Page 1

Owner’s Operation and Installation Manual

RHFE-431WTA

ENERGYSAVER

GAS DIRECT VENT WALL FURNACE

INSTALLER: Leave this manual with the appliance.

CONSUMER: Retain this manual for future reference.

This appliance may be installed in an aftermarket, permanently

located, manufactured home (USA) or mobile home, where not

prohibited by local codes.

This appliance is only for use with the type of gas indicated on

the rating plate. This appliance is not convertible for use with

other gases, unless a certified kit is used.

─ Do not store or use gasoline or other flammable vapors and

liquids in the vicinity of this or any other appliance.

─ WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

Do not touch any electrical switch; do not use any phone in

your building.

Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire

department.

─ Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

WARNING: If the information in these instructions are not

followed exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

HOME OWNER / INSTALLER

FOR YOUR SAFETY

THIS MANUAL MUST BE READ IN ITS

ENTIRETY BEFORE OPERATING HEATER

Register your product at www.rinnairegistration.com or

call 1-866-RINNAI1 (746-6241)

Page 2

WARNING

IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION,

SERVICE OR MAINTENANCE CAN CAUSE PROPERTY

DAMAGE, PERSONAL INJURY OR LOSS OF LIFE.

REFER TO THE OWNER'S INFORMATION MANUAL

PROVIDED WITH THIS APPLIANCE. INSTALLATION AND

SERVICE MUST BE PERFORMED BY A QUALIFIED

INSTALLER, SERVICE AGENCY OR THE GAS SUPPLIER.

ENERGYSAVER RHFE-431WTA

Table of Contents

Page

FEATURES OF THE RHFE-431WTA UNITS/SAFETY DEVICES.................................1

TECHNICAL DATA.........................................................................................................2

IMPORTANT POINTS/USAGE AND INSTALLATION MUSTS ......................................2

DIMENSIONS.................................................................................................................4

SPECIFICATIONS..........................................................................................................5

SAFETY POINTS ...........................................................................................................7

GETTING TO KNOW YOUR NEW RHFE-431 ..............................................................9

CONTROL PANEL/LED DISPLAY .................................................................................10

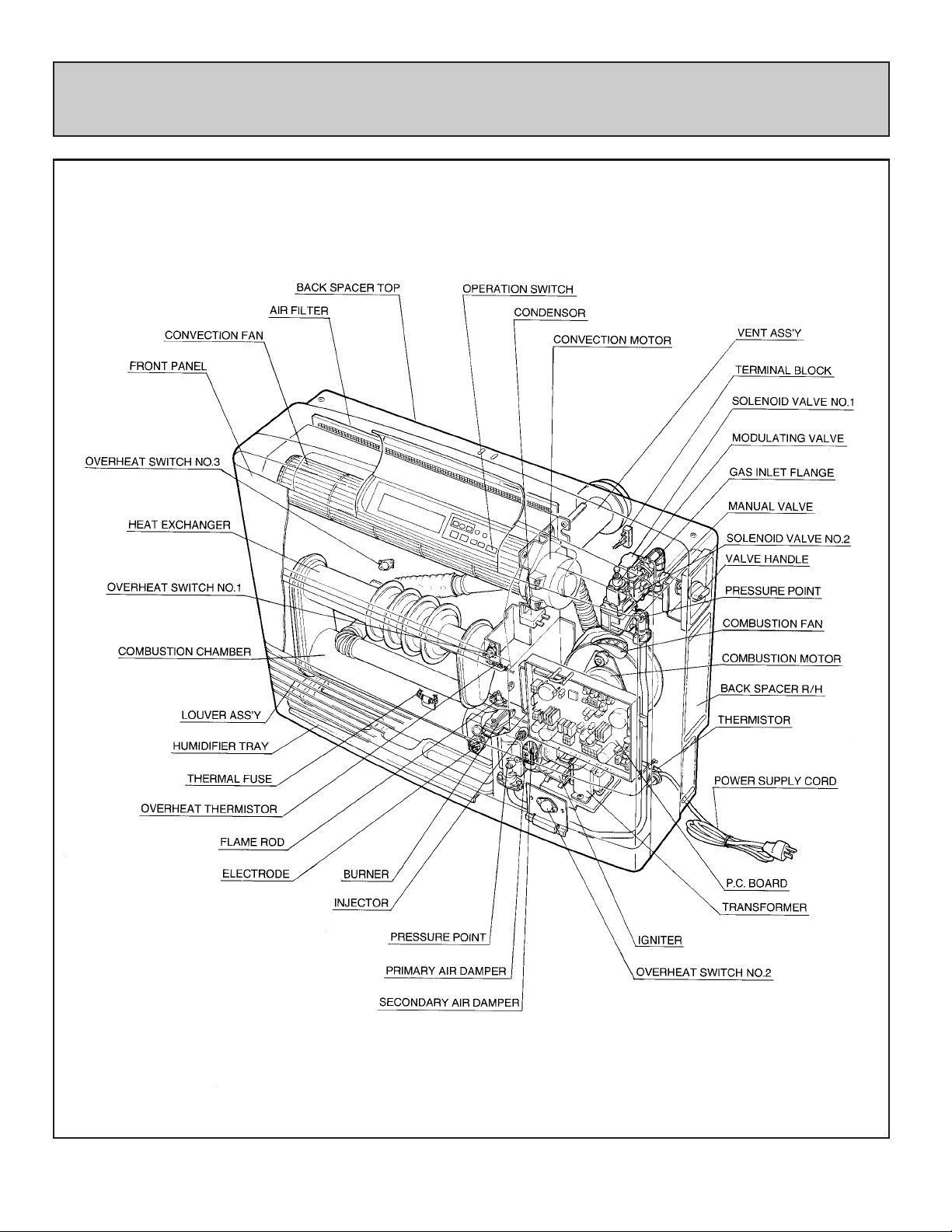

CUT-AWAY DIAGRAM ...................................................................................................11

NOTICE BEFORE INSTALLATION................................................................................12

INSTALLATION INSTRUCTIONS ..................................................................................13

GAS CONNECTION.......................................................................................................14

VENT LOCATION...........................................................................................................15

FITTING TOP SPACE+WALL CLIP ...............................................................................15

VENT TERMINATION CLEARANCES ...........................................................................16

LOCATION/CLEARANCES ............................................................................................17

SLEEVE AND MANIFOLD INSTALLATION ...................................................................19

OPERATING INSTRUCTION LABEL.............................................................................23

SETTING THE CLOCK ..................................................................................................24

OPERATING THE HEATER MANUALLY.......................................................................25

PROGRAMABLE WEEKLY TIMER................................................................................26

OVERRIDE FUNCTION .................................................................................................33

FROST PROTECTION...................................................................................................34

ENERGY SAVING MODE ..............................................................................................35

FUNCTION LOCK ..........................................................................................................36

TESTING/CHECK ..........................................................................................................37

PRE-SERVICE CHECK .................................................................................................38

TROUBLE SHOOTING ..................................................................................................39

ERROR MESSAGES .....................................................................................................40

MAINTENANCE/SERVICE ............................................................................................41

WIRING DIAGRAM ........................................................................................................42

CONSUMER SUPPORT ................................................................................................43

SCHEMATIC DIAGRAM/PARTS LIST ...........................................................................45

RHFE-431WTA FLOW DIAGRAM .................................................................................55

EXTENDED FLUE PIPE KIT..........................................................................................56

Page 3

FEATURES OF THE RHFE-431WTA UNITS

SAFETY DEVICES

– 1 –

◆ Clean Heating Forced Flue Type

◆ Easy Operation One-Touch Ignition

◆ Sensible Temperature Control Feature

◆ Comfortable Room Temperature Control and Display

◆ Warm Air Outlet at Floor Level (Keeps Your Feet Warm

)

◆ Child Safety Function Lock

◆ Room Temperature Setting Memory

◆ Dirty Air Filter Indicator Lamp

◆ Energy-Saving Economy Setting

◆ Humidifier Tray

◆ Air Flow Directional Louvers

◆ Direct Vent Easily Installed

◆ Proportional Heating Variable Capacity

◆ Hush! Quiet Operation

◆ Modern Design Minimizes Floor Space Requirements

◆ Failure Message Display

◆ Timer Override Mode

Spark Safety Device: Automatically shuts unit down when there is an abnormal spark at time

of ignition.

Flame Failure Device: Activated when burner flame fails. This prevents raw gas from being

released.

Overheat Switch: This device automatically cuts the gas off if the heater exceeds a

predetermined temperature. This is normally caused by an

obstruction in front of the louvers, or a blocked fan filter.

Fusible Links: Backs up the overheat switch. If the fusible link cuts the unit off, a

service call by an authorized person is required to replace the link.

Overcurrent Prevention Device: This is a 3 amp. glass fuse found on P.C. board. Design

to shut unit down in case of overcurrent. If fuse blows all

indicator lamps will be "OFF".

Power Outage Safety Device: This safety device cuts off gas passage and stops

operation.

Page 4

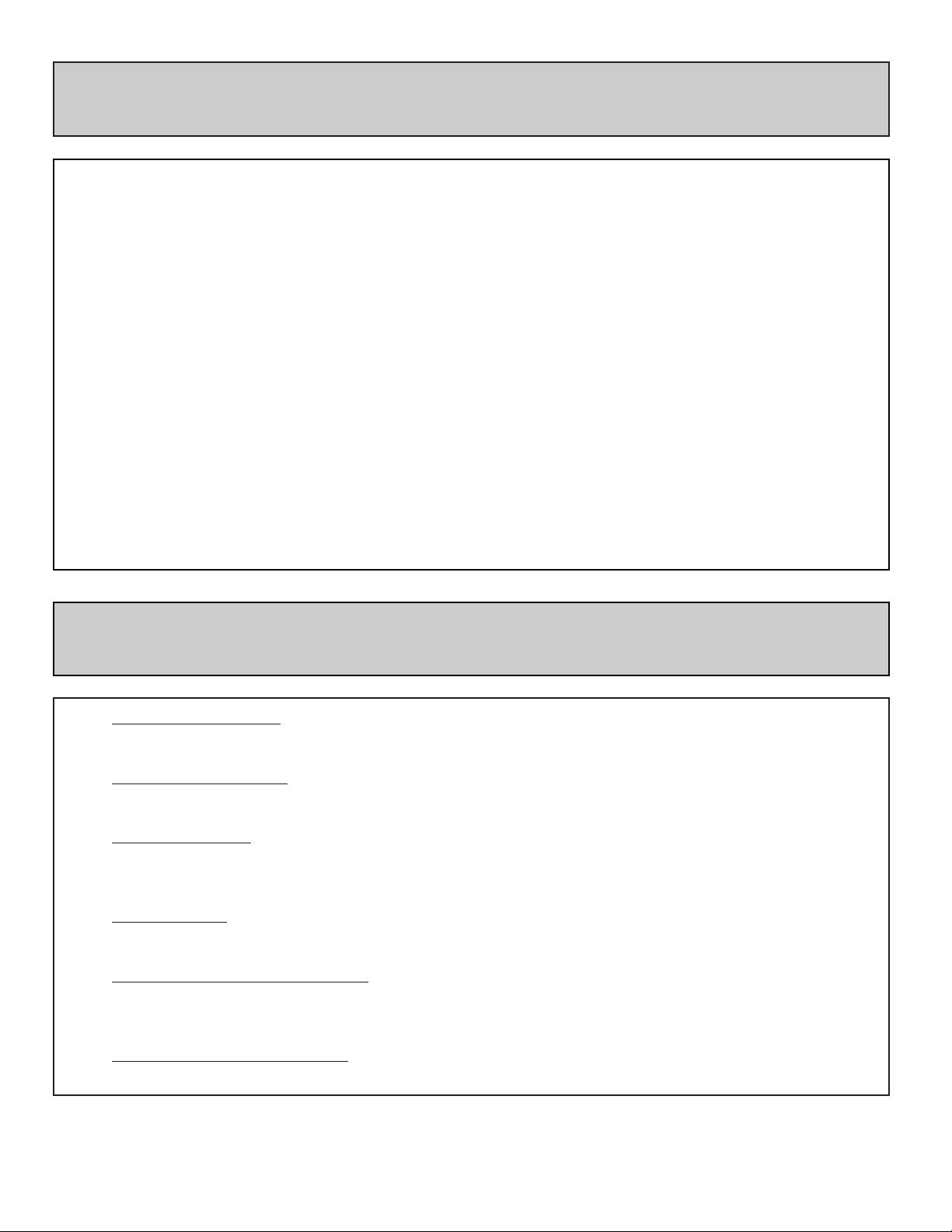

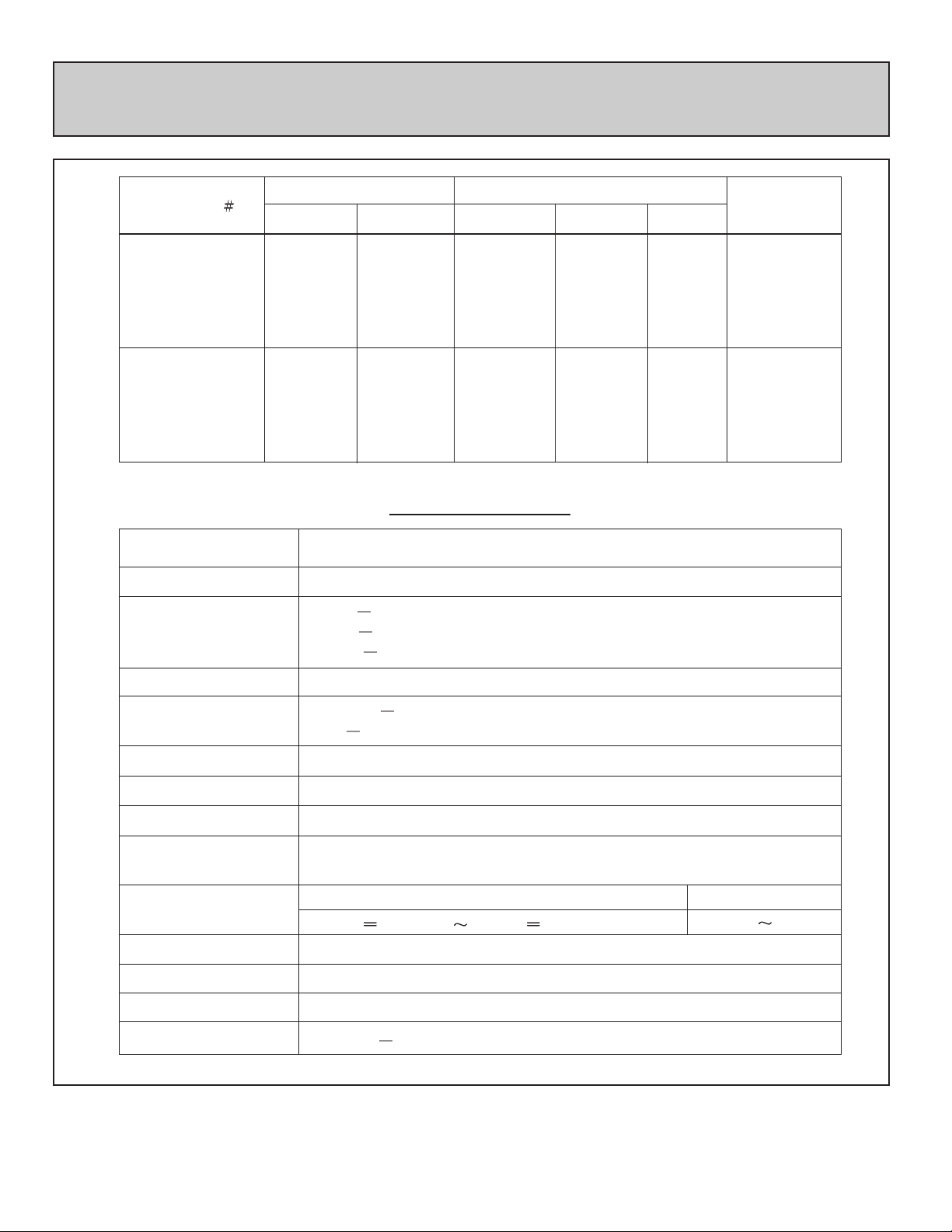

TECHNICAL DATA

– 2 –

Burner Orifices:

RHFE-431WTA-P use: Orifice part #AU129-210×02-0.85(0.033")

RHFE-431WTA-N use: Orifice part #AU129-210×02-1.13(0.044")

GAS CONVERSION SPECIFICATIONS

WEIGHT DIMENSIONS GAS RATE (BTU/h)

51 Lbs. Width: 29 1/2

"

Height:21 13/16"

Depth: 9 13/16"

INPUT

NG LP

LOW 8,200 8,200

HIGH 16,700 16,700

OUTPUT

NG LP

LOW 6,640 6,640

HIGH 13,400 13,400

GAS SUPPLY PRESSURE

・The minimum inlet gas supply pressures is for the purpose of input adjustment.

