and gas enters the chamber. Ignition occurs and the flame rod begins

to prove flame. The blower motor stages back up to high. When the burner is on the LED

glows red indicating the burner is on. If the flame is correct and a secure ground is

available, then the flame rod produces micro-amps and the unit will fire trying to reach your

set room temperature.

3. The convection (room blower) will start on low speed circulating warm air into the structure.

After the PCB compares the set temperature to the room temperature, the seven stage gas

valve and fan control will fire the unit at the most efficient rate to obtain the comfort level as

set.

4. The negative co-efficient thermistor will sense the room temperature at the floor level and

will provide feedback to the PCB to determine the firing rate, fan speed, and run time.

When the set temperature is reached, the red indicator will return to green indicating the

burner is off. The convection fan will continue to run cooling the exchangers and

electronics for about 4 minutes.

5. The LED will be green indicating the unit is on standby. When the structure temperature

drops, the process starts over again.

6. Fresh air for combustion is drawn from outside and exhaust air is eliminated to the outside.

Moisture coming from the vent outside is normal as most high efficient units produce

moisture.

6 Rinnai Direct Vent Service Manual

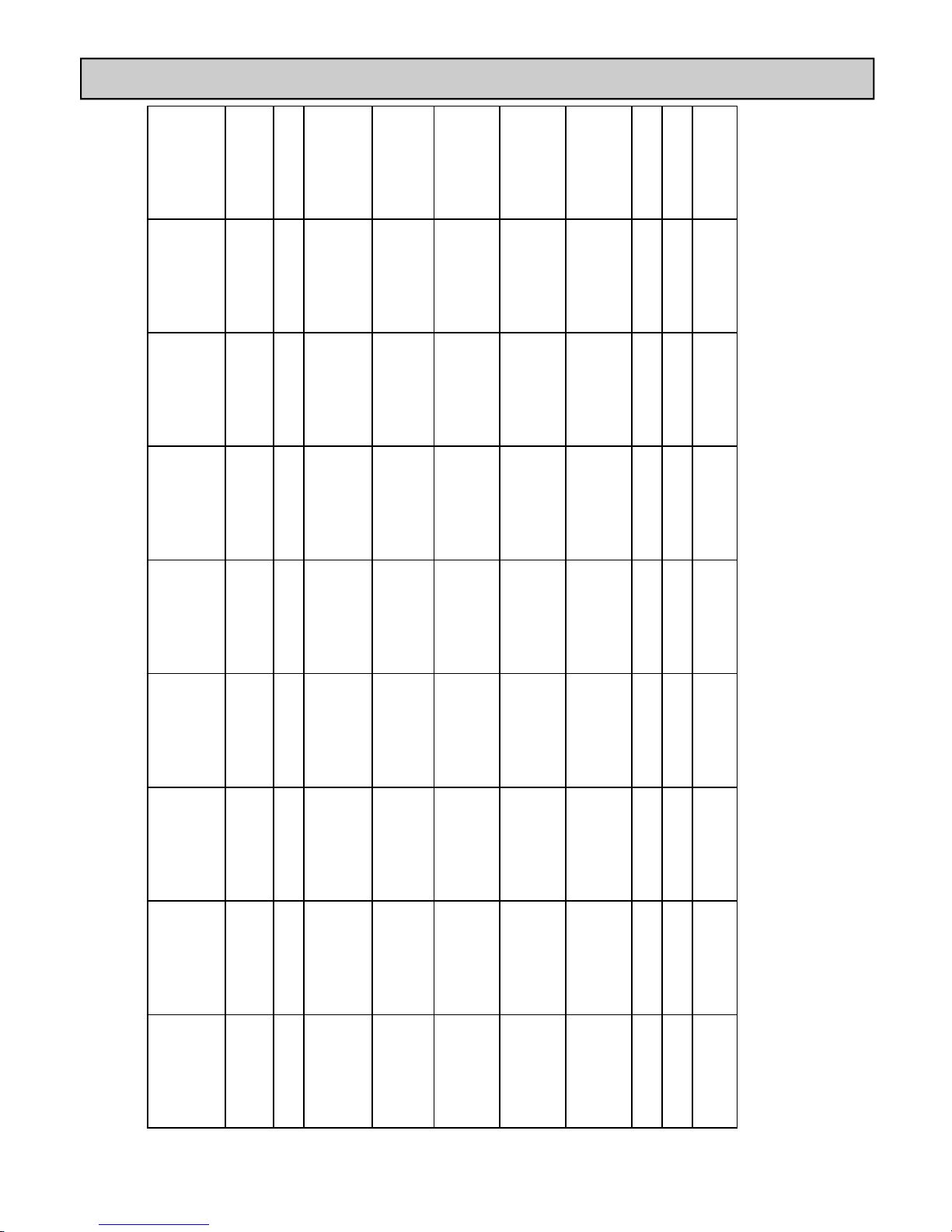

Fault Isolation

If there is a malfunction the appliance may shut down

as a safety precaution and display a fault code to

assist in diagnosing the problem. The fault code will

flash in the display on the control panel.

Fault codes should be used to assist in identifying the

cause of the failure.

Accessing Fault Codes

Up to 10 fault codes are stored in the PC Board and can be recalled by simultaneously pressing the “Economy”

button and both temperature control buttons for 2.5 seconds while the appliance is turned OFF. After the buttons

are released, the fault codes will be displayed in 2 second intervals beginning with the most recent fault code.

Models with analog controls and models with digital LED’s each have their own set of fault codes.

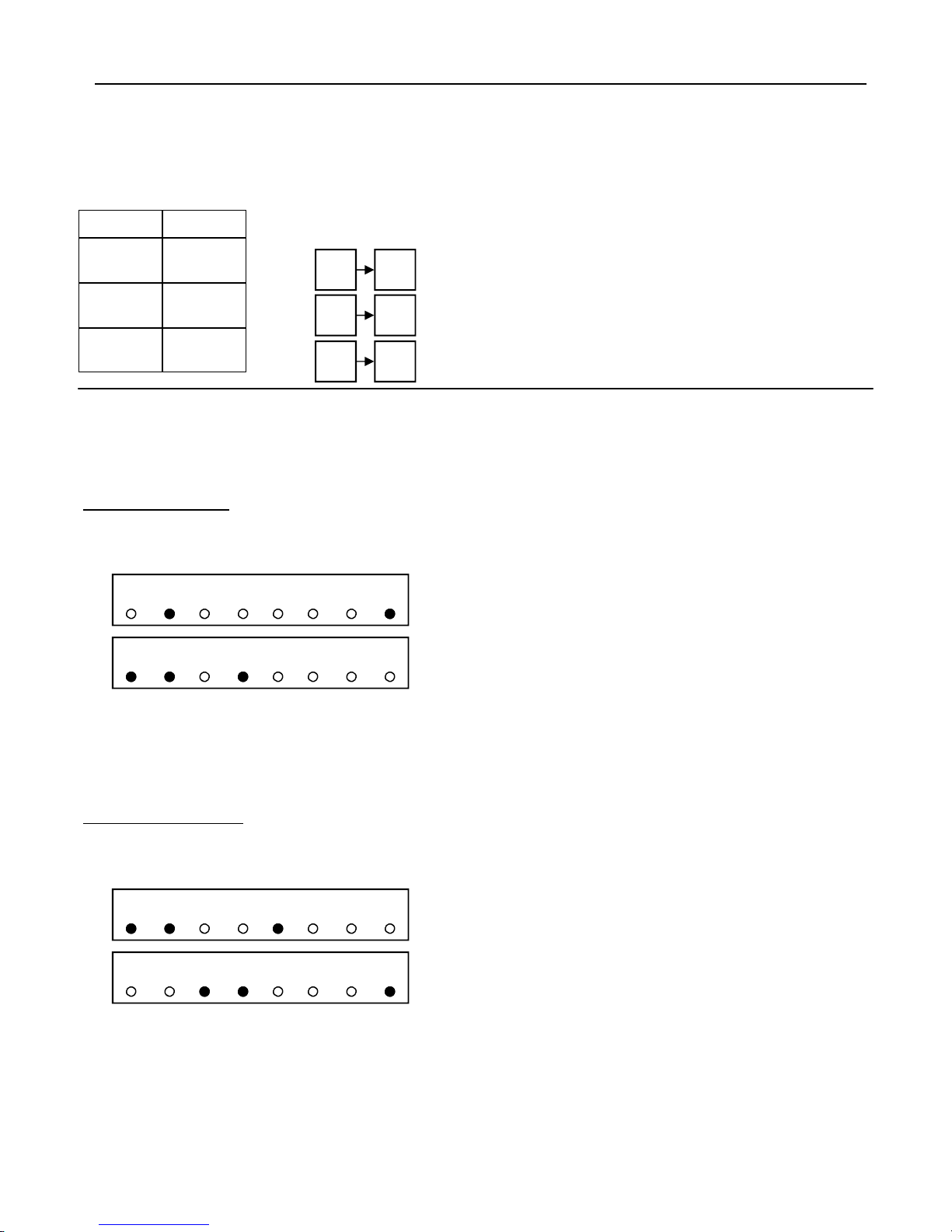

Models with analog controls:

The fault code will display by lighting up 1 to 4 of the temperatures at

the same time. For example, if the temperatures 60, 64, and 68 are lit

up then the fault code is 60*64*68 - Abnormal Combustion Fan RPM.

After the problem has been corrected, the fault code

will clear only after the appliance has been turned off

and back on. The code will be stored into the memory.

Some faults may cause a hard lockout where the

appliance shuts off and corrective action is required

before the appliance will operate.

