Page 1

Rinnai

Cosypanel

Convector Wall Heaters

- ------.- :.. ..

CUSTOMER’S OPERATING

INFORlWXTION AND

INSTALLATION INSTRUCTIONS

This appliance shall be installed in accordance with:

l Manufacturer’s Instructions

l Local Authority Building Codes

Rinnai

l NZS 5261 Installation Code for Gas Burning

GAS SPACE HEATERS

Appliances and Equipment

l Any other relevant Statutory Regulation

This appliance must be installed, serviced and

removed by an authorised person.

Page 2

CUSTOMER’S OPERATING INFORMATION

For trouble free operation please read the following information carefully.

For your convenience the controls are situated on the top right hand side

of the heater.

IMPORTANT

Postinq of Objects

HEAT SETTINGS

Your heater has variable heat settings between high and min.

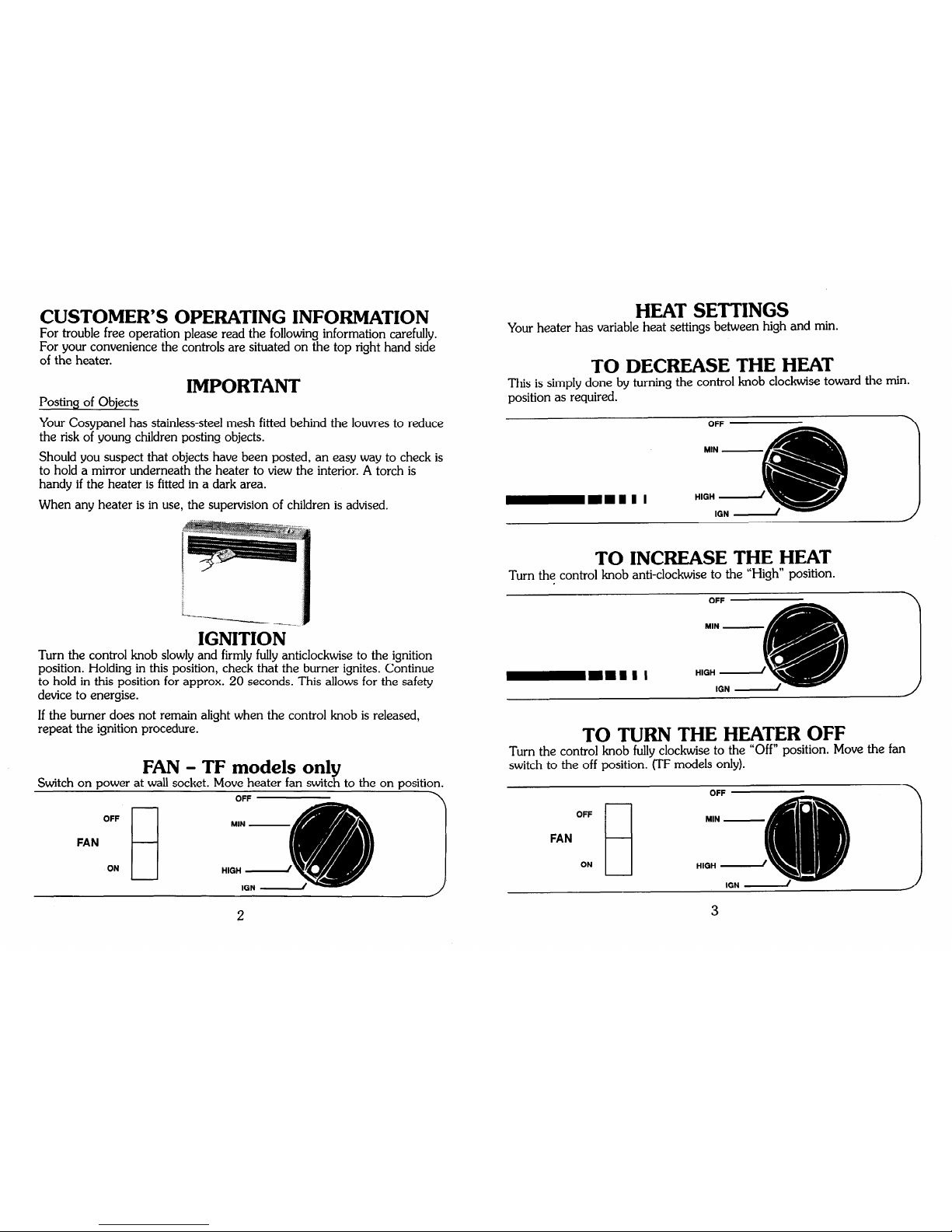

TO DECREASE THE HEAT

This is simply done by turning the control knob clockwise toward the min.

position as required.