・Heaters may be converted from one gas to another using Rinnai conversion kits.

MODEL GAS

TYPE

DIAMETER OF

ORIFICE(mm)

PRIMARY

DAMPER

SECONDARY

DAMPER

MANIFOLD DIFFERENTIAL

PRESSURE (W.C.)

HI LO

RHFE-431WTA 556F-209-15LPG

0.85

556F-208-5

( 2.5×15)

ON

OFF

2.8"W.C. 0.8"W.C.

DIP SWITCH

POSITION

MINIMUM

MAXIMUM

NATURAL

3.5"W.C.

10.5"W.C.

PROPANE

8"W.C.

13"W.C.

RHFE-431WTA 556F-209-7NG

1.13

ON

OFF

2.4"W.C. 0.7"W.C.

556F-208-7

(33×47hole)

IMPORTANT POINTS / USAGE AND INSTALLATION MUSTS

Unpack heater and check for damage. (DO NOT INSTALL DAMAGED HEATER.)If heater is damaged,

contact your supplier for advice. Before installing a heater, check the label for the correct gas type (see

label on side of heater). Refer to local gas authority for confirmation of gas type if you are in doubt.

Included in Carton:

・Customers Operating Information

・Conversion kits

IMPORTANT

Before using this product, please read this manual carefully to insure proper use of product.

1. The installation must conform with local codes or, in absence of local codes, the National Fuel Gas

Code, ANSI Z223.1 or the Canadian Installation Code, CAN/CGA-B149.

2. For information on gas type, see data plate on the appliance.

3. This heater must not be installed where curtains or other combustible materials could come into

contact with it. In some cases curtains may need restraining.

Page 5

– 3 –

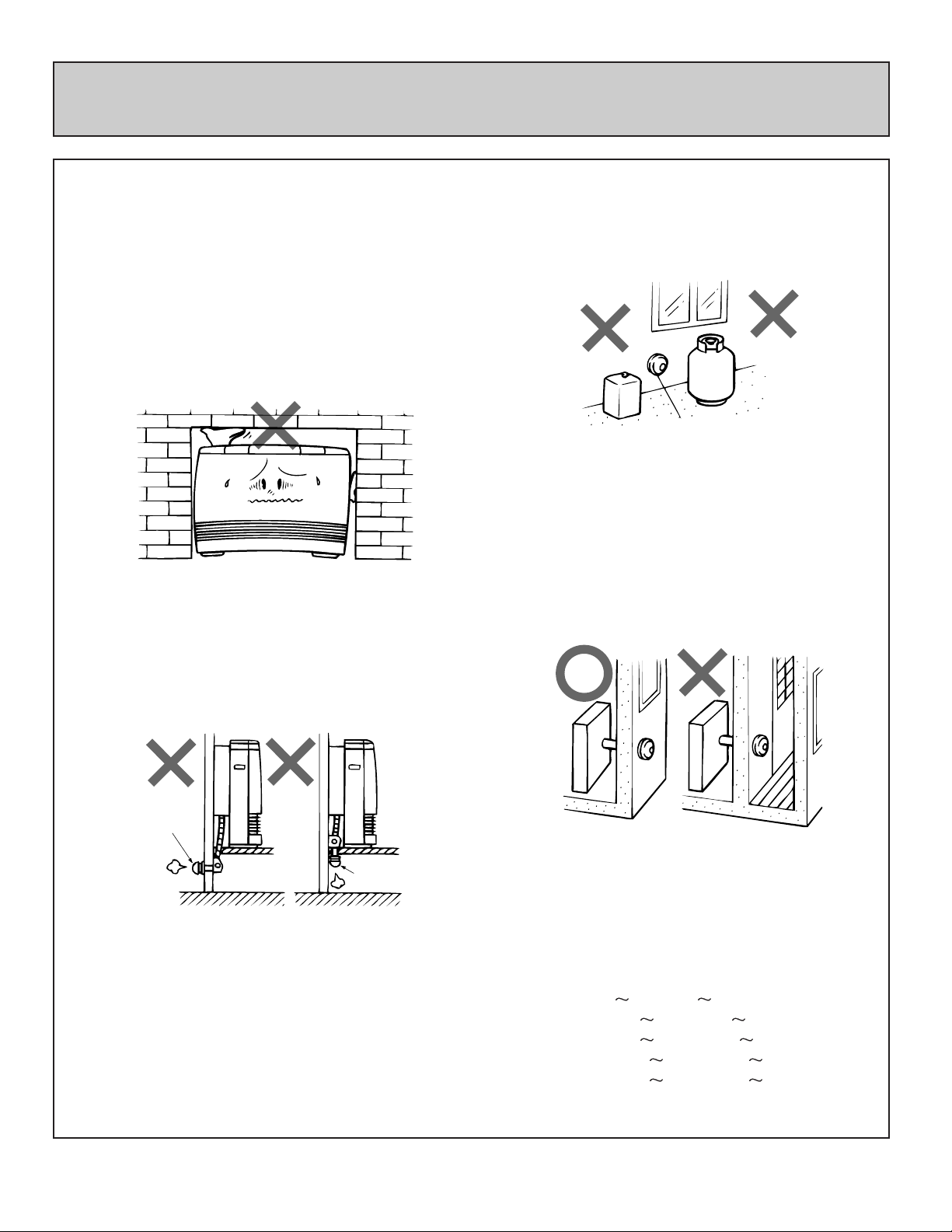

4. This appliance is not designed to be built in.

5. If you move, check the gas type in the area where you are moving to. The local gas authority will be

able to advise on local regulations.

6. This heater discharges a large volume of warm air at low level to provide even heat distribution. If

the air in the room contains cooking vapor or cigarette smoke, and the heater is used on a carpet,

the surface of the carpet may become discolored. In addition, some nylon carpets contain dyes

which may be affected by the warm air flow. Some soft vinyl surfaces are also subject to distortion,

or discoloration by warm air. To prevent discoloration of carpets, etc., a mat should be placed under

the appliance, extending about 30" (750mm) in front of it.

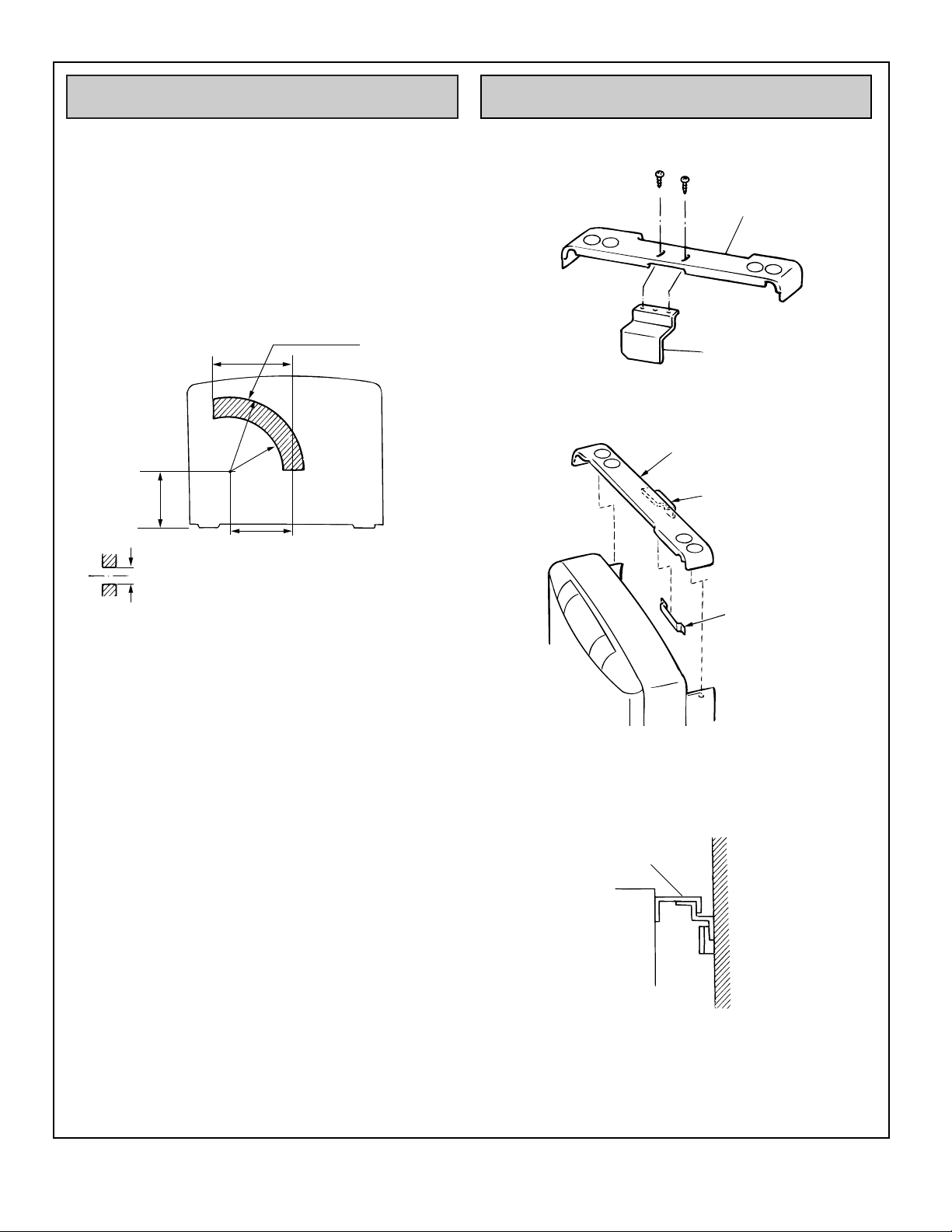

Diagram shows minimum

clearances from combustible

materials.

7. Read these rules and the instructions carefully. Check all local codes. Failure to follow these could

cause a malfunction of the heater resulting in death, serious bodily injury and/or property damage.

8. This appliance is only for use with the type of gas indicated on the rating plate. This appliance is not

convertible for use with other gases, unless a certified kit is used.

If a conversion of the unit is needed, conversions must be performed at Rinnai America or

anthorized agent at owner's expense.

9. WARNING: Any change to this heater or its controls can be dangerous.

10. If a gas leak is suspected, turn heater off, turn gas supply valve off at appliance connector valve.

Open windows to ventilate area immediately and contact your dealer or gas company.

11. DO NOT PLACE CLOTHING OR FLAMMABLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS, ON OR NEAR THE HEATER.

12. YOUNG CHILDREN SHOULD BE CAREFULLY SUPERVISED WHEN THEY ARE IN THE SAME

ROOM WITH THE HEATER.

13. LPG containers must not be installed indoors.

14. Do not use this room heater if any part has been under water. Immediately call a qualified service

technician to inspect the room heater and to replace any part of the control system and any gas

control which has been under water.

15. Adequate clearances for accessibility for purposes of servicing and proper operation should be

provided.

16. Adequate clearances around air openings should be provided.

17. Do not install in areas where curtains, drapes, clothing, or other moving flammables are within 12

inches of this unit.

18. Periodic examination of the venting system is required.

19. The flow of combustion and ventilation air should not be obstructed.

20. A manufactured home (USA only) or mobile home OEM installation must conform with the

Manufactured Home Construction and Safety Standard, Title 24CFR, Part 3280, or, when such a

standard is not applicable, the Standard for Manufactured Home Installations, ANSI Z225.1 or

Standard for Gas Equipped Recreational Vehicles and Mobile Housing, CSA Z240.4.

21. "This appliance must be installed in accordance with the current standard CSA Z240.4 GAS

EQUIPPED RECREATIONAL VEHICLES AND MOBILE HOUSING. Cet appareil doit ette installe

conformement aux, exigences de la norme Z240.4 en vigeuer de l’ACNOR, Installations de gaz dans

les constructions mobiles et vehicules recreatifs."