LO 60 64 68 72 76 80 HI

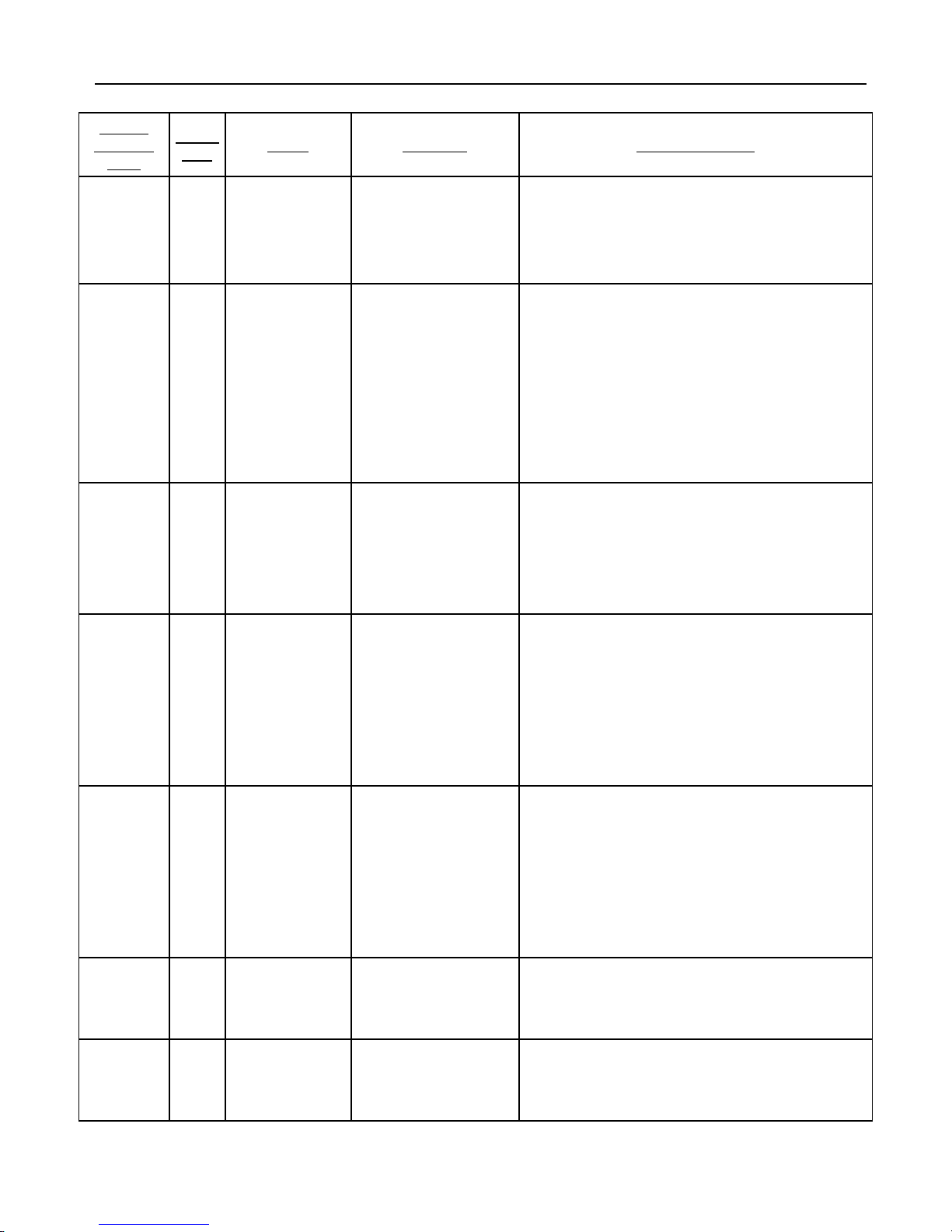

On models RHFE-431WTA, RHFE-556WTA, RHFE-556FTRA:

Under SET the codes in memory are numbered 1 through 10 with “1” as the

most recent. Under ROOM the fault code will be displayed.

On models all other models with digital controls:

The codes in memory are numbered 1 through 10 with “1” as the most

recent. The temperature display will show “1” and then show the most

recent fault code. A “2” will then be displayed followed by the second

most recent fault code. The 10 most recent fault codes will be displayed

in this manner.

SET ROOM

1 61

SET ROOM

2 14

1 61 2 14

Rinnai Direct Vent Service Manual 7

Accessing Operation History

RHFE-431WTA,

RHFE-556WTA,

RHFE-433RWTA,

RHFE-558RWTA

SET ROOM

RHFE-201FA,

RHFE-263FA,

RHFE-263FAII,

RHFE-1004FA,

RHFE-556FTRA,

RHFE-1004RFA,

RHFE-1004FTA

RHFE-201RFA,

RHFE-263RFA,

RHFE-433RFA,

RHFE-558RFA,

RHFE-202FTA,

RHFE-265FTA

After the fault codes, the heater will display the

combustion hours, combustion cycles (number of

times the unit is turned on and off), and power

failure frequency.

50 82

18 42

1 25

50 82

18 42

1 25

5082 combustion hours

18420 combustion cycles (multiply displayed number by 10)

125 power failures

RHFE-431FA, RHFE-556FA

After the fault codes, the heater will display the combustion hours and combustion cycles (number of times the

unit is turned on and off). The combustion time will display first in two parts followed by the combustion cycles

displayed in two parts.

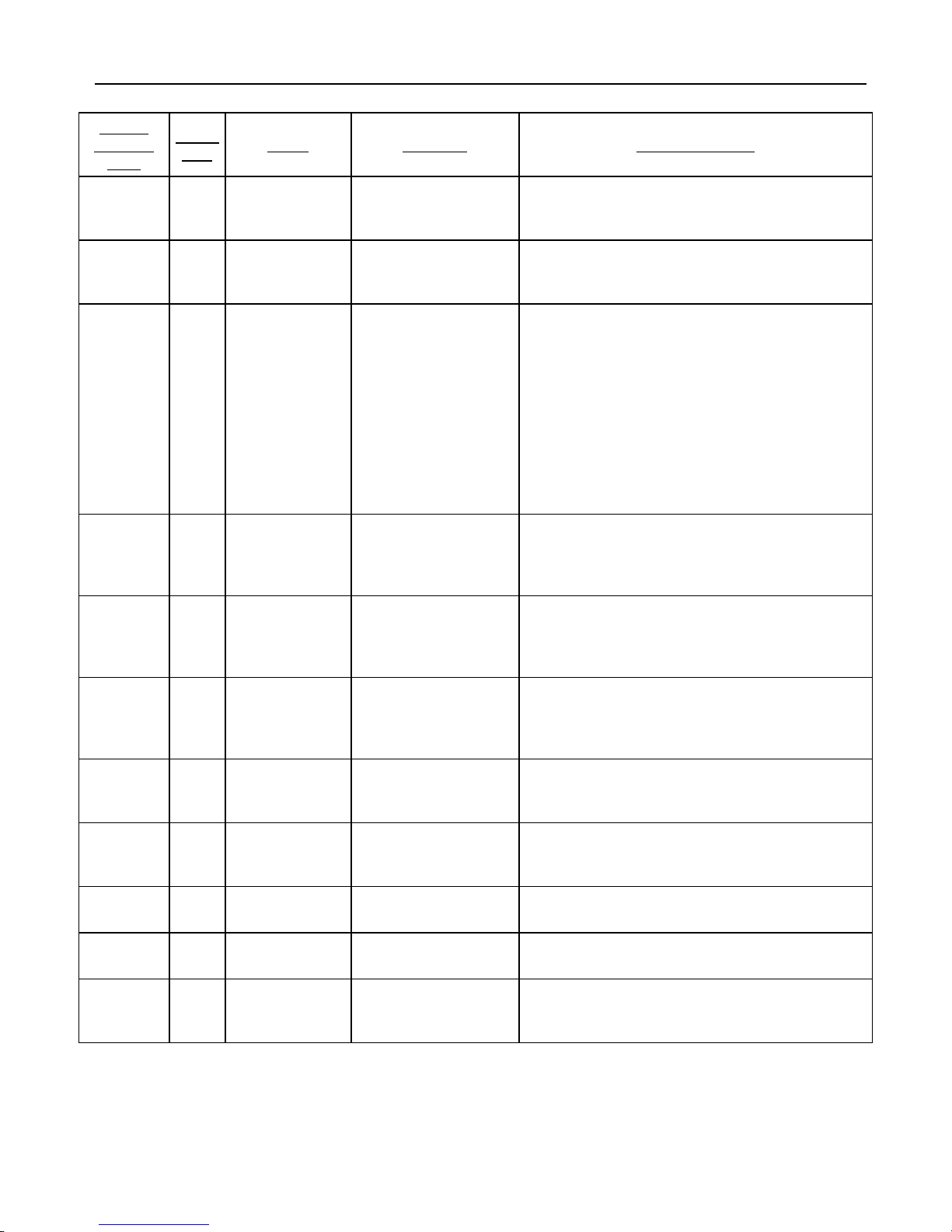

Combustion Time

1. The temperature display will indicate a 16 digit binary number. A light indicates a “1”. A position not lighted,

indicates a “0”. Read this number using the example below.

LO 60 64 68 72 76 80 HI

LO 60 64 68 72 76 80 HI

This indicates the first 8 digits as follows: 0 1 0 0 0 0 0 1

This indicates the next 8 digits as follows: 1 1 0 1 0 0 0 0

2. Use a calculator with binary and decimal functions. Set the calculator to binary, “BIN”, and enter the 16 digits.

(0 1 0 0 0 0 0 1 1 1 0 1 0 0 0 0 in the example above.)

3. Press the decimal function, “DEC”, and the combustion time in hours will display. The combustion hours in

this example is 16848.

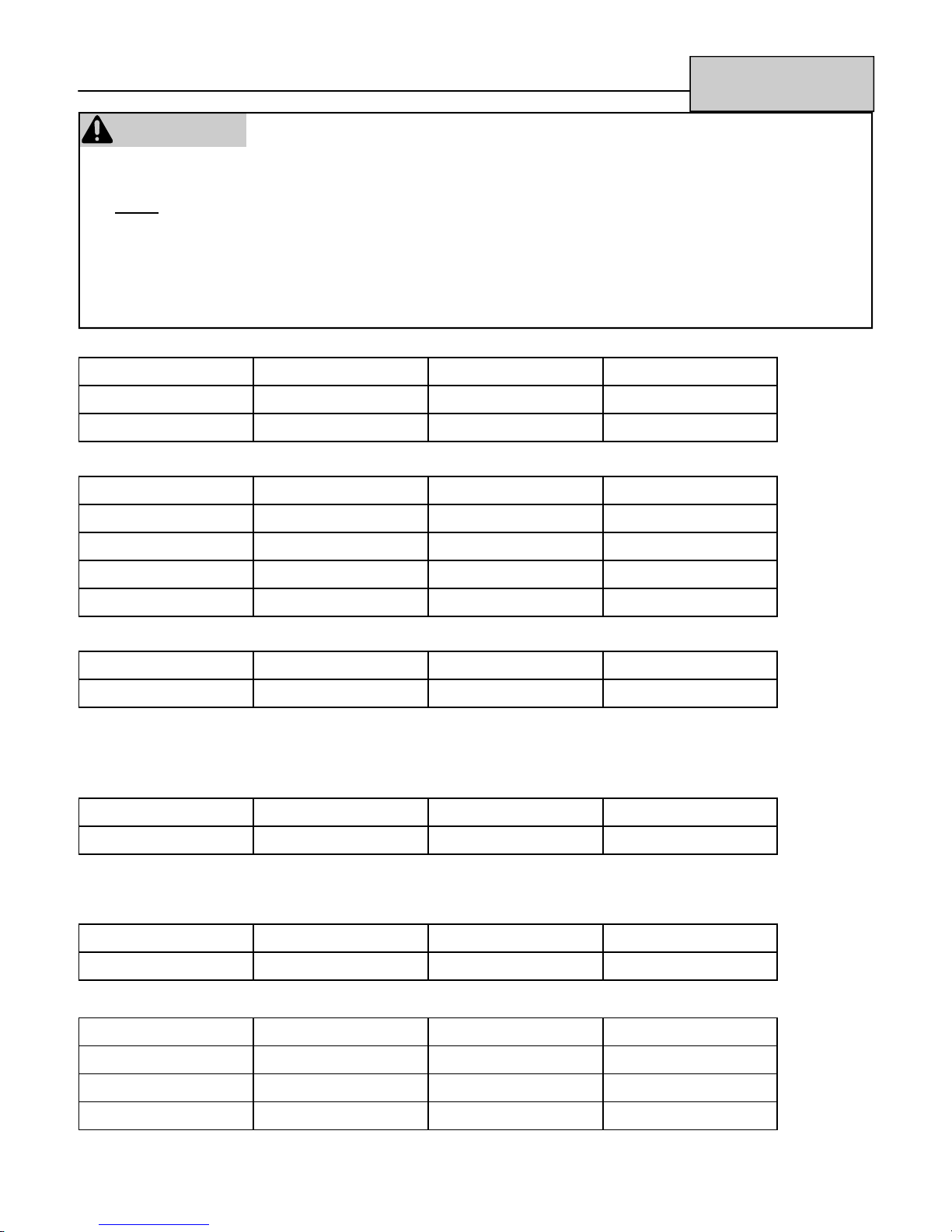

Combustion Cycles

1. The temperature display will indicate a 16 digit binary number. A light indicates a “1”. A position not lighted,

indicates a “0”. Read this number using the example below.

