Rinnai RHFE-263F II Conversion Manual

C

onversion Manual for the

RHFE-263FAⅡ

Energysaver

Gas Direct V ent W a ll Furnace

for the conversion from

⇒

Natural Gas (NG) to Liquid

Propane Gas (LPG)

for the conversion from

⇒

Liquid Propane Gas (LPG) to

Natural Gas (NG)

for adjustments at high altitude

⇒

(greater than 2000 ft / 610m)

WARNING

English

Technical Data................................. 2

High Altitude ................................... 2

Conversion Procedure .................... 3

Parts List........................................ 11

Francais

Données Techniques....................... 7

Haute Altitude ................................. 7

Procédure de conversion ............... 8

Liste des Pièces............................ 11

This conversion kit shall be installed by a qualified service

agency in accordance with the manufacturer’s instructions

and all applicable codes and requirements of the authority

having jurisdiction. If the information in these instructions is

not followed exactly, a fire, explosion or production of carbon

monoxide may result causing property damage, personal

injury or loss of life. The qualified service agency is

responsible for the proper installation of this kit. The

installation is not proper and complete until the operation of

the converted appliance is checked as specified in the

manufacturer’s instructions supplied with the kit.

Safety Symbols

High Altitude Installation

Technical Data

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill

or hurt you and others.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in minor or

moderate injury. It may also be used to alert against unsafe practices.

Conversion of the appliance for operation at high altitudes (> 2000 ft, 610 m) requires the completion of the

section, Adjust Gas Pressure Settings, using the high altitude manifold test pressures above. No parts need to

be replaced for high altitude.

For high altitude installations in Canada, the conversion shall be carried out by a manufacturer’s authorized

representative, in accordance with the requirements of the manufacturer, provincial or territorial authorities

having jurisdiction and in accordance with the requirements of CAN/CGA-B149.1 or CAN/CGA-B149 installation

codes.

The input rate can be verified by following the procedure in the National Fuel Gas Code (NFPA54 / ANSI Z223.1,

2006 or latest edition).

Weight 37 lbs (16.8kg) Dimensions Width 16 3/4 in (425mm)

Height 26 5/8 in (676.5mm)

Depth 9 13/16 in (250mm)

Minimum supply gas pressure

Maximum supply gas pressure

Manifold test pressure (Low)

Manifold test pressure (High)

High Altitude - Manifold test pressure (Low)

High Altitude - Manifold test pressure (High)

BTU/hour input

BTU/hour output

Injector

Primary damper

Secondary damper

3.5 in (89mm) W.C.

10.5 in (267mm) W.C.

0.6 in (16mm) W.C.

2.3 in (58mm) W.C.

0.6 in (16 mm) W.C

1.7 in (42 mm) W.C.

Low 5500 - High 11000

Low 4450 - High 8800

AU129-210-1.30

0.051 in (1.30mm)

308F-209-13

308F-218-1 (Φ3.0×10)

8.0in (203mm) W.C.

13.0 in (330mm) W.C.

1.1 in (27mm) W.C.

3.7 in (94mm) W.C.

1.1 in (27 mm) W.C.

2.7 in (68 mm) W.C.

Low 5700 - High 11000

Low 4600 - High 8800

AU129-210-0.90

0.035 in (0.90mm)

308F-209-7

308F-218-3 (Φ2.5×10)