10"

0"

2"

2"

40"

Page 6

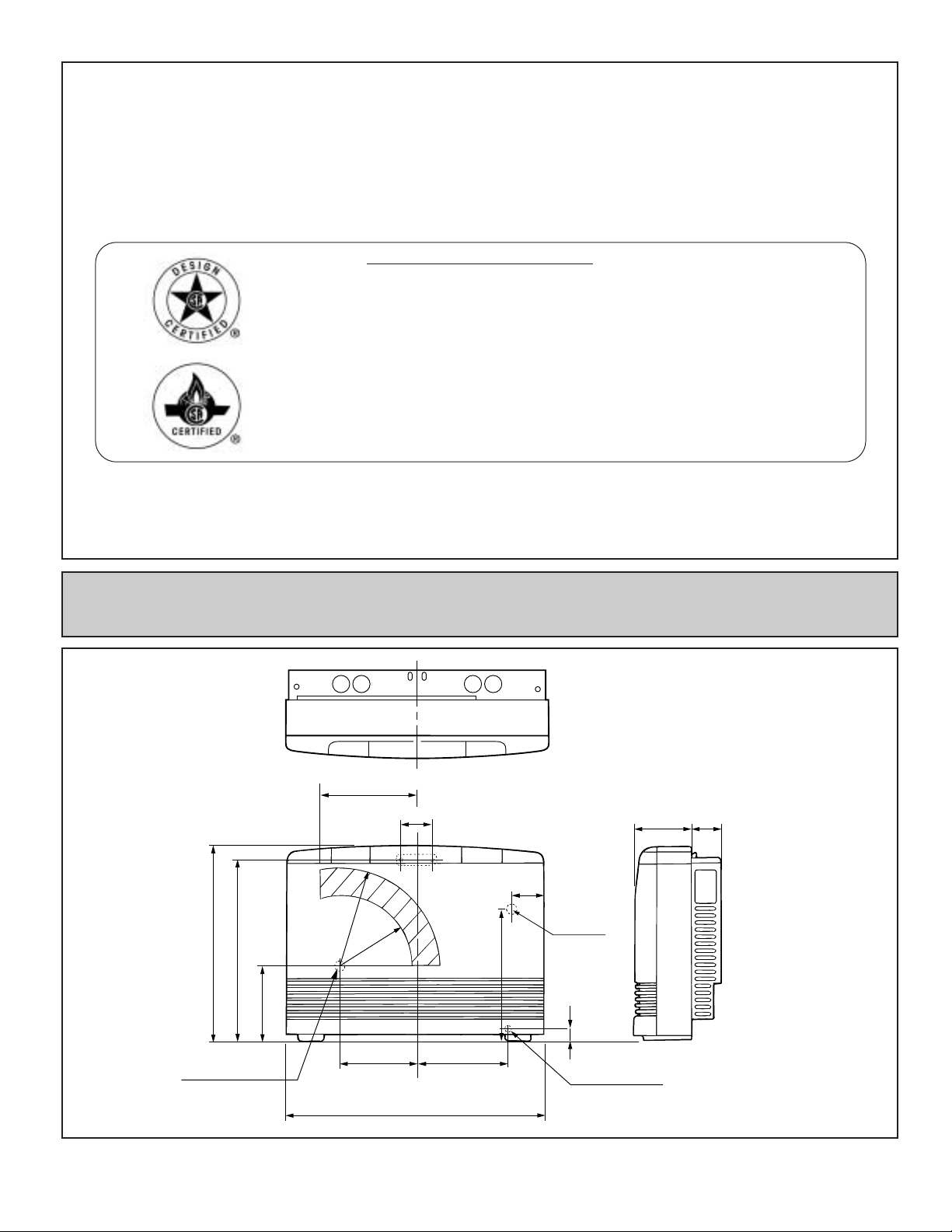

– 4 –

DIMENSIONS

GENERAL INFORMATION

THIS SERIES HEATER IS DESIGN CERTIFIED BY CSA

INTERNATIONAL AS A DIRECT VENT WALL FURNACE AND

MUST BE INSTALLED ACCORDING TO THESE INSTRUCTIONS.

ALTERATION OF THE ORIGINAL DESIGN INSTALLED OTHER

THAN AS SHOWN IN THESE INSTRUCTIONS OR USED WITH

A TYPE OF GAS NOT SHOWN ON THE RATING PLATE, IS

THE RESPONSIBILITY OF THE PERSON AND COMPANY

MAKING THE CHANGE.

・Rinnai is continually updating and improving products. Therefore, specifications are subject to

change without notice.

・Thank you for purchasing Rinnai forced flue gas heater.

・Please read the warranty thoroughly and keep it in a safe place.

22. If a blockage occurs at vent terminal due to snow, leaves or other type of obstruction the unit will

stop working. The unit will not function until blockage has been removed then if unit fails to operate,

contact a qualified service agency.

23. For a manufactured home (USA only) or mobile home OEM or residential or light commercial installation, this

unit has been designed and certified to be converted from natural gas to propane or vice-versa. When

provisions are being made to convert this unit, a certified conversion kit must be used. You must also

readjust manifold gas pressure to specifications indicated in the conversion manual. If in doubt, contact

Rinnai America for assistance.

21 13/16" (554mm)

19 15/16" (506mm)

8 7/16"(214mm)

11 " (280mm)

3 7/16" (88mm)

3"

R11"

R8.0"

(R279mm)

(R206mm)

18"

Gas Inlet

1"

(25mm)

6 1/2" (165mm)

3 3/8" (85mm)

Exhaust at rear of unit

8 9/16"

(217mm)

29 1/2" (750mm)

9 5/8"

(245mm)

Power supply cable

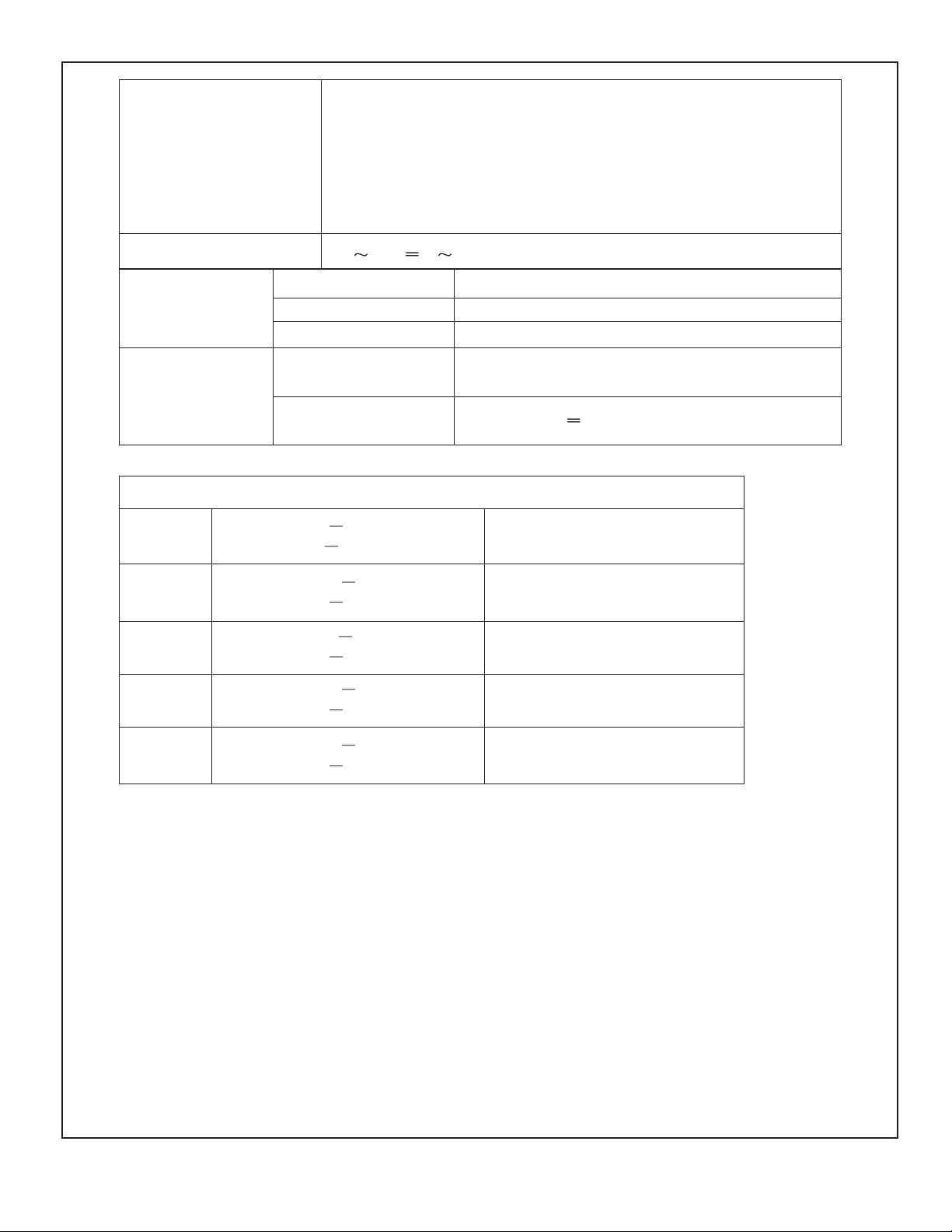

Page 7

Frost Function

LOW 50°F 60°F 80°F HI High Combustion

Normal Operation

– 5 –

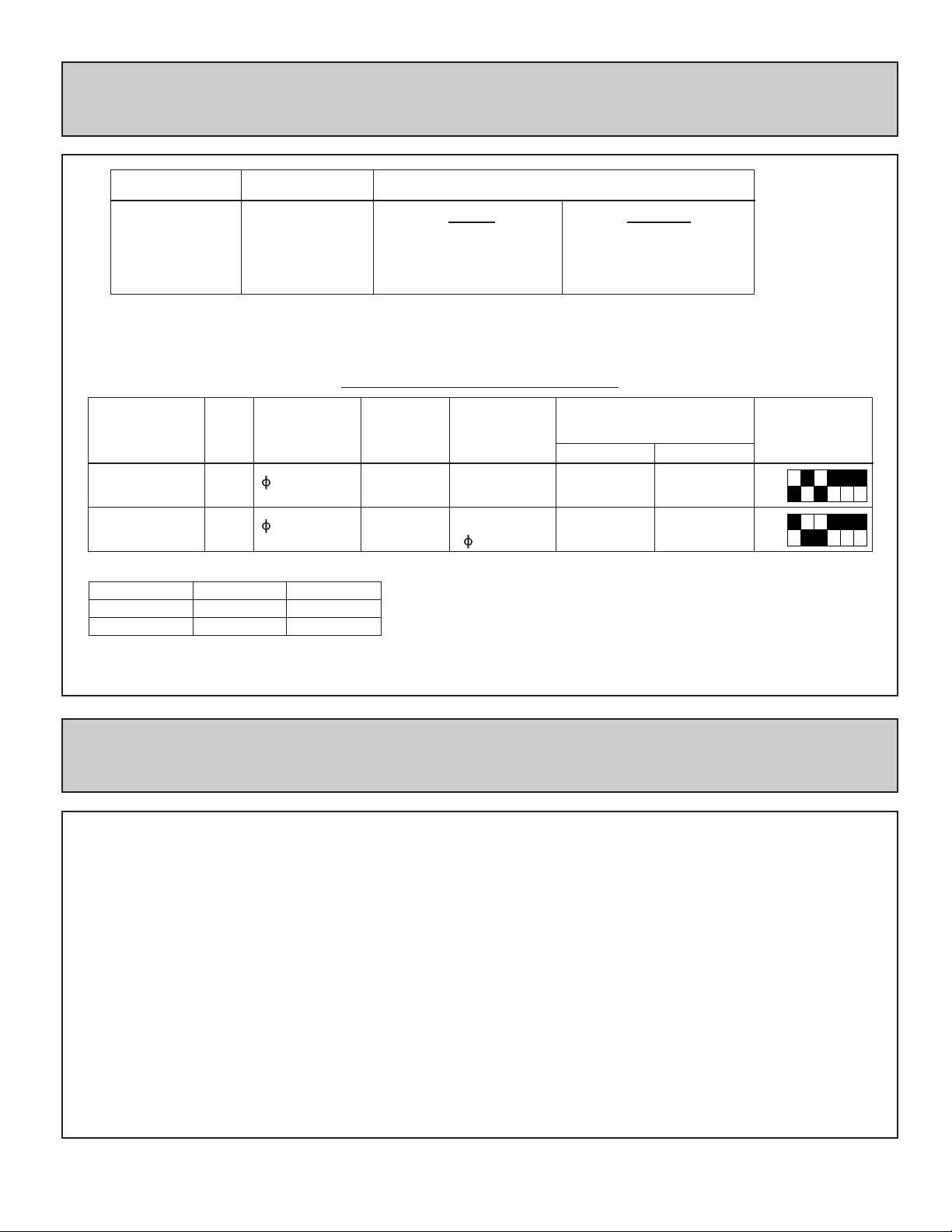

SPECIFICATIONS

MODEL

PROPANE

BTU/h MIN. CLEARANCES

INPUT

OUTPUT

SIDE

TOP

LO:110.5

HI:141.3

LO:110.5

HI:141.3

FRONT

2"

(50mm)

10"

(250mm)

40"

(1m)

40"

(1m)

FAN CFM

OUTPUT

10"

(250mm)

2

"

(50mm)

Low

8,200

Low

6,640

High

13,400

Low

6,640

High

13,400

High

16,700

Low

8,200

High

16,700

SPECIFICATIONS

Type of Appliance Fan Type Direct Vent Wall Furnace

Model RHFE-431WTA ENERGY SAVER

Width 29 1/2" (750mm)

Dimensions Depth 9 13/16" with back spacer (250mm with back spacer)

Height 21 13/16" (554mm)

Weight Approx. 51 lbs.

Connections

Electrical AC 120V 60Hz 43 watts

Gas 1/2" female NPT

Combustion System Stainless steel bunsen burner

Ignition System Continuous spark

Operation Finger touch control buttons

Temperature Control

Electronic thermostat HI-LOW/OFF

Up/down switch

Temperature Range

Warm Air Outlet Bottom front louver

Operating Buttons On/off, Auto, Override, Economy, Frost, Timers, Select, Clock, Up/down

Economy Mode Energy saving feature

Humidifier Tray Capacity

3 pints (1300cc)

RHFE-431WTA

NATURAL

RHFE-431WTA

38°F 60°F

Page 8

– 6 –

Safety Devices

Noise Level Range

HI LOW 38 32dB(A)

TYPE

SPECIFICATIONS FOR VENT SIZES

S Thin Walls Mobile Home

Wood Walls

Wood/Brick

Brick/Block

Special

3

" 4 1/2"

(75 115mm)

4 1/2" 9 1/2"

(115 240mm)

9 1/2" 15 3/4"

(240 400mm)

15 3/4" 23 5/8"

(400 600mm)

23 5/8" 31 1/2"

(600 800mm)

A

B

C

D

3 1/8

" (80mm)

(4m, 2 bends) 13ft., 2 bends

Combustion Method

Air Supply Exhaust

Radiation Method

Forced combustion

Closed Type

Forced convection

Wall Penetration

Hole

AIR SUPPLY/

EXHAUST PIPE

Flame failure – Flame rod

Over heat – Bi-metal switch, thermal fuse, thermistor

Power failure – PCB

Power surge – 3 Amp. fuse

Fan delay – Micro computer timer

Pre-purge – Combustion fan, pre-purge timer, spark sensor

Room over heat – Automatic cut off at 104°F after 10 minutes

** BTU - Efficiency increases with vent Extension. Clearances from combustibles see pages 3 and 18.

** Thermal efficiency rating determined under continuous operating conditions, and was determined

independently of any installed system.