LO 60 64 68 72 76 80 HI

LO 60 64 68 72 76 80 HI

2. Use a calculator with binary and decimal functions. Set the calculator to binary, “BIN”, and enter the 16 digits.

(1 1 0 0 1 0 0 0 0 0 1 1 0 0 0 1 in the example above.)

3. Press the decimal function, “DEC”, and multiply the displayed number by 10 to obtain the combustion cycles.

The combustion cycles in this example is 512,490.

This indicates the first 8 digits as follows: 1 1 0 0 1 0 0 0

This indicates the next 8 digits as follows: 0 0 1 1 0 0 0 1

8 Rinnai Direct Vent Service Manual

Fault Isolation Codes

Analog

Indicator

Light

LO-HI PF --

60 11 Missed Ignition Flame rod current

LO 12 Flame Failure Flame rod current

Digital

LED

:--

Name Definition Corrective Action

Power Failure Electric power has

been lost while the

appliance was running

does not reach 1.0

microamp within a

certain time after the

solenoid opens.

remains below 1.0

microamp for 3

seconds during initial

combustion

Check that the power cord is firmly inserted into

the electrical outlet.

Check the 3 amp fuse.

Check whether the fuse or breaker has blown at

Check that the flame rod is firmly positioned.

Check the flame rod lead.

Check the flame rod for carbon build up.

Check that the correct gas is being used.

Check the supply pressure at the meter and at

the appliance.

Check that there are no leaks in the gas supply

line or appliance.

Check for air in the gas supply.

Check that the correct gas is being used.

Check the supply pressure at the meter and at

the appliance.

Check that there are no leaks in the gas supply

line or appliance.

Check for air in the gas supply.

68 14 Overheat Safety

Device

HI 16 Over

Temperature

Cut Off

72 76 31 Room

Temperature

Thermistor

Disconnection

76 80 32 Room

temperature

thermistor short

circuit

High limit temperature

thermistor or thermal

fuse has activated

Room temperature is

above 104ºF for

longer than 10

minutes

Room temperature

thermistor circuit is

open

Room temperature

thermistor wire is

trapped or touching

bare metal.

Check that the correct gas is being used.

Check the supply pressure at the meter and at

the appliance.

Check that the flue terminal is not blocked.

Check that the air filter is not blocked.

Check that the warm air flow is not blocked.

(There should be a clearance of 40 inches in front

of the appliance.)

Check that the correct gas is being used.

Check the supply pressure at the meter and at

the appliance.

Check that the flue terminal is not blocked.

Check that the air filter is not blocked.

Check that the warm air flow is not blocked.

(There should be a clearance of 40 inches in front

of the appliance.)

Check the circuit. (troubleshooting)

Check the circuit. (troubleshooting)

Rinnai Direct Vent Service Manual 9

Fault Isolation Codes

Analog

Indicator

Light

64 68 72 33 High-limit

68 72 76 34 High-limit

LO 60 64 53 Abnormal spark

60 64 68 61 Abnormal

Digital

LED

Name Definition Corrective Action

thermistor

disconnection

thermistor short

circuit

sensed

Combustion Fan

RPM

High limit thermistor

circuit is open.

High limit thermistor

wire is trapped or

touching bare metal.

• Sparker is not off

within 20 seconds of

ignition.

• 1st spark is not

sensed within 2

seconds

• 2nd spark is not

continuous for 1

second after

solenoid valve

opens

RPM is not achieved

within a certain time or

exceeds the RPM

limit.

Check the circuit. (troubleshooting)

Check the circuit. (troubleshooting)

Replace sparker

Check for obstacle preventing fan from turning

freely.

Check wiring harness to motor for damage or

loose connections.

64 68 70 ON/OFF Switch

Failure

LO 60 71 Solenoid Valve

Failure

80 72 Flame Rod

Failure

72 76 80

HI

NA 49 Pressure Sensor No signal from the

NA 99 Flue Block The pressure sensor

60 64 68

72 76

73 Communication

Failure

NA Flue Block Flue blockage has

The ON/OFF switch

connects continuously

for more than 15

seconds.

For either solenoid

valve, SV1 or SV2, the

signal and response

signal are different.

Flame rod output does

not cease within 20

seconds

Data transfer between

CPU and E2PROM

fails.

pressure sensor.

signal is below its limit.

been detected based

on fan speed.

Check the circuit. (troubleshooting)

Replace switch.

Check the circuit. (troubleshooting)

Replace gas valve.

Check the circuit. (troubleshooting)

Replace flame rod.

Disconnect the power and re-apply power.

Check the circuit. (troubleshooting)

Check the flue and termination for proper

installation and blockage.

Check the flue and termination for proper

installation and blockage.

10 Rinnai Direct Vent Service Manual

Fault Isolation - Other Issues

AT IGNITION:

Heater does not operate.

Warm air does not flow when the burner

lights.

Smoke or strange smells are produced

on the first trial light up after installation.

Sharp clicking noised at ignition, or

when unit shuts down, or goes out.

DURING COMBUSTION:

Clunking noise when the thermostat

operates.

Unit is not heating room.

Is the heater plugged in?

Have the fuses or breaker blown at the fuse box / breaker panel?

Is there a power failure?

Is the air filter blocked?

Is anything blocking the outlet for the hot air?

Is the flue blocked?

The fan is started automatically after a short delay. This is to allow the

heat exchanger to warm up, helping to avoid cold draughts.

This is caused by grease, oil, or dust on the heat exchanger and will stop

after a short time.

This is simply expansion noise from the heat exchanger.

This is the sound of the solenoid gas valves opening and closing.

Is the air filter blocked?

Is the set temperature high enough?

Is the warm air outlet blocked by anything?

Are the doors and windows of the room closed?

Was the appliance correctly sized for the space?

Air filter is blocked or the louvers are

blocked.

Heater will not re-ignite after overheating Even after unit has cooled down, the heater does not ignite again. Repair

Allow heater to cool, clean air filter, and operate again.

is necessary by a qualified service provider.

DURING COMBUSTION:

Convection fan continues to run after

turning OFF

This is to remove the residual heat from the heat exchanger. The fan will

stop when the heater cools down.

OTHER POINTS:

Steam is discharged from the flue

terminal.

Unit shuts off without apparent reason. Check whether filters are blocked. Dirty filters will cause the heater to

Power Failure

High efficiency appliances tend to discharge water vapor on cold days.

This is normal.

overheat.

Switch OFF, then ON again when power is restored to re-set controls.

Rinnai Direct Vent Service Manual 11

Troubleshooting

RHFE-201FA

WARNING

There are a number of live tests that are required when fault finding this product. Extreme care should be used at

all times to avoid contact with energized components inside the furnace.

You MUST be a qualified service person before proceeding with these test instructions.

Before checking resistance readings, turn off power source to unit and then isolate each item to be checked from

the circuit by unplugging it.

When setting gas pressures on one of these units, please check the complete model number you are trouble-

shooting. Gas pressures and dip switches can vary among models. Always check the rating plate for complete

information and follow directions.

(AC IN) (Connector B)

Black-White 120 VAC CONNECTOR B Pin # 1-2

Black-Ground 120 VAC Pin #2-Ground

White-Ground 0 VAC Pin #1-Ground

(TR) Transformer: (Connector C) (AC Out)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Grey-Grey 90-110 VAC 3-6 Pin #1-7

Red-Yellow 30-42 VAC 0.8-1.5 Pin #4-5

Blank pin-Grey 15-21 VAC 0.6-1.2 Pin #6-7

Grey-Black 180-220VAC 155-260 Pin #7-8

(SP) Sparker: (Connector D) (Voltage potential while Sparking)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Red-Blue 85-100 VAC 100K-120K Pin #3-6

The spark must be sensed as being at the correct location and intensity before it will allow the gas valve to open. Check

across Pin # 1-2 at Connector F and you should read 4-6 VDC potential. When sparking, if the spark is in the right location and

intensity the voltage potential will drop to almost 0 (zero) and then return to the 4-6 VDC potential.

(SV1 and SV2) Main Solenoid Valves: (Connector D)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Black-Yellow 85-90 VDC 700-1000 Pin #1-4

*Resistance across each coils terminals should be 1400-2000 when isolated.

(POV) Modulating Gas Valve (Co nnector G)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Grey-Grey 6-16 VDC 80-90 Pin #2-6

(BL) Combustion Blower Motor: (Connector G) DC Motor 37VDC 8 Watts

Read voltage across: Voltage Potential Read resistance Pin Numbers

Black-White 7-12 VDC 8K-10K Pin #7-8

Yellow-White 4-5 VDC 4K-6K Pin #4-8

Red-White 10-30 VDC N/A Pin # 3-8

12 Rinnai Direct Vent Service Manual

Troubleshooting

(FM) Convection Fan Motor: (Connector E) Variable 100VAC Motor 60 Hz

Read voltage across: Voltage Potential Read resistance Pin Numbers

Black-Red 37-105 VAC 100-120 Pin #1-2

* Be sure to check for obstructions to blades. Check the capacitor before replacing motor.

(PS) Pressure Sensor: (Connector A) Omron Electronic Pressure Switch

RHFE-201FA

Omron Electronic

Note: Insure clear and black hose from pressure switch to blower air chamber is not blocked or

crimped with any obstructions including spider webs.

(TF 216ºC, OHS1 90ºC, OHS2 70ºC) (Connector G) Safety Circuit:

Disconnect connector G from PCB. Check for continuity reading from Pin #1 to Pin #5 on the wiring

harness White to White wires. If you do not read continuity through this circuit, locate open thermal

fuse, bimetal OHS1, or bimetal OHS2, and replace. You must immediately determine what caused

the overheat situation and correct. Check combustion specifications, gas pressures, gas type, and

for any obstructions to air flow.

(R.TH) Room Thermistor: (Co nnector H) Negative Co-efficient Therm istor

(the resistance decreases as the temperature increases)

Disconnect connector H from PCB. Set your meter to the 200K scale. Place your meter leads into

Yellow to Yellow. Apply heat to the thermistor bulb. The resistance will decrease. Apply cold and the

resistance will increase. Examples of readings:

41ºF=91K 50ºF=65K 68ºF=39K 86ºF=23K

(OH.TH) Over Heat Thermistor: (Connector H)

0.31 in (8.0 mm) WC

ON

0.11 in (2.8 mm) WC

OFF

5 VDC

Disconnect connector H from PCB. Set your meter to the proper scale. Place your meter leads

into White to White. A reading below 0.38k indicates a short. A reading above 1255k indicates

an open circuit or broken wire. Insure air flow is not obstructed.

(FR) Flame Rod (Connector C1)

Set your meter to read micro-amps (µ). Disconnect connector C1 and place your meter in series

with the Yellow to Yellow wires. Upon flame development you should read 1 -2 micro-amps.

Depending on gas type and firing rate you should read 4 to 8 micro-amps. You must have a

grounded and polarized electrical supply with no obstructions in burner or build up on flame rod to

proof flame. The micro-amp symbol on your meter is µ.

(Hard Lock Out Information)

Improper sized gas lines, low pressure drops, defective or freezing pressure regulators, improper

electrical supply and failure to ground, spider webs in burners, intake and exhaust air blockage of

vents, broken or damaged wiring harnesses, or blown fuses can cause hard lock outs. Before

replacing components in furnace, insure the above items are within the specifications. The above

listed items are not a warranty issue or defect in unit.