Natural Gas Propane Gas

2

Rinnai Corporation RHFE-263FAⅡ Conversion Manual

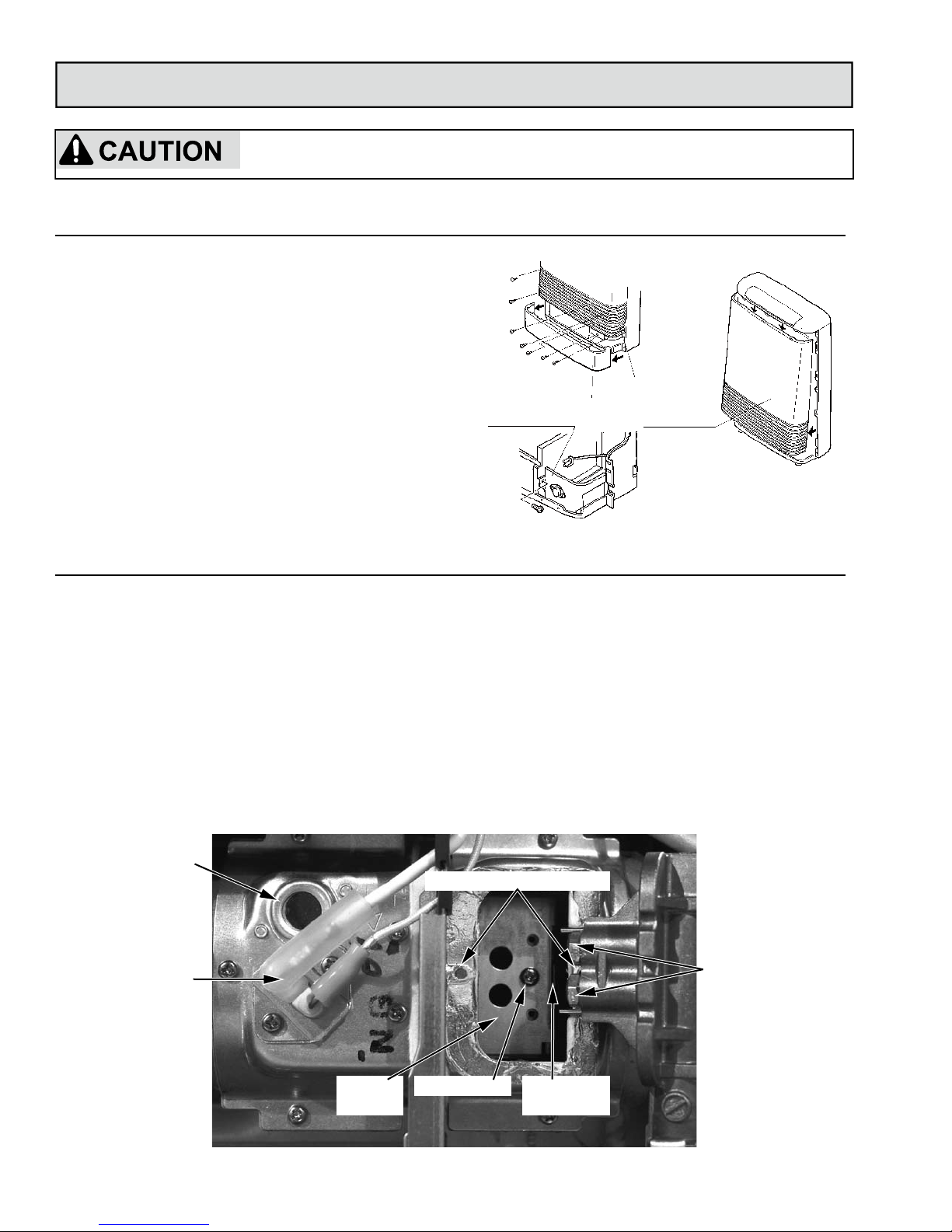

Manifold screw locations

Conversion Procedure

The gas supply shall be shut off prior to disconnecting the electrical power, before

proceeding with the conversion.

Gain Access

Replace Components

Confirm that the inlet gas pressure is between the minimum and maximum pressures allowed for this appliance.

1. Hold both ends of the bottom cover (Undercover

assembly) and pull toward you to remove the

cover. Cover snaps in place.

2. Remove the 7 screws that hold the front panel and

the louver assembly to remove panel from the unit.

Pull the panel out at the bottom about 4 inches

(100mm) and lift up over clips that hold it in place at

the unit’s top.

3. Remove 1 screw from the bracket with the overheat

switch. Place bracket to the side out of your way.

Refer to the Technical Data and Parts List to ensure to

the correct injectors and dampers are installed.

1. Remove the 2 manifold screws. Rotate the

manifold and connecting tube to access the

injectors.

2.

Replace the 2 injectors with the proper size for the

gas type to be used.

3.

Remove the burner screw from the burner

assembly.

4. Replace the primary and secondary dampers with

the dampers for the gas type to be used. (Pull the

secondary damper straight out using the tab on the

side.)

5. Install the manifold (2 screws) and overheat switch

bracket (1 screw).

6. Confirm that the electrode and leads are installed.

7. Complete the procedure, Adjust Gas Pressure

Settings.