Max. Extended

Length

Page 9

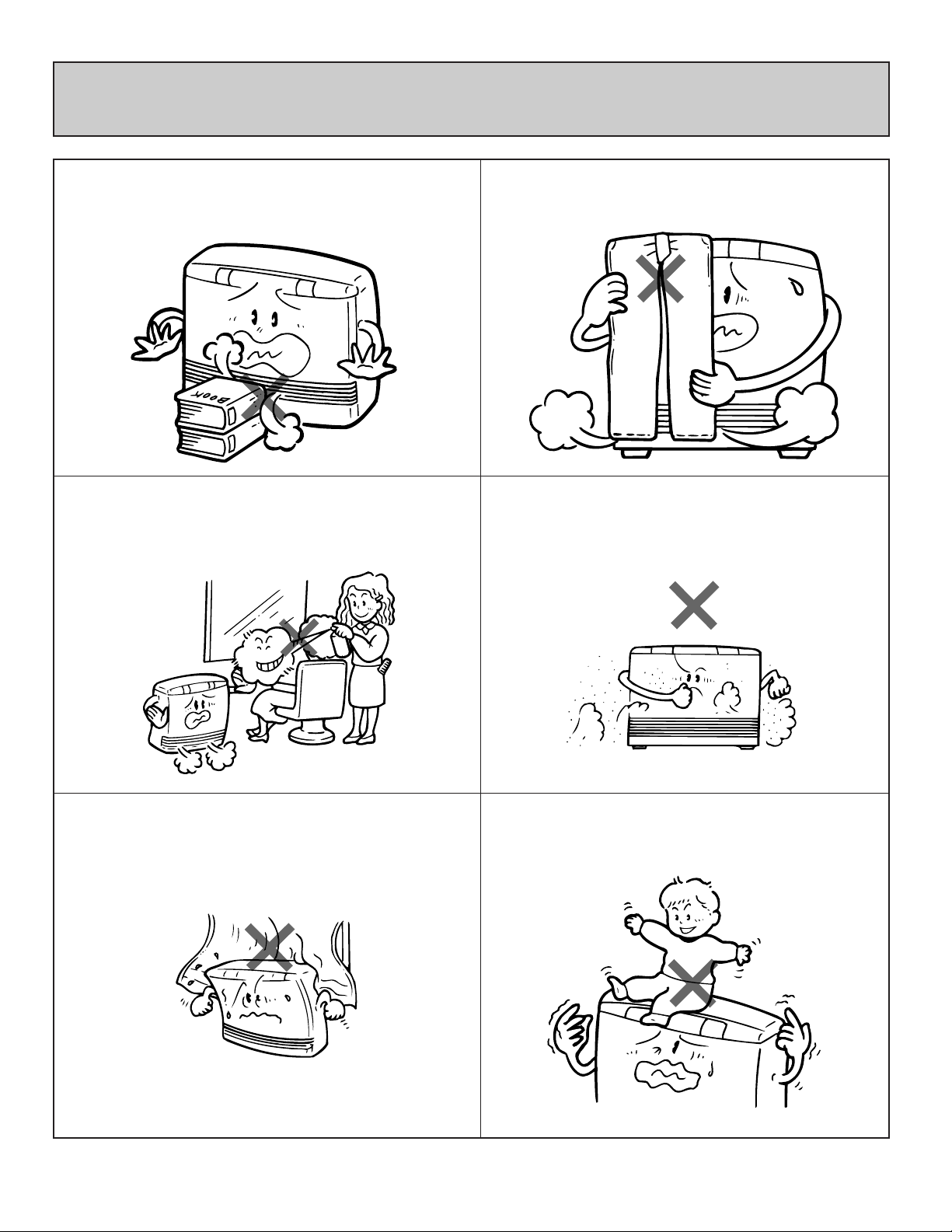

– 7 –

SAFETY POINTS

Do not restrict the warm air discharge by

placing articles in front of the heater.

This appliance must not be used for any

purpose other than heating.

Do not install the heater in an unusually

dusty area.

Do not allow anyone to sit on or lean against

the appliance.

Do not spray aerosols while the heater is

operating. Most aerosols contain butane

gas, and can be a fire hazard if used near

this heater when it is in use.

Do not allow curtains or other flammable or

combustible materials to come into contact

with the heater.

Combustible materials must not be placed

where the heater could ignite them.

Page 10

– 8 –

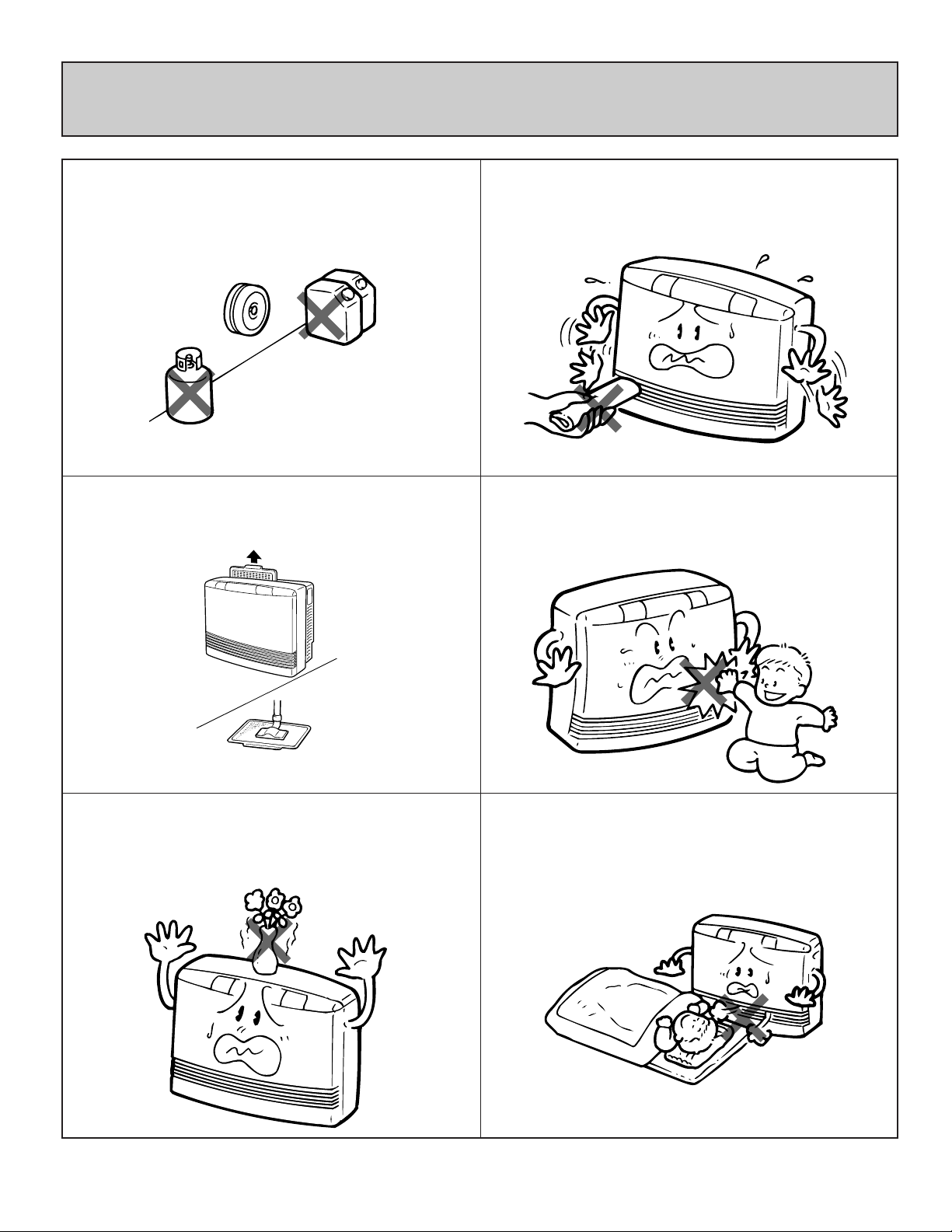

SAFETY POINTS

Keep flammable materials, trees, shrubs,

etc., away from the flue terminal.

Do not allow anyone to poke articles

through the louvers.

Young children should be supervised at all

times. Hand or body contact with the

louvers should be avoided.

Do not allow young children or an infant to

sleep directly in front of the heater.

Filter should be cleaned at regular intervals.

See page 31.

Do not place articles containing liquids on

top of the heater. Liquids spilled on the

controls may cause extensive damage.

Clean as needed.

LPGAS

GAS

Gasoline

Page 11

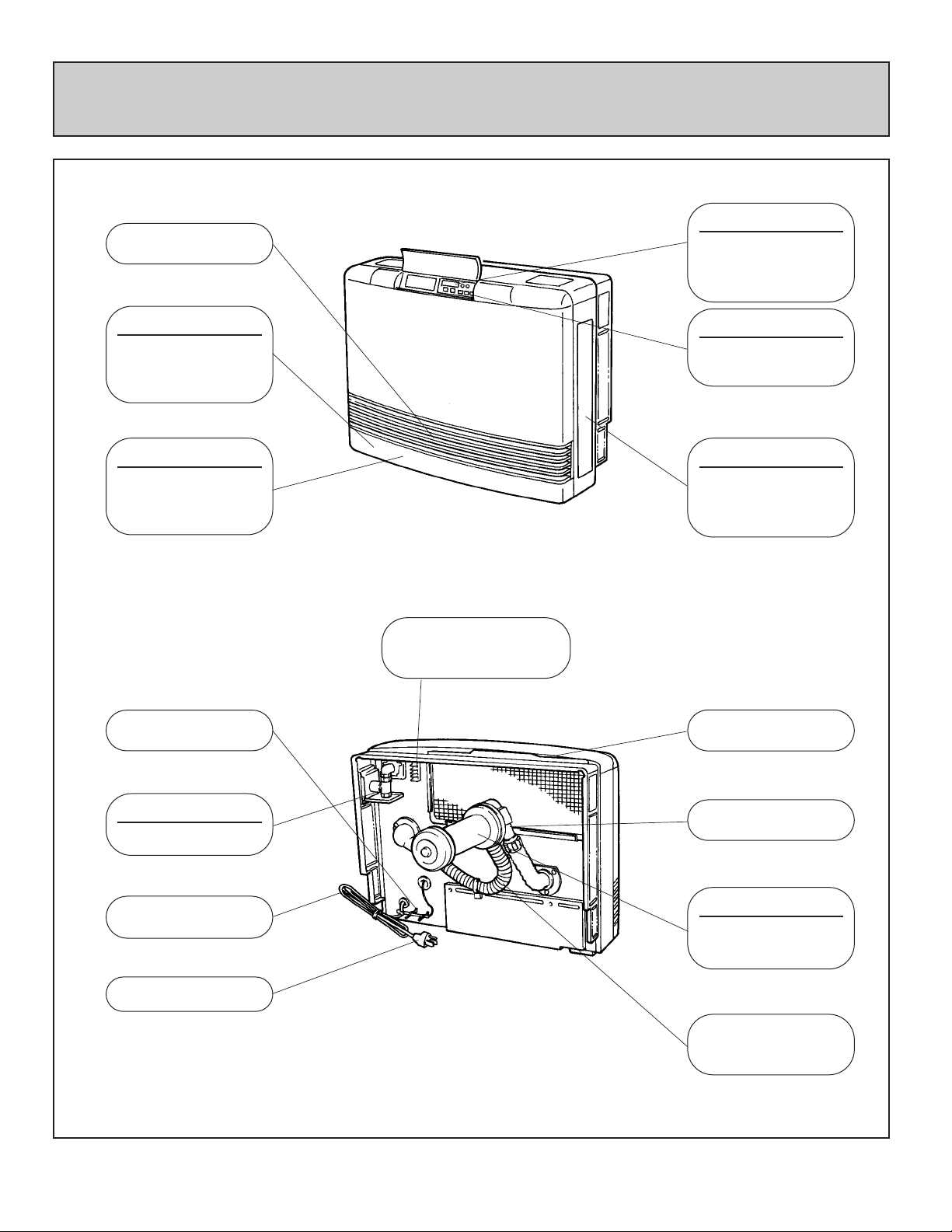

– 9 –

VENT TERMINAL

COMBUSTION/

EXHAUST

GETTING TO KNOW YOUR NEW RHFE-431

WARM AIR OUTLET

HUMIDIFIER

REMOVE BOTTOM

COVER AND PULL

OUT TO REFILL

BOTTOM COVER

HOLD BOTH SIDES

AND PULL TOWARD

YOU

THERMISTOR

GAS CONNECTIONS

1/2" NPT

POWER CORD

PLUG 120V AC

COMBUSTION AIR

INTAKE HOSE

EXHAUST PIPE

AIR FILTER

DISPLAY

TEMPERATURE/

TIMERS

SETTING CONTROLS

ON/OFF SWITCH

TURNS MAIN POWER

ON/OFF

RATING PLATE

MODEL NUMBER,

SERIAL NUMBER,

GAS TYPE, ETC.