Rinnai Direct Vent Service Manual 13

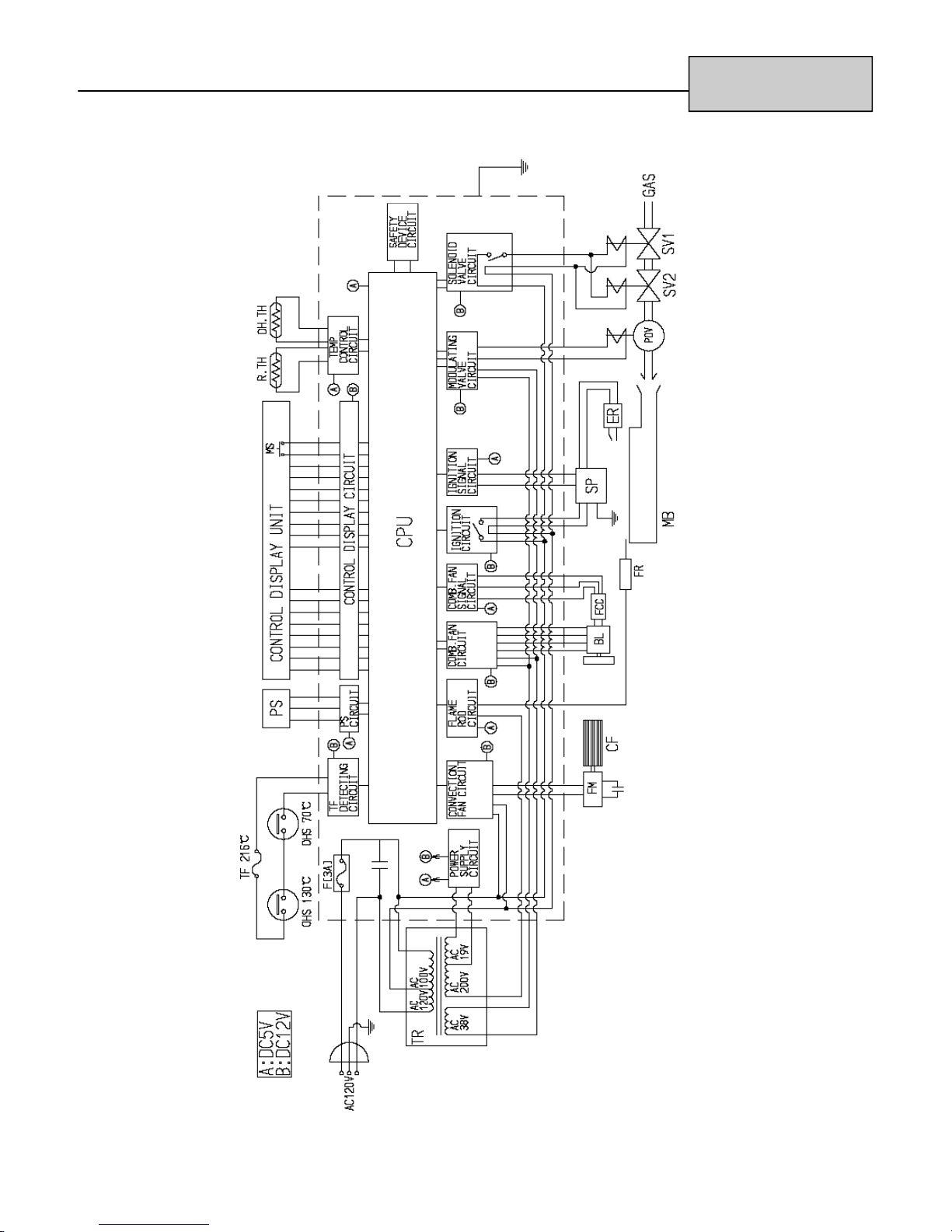

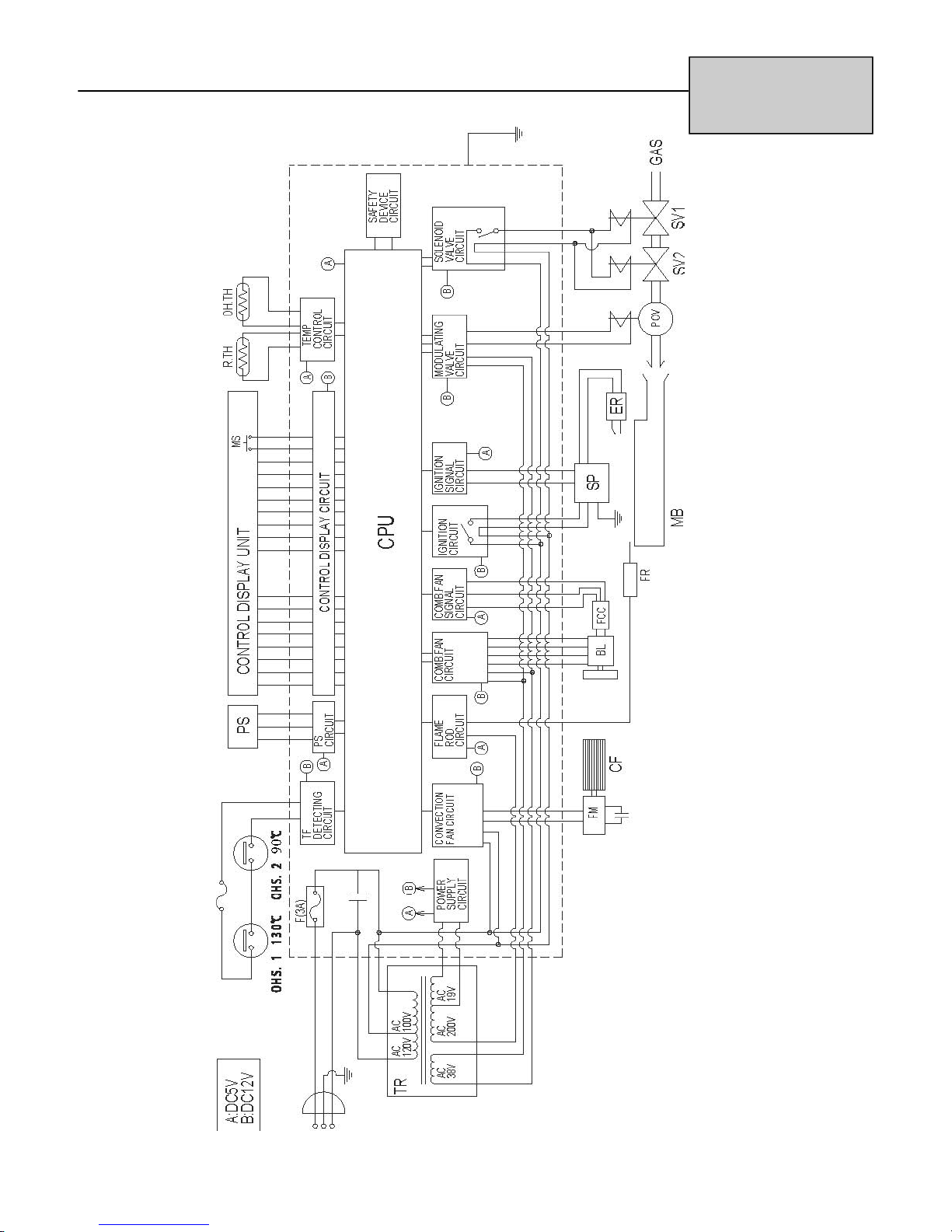

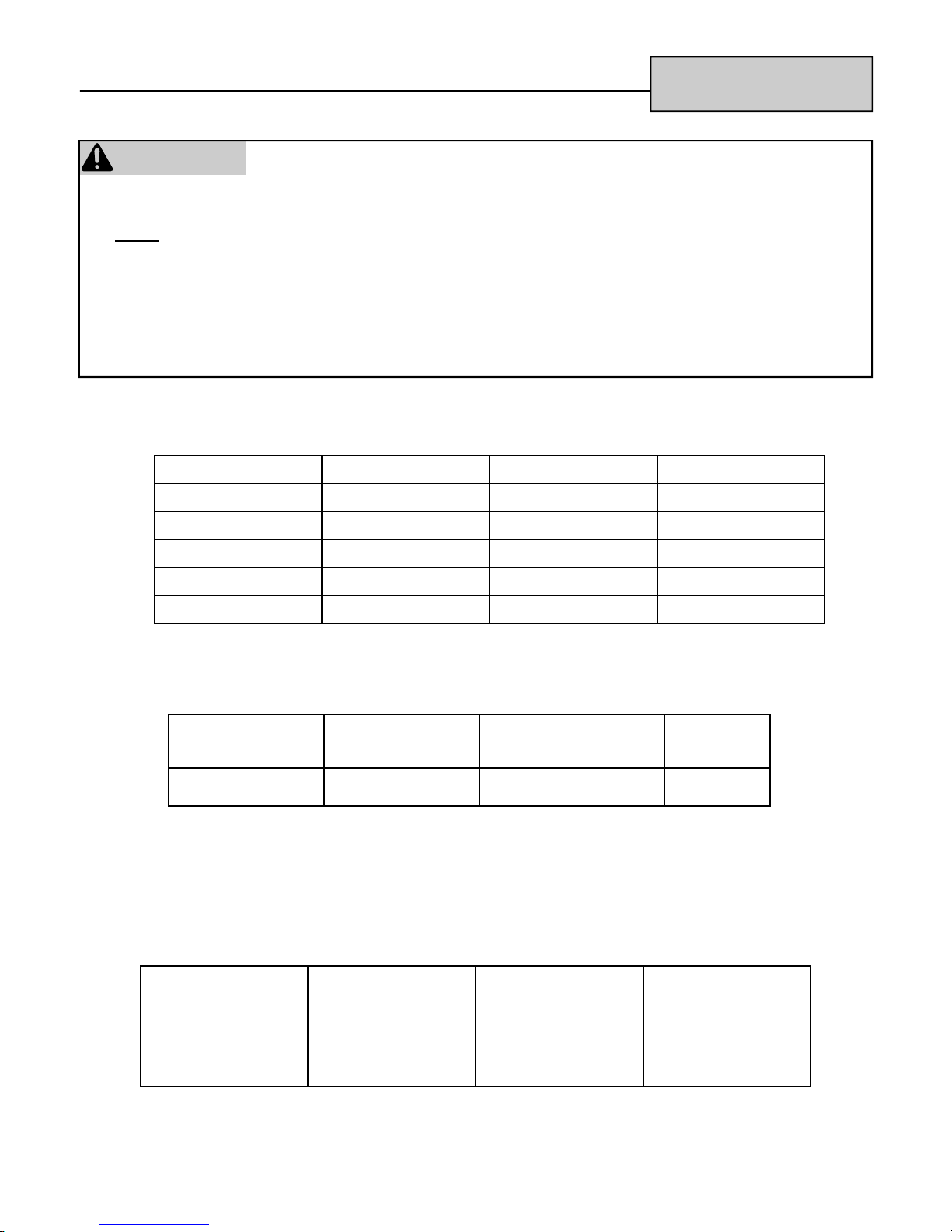

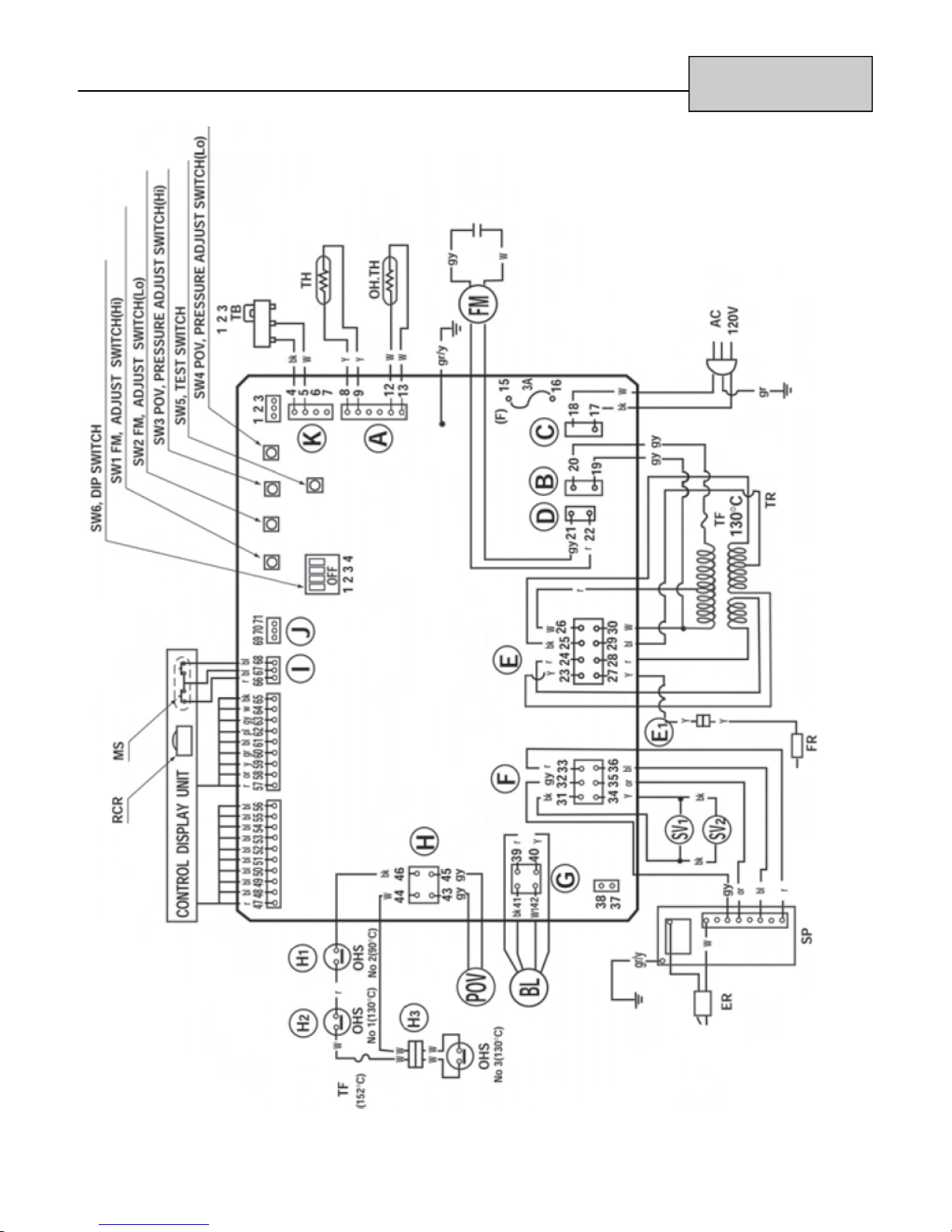

Wire Diagram

RHFE-201FA

RHFE-201RFA

14 Rinnai Direct Vent Service Manual

Ladder Diagram

RHFE-201FA

RHFE-201RFA

Rinnai Direct Vent Service Manual 15

Troubleshooting

RHFE-263FA

RHFE-263FAII

RHFE-263RFA

WARNING

(AC IN)

Black-White 120 VAC Pin # 1-2

Black-Ground 120 VAC Pin #2-Ground

White-Ground 0 VAC Pin #1-Ground

(TR) Transformer: (Connector CN2 AC Out)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Gray - Gray 98-125 VAC 4--16 1-7

White - White 98-125 VAC 4--14 2-3

Red - Red 35 VAC 1--3 4-10

Black - Yellow 200-220 VAC 250--400 5-8

There are a number of live tests that are required when fault finding this product. Extreme care

should be used at all times to avoid contact with energized components inside the furnace.

You MUST be a qualified service person before proceeding with these test instructions.

Before checking resistance readings, turn off power source to unit and then isolate each item to be

checked from the circuit by unplugging it.

When setting gas pressures on one of these units, please check the complete model number you

are trouble-shooting. Gas pressures and dip switches can vary among models. Always check the

rating plate for complete information and follow directions.

Black - Blue 12-20 VAC 1--3 8-9

(SP) Sparker: (Connector CN4)

Read voltage across: Voltage Potential Read resistance Pin Numbers

Red-Blue 85-100 VAC 100K-120K 3-6

The spark must be sensed as being at the correct location and intensity before it will allow the gas valve to open. Check

across Pin # 1-2 at Connector F and you should read 4-6 VDC potential. When sparking, if the spark is in the right location and

intensity the voltage potential will drop to almost 0 (zero) and then return to the 4-6 VDC potential.

(SV1, SV2, POV) Main Solenoid Valves: (Connector CN4)

Read voltage across: Voltage Potential Read resistance Pin Numbers

SV1 - Yellow ~ Black (hold) 85-90 VDC 1400-2000 1-4

SV2 - Yellow ~ Black (assist) 85-90 VDC 1400-2000 1-4

POV - Gray ~ Gray 6-16 VDC 80-90 2-6

*Resistance across each coils terminals should be 1400-2000 when isolated.

(BL) Combustion Fan Motor: (Connector CN8) DC Motor 37VDC 8 Watts

Read voltage across: Voltage Potential Read resistance Pin Numbers

Black-White 7-12 VDC 8-10 K 7-8

Yellow-White 4-5 VDC 4-6 K 4-8

Red-White 10-30 VDC N/A 3-8

16 Rinnai Direct Vent Service Manual

Troubleshooting

RHFE-263FA

RHFE-263FAII

RHFE-263RFA

(FM) Convection Fan Motor: (Connector CN3) AC Motor 60 Hz, 100VAC

Read voltage across: Voltage Potential Read resistance Pin Numbers

Black-Red 40-105 VAC 100-120 1-2

* Be sure to check for obstructions to blades. Check the capacitor before replacing motor.