Your Cosypanel has stainless-steel mesh fitted behind the louvres to reduce

the risk of young children posting objects.

Should you suspect that objects have been posted, an easy way to check is

to hold a mirror underneath the heater to view the interior. A torch is

handy if the heater is fitted in a dark area.

When any heater is in use, the supervision of children is advised.

-.-.-_-_

IGNITION

Turn the control knob slowly and firmly fully anticlockwise to the ignition

position. Holding in this position, check that the burner ignites. Continue

to hold in this position for approx. 20 seconds. This allows for the safety

device to energise.

If the burner does not remain alight when the control knob is released,

repeat the ignition procedure.

FAN - TF models only

Switch on power at wall socket. Move heater fan switch to the on position.

OFF

FAN

ON

El

TO INCREASE THE HEAT

Turn the control knob anti-clockwise to the “High” position.

-mm1 1 I

TO TURN THE HEATER OFF

Turn the control knob fully clockwise to the “Off” position. Move the fan

switch to the off position. (TF models only).

2

IGN -

Page 3

CARE OF THE HEATER

Your Cosypanel needs very little maintenance, but the following

information will help you keep it looking good, and working efficiently.

l Unplug unit before cleaning

l All parts of the heater can be cleaned using a soft, damp cloth.

l Do not use solvents to clean any parts.

l Do not spray aerosols in the vicinity of this appliance while it is in

operation.

l Do not place articles on or against this appliance.

l Do not store flammable materials near this appliance.

Service

The internal gas controls are factory set and in normal circumstances will

not require any adjustment in service. If however the unit fails or requires

attention then any approved Rinnai Service Centre or Gas Utility should be

contacted.

NOTE:

Servicing may only be undertaken by an authorised person

Rinnai recommends your Cosypanel is checked and serviced

annually.

INSTALLATION INSTRUCTIONS

Unoack Heater

Preferably undo bottom of carton, place carton correct way up, then lift

carton off the heater. Never lift the heater by its top louvres. Check for

damage. If unit is damaged, contact your Supplier for advice. Before

installing the heater, check unit is labelled for the correct gas type.

Included in Carton

Customer’s instructions.

Wall mounting bracket.

IMPORTANT

1.

The appliance must be installed to the requirements of the local gas

authority.

2.

Do not fix in close proximity to curtains or other combustible

materials.

4

2

2:

7.

8.

9.

For information on gas rate, see data plate on the appliance.

When installing this appliance, ensure that the room is correctly

ventilated.

Do not install in bedroom or bathroom.

This appliance is fitted with variable control and the burner can be

operated at any setting between high and min.

The recommended clearance for installation is 1OOmm from the floor

and 150mm clearance from either of the side panels.

Do not install heater under a shelf, mantlepiece or other projection

within a distance of 800 mm from top of heater.

Do not install heater under a window.

_ .

10. This unit is not designed to be built in.

11. This heater has been designed for convenient wall mounting using the

mounting bracket provided.

NOTE:

MINIMUM ROOM SIZE REQUIREMENT

RSOOT / TF

42 Cu Metres

R501T / TF

29 Cu Metres

In halls, passages and shops where ventilation is greater than normally

obtainable in living rooms, it shall be permissible to increase continuous

heat input to 0.4 MJ/h per cubic metre of enclosed space.

INLET CONNECTION

The inlet to the heater is a 3/8” B.S.P. flare fitting with nut and will fit

1Omm O.D. copper pipe. It is situated 103mm from the right hand end of

the heater and 42mm from the rear of the heater.

INSTALLATION

The rear panel incorporates a combined wall spacer and mounting bracket

extending the full width of the heater. The wall mounting bracket is

supplied taped to the rear of the heater. To maintain 1OOmm clearance

from the floor, the wall bracket should be screwed to the wall at 425mm

from the floor to the centre of the screw holes.

Position the heater on the wall bracket, then secure the heater to the wall

using the bracket provided on the underside of the base panel.

Do not remove the lower rubber wall spacers as these provide an air gap

between the heater and wall.