TERMINAL BLOCK

FOR COMBUSTION FAN

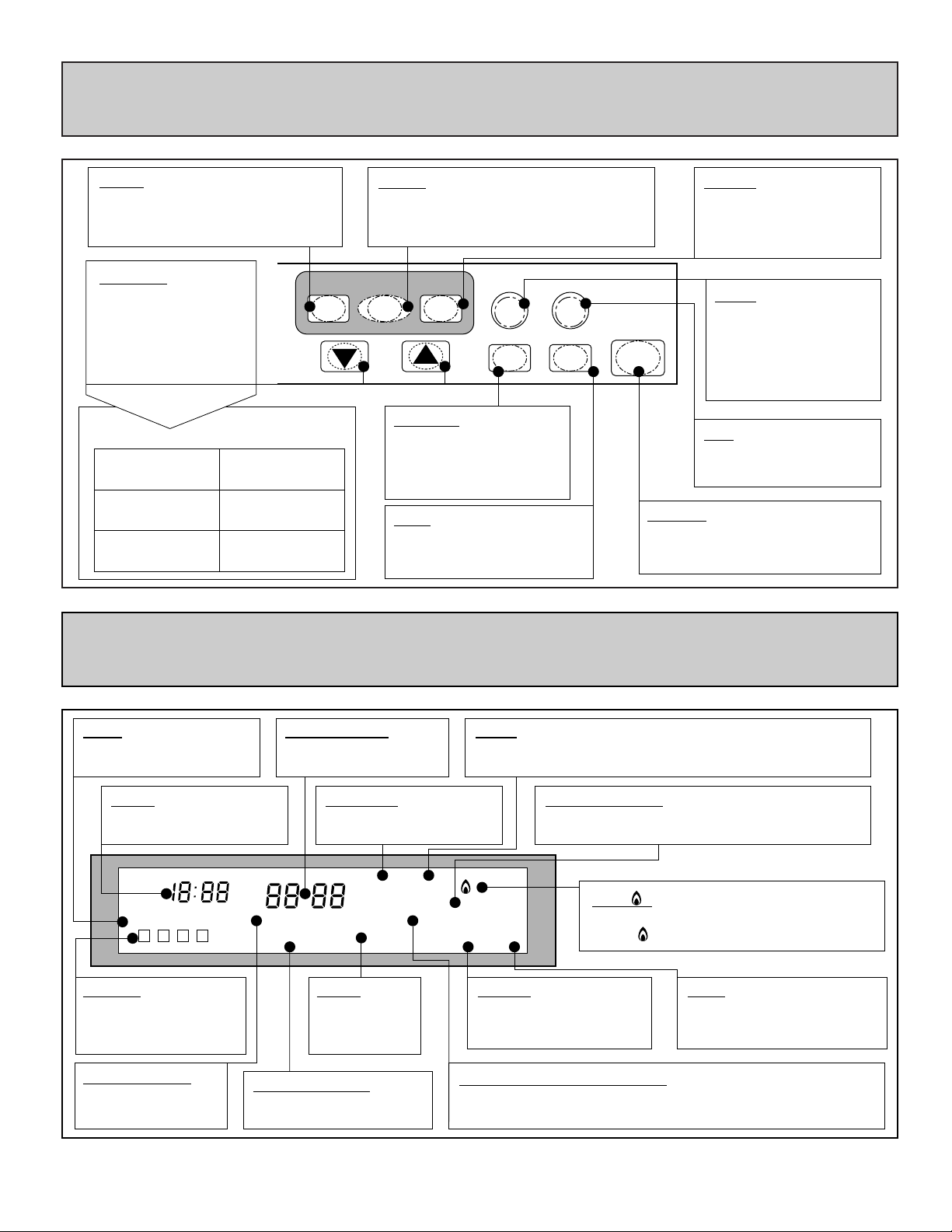

Page 12

Programming

EcoFrost

Override

Auto

Clock Select

ON/OFF

Timers

– 10 –

am

Set Room

Auto

Man

Select

Clock

Frost ON

Override On Off

Program Timer

Temp Review Filter

pm

1 2 3 4 OFF

Mo Tu We Th Fr Sa Su

Function Lock

Economy Mode

CONTROL PANEL

LED DISPLAY

Clock: used to set the current

time and day.(refer to page 24).

Up/Down: function

of these buttons

varies depending on

the operating mode.

(refer to the table

below for details).

MODE OPERATION

Clock Set

Timer Program

Frost Protection

To set current time

and day

Select days of

week, time and

temperature

Set Frost

Protection

temperature

Select: When programing the

timers, this button is used to select

and confirm day, time and

temperature settings.

Override: overrides

the current timer

setting by reversing

the current operation

(see page 33).

Auto: toggles the heater

between AUTO(for timer

operation) and MANUAL

operation modes.

Timers: used to carry

out timer programing

and confirm all

settings.

Frost: used to initiate

the Frost mode and

allows for a minimum

frost temperature to

be set(refer to page

34).

Eco: used to select the

Economy mode(refer

to page 35).

ON/OFF: this is the main on/

off switch for the heater.

Days:shows current

day of week or day(s)

being programmed.

Clock:shows current

time or pre-set program

time for timer.

Periods:shows

current operating

period or period

being programed.

Function Lock:

indicates that the

function lock is on.

Economy Mode:

indicates that the

Economy Mode is on.

Temperatures:

shows pre-set and

room temperatures.

Auto/Man: indicates

Manual or Timer

operation mode.

Clock:

shows when

the clock is

being set.

Frost:indicates that the anti-frost mode is on and that

a minimum anti-frost temperature can be entered.

Override On/Off: indicates whether the

Override function is on and whether it has

turned the heater on or off(reverse function).

ON/ : indicates when the heater is

operating and whether the burner is

alight( ).

Review: indicates that

the review mode is on.

Filter:shows when the

filter needs to be cleaned.

Select Program Timer/Temp: indicates when the timers

are being programed-Start time "Select Program Timer"

or Temperature "Select Program Temp".

Page 13

– 11 –

CUT-AWAY DIAGRAM

Page 14

– 12 –

NOTICE BEFORE INSTALLATION

The heater must be installed by a qualified service

person according to this installation instruction.

Check your local building codes for the proper method

of installation. In the case of absence of local codes,

this heater should be installed in accordance with the

National Fuel Gas Code ANSI Z223 1.

Check local codes or, in the absence of local codes,

the current CAN/CGA B149 INSTALLATION

CODE.

DUE TO HIGH TEMPERATURES, THE

APPLIANCE SHOULD BE LOCATED OUT OF

TRAFFIC AND AWAY FROM FURNITURE AND

DRAPERIES.

CHILDREN AND ADULTS SHOULD BE ALERTED

TO THE HAZARDS OF HIGH SURFACE

TEMPERATURES AND SHOULD STAY AWAY TO

AVOID BURNS OR CLOTHING IGNITION.

“WARNING” Do not operate appliance with the

panel(s) removed, cracked or broken. Replacement

of the panel(s) should be done by a licensed or

qualified service person.

INSTALLATION AND REPAIR SHOULD BE DONE

BY A QUALIFIED SERVICE PERSON. THE

APPLIANCE SHOULD BE INSPECTED BEFORE

USE AND AT LEAST ANNUALLY BY A QUALIFIED

SERVICE PERSON. MORE FREQUENT

CLEANING MAY BE REQUIRED DUE TO

EXCESSIVE LINT FROM CARPETING, BEDDING

MATERIAL, ETC. IT IS IMPERATIVE THAT

CONTROL COMPARTMENTS, BURNERS AND

CIRCULATING AIR PASSAGEWAYS OF THE UNIT

BE KEPT CLEAN.

The appliance, when installed, must be electrically

grounded in accordance with local codes or, in the

absence of local codes, with the National Electrical

Code, ANSI/NFPA 70 or Canadian Electrical Code,

CSA C22.1, if an external electrical source is utilized.

WARNING: THIS APPLIANCE IS EQUIPPED

WITH A THREE PRONG (GROUNDING) PLUG

FOR YOUR PROTECTION AGAINST SHOCK

HAZARD AND SHOULD BE PLUGGED DIRECTLY

INTO A PROPERLY GROUNDED THREE PRONG

RECEPTACLE. Do not cut or remove the grounding

prong from the plug.

This gas appliance must not be connected to a

chimney flue serving a separate solid-fuel burning

appliance.

When the appliance is installed directly on carpeting,

tile or other combustible material other than wood

flooring, the appliance shall be installed on a metal or

wood panel extending the full width and depth of the

appliance.

Rinnai recommends a dedicated electrical circuit.

Appliance input ratings are based on sea level

operation and need not be changed for operation up

to 2,000 feet elevation. For operation at elevations

above 2,000 feet, manufactured to specified deration

conditions for Canada and the United States.

Page 15

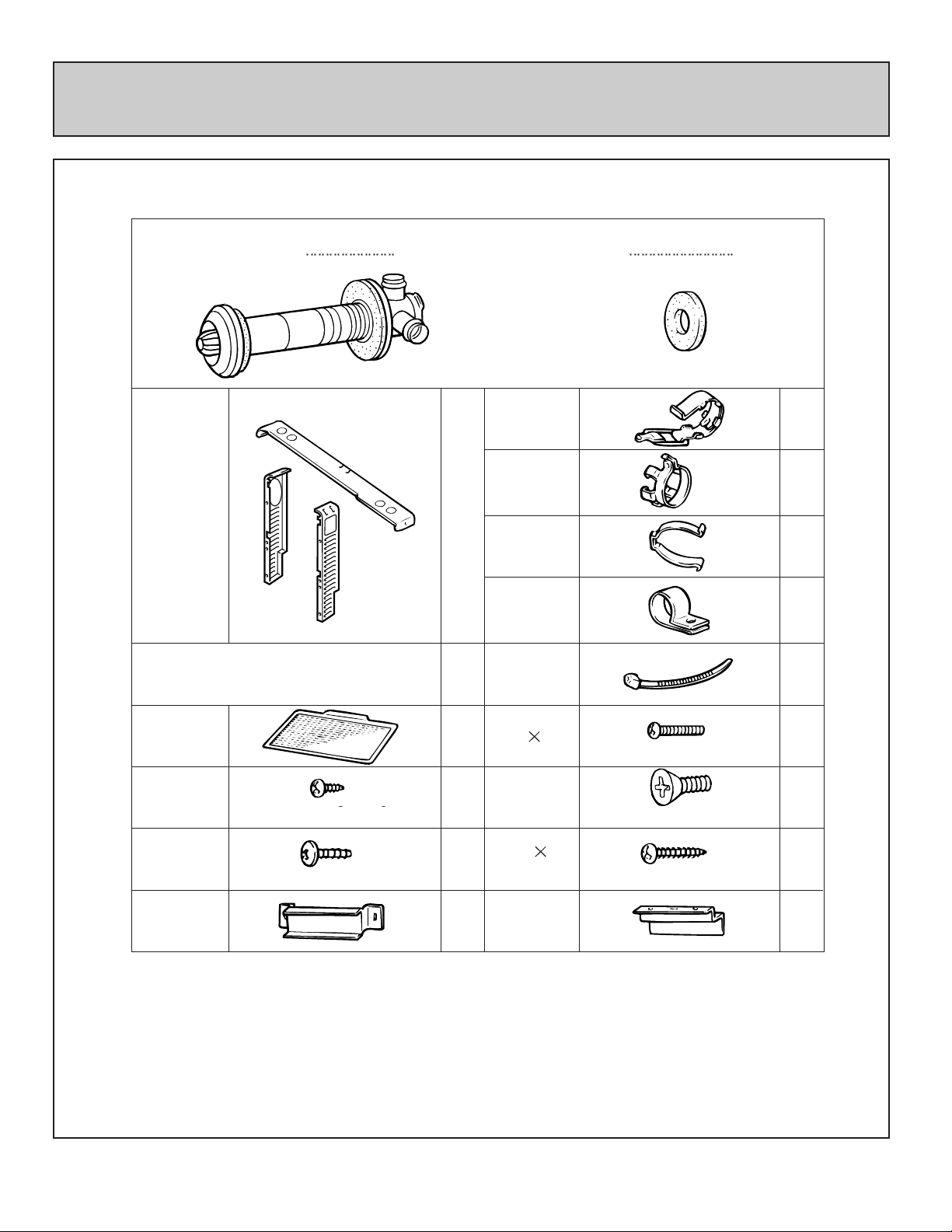

– 13 –

INSTALLATION INSTRUCTIONS

Flue Manifold 1

Back Spacer

Set

Flue Locking

Clamp

Flue Lock

Stopper

Insulation

Clip

Hose Clip

Plastic tie

for air inlet

(M4

20)

For Flue Lock Stopper

For Flue Manifold

Wall Bracket Screws

(M4)

(M4.8 32)

Wood Screws

1

1

1

1

2

1

1

3

5

1

1

6

2

Air Filter

(M4)

For Back Spacer Set

For Air Intake Clip

(M4)

Customers operating

information and

Installation Instructions

Spare rubber seal

1

(‘A’ Flue units only)

(For weatherboard installations)

Check to ensure gas supply matches that of the appliance.

Refer to local gas authority for confirmation of gas type if in doubt.

Refer to data plate located inside of the front panel.

Check for damage, if the unit is damaged contact your supplier or Rinnai.

Do not install a damaged unit before checking with your supplier.

Refer to an approved pipe sizing chart if in doubt about size of gas line.

Wall Bracket

Spacer Bracket

1

1

Page 16

– 14 –

GAS CONNECTION

1. The gas supply line shall be gas tight, sized and so installed as to provide a supply of gas sufficient

to meet the maximum demand of the heater without loss of pressure.

2. A shut off valve (and appliance connector valve) should be installed in the upstream of the gas line

to permit servicing.

3. Flexible pipe and any appliance connector valve used for gas piping shall be types approved by

nationally recognized agencies.

4. Any compound used on the threaded joint of the gas piping shall be a type which resists the action

of liquefied petroleum gas.

5. Supplied gas pressure must be within the limits shown in the specifications.

6. After completion of gas pipe connections, all joints including the heater must be checked for gas

tightness by means of leak detector solution, soap and water, or an equivalent nonflammable

solution, as applicable.

CAUTION: Since some leak test solutions, including soap and water, may cause corrosion or stress

cracking, the piping shall be rinsed with water after testing, unless it has been determined that the

leak test solution is noncorrosive.

7. The appliance and its appliance main gas valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of 1/2 P.S.I (3.5kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual

shut off valve during any pressure testing of the gas supply system at test pressures equal to or less

than 1/2 psig.

8. Two 1/8" test plugs are provided for testing of manifold differential pressure see schematic for location.

At time of installation installer must supply a 1/8" N.P.T. plugged tapping, accessible for test manometer

connection, immediately up stream of the gas supply connection to the appliance.