(PS) Pressure Sensor: (Connector CN13) Electronic Pressure Switch, 125 V, 0.1 A

Electronic

Note: Ensure clear and black hose from pressure switch to blower air chamber is not blocked or

crimped with any obstructions including spider webs.

(RT) Room Temperature Control:

Integrated into the PCB program and works in conjunction with the thermistor as noted below.

(TH) Room Thermistor:

Check thermistor by inserting meter leads into each end of thermistor plug. Set your meter to the

200 K scale. Apply heat to the thermistor bulb and the resistance should decrease. Apply cold

and the resistance should increase. Examples of readings:

41ºF=91K 50ºF=65K 68ºF=39K 86ºF=23K

(FR) Flame Rod

Set your meter to read micro-amps (µ). Located on the combustion chamber, the lfame rod proofs

flame for proper operations. A properly grounded electrical supply is a must. Flame rod current

through this rod should range between 4 to 8 icro amps depending on gas type. Low fire flame

current should be 1.2 to 2.0 micro amps.

Improperly setup and /or converted units can soot and cause hard lockouts. If carbon is found on the

flame rod, clean the carbon from it. Then you need to confirm your manifold differential gas pressure on

Hi fire and Lo fire is correct. Insure primary and secondary air dampers are correct. Also, check to ensure

proper orifices were placed in the unit..

IMPORTANT INFORMATION CONCERNING HARD LOCKOUTS:

Other items that can cause hard lockouts are: improper sized gas lines, low gas pressures or pressure drops due

to other appliances on the gas system, spider webs in the burner and air intake of vent system, improper ground

or no ground at receptacle, supply regulators freezing up or defective, voltage drops or bad receptacles, winds in

excess of 40 mph causing turbulence inside the vent terminal, etc.

(OHS1, OHS2, TF) Safety Circuit Check: CN8

Check for continuity reading from pin #1 white wire to pin #5 white wire. If you do not read continuity through this

circuit, locate defective switch and replace that component. Then determine what caused overheat condition.

(MS) Main Switch: CN11

Disconnect CN11 from PCB, being careful not to break wires. Read Blue to Blue, pin #9 and 10 on 40K . When

ON/OFF is in the ON position, you should read 10--18K. When released, you should read open or 0

Wiring harness, connectors, and fuses should be checked if all above readings are normal.

0.31 in (8.0 mm) WC

ON

0.11 in (2.8 mm) WC

OFF

5 VDC

Rinnai Direct Vent Service Manual 17

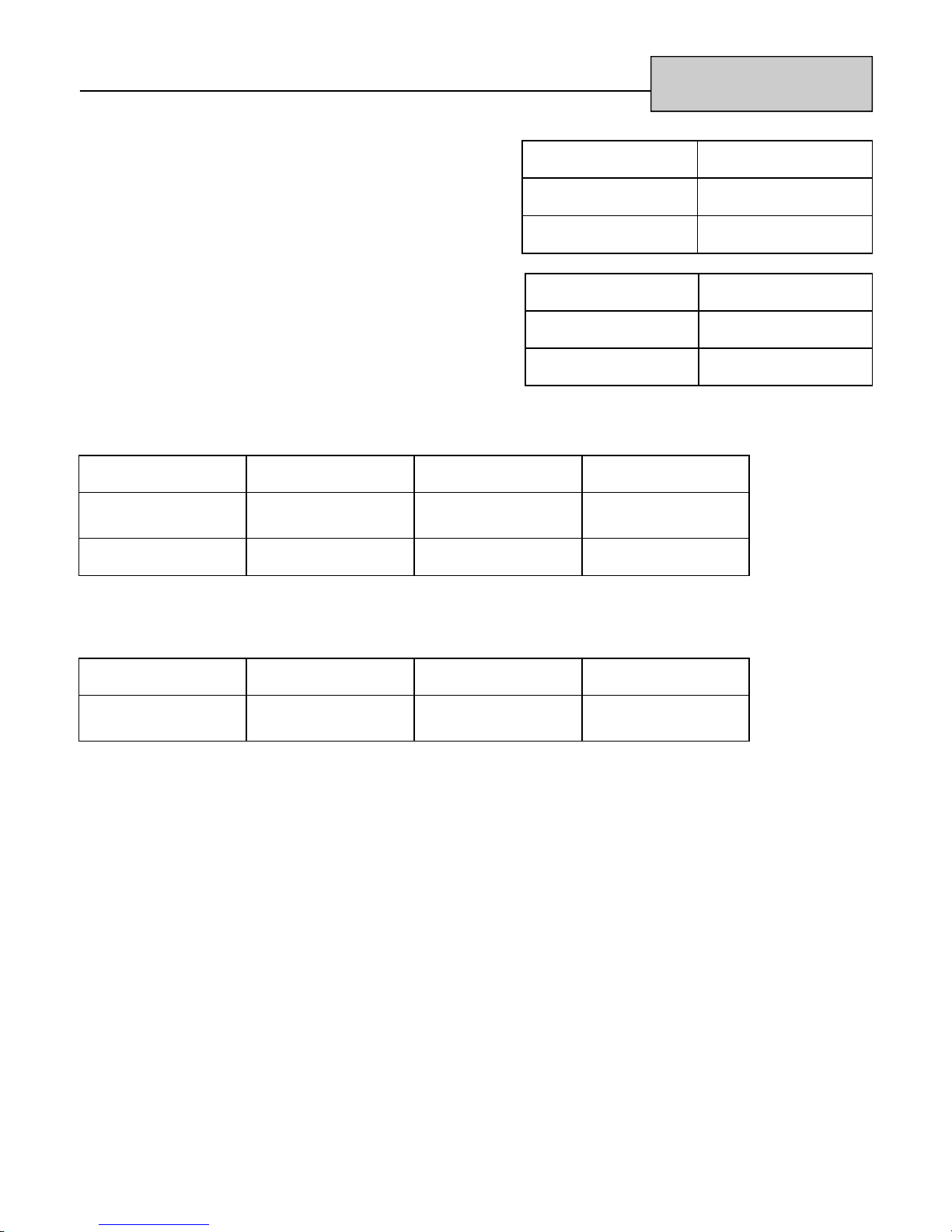

Wire Diagram

RHFE-263FA

RHFE-263FAII

RHFE-263RFA

18 Rinnai Direct Vent Service Manual

Ladder Diagram

RHFE-263FA

RHFE-263FAII

RHFE-263RFA

Rinnai Direct Vent Service Manual 19

Troubleshooting

Part Wire 202FTA 265FTA

Control Panel

OHS.