5

Page 4

Front Panel Removal

The front panel is held in position by four screws, one at either end of the

top louvre and at either end of the underside of the base panel. After

removing all screws ease the panel straight forward clear of the heater.

TF Model Only

An earthed power point is required within 1.5m from the heater.

TESTING PROCEDURE

After clearing .a11 swarf and purging the gas supply to the heater, connect

the gas and check for leakage at connections.

Check Burner Pressure

Turn knob to ignition position to light burner. If burner fails to light,

repeat. The heater is fitted with a flame failure valve included in the gas

valve. Hold valve in the ignition position for 20 seconds and then release.

The heater should continue to operate. If burner goes out check position

of thermocouple in flame and repeat ignition procedure.

Turn control to “Off” position. Remove test point screw and attach

manometer. Light unit in usual way. Leave full on and check pressure.

Reset pressure by adjusting regulator screw if necessary. Regulator is

situated on the side of the gas cock assembly. Check the supply pressure

before making adjustments to unit as the regulator has been factory preset.

Turn control to “Off” position before removing manometer. Replace the

test point screw. Pilot gas rate cannot be adjusted. Turn heater on and off

again a few times to check ignition.

Fan - TF models only

Connect power lead to wall socket and switch on power. Move heater fan

switch to on position and check operation of fan.

Fault Failure Procedure

If you cannot get the heater to work properly, contact Rinnai NZ Ltd, their

nearest Service Centre or Gas Utility.

INSTRUCT CUSTOMER IN USE AND CARE OF THE HEATER

Make sure the customer understands the instructions.

*

3.

4.

SERVICING INSTRUCTIONS

Rinnai recommend your Cosypanel heater is serviced every year.

1. Multifunctional Gas Valve incornoratincr oiezo ianition,

regulator and flame failure safetv device

This valve is designed as a sealed unit and as such it should not be

?

$s.isnan;~d except to replace the flame failure safety device magnetic

2. Thermocounle

The thermocouple may be replaced b

t:

removin

from it’s mounting bracket above the

%

the thermocouple

urner an

releasinq the

connector from the gas valve.

Burner and Injector

Remove the mounting screw from the left hand end of the burner and

slide burner sideways clear of the injector. The injector may now be

unscrewed if required.

Gas Valve

Turn off

from wal P

as supply and disconnect from heater. Remove the heater

and remove screws from the valve mounting bracket, two

from rear panel and one from burner chamber.

Release thermocouple, pilot tube, gas supply pipe and piezo ignition

lead. Lift the valve clear of the heater.

Description

SPECIFICATIONS

-

-

Rinnai Cosypanel R800 / 501T convector wall

heater

Type

-

Description

-

Type

-

Input

-

Gas Control

-

Burner

Test Point Pressure

Gas Inlet

Ignition

Injectors and Gas Rate -

Dimensions

-

Electric Supply -

Fan

-

6

7

Natural convection

Rinnai Cosypanel R800 / 501TF convector wall

heater with fan

Natural or forced convection

R800 NG 8.0 MJ/h R501 NG 5.3 MJ/h

Rinnai multi-functional one touch gas valve

Aeromatic single entry

NG only 1.0 kPa.

Flare fitting to suit 1Omm O.D. copper pipe

Piezo electric

Please see data plate LH side of front panel

Width 540mm, height 390mm, depth 128mm

over mounting bracket

(TF only) 230~ 50Hz A.C. only 0.06 AMP

(TF only) Royal 40mm single speed

Page 5

WIRING DIAGRAM

WIRING DIAGRAM R800TF Cosypanel

Switch

230V

50Hz

2YEARwARRANTY

The Rinnai commitment to quality is backed by our 2 year warranty.

This warranty covers parts and labour for the first year

and parts only for the second year.

This warranty covers domestic use only.

The benefits conferred by the warranty are in addition to all other rights and

remedies in respect of the product you-have purchased, under the terms of the

CONSUMER GUARANTEES ACT.

This warranty does not cover cleaning and normal wear and tear.

Calls of this nature may be chargeable.

RINNAI NEW ZEALAND LTD.

691 MT ALBERT RD, ROYAL OAK

AUCKLAND

p.0. BOX 24-068, AUCKLAND

PHONE: 6254285

FAX: 624-3018

PNo. 6792

Rinnai are continually updating and improving products. Therefore specifications are subject to alterations without notice.

Loading...

Loading...