Page 17

– 15 –

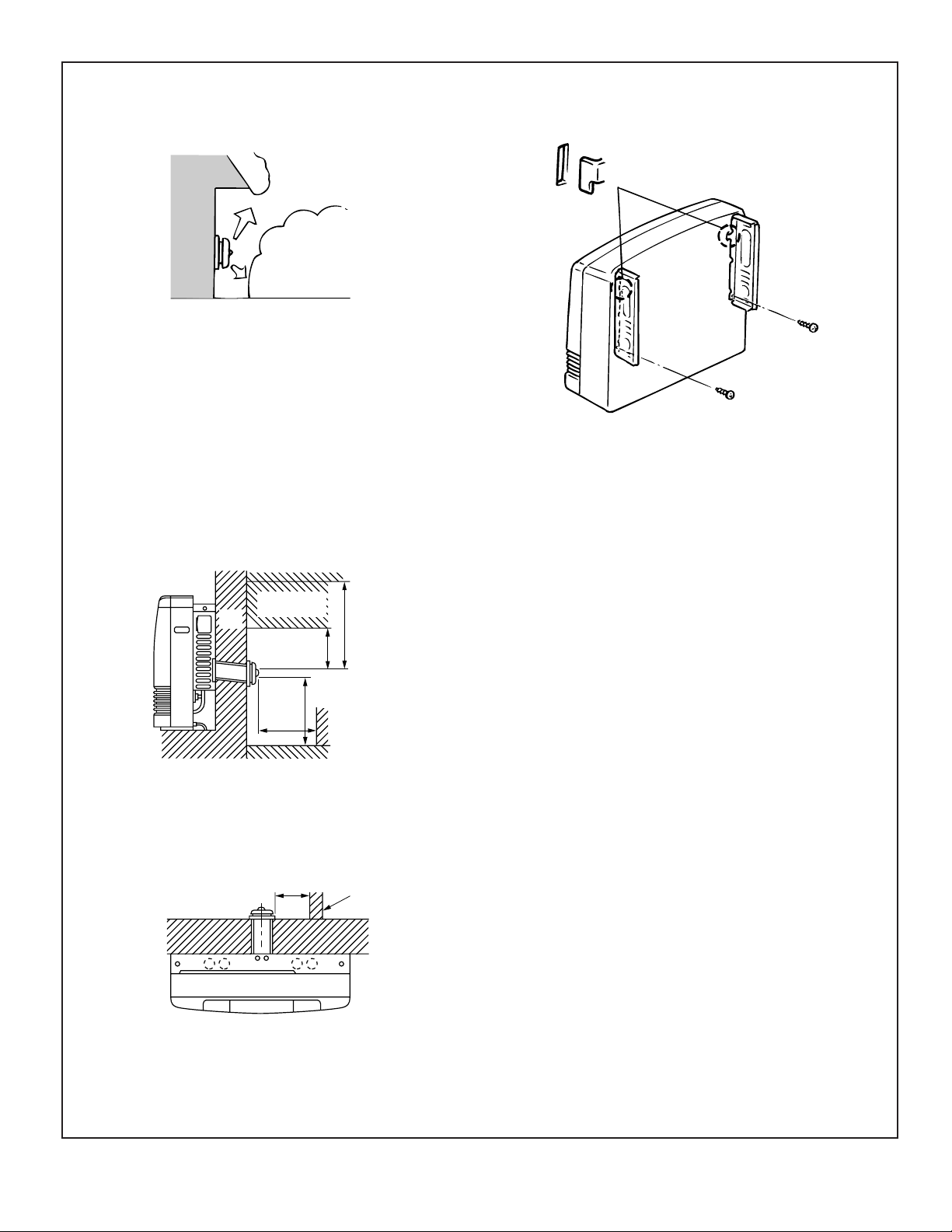

VENT LOCATION FITTING TOP SPACER + WALL CLIP

FLUE MANIFOLD POSITION

Center of hole for flue manifold can be drilled

anywhere within the shaded area. (To avoid studs,

etc.)

FOR WEATHERBOARD WALLS DRILL THROUGH

CENTER OF WEATHER BOARD FROM OUTSIDE,

THEN DRILL FROM INSIDE THROUGH PLASTERBOARD.

Before drilling the flue hole, check for water and gas

pipes as well as electric cables. Use a 3 1/8"

(80mm) drill for hole through wall.

WALL MOUNTING BRACKETS

Place top back spacer in position. Mark the position

of the top edge of the top space on the wall. Move

the heater away from the wall. Mark center lines

1 1/8

" (30mm) down from the top edge mark, and

1 9/16" (40mm) From the left and right hand sides of

the top spacer. Attach wall brackets at the marked

position.

Tighten all screws.

Replace top spacer, clipping the spacer into the wall

brackets at the same time as attaching it to the

heater. Secure top spacer with the screws provided.

THE HEATER IS NOW SECURED TO THE WALL.

Replace fan filter.

SECURE HEATER TO WALL

Flue Hole

3 1/8"

(80mm)

8 7/16"

(214mm)

R11"

(R279mm)

R8.0"

(R206mm)

8 9/16"

(217mm)

11"

(280mm)

Cavity Opening

Spacer bracket

Top spacer

Top spacer

Wall bracket

Spacer bracket

Spacer

Page 18

– 16 –

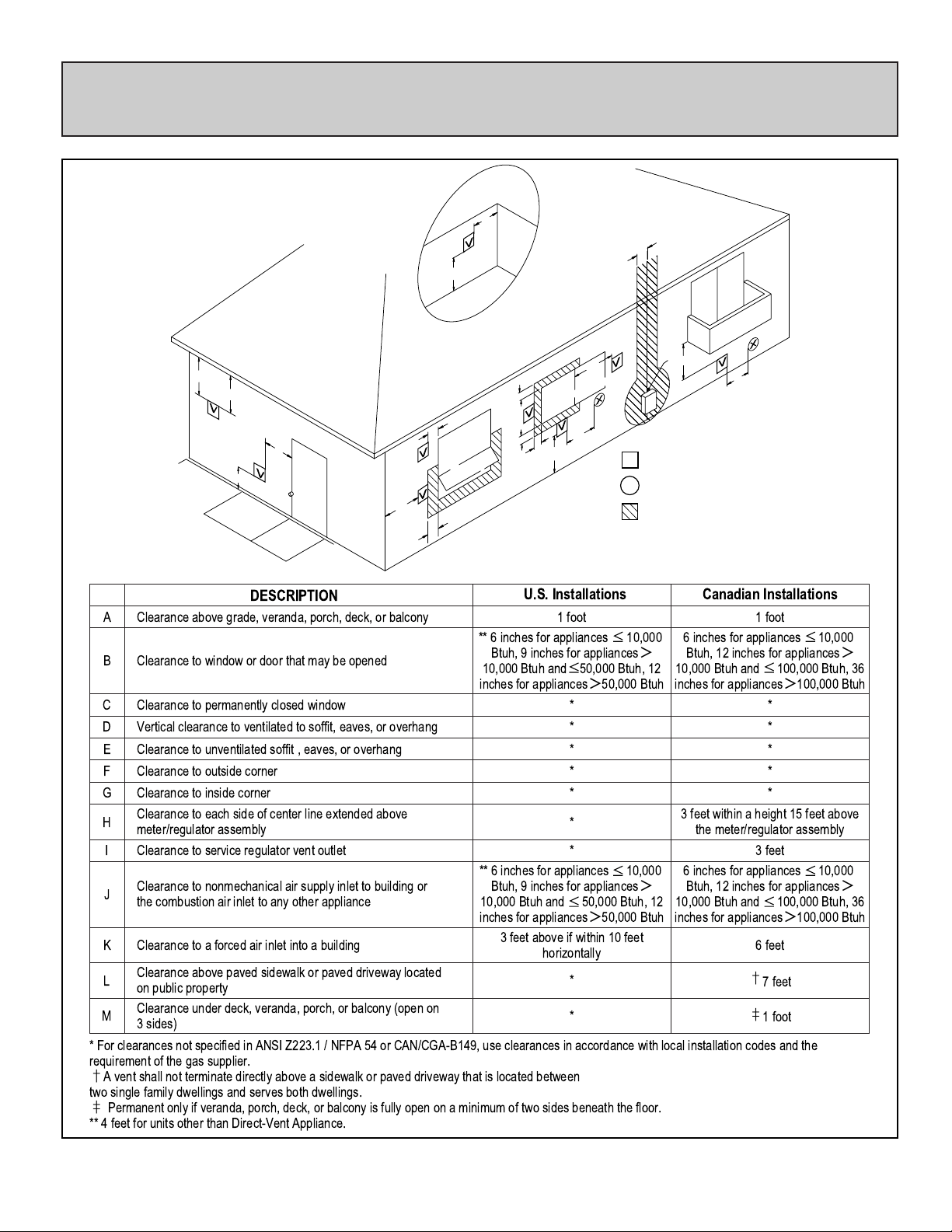

VENT TERMINATION CLEARANCES

INSIDE

CORNER DETAIL

G

H

A

I

B

OPERABLE

FIXED

CLOSED

D

E

B

M

K

B

J

B

A

VENT TERMINAL

V

AIR SUPPLY INLET

X

AREA WHERE

TERMINAL IS NOT

PERMITTED

1 foot

** 6 inches for appliances

Btuh, 9 inches for appliances

10,000

>

10,000 Btuh and 50,000 Btuh, 12

inches for appliances>50,000 Btuh

*

*

*

*

*

*

*

** 6 inches for appliances

Btuh, 9 inches for appliances

10,000 Btuh and

50,000 Btuh, 12

10,000

>

inches for appliances>50,000 Btuh

3 feet above if within 10 feet

horizontally

*

*

Canadian InstallationsU.S. Installations

1 foot

6 inches for appliances

Btuh, 12 inches for appliances

10,000 Btuh and

inches for appliances>100,000 Btuh

3 feet within a height 15 feet above

the meter/regulator assembly

3 feet

6 inches for appliances

Btuh, 12 inches for appliances

10,000 Btuh and

inches for appliances>100,000 Btuh

6 feet

†

‡

100,000 Btuh, 36

*

*

*

*

*

100,000 Btuh, 36

7 feet

1 foot

B

L

REF

A

Clearance above grade, veranda, porch, deck, or balcony

B

Clearance to window or door that may be opened

C

Clearance to permanently closed window

D

Vertical clearance to ventilated to soffit, eaves, or overhang

E

Clearance to unventilated soffit , eaves, or overhang

F

Clearance to outside corner

G

Clearance to inside corner

Clearance to each side of center line extended above

H

meter/regulator assembly

I

Clearance to service regulator vent outlet

Clearance to nonmechanical air supply inlet to building or

J

the combustion air inlet to any other appliance

K

Clearance to a forced air inlet into a building

Clearance above paved sidewalk or paved driveway located

L

on public property

Clearance under deck, veranda, porch, or balcony (open on

M

3 sides)

DESCRIPTION

C

FIXED

CLOSED

OPERABLE

F

B

* For clearances not specified in ANSI Z223.1 / NFPA 54 or CAN/CGA-B149, use clearances in accordance with local installation codes and the

requirement of the gas supplier.

†

A vent shall not terminate directly above a sidewalk or paved driveway that is located between

two single family dwellings and serves both dwellings.

‡

Permanent only if veranda, porch, deck, or balcony is fully open on a minimum of two sides beneath the floor.

** 4 feet for units other than Direct-Vent Appliance.

10,000

>

10,000

>

Page 19

– 17 –

LOCATION / CLEARANCES

When positioning the heater the main points

governing the location are:

1. Flueing

2. Warm air distribution

This heater is not designed to be build in.

The flue terminal should be positioned away from

flammable materials.

Do not flue into natural draught flues or fireplaces,

this unit can only be used with one of the five types

of Rinnai flue kits. Do not flue unit into other rooms.

Flue terminal must be outside.

Flue may be positioned directly under opening

windows, with a minimum clearance of 9

" (230mm).

FLUE SIZES:

5 Flue lengths are available.

S flue walls 3

" 4 1/2" (75 115mm)

A flue walls 4 1/2" 9 1/2" (115 240mm)

B flue walls 9 1/2" 15 3/4" (240 400mm)

C flue walls 15 3/4" 23 5/8" (400 600mm)

D flue walls 23 5/8" 31 1/2" (600 800mm)

The flue is not designed to be positioned under

floors, or below the level of the heater.

Flue Terminal

LP GAS

Flue

Terminal

Flue

Terminal

Page 20

– 18 –

SNOW AREAS FIT BACK COVERS (SIDES ONLY)

Fit back covers (sides only) as shown below.

In areas subject to heavy snowfall, keep snow clear

of flue terminal at all times.

STANDARD INSTALLATION OF FLUE MANIFOLD.

Diagram below shows minimum clearances and

distances from obstructions.

Also check local regulations.

Side Clearances

Snow

Flammable

Wall

Non

Flammable

(600mm)24"

10"(250mm)

Opposite

Wall

Floor

24"

(600mm)

20"(500mm)

Obstruction

20"

(500mm)

Engage Lugs

Secure With

Screws

Clearance in accordance with local installation

codes and the requirements of the gas supplier.

Page 21

– 19 –

SLEEVE AND MANIFOLD INSTALLATION

METHOD FOR STANDARD WALLS

1. Disassemble Manifold from Sleeve.

The flue consists of 3 parts, sleeve, inside connectors

and tube, outside terminal; (dis-assembly by pulling

hard on outside terminal and inner connections, then

pull sleeve off outer terminal.)

NOTE: Clearance to combustibles for terminal

assembly sleeve and flanges is 0".

2. Adjustment of Sleeve Length.

Measure wall thickness through previously drilled

3 1/8

(80mm) hole.

End of sleeve should protrude 3/16" 3/8" (5 10mm)

from outside wall. Adjust sleeve length to wall

thickness plus 3/16" 3/8" (5 10mm). (Sleeve is

threaded for adjustment.) Do not extend beyond red

line.

3. For S and A flue only.

Depending on flue set and wall thickness extension

piece “C” may need to be removed.

Cut plastic, remove extension, then follow instruction 2.

This applies to “S” and “A” flues only.

There is no extension on other flues, they can be fully

adjusted by turning the threaded section.

4. Fixing Sleeve.

Fix to the wall, using the 3 screws provided.

NOTE: The flange is marked “TOP”, sleeve must be

fitted with this mark

Up. Check sleeve protrudes 3/16"

3/8" (5 10mm) on the outside.

Connection

Sleeve

Flanges

Terminal

Extension joint

under plastic

Extension

("S" and "A" flues only)

Adjust length by turning sleeve.

Do not extend

beyond red line

A

B

C

Remove extension at this

point it necessary.

"A" Flue only

Fixing Screw

2°

"TOP"

5-10mm

Don't remove green plastic covering from sleeve.

Page 22

– 20 –

5. Check rubber seal is in place on terminal.

*For weather board walls, add spare rubber seal

provided to compensate for weather board angle.

6. Installation of Terminal

From outside, insert terminal into sleeve with the “A”

mark at the top. Left hand side fixing tie is marked

“LEFT” (from inside).

7. Attached Ties

Pull hard on left and right hand side ties, clip ties over

lugs inside sleeve. You should be able to pull ties 2 or

3 slots past the starting point. Cut the ties, leaving

about 3/4" (20mm) past the lugs. Bend ties so they

are parallel with the wall.

8. Insert Inner Connection Assembly.

Push assembly into the terminal tube, make sure

“TOP” mark is uppermost. Fix with 3 screws provided.

9. Manifold can still be turned after attaching.

Terminal seal

(Add "weather board"

seal here)

Label

Fixing tie

Terminal

"TOP" mark "A"

Cut (leave 20mm free)

Pull hard

Fixing tie

Lug

Sleeve

Terminal

lnner

Connections

Screw

Top Mark

Inlet

20˚

Outlet

Rubber cap

Page 23

– 21 –

FITTING UNIT

AIR INLET HOSE 2. Fit the locking clamp over connection between

sliding tube and manifold. Engage the hook and

rotate it until it snaps against the body of the clamp.

3. Fit the screw clamp between the sliding tube and

the flue elbow. Secure with the 4mm screws

supplied. The flue outlet is now locked into position.

4. Slide the insulation sleeve up to the flue

manifold, slip the securing clip over the sleeve as

shown.

When servicing unit replace plastic tie with new one.

(Available at local hardware store or contact local

distributor.)

LOCKING CLAMP SCREW CLAMP AND

INSULATION.