TF White - White (TF)

O.H. TH

Room

Thermistor

White - White

White - White

(TH operates)

Red - Blue

Blue - Blue

White - White

Blue - White (OHS1)

Blue - White (OHS2)

White - White 0.87-482k; (<0.87k:Short, >482k:Open)

Temperature

High Flashes below 4.5k

(Filter sign)

Yellow - Yellow 1.82-707k; (<1.82k:Short, >707k:Open)

Temperature

Low Flashes below 4.5k

High Operates below 3.4k

Low Operates below 3.4k

DC0-5V (Pulsed voltage); Resistance is infinity, but the current flows

when the switch is pushed.

Below DC 1V, Below 2

32°F (0°C):214k, 68°F (20°C):78k, 122°F (50°C):21k

176°F (80°C):7.3k, 212°F (100°C):3.6k, 135°F (275°C):1.5k

32°F (0°C):113k, 68°F (20°C):39k,

86°F (30°C):24k, 104°F (40°C):15k

RHFE-202FTA

RHFE-265FTA

FR Yellow - Yellow

White - Black Below ignition revolution +2Hz Below ignition revolution +2Hz

Combustion Fan

(In case of short

vent.)

Combustion Fan

(In case of long vent.)

Ignitor Red - Blue 90-120V

SV

Modulating Valve Red-White

Convection Fan Red - Black 50-110V, 90-180

Pressure Sensor Red - White DC3 - 7V

Ignition

revolution

Normal

revolution

White - Black - Below ignition revolution +2Hz

Ignition

revolution

Normal

revolution

Black-White

Black-Yellow

Initial LP: 75Hz, NG: 80Hz LP: 80Hz, NG: 85Hz

Re-attempt LP: 75Hz, NG: 80Hz LP: 80Hz, NG: 85Hz

High LP: 110Hz, NG: 110Hz LP: 128Hz, NG: 118Hz

Low LP: 83Hz, NG: 83Hz LP: 82Hz, NG: 81Hz

Initial - LP: 80Hz, NG: 85Hz

Re-attempt - LP: 80Hz, NG: 85Hz

High - LP: 128Hz, NG: 128Hz

Low - LP: 82Hz, NG: 89Hz

Below 0.1A (During Stop)