Flame view port

Electrode and leads

Primary

damper

Burner screw

Secondary

damper tab

Injectors

Bracket

Bottom cover

Front panel

Louvers

Rinnai Corporasion RHFE-263FAⅡ Conversion Manual

3

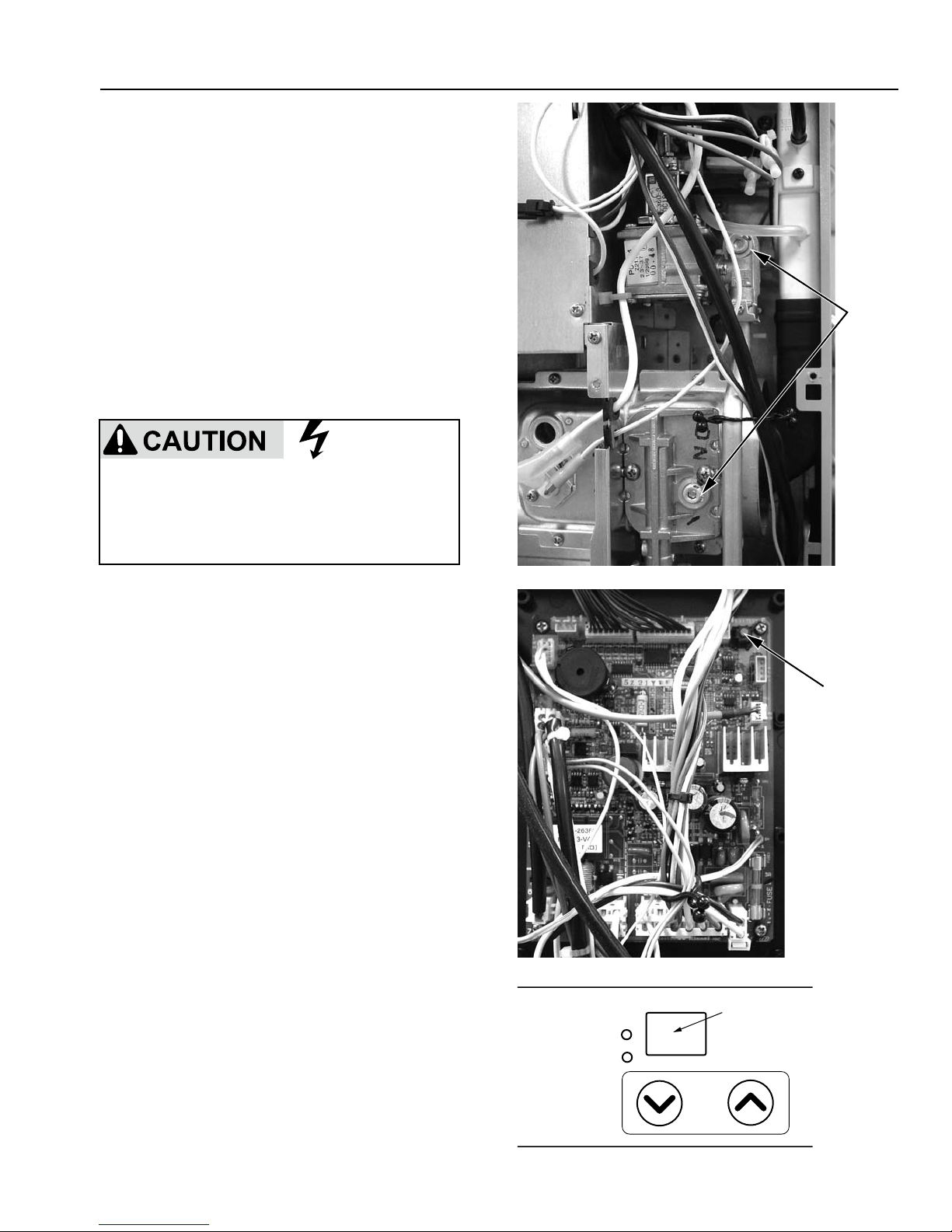

Adjust Gas Pressure Settings

1. Turn off the gas and the power supply.

2. Hold both ends of the bottom cover (undercover

assembly) and pull toward you to remove the

cover. Cover snaps in place.

3. Remove the 7 screws that hold the front panel

and the louver assembly to remove panel from

the unit. Pull the panel out at the bottom about 4

inches (100 mm) and lift up over clips that hold it

in place at the unit’s top.

4. Remove two test point screws (1/8 NPT tap) with

3/16 Allen wrench and attach the manometer to

both test ports. Both ports must be used in order

to measure the differential pressure. Ensure that

the manometer is properly calibrated.

5. Turn on the gas and power supply to the

appliance. With the unit in the Off position, press

the SW1 switch at the top of PC board until it

beeps.

6. Select the correct code on the LED display using

▲ and ▼ buttons:

High altitude is above 2000 ft (610 m).

L1: Propane gas at low (sea level) altitude

L2: Propane gas unit at high altitude

A1: Natural gas at low (sea level) altitude

A2: Natural gas unit at high altitude

7. Press the SW1 test button to record the gas type

code into memory. The LED will display “F1”. If

not shown, use the ▲ and ▼ buttons to obtain

“F1”.

8. Press the SW1 switch to enter this code into

memory.

9. The LED will display the temperature scale. Use

the ▲ and ▼ buttons to select the Fahrenheit or

Celsius scale.

10.Press the SW1 switch to enter the temperature

scale into memory.

Test

points

SW1

Do not touch any other areas on the PC board

besides the “SW” switches while power is supplied

to the appliance. Parts of the PC board are

supplied with 120 volts AC.

SetTemp

RoomTemp

Temp

Control

LED

display

4

Rinnai Corporation RHFE-263FAⅡ Conversion Manual

Loading...

Loading...