The following components can be fitted by reaching

down the rear of the appliance as it is positioned

against the wall.

1. Connect the flue outlet to the manifold by

extending the stainless steel sliding tube until it is

fully inserted into the manifold.

Detail of Hose clip

Hose clip

Inlet hose

Manifold

Locking

clamp

Flue outlet

Sliding tube

Manifold

Hook

Locking

Clamp

Flue elbow

Flue Outlet

sliding tube

Manifold

Locking clamp

screw

Flue Outlet tube

screw clamp

Flue elbow

Sock

Flue outlet

Sliding tube

Slide to here

Fit clip

Slide insulation sock

Sliding Tube

Slide

Do not extend flue tube

beyond red line.

Manifold

Inlet hose

Inlet elbow

Plastic tie

Page 24

– 22 –

If necessary, the unit can be leveled using the

adjustable legs under the front right and left hand

side legs.

INSTRUCT CUSTOMER ON USE OF HEATER

When you are satisfied that the appliance is

operating correctly, explain operation of heater to

the customer.

Fault-Failure Procedure

If unable to get the heater to operating correctly,

contact Rinnai directly or your Agent or Gas Utility.

Do not use electrical extension cords to connect unit

to power supply. Keep the power cord away from

the flue.

Some items are not covered under the unit's

warranty. Example: annual maintenance, carbon on

flame rods/ignitor, dust, spider webs, etc.

Adjustable Leg

Up to 10 mm

Levelling screws(Adjustable legs)

Page 25

– 23 –

OPERATING INSTRUCTION LABEL

ENERGYSAVER RHFE-431WTA

FOR YOUR SAFETY READ BEFORE OPERATING

OPERATING INSTRUCTIONS

TO TURN OFF GAS TO APPLIANCE

WARNING: If you do not follow these instructions exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

A. This appliance does not have a pilot. It is equipped

with an ignition device which automatically lights the

burner. Do not try to light the burner by hand.

B. BEFORE OPERATING smell all around the appliance

area for gas. Be sure to smell next to the floor

because some gas is heavier than air and will settle on

the floor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not use any

phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions.

STOP! Read the safety information above on this

label.

1. Set the thermostat to lowest setting.

2. Turn off all electric power to the appliance via the

ON/OFF button on the control panel. Locate manual

gas valve to be found on back side of heater.

3. Turn Manual valve clockwise to the full OFF

position.

4. Wait five (5) minutes to clear out any gas. Then smell

for gas, including near the floor. If you then smell gas,

STOP! Follow “B” in the safety information above on

this label. If you don't smell gas go to next step.

1. Turn off electric power to the appliance using the

ON/OFF button located on the control panel.

2. Locate manual valve on back side of unit.

3. Turn manual valve clockwise to the full OFF position.

NOTE: The fan will continue to operate until the appliance is

cool, do not turn the appliance off by unplugging it from the

wall.

Keep burner and control compartment clean. See

installation and operating instructions accompanying heater.

5. Turn Manual gas valve to the full on position.

6. Turn on all electric power to the appliance via ON/OFF

button.

7. Set the thermostat to desired setting.

8. Burner is lit when indicator lamp “ON” turns red.

9. “ON” indicator flashes when burner fails to ignite.

10. If the appliance will not operate, follow the instruction

“TO TURN OFF GAS TO APPLIANCE” and call your

service technician or gas supplier. See manual for

additional information.

• If you cannot reach your gas supplier, call the fire

department.

C. Use only your hand to push in or turn the gas control

knob. Never use tools. If the knob will not push in or

turn by hand, don't try to repair it, call a qualified

service technician. Force or attempted repair may

result in a fire or explosion.

D. Do not use this appliance if any part has been under

water. Immediately call a qualified service technician

to inspect the appliance and to replace any part of the

control system and any gas control which has been

under water.

BACK SIDE OF HEATER

MANUAL GAS VALVE

OPEN

CLOSED

LED Indicator

Thermost button

On/Off

Button

Economy button

Timer setting button

Page 26

– 24 –

1

2

3

4

5

SETTING THE CLOCK

■ TO OPEN THE CONTROL PANEL

Lift lightly in the center of the lid. The control

panel lid will then drop backward to an angle.

Note: When the appliance is first

plugged in or after a power failure

longer than 24 hours the display

will show “PF”.

■ SETTING THE CURRENT TIME & DAY

(This example shows setting the clock to 8:20am on Saturday).

DAY OF THE WEEK

Press the “Clock” button

once. The day of the week

and is displayed.

Press either of the “▲” or “▼”

buttons until the correct day of

the week is displayed.

Press the “Select” button once

to lock in and complete day of

the week selection. The time of

day will then flash.

TIME OF DAY

To set the time press the “▲”

or “▼” buttons until the correct

time of day is displayed.

Pressing either button once will change the time in single minutes.

Holding eigther button down will change the time rapidly, first in minutes, then in hours.

CONFIRM SETTINGS

Press the “Select”or “Clock”

button once to lock in and

complete setting the time.

The indicators will go out.

Select

Clock

Select

Clock

Select

Clock

Mo

Programming

Clock Select

Timers

Select

Clock

Sa

Programming

Clock Select

Timers

am

Select

Clock

Sa

Programming

Clock Select

Timers

am

Select

Clock

Sa

Programming

Clock Select

Timers

am

Sa

Programming

Clock Select

Timers

Page 27

– 25 –

OPERATING THE HEATER MANUALLY

■ To turn the heater ON:

Press the “ON/OFF” button.

Check to see if the “Man” or “Auto”

indicator is displayed:

If the “Auto” indicator is displayed

then press the “Auto” button. The

indicator will change to “Man”.

Go to Step 3.

If the “Man” indicator is displayed

go to Step 3.

Select the desired room temperature

by pressing the “▲” or “▼” buttons.

The heater will start and run for 90 seconds so that it can check the room temperature

(the indicator will show).

If the room temperature is lower than the pre-set or desired temperature the heater will continue to run.

If the room temperature is higher than the pre-set or desired temperature, the heater will go into “standby” mode, and will start when the room temperature falls below the pre-set temperature.

If the heater does not ignite on initial use, this may be due to air remaining in the gas supply line. The

spark generator will only continue for 15 seconds. After this it will be necessary to press the ON/OFF

button OFF, then ON again.

■ To turn the heater OFF:

Press the “ON/OFF” button.

DO NOT turn heater off by unplugging the power cord.

The convection fan will continue to run until the appliance cools.

1

ON/OFF

2

3

pm

Tu

1

pm

Tu

Set Room

Set Room

indicator

Auto ON

indicator

Man

EcoFrost

Override

ON

Auto ON/OFF

pm

Tu

Set Room

Man

ON

Programming

Clock Select

Timers

1

pm

Tu

Override

EcoFrost

Auto ON/OFF

Page 28

– 26 –

PROGRAMABLE WEEKLY TIMER

The Rinnai 431WTA features a weekly timer which allows four separate time periods, each with its own temperature,

to be set.

These periods can be programed differently for each day of the week, or for a group of days: weekdays, weekends

or all days of the week together.

The four timer periods create up to four separate operating intervals, each with its own temperature setting.

The programing covers a 24 hour time span(one day).

A detailed step-by-step guide of setting the times and temperatures shown in the two examples above are given on

pages 28-29.

Before setting the heater we encourage you to think about and write down your own program. A blank table is provided

on page 31 for you to do just this.

The example weekday

program period 1 has been

programed to start at 5:30

am with a temperature setting

of 76°F.

The heater will heat the room

to 76°F from 5:30 am until

8:00 am, when period 2

starts.

Period 2 has a temperature

setting of “nothing” or

OFF,

and so the heater will not

operate again until the start

of period 3 at 5:00 pm, when

it will heat the room to 72°F.

Period 4 turns the heater

OFF again until period 1

starts the timer cycle on the

next day.

The two diagrams below graphically represent an example weekday and weekend program.

For example if you get up

later on the weekends

period 1 begins heating the

home to 76°F at 9:00am.

The heater has also been

programed to start heating

the home earlier in the

afternoon, and so period 3

starts at 4:00pm with a

temperature setting of 72°F.

Period 4 now has a

temperature of

LOW [50°F],

and runs the heater on this

setting all night.

OFF

OFF

72°F

76°F

MIDNIGHT

MIDDAY

9:30pm

5:00pm

8:00am

5:30am

1

4

3

2

MIDNIGHT MIDDAY

4:00pm

11:00pm

9:00am

11:00am

1

2

3

4

LOW

72°F

76°F

OFF

WEEKDAY PROGRAM

WEEKEND PROGRAM

Page 29

– 27 –

am

Set

Auto

Man

Select

Clock

Frost

Override

Progr

Temp R

1 2 3 4 OFF

Mo Tu We Th Fr Sa Su

PROGRAMING THE WEEKLY TIMERS

The following is a general outline of the setting options and procedures avaliable when

programing the weekly timers. A detailed step-by-step example is given on pages 28 to 29.

Note: Before programing the current time and day must be set. See page 24 for instructions.

The weekly timers can be easily programed by following the steps illustrated below:

Press the “Timers”

button once to

activate the timer

programing mode.

Repeat steps → for periods 1 through to 4 until you are happy with all the settings.

Press the “Timers“ button again to confirm your program and lock in all settings.

Select the day or

group of days you

wish to program by

pressing the “up” and

“down” buttons:

Choose from the

following options:

Mo Tu We Th Fr Sa Su

Mo Tu We Th Fr

Sa Su

or each day of the

week in turn.

If a group of days is

chosen, the times and

temperatures selected

in steps 3 → 5 will

automatically apply

for those days.

Press the “Select”

button to confirm your

choice.

Select the period you wish

to program by pressing

the “up” and “down”

buttons:

Periods 1 → 4 will

automatically appear in

order as you follow this

programing sequence, so

you may not need to

manually select a timer

period.

Press the “Select” button

to confirm your choice.

Set the start time for this

period by pressing the

“up” and “down”buttons:

The time will move up or

down in 10 minute

increments.

Each period must be set

to a later time than the

period before it.

No period can be set

past 11:50pm, as this is

the end of the 24hour

program.

Press the “Select”button

to confirm the time.

Set the temperature

you want for this period

by pressing the “up”

and “down” buttons:

Choose from the

following temperature

settings:

H(high) 80 → 60 L(low)

and

- - (OFF)

If you want heat during

this period, choose a

temperature.

If you do not want heat,

choose the OFF setting.

Press the “Select” button

to confirm the

temperature setting.

For a description of how to operate the heater with these programed settings, turn to page 26.

2

1

Timers

Select

3

Select

4

Select

5

Select

6

7

3

5

Page 30

– 28 –

PROGRAMING THE TIMERS : EXAMPLE

Note: Before programing the timers, the clock must be set to the correct time(see page 24).

The following is a step by step guide to programing the timers by an example schedule.

A general outline for programing the timers is provided on page 26.

If programing is paused for longer than 2 minutes the display will return to the current time,

and all programing up to that stage will be lost.

The times and temperatures in the EXAMPLE box below can be used for learning how to set the program

able thermostat.

EXAMPLE Let's use the following schedule to program the weekdays...

Press the “Timers” button once. The

display will show “Select Program

Timer” and the “Mo Tu We Th Fr Sa Su”

indicators will flash.

1

Press the “▲” button once, the “Mo Tu

We Th Fr” indicators will flash.

2

Press the “Select” button once, the period □

1

indicator will flash and the time and

temperature display will be shown.

3

Press the “Select” button again. The

period □1indicator will become stable,

the temperature display will go out and

the clock will flash.

4

Press the “▼” button until the display

shows “am5:30”(as shown in the

example schedule for period □1).

5

Press the “Select” button again. The clock

indicator will become stable, the pre-set

temperature will flash and “Select Program

Temp” will be shown.

6

EXAMPLE SCHEDULE

5:30 am

8:00 am

5:00 pm

9:30 pm

76°F

OFF

72°F

OFF

Time Setting Temperature

Periods

1

2

3

4

This example schedule is the same as the WEEKDAY PROGRAM on page 26.

Select

Program Timer

Tu WeTh Fr SuMo Sa

Programming

Clock Select

Timers

Select

Program Timer

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Set

Select

Program Timer

1

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Select

Program Timer

1

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Select

Program Timer

1

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Set

Select

Program

Temp

1

Tu WeTh FrMo

Programming

Clock Select

Timers

Page 31

– 29 –

14

73

16

73

PROGRAMING THE TIMERS : EXAMPLE cont...

Press the “Select” button again. Now the

period □2indicator will flash and the time

and temperature display will be shown.

8

Press the “Select” button again. The

period □2indicator will become stable,

the temperature display will go out and

the clock indicator will flash.

9

Press the “▼” button until the display

shows “am8:00”(as in the example on

page 28 for period □2).

10

Press the “Select” button again. The clock

indicator will become stable, the pre-set

temperature will flash and “Select Program

Temp” will be shown.

11

Press the “▼” button until the

temperature shows “- -” and the “OFF”

indicator is displayed.

12

Press the “Select” button again. The

period 1 indicator will flash and “Sa Su”

will be displayed.

14

Once all timers are programed, Press the

“Timers” button once to save all timer

settings. The display will return to the

current time and the “Set Program Timer”

indicator will go out.

16

Set periods □3and □4following/repeating steps to , and then go to step .

13

You can now program a Weekend schedule by repeating steps to , and then go to step .

15

Press the “▲” button to set the pre-set

temperature to 76°F(remember, we are

using the example schedule on page 28).

7

To review all of the programed settings turn to page 30- “WEEKLY TIMER REVIEW FUNCTION”.

For a description of how to operate the heater with these programed settings, turn to page 32- “OPERATING

THE TIMERS”.

am

Set

Select

Program

Temp

1

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Select

Program Timer

2

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Select

Program Timer

2

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Set

Select

Program

Temp

2

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Set

Select

Program

Temp

2 OFF

Tu WeTh FrMo

Programming

Clock Select

Timers

am

Set

Select

Program Timer

1

SuSa

Programming

Clock Select

Timers

pm

Mo

Programming

Clock Select

Timers

am

Set

Select

Program Timer

2

Tu WeTh FrMo

Programming

Clock Select

Timers

Page 32

– 30 –

1

1

2

WEEKLY TIMER REVIEW FUNCTION

This function lets you review all of the programed Weekly Timer settings(times and temperatures)

without the option of adjusting these settings, removing the danger of accidently changing the

program.

This is a quick way to review the Weekly Timer program before operating the timers.

■ To enter the Weekly Timer Review mode:

NOTE: If the heater is left in “Timer Review Mode” for longer than 10 seconds without the “ ▲” or “ ▼” buttons being

pressed, it will exit this mode and return the previous operation.

Press and hold the “Timers” button

for approximately 3 seconds(an

audible “beep” will be heard).