80-100V, 1.5-2.5k

DC2-15V(Low-High), 60-90

Transformer 60Hz-120V

Gray - Gray AC108-132V, 5-20

White - White AC95-120V, 5-20

Red - Red AC20-40V, 0.5-2.0

Brown - Brown AC10-30V, 1-5

Black - Blue AC10-30V, 1.0-3.0

Black - Yellow AC200-240V, 200-450

20 Rinnai Direct Vent Service Manual

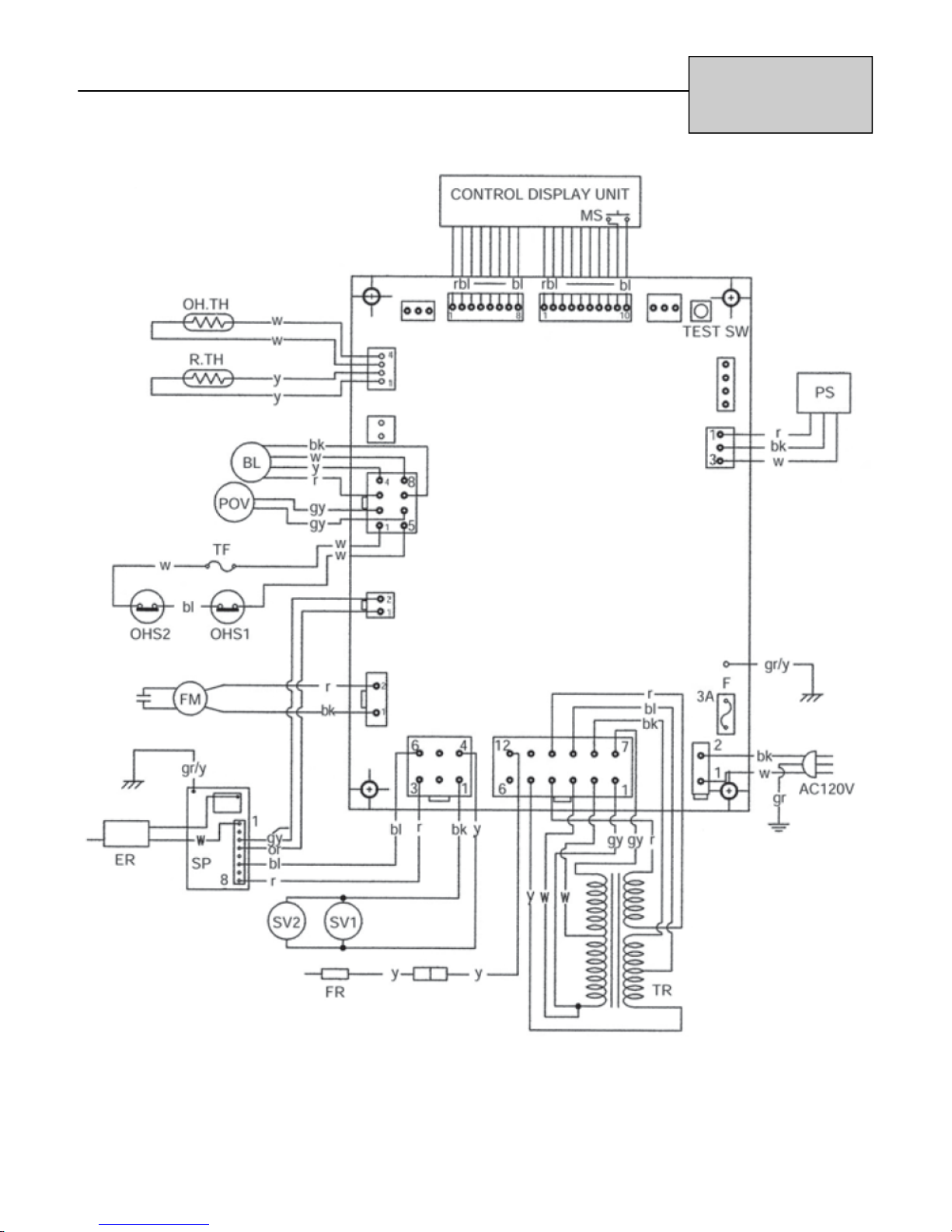

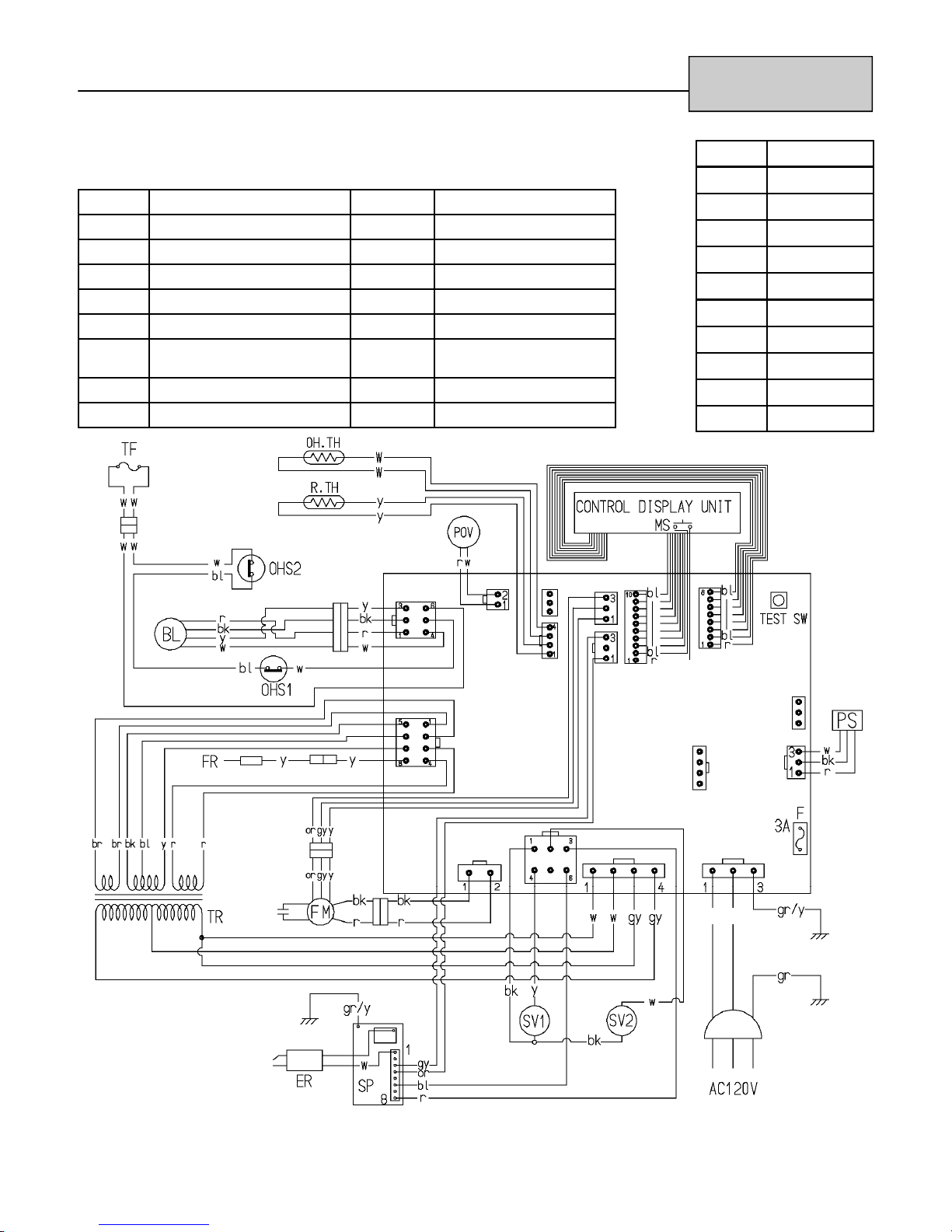

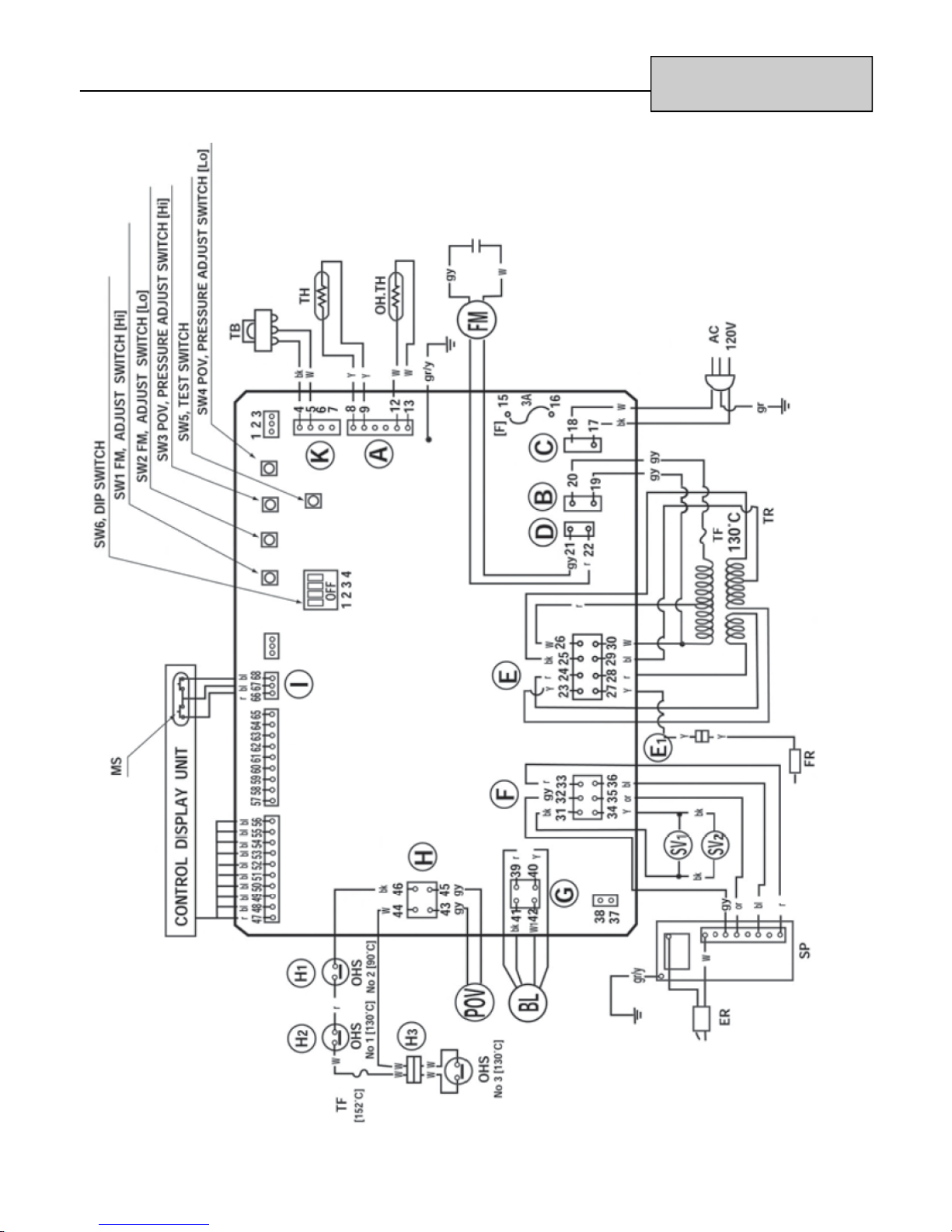

Wire Diagram

MARK PART NAME

MS MAIN SWITCH

R.TH THERMISTOR

TF THERMAL FUSE

F FUSE

ER ELECTRODE

POV MODULATING SOLENOID

VALVE

TR TRANSFORMER

FR FLAME ROD

MARK PART NAME

OH.TH OVER HEAT THERMISTOR

OHS1, 2 OVER HEAT SWITCH 1, 2

FM CONVECTION FAN MOTOR

SP SPARKER

SV1, 2 MAIN SOLENOID VALVE 1, 2

BL COMBUSTION FAN MOTOR

PS PRESSURE SENSOR

RHFE-202FTA

RHFE-265FTA

CODE COLOR

bk black

bl blue

gr green

gr/y green/yellow

r red

w white

y yellow

gy gray

or orange

br brown

Rinnai Direct Vent Service Manual 21

w

bk

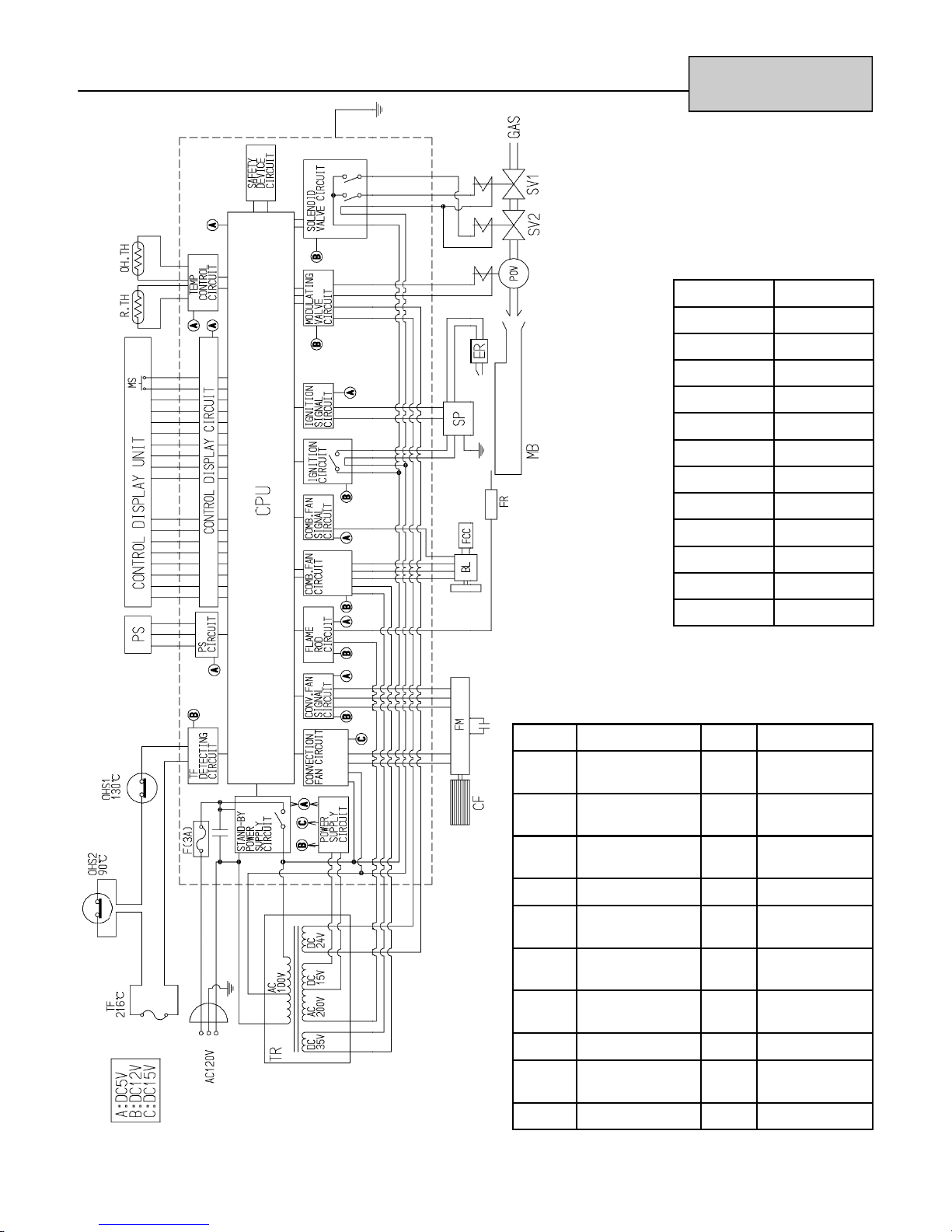

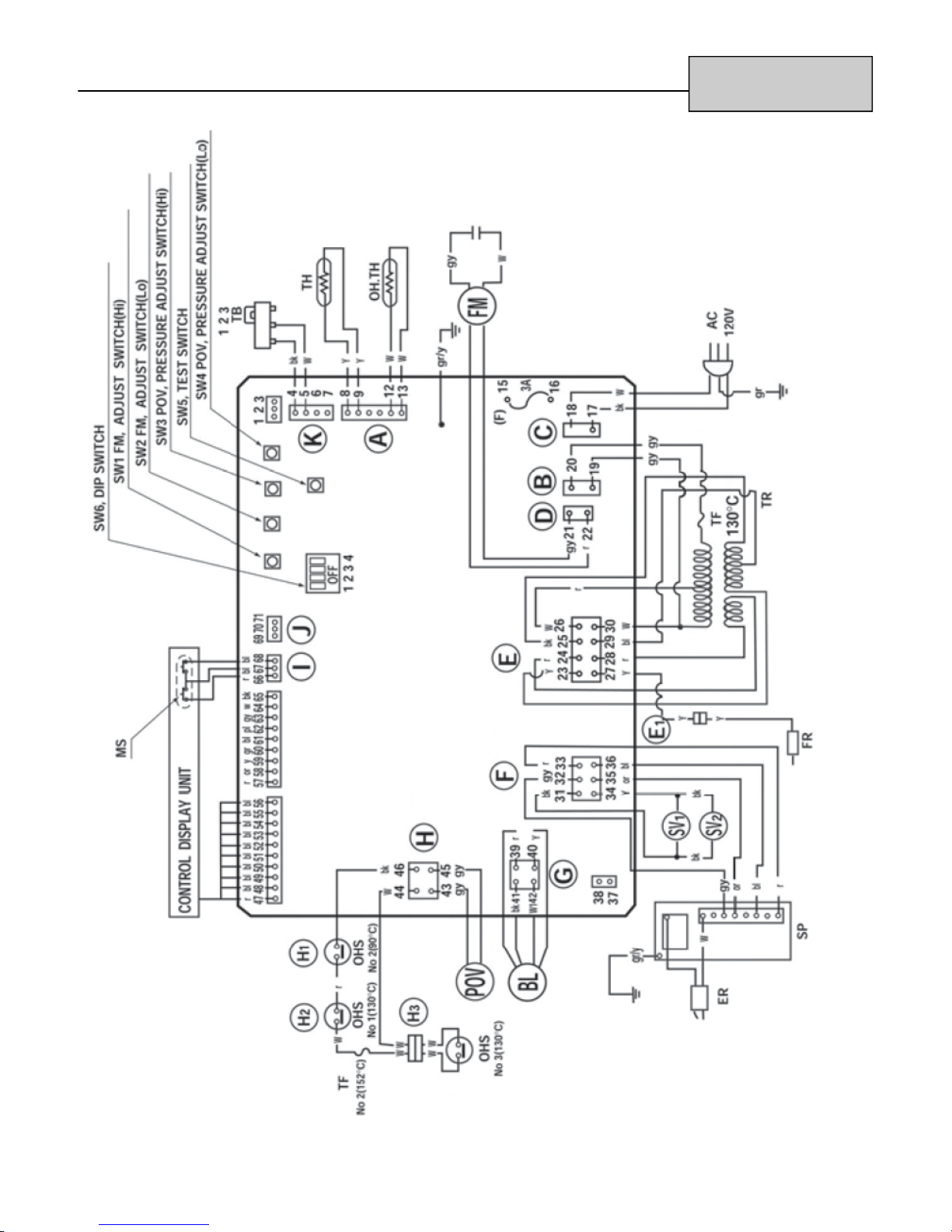

Ladder Diagram

RHFE-202FTA

RHFE-265FTA

CODE COLOR

bk black

bl blue

gr green

gr/y green/yellow

r red

w white

y yellow

gy gray

or orange

pk pink

br brown

lb light blue

MARK PARTS NAME MARK PARTS NAME

MS Main switch OH,

TH

R, TH Thermistor OHS1, 2 Over heat switch

TF Thermal fuse FM Convection fan

F Fuse SP Sparker

ER Electrode SV1, 2 Main solenoid

POV Modulating

solenoid valve

BL Combustion fan

Over heat

thermistor

1,2

motor

valve 1,2

motor

22 Rinnai Direct Vent Service Manual

TR Transformer FCC Fan control

circuit

FR Flame rod MB Main burner

PS Pressure sensor CPU Central

processing unit

CF Convection Fan

Troubleshooting

RHFE-556FA/FTRA Series

RHFE-431FA Series

WARNING

There are a number of live tests that are required when fault finding this product. Extreme care should be used at

all times to avoid contact with energized components inside the furnace.