NOTE:

The Period □1, “Mo”, time,

temperature, and “Review”

indicators will show.

Press the “ ▲ ” button repeatedly

to review the Weekly Timer

program.

The four timer periods for each

day of the week will show in turn,

starting with “Mo”(Monday) then

“Tu” etc.

Press the “ ▼ ” button to go

backwards through the program.

■ To exit the Weekly Timer Review mode:

Press the “Timers” button.

Set

Review

pm

1

Mo

Programming

Clock Select

Press and hold.

Timers

pm

Tu

1

pm

Tu

Set

Review

Programming

Clock Select

Programming

Clock Select

Timers

Timers

Page 33

– 31 –

YOUR WEEKLY TIMER PROGRAM

■ Points to consider before writing your program:

When do I want the heater to operate, and what temperature do I want?

When do I not want the heater to operate?

Will I use the same settings for everyday day of the week, or do I need a separate program for the

weekdays, and the weekend? Do I need a separate setting for each day of the week?

■ Points to remember when writing your program:

The four periods are set within a 24 hour time span.

The start of a new period marks the end of the previous one, so each period only requires a START time.

Period 4 ends with the start of period 1 on the next day(see page 26 for a reminder).

Each period must be set to a later time than the one before it.

If you want to heat during the period, select a temperature: H(high), 80 → 60, L(low).

If you do not want to heat during this period, select the OFF setting.

■ Write your own program:

Use the tables below to write your own weekly timer program, then turn to page 28 to program the timers.

Start Time Temperature or OFF

1

2

3

4

Start Time Temperature or OFF

1

2

3

4

6:00 am

8:30 am

5:00 pm

11:30 pm

72°F

60°F

74°F

60°F

7:00 am

12:00 pm

5:00 pm

11:30 pm

72°F

70°F

74°F

60°F

Start Time Temp or OFF

1

2

3

4

WEEK DAY

Temp or OFF

1

2

3

4

WEEK END

Start Time

FACTORY PRE-SET PROGRAM

The heater comes shipped with a factory set

program(opposite).

If the heater is not set with a new program it will run

according to this program when you operate the

timers(“Auto” mode-see page 32).

If the Weekly Timer program settings are erased

(see page 24), the heater will revert to this program.

Page 34

– 32 –

1

1

2

3

OPERATING THE TIMERS

■ Before operating the timers, please check the following points:

The clock must be set to the current time and day - refer to page 24 for clock setting procedure.

You may want to enter your own timer program. See page 26 for an overview of how the timers work, and

page 27 for an explaination of how to set the timers. Page 31 also provides a space for you to write your own

individual program.

If no personal program is entered, the heater will operate according to the the default factory settings as

shown on the bottom of page 31.

RETURNING TO MANUAL MODE

Press the “Auto” button. The “Auto”

indicator will go out and be replaced

by the “Man”(Manual) indicator.

The heater will now heat depending

on your manual settings(page 25).

■ Follow the steps below to operate the timers:

Press the “ON/OFF” button. The

“Man”(Manual) and “ON” indicators

will come on as well as the preset

and room temperatures.

Press the “Auto” button. The “Man”(Manual) indicator will be replaced by the “Auto”(Automatic) indicator,

and the current timer period will show.

If the current period has been

programed with a temperature,

the heater will start heating.

If the current period has been

programed with an OFF setting

the heater will not heat during

this period.

The heater will now operate according to the four periods programed into the Weekly Timer.

Set Room

Man

ON

pm

Tu

EcoFrost

Override

Auto ON/OFF

Set Room

Auto ON

pm

3

Tu

Set Room

Auto ON

pm

4 OFF

Tu

EcoFrost

Override

Auto ON/OFF

Set Room

Man

ON

pm

Tu

EcoFrost

Override

Auto ON/OFF

Page 35

– 33 –

1

1

2

OVERRIDE FUNCTION

■ This function is used when the heater is in “Auto” mode(timer operation).

■ It allows you to “Override” the preset timer setting until the beginning of the next period.

For example, if the heater is ON, pressing the “Override” button will turn it OFF until the next priod. If the

heater is OFF, pressing the “Override” button will turn the heater ON, and allow you to select a

temperature, until the next period.

■ To turn on the Override function:

Remember: The Override function is for use in the “Auto”(timer) mode only.

Press the “Override” button.

One of the following will happen depending on the current timer period setting:

■ To turn off the Override function:

Press the “Override” button.

Then the heater will return to the operation of the current timer period.

If the current timer

period is ON (heating)

If the current timer

period is OFF

The heater will turn OFF, the

temperatures will display “-”, and the

“Override” and “Off” indicators will light.

The heater will remain OFF until

a. the next timer period, or

b. the Override function is turned off

manually(see step below).

Press the “ ▲ ” or “ ▼ ” buttons to manually

adjust the pre-set room temperature.

The heater will remain heating until

a. the next timer period, or

b. the Override function is turned off

manually (see step below).

The heater will turn ON, the manual

pre-set temperature and room

temperature will show , and the

“Override” and “On” indicators will light.

or

Override

Set Room

Auto ON

Override Off

pm

3

Tu

Set Room

Auto ON

Override On

pm

3 OFF

Tu

Page 36

– 34 –

FROST PROTECTION

■ This function allows a minimum room temperature to be pre-set, between 38°F and 60°F. Once the

Frost Protection function is selected the appliance will start heating whenever the room

temperature falls below the selected temperature, regardless of timer or manual settings.

■ In addition this function can be used to protect the elderly of infirm who may suffer from

hypothermia.

■ Follow the steps below to set and operate the Frost Protection:

Make sure the heater is turned OFF.

Press the “Frost” button. The

Frost Protection temperature

and the “Frost” indicator will be

displayed.

Press the “ ▲ ” and “ ▼ ”

buttons to select the Frost

Protection temperature.

(Between 38°F and 60°F).

When the “Frost” indicator is displayed the Frost Protection is operating, and will always prevent the

room temperature from falling below the pre-set Frost Protection temperature.

■ To turn off the Frost Protection:

Press the “Frost” button. The

“Frost” indicator will go out.

Set

Frost

pm

Tu

EcoFrost

Override

Auto ON/OFF

Set

Frost

pm

Tu

Programming

Clock TimerSelect

pm

Tu

EcoFrost

Override

Auto ON/OFF

1

2

3

1

Page 37

– 35 –

30 min

2°F reduction

2°F reduction

30 min

Preset Temperature

ENERGY SAVING MODE

■ The Economy mode can only be set while the heater is operating (heating), but once set it will

remain in the system memory until deactivated.

■ To turn on the Economy mode:

Note: The Economy Mode may only be set while the heater is operating(heating).

Press the “Eco” button. The

“Economy Mode” indicator will

light.

The Economy Mode now remains in the system memory.

If the appliance is turned off manually, or stops heating as a result of an OFF timer period, the “Economy

Mode” indicator will go out.

Whenever the appliance starts heating again, the “Economy Mode” indicator will light.

■ To turn off the Economy Mode:

Note: The Economy Mode can only be turned off while the heater is operating(heating), i.e when the “Economy

Mode” indicator is showing.

Press the “Eco” button. The

“Economy Mode” indicator will

go out.

■

Economy Mode: Information

After the room is heated initially the air

temperature may be dropped to a lower level

without affecting comfort. 30 minutes after the

selected room temperature (set manually with

the “ ▲ ” and “ ▼ ” buttons or in an On timer

period) is reached, the Economy Mode, if set,

reduces the temperature by 2°F. After another

30 minutes it reduces the temperature by a

further 2°F, effectively saving energy.

The Economy Mode will not operate if the

heater is under capacity for the room size.

Set Room

Man

ON

pm

Tu

Economy Mode

EcoFrost

Override

Auto ON/OFF

Set Room

Man

ON

pm

Tu

EcoFrost

Override

Auto ON/OFF

1

1

Preset Temperature

30 min

2°F reduction

2°F reduction

30 min

Page 38

– 36 –

FUNCTION LOCK

■ The Function Lock will help to prevent accidental operation of the appliance as well as children from

altering the controls.

■ To activate the Function Lock:

Press the “ ▲ ” and “ ▼ ” buttons

at the same time. The “Function

Lock” indicator will light.

■ To deactivate the Function Lock:

Press the “ ▲ ” and “ ▼ ” buttons

at the same time for approx 2

seconds until a “beep” is heard.

The “Function Lock” indicator will

go out.

NOTE:

The lock can be activated when the heater is ON or OFF.

If activated while the heater is ON, all controls other than the OFF switch will be locked.

If activated while the heater is OFF, then all controls will be locked.

If the heater is turned off while the Function Lock is activated, it cannot be turned on again until the lock

is deactivated.

Deactivating the lock releases the controls.

Set Room

Man

ON

pm

Tu

Function Lock

Programming

Clock Select

At the same time

Timers

Set Room

Man

ON

pm

Tu

Programming

Clock Select

At the same time for 2 seconds

Timers

1

1

Page 39

– 37 –

TESTING CHECK

Testing Unit

Purge air from gas line.

Refer to pipe sizing chart if in doubt about the size of

the gas line.

Connection can easily be reached from the top, rear

of the unit. Check for leaks, using soapy water after

turning gas on.

Plug unit in and turn power on, (CAUTION 120V

inside unit).

Turn thermostat to “HI”, turn control to “ON”. Unit

should ignite within 10 seconds.

If unit does not ignite, there may be air in the gas

line, turn control “OFF” then “ON” again.

Check pressures, regulator is factory set, if

pressures are incorrect, check supply before altering

regulator. Turn control to “OFF” position, remove

pressure manometer and replace test point screws.

Re light unit, on “HI” setting. Set thermostat to “LO”

the heater will cut down, then cut out.

(Depending on the room temperature).

Turn the power off. Replace the casing.

Turn power on.

Re check operation.

Fault-Failure Procedure

If unable to get the unit to operate correctly, contact

Rinnai Agent, or Gas Utility. Please read the fault

finding charts before reporting faults.

Do not use this heater if any part has been under

water. Immediately call a qualified service

technician to inspect the heater and to replace any

part of the control system and any gas control which

has been under water.

“WARNING” Do not operate appliance with the

panel(s) removed, cracked or broken.

Installation and repair should be done by a qualified

service person. The appliance should be inspected

before use and at least annually by a qualified

service person.

More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc..

It is imperative that control compartments, burners

and circulating air passageways of the appliance be

kept clean. Ventilating system should be inspected

and cleaned annually.

Rinnai's service assistance telephone number is

1/800/621 9419.

WARNING: DO NOT OPERATE UNIT UNTIL PROPER INSTALLATION HAS BEEN COMPLETED.

Page 40

– 38 –

PRE-SERVICE CHECK

Before asking for a service call please check the following points.

These points are part of the normal operation of the unit.

■ At Ignition:

Heater does not operate.

Warm air does not flow when the burner

lights.

Smoke or strange smells are produced

on the first trial light up after installation.

Sharp clicking noises at ignition, or when

unit cuts down on the thermostat, or goes

out.

■ During Combustion:

Clunking noise when the thermostat

operates.

Unit is not heating room.

Air filter is blocked or the louvers are

blocked or obstructed.

Heater will not re-ignite after overheating.

■ When the unit is turned off.

Convection fan continues to run after

turning OFF.

■ Other Points:

Steam is discharged from the flue terminal.

Unit cuts off without apparent reason.

Power Failure longer than 24 hours.

Is the heater plugged in?

Have the fuses or breaker blown at the switch board?

Is there a power failure?

Is the air filter blocked?

Is anything blocking the outlet for the hot air?

Is the flue blocked?

Are timers set? Clear timers and operate again.

The fan is started automatically after a short delay.

This is to allow the heat exchanger to warm up, helping to avoid cold draughts.

This is caused by grease or oil and dust on the heat exchanger and will stop

after a short time.

This is simply expansion noise from the heat exchanger.

This is the sound of the solenoid gas valves opening and closing.

Is the air filter blocked?

Is the set temperature high enough?

Is the warm air outlet blocked by anything?

Are the doors and windows of the room closed?

Allow heater to cool, clean air filter, operate again.

Even after unit has cooled down the heater does not ignite again. Repair is

necessary.

Contact your local agent or Rinnai for a Service call.

This is to remove the residual heat from the heat exchanger, the fan will stop

when the heater cools down.

High efficiency appliances tend to discharge water vapor on cold days, this is

normal.

Check whether filters are blocked, dirty filters will cause the heater of overheat.

Switch OFF, then ON again when power is restored to re-set controls.

Page 41

– 39 –

TROUBLE SHOOTING

Your RHFE-431WTA requires very little maintenance, simply clean the rear fan filter as needed and

wipe the outer case and louver section with a damp cloth.

General maintenance items are not covered under unit's warranty, such as cleaning dust, debris and

carbon from flame rod, and improper set up of unit.

Problem

Remedy

Cause

Not Plugged In

Power Cut

(Initial Installation)

Air In Gas Pipe

Gas Filter Blocked

Miss Ignition

Flue terminal obstructed

Flue manifold not connected

Louver obstructed

Air filter blocked

Gas Escape

Function Lock Set

Gas turned off at meter

On Timer is set

Plug In

Re-ignite manually after

power is restored

Purge air

(Installer)

Service Call

Service Call

Clear obstruction

Service Call

Clear obstruction

Clean filter

Service Call

Cancel Function Lock

Turn gas on

Cancel “Auto” mode

No ON indicator

Burner doesn't ignite

Unusual combustion

Combustion stops

during operation

Smell of gas

Noisy ignition

Takes too long to

warm the room

Page 42

– 40 –

ERROR MESSAGES

In all cases, you may be able to clear the Error Message simply by turning the heater OFF, then ON again.

If the Error Message still remains or returns on the next operation, contact Rinnai or your nearest service

agent and arrange for a service call.

The Energysaver 431 has the ability to check its own operation continuously. If a fault occurs, an Error Message

will flash on the Digital Display of the control panel. This assists with diagnosing the fault, and may enable you to

overcome a problem without a service call. Please quote the code displayed when inquiring about service.

CODE DISPLAYED FAULT REMEDY

11

12

14

16

31

32

33

34

53

61

70

Ignition failure

Flame failure

Overheat

Room overheat

Room Temperature

Sensor faulty

Overheat Temperature

Sensor faulty

Sparker failure

Combustion fan failure

Faulty ON/OFF switch

Check gas is turned ON.

Service call if repeated.

Check gas is turned ON.

Service call if repeated.

Clean filter

Service call if repeated.

Lower room temperature

to less than 40°C(104°F).

Service call.

Service call.

Service call.

Service call.

Service call.

71

72

73

99

Faulty solenoids

Faulty Flame Rod

Communication Error

Flue block

Service call.

Service call.

Turn heater OFF,

then ON again.

Check around flue terminal

Page 43

– 41 –

MAINTENANCE / SERVICE

MAINTENANCE SUGGESTIONS