You MUST be a qualified service person before proceeding with these test instructions.

Before checking resistance readings, turn off power source to unit and then isolate each item to be checked from

the circuit by unplugging it.

When setting gas pressures on one of these units, please check the complete model number you are trouble-

shooting. Gas pressures and dip switches can vary among models. Always check the rating plate for complete

information and follow directions.

(TR) Transformer:

Read Voltage across:

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

White - White 98 - 105 VAC 6 - 19 ohms 26 - 30

Red - Red 28 - 50 VAC 1 - 3 ohms 24 - 28

Black - Blue 10 - 15 VAC 0.5 - 2 ohms 25 - 29

Blue - Yellow 130 - 185 VAC 200 - 400 ohms 23 - 29

Gray - Gray 110 - 120 VAC 10 - 14 ohms 19 - 20

(SP) Sparker Board:

WIRE COLOR

Blue - Red

Set your voltage meter on the 400k scale, unplug the (5) pin connector on the sparker board. When reading

across the two lugs the blue and red wire connect to, you should read somewhere between 100k and 120k ohms

of resistance. When checking the spark sensing circuit, check across the orange wire (pin #35) and grey wire (pin

#32) on your 40 VDC scale. You should read between 4 - 5 VDC. During the spark this voltage will drop to

approximately 0 VDC. Once unit ignites the voltage will go back up to 4 - 5 VDC.

(POV, SV1, and SV2) Gas valve solenoids:

VOLTAGE

85 - 110 VAC

RESISTANCE PIN

see below

33 - 36

WIRE COLOR VOLTAGE RESISTANCE * PIN NO.

Gray - Gray

Black - Yellow 85 - 90 VDC 1,300 - 2,000 ohms 31 - 34

*Remember, when reading the resistance of a solenoid coil, you should read across the lugs on the coil.

Rinnai Direct Vent Service Manual 23

4.5 VDC low fire to

11.5 VDC high fire

80 - 100 ohms 43 - 45

Troubleshooting

(BL) Combustion Motor:

NOTE: If your meter does not have a hertz scale, please

refer to voltage and resistance readings listed

below. If you have a hertz scale, check the

following items first. Hertz reading across black white wires, pins 41 and 42.

Voltage and resistance check for (BL).

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

RHFE-431 - LP UNITS

Lo fire - 44 Hz.

Hi fire - 81 Hz.

RHFE-431 NG UNITS

Lo fire - 44 Hz.

Hi fire - 81 Hz.

RHFE-431FA Series

RHFE-556FA/FTRA Series

RHFE-556 LP UNITS

Lo fire - 47 Hz.

Hi fire - 106 Hz.

RHFE-556 NG UNITS

Lo fire - 48 Hz.

Hi fire - 106 Hz.

Red - Yellow

Black - White N/A 9.4 k - 9.9 k ohms 41 - 42

(FM) Convection fan motor:

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

Red - Gray

(TH) Thermistor:

Check the thermistor by inserting meter leads into each end of the thermistor plug. Set your meter to the 200k

scale and read resistance. You should be able to apply heat to the thermistor bulb and see the resistance

decrease. Then apply ice to the thermistor bulb and the resistance should increase.

EXAMPLES: 41 °F = 91 k ohms

50 °F = 65 k ohms

68 °F = 39 k ohms

86 °F = 23 k ohms

(FR) Flame Rod:

Flame rod - yellow wire = pin #27. Low fire current should be 1.3 to 2.0 micro amps (Fa). High fire current should

be 4 to 8 micro amps, depending on gas type being used.

NOTE: Improperly setup and/or converted units can soot and cause carbon to accumulate on flame rods. This

will cause hard lockouts. If carbon is found on the flame rod, remove and clean carbon from rod. Then

you will need to confirm manifold gas pressure, proper air dampers and ensure vent is clear. Also, check

for proper orifices.

1-2 VDC low fire to 7.6

-18 VDC high fire

80-94 VAC low fire to

95-104 VAC high fire

1.2 - 1.8 mega ohms 39 - 40

90-180 ohms 21 - 22

24 Rinnai Direct Vent Service Manual

Troubleshooting

(H

, H2 and H3) Safety Circuit:

1

Check for continuity across pins 44 and 46 at terminal H on the PC board. If you have no continuity, this means

one of these switch/thermal fuses is open. Replace defective component.

(OH - TH) Overheat Thermistor:

Check resistance reading across pins 12 and 13 at terminal A on the PC board. Proper readings should be 0.6 k

and 523 k. A reading below 0.6 k ohms indicates a short and a reading above 523k indicates an open circuit.

(MS) On/Off Control:

To check to ensure the on/off button is functioning, unplug terminal I. Place (1) lead of your meter on the red wire

for pin #66 and the other lead on the blue wire for pin#68. Now press the on/off button and you should be able to

read continuity through this switch each time the button is pressed.

(TB) Terminal Block:

This terminal is located on the right rear upper portion of the unit. On direct vents the jumper should be across

terminals 2 and 3. On units with vent extensions over four feet, this jumper should be across terminals 1 and 2.

IMPORTANT INFORMATION CONCERNING HARD LOCKOUTS:

Other items that can cause lockouts are: Improperly converted units, spider webs in burner and

air intake of vent system, improperly sized gas lines, low gas pressures or pressure drops due to other appliances

on the gas system, improper ground or no ground at receptacle, supply regulators freezing up or defective,

voltage drops or bad receptacle, winds in excess of 30 to 40 MPH causing turbulence inside the vent terminal, etc.

RHFE-556FA/FTRA Series

RHFE-431FA Series

Rinnai Direct Vent Service Manual 25

Wire Diagram

RHFE-431FA Series

RHFE-556FA/FTRA

26 Rinnai Direct Vent Service Manual

Wire Diagram

RHFE-556FAIII

Rinnai Direct Vent Service Manual 27

Wire Diagram

RHFE-556FTRAIII

28 Rinnai Direct Vent Service Manual

Troubleshooting

RHFE-431WTA

RHFE-556WTA

WARNING

There are a number of live tests that are required when fault finding this product. Extreme care should be used at

all times to avoid contact with energized components inside the furnace.

You MUST be a qualified service person before proceeding with these test instructions.

Before checking resistance readings, turn off power source to unit and then isolate each item to be checked from

the circuit by unplugging it.

When setting gas pressures on one of these units, please check the complete model number you are trouble-

shooting. Gas pressures and dip switches can vary among models. Always check the rating plate for complete

information and follow directions.

(TR) Transformer:

Read Voltage across:

WIRE COLOR

White - White

Red - Red

Black - Blue

Blue - Yellow

Grey - Grey

VOLTAGE

130 - 185 VAC

110 - 120 VAC

98 - 105 VAC

28 - 50 VAC

10 - 15 VAC

RESISTANCE

READING

6 - 19 ohms

1 - 3 ohms

0.5 - 2.5 ohms

200 - 400 ohms

10 - 14 ohms

PIN

NUMBERS

21 - 27

30 - 31

22 - 23

23 - 32

17 - 18

Purple - Purple 4.5 - 5.5 VAC

Black - Yellow 165 - 185 VAC 200 - 212 ohms 22 - 32

Brown - Purple 2.2 - 2.8 VAC 0.7 - 1.2 ohms 24 - 28

(SP) Sparker Board:

WIRE COLOR

Blue - Red 85 - 110 VAC see below 33 - 36

Set your voltage meter on the 400k scale, unplug the (5) pin connector on the sparker board. When reading

across the two lugs the blue and red wire connect to, you should read somewhere between l00k and 120k ohms

of resistance. When checking the spark sensing circuit, check across the orange wire (pin #35) and gray wire (pin

#32) on your 40 VDC scale. You should read between 4 - 5 VDC. During the spark this voltage will drop to

approximately 0 VDC. Once unit ignites the voltage will go back up to 4 - 5 VDC.

VOLTAGE

1 - 2 ohms

RESISTANCE

READING

24 - 25

PIN

NUMBERS

Rinnai Direct Vent Service Manual 29

Troubleshooting

(POV, SV1, and SV2) Gas valve solenoids:

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

RHFE-431WTA

RHFE-556WTA

Gray - Gray

Black - Yellow 85 - 90 VDC 1,300 - 2,000 ohms 35 - 38

*Remember, when reading the resistance of a solenoid coil, you should read across the lugs on the coil.

(BL) Combustion Motor:

NOTE: If your meter does not ha ve a hertz scale,

please refer to voltage and resistance

readings listed below. If you have a hertz

scale, check the following items first.

Hertz reading across black - white wires,

pins 41 and 42.

Voltage and resistance check for (BL).

4.5 VDC low fire to

11.5 VDC high fire

80 - 100 ohms 45 - 47

RHFE-431 - LP UNITS

Lo fire - 46 Hz.

Hi fire - 82 Hz.

RHFE-431 NG UNITS

Lo fire - 62 Hz.

Hi fire - 81 Hz.

RHFE-556 LP UNITS

RHFE-556 NG UNITS

Lo fire - 47 Hz.

Hi fire - 106 Hz.

Lo fire - 48 Hz.

Hi fire - 106 Hz.

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

Red - Yellow

Black - White N/A 9.4 k - 9.9 k ohms 41 - 42

(FM) Convection fan motor:

WIRE COLOR VOLTAGE RESISTANCE PIN NO.

Red - Gray

(TH) Thermistor:

Check the thermistor by inserting meter leads into each end of the thermistor plug. Set your meter to the 200k

scale and read resistance. You should be able to apply heat to the thermistor bulb and see the resistance

decrease. Then apply ice to the thermistor bulb and the resistance should increase. Pins 5 and 6 on the P.C.

board.

EXAMPLES: 41 ºF = 91 k ohms

50 ºF = 65 k ohms

68 ºF = 39 k ohms

86 ºF = 23 k ohms

1-2 VDC low fire to 7.6

-18 VDC high fire

80-94 VAC low fire to

95-104 VAC high fire

1.2 - 1.8 mega ohms 43 - 44

90-180 ohms 19 - 20

30 Rinnai Direct Vent Service Manual

Loading...

Loading...